Wood’S Glass For Sale Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for wood’s glass for sale

In today’s competitive landscape, sourcing Wood’s glass for sale presents a unique challenge for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe increasingly rely on high-quality glass solutions for construction, manufacturing, and specialized applications, the demand for reliable suppliers has never been more critical. This guide provides an in-depth exploration of the Wood’s glass market, covering essential aspects such as product types, diverse applications, effective supplier vetting processes, and cost considerations.

Navigating this complex market requires a strategic approach, and our comprehensive resource is designed to empower decision-makers with actionable insights. From understanding the specifications of vacuum lifters to identifying trusted manufacturers, this guide equips buyers with the knowledge necessary to make informed purchasing decisions. By addressing the nuances of sourcing Wood’s glass, we aim to facilitate smoother transactions and foster long-term partnerships.

Whether you are in Saudi Arabia looking to enhance your construction projects or in Germany seeking innovative glass solutions for manufacturing, this guide serves as your roadmap to success. It highlights best practices, emerging trends, and crucial factors to consider, ensuring that you are well-prepared to navigate the global market effectively. Empower your business with the insights contained within this guide and take the first step toward securing the best Wood’s glass products for your needs.

Understanding wood’s glass for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hand-held Vacuum Cups | Portable, easy to use, various sizes available | Glass handling, construction, remodeling | Pros: User-friendly, versatile. Cons: Limited load capacity. |

| Below-the-Hook Vacuum Lifters | Designed for overhead cranes, heavy-duty lifting | Industrial manufacturing, stone handling | Pros: High load capacity, efficient for large items. Cons: Requires equipment for operation. |

| Mounting Cups | Fixed positioning, designed for specific applications | Equipment mounting, HVAC installations | Pros: Stability, tailored solutions. Cons: Less flexibility compared to hand-held options. |

| Specialized Vacuum Lifters | Custom designs for unique applications | Custom manufacturing, specialized industries | Pros: Tailored to needs, enhances safety. Cons: Longer lead times, potentially higher costs. |

| Multi-Surface Lifters | Adaptable for various materials and surfaces | Flooring, glass, stone, and appliance handling | Pros: Versatile use, reduces equipment needs. Cons: May not perform optimally on all surfaces. |

What are Hand-held Vacuum Cups and Their Applications?

Hand-held vacuum cups are portable lifting devices that enable operators to easily handle glass and other smooth, non-porous materials. These cups come in various sizes, making them suitable for different tasks, from small glass panels to larger sheets. B2B buyers should consider the weight capacity and ergonomics of these tools, as they are ideal for applications in construction and remodeling where flexibility and ease of use are paramount.

How Do Below-the-Hook Vacuum Lifters Enhance Operations?

Below-the-hook vacuum lifters are engineered for heavy-duty lifting and are often used with cranes and hoists. They are capable of handling substantial loads, which makes them essential for industrial manufacturing and stone handling applications. When purchasing, B2B buyers should evaluate the weight capacity, safety features, and compatibility with existing lifting equipment to ensure operational efficiency and safety.

What Advantages Do Mounting Cups Offer for B2B Buyers?

Mounting cups are designed for fixed positioning and are often utilized in equipment mounting and HVAC installations. They provide a stable solution for securing various items, ensuring safety and reliability. Buyers should assess the specific requirements of their projects, including the type of materials being mounted and the environmental conditions, to select the most appropriate mounting cup.

Why Consider Specialized Vacuum Lifters for Unique Needs?

Specialized vacuum lifters are custom-designed to meet unique application requirements, making them invaluable in niche industries. These products enhance safety and efficiency, especially when standard solutions do not suffice. B2B buyers should consider the lead times and potential costs associated with custom orders, but the investment often results in improved operational outcomes.

How Do Multi-Surface Lifters Benefit Diverse Industries?

Multi-surface lifters are adaptable tools capable of handling a range of materials, including glass, stone, and appliances. Their versatility allows businesses to streamline operations by reducing the need for multiple lifting devices. When considering a purchase, buyers should evaluate the performance of these lifters on various surfaces to ensure they meet the specific demands of their applications effectively.

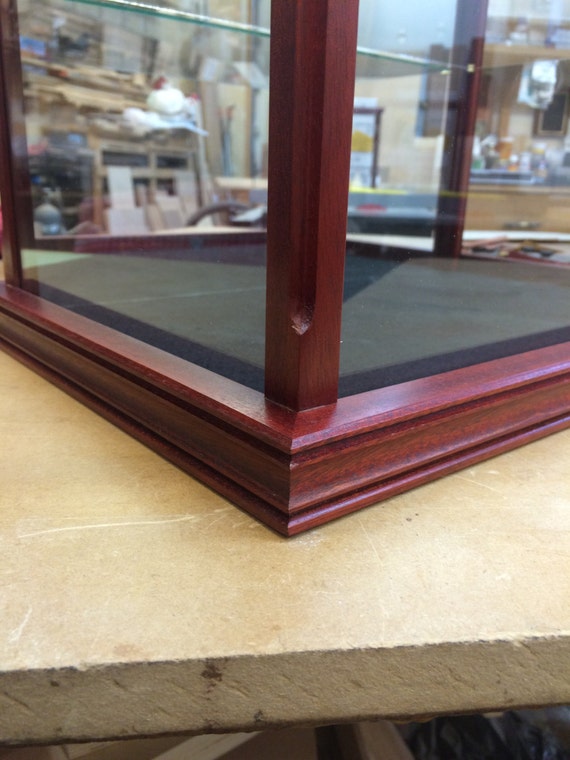

Illustrative image related to wood’s glass for sale

Key Industrial Applications of wood’s glass for sale

| Industry/Sector | Specific Application of wood’s glass for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction and Remodeling | Installation of glass facades and partitions | Enhances aesthetic appeal and energy efficiency | Compliance with local building codes and safety standards |

| Automotive Manufacturing | Production of glass components for vehicles | Improves safety and durability of automotive products | Quality assurance and compatibility with manufacturing processes |

| Electronics and Appliances | Utilization in display screens and appliance surfaces | Provides a premium look while ensuring functionality | Sourcing from reliable suppliers with high-quality standards |

| Renewable Energy | Use in solar panels and glass structures | Increases energy efficiency and sustainability | Consideration of environmental regulations and certifications |

| Art and Design | Creation of glass artworks and installations | Supports artistic expression and innovation | Need for custom sizes and designs tailored to specific projects |

How is wood’s glass utilized in the construction and remodeling sector?

In the construction and remodeling industry, wood’s glass is primarily used for installing glass facades and interior partitions. This material not only enhances the aesthetic appeal of buildings but also contributes to energy efficiency through better insulation. International buyers, particularly from regions like Europe and the Middle East, must ensure compliance with local building codes and safety standards when sourcing wood’s glass, as these regulations can vary significantly across countries.

What role does wood’s glass play in automotive manufacturing?

Wood’s glass finds significant application in the automotive sector, especially in the production of windshields and other glass components. The material’s durability and safety features are critical for vehicles, making it a preferred choice among manufacturers. Buyers in this industry should focus on quality assurance and ensure that the glass meets stringent safety regulations, which can differ from one market to another, particularly in diverse regions like Africa and South America.

Why is wood’s glass important for electronics and appliances?

In the electronics and appliances sector, wood’s glass is utilized in the production of display screens and appliance surfaces, offering a sleek look while ensuring functionality. The glass enhances the overall user experience by providing clarity and durability. For B2B buyers, sourcing from reputable suppliers with a proven track record of high-quality standards is crucial, especially when dealing with international trade where quality discrepancies can arise.

How is wood’s glass contributing to renewable energy solutions?

Wood’s glass is increasingly being used in renewable energy applications, particularly in solar panels and glass structures designed for energy efficiency. This application aligns with global sustainability goals and offers businesses a competitive edge in an eco-conscious market. Buyers should be aware of environmental regulations and certifications that may affect sourcing, especially in regions with strict sustainability mandates like Europe.

What is the significance of wood’s glass in art and design?

In the art and design industry, wood’s glass serves as a medium for creating intricate glass artworks and installations. Artists and designers value its versatility and quality, which allow for innovative expressions. B2B buyers in this sector often require custom sizes and designs tailored to specific projects, necessitating a close collaboration with suppliers to achieve desired outcomes.

3 Common User Pain Points for ‘wood’s glass for sale’ & Their Solutions

Scenario 1: Navigating Quality Assurance for Wood’s Glass

The Problem:

B2B buyers often face significant challenges in ensuring the quality of wood’s glass products before purchase. In regions like Africa and South America, where standards and regulations may vary widely, verifying product quality can become a daunting task. Buyers may worry about defects, safety compliance, and whether the glass will perform under specific conditions. This uncertainty can lead to costly delays, project overruns, and reputational damage if inferior products are used in their applications.

Illustrative image related to wood’s glass for sale

The Solution:

To effectively navigate quality assurance, buyers should prioritize sourcing from reputable manufacturers with a proven track record, such as Wood’s Powr-Grip. It is essential to request detailed specifications and certifications for the wood’s glass, including safety and performance standards relevant to the buyer’s local regulations. Establishing a relationship with a reliable distributor can also facilitate better communication and support regarding quality checks. Before finalizing any purchase, consider ordering samples for rigorous testing within your operational environment. This approach not only ensures that the product meets your expectations but also minimizes the risk of costly mistakes during installation or use.

Scenario 2: Overcoming Logistics Challenges in Sourcing Wood’s Glass

The Problem:

International B2B buyers often grapple with logistical challenges when sourcing wood’s glass, particularly when dealing with cross-border shipments. Issues such as customs delays, transportation costs, and the fragility of glass products can complicate the supply chain. Buyers from the Middle East and Europe might find that lead times are extended due to unforeseen shipping complications, ultimately affecting project timelines and budgets.

The Solution:

To mitigate logistics challenges, it’s advisable to collaborate with experienced logistics partners familiar with the specifics of transporting glass products. Buyers should look for suppliers who offer comprehensive shipping solutions, including options for insurance and specialized packaging to protect the glass during transit. Additionally, utilizing a just-in-time (JIT) inventory approach can help manage stock levels more efficiently, allowing businesses to minimize holding costs while ensuring that they have the necessary materials when needed. Clear communication with suppliers regarding expected timelines and potential delays can also help buyers plan more effectively and avoid disruption to their operations.

Illustrative image related to wood’s glass for sale

Scenario 3: Understanding the Technical Specifications of Wood’s Glass

The Problem:

B2B buyers frequently encounter difficulties in understanding the technical specifications of wood’s glass products, especially when assessing their suitability for specific applications. In industries such as construction and manufacturing, incorrect assumptions about thickness, weight capacity, and thermal resistance can lead to significant safety hazards and operational inefficiencies. This lack of technical understanding can create barriers to making informed purchasing decisions.

The Solution:

To overcome this knowledge gap, buyers should invest time in thorough research and training regarding the technical specifications of wood’s glass. Engaging with suppliers who provide in-depth product training and technical support is crucial. Buyers can also benefit from participating in industry workshops or webinars focused on glass handling and application best practices. Additionally, creating a checklist of required specifications for each project can help in systematically evaluating the products. This proactive approach ensures that buyers select wood’s glass that not only meets their project requirements but also adheres to safety standards, enhancing overall operational integrity.

Strategic Material Selection Guide for wood’s glass for sale

What Are the Key Materials for Wood’s Glass in B2B Applications?

When selecting materials for Wood’s glass products, it is essential to consider various factors that influence performance, durability, and suitability for specific applications. Below, we analyze four common materials used in the production of Wood’s glass, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Glass in Wood’s Glass Applications?

1. Tempered Glass

Key Properties: Tempered glass is heat-treated to increase its strength and thermal resistance. It can withstand high temperatures up to 300°C and is less prone to breakage.

Pros & Cons: The key advantage of tempered glass is its durability and safety; when broken, it shatters into small, blunt pieces, reducing injury risk. However, it can be more expensive than standard glass due to the manufacturing process, which may not be suitable for all budget constraints.

Illustrative image related to wood’s glass for sale

Impact on Application: Tempered glass is ideal for high-stress environments, such as construction and automotive applications. Its ability to handle temperature fluctuations makes it suitable for regions with extreme weather conditions.

Considerations for International Buyers: Buyers from regions such as Europe and the Middle East should ensure compliance with relevant safety standards (e.g., EN 12150 in Europe). Understanding local regulations regarding glass installation and safety is crucial.

2. Laminated Glass

Key Properties: Laminated glass consists of two or more glass layers bonded with a plastic interlayer, providing enhanced safety and sound insulation. It can resist impacts and UV radiation.

Pros & Cons: A significant advantage is its ability to hold together when shattered, making it suitable for safety applications. However, the manufacturing process is complex, which can lead to higher costs compared to regular glass.

Impact on Application: Laminated glass is commonly used in skylights, facades, and safety glass for buildings. Its sound-dampening properties are beneficial in urban environments.

Considerations for International Buyers: Buyers in Africa and South America should be aware of local building codes that may specify laminated glass for safety in public buildings. Familiarity with ASTM standards can also guide compliance.

3. Low-E Glass

Key Properties: Low-E (low emissivity) glass is coated with a thin layer of metal oxide that reflects infrared light while allowing visible light to pass. This property significantly improves energy efficiency.

Pros & Cons: The primary advantage is energy savings, making it ideal for climate-sensitive regions. However, the coating can be sensitive to scratches during installation, necessitating careful handling.

Impact on Application: Low-E glass is particularly beneficial in residential and commercial buildings where energy efficiency is a priority. It can reduce heating and cooling costs significantly.

Considerations for International Buyers: Buyers in Germany and other European countries should ensure compliance with energy efficiency regulations and standards such as the German Energy Saving Ordinance (EnEV). Understanding local preferences for energy-efficient products can also influence purchasing decisions.

4. Annealed Glass

Key Properties: Annealed glass is produced through a slow cooling process, which reduces internal stresses. It is less expensive and easier to manufacture than tempered or laminated glass.

Pros & Cons: The main advantage is its cost-effectiveness, making it suitable for large-scale projects. However, it is less durable and can break more easily under stress compared to other types of glass.

Illustrative image related to wood’s glass for sale

Impact on Application: Annealed glass is often used in applications where safety is not a primary concern, such as interior partitions and decorative features.

Considerations for International Buyers: Buyers in regions with less stringent safety regulations may find annealed glass suitable for various applications. However, understanding local market trends is essential to ensure compliance with safety standards.

Summary Table of Material Selection for Wood’s Glass

| Material | Typical Use Case for Wood’s Glass for Sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Tempered Glass | Construction, Automotive | High durability and safety | Higher manufacturing costs | High |

| Laminated Glass | Skylights, Facades | Holds together when shattered | Complex manufacturing process | High |

| Low-E Glass | Residential/Commercial Buildings | Energy efficiency | Sensitive to scratches during handling | Medium |

| Annealed Glass | Interior Partitions, Decorative Features | Cost-effective for large projects | Less durable under stress | Low |

This strategic material selection guide provides essential insights for international B2B buyers, enabling informed decisions when sourcing Wood’s glass products tailored to specific applications and regional requirements.

Illustrative image related to wood’s glass for sale

In-depth Look: Manufacturing Processes and Quality Assurance for wood’s glass for sale

What Are the Key Stages in the Manufacturing Process of Wood’s Glass?

The manufacturing process of Wood’s glass involves several critical stages that ensure the product meets high standards of quality and performance. Understanding these stages can help B2B buyers make informed decisions when sourcing from suppliers.

Material Preparation: What Is Involved in Sourcing and Prepping Raw Materials?

The first step in the manufacturing process is the careful selection and preparation of raw materials. High-quality glass is typically sourced from reliable suppliers, ensuring it meets industry standards. The raw materials are thoroughly inspected for impurities and defects. This stage may involve cutting, grinding, or washing the materials to prepare them for the next phase. Buyers should inquire about the material sourcing practices of potential suppliers, as this can significantly impact the final product’s quality.

Forming: How Is Glass Shaped and Molded?

Once the materials are prepared, the next stage is forming. This can involve several techniques, including blowing, pressing, or molding, depending on the desired shape and specifications of the glass product. For Wood’s glass, vacuum forming is often employed to create specific shapes that allow for efficient handling and lifting. The forming process is critical, as it determines the structural integrity and aesthetic qualities of the glass. Buyers should consider suppliers that use advanced forming technologies to ensure consistent quality and precision.

Assembly: What Is the Process of Joining Components Together?

In the assembly phase, various components of the glass products are joined together. This can include attaching handles or fittings to the glass itself. Depending on the complexity of the product, this stage may also involve the integration of electronic components or safety features, such as vacuum systems. Quality assurance during assembly is crucial; thus, suppliers should have skilled technicians who can ensure that all components are correctly assembled and function as intended.

Finishing: How Are Final Touches Applied to Enhance Quality?

The finishing stage involves several processes aimed at enhancing the appearance and functionality of the glass. This may include polishing, coating, or treating the glass to improve its durability and resistance to environmental factors. For Wood’s glass products, a rigorous finishing process ensures that each piece meets aesthetic and functional standards. B2B buyers should look for suppliers who implement multi-stage finishing processes to guarantee that the final products are free from defects and ready for use.

What Quality Assurance Measures Are Typically Implemented?

Quality assurance (QA) is a critical aspect of the manufacturing process, especially for B2B buyers who require reliable and durable products. Understanding the quality control measures in place can help buyers mitigate risks associated with sourcing.

Which International Standards Should B2B Buyers Be Aware Of?

Manufacturers of Wood’s glass typically adhere to international quality standards, such as ISO 9001, which focuses on consistent quality management systems. Additionally, industry-specific certifications like CE (European Conformity) and API (American Petroleum Institute) may also apply, particularly for specialized applications. Buyers from regions such as Europe, Africa, and the Middle East should verify that suppliers possess relevant certifications, as this indicates compliance with international safety and quality benchmarks.

What Are the Key Quality Control Checkpoints?

Quality control is often segmented into various checkpoints throughout the manufacturing process, including:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet predefined specifications.

- In-Process Quality Control (IPQC): Throughout the manufacturing stages, various checks are conducted to ensure that processes are being followed correctly and that quality is maintained.

- Final Quality Control (FQC): Before products are packaged and shipped, a final inspection is performed to verify that all quality standards have been met.

By understanding these checkpoints, B2B buyers can gauge the thoroughness of a supplier’s quality assurance processes.

What Common Testing Methods Are Used?

Common testing methods for Wood’s glass products include:

- Vacuum Testing: To ensure the integrity of vacuum systems used in lifting applications.

- Visual Inspection: Checking for surface defects, clarity, and overall aesthetics.

- Dimensional Testing: Verifying that the product meets specified dimensions and tolerances.

- Stress Testing: Assessing the durability and resistance of glass to various loads and environmental conditions.

B2B buyers should inquire about the specific testing methods employed by potential suppliers to ensure their products meet rigorous quality standards.

How Can B2B Buyers Verify Supplier Quality Control Measures?

Verification of a supplier’s quality control measures is crucial for B2B buyers. Here are several actionable strategies:

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request access to supplier audit reports that outline quality management practices and any certifications obtained. Regular audits conducted by third-party organizations can provide an unbiased evaluation of a supplier’s quality assurance processes. Additionally, buyers can ask for documentation detailing past performance and any corrective actions taken to address quality issues.

How Do Third-Party Inspections Enhance Confidence in Quality?

Engaging third-party inspection services can provide an added layer of assurance. These services conduct independent evaluations of the manufacturing processes and products, offering buyers peace of mind that quality standards are being met. Buyers should consider incorporating third-party inspections into their procurement processes, especially when dealing with international suppliers.

Illustrative image related to wood’s glass for sale

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers must navigate various certification requirements and quality assurance nuances that may differ by region. For example, European buyers may prioritize CE certification, while those in the Middle East may require compliance with local standards. Understanding these nuances can help buyers avoid compliance issues and ensure that the products they source are suitable for their markets.

In conclusion, understanding the manufacturing processes and quality assurance measures associated with Wood’s glass is crucial for B2B buyers. By focusing on material preparation, forming, assembly, finishing, and rigorous quality control, buyers can make informed decisions when sourcing glass products. Engaging with suppliers who prioritize quality and adhere to international standards can lead to successful partnerships and enhanced operational efficiency.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wood’s glass for sale’

To successfully procure Wood’s glass products, it’s essential to follow a structured approach. This checklist will guide you through the sourcing process, ensuring you make informed decisions and establish reliable partnerships.

Illustrative image related to wood’s glass for sale

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements for Wood’s glass. Consider factors such as size, thickness, and specific applications. This clarity will help you communicate effectively with potential suppliers and ensure that you receive products that meet your operational needs.

- Identify specific use cases: Whether for construction, remodeling, or other applications, understanding how you will use the glass can help refine your specifications.

- Establish performance standards: Determine any necessary certifications or quality standards, such as safety ratings or compliance with local regulations.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of Wood’s glass. Utilize industry directories, trade shows, and online platforms to compile a list of potential partners.

- Look for established brands: Companies with a long-standing reputation, like Wood’s Powr-Grip, often provide better quality and service.

- Check geographical reach: Ensure that the suppliers can meet your shipping needs, particularly if you are sourcing internationally.

Step 3: Evaluate Supplier Certifications

It’s crucial to verify that suppliers possess the necessary certifications and quality assurance processes. This step ensures that the products meet industry standards and regulations.

- Request documentation: Ask for ISO certifications, safety standards, and product testing results.

- Assess manufacturing practices: Inquire about their production processes to ensure they align with your quality requirements.

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples of Wood’s glass to evaluate quality firsthand. This step allows you to assess the product’s suitability for your specific applications.

- Perform quality checks: Examine the samples for defects, clarity, and durability.

- Test for compatibility: Ensure the glass meets the performance standards required for your projects.

Step 5: Compare Pricing and Terms

Once you have identified potential suppliers, compare pricing, payment terms, and delivery schedules. This step helps you find the best value for your investment.

- Look for bulk discounts: Inquire about pricing tiers for larger orders.

- Evaluate total cost of ownership: Consider shipping costs, potential tariffs, and other fees that may affect your budget.

Step 6: Negotiate Contracts Carefully

When you have selected a supplier, negotiate the terms of your contract carefully. Ensure that all aspects of the agreement are clear and mutually beneficial.

- Include performance clauses: Establish expectations regarding delivery times and product quality.

- Discuss after-sales support: Ensure there are provisions for handling defects or service issues post-purchase.

Step 7: Establish a Communication Plan

Finally, set up a clear communication plan with your chosen supplier. Effective communication is key to maintaining a successful business relationship.

Illustrative image related to wood’s glass for sale

- Define points of contact: Identify who will be responsible for communications on both sides.

- Schedule regular check-ins: Establish a routine for updates and feedback to ensure ongoing alignment and satisfaction.

Following this checklist will streamline your sourcing process for Wood’s glass, helping you make informed decisions and build successful partnerships with suppliers.

Comprehensive Cost and Pricing Analysis for wood’s glass for sale Sourcing

What Are the Key Cost Components for Wood’s Glass Products in B2B Sourcing?

When sourcing wood’s glass products, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The quality of glass and other materials significantly affects the overall cost. Higher-grade materials will lead to increased prices, but they can offer better durability and performance.

-

Labor: Labor costs vary by region and depend on the complexity of the manufacturing processes involved. Skilled labor is often required for precision tasks, which can drive up costs.

-

Manufacturing Overhead: This includes utilities, rent, and general operational costs associated with the manufacturing facility. Efficient production processes can minimize overhead costs.

-

Tooling: Custom tooling for specific glass shapes or applications can be a significant upfront investment. This cost is often amortized over the production volume.

-

Quality Control (QC): Implementing rigorous QC processes ensures that products meet safety and performance standards. This can add to costs but is crucial for maintaining product integrity and customer satisfaction.

-

Logistics: Transportation and handling costs can vary widely based on shipping methods, distances, and import/export regulations. Efficient logistics management is essential for minimizing these expenses.

-

Margin: Suppliers will typically add a margin to cover their costs and ensure profitability. This margin can vary based on market demand and competitive pressures.

How Do Pricing Influencers Affect Wood’s Glass Costs?

Several factors influence the pricing of wood’s glass products, impacting the final cost to B2B buyers:

-

Volume/MOQ (Minimum Order Quantity): Ordering in larger quantities often leads to lower per-unit costs. Establishing a strong relationship with suppliers can help negotiate better terms.

-

Specifications and Customization: Custom designs or specifications can significantly increase costs due to additional tooling and labor requirements. Buyers should weigh the benefits of customization against the added expense.

-

Materials and Quality Certifications: Premium materials and certifications (like ISO or CE marking) can enhance product quality and compliance, but they also raise costs. Buyers should consider their specific quality requirements.

-

Supplier Factors: Supplier reputation, reliability, and service levels can influence pricing. Established suppliers may charge more due to their proven track record and support services.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) can affect shipping costs and responsibilities. Understanding these terms is crucial for managing total logistics costs effectively.

What Negotiation Strategies Can B2B Buyers Use for Wood’s Glass Products?

When negotiating prices for wood’s glass products, consider these strategies:

-

Understand Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also long-term costs, including maintenance and potential downtime. A higher upfront cost might be justified by lower ongoing expenses.

-

Leverage Market Research: Familiarize yourself with market prices and trends to strengthen your negotiation position. This knowledge allows you to challenge inflated pricing effectively.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and terms over time. Trust and reliability often translate into cost savings.

-

Consider Alternative Suppliers: Exploring multiple suppliers can provide leverage in negotiations. It’s essential to balance quality and cost when evaluating options.

What Should International Buyers Keep in Mind When Sourcing Wood’s Glass?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, specific considerations include:

-

Pricing Nuances: Currency fluctuations can impact pricing. Always consider the exchange rates and payment terms when negotiating costs.

-

Regulatory Compliance: Different countries have varying regulations regarding imports, which may affect costs. Ensure that the supplier complies with all relevant certifications and standards.

-

Cultural Differences: Understanding cultural nuances in negotiation styles can facilitate smoother transactions. This awareness can lead to better communication and relationship-building.

Disclaimer on Indicative Prices

Prices for wood’s glass products can fluctuate based on the factors discussed above. It is advisable to request detailed quotes from suppliers to obtain the most accurate pricing tailored to your specific needs.

Alternatives Analysis: Comparing wood’s glass for sale With Other Solutions

Exploring Alternative Solutions to Wood’s Glass for Sale

In the realm of glass handling and lifting solutions, various technologies and methodologies are available to meet the diverse needs of B2B buyers. This section examines how Wood’s glass for sale compares with other viable alternatives, focusing on key performance indicators and practical applications. By understanding the strengths and weaknesses of each option, international buyers can make informed decisions that align with their operational requirements.

| Comparison Aspect | ‘Wood’s Glass For Sale’ | Alternative 1: Suction Cups | Alternative 2: Mechanical Grippers |

|---|---|---|---|

| Performance | High grip strength; reliable for smooth surfaces | Moderate grip strength; effective for flat surfaces | High grip strength; versatile for various shapes |

| Cost | Moderate pricing; investment in quality | Low to moderate; cost-effective for simple tasks | Higher upfront cost; maintenance may increase long-term expenses |

| Ease of Implementation | User-friendly; requires minimal training | Simple setup; limited training needed | Requires more technical knowledge; may need training |

| Maintenance | Low; durable materials with minimal upkeep | Low; occasional checks needed | Moderate; regular maintenance required for moving parts |

| Best Use Case | Ideal for heavy glass and specialized applications | Best for lightweight glass and temporary setups | Suitable for heavy-duty tasks and irregular shapes |

What Are the Benefits and Drawbacks of Using Suction Cups?

Suction cups represent a straightforward alternative to Wood’s glass solutions, particularly favored for their simplicity and cost-effectiveness. They excel in handling lightweight glass and are ideal for temporary applications, such as installations or repairs where mobility is crucial. However, their performance may be limited when it comes to handling heavier loads or curved surfaces, which can compromise safety and efficiency. Buyers looking for a budget-friendly option for lighter materials may find suction cups appealing, but they should consider the potential risks associated with weight limitations.

How Do Mechanical Grippers Compare to Wood’s Glass Solutions?

Mechanical grippers provide a robust alternative, particularly in environments requiring high grip strength and versatility. They are capable of handling irregular shapes and heavy loads, making them suitable for industrial applications. However, mechanical grippers often come with a higher upfront cost and necessitate more technical expertise for operation. Maintenance can also be more intensive due to the moving parts involved. While they can be an excellent investment for businesses with demanding lifting needs, buyers should assess whether the higher costs and complexity align with their operational capabilities.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the right glass handling solution, B2B buyers should carefully consider their specific requirements, including the weight and type of materials they will be handling, the frequency of use, and the available technical expertise. Wood’s glass for sale offers a strong combination of reliability and user-friendliness, making it a preferred choice for many applications. However, alternatives like suction cups and mechanical grippers may serve better in specific contexts, particularly when budget constraints or unique handling needs arise. A thorough analysis of each option’s pros and cons, alongside a clear understanding of operational goals, will empower buyers to make the best choice for their business.

Essential Technical Properties and Trade Terminology for wood’s glass for sale

What Are the Key Technical Properties of Wood’s Glass for Sale?

When evaluating wood’s glass for sale, understanding its technical properties is crucial for B2B buyers seeking to make informed purchasing decisions. Here are several key specifications:

-

Material Grade: This refers to the quality and type of glass used, which can significantly impact durability and application. Higher-grade glass typically offers better clarity, strength, and resistance to environmental factors, making it suitable for various applications, from architectural installations to specialized industrial uses.

-

Tolerance: Tolerance specifies the allowable deviation from specified dimensions. In glass products, tight tolerances ensure that pieces fit together precisely, which is essential in applications like window installations or glass facades. A small variation can lead to significant problems in assembly and functionality.

-

Thickness: The thickness of the glass affects its strength, insulation properties, and weight. For instance, thicker glass is often required for structural applications, while thinner options may suffice for decorative purposes. Understanding thickness helps buyers choose the right product for their specific needs.

-

Finish Type: The surface finish can vary from polished to frosted, influencing both aesthetics and functionality. A polished finish enhances clarity and light transmission, while a frosted finish offers privacy. Buyers must consider the intended application when selecting the finish type.

-

Thermal Resistance: This property indicates how well the glass can withstand temperature fluctuations without breaking or warping. For regions with extreme weather conditions, thermal resistance is a critical factor to ensure longevity and performance.

-

UV Resistance: Wood’s glass may also come with UV-resistant coatings that protect against sun damage. This property is particularly important for applications involving artworks or sensitive materials, as it helps prevent fading and degradation over time.

What Are the Common Trade Terms Related to Wood’s Glass?

Familiarity with industry jargon can help B2B buyers navigate negotiations and product specifications effectively. Here are some essential terms:

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of wood’s glass, OEMs may provide custom glass solutions tailored to specific machinery or structures.

-

MOQ (Minimum Order Quantity): MOQ indicates the smallest number of units that a supplier is willing to sell. Understanding MOQ is vital for buyers to manage inventory and budgeting effectively, especially when considering bulk purchases.

-

RFQ (Request for Quotation): An RFQ is a formal process where buyers request price quotes from suppliers for specific quantities and specifications of products. This step is crucial in comparing costs and ensuring competitive pricing.

-

Incoterms: Short for International Commercial Terms, Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and risks during international transactions.

-

Lead Time: This term refers to the amount of time it takes from placing an order to receiving the product. Knowing the lead time is essential for project planning and ensuring timely delivery, especially in industries with strict deadlines.

-

Certification Standards: These are regulatory standards that glass products must meet for safety and performance. Understanding the relevant certification standards, such as ANSI or ASTM, ensures that the glass meets industry regulations and quality expectations.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when purchasing wood’s glass, ensuring they select products that meet their specific needs and requirements.

Navigating Market Dynamics and Sourcing Trends in the wood’s glass for sale Sector

What Are the Key Market Dynamics and Trends in the Wood’s Glass for Sale Sector?

The global wood’s glass market is experiencing a transformation driven by several key factors. Increased demand for sustainable building materials, particularly in regions like Europe and the Middle East, is steering buyers toward eco-friendly alternatives. The construction industry, recovering from pandemic-related disruptions, is witnessing a resurgence in projects that incorporate wood’s glass due to its aesthetic appeal and energy efficiency. Additionally, advancements in technology are reshaping the sourcing landscape. Automation and digital platforms facilitate smoother transactions and improve supply chain transparency, making it easier for international buyers from Africa, South America, and Europe to connect with suppliers.

Emerging trends highlight the growing importance of customization and adaptability in product offerings. Buyers are increasingly seeking tailored solutions that meet specific project requirements, particularly in regions with unique climatic conditions. Moreover, the rise of e-commerce platforms is enabling suppliers to reach a broader audience, offering competitive pricing and faster delivery times. This shift toward online procurement is particularly beneficial for B2B buyers looking to streamline operations and reduce overhead costs.

How Is Sustainability Influencing Sourcing Decisions in the Wood’s Glass Market?

Sustainability and ethical sourcing have become critical considerations for B2B buyers in the wood’s glass sector. Environmental impacts associated with traditional glass production, such as high energy consumption and greenhouse gas emissions, are prompting businesses to seek greener alternatives. Suppliers that prioritize sustainable practices—such as using recycled materials, energy-efficient production methods, and responsible sourcing of wood—are gaining traction in the market.

In addition to environmental benefits, ethical supply chains are increasingly important for maintaining corporate social responsibility (CSR) standards. Buyers are looking for partners who can demonstrate compliance with international sustainability certifications, such as FSC (Forest Stewardship Council) and LEED (Leadership in Energy and Environmental Design). These certifications not only enhance a company’s reputation but also appeal to consumers who are becoming more environmentally conscious. By prioritizing sustainability, B2B buyers can reduce risks associated with regulatory changes and improve their market positioning.

What Is the Historical Context of Wood’s Glass for Sale?

The evolution of wood’s glass for sale can be traced back to innovative manufacturing practices that emerged in the mid-20th century. Initially developed as a solution for the glass industry, vacuum lifting tools, such as those created by Wood’s Powr-Grip, revolutionized how glass was handled and transported. These tools enhanced safety and efficiency, setting a precedent for the types of products available today.

Illustrative image related to wood’s glass for sale

Over the decades, as construction techniques and materials evolved, the demand for wood’s glass grew, particularly in sectors focused on sustainable design. The combination of aesthetics and functionality in wood’s glass products appealed to architects and builders, leading to increased adoption in residential and commercial projects. Today, the sector continues to thrive, with a focus on innovation and sustainability driving future developments.

Frequently Asked Questions (FAQs) for B2B Buyers of wood’s glass for sale

-

How do I ensure the quality of wood’s glass before purchase?

To ensure quality, request samples from potential suppliers to assess the material firsthand. Additionally, verify that the supplier adheres to international quality standards, such as ISO certifications. You can also inquire about their quality assurance processes, including inspections and testing methods used during production. Engaging in direct communication with the supplier about their sourcing and manufacturing processes can provide further insights into the quality of the wood’s glass they offer. -

What are the best types of wood’s glass for construction projects?

The best types of wood’s glass for construction depend on the specific application. For structural support, laminated wood’s glass provides enhanced strength and durability. For aesthetic purposes, decorative glass options can add visual appeal while maintaining functionality. Always consider factors like load-bearing capacity, insulation properties, and environmental resistance when selecting the appropriate type for your project. -

How do I vet suppliers of wood’s glass for international trade?

Vetting suppliers involves several steps. Start by researching their reputation through reviews and testimonials from previous clients. Verify their business credentials, including registration and any relevant industry certifications. Request references and reach out to those clients to gauge their experience. Additionally, consider visiting the supplier’s facility or utilizing third-party inspection services to ensure compliance with quality and safety standards before making a commitment. -

What is the typical minimum order quantity (MOQ) for wood’s glass?

The MOQ for wood’s glass can vary significantly among suppliers, often ranging from a few hundred to several thousand units depending on the product and customization level. When negotiating, inquire about flexibility in MOQ, especially if you are testing the market or seeking smaller quantities. Some suppliers may offer reduced MOQs for first-time orders or for specific products, particularly if they have existing stock. -

What payment terms should I expect when sourcing wood’s glass internationally?

Payment terms can differ by supplier and region. Common terms include a percentage upfront (usually 30-50%) with the balance due upon delivery or before shipping. Some suppliers may offer credit terms for established clients. It’s essential to discuss payment methods, such as bank transfers or letters of credit, and to ensure that the terms are documented in the purchase agreement to avoid misunderstandings. -

How can I customize wood’s glass products to meet specific requirements?

Many suppliers offer customization options, including size, thickness, and finishes. Discuss your requirements directly with the supplier to explore available customization services. Be prepared to provide detailed specifications and, if possible, drawings or samples of what you need. Some suppliers may also have design teams to assist in creating tailored solutions that meet your project’s unique demands. -

What logistics considerations should I keep in mind when importing wood’s glass?

When importing wood’s glass, consider shipping methods, costs, and timelines. Ensure that the supplier can accommodate your preferred shipping method, whether by air or sea, and inquire about packaging to prevent damage during transit. Additionally, familiarize yourself with import regulations and duties in your country to avoid unexpected costs. Engaging a reliable freight forwarder can streamline the logistics process and help navigate customs clearance. -

How do I handle potential disputes with suppliers of wood’s glass?

To handle disputes effectively, maintain clear and open communication with your supplier throughout the transaction. Establish a formal contract outlining terms, conditions, and procedures for resolving conflicts. Should a dispute arise, document all communications and any evidence related to the issue. Many suppliers are open to mediation or arbitration to resolve disputes amicably, so consider these options before escalating to legal action.

Top 2 Wood’S Glass For Sale Manufacturers & Suppliers List

1. Wood’s Powr-Grip – Vacuum Lifting Tools

Domain: diamondtoolstore.com

Registered: 2000 (25 years)

Introduction: Wood’s Powr-Grip is a leading manufacturer of vacuum lifting tools and equipment, based in Laurel, Montana. The company was founded in 1947 by Howard Wood, who initially created a valve grinder that led to the development of vacuum cups for glass handling in 1963. Wood’s Powr-Grip offers a range of vacuum lifters, including manual, AC, DC, and air-powered options, capable of handling loads up to 6…

2. WhimsicalKeepsakes12 – Personalized Charred Wooden Bourbon Drinking Glass

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: 1. Personalized Charred Wooden Bourbon Drinking Glass: 10 oz, Sale Price: $40.99, Original Price: $58.56 (30% off), Seller: WhimsicalKeepsakes12.

2. Tempered Glass Backsplash: Sale Price: $30.94, Original Price: $47.60 (35% off), Seller: MOONLIKEDESING.

3. Wood Whiskey Bourbon Glass with Charred Interior: Sale Price: $24.89, Original Price: $35.56 (30% off), Free shipping.

4. LARGE Molten Glass Bo…

Strategic Sourcing Conclusion and Outlook for wood’s glass for sale

How Can Strategic Sourcing Enhance Your Procurement of Wood’s Glass?

In the competitive landscape of wood’s glass procurement, strategic sourcing stands out as a critical approach for international buyers. By understanding the unique offerings from reputable manufacturers, such as Wood’s Powr-Grip, businesses can ensure they acquire high-quality vacuum lifting tools that enhance operational efficiency and safety. Prioritizing supplier relationships and leveraging market insights can lead to better pricing, customized solutions, and improved service levels, ultimately driving profitability.

Moreover, as industries across Africa, South America, the Middle East, and Europe continue to innovate, the demand for reliable and specialized equipment is set to grow. Engaging in strategic sourcing not only mitigates risks associated with supply chain disruptions but also positions your organization as a leader in adopting advanced technologies.

As we look to the future, now is the time to reassess your sourcing strategies. Consider collaborating with established suppliers who can provide tailored solutions to meet your specific needs. Embrace this opportunity to transform your procurement processes and unlock the full potential of wood’s glass products, ensuring your business remains competitive in an evolving global market. Reach out to trusted distributors today and take the first step toward optimizing your sourcing strategy.

Illustrative image related to wood’s glass for sale

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.