Wood Processor For Sale Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for wood processor for sale

In the rapidly evolving landscape of the global wood processing industry, sourcing the right wood processor for sale can present a significant challenge for B2B buyers. With diverse applications ranging from firewood production to industrial timber processing, selecting the ideal equipment requires a deep understanding of market offerings, technological advancements, and supplier reliability. This guide aims to empower international buyers, particularly those from Africa, South America, the Middle East, and Europe, by providing a comprehensive overview of wood processors available in the market.

From examining various types of wood processors—such as mobile and stationary models—to exploring their applications in different business contexts, this resource is designed to facilitate informed purchasing decisions. Buyers will find insights into critical considerations such as supplier vetting processes, essential features to look for, and a detailed analysis of costs associated with different models.

Additionally, we will address common challenges faced in the procurement process, including logistics, maintenance, and support services. By equipping buyers with this knowledge, this guide serves as a valuable tool for navigating the complexities of sourcing wood processing equipment, ensuring that businesses can enhance their operational efficiency and profitability in a competitive market.

Understanding wood processor for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Firewood Processor | Hydraulic systems, auto-cycle features, various engine sizes | Firewood production for resale | Pros: High efficiency, customizable features. Cons: Initial high investment. |

| Log Splitter | Manual or powered splitting, compact design | Small-scale operations | Pros: Lower cost, easy to operate. Cons: Limited output compared to processors. |

| PTO Firewood Processor | Connects to tractor power take-off, high output capacity | Large-scale forestry operations | Pros: Cost-effective for large operations. Cons: Requires compatible tractor. |

| Mobile Firewood Processor | Portable design, versatile applications | On-site firewood processing | Pros: Flexibility in location, efficient. Cons: May have reduced capacity compared to stationary models. |

| Electric Firewood Processor | Quiet operation, lower maintenance needs | Urban settings, small businesses | Pros: Eco-friendly, low noise. Cons: Limited power and output compared to diesel models. |

What Are the Key Characteristics of Firewood Processors?

Firewood processors are robust machines designed for high-efficiency firewood production. They typically feature hydraulic systems that automate cutting and splitting, making them ideal for businesses focused on large-scale firewood sales. Buyers should consider engine size, output capacity, and available customization options. The initial investment can be substantial, but the long-term productivity gains often justify the cost.

How Do Log Splitters Differ from Firewood Processors?

Log splitters are generally smaller and designed for manual or powered splitting of logs into firewood. They are suitable for small-scale operations where lower output is acceptable. While they are less expensive and easier to operate, log splitters do not offer the same efficiency as firewood processors. B2B buyers should assess their production needs carefully when choosing between these two types of equipment.

Why Consider PTO Firewood Processors for Large Operations?

PTO (Power Take-Off) firewood processors connect directly to a tractor’s power system, making them ideal for large-scale forestry operations. They offer high output capacities and are often more cost-effective for businesses that already own compatible tractors. However, potential buyers must ensure they have access to suitable equipment to maximize the benefits of PTO processors.

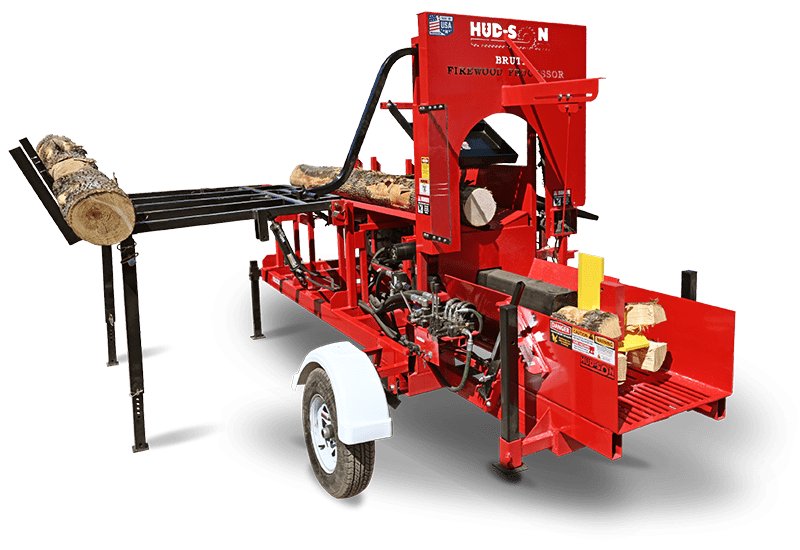

Illustrative image related to wood processor for sale

What Advantages Do Mobile Firewood Processors Offer?

Mobile firewood processors are designed for on-site operations, allowing businesses to process wood directly at the source. This flexibility can lead to significant time and cost savings. While they are efficient, mobile processors may have lower output capacities compared to stationary models. Businesses operating in remote areas or those requiring flexibility should consider these machines for their operations.

Are Electric Firewood Processors a Viable Option for Urban Settings?

Electric firewood processors provide an eco-friendly and quieter alternative for businesses operating in urban environments. They typically require less maintenance than their diesel counterparts and are easier to operate. However, their power and output capabilities can be limited, making them less suitable for high-volume production. Urban businesses should weigh the benefits of a quieter operation against potential output limitations when considering electric models.

Key Industrial Applications of wood processor for sale

| Industry/Sector | Specific Application of wood processor for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Forestry and Timber | Processing logs into firewood for sale | Increases efficiency and reduces labor costs | Consider machine capacity and output speed for high demand. |

| Agriculture and Farming | Producing firewood for heating and energy | Provides a sustainable energy source, reducing costs | Look for processors that handle various log sizes efficiently. |

| Construction and Building | Creating wood chips and mulch for landscaping | Enhances project value by utilizing waste materials | Assess durability and portability for on-site operations. |

| Retail and Firewood Sales | Packaging and selling firewood bundles | Maximizes profit margins through effective processing | Evaluate integration with conveyors and bundling systems. |

| Biomass Energy Production | Converting wood into biomass fuel | Supports renewable energy initiatives and sustainability | Ensure compatibility with biomass energy systems and standards. |

How is a Wood Processor Used in the Forestry and Timber Industry?

In the forestry and timber sector, wood processors are essential for transforming raw logs into ready-to-sell firewood. These machines streamline the processing workflow, allowing businesses to maximize output while minimizing labor costs. Key considerations for buyers include the processor’s capacity to handle different log sizes and its efficiency in converting logs into firewood quickly. International buyers, particularly from regions like Africa and South America, should prioritize models that can operate in diverse environmental conditions and offer robust after-sales support.

Illustrative image related to wood processor for sale

What Role Does a Wood Processor Play in Agriculture and Farming?

Agricultural operations often rely on wood processors for producing firewood, which serves as a cost-effective energy source for heating and cooking. By converting excess or damaged timber into usable firewood, farmers can enhance their sustainability efforts while reducing external energy costs. Buyers in this sector should focus on processors that can efficiently handle a range of log sizes and types, ensuring versatility in their operations. Additionally, understanding local regulations regarding firewood production can guide procurement decisions.

How Can Construction and Building Industries Benefit from Wood Processors?

In construction, wood processors are valuable for creating wood chips and mulch from scrap wood, which can be used in landscaping and erosion control. This not only reduces waste but also adds value to construction projects by providing sustainable materials. When sourcing wood processors for this application, businesses should consider the machine’s durability and portability, as they may require frequent on-site use. Buyers should also assess the processor’s ability to handle various wood types to accommodate different project needs.

Why Are Wood Processors Important for Retail and Firewood Sales?

Retailers in the firewood market utilize wood processors to efficiently package and sell firewood bundles, enhancing their operational efficiency and profitability. These machines allow for rapid processing and bundling, which is crucial during peak sales periods. When sourcing wood processors, retailers should evaluate integration capabilities with conveyors and bundling systems to streamline their workflow. Additionally, understanding market demand trends can inform the choice of processor features and capacities.

Illustrative image related to wood processor for sale

How Do Wood Processors Support Biomass Energy Production?

Wood processors play a critical role in biomass energy production by converting wood waste into biomass fuel, contributing to renewable energy initiatives. This application supports sustainability goals while providing a viable energy alternative. Buyers interested in this sector should ensure that the processors they choose meet the necessary compatibility and regulatory standards for biomass fuel production. Additionally, the efficiency of the processor in converting logs into biomass is a key factor in maximizing energy output.

3 Common User Pain Points for ‘wood processor for sale’ & Their Solutions

Scenario 1: Difficulty in Identifying the Right Wood Processor for Specific Needs

The Problem: Many B2B buyers face the challenge of selecting a wood processor that aligns with their specific operational requirements. With numerous options available, including variations in engine power, processing speeds, and features, it can be overwhelming to determine which machine will effectively meet their production goals. For instance, a business that primarily processes small logs may find it unnecessary to invest in a high-capacity processor designed for larger operations, leading to wasted resources and inefficiency.

The Solution: To overcome this challenge, buyers should conduct a thorough needs assessment before exploring options. Start by analyzing your production volume, types of wood being processed, and the desired output speed. Utilize this data to create a specification sheet that outlines essential features, such as engine power (e.g., 22HP vs. 74HP), processing capacity (cords per hour), and necessary attachments like integrated conveyors. Engage with manufacturers or trusted suppliers who can provide tailored advice based on your specifications. Request demonstrations or trials to ensure the selected machine performs as expected under real operational conditions.

Scenario 2: Concerns About Maintenance and Downtime

The Problem: Another common pain point for B2B buyers is the concern over the maintenance requirements and potential downtime of wood processors. With significant investments at stake, the prospect of operational halts due to equipment failure can be daunting. Buyers often worry about the availability of spare parts and service support, especially in regions with limited access to specialized machinery maintenance.

The Solution: To mitigate these concerns, buyers should prioritize manufacturers known for their reliable after-sales support and comprehensive warranty options. Before making a purchase, inquire about the availability of spare parts and the manufacturer’s service network in your region. Additionally, consider investing in a processor that features robust construction and is designed for easy maintenance. Regularly scheduled preventative maintenance should also be established to identify and address potential issues before they lead to costly downtime. Documenting maintenance logs and adhering to the manufacturer’s recommended service intervals can further enhance the longevity and reliability of the equipment.

Illustrative image related to wood processor for sale

Scenario 3: Navigating Financial Constraints and Return on Investment

The Problem: B2B buyers often grapple with financial constraints, making it challenging to justify the investment in a new wood processor. The high upfront costs of industrial-grade machinery can deter companies from upgrading or expanding their capabilities. Additionally, without a clear understanding of potential return on investment (ROI), buyers may hesitate to commit to a purchase.

The Solution: To address this issue, buyers should perform a comprehensive cost-benefit analysis before making a purchase decision. Start by calculating the expected increase in productivity and efficiency that a new processor could bring to your operations. Compare this with the costs associated with the current equipment, including maintenance and operational inefficiencies. Seek financing options that manufacturers or suppliers may offer, such as installment plans or leasing, which can make the investment more manageable. Moreover, consider the long-term savings in labor and time that an advanced processor can provide, ultimately contributing to a favorable ROI. Engaging with industry peers who have successfully navigated similar investments can also provide valuable insights and confidence in the decision-making process.

Strategic Material Selection Guide for wood processor for sale

What Materials Are Commonly Used in Wood Processors for Sale?

When selecting a wood processor, the choice of materials significantly impacts performance, durability, and cost. Here, we analyze four common materials used in the construction of wood processors, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Steel

Key Properties:

Steel is known for its high tensile strength and durability, making it ideal for heavy-duty applications. It can withstand high pressure and is resistant to deformation under load. Common grades include carbon steel and alloy steel, which can be treated for enhanced hardness and wear resistance.

Pros & Cons:

Steel’s primary advantage is its strength and longevity, which translates to lower maintenance costs over time. However, it can be heavy, increasing transportation costs and complicating installation. Additionally, untreated steel is prone to corrosion, which can be a significant drawback in humid or wet environments.

Illustrative image related to wood processor for sale

Impact on Application:

Steel is compatible with various processing media, including logs of different sizes and densities. Its strength allows for efficient processing without the risk of structural failure.

Considerations for International Buyers:

Buyers should ensure compliance with local standards, such as ASTM in the U.S. or DIN in Germany, to guarantee quality and safety. In regions like Africa and South America, where environmental conditions vary, selecting corrosion-resistant steel or applying protective coatings may be necessary.

2. Aluminum

Key Properties:

Aluminum is lightweight and corrosion-resistant, making it suitable for portable wood processors. It has a lower density than steel, which reduces transportation costs and makes handling easier.

Pros & Cons:

The primary advantage of aluminum is its resistance to rust and corrosion, which is beneficial in humid climates. However, it has a lower tensile strength compared to steel, which may limit its use in heavy-duty applications. Additionally, aluminum can be more expensive to manufacture and process.

Illustrative image related to wood processor for sale

Impact on Application:

Aluminum processors are well-suited for smaller operations or mobile units, where weight is a critical factor. However, they may not handle larger logs as effectively as steel counterparts.

Considerations for International Buyers:

Buyers should be aware of the varying costs of aluminum in different regions, as well as the potential need for specialized manufacturing processes. Compliance with international standards for aluminum alloys is also crucial.

3. High-Strength Composite Materials

Key Properties:

Composite materials combine various elements to enhance strength while reducing weight. They often exhibit excellent resistance to corrosion and wear, making them suitable for harsh environments.

Illustrative image related to wood processor for sale

Pros & Cons:

The main advantage of composites is their lightweight nature, which can improve fuel efficiency in mobile processors. However, they can be more expensive than traditional materials and may require specialized manufacturing techniques.

Impact on Application:

Composites can be used in non-structural components, reducing overall weight without sacrificing performance. They are particularly effective in environments where corrosion is a concern.

Considerations for International Buyers:

Buyers should investigate the availability of composite materials in their regions and consider the potential for higher costs. Compliance with local and international standards for composites is essential for ensuring product quality.

4. Cast Iron

Key Properties:

Cast iron is known for its excellent wear resistance and ability to absorb vibrations, making it ideal for components that experience heavy wear.

Illustrative image related to wood processor for sale

Pros & Cons:

The durability of cast iron is a significant advantage, especially in high-impact applications. However, it is brittle and can crack under stress, which may limit its use in certain structural components. Additionally, cast iron is heavier, which can increase shipping costs.

Impact on Application:

Cast iron is often used in critical components such as the splitting wedge and frame, where durability is paramount. Its vibration-damping properties can enhance the overall performance of the processor.

Considerations for International Buyers:

Buyers should consider the availability of cast iron and its associated costs in their regions. Compliance with international standards for cast iron products is crucial for ensuring reliability and safety.

Summary Table of Material Selection for Wood Processors

| Material | Typical Use Case for wood processor for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components and frames | High strength and durability | Prone to corrosion without treatment | Medium |

| Aluminum | Portable and mobile processors | Lightweight and corrosion-resistant | Lower strength than steel | High |

| High-Strength Composite | Non-structural components | Lightweight and corrosion-resistant | Higher manufacturing costs | High |

| Cast Iron | Splitting wedges and heavy-duty components | Excellent wear resistance | Brittle and heavy | Medium |

This strategic material selection guide provides valuable insights for B2B buyers in the wood processing industry, helping them make informed decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for wood processor for sale

What Are the Main Stages in the Manufacturing Process of Wood Processors?

The manufacturing of wood processors involves several critical stages, each designed to ensure the final product meets the high standards required for efficient and reliable operation. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Wood Processors?

Material preparation is the first step in the manufacturing process. High-quality raw materials such as steel and aluminum are selected based on their strength, durability, and resistance to wear. Suppliers often provide certifications to verify the material quality. The materials are then cut to size using precision machinery, ensuring that they meet the specifications required for subsequent processes. This stage is crucial because the strength of the final product largely depends on the quality of the materials used.

What Forming Techniques Are Commonly Used in Wood Processor Manufacturing?

Once the materials are prepared, the next step is forming. This involves various techniques such as welding, bending, and machining. Advanced technologies, including CNC (Computer Numerical Control) machines, are often employed to achieve precise cuts and shapes. For instance, components like the frame and feed trough are fabricated to ensure they can withstand the rigors of heavy-duty use. Additionally, forming processes may include stamping and forging to create specific parts that require enhanced strength and durability.

How Is Assembly Conducted in the Manufacturing of Wood Processors?

The assembly stage is where all components come together to form the complete wood processor. This process typically involves multiple sub-assemblies, including the hydraulic system, engine installation, and the clamping mechanisms. Skilled technicians follow detailed assembly instructions and utilize specialized tools to ensure each component is correctly fitted and calibrated. During this phase, quality control checks are integrated to catch any discrepancies before moving on to the finishing stage.

Illustrative image related to wood processor for sale

What Finishing Techniques Are Employed for Wood Processors?

Finishing is the final stage of manufacturing, which involves applying protective coatings and surface treatments. This may include powder coating or galvanizing to enhance corrosion resistance, especially important for equipment that may be exposed to outdoor elements. Additionally, final inspections are conducted to ensure that all components function correctly and meet the design specifications. The finishing stage not only improves aesthetics but also extends the operational life of the wood processor.

What International Standards Should B2B Buyers Consider for Quality Assurance?

For B2B buyers, understanding quality assurance standards is crucial in selecting a reliable supplier. International standards such as ISO 9001 are essential, as they outline the criteria for a quality management system. Compliance with ISO 9001 indicates that the manufacturer has a systematic approach to managing quality and is committed to continuous improvement.

Additionally, industry-specific certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards may also be relevant depending on the intended use of the wood processors. These certifications ensure that products meet safety, health, and environmental protection standards.

What Are the Key Quality Control Checkpoints in Wood Processor Manufacturing?

Quality control (QC) checkpoints are integral throughout the manufacturing process. Key QC stages include:

-

Incoming Quality Control (IQC): This is conducted on raw materials upon delivery. Suppliers are expected to provide documentation verifying that the materials meet specified standards.

-

In-Process Quality Control (IPQC): This involves monitoring the manufacturing process at various stages. Operators check dimensions, weld quality, and assembly accuracy to ensure compliance with design specifications.

-

Final Quality Control (FQC): Conducted after assembly, this stage verifies the functionality and safety of the finished product. Tests may include operational checks, hydraulic pressure tests, and load testing to ensure the wood processor can handle the expected workload.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying a supplier’s quality control practices is essential for international B2B buyers. Here are some actionable steps:

Illustrative image related to wood processor for sale

-

Request Quality Assurance Documentation: Buyers should ask for copies of the supplier’s quality management certifications (e.g., ISO 9001) and any relevant industry-specific certifications.

-

Conduct Supplier Audits: Performing on-site audits allows buyers to assess the manufacturing processes and QC measures firsthand. This can provide insights into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing process and the final product. This is particularly important when dealing with international suppliers.

-

Review Quality Reports: Suppliers should provide regular QC reports detailing any issues encountered during production, corrective actions taken, and overall quality performance.

What Are the QC Considerations for International Buyers from Different Regions?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, there are specific QC considerations to keep in mind:

-

Regional Compliance: Ensure that the products meet local regulations and standards in the buyer’s country. For instance, EU buyers may require CE marking for compliance with European directives.

-

Cultural and Logistical Factors: Be aware of potential cultural differences that may affect communication and expectations regarding quality. Additionally, consider logistical challenges that could impact product delivery and quality assurance, such as shipping conditions and customs regulations.

-

Market-Specific Needs: Different markets may have unique requirements for wood processors, including size, output capacity, and additional features. Suppliers should be able to adapt their QC processes to meet these varying demands.

Conclusion

Understanding the manufacturing processes and quality assurance protocols for wood processors is essential for B2B buyers seeking reliable equipment. By being informed about the key stages of manufacturing, relevant quality standards, and effective verification methods, buyers can make more informed purchasing decisions and ensure they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wood processor for sale’

Introduction

Sourcing a wood processor is a critical investment for businesses involved in timber and firewood production. This guide provides a comprehensive checklist to streamline the procurement process, ensuring you select the right machinery that meets your operational needs while maximizing efficiency and profitability.

Step 1: Define Your Technical Specifications

Before exploring options, establish clear technical specifications based on your production needs. Consider factors such as the type of wood you will process, desired output capacity (cords per hour), and log dimensions (diameter and length). Having well-defined specifications helps narrow down suitable models and prevents costly mismatches later.

Illustrative image related to wood processor for sale

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers. Look for companies with a solid track record in the wood processing industry, especially those that cater to your target market. Key aspects to investigate include:

– Experience and Reputation: Check online reviews and industry ratings.

– Product Range: Ensure they offer various models to match your specifications.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers have the necessary certifications and compliance with international standards. This step is crucial for ensuring product quality and safety. Look for certifications such as ISO, CE, or relevant local standards that demonstrate adherence to manufacturing and operational regulations.

Step 4: Request Product Demonstrations

Whenever possible, request demonstrations or trials of the wood processors you are considering. This allows you to assess performance firsthand and evaluate features such as speed, ease of use, and maintenance requirements. Pay attention to:

– Cycle Time: How quickly the processor can handle logs.

– User-Friendliness: Ease of operation for your team.

Step 5: Compare Pricing and Financing Options

Collect detailed quotes from multiple suppliers and compare pricing structures. Consider the total cost of ownership, which includes maintenance, parts, and operational costs. Additionally, inquire about financing options, as many suppliers offer tailored financing plans that can ease cash flow constraints.

Step 6: Review Warranty and After-Sales Support

Thoroughly examine warranty terms and the level of after-sales support offered by suppliers. A robust warranty can safeguard your investment against defects, while reliable after-sales support ensures that you have access to technical assistance and spare parts. Key points to confirm include:

– Duration of Warranty: What is covered and for how long?

– Availability of Spare Parts: Ensure parts are readily available for maintenance.

Step 7: Finalize the Purchase Agreement

Once you’ve selected a supplier, ensure that all terms are clearly outlined in a purchase agreement. This should include delivery timelines, payment terms, and service level agreements. A well-defined contract protects both parties and sets clear expectations for the transaction.

By following this structured checklist, B2B buyers can navigate the complexities of sourcing a wood processor more effectively, ultimately leading to informed decisions that support business growth.

Illustrative image related to wood processor for sale

Comprehensive Cost and Pricing Analysis for wood processor for sale Sourcing

What Are the Key Cost Components in Sourcing Wood Processors?

When sourcing wood processors, understanding the cost structure is vital for B2B buyers. The primary components include:

-

Materials: The choice of materials significantly influences the cost. High-quality steel, hydraulic systems, and engines (like Hatz or Kohler) are common in premium models. The durability and performance of these materials can justify higher initial investments, especially in demanding environments.

-

Labor: Labor costs encompass both skilled assembly and manufacturing processes. Countries with lower labor costs may offer competitive pricing, but it’s essential to assess the quality of craftsmanship, as this can impact long-term reliability.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Manufacturers with efficient operations typically pass on savings to buyers, thus affecting pricing structures.

-

Tooling: Specialized tooling for production can drive costs up, especially for customized or high-spec models. Buyers should inquire about tooling costs, particularly if they require unique configurations.

-

Quality Control (QC): Rigorous QC processes ensure that the machinery meets safety and performance standards. While this adds to the overall cost, it is a necessary investment to avoid future operational issues.

-

Logistics: Transporting wood processors involves significant logistics costs, influenced by distance, shipping methods, and any import tariffs applicable to the buyer’s country. Understanding these factors can help buyers estimate total acquisition costs.

-

Margin: Suppliers typically build a margin into their pricing to cover operational costs and profit. This margin can vary widely based on market demand, brand reputation, and exclusivity of the product.

How Do Price Influencers Affect Wood Processor Costs?

Several factors influence the pricing of wood processors, making it crucial for buyers to understand their implications:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often attract discounts. Buyers should negotiate for better pricing based on anticipated volume, as suppliers may offer tiered pricing structures.

-

Specifications and Customization: Custom features can significantly increase costs. Buyers should weigh the benefits of specific enhancements against their budget and operational needs.

-

Material Quality and Certifications: Processors made from higher-grade materials or those that meet international certifications (ISO, CE) may command higher prices, but they often promise better performance and longevity.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established brands may charge more due to perceived quality, while newer companies might offer lower prices to gain market share.

-

Incoterms: Understanding the shipping terms (like FOB, CIF) is essential for calculating the total cost of ownership. Different Incoterms can significantly impact the final price due to varying responsibilities for shipping and insurance.

What Tips Can Help Buyers Negotiate Better Pricing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, negotiating effectively can lead to cost savings:

-

Conduct Market Research: Familiarize yourself with current market prices and competitor offerings. This knowledge empowers you during negotiations.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, operational costs, and potential downtime. A more expensive machine may offer lower TCO if it operates more efficiently.

-

Build Relationships: Establishing a rapport with suppliers can lead to better deals and more favorable terms. Long-term relationships often result in loyalty discounts.

-

Be Aware of Pricing Nuances: International buyers should be mindful of currency fluctuations, tariffs, and local regulations that can affect pricing. Understanding these factors can help in making informed purchasing decisions.

-

Request Quotes from Multiple Suppliers: This practice not only gives you a broader view of the market but also provides leverage in negotiations.

Conclusion

While indicative prices for wood processors can range from $21,995 to over $100,000, the actual cost will depend on various factors discussed above. Buyers should approach sourcing with a comprehensive understanding of cost components and pricing influencers to make informed decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing wood processor for sale With Other Solutions

Introduction: Exploring Alternative Solutions to Wood Processors

In the quest for efficient firewood production, buyers often explore various equipment and methods beyond traditional wood processors. Understanding the alternatives available can significantly impact operational efficiency, cost-effectiveness, and overall productivity. This analysis compares wood processors for sale with two viable alternatives: firewood splitters and manual methods, such as chainsaw and splitting maul techniques.

Comparison Table

| Comparison Aspect | Wood Processor For Sale | Firewood Splitter | Manual Method (Chainsaw & Splitting Maul) |

|---|---|---|---|

| Performance | High output (up to 5 cords/hour) | Moderate output (1-3 cords/hour) | Low output (varies significantly) |

| Cost | $21,995 to $100,000+ | $1,500 to $10,000 | $100 to $500 (tools only) |

| Ease of Implementation | Requires training and setup | Generally easy to use | Requires skill and physical labor |

| Maintenance | Regular maintenance needed for optimal use | Minimal maintenance | Low maintenance, but physically demanding |

| Best Use Case | Commercial operations needing high volume | Small to medium-scale operations | DIY or small-scale personal use |

Detailed Breakdown of Alternatives

Firewood Splitter

Firewood splitters are a popular alternative for those looking to process logs into usable firewood. These machines can split logs efficiently, especially when dealing with smaller diameters. They typically range from $1,500 to $10,000, making them a more affordable option for smaller operations. While they offer moderate output, often between 1 to 3 cords per hour, they are easier to operate than full wood processors and require less training. However, they may not handle larger logs as effectively, limiting their use in high-demand environments.

Manual Method (Chainsaw & Splitting Maul)

For those on a tight budget or with limited firewood needs, manual methods such as using a chainsaw followed by a splitting maul can be effective. The initial investment is significantly lower, with costs ranging from $100 to $500 for basic tools. However, the output is highly variable and dependent on the operator’s skill and physical stamina. This method demands considerable physical effort and time, making it less suitable for commercial applications. While it offers flexibility and can be used in remote locations without electricity, the labor intensity may deter some users.

Illustrative image related to wood processor for sale

Conclusion: Choosing the Right Solution for Your Needs

When selecting the right equipment for firewood processing, B2B buyers should carefully assess their specific needs, including the scale of operations, budget, and available labor. A wood processor for sale is ideal for large-scale operations requiring high throughput and efficiency. Firewood splitters serve as a practical middle ground for moderate processing needs, while manual methods can cater to budget-conscious buyers or those requiring minimal output. Ultimately, understanding the strengths and limitations of each option will enable buyers to make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for wood processor for sale

What Are the Essential Technical Properties of a Wood Processor for Sale?

When considering the purchase of a wood processor, understanding its technical properties is crucial for making informed decisions. Here are several key specifications that international B2B buyers should pay attention to:

1. Engine Power (Horsepower)

Engine power, measured in horsepower (HP), directly impacts the efficiency and productivity of a wood processor. A higher horsepower typically indicates a machine capable of handling larger logs and performing tasks more quickly. For example, processors with 38HP can output up to 2 cords of firewood per hour, whereas those with 74HP can reach outputs of 5 cords per hour. Buyers should assess their operational needs to determine the appropriate engine power for their processing volume.

2. Log Capacity

Log capacity refers to the maximum diameter and length of logs that a processor can handle. Specifications might include measurements like 24 inches in diameter and lengths exceeding 32 feet. This property is essential for B2B buyers, as it dictates the types of wood that can be processed and influences overall productivity. Ensuring the processor can accommodate the typical log sizes in a buyer’s region can prevent operational bottlenecks.

3. Cycle Time

Cycle time is the duration it takes for a wood processor to complete one full cycle of cutting and splitting logs. Shorter cycle times, such as 3 to 5 seconds, lead to higher throughput, making the equipment more efficient for large operations. This metric is especially important for businesses focused on maximizing output and minimizing labor costs.

Illustrative image related to wood processor for sale

4. Hydraulic System

The hydraulic system plays a vital role in the operation of a wood processor, controlling the movement of the log clamping system and splitting wedges. Specifications may include the size of hydraulic tanks and the type of hydraulic pump. A robust hydraulic system enhances the processor’s performance, ensuring consistent operation and reducing downtime, which is crucial for maintaining productivity in a commercial setting.

5. Material Grade and Construction

The material grade used in constructing a wood processor can affect its durability and maintenance needs. High-grade steel or specialized alloys may be utilized to enhance the machine’s resistance to wear and tear. For B2B buyers, understanding the material composition can inform decisions regarding long-term investment and potential maintenance costs.

What Are Common Trade Terms Related to Wood Processors?

Familiarizing oneself with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are several important terms related to wood processors:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of wood processors, knowing the OEM can help buyers evaluate the quality and reliability of the machine, as well as potential support and service options.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. This term is particularly relevant for buyers looking to purchase in bulk, as it can affect pricing and inventory management. Understanding MOQ helps businesses plan their purchasing strategies effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent by a buyer to suppliers to request pricing and other details for a specific product or service. For wood processors, an RFQ can help buyers gather competitive offers and make informed purchasing decisions based on specifications and costs.

4. Incoterms (International Commercial Terms)

Incoterms are standardized terms that define the responsibilities of buyers and sellers in international trade. They specify who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms is vital for B2B buyers to understand their obligations and risks in cross-border transactions.

5. Tolerance

In manufacturing, tolerance refers to the permissible limit of variation in a physical dimension or measured value. For wood processors, understanding tolerance levels is essential to ensure that components fit and function correctly, thereby maintaining the machine’s efficiency and safety.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of purchasing a wood processor with greater confidence and make decisions that align with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the wood processor for sale Sector

What Are the Current Market Dynamics and Key Trends in the Wood Processor Sector?

The global wood processor market is experiencing significant growth driven by the increasing demand for processed firewood in both residential and commercial sectors. Regions such as Africa, South America, the Middle East, and Europe are at the forefront of this expansion, influenced by rising construction activities and a growing preference for renewable energy sources. Innovations in technology, such as automated processing and integrated conveyor systems, are becoming essential features that improve efficiency and productivity, allowing businesses to maximize output while minimizing labor costs.

Illustrative image related to wood processor for sale

Emerging trends also highlight the shift towards mobile and compact processors, which are particularly appealing in regions where transportation of heavy machinery is a challenge. The demand for versatile equipment capable of processing various wood sizes and types is increasing, as buyers seek solutions that can adapt to diverse operational needs. Moreover, the integration of software solutions for inventory management and processing analytics is becoming common, enabling businesses to optimize their operations and make data-driven decisions.

How Is Sustainability and Ethical Sourcing Shaping the Wood Processor Market?

Sustainability has emerged as a critical factor influencing purchasing decisions in the wood processor market. International buyers are increasingly aware of the environmental impact of wood processing and are prioritizing suppliers who demonstrate a commitment to sustainable practices. This includes sourcing wood from managed forests and utilizing energy-efficient machinery that reduces carbon footprints.

Ethical sourcing is vital, as it not only supports local economies but also ensures compliance with global regulations concerning timber legality and environmental preservation. Certifications such as Forest Stewardship Council (FSC) and Programme for the Endorsement of Forest Certification (PEFC) are essential for suppliers to establish credibility in the market. These certifications assure buyers that the wood used in their processors comes from responsibly managed sources, thus enhancing their brand reputation and appeal to environmentally conscious consumers.

What Is the Brief Evolution and History of Wood Processors?

The evolution of wood processors can be traced back to traditional manual methods of wood splitting and cutting, which were labor-intensive and time-consuming. The introduction of mechanized solutions in the mid-20th century marked a significant transformation in the industry, allowing for faster and more efficient processing. Early models were primarily designed for small-scale operations, but advancements in technology have led to the development of sophisticated machines capable of handling large volumes of wood with minimal human intervention.

Illustrative image related to wood processor for sale

Today, wood processors are equipped with hydraulic systems, computer controls, and conveyor belts, allowing for seamless operations and increased productivity. The trend toward automation and digitalization is poised to shape the future of the industry, making wood processing more efficient and cost-effective for businesses worldwide. This evolution not only reflects technological advancements but also aligns with the growing demand for sustainable practices and efficiency in the processing of wood products.

Frequently Asked Questions (FAQs) for B2B Buyers of wood processor for sale

-

How do I choose the right wood processor for my business needs?

Selecting the appropriate wood processor involves evaluating your production capacity, the types of logs you will be processing, and your budget. Consider factors such as engine power, output speed, and log size capacity. It’s also important to assess whether you need features like an integrated conveyor or specific wedge options for splitting. Additionally, consult with suppliers about customization options to tailor the machine to your operational requirements, ensuring it meets your specific production goals. -

What features should I look for in a firewood processor?

When sourcing a firewood processor, prioritize features such as engine horsepower, cycle times, and log diameter capacity. Look for processors with automatic cycles for efficiency and those that can handle varying log sizes. Integrated conveyors can streamline operations, while durable wedge options enhance splitting efficiency. Assess user reviews and product specifications to ensure the processor aligns with your production demands and quality expectations. -

What are the typical payment terms for purchasing wood processors internationally?

Payment terms for international purchases often vary by supplier but typically include options such as advance payment, letter of credit, or payment upon delivery. It’s essential to discuss and negotiate terms that suit both parties, considering factors like the machine’s cost, shipping fees, and potential import duties. Ensure clarity on the currency of payment and whether deposits are required before processing your order. -

How can I vet suppliers when sourcing wood processors from abroad?

To vet suppliers, conduct thorough research on their reputation, experience, and customer reviews. Check their certifications and compliance with international standards for quality and safety. Request references from previous clients and consider visiting their facilities if possible. Engaging in direct communication can help assess their responsiveness and willingness to meet your specific needs, further ensuring a reliable partnership. -

What is the minimum order quantity (MOQ) for wood processors?

The minimum order quantity (MOQ) for wood processors can vary significantly among manufacturers. Some suppliers may have no MOQ for individual machines, while others might require bulk orders for cost efficiency. It’s advisable to inquire about MOQs during your initial discussions, especially if you are looking to establish a long-term relationship or if you anticipate future needs for multiple units. -

What logistics should I consider when importing wood processors?

When importing wood processors, consider shipping methods, transit times, and customs clearance procedures. Evaluate the total landed cost, including freight, insurance, and any applicable tariffs or duties. Work with a freight forwarder experienced in heavy machinery to ensure proper handling and timely delivery. Additionally, be aware of local regulations regarding machinery imports to avoid compliance issues. -

How do I ensure quality assurance when purchasing wood processors?

To ensure quality assurance, request detailed product specifications and certifications from the supplier. Consider third-party inspections before shipment to verify that the machinery meets agreed-upon standards. Establish clear communication about warranties and after-sales support, which can be critical for addressing any issues that arise post-purchase. Document all agreements to maintain accountability throughout the transaction. -

Can I customize the wood processor to meet specific production needs?

Yes, many manufacturers offer customization options for wood processors, allowing you to tailor the equipment to your specific production needs. Customizations may include engine specifications, log handling features, and additional attachments like conveyors or specialized wedges. Discuss your requirements with suppliers to explore available options, ensuring that the machine aligns with your operational goals and enhances productivity.

Top 9 Wood Processor For Sale Manufacturers & Suppliers List

1. Hud-Son – Firewood Processors

Domain: hud-son.com

Registered: 1998 (27 years)

Introduction: Firewood Processors: 1. Wolverine M 2. Badger – $21,995.00 (Rated 4.67/5) 3. Badger Winch Processor w/ 10′ Conveyor – $25,495.00 4. Brute – 35hp Firewood Processor 14′ 3 Strand Deck – $45,795.00 5. BRUTE 23 FIREWOOD PROCESSOR – $35,995.00 (Rated 5.00/5) 6. BRUTE CIRCLE FIREWOOD PROCESSOR 7. BRUTE EXT FIREWOOD PROCESSOR – $41,595.00 (Original price: $45,795.00) 8. BRUTE JR FIREWOOD PROCESSOR – $21,…

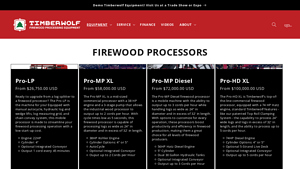

2. Timberwolf – Firewood Processors

Domain: timberwolfequip.com

Registered: 2017 (8 years)

Introduction: This company, Timberwolf – Firewood Processors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Cord King – Firewood Processor

Domain: lumbermenonline.com

Registered: 2001 (24 years)

Introduction: Firewood Equipment For Sale includes various categories: Firewood Processors (38), Firewood Splitters (40), Boilers (20), Conveyors (13), Dry Kilns (37), Firewood Packagings (1), Firewood Tumblers (5), Firewood Wrappers (2), Misc (1), Wood Furnaces (1). Listings include: 2002 Cord King Firewood Processor – $65,000, 2002 Cord King Wood Processor with 85HP JD turbo diesel, 60″ blade, 32 ft conveyor,…

4. DYNA – Used Firewood Processing Equipment

Domain: dyna-products.com

Registered: 2005 (20 years)

Introduction: Used Firewood Processing Equipment: 1. 2018 DYNA SC-16 CAT Diesel – $51,700, Serial Number: 181239-16, Hours: 2683, Factory Refurbished, 14 FT Conveyor, 6-Way Wedge, 1 Year Warranty, 51 hp CAT Diesel Engine, 4 Deck Arms. 2. 2025 DYNA T-100 Honda Gas – $24,600, Serial Number: T1031, Hours: 5, New, 16 Foot Conveyor, 3 Year Warranty, 6.5 hp Honda Gas Engine. 3. 2022 DYNA SC-16 Kohler Diesel – $78,000…

5. Built-Rite – 18 SCP Log Handling System

Domain: built-rite.com

Registered: 1999 (26 years)

Introduction: {‘models’: [{‘name’: ’18 SCP’, ‘clamp’: ‘Patented Built-Rite Scissor Clamp holds logs from 4″ to 16″ in diameter’, ‘log_capacity’: ‘Handles 16\’ logs by 16″ in diameter (optional 4\’ feed trough extension for 22\’ logs)’, ‘chainsaw’: ’20” hydraulic chainsaw with Oregon bar and .404 chain’, ‘wedge’: ‘Hydraulic 4 way wedge for two or four way splitting’, ‘cycle_time’: ‘6 second cycle time with auto-…

6. Backcountry Equipment Inc – EcoPro Firewood Processors

Domain: backcountryequipmentinc.com

Registered: 2022 (3 years)

Introduction: Firewood Processors: EcoPro200, EcoPro300, EcoPro350. EcoPro200: Budget-friendly, processes logs up to 16 inches in diameter and 8-10 feet long, 27-ton splitting ram, manual hydraulically powered chainsaw, maximum splitting length 24 inches, 40″ output chute, $4,830. EcoPro300: 14hp Kohler engine, processes logs up to 16 inches in diameter and 8-10 feet long, 27-ton splitting ram, 10-foot output c…

7. BruteForce USA – BF-2 Log Splitter

Domain: bruteforceusa.com

Registered: 2020 (5 years)

Introduction: BruteForce USA offers a range of high-quality firewood equipment, including wood splitters and firewood processors, designed and built in the USA. Key products include:

1. **BF-2 Log Splitter**:

– Price: From $6,000.00 USD

– Engine: 8.5HP

– Features: Hydraulic log lift, 4-Way wedge, outputs 1 cord of firewood per hour.

2. **Semi-Pro Log Splitter**:

– Price: $9,995.95 USD

– …

8. Cord King – M20-30 Bar Saw Firewood Processor

Domain: machinerypartner.com

Registered: 2014 (11 years)

Introduction: [{‘model’: ‘Cord King M20-30 Bar Saw Firewood Processor’, ‘price’: ‘Price on Request’, ‘production_rate’: ‘Up to 0.0 Cords/hour’, ‘earliest_delivery’: ‘Mid December’}, {‘model’: ‘Cord King CS20-30 Circular Saw Firewood Processor’, ‘price’: ‘$154,100’, ‘production_rate’: ‘Up to 0.0 Cords/hour’, ‘earliest_delivery’: ‘Mid December’}, {‘model’: ‘Cord King CS18-30 Circular Saw Firewood Processor’, ‘pri…

9. Bad Boys of Maine – Firewood Processors

Domain: badboysofmaine.com

Registered: 2024 (1 years)

Introduction: This company, Bad Boys of Maine – Firewood Processors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for wood processor for sale

In conclusion, the strategic sourcing of firewood processors is crucial for international B2B buyers looking to optimize their operations and enhance profitability. The range of available processors, from compact models suitable for small businesses to high-capacity machines designed for large-scale production, offers diverse options to meet varying market demands. Key considerations include engine power, processing speed, and additional features such as integrated conveyors and customizable wedges, which can significantly impact operational efficiency and output.

For buyers in Africa, South America, the Middle East, and Europe, establishing strong supplier relationships is vital. By leveraging local and international networks, businesses can gain access to advanced technology and competitive pricing, ensuring they remain agile in a dynamic market.

Illustrative image related to wood processor for sale

As the global demand for processed firewood continues to rise, the outlook for investment in high-quality wood processors remains positive. We encourage you to explore the market thoroughly, engage with reputable suppliers, and consider the long-term benefits of investing in robust processing equipment. By making informed decisions today, your business can thrive in the competitive landscape of firewood production tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to wood processor for sale