White Picket Fence Panels: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for white picket fence panels

The global market for white picket fence panels presents both opportunities and challenges for B2B buyers looking to enhance property aesthetics and security. Sourcing high-quality white picket fence panels can be daunting, especially when navigating varying standards and regulations across regions such as Africa, South America, the Middle East, and Europe. As international buyers face the complexities of material selection, supplier reliability, and cost management, this comprehensive guide aims to simplify the decision-making process.

In this guide, we delve into a variety of white picket fence panel types, including vinyl, wood, and composite options, highlighting their applications in residential, commercial, and industrial settings. We provide essential insights on how to effectively vet suppliers, ensuring that buyers choose manufacturers who meet stringent quality and compliance standards. Additionally, we explore cost considerations, helping businesses budget effectively while maximizing value.

By arming B2B buyers with in-depth knowledge and actionable strategies, this guide empowers them to make informed purchasing decisions that align with their unique needs and market conditions. Whether you are a distributor, contractor, or retail buyer, understanding the landscape of white picket fence panels will enable you to navigate this market with confidence and success.

Understanding white picket fence panels Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vinyl Picket Fence Panels | Durable, low-maintenance, available in various heights | Residential, commercial landscaping | Pros: Long-lasting, no painting required. Cons: Higher initial cost compared to wood. |

| Classic Scallop Picket Panels | Scalloped design, typically 4-6 feet tall, decorative caps | Aesthetic enhancement for properties | Pros: Attractive design. Cons: May require more frequent cleaning. |

| Composite Picket Fence Panels | Made from recycled materials, eco-friendly options available | Sustainable projects, eco-conscious businesses | Pros: Environmentally friendly, durable. Cons: Can be more expensive than vinyl. |

| Wood Picket Fence Panels | Traditional look, customizable, available in various woods | Custom builds, rustic designs | Pros: Natural appearance, customizable. Cons: Requires regular maintenance and treatment. |

| Aluminum Picket Fence Panels | Lightweight, rust-resistant, available in various colors | Security fencing, commercial properties | Pros: Durable, low maintenance. Cons: Less traditional aesthetic. |

What Are the Characteristics of Vinyl Picket Fence Panels?

Vinyl picket fence panels are a popular choice for both residential and commercial applications due to their durability and low maintenance requirements. They typically come in various heights and can be installed easily, making them suitable for a wide range of projects. B2B buyers should consider the long-term cost savings associated with vinyl, as they do not require painting or staining and resist fading and cracking.

Illustrative image related to white picket fence panels

Why Choose Classic Scallop Picket Panels?

Classic scallop picket panels are characterized by their decorative scalloped tops, adding a visually appealing element to properties. They are commonly used in residential landscaping to enhance curb appeal. B2B buyers should note that while these panels can elevate the aesthetic value, they may require more frequent cleaning to maintain their appearance due to dirt accumulation on the scalloped edges.

How Do Composite Picket Fence Panels Stand Out?

Composite picket fence panels are made from recycled materials, making them an environmentally friendly option. They offer a unique blend of durability and sustainability, appealing to eco-conscious businesses and projects. Buyers should weigh the benefits of reduced environmental impact against the typically higher cost compared to traditional materials like wood or vinyl.

What Are the Benefits of Wood Picket Fence Panels?

Wood picket fence panels provide a classic and customizable option for various applications, from residential gardens to rustic commercial properties. Their natural look can be appealing, and they can be painted or stained to match specific designs. However, B2B buyers must consider the ongoing maintenance required to prevent rot and decay, which can increase long-term costs.

Why Consider Aluminum Picket Fence Panels?

Aluminum picket fence panels are lightweight and rust-resistant, making them an excellent choice for security fencing in commercial properties. They are available in various colors and styles, providing versatility for different aesthetics. While they offer low maintenance and durability, B2B buyers should be aware that aluminum may not provide the same traditional look as wood or vinyl options.

Key Industrial Applications of white picket fence panels

| Industry/Sector | Specific Application of white picket fence panels | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Residential Construction | Home perimeter security and aesthetic appeal | Enhances property value and curb appeal | Durability, UV resistance, and compliance with local regulations |

| Agriculture | Livestock containment and garden protection | Prevents livestock from straying and protects crops | Weather resistance, height specifications, and ease of installation |

| Hospitality | Outdoor event spaces and guest areas | Creates inviting and secure environments for guests | Customization options, ease of maintenance, and design appeal |

| Retail | Storefront demarcation and customer areas | Attracts customers and defines property boundaries | Cost efficiency, style variety, and durability against wear |

| Municipal Infrastructure | Parks and public spaces | Enhances community aesthetics and safety | Compliance with municipal standards, environmental impact, and maintenance requirements |

How Are White Picket Fence Panels Utilized in Residential Construction?

In residential construction, white picket fence panels are primarily used to enhance home security while providing aesthetic appeal. They serve as a boundary that delineates property lines and offers a welcoming look to homes. B2B buyers in this sector must consider the durability of materials, particularly in regions with extreme weather, and ensure compliance with local building codes. High-quality vinyl options are favored for their long lifespan and minimal maintenance, making them a cost-effective solution in the long run.

What Role Do White Picket Fence Panels Play in Agriculture?

In agriculture, white picket fence panels are often employed to contain livestock and protect gardens from wildlife. They effectively prevent animals from straying while safeguarding crops from damage. For buyers in this industry, sourcing panels that can withstand harsh weather conditions is crucial. Additionally, the height and strength of the panels should be tailored to the specific types of livestock being contained. This ensures safety and efficiency, reducing potential losses from escaped animals or crop damage.

How Do Hospitality Businesses Benefit from White Picket Fence Panels?

Hospitality businesses utilize white picket fence panels to create defined outdoor event spaces and enhance guest areas. These panels contribute to an inviting atmosphere, making outdoor dining or event hosting more appealing. For B2B buyers in the hospitality sector, customization options are vital to match the venue’s aesthetic. Additionally, ease of maintenance is a significant consideration, as these businesses require solutions that remain attractive over time without extensive upkeep.

Illustrative image related to white picket fence panels

In What Ways Are White Picket Fence Panels Used in Retail Settings?

In retail, white picket fence panels are used for storefront demarcation and to create inviting customer areas. They help attract foot traffic by presenting a charming façade that draws customers in. When sourcing for retail applications, businesses should prioritize cost efficiency and a variety of styles to suit different branding needs. The durability of the panels against wear and tear is also essential, particularly in high-traffic areas where they may be subject to damage.

Why Are White Picket Fence Panels Important for Municipal Infrastructure?

Municipal infrastructure projects often incorporate white picket fence panels in parks and public spaces to enhance aesthetics and ensure safety. These panels can define boundaries, guide foot traffic, and create a sense of community within public areas. For B2B buyers in this sector, compliance with municipal standards is critical. Additionally, considerations around environmental impact and long-term maintenance requirements are essential to ensure that installations remain sustainable and functional over time.

3 Common User Pain Points for ‘white picket fence panels’ & Their Solutions

Scenario 1: Sourcing Quality Materials for Diverse Markets

The Problem: B2B buyers often face significant challenges when sourcing white picket fence panels that meet varying quality standards across different markets. For instance, a distributor in Saudi Arabia may struggle to find panels that withstand extreme heat and humidity, while a buyer in Germany might be concerned about compliance with EU standards for environmental sustainability. This inconsistency can lead to costly delays, returns, and reputational damage if the product fails to meet local regulations or consumer expectations.

The Solution: To effectively navigate these challenges, buyers should establish relationships with reputable manufacturers who provide detailed specifications and testing results for their products. Consider sourcing from companies that have a global presence and can offer products tailored to specific environmental conditions. Engaging in thorough due diligence, such as requesting samples and certifications, will ensure that the panels meet the necessary durability and regulatory requirements. Additionally, leveraging online platforms that connect buyers with manufacturers can simplify the procurement process and facilitate access to a wider range of products.

Scenario 2: Installation Complexity and Cost Management

The Problem: Another common pain point for B2B buyers is the complexity and cost associated with the installation of white picket fence panels. Many buyers underestimate the labor and tools required for a proper installation, which can lead to budget overruns and project delays. Furthermore, local contractors may lack experience with specific types of vinyl fencing, impacting the overall quality of the installation.

Illustrative image related to white picket fence panels

The Solution: To mitigate these issues, buyers should invest time in understanding the installation requirements specific to the panels they choose. This includes reviewing installation guides provided by manufacturers and attending training workshops or webinars focused on best practices. When selecting contractors, it’s essential to seek out those with proven experience in installing vinyl fencing. Buyers can also consider purchasing pre-assembled panels, which can significantly reduce installation time and labor costs. Additionally, creating a detailed project plan that outlines all necessary tools and labor requirements can help keep the project on budget and on schedule.

Scenario 3: Ensuring Long-Term Durability and Maintenance

The Problem: Many B2B buyers worry about the long-term durability of white picket fence panels, especially in regions with extreme weather conditions. Issues such as fading, warping, or cracking can lead to increased maintenance costs and dissatisfied customers. Buyers may also be unsure about the best maintenance practices for different types of materials, which can further complicate their purchasing decisions.

The Solution: To address durability concerns, it is crucial to choose high-quality, UV-resistant materials designed to withstand specific environmental challenges. Buyers should look for products that come with warranties, as this can serve as an assurance of quality and longevity. Regular maintenance, such as cleaning and inspecting for damage, should be part of a scheduled plan to extend the lifespan of the fence panels. Manufacturers often provide maintenance guidelines that should be followed to ensure the panels remain in optimal condition. Furthermore, considering the long-term cost of ownership rather than just the initial purchase price can help buyers make more informed decisions that balance quality and affordability.

Illustrative image related to white picket fence panels

Strategic Material Selection Guide for white picket fence panels

When selecting materials for white picket fence panels, B2B buyers must consider several factors, including durability, cost, and compliance with international standards. Below is a detailed analysis of four common materials used in the manufacturing of white picket fence panels, focusing on their properties, advantages, disadvantages, and specific considerations for international buyers.

What Are the Key Properties of Vinyl for White Picket Fence Panels?

Vinyl is one of the most popular materials for white picket fence panels due to its impressive durability and low maintenance requirements. It is resistant to rot, insects, and extreme weather conditions, making it suitable for various climates. Vinyl can withstand temperatures ranging from -40°F to 140°F, ensuring performance in both hot and cold environments.

Pros: Vinyl is lightweight, easy to install, and does not require painting or staining. It is also available in various styles and colors, allowing for aesthetic flexibility.

Illustrative image related to white picket fence panels

Cons: While vinyl is durable, it can become brittle over time when exposed to extreme UV light, leading to potential cracking. Additionally, the initial cost of vinyl fencing can be higher than wood or metal options.

Impact on Application: Vinyl’s chemical resistance makes it suitable for residential and commercial applications where exposure to chemicals or pollutants is a concern.

Considerations for International Buyers: Buyers from regions with high UV exposure, like the Middle East, should ensure that the vinyl meets specific UV resistance standards. Compliance with ASTM standards is essential for ensuring quality and safety.

Illustrative image related to white picket fence panels

How Does Wood Compare as a Material for White Picket Fence Panels?

Wood is a traditional choice for white picket fence panels, offering a classic aesthetic that many consumers prefer. Commonly used woods include cedar and pine, which possess natural resistance to decay and insects.

Pros: Wood is generally more affordable than vinyl and can be easily customized through painting or staining. It also provides a natural look that blends well with landscaping.

Cons: Wood requires regular maintenance, including painting or sealing, to prevent rot and damage from weather elements. It is also susceptible to warping and splitting over time.

Illustrative image related to white picket fence panels

Impact on Application: Wood’s compatibility with various finishes allows for versatility in design, but its susceptibility to moisture makes it less suitable for humid environments.

Considerations for International Buyers: Buyers should consider the availability of sustainably sourced wood and compliance with local environmental regulations, such as those in Germany or South America.

What Are the Benefits and Limitations of Aluminum for White Picket Fence Panels?

Aluminum is a lightweight and corrosion-resistant material ideal for white picket fence panels. It can withstand harsh weather conditions without rusting or deteriorating.

Illustrative image related to white picket fence panels

Pros: Aluminum is durable, requires minimal maintenance, and is available in various styles and finishes, including powder coating for added color.

Cons: The initial cost of aluminum fencing can be higher than wood or vinyl. Additionally, while it is strong, it may not be as sturdy as steel options.

Impact on Application: Aluminum is suitable for areas with high humidity or salt exposure, such as coastal regions, due to its corrosion resistance.

Considerations for International Buyers: Compliance with international standards such as DIN for aluminum products is essential, especially for buyers in Europe. Buyers should also consider local manufacturing capabilities to reduce shipping costs.

Why Consider Composite Materials for White Picket Fence Panels?

Composite materials, made from a mix of wood fibers and plastic, offer a balance between the aesthetics of wood and the durability of vinyl.

Illustrative image related to white picket fence panels

Pros: Composites are resistant to rot, insects, and fading while providing a natural wood-like appearance. They require less maintenance than traditional wood.

Cons: Composite materials can be heavier and more expensive than both wood and vinyl. Additionally, they may not be as widely available in all regions.

Impact on Application: Composites are suitable for various climates and environments, combining the benefits of both wood and plastic.

Considerations for International Buyers: Buyers should verify that composite materials meet local environmental standards and regulations, particularly in regions with strict building codes.

| Material | Typical Use Case for white picket fence panels | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vinyl | Residential and commercial fencing | Low maintenance and durable | Can become brittle with UV exposure | High |

| Wood | Traditional residential fencing | Affordable and customizable | Requires regular maintenance | Low |

| Aluminum | Coastal and high-humidity areas | Corrosion-resistant and lightweight | Higher initial cost | Medium |

| Composite | Versatile applications with wood-like aesthetics | Resistant to rot and insects | Heavier and potentially more expensive | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the various materials available for white picket fence panels, enabling informed purchasing decisions tailored to their specific needs and regional considerations.

Illustrative image related to white picket fence panels

In-depth Look: Manufacturing Processes and Quality Assurance for white picket fence panels

What Are the Key Stages in the Manufacturing Process of White Picket Fence Panels?

The manufacturing process for white picket fence panels involves several key stages that ensure the final product meets both aesthetic and functional requirements. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: What Materials Are Used?

The primary materials used in manufacturing white picket fence panels include high-quality vinyl and sometimes wood composites. Vinyl is favored for its durability, low maintenance, and resistance to weathering, while wood composites offer a traditional look with enhanced longevity. The process begins with sourcing raw materials, which must meet specific industry standards. Suppliers often rely on reputable manufacturers to provide certified materials, ensuring they are free from harmful substances.

Once materials are sourced, they undergo rigorous inspections to confirm compliance with international and regional regulations. Buyers should inquire about the supplier’s sourcing practices and the certifications of their materials to ensure quality and sustainability.

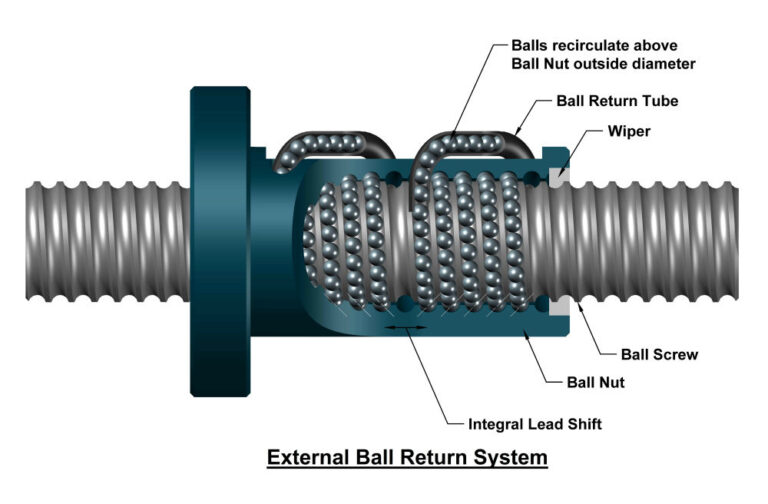

How Are White Picket Fence Panels Formed?

The forming stage involves shaping the raw materials into the desired panel structure. For vinyl panels, this typically includes extrusion, where heated vinyl is forced through a die to create the profile of the pickets and rails. This method allows for precision in dimensions and uniformity across panels, which is crucial for assembly.

Illustrative image related to white picket fence panels

For wood composite panels, the process may involve molding or pressing, where wood fibers are combined with resins under heat and pressure to form durable panels. The choice of manufacturing technique can affect the strength, flexibility, and overall quality of the fence panels.

What Are the Assembly Techniques for Picket Fence Panels?

Once the individual components are formed, they move on to the assembly stage. This includes connecting the pickets to the top and bottom rails, often using locking mechanisms or adhesive solutions to ensure stability. Advanced assembly techniques may involve routing and notching, which enhances the structural integrity of the panels by allowing components to interlock securely.

Quality assurance during assembly is critical. Buyers should look for suppliers that employ skilled labor and automated processes to minimize human error. This attention to detail not only enhances the product’s durability but also its aesthetic appeal.

How Are White Picket Fence Panels Finished?

The finishing process is where the panels receive their final treatment, which may include UV stabilizers, color additives, and surface coatings. These treatments enhance the panels’ resistance to fading and environmental damage, ensuring they maintain their pristine appearance over time.

Illustrative image related to white picket fence panels

For vinyl panels, a smooth finish is achieved through advanced techniques like polishing or applying a protective layer. In contrast, wood composite panels might receive a protective sealant to prevent moisture absorption. Buyers should inquire about the finishing processes used by suppliers to ensure they align with industry standards and customer expectations.

What Quality Control Measures Are Essential for White Picket Fence Panels?

Quality control (QC) is a critical component of the manufacturing process, ensuring that each product meets stringent standards before it reaches the market. B2B buyers should be familiar with the various QC measures in place to safeguard their investments.

What International Standards Govern the Quality of Fence Panels?

Manufacturers of white picket fence panels often adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards helps ensure that products are consistently produced and controlled according to quality standards.

In addition to ISO certifications, industry-specific standards such as CE marking for products sold in Europe and API standards for materials used in construction may apply. Buyers should confirm that their suppliers possess relevant certifications, as these can serve as a benchmark for quality.

Illustrative image related to white picket fence panels

What Are the Checkpoints in the Quality Control Process?

Quality control typically involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival at the manufacturing facility. Suppliers should check for certification documents and perform random sampling tests to ensure that materials meet specified criteria.

-

In-Process Quality Control (IPQC): During the manufacturing stages, regular inspections are conducted to monitor processes and ensure adherence to quality standards. This might include checking dimensions, strength, and finish quality at various stages.

-

Final Quality Control (FQC): Before packaging, finished products undergo a final inspection. This includes visual checks for defects, testing for durability, and ensuring that panels conform to specifications.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, verifying a supplier’s quality control practices is essential. This can be accomplished through:

-

Supplier Audits: Conducting audits at the manufacturing facility provides insight into the supplier’s processes, compliance with standards, and overall operational efficiency.

-

Quality Control Reports: Requesting detailed QC reports can help buyers understand the testing methods employed and the outcomes of inspections. These reports should outline any defects found and corrective actions taken.

-

Third-Party Inspections: Utilizing third-party inspection services can provide an unbiased assessment of product quality and manufacturing practices. This is particularly valuable when sourcing from overseas suppliers.

What Unique Considerations Should B2B Buyers from Different Regions Keep in Mind?

B2B buyers from Africa, South America, the Middle East, and Europe face unique challenges and considerations when sourcing white picket fence panels. Understanding regional market dynamics, regulations, and cultural preferences is crucial.

How Do Regional Regulations Affect Sourcing?

Different regions have varying regulations regarding construction materials, including environmental standards and safety regulations. Buyers should familiarize themselves with local laws to ensure compliance. For instance, certain materials may be restricted in specific countries due to environmental concerns.

What Cultural Preferences Influence Product Design?

Cultural preferences can significantly influence the design and aesthetic of fencing products. Buyers should consider regional styles and customer preferences when selecting suppliers. For instance, in some markets, traditional wooden fences may be preferred over vinyl, while others may prioritize modern, low-maintenance options.

In summary, a thorough understanding of the manufacturing processes and quality assurance measures for white picket fence panels is essential for B2B buyers. By focusing on material quality, manufacturing techniques, and stringent QC measures, buyers can ensure they choose suppliers that align with their business needs and market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘white picket fence panels’

In the competitive landscape of fencing solutions, sourcing high-quality white picket fence panels requires a strategic approach. This guide serves as a practical checklist for B2B buyers, ensuring you make informed decisions while navigating the procurement process.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for aligning your needs with supplier offerings. Consider factors such as panel height, width, material (vinyl, wood, or composite), and design style. Detailing these specifications helps streamline communication with suppliers and minimizes misunderstandings.

Illustrative image related to white picket fence panels

- Height & Width: Common sizes include 3 ft high by 8 ft wide or 4 ft high by 8 ft wide panels.

- Material Preference: Vinyl panels are popular for their durability and low maintenance.

Step 2: Research Market Trends

Understanding current market trends can provide insights into pricing, popular designs, and emerging materials. This knowledge can help you negotiate better terms and select products that meet consumer demand in your target market.

- Regional Preferences: For instance, certain regions may prefer scalloped designs over straight-top panels.

- Sustainability: Increasingly, buyers are looking for eco-friendly materials; consider this in your sourcing decisions.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers with a proven track record of reliability and quality.

- Certifications: Verify if suppliers hold relevant industry certifications or standards, such as ISO or ASTM compliance.

- Customer Reviews: Research online reviews and testimonials to gauge supplier reputation.

Step 4: Request Samples and Specifications

Always request product samples to evaluate quality firsthand. This step is critical to assess the durability, finish, and overall appearance of the fence panels.

Illustrative image related to white picket fence panels

- Material Assessment: Check for resistance to fading, warping, and weather conditions.

- Design Verification: Ensure the samples match your design specifications and aesthetic requirements.

Step 5: Compare Pricing and Terms

Once you have identified potential suppliers, compare their pricing structures and payment terms. Look beyond the initial cost and consider factors such as shipping fees, bulk discounts, and warranty provisions.

- Volume Discounts: Inquire about discounts for larger orders, which can significantly impact your overall budget.

- Warranty Information: A solid warranty can provide peace of mind regarding product longevity.

Step 6: Confirm Logistics and Delivery Times

Understanding logistics is crucial for planning your project timeline. Confirm lead times for production and shipping, especially if you’re working on a tight schedule.

- Delivery Options: Clarify whether the supplier offers direct shipping or if you need to arrange transportation.

- Customs and Duties: For international orders, ensure you understand any customs requirements and potential duties involved.

Step 7: Finalize Contracts and Terms

Once you’ve selected a supplier, ensure all terms are documented in a clear contract. This should include pricing, delivery schedules, warranties, and any specific agreements made during negotiations.

- Legal Review: Consider having a legal expert review the contract to safeguard your interests.

- Clear Communication: Maintain open lines of communication with your supplier throughout the process to address any issues promptly.

By following this checklist, B2B buyers can navigate the sourcing of white picket fence panels effectively, ensuring they secure quality products that meet their specific needs.

Comprehensive Cost and Pricing Analysis for white picket fence panels Sourcing

Understanding the cost structure and pricing dynamics of white picket fence panels is crucial for international B2B buyers aiming to make informed sourcing decisions. This analysis outlines the various components that influence costs and pricing, providing actionable insights for businesses in regions such as Africa, South America, the Middle East, and Europe, including Germany and Saudi Arabia.

Illustrative image related to white picket fence panels

What Are the Key Cost Components of White Picket Fence Panels?

The pricing of white picket fence panels is determined by several cost components:

-

Materials: The choice of materials significantly impacts costs. Vinyl, for instance, is popular due to its durability and low maintenance, but it can be more expensive than wood. High-quality materials may increase the initial investment but often result in lower long-term costs due to reduced maintenance needs.

-

Labor: Labor costs can vary based on location and the complexity of manufacturing processes. Regions with lower labor costs may offer more competitive pricing, but buyers should consider the balance between cost and quality.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize overhead, ultimately influencing the final price.

-

Tooling: Custom designs may require specific tooling, which can add to the initial costs. Buyers should inquire about tooling fees for customized panels and factor these into their total cost.

-

Quality Control (QC): Robust QC measures ensure product consistency and reliability. While this may increase costs, it is crucial for minimizing defects and ensuring customer satisfaction.

-

Logistics: Shipping costs can vary widely depending on the supplier’s location and the buyer’s destination. Understanding freight costs and potential tariffs is essential for accurate pricing.

-

Margin: Suppliers will typically include a margin in their pricing to cover risks and ensure profitability. Understanding typical margins in the industry can help buyers negotiate better terms.

How Do Price Influencers Affect White Picket Fence Panel Costs?

Several factors can influence the pricing of white picket fence panels:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for volume discounts. Buyers should assess their needs and potential storage capabilities to negotiate favorable pricing.

-

Specifications and Customization: Custom features such as unique colors or designs can lead to increased costs. Buyers should clearly define their specifications to avoid unexpected expenses.

-

Quality and Certifications: Panels that meet specific industry standards or certifications may carry a premium price. Buyers should consider the long-term benefits of investing in higher-quality products that adhere to safety and environmental regulations.

-

Supplier Factors: The reputation, reliability, and experience of suppliers can influence pricing. Established suppliers may charge more but often provide better service and product assurance.

-

Incoterms: Understanding the agreed terms of shipment and delivery (Incoterms) is vital. They dictate who is responsible for shipping costs, insurance, and risk, impacting the overall pricing structure.

What Are the Best Practices for Negotiating Prices?

International B2B buyers can adopt several strategies to ensure cost efficiency when sourcing white picket fence panels:

-

Conduct Thorough Market Research: Understanding regional pricing norms and competitor offerings can empower buyers during negotiations.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, consider the TCO, which includes maintenance, installation, and potential replacement costs. This broader perspective can justify higher initial costs for better-quality products.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Long-term partnerships often yield more favorable negotiations.

-

Be Aware of Pricing Nuances: International buyers should be cognizant of currency fluctuations, local market conditions, and geopolitical factors that may impact pricing.

Disclaimer on Indicative Prices

Prices for white picket fence panels can vary widely based on the factors discussed above. The figures provided in various resources are indicative and may not reflect actual market prices. Buyers should obtain detailed quotes from multiple suppliers to ensure competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing white picket fence panels With Other Solutions

Exploring Alternatives to White Picket Fence Panels

When considering fencing solutions, it’s crucial to evaluate various options that can serve similar purposes as white picket fence panels. This analysis will compare white picket fence panels with two viable alternatives: chain link fencing and composite fencing. Each option offers unique advantages and drawbacks, making it essential for B2B buyers to assess their specific needs and contexts before making a decision.

| Comparison Aspect | White Picket Fence Panels | Chain Link Fencing | Composite Fencing |

|---|---|---|---|

| Performance | Aesthetic appeal and durability; provides a classic look. | Offers security and visibility; less privacy. | High durability and aesthetic flexibility; can mimic wood appearance. |

| Cost | Moderate; typically higher than chain link but lower than composite. | Low initial cost; economical for large areas. | Higher upfront cost due to materials and design. |

| Ease of Implementation | Requires proper installation and alignment; can be DIY-friendly. | Simple installation; often requires minimal tools. | Requires skilled installation for best results. |

| Maintenance | Low; requires occasional cleaning, no painting needed. | Very low; occasional rust maintenance may be required. | Low; resistant to rot and insects, no painting needed. |

| Best Use Case | Residential areas, gardens, and decorative boundaries. | Commercial properties, secure areas, and playgrounds. | Residential and commercial applications where aesthetics and durability are priorities. |

In-Depth Analysis of Alternatives

Chain Link Fencing

Chain link fencing is a popular choice for those prioritizing security and low costs. It provides an effective barrier without obstructing visibility, making it ideal for commercial properties or areas where surveillance is necessary. However, its lack of privacy can be a significant drawback in residential settings, where aesthetics and personal space are often more valued. Additionally, while chain link fences are easy to install and maintain, they may not provide the visual appeal that a white picket fence offers.

Composite Fencing

Composite fencing represents a more modern approach, combining wood fibers and recycled plastic to create a highly durable product. This fencing type can mimic the look of wood while providing superior resistance to weather and pests. While it offers an excellent balance of aesthetics and functionality, composite fencing comes with a higher upfront cost compared to both white picket and chain link fences. Installation may also require professional services to ensure structural integrity, which can add to the overall expense. Nevertheless, composite fencing is an excellent choice for buyers looking for a long-lasting and visually appealing solution.

Illustrative image related to white picket fence panels

Making the Right Choice for Your Needs

For B2B buyers, choosing the right fencing solution depends on various factors, including budget constraints, desired aesthetic appeal, and the specific environment in which the fence will be installed. White picket fence panels excel in residential aesthetics and low maintenance but may not suit every application. In contrast, chain link fencing offers a budget-friendly option with excellent security features, while composite fencing provides a blend of durability and visual appeal, albeit at a higher cost. By carefully evaluating these alternatives, buyers can select a fencing solution that aligns with their operational needs and enhances their properties effectively.

Essential Technical Properties and Trade Terminology for white picket fence panels

What Are the Key Technical Properties of White Picket Fence Panels?

When sourcing white picket fence panels, understanding their technical specifications is crucial for ensuring quality, durability, and suitability for specific applications. Here are some key properties to consider:

-

Material Grade

White picket fence panels are typically made from vinyl or wood. Vinyl panels are favored for their durability, resistance to weathering, and low maintenance needs. In contrast, wood panels offer a classic aesthetic but require regular upkeep. Knowing the material grade helps buyers determine the expected lifespan and maintenance requirements of the fence. -

Panel Dimensions

Standard dimensions for white picket fence panels usually range from 3 to 6 feet in height and 8 feet in width. This specification is vital for planning installations, ensuring that the panels fit the intended space, and maintaining aesthetic continuity across a property. -

Thickness and Tolerance

The thickness of the panels affects their strength and resilience. A typical vinyl panel might have a thickness of around 0.150 inches. Tolerance levels indicate the acceptable range of deviation from the stated dimensions. Understanding these tolerances is essential for ensuring that panels fit together properly during installation and provide the desired structural integrity. -

UV Resistance

Given that outdoor fences are exposed to sunlight, UV resistance is an important property, particularly for vinyl panels. This characteristic helps prevent fading and discoloration over time, ensuring that the fence maintains its aesthetic appeal. Buyers should look for panels with UV inhibitors to enhance longevity. -

Wind Load Capacity

Especially relevant in regions prone to strong winds, the wind load capacity indicates how much wind pressure a fence panel can withstand without damage. Knowing this specification is crucial for buyers in areas with extreme weather conditions, ensuring that the fence will remain intact and functional. -

Gate Compatibility

Many fencing projects require gates for access. Compatibility with standard gate kits, including hinge and latch systems, is a vital consideration. This ensures that the overall fencing system is functional and cohesive.

What Are Common Trade Terms Related to White Picket Fence Panels?

Understanding industry-specific terminology can streamline communication and negotiation between buyers and suppliers. Here are some common trade terms relevant to white picket fence panels:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components or products that are sold under another company’s brand. In the context of fencing, an OEM might manufacture the panels for a retailer who then sells them under their brand name. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity of a product that a supplier is willing to sell. This is crucial for buyers to understand, as it impacts inventory management and cost structures. Ensuring that the MOQ aligns with project needs can prevent excess inventory or insufficient supply. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. For buyers, submitting an RFQ is essential for obtaining competitive pricing and understanding the range of options available for white picket fence panels. -

Incoterms (International Commercial Terms)

These are a set of international rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities associated with the delivery of fence panels. -

Lead Time

Lead time is the period between placing an order and receiving the goods. Understanding lead times is crucial for project planning and scheduling, ensuring that fencing materials arrive when needed for installation. -

Warranty

A warranty provides buyers with assurance regarding the quality and durability of the product. It typically outlines the conditions under which a product can be repaired or replaced. Knowing the warranty terms is essential for making informed purchasing decisions and assessing long-term value.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing white picket fence panels, ensuring that they meet their specific needs and project requirements.

Navigating Market Dynamics and Sourcing Trends in the white picket fence panels Sector

What Are the Current Market Dynamics and Key Trends in the White Picket Fence Panels Sector?

The global market for white picket fence panels is influenced by various dynamic factors, including increasing urbanization, a rising interest in home aesthetics, and the growing demand for sustainable building materials. The trend towards outdoor living spaces has surged, as consumers invest in their homes, leading to an uptick in fencing solutions that enhance property value and curb appeal. Internationally, B2B buyers from regions such as Africa, South America, the Middle East, and Europe are particularly interested in vinyl fencing due to its durability and low maintenance requirements.

Illustrative image related to white picket fence panels

Technological advancements in manufacturing processes have also played a pivotal role. Innovations in materials science have led to the development of high-quality, UV-resistant vinyl that can withstand diverse climates, making it appealing for buyers in varying geographies. Furthermore, e-commerce platforms are increasingly facilitating easier access to suppliers, allowing international buyers to compare products and prices effectively, streamlining the sourcing process.

Another key trend is the customization of fencing solutions. Buyers are increasingly looking for options that cater to specific aesthetic preferences and functional requirements, such as height variations and decorative elements. As a result, suppliers that offer customizable solutions are gaining a competitive edge.

How Is Sustainability and Ethical Sourcing Impacting the White Picket Fence Panels Industry?

Sustainability has become a critical consideration for B2B buyers in the white picket fence panels sector. The environmental impact of materials used in fencing is under scrutiny, leading to a growing demand for eco-friendly options. Buyers are now prioritizing suppliers who can demonstrate sustainable practices, such as using recycled materials or implementing energy-efficient manufacturing processes.

Ethical sourcing is also becoming essential. Buyers are increasingly aware of the supply chain implications, including labor practices and environmental regulations. Companies that can provide transparency about their sourcing practices and adhere to ethical standards are likely to build stronger relationships with international buyers. Certifications such as FSC (Forest Stewardship Council) and other environmental labels can serve as critical differentiators in the market.

Moreover, as consumers become more environmentally conscious, the demand for green materials is rising. Vinyl fencing that is manufactured with low-impact processes and offers recyclability at the end of its lifecycle is appealing to buyers looking to meet their sustainability goals.

Illustrative image related to white picket fence panels

What Is the Evolution of the White Picket Fence Panels Market and Its Relevance Today?

The white picket fence has long been a symbol of suburban life, but its evolution reflects broader changes in consumer preferences and construction practices. Initially crafted from wood, the introduction of vinyl fencing in the 1980s revolutionized the market. Vinyl offered a durable, low-maintenance alternative that did not require regular painting or treatment, making it increasingly popular among homeowners and builders alike.

As the market matured, the focus shifted from merely functionality to aesthetics and customization. Today, buyers are looking for not just a fence but a statement piece that enhances their property’s visual appeal. The rise of online platforms has further transformed how buyers source these products, allowing for greater comparison shopping and access to a wider array of choices.

In summary, understanding the market dynamics, sustainability implications, and historical context of white picket fence panels can empower B2B buyers to make informed sourcing decisions that align with their business goals and customer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of white picket fence panels

-

How do I choose the right supplier for white picket fence panels?

When selecting a supplier for white picket fence panels, evaluate their reputation, experience, and product range. Look for suppliers who specialize in vinyl or wood fencing and have a proven track record in international trade. Request samples to assess quality, and consider their ability to meet your specific needs, such as customization options. Don’t hesitate to ask for references or testimonials from other B2B buyers to gauge reliability and service quality. -

What is the best material for white picket fence panels?

Vinyl and wood are the most common materials for white picket fence panels. Vinyl is durable, low-maintenance, and resistant to rot and fading, making it an ideal choice for various climates, especially in humid or coastal regions. Wood offers a classic aesthetic but requires more maintenance and treatment against weather elements. Consider your local climate, budget, and aesthetic preferences when deciding which material best suits your project. -

What are the typical minimum order quantities (MOQs) for white picket fence panels?

Minimum order quantities (MOQs) for white picket fence panels can vary significantly among suppliers. Some manufacturers may require MOQs as low as 50 panels, while others might set higher thresholds, especially for customized orders. Always confirm MOQs with potential suppliers and assess how they align with your project needs. This will help you manage inventory and budget effectively while ensuring you meet demand. -

What customization options are available for white picket fence panels?

Many suppliers offer customization options for white picket fence panels, including height, panel width, picket style, and color variations. Some manufacturers may also allow for personalized designs or additional features like decorative post caps. Discuss your specific requirements with suppliers to understand the extent of customization available and any associated costs or lead times. -

How do I ensure quality assurance (QA) for my order?

To ensure quality assurance for your white picket fence panels, request detailed product specifications and certifications from suppliers. Inquire about their manufacturing processes, including quality control measures and testing protocols. Consider arranging for third-party inspections during production or before shipment to verify that the panels meet your quality standards and comply with international regulations. -

What payment terms should I expect when ordering white picket fence panels internationally?

Payment terms for international orders of white picket fence panels can vary widely. Common terms include a deposit upfront (usually 30% to 50%) with the balance due before shipping. Some suppliers may offer letters of credit or payment through escrow services for added security. Always clarify payment terms in your contract and ensure they align with your financial capabilities and risk tolerance. -

What are the shipping and logistics considerations for importing white picket fence panels?

When importing white picket fence panels, consider shipping methods, costs, and delivery timelines. Options include sea freight for larger shipments, which is cost-effective but slower, or air freight for quicker delivery at a higher cost. Understand customs regulations and duties applicable to your region, and work with logistics partners experienced in international shipping to ensure a smooth import process. -

How can I effectively communicate with suppliers from different regions?

Effective communication with suppliers from different regions involves being clear, concise, and culturally sensitive. Utilize professional translation services if language barriers exist. Be explicit about your requirements, timelines, and expectations. Establish regular communication channels, such as emails or video calls, to build rapport and ensure that both parties are aligned on project goals and progress.

Top 3 White Picket Fence Panels Manufacturers & Suppliers List

1. Vinyl Fence and Deck – Vinyl Picket Fence Panels

Domain: vinylfenceanddeck.com

Registered: 1998 (27 years)

Introduction: Vinyl Picket Fence Panels for sale, heavy-duty, fast shipping. Features include: classic all-American look, no painting required, transferable lifetime warranty, low maintenance, available colors (white, tan, clay), quick assembly with pre-routed posts and aluminum U-channel for strength. Designed for durability against weather, cost-effective compared to wood and metal, lightweight materials for …

2. Weatherables – 4′ Plymouth™ Vinyl Picket Fence

Domain: weatherables.com

Registered: 2008 (17 years)

Introduction: 4′ Plymouth™ Vinyl Picket Fence

– Picket Size: 7/8″ x 3″

– Picket Spacing: 3″

– Bottom Rail: 1.5″ x 5.5″

– Accommodates slope of 10″ over 8ft

– DIY-Friendly: Low maintenance and easy to assemble

– Environmental Impact: One panel keeps approx. 3,175 credit cards worth of plastic out of landfills

– Available Heights: 3′, 4′, 5′

– Picket Caps: Dogear or Spade

– Color Options: White, Tan, Khaki

– Cust…

3. Fencing Direct – Vinyl Picket Fence Products

Domain: fencingdirect.com

Registered: 2007 (18 years)

Introduction: Vinyl Picket Fence Products: 17 total options available. Key features include: 4′ H x 8′ W and 5′ H x 8′ W sizes; colors include White and Tan; various styles such as Closed Picket, Straight, and Scallop; made from high-quality vinyl that is resistant to fading, rotting, termites, and extreme weather; low maintenance and durable; pricing and details available for each product; promotional offer: E…

Strategic Sourcing Conclusion and Outlook for white picket fence panels

In the evolving landscape of fence solutions, the strategic sourcing of white picket fence panels stands out as a crucial consideration for international B2B buyers. Key takeaways emphasize the importance of selecting high-quality materials, such as vinyl, which offer durability and low maintenance, making them ideal for diverse climates across Africa, South America, the Middle East, and Europe. Understanding regional preferences and compliance with local regulations can further enhance sourcing effectiveness and customer satisfaction.

By leveraging strategic sourcing, businesses can optimize their supply chain efficiency, reduce costs, and ensure timely delivery of products. Engaging with reliable manufacturers and suppliers will not only secure high-quality panels but also foster long-term partnerships that can adapt to market changes and demand fluctuations.

Looking ahead, the demand for aesthetically pleasing and sustainable fencing solutions is expected to rise. Buyers are encouraged to explore innovative options that align with their brand values and customer expectations. Now is the time to act—evaluate your sourcing strategies, connect with trusted suppliers, and position your business to thrive in the competitive market of white picket fence panels. Your proactive approach today will shape the success of your fencing projects tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to white picket fence panels