What Is The Function Of Torus Isolation Transformer Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for what is the function of torus isolation transformer

In an increasingly interconnected world, the function of torus isolation transformers has emerged as a critical solution for businesses grappling with the challenges of power quality and reliability. As organizations across Africa, South America, the Middle East, and Europe strive to optimize their electrical systems, understanding the role of these specialized transformers becomes essential. This comprehensive guide delves into the intricacies of torus isolation transformers, highlighting their importance in mitigating electrical noise, enhancing performance, and safeguarding sensitive equipment.

Throughout this guide, we will explore various aspects of torus isolation transformers, including their types, applications across different industries, and key considerations for supplier vetting. Additionally, we will provide insights into cost factors, allowing B2B buyers to make informed purchasing decisions tailored to their unique needs. By addressing common challenges such as power surges, voltage fluctuations, and electromagnetic interference, this guide equips international buyers with the knowledge necessary to enhance their operational efficiency and protect their investments.

Whether you are a technology integrator in Vietnam seeking reliable power solutions or a manufacturer in Brazil aiming to improve equipment longevity, understanding the function of torus isolation transformers will empower you to navigate the global market with confidence. As we unpack the benefits and applications of these vital components, you will be better positioned to ensure that your organization thrives in today’s demanding electrical landscape.

Understanding what is the function of torus isolation transformer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Torus Isolation | Basic design with toroidal core for noise reduction | Commercial audio/video systems | Pros: Cost-effective; reliable performance. Cons: Limited dynamic power capabilities. |

| High-Dynamic Torus Transformer | Enhanced current delivery for demanding applications | Professional audio, broadcasting, and studios | Pros: Superior performance; handles peak loads. Cons: Higher initial investment. |

| Automatic Voltage Regulation (AVR) | Integrates voltage regulation with isolation features | Sensitive electronic equipment in industrial settings | Pros: Protects against voltage fluctuations; improves equipment lifespan. Cons: More complex setup. |

| Surge Protection Torus | Combines isolation with advanced surge suppression | Data centers, IT infrastructure | Pros: Protects against power surges; enhances reliability. Cons: May require additional maintenance. |

| Compact Torus Transformer | Smaller form factor with similar benefits as larger models | Space-constrained environments like retail stores | Pros: Space-efficient; retains performance. Cons: Limited capacity for larger systems. |

What are the characteristics and suitability of Standard Torus Isolation Transformers for B2B buyers?

Standard Torus Isolation Transformers are designed with a toroidal core that effectively reduces electrical noise, making them ideal for commercial audio and video systems. Their primary function is to deliver cleaner power, which is essential for maintaining high-quality audio and video performance. B2B buyers should consider these transformers for environments where basic noise reduction is necessary, but the demand for dynamic power is moderate. They are cost-effective solutions for businesses looking to enhance their audio-visual setups without significant investment.

How do High-Dynamic Torus Transformers meet demanding power needs?

High-Dynamic Torus Transformers are specifically engineered to provide enhanced current delivery, making them suitable for professional audio, broadcasting, and studio applications. These transformers excel in environments where audio and video systems require the ability to handle peak power loads without distortion. B2B buyers in industries that rely on high-performance audio and video should consider these transformers for their superior dynamic capabilities, although they come with a higher initial cost. Their ability to deliver instantaneous current makes them invaluable in settings demanding peak performance.

What advantages do Automatic Voltage Regulation (AVR) Torus Transformers offer?

Automatic Voltage Regulation (AVR) Torus Transformers integrate voltage regulation technology with isolation features, providing a solution for sensitive electronic equipment in industrial settings. By stabilizing voltage levels, these transformers protect against fluctuations that can damage equipment, thereby extending its lifespan. B2B buyers should prioritize AVR models when operating in environments with unstable power supply, as they ensure reliable performance and reduce maintenance costs. While they may involve a more complex setup, the long-term benefits justify the investment.

Why should businesses consider Surge Protection Torus Transformers?

Surge Protection Torus Transformers combine isolation with advanced surge suppression capabilities, making them ideal for data centers and IT infrastructure. They effectively protect sensitive equipment from power surges that can lead to costly downtime and equipment failure. B2B buyers in sectors where data integrity and system uptime are critical should consider these transformers for their enhanced reliability. However, potential buyers should be aware that these units may require additional maintenance to ensure optimal performance over time.

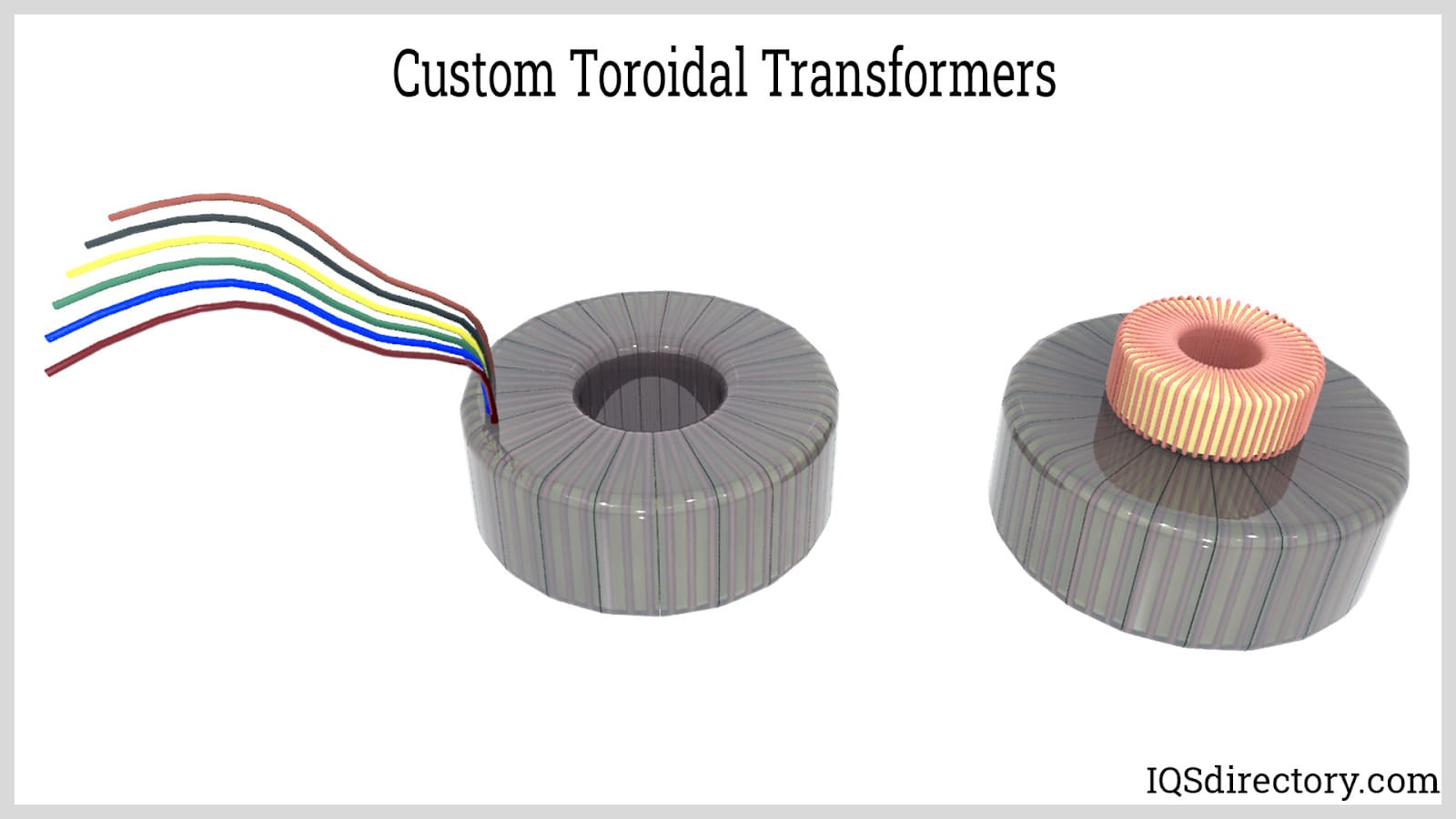

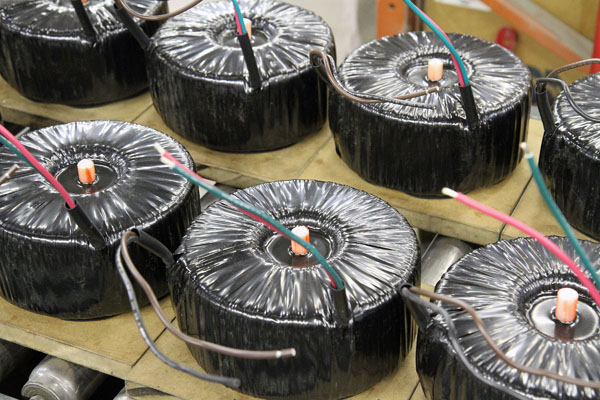

Illustrative image related to what is the function of torus isolation transformer

What benefits do Compact Torus Transformers provide for space-constrained environments?

Compact Torus Transformers offer a space-efficient solution without compromising on the benefits of larger models. They are particularly advantageous in retail stores and other environments where space is limited but the need for clean power remains. B2B buyers looking for a balance between performance and space efficiency should consider these transformers. However, it is essential to note that their capacity may be limited compared to larger models, making them less suitable for high-demand applications.

Key Industrial Applications of what is the function of torus isolation transformer

| Industry/Sector | Specific Application of what is the function of torus isolation transformer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Audio/Video Production | Integration into high-end audio and video systems | Enhances sound and image quality, reducing noise | Ensure compatibility with existing equipment and power needs |

| Data Centers | Powering sensitive IT equipment and servers | Provides stable voltage and surge protection | Evaluate load requirements and redundancy capabilities |

| Healthcare Facilities | Supporting medical imaging and diagnostic equipment | Reduces electrical noise, ensuring accurate readings | Compliance with healthcare regulations and equipment compatibility |

| Manufacturing | Supplying power to CNC machines and robotic systems | Increases operational reliability and equipment life | Assess environmental factors and voltage regulation needs |

| Telecommunications | Powering network infrastructure and communication systems | Improves network stability and reduces downtime | Consider scalability and future power demands |

How is the Torus Isolation Transformer Used in Audio/Video Production?

In the audio and video production industry, Torus isolation transformers are integrated into high-end systems to mitigate electrical noise that can degrade sound and image quality. By providing a clean power source, these transformers enhance the dynamics of audio systems, resulting in clearer sound and more vivid visuals. For B2B buyers, ensuring compatibility with existing equipment and understanding specific power requirements are crucial when sourcing these transformers.

What Role Does the Torus Isolation Transformer Play in Data Centers?

In data centers, Torus isolation transformers are essential for powering sensitive IT equipment and servers. They deliver stable voltage while offering surge protection, which is vital for maintaining the integrity of data and preventing equipment damage. B2B buyers should evaluate the load requirements of their systems and consider the redundancy capabilities of the transformers to ensure optimal performance and reliability.

How Do Healthcare Facilities Benefit from Torus Isolation Transformers?

Healthcare facilities utilize Torus isolation transformers to support medical imaging and diagnostic equipment. These transformers help reduce electrical noise, ensuring that devices operate accurately and reliably, which is critical for patient care. Buyers in this sector must ensure compliance with healthcare regulations and confirm that the transformers are compatible with their specific medical equipment to maintain operational efficiency.

What Advantages Do Manufacturing Industries Gain from Using Torus Isolation Transformers?

In manufacturing, Torus isolation transformers supply power to CNC machines and robotic systems, enhancing operational reliability and extending equipment life. By providing a stable and clean power source, these transformers help minimize downtime and improve productivity. Buyers should assess environmental factors, such as temperature and humidity, along with their voltage regulation needs when sourcing these transformers to ensure they meet operational standards.

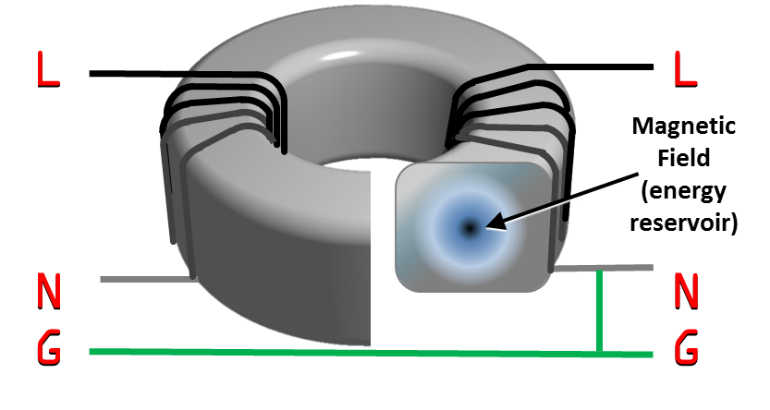

Illustrative image related to what is the function of torus isolation transformer

How Do Telecommunications Companies Leverage Torus Isolation Transformers?

Telecommunications companies rely on Torus isolation transformers to power network infrastructure and communication systems. These transformers improve network stability by reducing electrical noise and minimizing downtime, which is essential for maintaining service quality. When sourcing, B2B buyers should consider the scalability of the transformer solutions to accommodate future power demands and ensure long-term operational efficiency.

3 Common User Pain Points for ‘what is the function of torus isolation transformer’ & Their Solutions

Scenario 1: Navigating Electrical Noise in High-Demand Environments

The Problem: In many B2B settings, particularly in industries reliant on audio and video technology, electrical noise can severely hinder performance. For instance, a conference room equipped with advanced audio-visual systems may suffer from interference due to devices like computers, projectors, and lighting systems operating in parallel on the same electrical circuit. This noise can lead to poor sound quality, distorted images, and ultimately, a subpar user experience that can affect business presentations and client interactions.

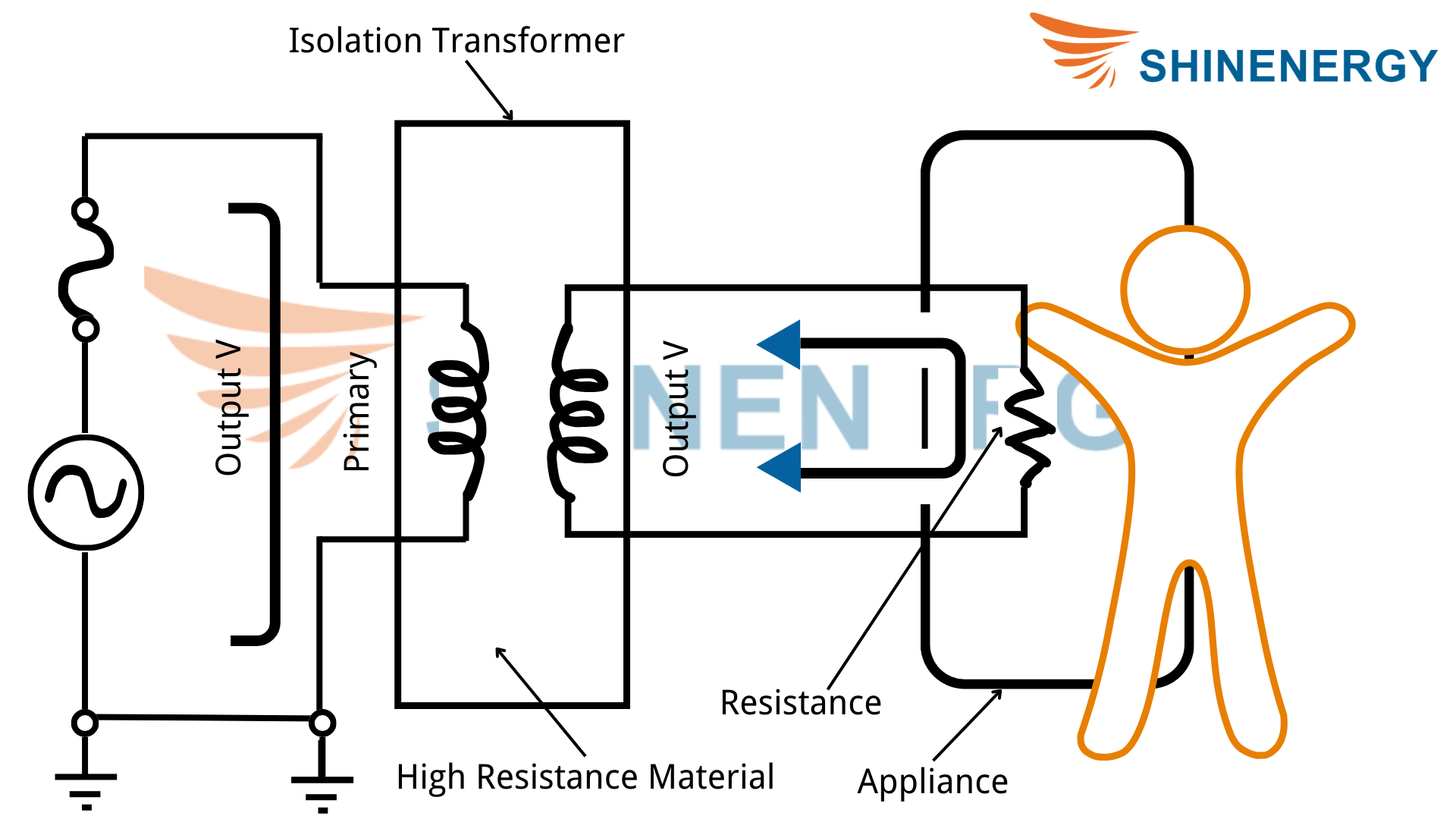

The Solution: To combat this issue, B2B buyers should consider integrating a Torus isolation transformer into their power setup. By specifically isolating the power supply, these transformers significantly reduce both common mode and differential mode noise. When sourcing a Torus isolation transformer, it’s essential to evaluate the power requirements of the connected equipment and select a unit that can handle peak loads while providing clean power. Additionally, installation should be conducted by a qualified electrician to ensure that the transformer is optimally positioned to maximize its noise-reduction capabilities. Regular maintenance checks can also help in assessing the effectiveness of the transformer in minimizing noise interference.

Scenario 2: Managing Voltage Fluctuations in Sensitive Equipment

The Problem: Many businesses operate in regions where power supply can be inconsistent, leading to voltage fluctuations that threaten the integrity of sensitive electronic equipment. For example, a medical facility relying on precise imaging technology may experience equipment malfunctions or failures due to sudden voltage drops or spikes, which can result in costly downtime and compromised patient care.

Illustrative image related to what is the function of torus isolation transformer

The Solution: Implementing a Torus isolation transformer equipped with Automatic Voltage Regulation (AVR) is a strategic move for businesses facing this challenge. These transformers continuously monitor the incoming voltage and adjust it to maintain a stable output, thus protecting sensitive devices. When selecting a transformer, buyers should ensure it meets the voltage requirements of their equipment and consider the total load to avoid overloading the unit. Collaborating with suppliers who understand local power quality issues can help businesses choose the right model. Furthermore, educating staff on the importance of using such transformers can foster a culture of proactive equipment care, enhancing operational reliability.

Scenario 3: Protecting Equipment from Power Surges and Overloads

The Problem: In industries where equipment longevity is critical, such as manufacturing or telecommunications, power surges can pose significant risks. For instance, a factory with multiple machines may face frequent surges from heavy machinery starting up, leading to potential damage to sensitive electronic controls and systems, resulting in costly repairs and operational interruptions.

The Solution: To effectively safeguard against power surges, businesses should invest in Torus isolation transformers that feature advanced surge suppression technologies. These transformers absorb excessive voltage without contaminating the ground, unlike traditional shunt mode surge protectors. When sourcing these transformers, it’s vital to consider the maximum surge protection ratings and ensure that the selected model can handle the specific demands of the equipment being protected. Additionally, businesses should conduct regular audits of their electrical systems to identify potential vulnerabilities and adjust their surge protection strategies accordingly. This proactive approach not only protects equipment but also extends its lifespan, ensuring smoother operations and reducing replacement costs.

Illustrative image related to what is the function of torus isolation transformer

Strategic Material Selection Guide for what is the function of torus isolation transformer

When selecting materials for toroidal isolation transformers, it is crucial to consider their properties and how they align with the specific functions of these devices. The following analysis examines common materials used in the construction of toroidal isolation transformers, focusing on their performance, advantages, disadvantages, and considerations for international B2B buyers.

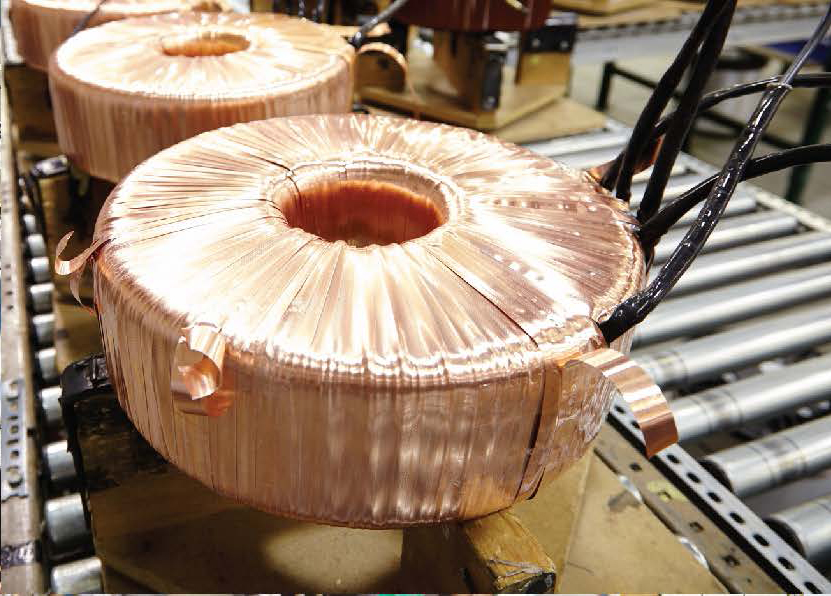

What are the Key Properties of Copper in Toroidal Isolation Transformers?

Copper is the most widely used conductor in electrical applications, including toroidal isolation transformers. Its excellent electrical conductivity (approximately 59.6 S/m) ensures minimal energy loss during power transmission. Additionally, copper offers good thermal conductivity, allowing for efficient heat dissipation.

Pros & Cons: Copper is highly durable and resistant to corrosion, especially when coated or treated. However, its high cost compared to alternatives like aluminum can be a drawback for budget-conscious buyers. Manufacturing complexity is moderate, as copper is easy to work with but requires careful handling to avoid oxidation.

Illustrative image related to what is the function of torus isolation transformer

Impact on Application: Copper’s compatibility with various media is excellent, making it suitable for high-performance audio and video applications where signal integrity is paramount.

Considerations for International Buyers: Compliance with international standards such as ASTM B170 (for copper wire) is essential. Buyers in regions like Africa and South America should also consider local sourcing options to reduce costs and ensure compliance with regional electrical standards.

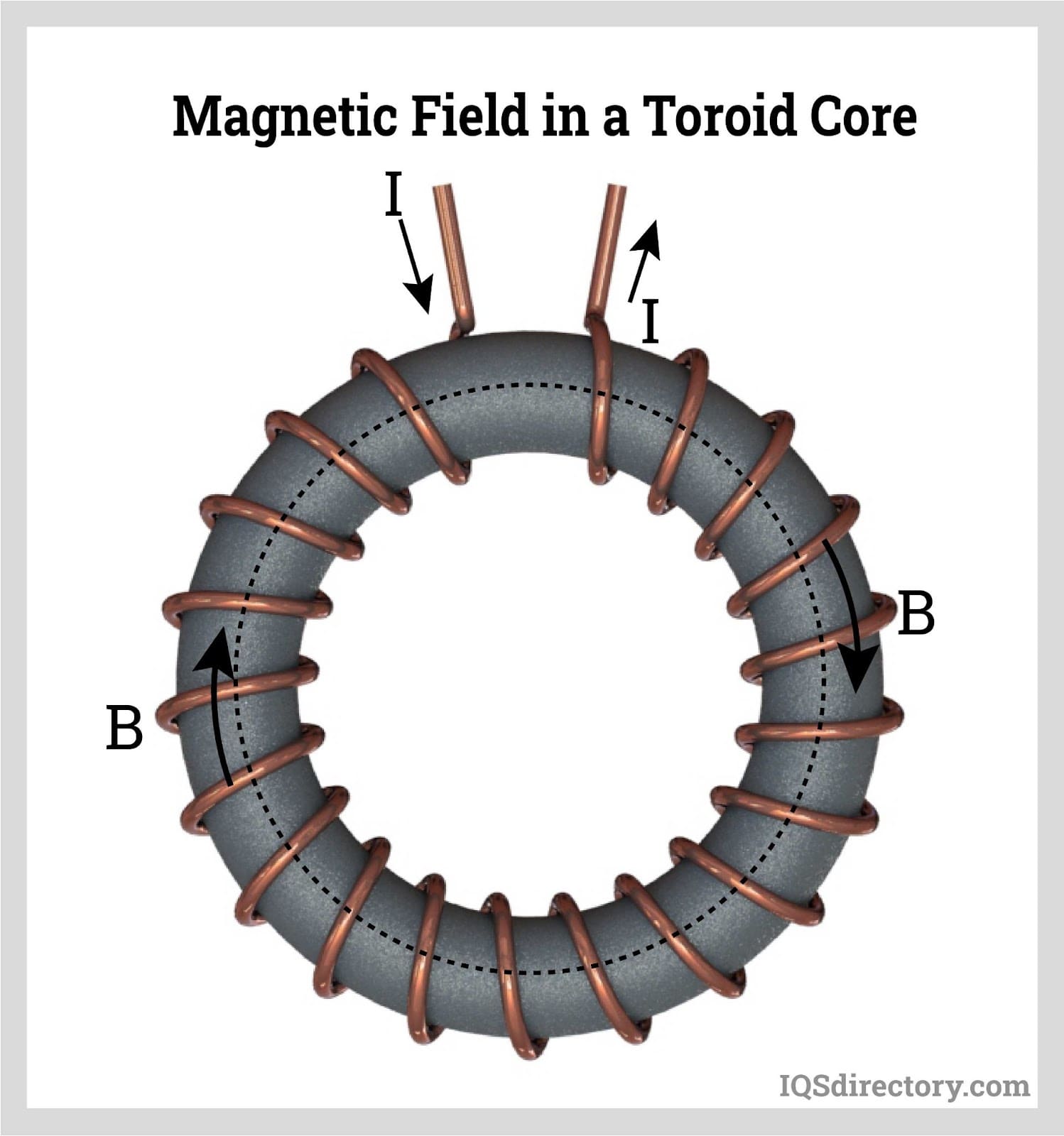

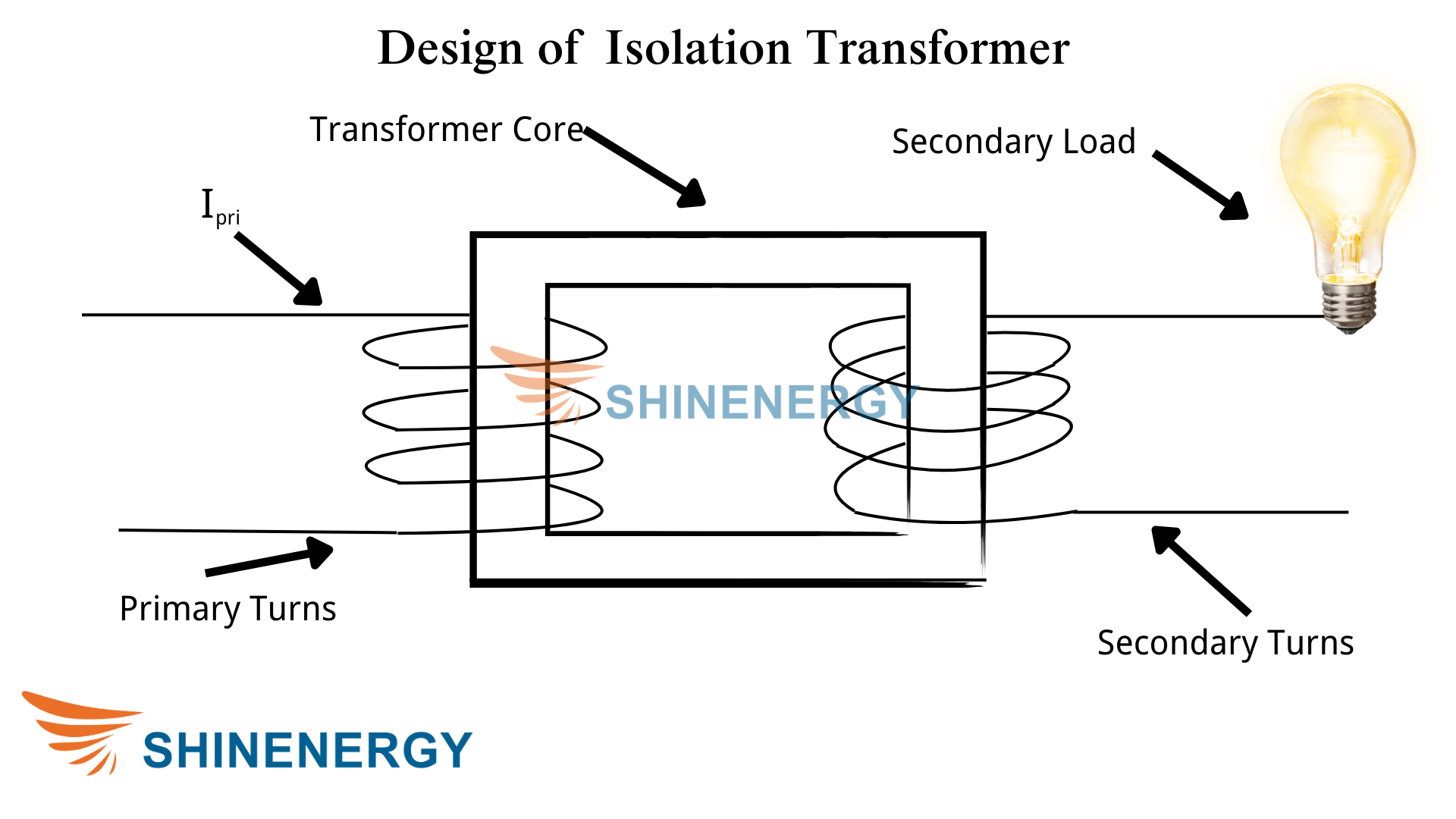

How Does Silicon Steel Enhance the Performance of Toroidal Isolation Transformers?

Silicon steel is commonly used in the cores of toroidal transformers due to its magnetic properties. The addition of silicon increases the electrical resistivity of the steel, which reduces energy losses due to eddy currents, thereby improving efficiency.

Pros & Cons: Silicon steel is relatively inexpensive and readily available, making it a cost-effective choice for transformer cores. However, it can be brittle and may require careful handling during manufacturing to prevent damage.

Impact on Application: The use of silicon steel enhances the magnetic performance of the transformer, allowing for better energy transfer and reduced noise interference, crucial for audio and video systems.

Considerations for International Buyers: Buyers should ensure that the silicon steel used meets international standards such as JIS G 3131 (for cold-rolled steel sheets) to guarantee quality and performance across different markets.

What Role Does Insulation Material Play in the Function of Toroidal Isolation Transformers?

Insulation materials, such as polyimide or epoxy resin, are vital for ensuring electrical safety and performance in toroidal isolation transformers. These materials prevent electrical shorts and protect against environmental factors.

Pros & Cons: High-quality insulation materials provide excellent thermal stability and resistance to moisture, enhancing the durability of the transformer. However, they can add to the manufacturing complexity and cost, particularly if specialized materials are used.

Impact on Application: The choice of insulation material directly affects the transformer’s ability to operate under varying environmental conditions, making it critical for applications in diverse climates, such as those found in Africa and the Middle East.

Illustrative image related to what is the function of torus isolation transformer

Considerations for International Buyers: Compliance with insulation standards such as IEC 60085 (thermal evaluation) is important for ensuring safety and reliability in different regions.

How Does Aluminum Compare to Copper in Toroidal Isolation Transformers?

Aluminum is sometimes used as an alternative to copper due to its lower cost and weight. While it has about 61% of the conductivity of copper, it can still be effective in certain applications.

Pros & Cons: Aluminum is lightweight and less expensive than copper, making it attractive for cost-sensitive projects. However, it is more prone to oxidation, which can impair conductivity over time. Manufacturing processes can be more complex due to the need for special connectors and treatments.

Impact on Application: While aluminum can be used in less demanding applications, it may not deliver the same level of performance as copper in high-end audio and video systems.

Considerations for International Buyers: Buyers should be aware of the local market preferences for copper versus aluminum and ensure compliance with relevant standards, such as ASTM B800 for aluminum wire.

Summary Table

| Material | Typical Use Case for what is the function of torus isolation transformer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Primary conductor for electrical windings | Excellent conductivity and durability | Higher cost compared to aluminum | High |

| Silicon Steel | Core material for magnetic performance | Reduces energy losses | Brittle and requires careful handling | Medium |

| Insulation Material | Electrical insulation for safety and performance | High thermal stability | Can increase manufacturing complexity | Medium |

| Aluminum | Alternative conductor for cost-sensitive applications | Lightweight and cost-effective | Lower conductivity and oxidation risk | Low |

This strategic material selection guide provides critical insights for B2B buyers seeking to optimize the performance and reliability of toroidal isolation transformers in various applications.

In-depth Look: Manufacturing Processes and Quality Assurance for what is the function of torus isolation transformer

What Are the Main Stages in the Manufacturing Process of Torus Isolation Transformers?

The manufacturing process of torus isolation transformers involves several key stages, each critical to ensuring the final product meets the required performance and quality standards.

Illustrative image related to what is the function of torus isolation transformer

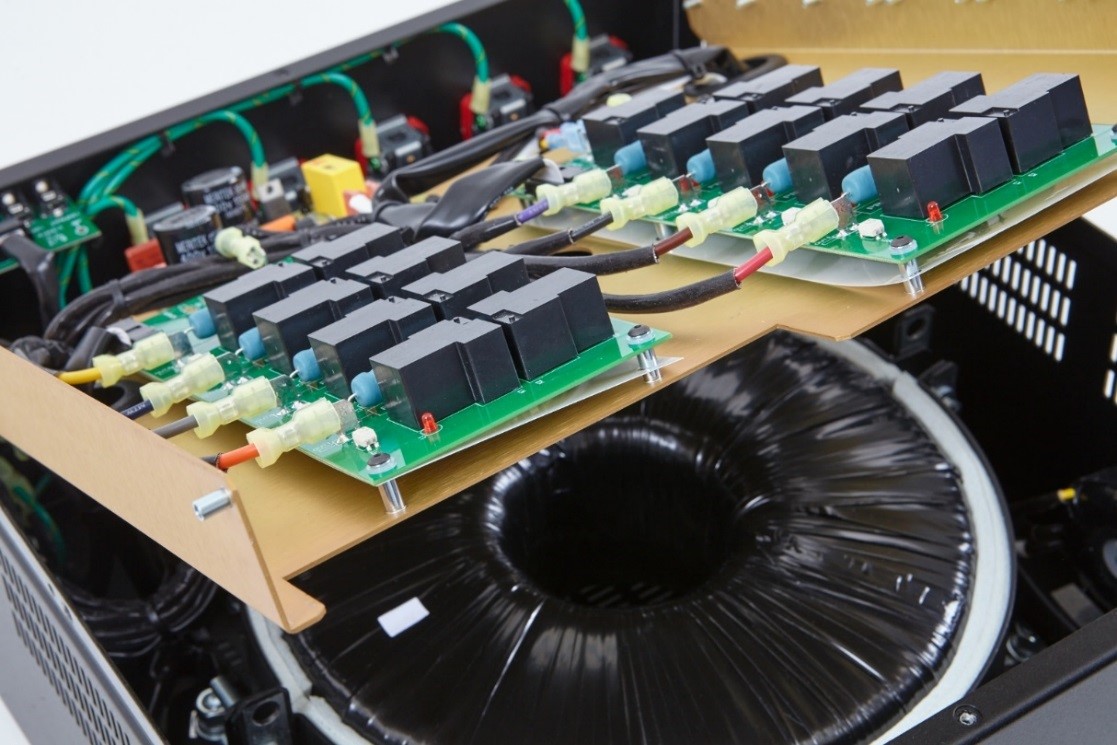

Material Preparation: What Materials Are Used in Manufacturing Torus Isolation Transformers?

The first stage involves sourcing high-quality materials, which is vital for the performance of torus isolation transformers. The core material, typically made from high-grade silicon steel, is selected for its magnetic properties. Copper windings are used due to their excellent conductivity, while specialized insulation materials are chosen to ensure electrical isolation between the primary and secondary windings. The use of these materials directly affects the efficiency and performance of the transformer, making careful selection essential.

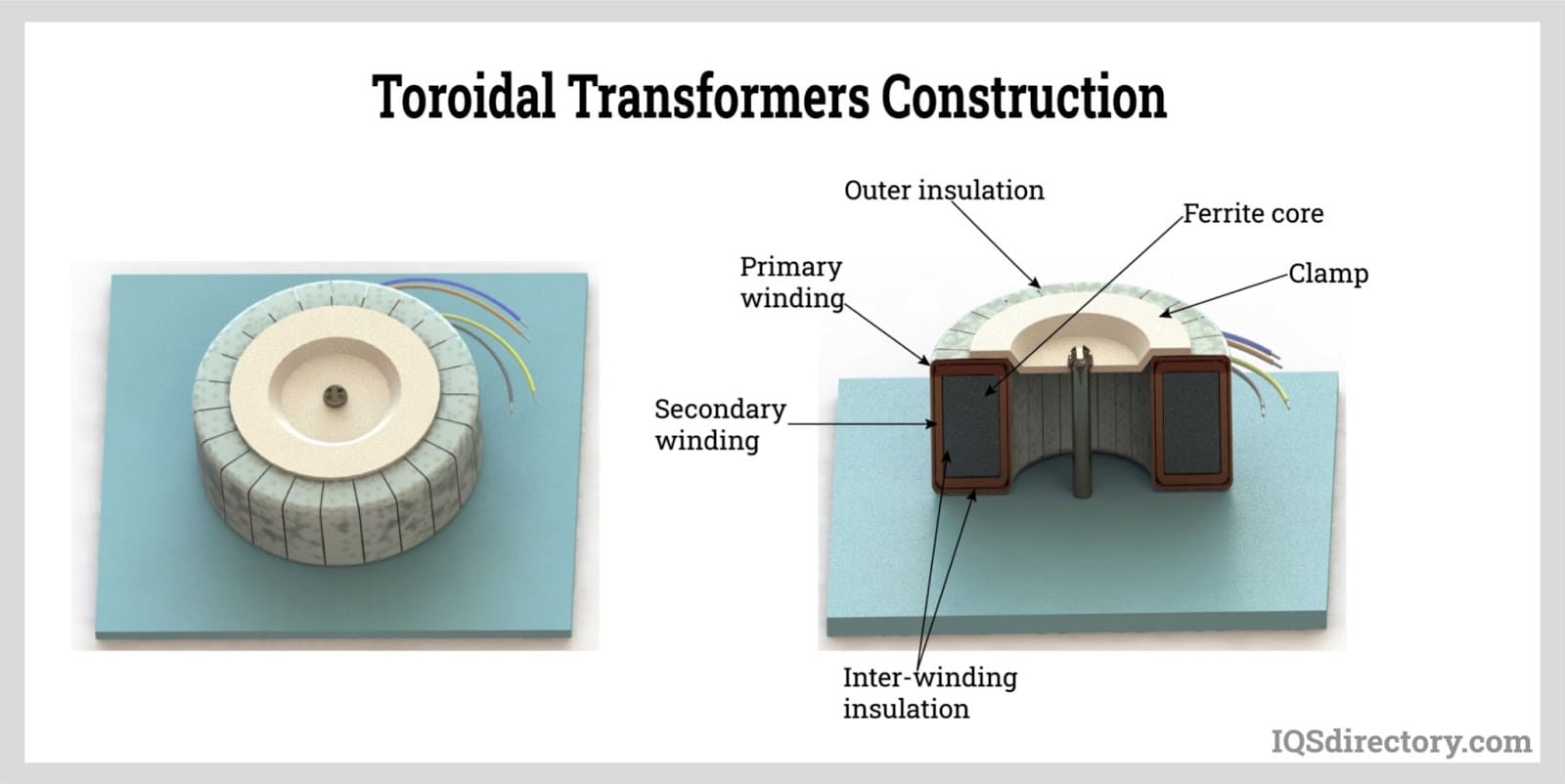

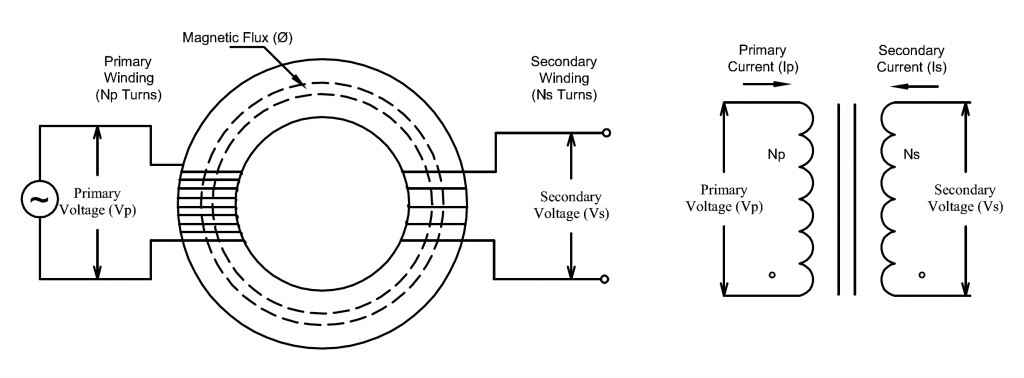

How Are Torus Isolation Transformers Formed and Assembled?

Once the materials are prepared, the next stage is forming. The silicon steel is cut and shaped into a toroidal core, which is crucial for minimizing electromagnetic interference and maximizing efficiency. This core is then wound with copper wire in a specific configuration to create the primary and secondary windings.

The assembly process is meticulous; workers or automated systems must ensure that the windings are evenly distributed and securely attached to the core. This is where the precision of the manufacturing process directly impacts the performance characteristics of the transformer, such as its ability to handle dynamic loads and suppress noise.

What Finishing Techniques Are Employed in the Production of Torus Isolation Transformers?

Finishing processes include insulation application, varnishing, and encapsulation. Insulation is applied to the windings to enhance electrical safety and performance. Varnishing protects the transformer from environmental factors, while encapsulation provides additional durability. These finishing techniques not only improve the longevity of the transformers but also help in maintaining consistent performance under varying load conditions.

Illustrative image related to what is the function of torus isolation transformer

What Quality Control Measures Are Implemented in the Manufacturing of Torus Isolation Transformers?

Quality assurance is a critical aspect of the manufacturing process. It ensures that every torus isolation transformer meets international standards and customer specifications.

Which International Standards Are Relevant for Quality Assurance?

ISO 9001 is a widely recognized international standard that outlines the requirements for a quality management system (QMS). Compliance with ISO 9001 indicates that a manufacturer has established a systematic approach to managing quality, which is crucial for B2B buyers seeking reliable suppliers. Additionally, CE marking is significant for products sold in Europe, ensuring they meet safety, health, and environmental protection standards.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are strategically placed throughout the manufacturing process. Incoming Quality Control (IQC) checks the raw materials against specifications before production begins. In-Process Quality Control (IPQC) monitors critical manufacturing stages, ensuring that any deviations are corrected in real time. Finally, Final Quality Control (FQC) inspects the finished transformers for performance, safety, and aesthetic quality before they are packaged for shipment.

What Common Testing Methods Are Used to Ensure Quality in Torus Isolation Transformers?

Common testing methods include electrical testing, insulation resistance testing, and thermal imaging. Electrical tests measure parameters like voltage output, current handling, and noise suppression capabilities. Insulation resistance testing ensures that the transformer meets safety standards by verifying that the insulation effectively prevents electrical leakage. Thermal imaging is utilized to identify any hot spots during operation, which could indicate potential failures.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers have several avenues to verify a supplier’s quality control practices. Conducting audits is one effective method; buyers can visit manufacturing facilities to assess compliance with established standards and practices. Additionally, suppliers should provide detailed quality reports that outline their testing methodologies and results.

Illustrative image related to what is the function of torus isolation transformer

Engaging third-party inspection services is another way to ensure product quality. These independent entities can perform audits and testing, providing an unbiased assessment of the manufacturer’s capabilities. For international buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of local regulations and standards can help in selecting suppliers that align with their quality expectations.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers must be aware of the various certifications that may differ across regions. For instance, while CE marking is crucial for products sold in Europe, other regions may require compliance with local standards, such as UL certification in the United States or SNI in Indonesia.

Understanding these certifications helps buyers make informed decisions, as non-compliance can lead to costly delays or product recalls. Additionally, cultural and regulatory differences can affect the interpretation of quality standards, making it essential for buyers to engage with suppliers who are familiar with these nuances.

Illustrative image related to what is the function of torus isolation transformer

Conclusion: The Importance of Manufacturing Processes and Quality Assurance in Torus Isolation Transformers

In summary, the manufacturing processes and quality assurance measures for torus isolation transformers are vital to ensuring that these devices perform optimally in various applications. By understanding the stages of manufacturing, the relevant quality control measures, and the nuances of international standards, B2B buyers can make informed decisions when selecting suppliers. This knowledge is particularly valuable for businesses operating in diverse markets, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is the function of torus isolation transformer’

To assist B2B buyers in understanding and procuring torus isolation transformers, this guide outlines essential steps to ensure a well-informed purchase decision. These transformers are critical in enhancing power quality and protecting sensitive electronic equipment, making it vital for buyers to follow a structured approach.

Step 1: Define Your Technical Specifications

Understanding your specific power requirements is the first step in sourcing a torus isolation transformer. Consider factors such as voltage ratings, current capacity, and the specific types of noise your equipment is susceptible to. This clarity will help you narrow down options that meet your operational needs effectively.

Illustrative image related to what is the function of torus isolation transformer

Step 2: Research Manufacturer Credentials

When selecting suppliers, it’s essential to verify their credibility and expertise in producing torus isolation transformers. Look for manufacturers with a strong reputation in the industry, relevant certifications, and proven track records. This step ensures you partner with a reliable source that adheres to quality standards.

Step 3: Evaluate Product Features

Not all torus isolation transformers are created equal. Assess product features such as noise filtering technology, surge protection capabilities, and automatic voltage regulation. These features significantly impact performance and reliability, so prioritize those that align with your system requirements.

Step 4: Request Detailed Product Documentation

Before finalizing your purchase, request comprehensive product documentation from potential suppliers. This should include technical data sheets, user manuals, and installation guides. Reviewing this documentation will provide insights into the transformer’s performance and installation requirements, helping you make an informed decision.

Step 5: Assess Support and Warranty Options

Reliable post-purchase support is crucial for maintaining the operational efficiency of your equipment. Inquire about warranty terms and the availability of technical support. A robust warranty and responsive customer service can save you from potential future issues and enhance your overall satisfaction with the product.

Step 6: Compare Pricing and Total Cost of Ownership

While price is a significant factor, consider the total cost of ownership, which includes installation, maintenance, and energy efficiency. Request quotes from multiple suppliers and compare not just the initial costs but also the long-term savings associated with energy efficiency and reliability. This thorough analysis will help you identify the best overall value.

Step 7: Seek Reviews and Case Studies

Before making a final decision, look for customer reviews and case studies related to the torus isolation transformers you are considering. Insights from other businesses, particularly those in similar sectors or regions, can provide valuable information about performance and reliability. This peer feedback can be instrumental in validating your choice.

By following these steps, B2B buyers can confidently navigate the procurement process for torus isolation transformers, ensuring they select the right solutions that enhance power quality and protect their sensitive electronic systems.

Comprehensive Cost and Pricing Analysis for what is the function of torus isolation transformer Sourcing

What Are the Key Cost Components for Torus Isolation Transformers?

Understanding the cost structure of torus isolation transformers is crucial for B2B buyers, especially in international markets. The primary components contributing to the overall cost include:

-

Materials: The core of a torus isolation transformer is typically made from high-quality magnetic materials, which can be expensive. Additionally, the copper windings and insulation materials play a significant role in determining the cost.

-

Labor: Skilled labor is required for the assembly and testing of these transformers. Labor costs can vary greatly depending on the region, impacting the final pricing.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and general administrative expenses. Efficient manufacturing processes can help reduce these costs.

-

Tooling: Custom tooling may be necessary for specific designs or modifications, which can add to the upfront costs.

-

Quality Control (QC): Ensuring that transformers meet rigorous performance standards involves extensive testing and quality assurance processes, which contribute to overall costs.

-

Logistics: Transportation costs, particularly for international shipping, can significantly affect pricing. Factors such as distance, mode of transport, and tariffs must be considered.

-

Margin: Suppliers typically add a margin to cover their costs and profit, which can vary based on the competitive landscape and market demand.

What Price Influencers Should Buyers Consider for Torus Isolation Transformers?

Several factors can influence the pricing of torus isolation transformers:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes can lead to better pricing. Suppliers often offer discounts for bulk purchases, making it advantageous for buyers to consider their long-term needs.

-

Specifications and Customization: Custom-designed transformers tailored to specific applications may incur additional costs. Buyers should evaluate whether standard models can meet their needs to avoid unnecessary expenses.

-

Material Quality and Certifications: The quality of materials used and any certifications (e.g., ISO, CE) can influence pricing. Higher-quality materials generally lead to better performance and longevity but come at a higher cost.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a track record of quality may charge a premium, but they often provide better support and assurance.

-

Incoterms: Understanding Incoterms is essential for international buyers. They dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly affect the total landed cost.

What Negotiation Tips Can Help Buyers Achieve Cost-Efficiency?

Effective negotiation strategies can lead to significant savings for B2B buyers:

-

Leverage Volume Discounts: When negotiating, emphasize potential future orders or bulk purchasing to secure better pricing.

-

Discuss Long-Term Partnerships: Building a long-term relationship with suppliers can lead to more favorable terms and pricing structures.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term operating costs, including energy efficiency and maintenance. A higher upfront cost may be justified by lower TCO.

-

Research Market Trends: Stay informed about market conditions and pricing trends to strengthen your negotiation position. Knowledge of the market can help in arguing for better terms.

-

Be Transparent About Needs: Clearly communicate your specifications and needs. This helps suppliers understand how they can best meet your requirements and potentially offer cost-effective solutions.

What Pricing Nuances Should International Buyers Be Aware Of?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several nuances must be considered:

-

Currency Fluctuations: Currency exchange rates can affect pricing. Buyers should consider hedging strategies to mitigate risks associated with currency volatility.

-

Import Tariffs and Duties: Be aware of any tariffs that may apply when importing transformers, as these can significantly increase the total cost.

-

Cultural Considerations: Understanding local business practices and negotiation styles can enhance communication and lead to better outcomes in pricing discussions.

-

Logistical Challenges: International shipping can introduce delays and additional costs. Buyers should factor in potential logistical challenges when planning their procurement strategies.

In summary, understanding the comprehensive cost structure and pricing influencers for torus isolation transformers is essential for B2B buyers. By leveraging negotiation strategies and being aware of international nuances, buyers can make informed decisions that enhance their procurement processes.

Alternatives Analysis: Comparing what is the function of torus isolation transformer With Other Solutions

Exploring Alternatives to Torus Isolation Transformers

In the realm of power management solutions, the Torus isolation transformer stands out for its ability to provide clean, stable power while minimizing electrical noise and interference. However, businesses often seek alternatives that can fulfill similar roles, especially in diverse markets across Africa, South America, the Middle East, and Europe. Understanding these alternatives allows B2B buyers to make informed decisions based on performance, cost, and specific application needs.

| Comparison Aspect | What Is The Function Of Torus Isolation Transformer | Power Conditioners | Linear Isolation Transformers |

|---|---|---|---|

| Performance | Excellent noise reduction, dynamic power delivery | Moderate noise reduction, stable output | Good noise isolation, but less dynamic response |

| Cost | Higher initial investment | Moderate cost | Variable cost, generally lower than Torus |

| Ease of Implementation | Simple plug-and-play setup | Requires integration with existing systems | Installation may require technical expertise |

| Maintenance | Low maintenance due to robust design | Periodic checks needed | Requires regular inspections for optimal performance |

| Best Use Case | High-performance audio/video systems | General electronic equipment | Sensitive equipment needing isolation |

What Are the Advantages and Disadvantages of Using Power Conditioners?

Power conditioners serve as a common alternative to Torus isolation transformers. They are designed to filter out electrical noise and regulate voltage levels, providing a more stable power source. The primary advantage of power conditioners is their moderate cost and easier implementation, making them suitable for small to medium-sized enterprises. However, they may not offer the same level of noise reduction and dynamic power delivery as Torus transformers, potentially leading to performance limitations in high-demand audio/video systems.

How Do Linear Isolation Transformers Compare?

Linear isolation transformers are another viable option, particularly for applications that require a degree of electrical isolation. They work by providing a barrier between the power source and the equipment, helping to mitigate noise. The pros of linear isolation transformers include their effectiveness in isolating sensitive equipment and their generally lower cost compared to Torus isolation transformers. However, they may not deliver the same high dynamic power needed for demanding audio/video applications and might require more technical expertise for installation and maintenance.

Conclusion: How Should B2B Buyers Choose the Right Power Management Solution?

Selecting the appropriate power management solution hinges on understanding the specific requirements of your application. Businesses focused on high-performance audio and video systems may find the Torus isolation transformer to be the best fit, despite its higher cost. For organizations looking for a balance between performance and budget, power conditioners can provide adequate support for a variety of electronic equipment. Meanwhile, linear isolation transformers serve well for applications needing basic isolation. By evaluating performance needs, budget constraints, and installation capabilities, B2B buyers can make informed choices that align with their operational goals.

Essential Technical Properties and Trade Terminology for what is the function of torus isolation transformer

What Are the Key Technical Properties of Torus Isolation Transformers?

Torus isolation transformers are engineered with specific technical properties that enhance performance in various applications, particularly in audio, video, and control systems. Understanding these properties is crucial for B2B buyers when selecting the right transformer for their needs.

Illustrative image related to what is the function of torus isolation transformer

1. Core Material and Design

The core of a torus isolation transformer is typically made from high-grade silicon steel, which is essential for minimizing energy losses. The toroidal shape allows for a compact design that reduces the size and weight of the transformer while maximizing efficiency. This is particularly important for businesses looking to save on space and energy costs.

2. Noise Filtering Capability

Torus transformers employ advanced noise filtering technology, such as Plitron’s patented NBT (Noise Blocking Technology). This feature effectively eliminates both common mode and differential mode noise, which can interfere with sensitive electronic systems. For B2B buyers, investing in transformers with superior noise filtering can lead to improved system performance and longevity of electronic equipment.

3. Power Rating and Load Capacity

Power ratings, often expressed in VA (volt-amperes), indicate the maximum load a transformer can handle without overheating. A typical torus transformer may range from 10 VA to over 3000 VA, allowing businesses to choose a model that fits their specific power requirements. Understanding power ratings is critical for ensuring that the transformer can support the intended application without risk of failure.

4. Surge Protection Mechanism

Many torus isolation transformers feature Series Mode Surge Suppression (SMSS), which protects connected equipment from voltage spikes. This technology absorbs surges and prevents contamination of audio and video signals. For B2B buyers, this translates to reduced maintenance costs and increased reliability of sensitive electronic systems, making it a valuable investment.

Illustrative image related to what is the function of torus isolation transformer

5. Automatic Voltage Regulation (AVR)

AVR technology continuously monitors and adjusts the voltage supplied to connected equipment, ensuring it remains within an optimal range. This feature is vital for preventing damage from voltage fluctuations, which are common in many regions. Businesses can benefit from AVR by ensuring consistent performance and extending the life of their equipment.

What Are Common Trade Terms Associated with Torus Isolation Transformers?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some common terms related to torus isolation transformers:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of torus transformers, businesses may source transformers from OEMs to integrate into their own products, ensuring quality and compatibility.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for businesses to manage inventory effectively and ensure that they meet their operational needs without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. When purchasing torus isolation transformers, businesses often use RFQs to obtain competitive bids and select the best supplier based on cost and specifications.

4. Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for managing logistics, shipping costs, and risk during the procurement of torus isolation transformers from global suppliers.

5. Lead Time

Lead time is the amount of time between placing an order and receiving the product. For B2B buyers, understanding lead times is critical for planning and ensuring that projects remain on schedule, especially when dealing with imported goods.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and product performance in their respective industries.

Illustrative image related to what is the function of torus isolation transformer

Navigating Market Dynamics and Sourcing Trends in the what is the function of torus isolation transformer Sector

What Are the Key Market Drivers for Torus Isolation Transformers?

The global market for Torus isolation transformers is primarily driven by the increasing demand for clean and stable power in diverse applications, including audio, video, and control systems. As electronic devices proliferate, particularly in regions such as Africa, South America, the Middle East, and Europe, the need for effective noise reduction and power conditioning becomes critical. These transformers help mitigate electrical noise—both differential and common mode—that can adversely affect the performance of sensitive electronic equipment.

Emerging trends indicate a shift towards integrated power solutions that combine isolation and power conditioning capabilities. International B2B buyers are increasingly looking for products that not only provide electrical isolation but also enhance the overall performance of audio and video systems through advanced technologies like noise filtering and automatic voltage regulation (AVR). Additionally, the growing awareness of the detrimental effects of power surges and fluctuations has propelled the demand for protective solutions, making Torus isolation transformers an essential component for safeguarding investments in high-end electronics.

How Is Sustainability and Ethical Sourcing Integrated into the Torus Isolation Transformer Market?

Sustainability is becoming a focal point in the procurement strategies of B2B buyers, influencing their sourcing decisions for Torus isolation transformers. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, such as utilizing energy-efficient manufacturing techniques and sourcing raw materials responsibly.

Ethical supply chains are essential for mitigating risks associated with environmental degradation and social injustices. Buyers are encouraged to seek out manufacturers who have obtained green certifications, which validate their adherence to sustainable practices and demonstrate a commitment to minimizing their ecological footprint. These certifications can include ISO 14001 for environmental management and RoHS compliance for restricting hazardous substances. As the market evolves, B2B buyers will find that partnering with environmentally responsible suppliers not only enhances their corporate social responsibility (CSR) profile but also aligns with the growing consumer demand for sustainable products.

What Is the Historical Context of Torus Isolation Transformers?

The evolution of isolation transformers dates back to the early 20th century when electrical systems began to proliferate in homes and industries. However, the need for advanced solutions like the Torus isolation transformer arose in response to the rapid expansion of electronic devices and the corresponding increase in electrical noise.

Initially used in industrial applications, isolation transformers have gradually found their way into residential and commercial audio-video systems. The introduction of toroidal design in isolation transformers marked a significant advancement, offering enhanced performance through lower magnetic fields and improved noise reduction capabilities. This innovation has made Torus isolation transformers a preferred choice for high-performance applications, allowing users to experience superior sound and image quality while ensuring the longevity of their electronic investments.

In summary, as B2B buyers navigate the complexities of sourcing Torus isolation transformers, understanding market dynamics, sustainability considerations, and historical context will be essential for making informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of what is the function of torus isolation transformer

-

How do I reduce electrical noise in my audio and video systems?

To effectively reduce electrical noise in audio and video systems, consider investing in a Torus isolation transformer. This device provides a clean, stable power source by isolating your equipment from the noisy electrical grid. It employs advanced noise filtering technology to eliminate both common and differential mode noise, significantly improving the sound and picture quality. By ensuring that your audio and video systems operate with a lower noise floor, you can enhance performance, achieving clearer sound and sharper images. -

What benefits does a toroidal isolation transformer offer for B2B applications?

A toroidal isolation transformer offers numerous benefits for B2B applications, particularly in sectors reliant on high-performance audio and video systems. It delivers cleaner power, which directly translates to improved performance and reliability. The transformer’s ability to manage dynamic power demands ensures that your equipment can handle peak loads without distortion. Additionally, its surge protection capabilities safeguard sensitive electronics from power spikes, while automatic voltage regulation maintains consistent voltage levels, enhancing operational stability. -

What factors should I consider when sourcing torus isolation transformers internationally?

When sourcing torus isolation transformers internationally, prioritize factors such as the supplier’s reputation, product certifications, and compliance with local electrical standards. Evaluate the manufacturer’s production capabilities and quality assurance processes to ensure consistent product performance. Additionally, consider logistics aspects, including shipping costs, delivery times, and potential tariffs. Establish clear communication regarding customization options and minimum order quantities (MOQs) to align with your business requirements. -

How can I customize torus isolation transformers for my specific needs?

Customization options for torus isolation transformers often include adjustments to voltage ratings, output configurations, and specific noise filtering technologies. When discussing your needs with potential suppliers, provide detailed specifications on your application requirements. This may include factors like power handling capacity, environmental conditions, and any particular standards your equipment must meet. Collaborating with manufacturers who offer flexible design capabilities can help you achieve a solution tailored to your operational needs. -

What are the typical payment terms for purchasing torus isolation transformers?

Payment terms for purchasing torus isolation transformers can vary widely based on the supplier and the size of your order. Common arrangements include upfront payments, partial payments upon order confirmation, and balance payments prior to shipping. For larger orders, you may negotiate more favorable terms, such as extended payment periods or discounts for early payment. Always clarify payment methods accepted, such as bank transfers or letters of credit, to ensure a smooth transaction. -

What quality assurance measures should I look for in torus isolation transformers?

When evaluating torus isolation transformers, look for manufacturers that implement rigorous quality assurance measures. This includes certifications such as ISO 9001, which indicates adherence to international quality management standards. Request information on testing protocols, including electrical performance tests and safety evaluations. A supplier that provides a warranty or guarantees product performance can also indicate confidence in their quality control processes. -

What logistics considerations should I keep in mind when importing torus isolation transformers?

Logistics considerations for importing torus isolation transformers include shipping methods, costs, and lead times. Assess whether air or sea freight is more appropriate based on your urgency and budget. Understand customs regulations in your country to avoid delays and additional fees. Additionally, ensure that the supplier can provide all necessary documentation, such as bills of lading and certificates of origin, to facilitate smooth customs clearance. -

How do I evaluate the total cost of ownership for torus isolation transformers?

To evaluate the total cost of ownership for torus isolation transformers, consider not only the initial purchase price but also factors such as installation costs, maintenance, and energy efficiency. Calculate potential savings from reduced power consumption and longer equipment lifespan due to improved power quality. Additionally, factor in the cost of any necessary accessories or additional components, as well as potential downtime costs if your current systems are inadequate. This comprehensive approach helps ensure you make a financially sound investment.

Top 8 What Is The Function Of Torus Isolation Transformer Manufacturers & Suppliers List

1. Torus Power – Isolation Transformers

Domain: toruspower.com

Registered: 2005 (20 years)

Introduction: Torus Power isolation transformers are designed specifically for high performance audio, video, and control systems. They utilize a toroidal core with special insulation between primary and secondary copper windings to isolate electrical power transfer, blocking electrical noise and interference. Key benefits include: 1. Cleaner power for improved sound and picture quality, utilizing Plitron’s pat…

2. Transformers – Torus Isolation Solutions

Domain: transformerguides.com

Registered: 2025 (0 years)

Introduction: Torus isolation transformers are designed to provide electrical isolation, reduce noise, and improve power quality. They feature a unique toroidal core that allows for a compact design and efficient operation. These transformers are commonly used in sensitive electronic equipment to protect against voltage spikes and electromagnetic interference. Key benefits include enhanced safety, improved perf…

3. KMBComm – Torus Power RM Series Transformers

Domain: kmbcomm.com

Registered: 2011 (14 years)

Introduction: Torus Power RM Series toroidal isolation transformers; designed for luxury residential AV applications; ideal for high-end audio systems; models range from 8 Amps to 200 Amps; popular models include RM-20 and RM-60; RM BAL units deliver 100 Amps of clean, isolated power; eliminates power-line noise artifacts; protects equipment from damaging AC power line events; increases system reliability and e…

4. Torus Power – All-in-One 12KVA Power Conditioner

Domain: whatsbestforum.com

Registered: 2010 (15 years)

Introduction: Torus Power All-in-One (AIO) 12KVA Power Conditioner

– Input Voltage: 240 V

– Output Voltage: 120 V or 240 V

– Output Current: 104A at 120 V or 52A at 240 V

– Power Rating: 12500 VA

– Frequency: 50/60 Hz

– Number of Output Breakers: 24 x 20A

– Weight: 282 lb

– Dimensions (W x H x D): 20 x 8 x 74 in

– Features: Toroidal Isolation transformer, advanced surge suppression, separately derived equipment…

5. Shinenergy – Isolation Transformers

Domain: shinenergy.net

Registered: 2010 (15 years)

Introduction: Isolation Transformer: An electrical device that uses electromagnetic induction to transfer power while electrically isolating input and output circuits to prevent interference and electric shock. Advantages include strong protection for electrical safety, reduction of electrical noise and electromagnetic interference, optimization of overall power quality, effective isolation protection, voltage …

6. Actsessory – Torus PowerBlock Series Isolation Transformer

Domain: actsessory.com

Registered: 2015 (10 years)

Introduction: Torus PowerBlock Series Isolation Transformer Power Conditioner

– Type: Toroidal Isolation Transformer

– Features: Noise Filtering, High Instantaneous Current Capability, Lightning and Surge Protection

– Power Rating: 1,000VA

– Suitable for: Mid-power compact systems, source components, TVs, projectors

– Protection: Transient Voltage Surge Suppression (TVSS)

– Models: PB2 515R (4 US outlets), PB4 …

7. Torus Power – Isolation Transformers

Domain: audiosoulultra.gr

Introduction: Torus Power isolation transformers improve audio and video system performance by enhancing dynamics, imaging, and bass quality. They provide crisper video with darker blacks and brighter colors. These transformers are favored by audiophiles, home theatre enthusiasts, and custom electronic system integrators for their performance and protection. They come in a variety of models, power ratings, chas…

8. Torus Power – Power Isolation Units

Domain: enjoythemusic.com

Registered: 1998 (27 years)

Introduction: Torus Power Power Isolation Units (PIUs) are designed in collaboration with Plitron Manufacturing, known for their high-quality toroidal transformers. These units utilize the electrical characteristics of the transformer to prevent AC line noise pass-through. Some models incorporate balanced AC power, using both sides of the incoming AC to enhance noise reduction and increase available current. Th…

Strategic Sourcing Conclusion and Outlook for what is the function of torus isolation transformer

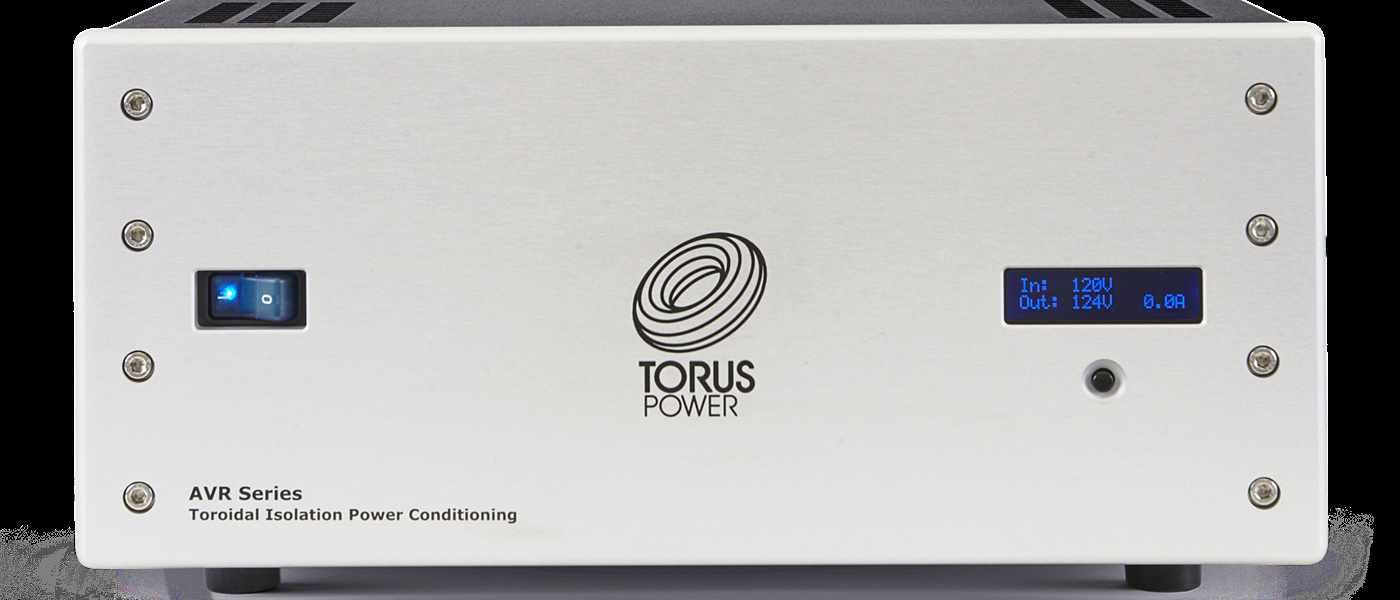

In summary, the Torus isolation transformer serves as a critical component in enhancing the performance and reliability of audio and video systems. By providing cleaner power through advanced noise filtration and surge protection, it mitigates the detrimental effects of electrical interference, ensuring superior sound and image quality. Moreover, the automatic voltage regulation feature guarantees consistent power delivery, safeguarding sensitive electronic equipment against fluctuations that can lead to failures.

For international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, strategic sourcing of Torus isolation transformers can significantly elevate the operational efficiency of audio and video installations. Investing in high-quality power solutions not only improves system performance but also extends the longevity of equipment, ultimately leading to cost savings and increased satisfaction for end-users.

As the demand for robust power solutions continues to grow, now is the time to prioritize sourcing from reliable manufacturers. Explore partnerships that align with your goals, ensuring your systems are equipped with the best technology available. Embrace the future of clean power and elevate your business offerings with Torus isolation transformers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to what is the function of torus isolation transformer