What Are Pressure Switches: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for what are pressure switches

In the fast-evolving landscape of industrial automation, understanding what pressure switches are and how they function is crucial for international B2B buyers. These devices play a pivotal role in maintaining optimal pressure levels across various systems, from HVAC and water pumps to industrial machinery. However, sourcing the right pressure switch can be a daunting task, especially when faced with diverse applications and specifications that vary significantly across regions.

This comprehensive guide aims to demystify pressure switches by exploring their types, applications, and the essential criteria for supplier vetting. We delve into the distinctions between mechanical and electronic pressure switches, highlighting their operational principles and advantages. Additionally, we address vital aspects such as cost considerations, compatibility with different process fluids, and the implications of regional standards in markets like Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Brazil.

By equipping B2B buyers with actionable insights and clear information, this guide empowers you to make informed purchasing decisions. Whether you’re looking to enhance safety protocols, improve system efficiency, or ensure compliance with local regulations, understanding the intricacies of pressure switches will enable you to navigate the global market with confidence and precision.

Understanding what are pressure switches Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mechanical Pressure Switch | Uses a spring and piston mechanism; robust and simple. | HVAC systems, water pumps, compressors | Pros: High voltage handling; durable. Cons: Less accurate than electronic types. |

| Electronic Pressure Switch | Incorporates a pressure transducer; offers higher accuracy. | Industrial automation, oil & gas, HVAC | Pros: Greater accuracy; long-term stability. Cons: Higher cost; may require more maintenance. |

| Differential Pressure Switch | Measures pressure difference between two points. | Filtration systems, HVAC, gas pipelines | Pros: Essential for monitoring pressure drops; versatile. Cons: More complex installation. |

| High-Pressure Switch | Designed for applications exceeding standard pressure levels. | Oil & gas, heavy machinery, industrial processes | Pros: Handles extreme conditions; reliable. Cons: Requires specific selection based on system needs. |

| Vacuum Pressure Switch | Measures negative pressure; essential for vacuum systems. | Boilers, HVAC, refrigeration systems | Pros: Critical for safety; prevents system failure. Cons: Limited to low-pressure applications. |

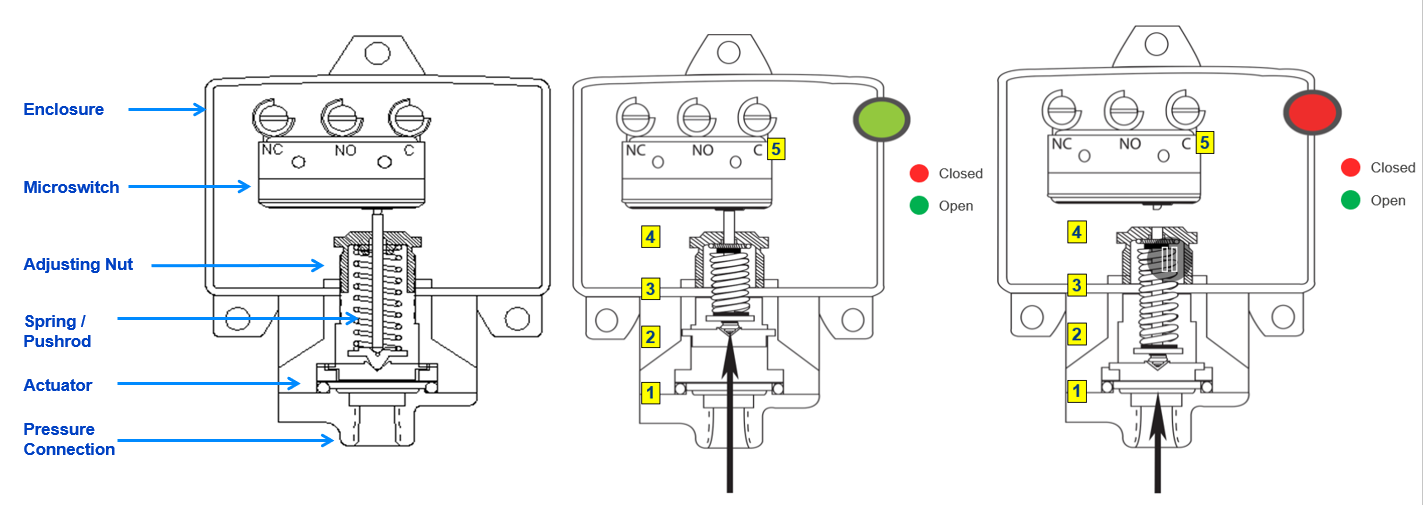

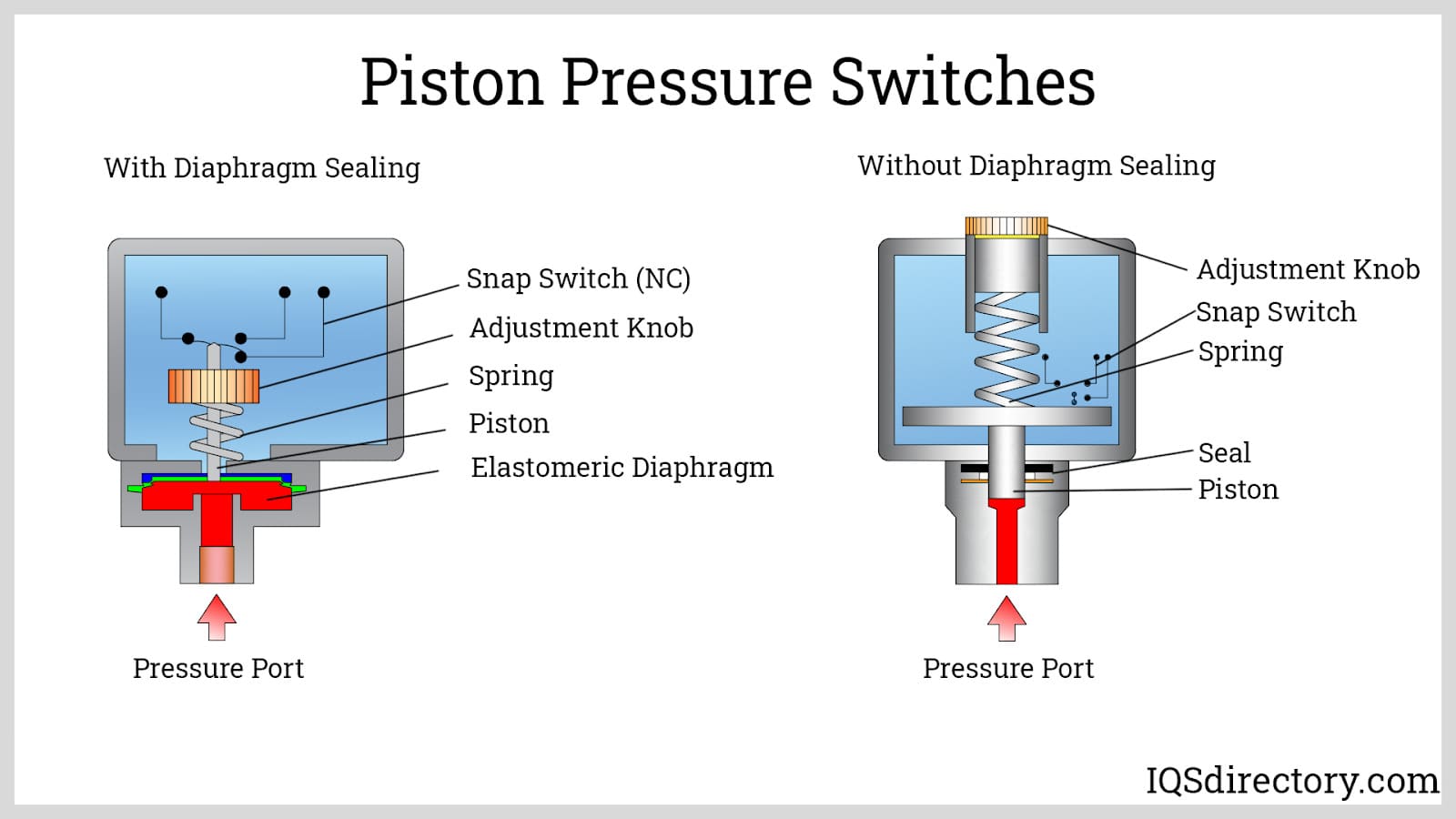

What Are the Key Characteristics of Mechanical Pressure Switches?

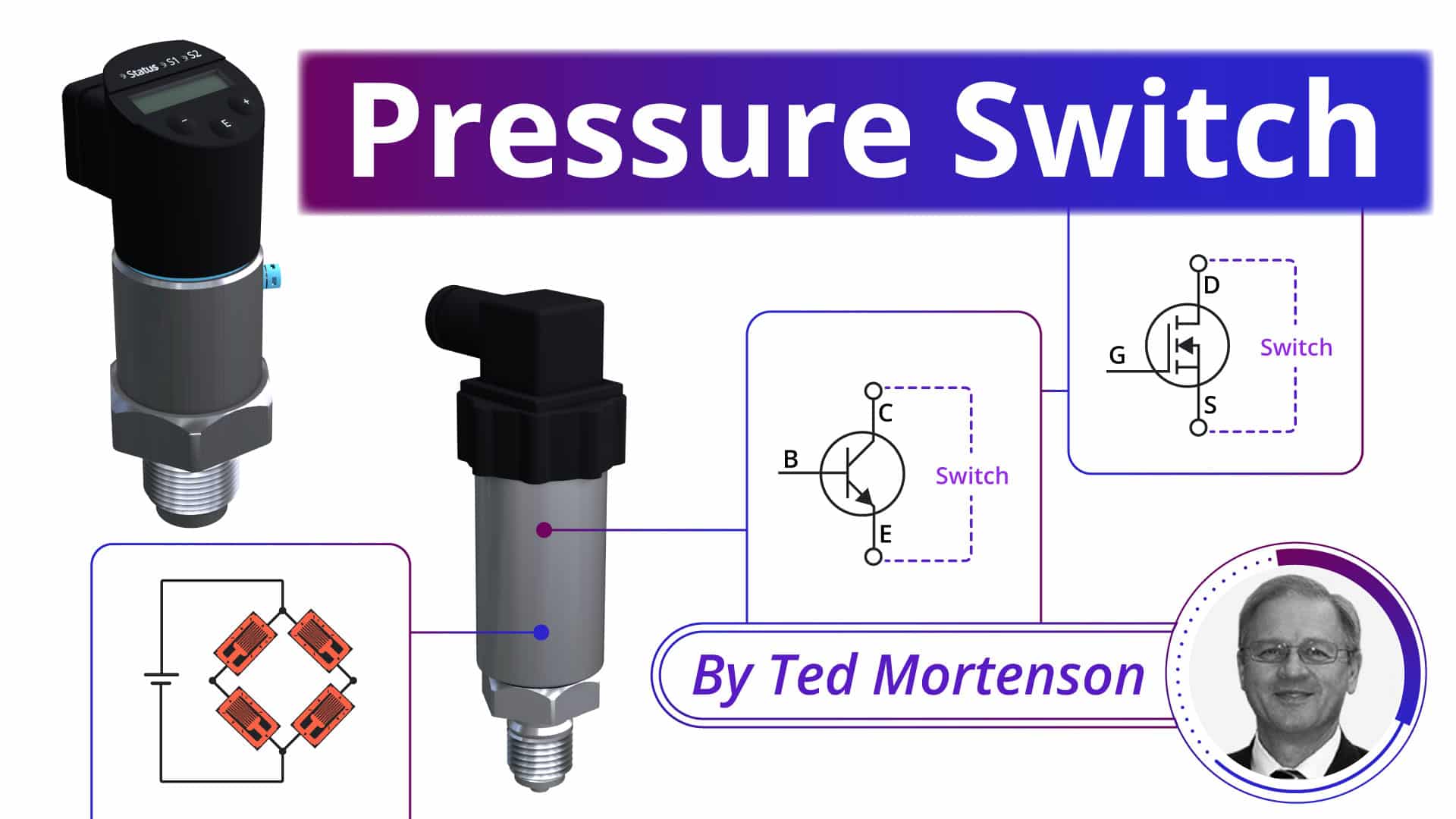

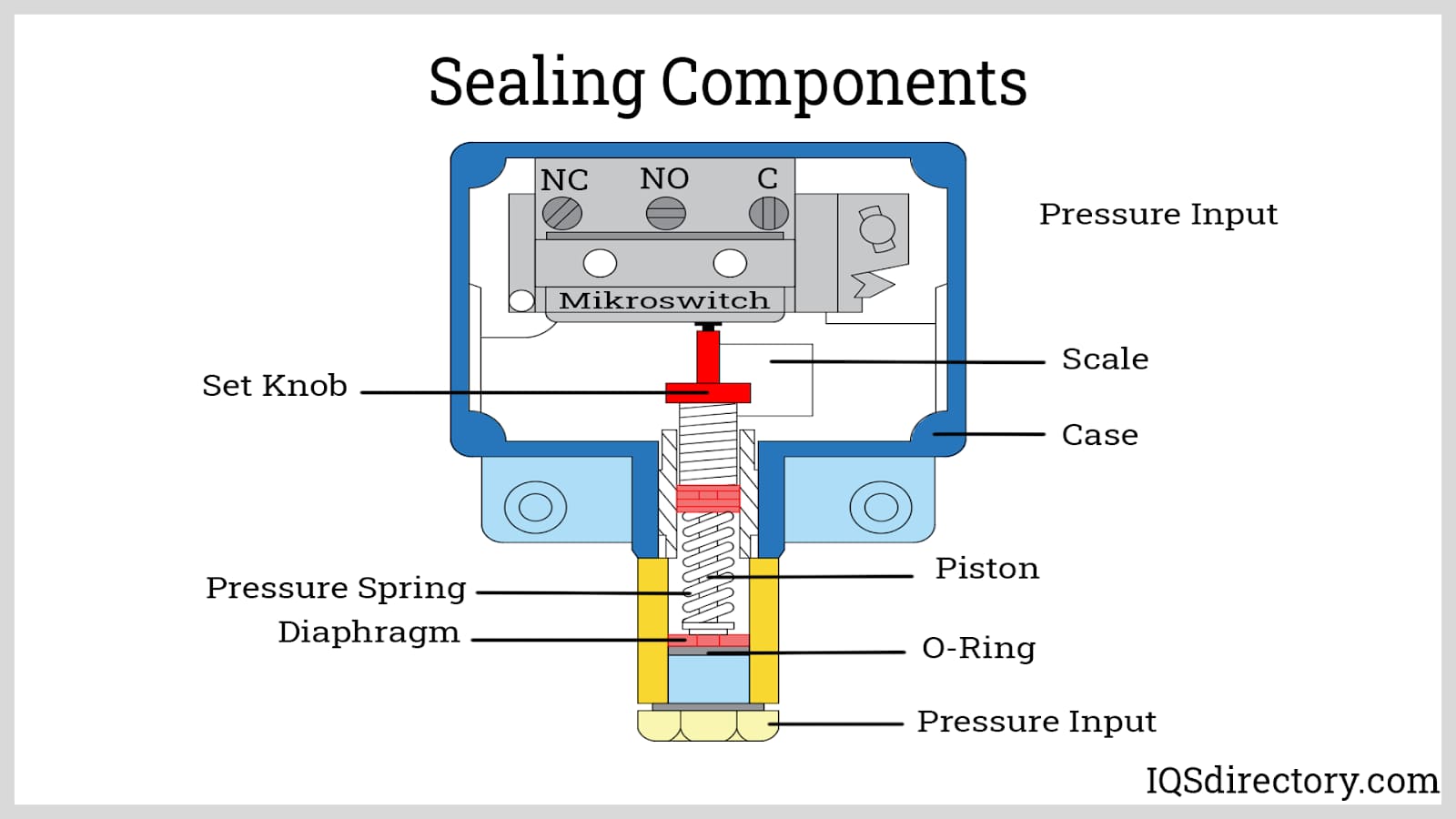

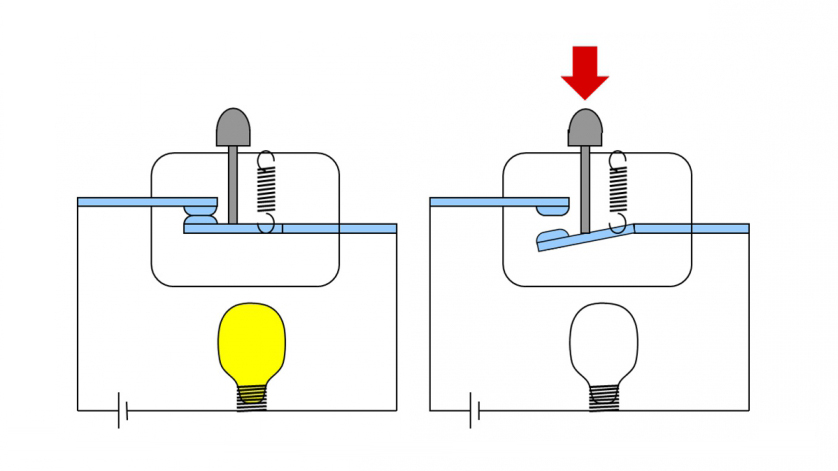

Mechanical pressure switches are characterized by their simplicity and robustness. These switches utilize a spring and piston mechanism, making them ideal for less complex tasks. They are commonly found in HVAC systems, water pumps, and air compressors, where they regulate pressure by opening or closing electrical contacts based on the system’s pressure levels. Buyers should consider the voltage ratings and the operational environment, as these switches are well-suited for high-voltage applications but may lack the precision of electronic alternatives.

How Do Electronic Pressure Switches Differ from Mechanical Ones?

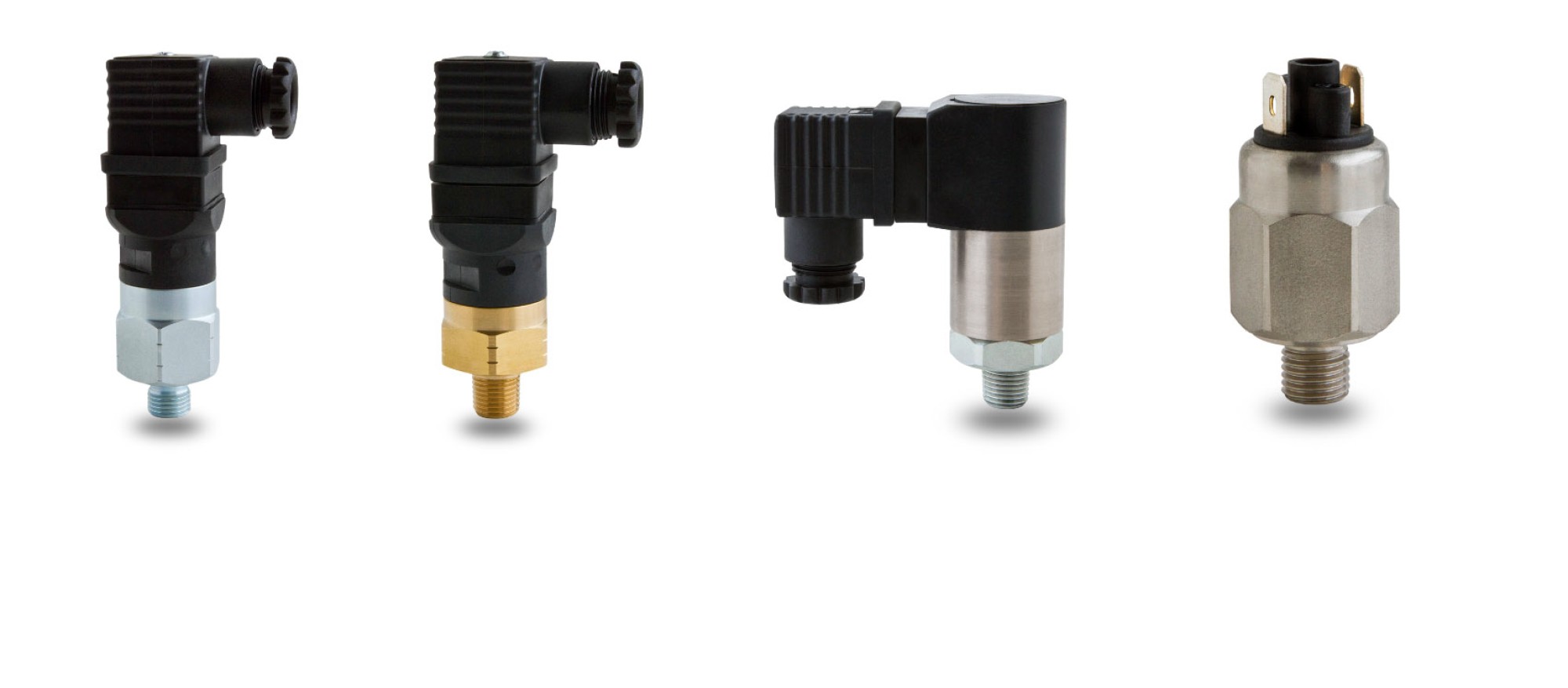

Electronic pressure switches incorporate advanced technology, including pressure transducers, to provide greater accuracy and reliability. They are commonly used in industrial automation, oil and gas applications, and HVAC systems. The electronic design allows for more precise pressure readings and longer operational life due to less mechanical wear. However, buyers should be aware of the higher initial costs and potential maintenance needs associated with these devices, as well as the requirement for proper integration with existing systems.

What Applications Benefit from Differential Pressure Switches?

Differential pressure switches are essential for measuring the difference in pressure between two points, making them crucial in filtration systems, HVAC applications, and gas pipelines. Their ability to monitor pressure drops ensures that systems operate efficiently and safely. When selecting a differential pressure switch, buyers should consider installation complexity and compatibility with existing equipment, as these switches can be more intricate than standard pressure switches.

Why Choose High-Pressure Switches for Industrial Applications?

High-pressure switches are specifically designed to handle applications that exceed standard pressure levels, making them ideal for industries such as oil and gas, heavy machinery, and various industrial processes. These switches provide reliability under extreme conditions, ensuring system safety and performance. Buyers must carefully evaluate the specifications and pressure ratings to ensure the switch meets the demands of their specific applications.

What Role Do Vacuum Pressure Switches Play in System Safety?

Vacuum pressure switches are specialized devices that measure negative pressure, playing a critical role in systems like boilers, HVAC, and refrigeration. They help maintain optimal operating conditions and prevent system failures by ensuring that vacuum levels remain within safe limits. When purchasing vacuum pressure switches, buyers should focus on the specific low-pressure requirements of their applications, as these switches are not suitable for high-pressure environments.

Key Industrial Applications of what are pressure switches

| Industry/Sector | Specific Application of what are pressure switches | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Monitoring oil pressure in drilling operations | Ensures operational safety and equipment longevity | High-pressure tolerance, resistance to corrosive fluids |

| HVAC | Regulating air pressure in climate control systems | Enhances energy efficiency and equipment reliability | Temperature range, compatibility with refrigerants |

| Water & Wastewater | Controlling water pump pressure in municipal systems | Prevents system failures and ensures consistent supply | Durability in harsh environments, response time |

| Automotive | Monitoring oil and fuel pressure in engines | Improves engine performance and prevents damage | Temperature and pressure range, compliance with standards |

| Manufacturing | Managing pressure in pneumatic systems for automation | Increases efficiency and reduces downtime in production | Precision in pressure settings, reliability under load |

How Are Pressure Switches Used in the Oil & Gas Industry?

In the oil and gas sector, pressure switches are critical for monitoring oil pressure during drilling operations. These devices help ensure that pressure levels remain within safe limits, thereby preventing equipment failure and potential hazards. For B2B buyers in regions like the Middle East, where oil extraction is paramount, sourcing pressure switches with high-pressure tolerance and corrosion resistance is essential. Additionally, understanding the local environmental conditions can influence the choice of materials used in these switches.

What Role Do Pressure Switches Play in HVAC Systems?

In HVAC applications, pressure switches are used to regulate air pressure in climate control systems. This regulation is vital for maintaining energy efficiency and ensuring reliable operation of HVAC equipment. Buyers from Europe and South America should consider switches that can operate effectively across varying temperature ranges and are compatible with common refrigerants. Investing in high-quality pressure switches can lead to significant energy savings and prolonged equipment life.

How Are Pressure Switches Essential for Water & Wastewater Management?

In municipal water systems, pressure switches play a key role in controlling the pressure of water pumps. They ensure that the water supply is consistent and prevent system failures that could disrupt service. For international buyers, especially in Africa, where infrastructure may be challenged, selecting durable pressure switches that can withstand harsh environmental conditions is crucial. The response time and reliability of these devices directly impact the efficiency of water distribution systems.

Why Are Pressure Switches Important in Automotive Applications?

In the automotive industry, pressure switches monitor oil and fuel pressure within engines. This monitoring is vital for optimizing engine performance and preventing damage due to low pressure. B2B buyers in Brazil and other automotive markets should focus on sourcing switches that meet stringent automotive standards, ensuring they can withstand high temperatures and pressures. Proper selection can lead to enhanced vehicle reliability and performance.

How Do Pressure Switches Improve Manufacturing Processes?

Pressure switches are integral to managing pressure in pneumatic systems used for automation in manufacturing. They help maintain optimal pressure levels, which increases efficiency and reduces downtime. Buyers in the manufacturing sector should look for switches that offer precision in pressure settings and reliability under load. This investment can significantly enhance production capabilities, especially in fast-paced environments across diverse regions.

3 Common User Pain Points for ‘what are pressure switches’ & Their Solutions

Scenario 1: Inconsistent Pressure Control in Industrial Applications

The Problem:

B2B buyers often face challenges in maintaining consistent pressure levels in their industrial systems, such as HVAC units or pneumatic systems. Fluctuating pressure can lead to equipment inefficiencies, increased wear and tear, and even system failures. This inconsistency not only disrupts production schedules but can also result in costly downtime, affecting profitability. Buyers may struggle with selecting the right type of pressure switch that matches their specific pressure range and application needs, leading to further complications.

The Solution:

To combat pressure inconsistency, it’s crucial to select the appropriate type of pressure switch for your application. Start by assessing the operational requirements, including the pressure range, media type (gas or liquid), and environmental conditions. For example, if your application involves high-pressure air systems, a mechanical pressure switch with robust materials can handle the load effectively. Additionally, consider using electronic pressure switches, which offer greater accuracy and can provide real-time feedback on pressure levels, allowing for more precise control. Regular maintenance and calibration of the pressure switches will ensure their reliability, minimizing the risk of unexpected fluctuations.

Scenario 2: Misalignment Between Pressure Switch Specifications and System Requirements

The Problem:

Another prevalent issue for B2B buyers is the misalignment between the specifications of pressure switches and the actual requirements of their systems. Buyers may find themselves with pressure switches that do not meet the specific operational criteria, such as temperature limits or material compatibility, leading to malfunction or failure. This misalignment can stem from inadequate research or lack of understanding of the application environment, causing frustration and financial losses.

The Solution:

To avoid specification mismatches, it is essential to conduct thorough research before purchasing pressure switches. Engage with technical experts or manufacturers who can provide insights on the specific types of pressure switches suitable for your application. Consider the following factors: the type of fluid being monitored, the expected temperature range, and any potential chemical interactions that may affect the switch materials. Utilize datasheets and product specifications to ensure that the selected pressure switch aligns with your system’s operational parameters. Creating a checklist of necessary specifications can help streamline this process and ensure that the pressure switches are compatible with your equipment.

Illustrative image related to what are pressure switches

Scenario 3: Lack of Knowledge on Pressure Switch Maintenance and Troubleshooting

The Problem:

Many B2B buyers encounter difficulties with the maintenance and troubleshooting of pressure switches, which can lead to increased operational costs and equipment failure. A lack of understanding about how to properly maintain these devices or troubleshoot issues can result in prolonged downtime and operational inefficiencies. Buyers often feel overwhelmed by the technical aspects, leading to reliance on external service providers, which can be costly.

The Solution:

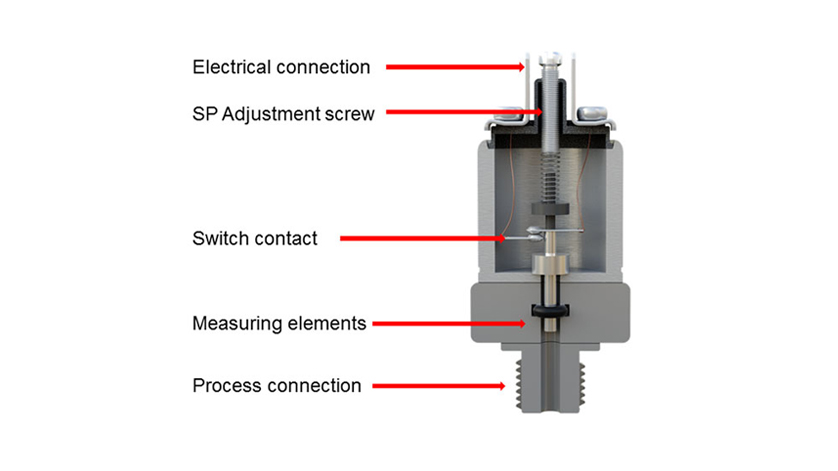

To empower your team and reduce reliance on external services, invest in training sessions focused on the maintenance and troubleshooting of pressure switches. Familiarize your staff with the components of the switches, such as diaphragms and electrical contacts, and provide clear guidelines for routine checks and maintenance protocols. Establish a preventive maintenance schedule that includes regular inspections and testing to identify any issues before they escalate. Moreover, leverage online resources, manuals, and manufacturer support to enhance your team’s knowledge base. This proactive approach will not only minimize downtime but will also foster a deeper understanding of the systems at play, leading to more efficient operations overall.

Strategic Material Selection Guide for what are pressure switches

When selecting materials for pressure switches, it is crucial to consider the specific requirements of the application, including pressure and temperature ratings, compatibility with process fluids, and environmental conditions. Below, we analyze four common materials used in pressure switches, highlighting their properties, advantages, disadvantages, and considerations for international B2B buyers.

What are the Key Properties of Stainless Steel in Pressure Switches?

Stainless Steel is a popular choice for pressure switches due to its excellent strength and corrosion resistance. Typically rated for high temperatures and pressures, stainless steel can withstand harsh environments, making it suitable for various industrial applications.

Pros:

– High durability and longevity, ensuring long-term performance.

– Excellent resistance to corrosion, particularly in chemical processing environments.

– Good mechanical properties at elevated temperatures.

Illustrative image related to what are pressure switches

Cons:

– Higher cost compared to other materials like plastic.

– Can be more complex to machine, leading to increased manufacturing costs.

Impact on Application:

Stainless steel is compatible with a wide range of fluids, including corrosive chemicals. However, it is essential to ensure that the specific grade of stainless steel is suitable for the intended media.

Considerations for International Buyers:

Buyers should verify compliance with standards such as ASTM or DIN for stainless steel grades. In regions like Europe and the Middle East, specific certifications may be required for pressure equipment.

How Does Plastic Perform as a Material for Pressure Switches?

Plastic, particularly thermoplastics like polycarbonate or nylon, is often used in pressure switches for lower-pressure applications. These materials are lightweight and can be molded into complex shapes, which can reduce manufacturing complexity.

Illustrative image related to what are pressure switches

Pros:

– Cost-effective compared to metals, making it suitable for budget-sensitive projects.

– Lightweight, which can be advantageous in portable applications.

– Good chemical resistance to many fluids.

Cons:

– Limited temperature and pressure ratings compared to metals.

– Susceptible to degradation from UV light and certain chemicals over time.

Impact on Application:

Plastic pressure switches are ideal for applications involving non-corrosive fluids at lower pressures. However, they may not be suitable for high-pressure or high-temperature environments.

Considerations for International Buyers:

Buyers should assess the chemical compatibility of the plastic material with the intended media. Compliance with local regulations regarding plastic materials is also essential, especially in regions with stringent environmental standards.

What are the Benefits and Limitations of Brass in Pressure Switches?

Brass is commonly used in pressure switches due to its good mechanical properties and resistance to corrosion, particularly in water applications. It offers a balance between cost and performance.

Pros:

– Good corrosion resistance, especially in water and mild chemical environments.

– Relatively easy to machine, which can lower manufacturing costs.

– Provides a good balance of strength and ductility.

Cons:

– Not suitable for highly corrosive environments, such as those involving strong acids or bases.

– Lower temperature and pressure ratings compared to stainless steel.

Impact on Application:

Brass is often used in HVAC systems and water pumps, where its properties align well with the operating conditions. However, care must be taken when using brass in applications involving aggressive chemicals.

Illustrative image related to what are pressure switches

Considerations for International Buyers:

Buyers should ensure that brass components meet relevant standards, such as JIS or DIN, especially in markets like Japan and Europe. Additionally, understanding local regulations regarding the use of brass in plumbing applications is crucial.

Why Choose Aluminum for Pressure Switches?

Aluminum is another viable option for pressure switches, particularly in applications where weight is a critical factor. It is lightweight and offers good corrosion resistance, especially when anodized.

Pros:

– Lightweight, which is beneficial for portable or mobile applications.

– Good corrosion resistance, especially with surface treatments.

– Cost-effective compared to stainless steel.

Cons:

– Lower strength compared to stainless steel, which may limit its use in high-pressure applications.

– Can be susceptible to galvanic corrosion when in contact with dissimilar metals.

Impact on Application:

Aluminum pressure switches are suitable for air and gas applications but may not be ideal for high-pressure hydraulic systems.

Considerations for International Buyers:

Buyers should consider the specific aluminum alloy used and its compliance with international standards. In regions like South America, understanding local manufacturing capabilities and material availability is essential.

Summary Table of Material Selection for Pressure Switches

| Material | Typical Use Case for what are pressure switches | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-pressure industrial applications | Excellent durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Plastic | Low-pressure applications | Cost-effective and lightweight | Limited temperature/pressure ratings | Low |

| Brass | HVAC and water pump systems | Good corrosion resistance | Not suitable for aggressive chemicals | Medium |

| Aluminum | Air and gas applications | Lightweight and cost-effective | Lower strength in high-pressure applications | Medium |

This strategic material selection guide provides critical insights for international B2B buyers, ensuring they make informed decisions based on the specific requirements of their applications.

Illustrative image related to what are pressure switches

In-depth Look: Manufacturing Processes and Quality Assurance for what are pressure switches

What Are the Main Stages in the Manufacturing Process of Pressure Switches?

The manufacturing process of pressure switches involves several key stages: material preparation, forming, assembly, and finishing. Each stage is critical in ensuring the final product meets both performance specifications and quality standards.

How Are Materials Prepared for Pressure Switch Manufacturing?

Material preparation begins with the selection of suitable raw materials, which often include metals, plastics, and elastomers. For example, the diaphragm of a pressure switch may be made from a durable and flexible material such as silicone or rubber, while the housing is typically constructed from metals like stainless steel or aluminum for durability.

Once selected, materials undergo processes such as cutting, machining, and surface treatment. These processes ensure that the components are shaped accurately and free of contaminants that could affect performance. Additionally, suppliers should provide certifications confirming the quality and composition of these materials, which is particularly important for international buyers concerned about compliance with local regulations.

What Techniques Are Used in Forming Pressure Switch Components?

Forming techniques vary depending on the component being produced. For instance, diaphragm elements may be formed through processes like stamping or molding, allowing for precise thickness and flexibility. Machining is commonly employed for creating housings and other metallic components, ensuring tight tolerances that are essential for the performance of pressure switches.

Another technique often utilized is injection molding, especially for plastic parts. This method is efficient for mass production and allows for complex geometries that can enhance the functionality of the switch. The choice of technique will significantly impact the cost, quality, and lead times, making it crucial for B2B buyers to understand these factors when evaluating suppliers.

How Are Pressure Switches Assembled?

The assembly of pressure switches involves integrating various components such as diaphragms, springs, levers, and electrical contacts. This stage is often performed in a cleanroom environment to minimize contamination, which can impact the switch’s functionality.

Automation plays a significant role in assembly, as robotic systems can ensure consistent placement and soldering of electronic components. However, skilled technicians are also essential for quality assurance, especially for critical components that require fine adjustments or calibration.

During assembly, manufacturers may employ methods such as pressure testing and functional checks to verify that each switch operates within specified parameters. This proactive approach helps identify issues early in the production process, reducing waste and improving overall efficiency.

What Finishing Processes Are Involved in Pressure Switch Manufacturing?

Finishing processes include surface treatments such as anodizing, painting, or plating, which enhance the corrosion resistance and aesthetic appeal of pressure switches. These treatments are vital, especially for switches intended for harsh environments, such as those found in oil and gas applications.

Additionally, final inspections are conducted to ensure that each unit meets both aesthetic and functional quality standards. This stage may involve visual inspections, dimensional checks, and functionality tests. Manufacturers should maintain detailed records of these inspections, which can be crucial for B2B buyers needing to verify quality compliance.

What Quality Assurance Standards Are Relevant for Pressure Switches?

Quality assurance in the manufacturing of pressure switches is governed by both international standards and industry-specific regulations. The ISO 9001 standard is widely recognized and outlines the criteria for a quality management system, emphasizing continuous improvement and customer satisfaction.

For pressure switches used in specific industries, additional certifications may be required, such as CE marking for compliance with European safety standards or API certifications for use in oil and gas applications. These certifications not only assure buyers of product quality but also facilitate smoother international trade.

What Are the Key Quality Control Checkpoints in Pressure Switch Manufacturing?

Quality control (QC) checkpoints are integral to ensuring that pressure switches meet the necessary standards throughout the manufacturing process. Common checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to verify they meet specified requirements.

-

In-Process Quality Control (IPQC): This stage includes monitoring the manufacturing process itself, ensuring that each step adheres to set quality standards. Techniques such as statistical process control (SPC) may be used to analyze process variability.

-

Final Quality Control (FQC): This is a comprehensive inspection performed on the finished products, assessing them against all functional and aesthetic criteria before they are shipped.

These checkpoints allow manufacturers to catch defects early, reducing the likelihood of faulty products reaching the market.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is crucial to ensure product reliability. Here are some effective methods:

-

Supplier Audits: Conducting regular audits can provide insights into a supplier’s manufacturing processes and quality assurance practices. These audits should focus on compliance with international standards and the effectiveness of their QC protocols.

-

Quality Assurance Reports: Requesting detailed reports on quality control measures and testing results can help buyers assess a supplier’s commitment to maintaining high standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide unbiased evaluations of a supplier’s manufacturing processes and product quality. This is particularly important in regions where buyers may have concerns about local manufacturing practices.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of various nuances that can affect quality control. These include:

-

Regulatory Compliance: Different regions may have specific regulatory requirements for pressure switches. Buyers should ensure that suppliers are compliant with local laws and industry standards.

-

Cultural Considerations: Understanding cultural differences in business practices can enhance communication and collaboration with suppliers. This is particularly relevant when discussing quality expectations and standards.

-

Logistical Challenges: Importing products may involve navigating complex customs regulations and inspections. Buyers should work with suppliers who have experience in international shipping and compliance to avoid delays.

By understanding the manufacturing processes and quality assurance protocols associated with pressure switches, B2B buyers can make informed decisions and build successful partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what are pressure switches’

Introduction

When sourcing pressure switches, it’s essential for B2B buyers to have a clear, structured approach to ensure they select the right products for their applications. This guide outlines a step-by-step checklist to facilitate informed decision-making, focusing on the critical factors that impact performance, reliability, and compliance.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for the pressure switch you need. Consider factors such as the pressure range, operating temperature, and the type of process fluid involved. This clarity will help narrow down your options and ensure compatibility with your systems.

Illustrative image related to what are pressure switches

- Pressure Range: Identify the minimum and maximum pressure levels the switch must operate within.

- Operating Temperature: Specify the temperature extremes the switch will encounter to avoid material degradation.

Step 2: Understand the Types of Pressure Switches

Familiarize yourself with the different types of pressure switches available, such as mechanical and electronic switches. Each type has distinct advantages and applications, which can influence your choice depending on your operational needs.

- Mechanical Pressure Switches: Typically more robust and suitable for high-voltage applications.

- Electronic Pressure Switches: Offer greater accuracy and longer life due to less wear on contacts.

Step 3: Evaluate Supplier Certifications

Before engaging with suppliers, verify their certifications and industry standards compliance. This step is crucial for ensuring product quality and reliability, particularly in regulated industries.

- ISO Certification: Confirm that the supplier adheres to international quality standards.

- Industry-Specific Certifications: Look for certifications relevant to your sector, such as ATEX for explosive environments.

Step 4: Assess Quality and Reliability

Investigate the quality assurance processes employed by potential suppliers. Understanding their manufacturing practices and testing protocols can give you confidence in the reliability of their products.

Illustrative image related to what are pressure switches

- Testing Protocols: Inquire about the types of tests conducted (e.g., pressure testing, environmental testing).

- Warranty and Support: Review warranty terms and the availability of technical support after purchase.

Step 5: Request Samples for Testing

Before finalizing your purchase, request samples to evaluate the performance of the pressure switches under your specific conditions. This hands-on approach can reveal important insights about functionality and compatibility.

- Testing in Real Conditions: Conduct tests that replicate actual operating conditions to assess performance.

- Evaluate Ease of Integration: Ensure the switch integrates seamlessly with your existing systems.

Step 6: Compare Pricing and Terms

Gather quotes from multiple suppliers to compare pricing, payment terms, and delivery schedules. This step ensures you receive competitive offers while also considering the total cost of ownership.

- Total Cost of Ownership: Factor in shipping, installation, and maintenance costs.

- Flexibility in Payment Terms: Look for suppliers who offer favorable payment options or discounts for bulk orders.

Step 7: Finalize Your Supplier Choice

Once you have gathered all necessary information and tested the products, make an informed decision on your supplier. Ensure they align with your company’s values and can provide ongoing support.

- Long-Term Relationship: Choose suppliers that are willing to engage in a long-term partnership, providing ongoing assistance and product updates.

- Feedback Mechanism: Establish a channel for feedback to improve future interactions and product offerings.

Following this checklist will help you navigate the complexities of sourcing pressure switches and ensure you make well-informed decisions that meet your operational needs.

Comprehensive Cost and Pricing Analysis for what are pressure switches Sourcing

What Are the Key Cost Components in Pressure Switch Sourcing?

When sourcing pressure switches, understanding the cost structure is critical. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Illustrative image related to what are pressure switches

-

Materials: The choice of materials significantly impacts the price. Common materials include stainless steel, plastics, and elastomers, each with varying costs based on their durability, chemical resistance, and application suitability. High-quality materials that can withstand extreme conditions often come at a premium.

-

Labor: Labor costs vary by region and depend on the complexity of the manufacturing process. Skilled labor is essential for the production of electronic pressure switches, which may require specialized training. In regions like Europe and the Middle East, labor costs tend to be higher than in parts of Africa and South America.

-

Manufacturing Overhead: This includes costs associated with the facility, utilities, and equipment maintenance. Efficient manufacturing processes can help lower overhead costs, which is particularly important for maintaining competitive pricing.

-

Tooling: Initial tooling costs can be significant, especially for custom designs. Buyers should consider these costs when negotiating prices, particularly if they require specialized pressure switches that necessitate unique tooling.

-

Quality Control (QC): Ensuring product reliability often involves rigorous testing, which adds to the overall cost. Buyers should prioritize suppliers with robust QC processes to ensure product quality, even if it raises the initial price.

-

Logistics: Transport costs can vary widely based on the shipping method, distance, and Incoterms. International buyers should factor in duties, tariffs, and freight charges when calculating total costs.

-

Margin: Suppliers typically include a profit margin that reflects their operational expenses and market positioning. Understanding the typical margins in your region can provide leverage during negotiations.

What Price Influencers Should Buyers Consider for Pressure Switches?

Several factors can influence the pricing of pressure switches beyond the basic cost components:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced per-unit costs due to economies of scale. Buyers should inquire about MOQs to maximize savings.

-

Specifications and Customization: Custom specifications can significantly increase costs. Buyers should clearly define their requirements and consider the implications of customization on lead times and pricing.

-

Quality Certifications: Products that meet international quality standards (like ISO certifications) may carry higher prices. However, investing in certified products can lead to lower long-term costs due to reduced failures and maintenance.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their track record of quality and service, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Different shipping terms can affect the final cost. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for accurately calculating total landed costs.

What Tips Can Help Buyers Optimize Costs in Pressure Switch Sourcing?

-

Negotiation: Effective negotiation strategies can lead to better pricing. Buyers should be prepared to discuss volumes, specifications, and payment terms to achieve favorable outcomes.

-

Cost-Efficiency: Focus on total cost of ownership (TCO), which includes initial purchase price, maintenance, and operational costs. Investing in higher-quality switches may yield long-term savings despite higher upfront costs.

-

Regional Pricing Nuances: Different regions may have varying price structures due to local market conditions. For instance, pressure switches sourced from Europe may be more expensive than those from Asia, but they may also offer superior quality and reliability.

-

Research and Comparison: Conduct thorough market research and obtain multiple quotes. This practice will provide insights into standard pricing and help identify potential cost-saving opportunities.

-

Long-term Relationships: Building long-term relationships with suppliers can lead to discounts and better service over time. Consider establishing partnerships with suppliers who understand your specific needs and can offer tailored solutions.

Conclusion

Understanding the comprehensive cost structure and pricing factors is essential for B2B buyers sourcing pressure switches. By considering these elements and employing strategic purchasing practices, buyers can optimize their sourcing processes and achieve significant cost savings. Always remember that prices can vary widely based on multiple factors, so conducting diligent research and negotiations is key to successful procurement.

Alternatives Analysis: Comparing what are pressure switches With Other Solutions

In the realm of industrial automation and control systems, pressure switches are widely recognized for their ability to monitor and manage pressure levels. However, various alternative technologies can also fulfill similar roles in ensuring operational efficiency and safety. Understanding these alternatives allows B2B buyers to make informed decisions that best suit their specific operational needs.

| Comparison Aspect | What Are Pressure Switches | Pressure Transducers | Pressure Gauges |

|---|---|---|---|

| Performance | Reliable for on/off control based on set pressure levels. | Continuous pressure monitoring with precise readings. | Provides pressure readings but does not control the system. |

| Cost | Generally low-cost, especially for mechanical types. | Higher initial investment due to advanced technology. | Low to moderate cost depending on type and accuracy. |

| Ease of Implementation | Simple installation; mechanical types require minimal setup. | Requires integration into electronic systems. | Easy to install but requires manual reading or additional setup for data logging. |

| Maintenance | Low maintenance; mechanical types are robust. | Requires periodic calibration and maintenance for accuracy. | Minimal maintenance; periodic recalibration may be needed for high accuracy. |

| Best Use Case | Ideal for applications needing basic on/off pressure control. | Best for applications requiring continuous monitoring and data logging. | Suitable for systems needing only pressure measurement without control. |

What are the Pros and Cons of Pressure Transducers as an Alternative?

Pressure transducers convert pressure into a measurable electrical signal, providing continuous and accurate monitoring. They are particularly beneficial in applications where real-time data is crucial, such as in process control systems. However, the complexity of these devices can lead to higher costs and may necessitate more intricate installation and calibration processes. While they offer great precision and durability, their reliance on electronic components can make them more susceptible to failure in harsh environments compared to mechanical pressure switches.

What are the Advantages and Disadvantages of Pressure Gauges?

Pressure gauges serve the primary function of measuring pressure within a system, providing visual feedback without the capability to control system operations. They are often more straightforward and less expensive than pressure switches and transducers, making them an attractive option for basic applications. However, their limitations lie in their inability to automate processes or provide alerts when pressure thresholds are exceeded. Thus, while they are valuable for monitoring, they may not suffice in systems where automated control is essential.

Illustrative image related to what are pressure switches

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting between pressure switches, pressure transducers, and pressure gauges, B2B buyers should assess their specific application requirements. Considerations such as the necessity for automation, the importance of real-time data, budget constraints, and the operational environment will guide the choice. For basic control needs, pressure switches offer an economical and reliable solution. In contrast, applications requiring continuous monitoring and data analytics may benefit from investing in pressure transducers, while pressure gauges are suited for straightforward measurement tasks. Understanding these alternatives enables businesses to optimize their operational efficiency and ensure safety in their processes.

Essential Technical Properties and Trade Terminology for what are pressure switches

What Are the Key Technical Properties of Pressure Switches?

Understanding the essential technical properties of pressure switches is crucial for B2B buyers to ensure they select the right device for their applications. Here are several critical specifications to consider:

1. Operating Pressure Range

The operating pressure range defines the minimum and maximum pressure levels at which the pressure switch can function effectively. This specification is vital because selecting a switch with an inappropriate range can lead to operational failures or inaccurate readings. Buyers should assess their system’s pressure requirements to ensure compatibility.

2. Electrical Ratings

This specification includes voltage and current ratings that indicate the maximum electrical load the switch can handle. Understanding electrical ratings is crucial for preventing equipment damage and ensuring safety in applications. It also helps buyers match the pressure switch with their existing electrical systems.

3. Material Composition

The material used in the construction of pressure switches, such as stainless steel, brass, or plastic, affects durability, resistance to corrosion, and suitability for specific fluids. Buyers should consider the chemical properties of the process fluid and environmental conditions to select materials that will withstand wear and tear, ensuring longevity and reliability.

4. Differential Pressure

Differential pressure refers to the difference in pressure that the switch can detect between two points. This is particularly important in applications where precise pressure control is necessary. Knowing the differential pressure capability helps buyers select switches that meet their specific monitoring and control needs.

5. Temperature Range

The temperature range indicates the environmental conditions in which the pressure switch can operate effectively. This property is essential for applications exposed to extreme temperatures, as improper temperature ratings can lead to device failure. Buyers should evaluate the thermal conditions of their working environment when making selections.

6. Response Time

Response time is the duration it takes for the pressure switch to react to changes in pressure. A shorter response time is often critical in dynamic systems where quick adjustments are necessary. Understanding this parameter helps in selecting switches that align with the operational speed requirements of specific applications.

What Are Common Trade Terms Associated with Pressure Switches?

Familiarizing yourself with industry jargon can streamline communications and improve procurement processes. Here are several common terms relevant to pressure switches:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that are used in another company’s end products. In the context of pressure switches, understanding OEM standards is essential for ensuring compatibility and performance within specific applications, especially for buyers looking for custom solutions.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is significant for B2B buyers, as it impacts purchasing strategies and inventory management. Buyers should inquire about MOQ when negotiating terms to avoid overstocking or incurring additional costs.

3. RFQ (Request for Quotation)

An RFQ is a document issued by buyers to solicit price offers from suppliers for specific products or services. This process is crucial for comparing costs and terms from different vendors, ensuring that buyers make informed decisions based on competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers, especially when importing pressure switches from global suppliers, as they dictate shipping costs, risk transfer, and delivery responsibilities.

5. Lead Time

Lead time is the period between placing an order and receiving the product. This term is critical for buyers to understand, as it affects project timelines and inventory management. Knowing lead times helps in planning for production schedules and avoiding delays in operational processes.

6. Calibration

Calibration refers to the process of adjusting a pressure switch to ensure accurate readings and performance. This is particularly important for applications requiring precise pressure control. Buyers should consider the calibration standards and processes offered by suppliers to maintain the integrity of their systems.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions when selecting pressure switches, ensuring optimal performance and reliability in their applications.

Navigating Market Dynamics and Sourcing Trends in the what are pressure switches Sector

What Are the Current Market Dynamics and Key Trends in Pressure Switches?

The pressure switch market is experiencing robust growth driven by increasing automation across various industries, including manufacturing, HVAC, and automotive sectors. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should note the rising demand for both mechanical and electronic pressure switches, which are integral for maintaining system efficiency and safety. As industries focus on optimizing operational costs, the adoption of pressure switches to monitor and control pressure levels has become a priority.

Emerging technologies, such as smart sensors and IoT integration, are transforming the pressure switch landscape. These advancements allow for real-time monitoring and predictive maintenance, enhancing operational efficiency and reducing downtime. Additionally, the growing emphasis on automation in industrial processes, particularly in regions like Saudi Arabia and Brazil, is propelling the demand for advanced pressure sensing solutions.

Moreover, the ongoing shift towards renewable energy and sustainable practices is influencing sourcing trends. Buyers are increasingly looking for suppliers that offer products with enhanced durability and efficiency, aligning with global sustainability goals. The pressure switch market is also witnessing a trend towards customization, allowing companies to tailor solutions that meet specific application requirements, further driving competition among manufacturers.

How Does Sustainability and Ethical Sourcing Impact the Pressure Switch Market?

Sustainability is becoming a cornerstone of the pressure switch sector, with significant implications for B2B buyers. The environmental impact of manufacturing processes and the lifecycle of pressure switches is under scrutiny. Buyers are encouraged to prioritize suppliers that adopt sustainable practices, such as reducing waste and energy consumption during production.

Ethical sourcing is equally vital. Companies are increasingly evaluating their supply chains to ensure they align with corporate social responsibility goals. This includes assessing the working conditions of laborers involved in the production of pressure switches and ensuring compliance with international labor standards.

In response to these trends, manufacturers are adopting ‘green’ certifications and materials in their products. For instance, using recyclable materials and non-toxic components not only mitigates environmental impact but also appeals to a growing base of eco-conscious customers. Buyers should seek out suppliers who can demonstrate their commitment to sustainability through certifications like ISO 14001 or the use of environmentally friendly materials in their pressure switches.

What is the Evolution of Pressure Switches and Its Significance for B2B Buyers?

The evolution of pressure switches dates back to the early 20th century when mechanical devices were first developed to regulate pressure in various applications. Initially, these switches were simple mechanical devices, relying on basic components like diaphragms and springs to function. Over the decades, advancements in materials science and electronics led to the development of electronic pressure switches, which offer enhanced accuracy, reliability, and longevity.

This transition from mechanical to electronic devices signifies a broader trend towards automation and smart technologies in industrial applications. For B2B buyers, understanding this evolution is crucial as it highlights the importance of selecting modern pressure switches that not only meet current operational demands but also future-proof their investments against evolving technology landscapes.

As businesses increasingly prioritize efficiency and sustainability, recognizing the historical context of pressure switches can inform better purchasing decisions and foster partnerships with manufacturers who are aligned with modern industry standards.

Frequently Asked Questions (FAQs) for B2B Buyers of what are pressure switches

-

How do I select the right pressure switch for my application?

Selecting the appropriate pressure switch involves assessing several factors, including the operating environment, the type of fluid being monitored, and the required pressure range. Start by determining the pressure type—positive, vacuum, or compound. Consider the switch’s operating temperature and the materials used, as they must withstand the chemical properties of the process fluid. Additionally, evaluate if you need mechanical or electronic switches based on accuracy and durability requirements. Always consult with suppliers to ensure compatibility with your specific applications. -

What are the common applications for pressure switches in industrial settings?

Pressure switches are utilized in various industrial applications, including HVAC systems, water pumps, and oil monitoring. They help maintain system pressure, ensuring equipment operates efficiently and safely. In HVAC, for instance, they monitor air pressure to optimize compressor operation. In oil systems, pressure switches alert operators when oil pressure drops below critical levels. Understanding the specific application can guide you in selecting the right switch type to enhance operational reliability. -

What factors should I consider when sourcing pressure switches internationally?

When sourcing pressure switches internationally, consider factors such as supplier reliability, product quality, and compliance with local regulations. Research potential suppliers’ reputations, certifications, and customer reviews. Ensure that the pressure switches meet international standards relevant to your industry. Additionally, assess the supplier’s capacity for customization, lead times, and support for logistics, particularly when shipping to regions like Africa or South America, where logistics can be complex. -

What are the minimum order quantities (MOQ) for pressure switches from suppliers?

Minimum order quantities (MOQ) for pressure switches can vary widely depending on the supplier and the type of switch. Some manufacturers may offer MOQs as low as 10 units, while others may require orders of 100 or more, especially for customized products. It’s essential to discuss your needs with potential suppliers to determine their MOQs and whether they can accommodate smaller orders or provide flexibility in order sizes, particularly for new buyers or trial orders. -

How can I ensure quality assurance when purchasing pressure switches?

To ensure quality assurance in your pressure switch purchases, request detailed specifications and certifications from suppliers. Look for ISO certifications and compliance with international standards specific to your industry. It’s beneficial to conduct factory visits or audits if feasible, or request samples for testing before placing large orders. Additionally, establish clear communication about quality expectations and return policies to safeguard against defects or non-compliance issues. -

What payment terms should I negotiate with pressure switch suppliers?

Negotiating payment terms is critical for managing cash flow and minimizing risk. Common terms include upfront deposits (usually 30-50%) with the balance due upon delivery or within a specified period after receipt. Consider discussing options for letters of credit or escrow services for larger orders to protect your investment. Always ensure that the agreed payment terms align with your financial capabilities and procurement timelines, especially when sourcing from international suppliers. -

Can I customize pressure switches to meet specific operational requirements?

Yes, many manufacturers offer customization options for pressure switches to meet unique operational requirements. Customizations can include adjustments to pressure ranges, materials used, or electrical configurations. When discussing your needs with suppliers, provide detailed specifications and any relevant operational conditions. Customization may affect lead times and costs, so it’s essential to understand these aspects during negotiations. -

What logistics considerations should I keep in mind when importing pressure switches?

When importing pressure switches, logistics considerations are crucial for timely delivery. Assess shipping methods (air vs. sea) based on urgency and cost, and ensure compliance with import regulations and tariffs in your country. Collaborate with reliable freight forwarders who understand the nuances of international shipping, especially for sensitive electronic components. Additionally, factor in potential delays at customs and ensure that your supplier provides all necessary documentation to facilitate smooth clearance.

Top 8 What Are Pressure Switches Manufacturers & Suppliers List

1. IQS Directory – Pressure Switches

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Pressure switches are devices activated by the pressure of fluids, air, or gases at a predetermined level. They consist of components such as bourdon tubes, pistons, diaphragms, or membranes that react to pressure changes. Key parts include: 1. Process (Inlet) Port: Connects to the process unit, allowing pressurized fluid to enter. Common fittings include NPT. 2. Pressure Sensing Element: Typicall…

2. Ashcroft – Pressure Switch

Domain: blog.ashcroft.com

Registered: 1995 (30 years)

Introduction: A pressure switch is a control device that senses changes in pressure and mechanically opens and closes an electrical circuit at a pre-determined point. It is used in various applications including hydraulic, oil and gas industries, agriculture, chemical/petrochemical, and water/wastewater operations. Pressure switches are typically used with pumps, boilers, burners, and power supplies. The operat…

3. Tameson – Pressure Switches

Domain: tameson.com

Registered: 2015 (10 years)

Introduction: Pressure switches are devices that monitor pressure levels in a system and activate or deactivate a circuit based on preset pressure thresholds. They are commonly used in various applications, including HVAC systems, water pumps, and industrial machinery. Key features include adjustable pressure settings, different electrical ratings, and compatibility with various media types. Pressure switches c…

4. JPC France – Pressure Switches

Domain: jpcfrance.eu

Introduction: Pressure Switch: A pressure control device used to control the pressure of a medium (air or water) and operate electrical devices. Types include positive pressure switches, negative (vacuum) pressure switches, and differential pressure switches. Features include a wide range of pressure connection systems, easy handling, riveted switch and mechanism, air switches with temperature and pressure comp…

5. Boshart – Pressure Switches

Domain: blog.boshart.com

Introduction: Boshart offers various types of pressure switches, including standard pressure switches, low pressure cut-off switches, Hubbell’s GARD-IT and HI-GARD switches, reverse action switches, and manual on/off switches. Standard pressure switches are suitable for pumps up to 1.5 horsepower on 120 volt motors and up to 2 horsepower on 240 volt motors, with NEMA 1 General Purpose Enclosures for indoor use….

6. Airtrol – Pressure Switch

Domain: airtrolinc.com

Introduction: A pressure switch is an electromechanical device that activates or deactivates an electrical circuit based on pressure thresholds. Key components include a diaphragm for pressure detection, an adjustment spring for set/cut out points, an AUTO/OFF lever for manual control, electrical contacts for current flow, and terminals for power connection. There are two types: normally open (NO) and normally …

7. WIKA – Pressure Switches

Domain: wika.com

Registered: 1996 (29 years)

Introduction: Pressure switches open or close a corresponding switch contact when a preset pressure is reached. They can have mechanical or electrical switch contacts, with or without displays, and various setting options. Suitable for a variety of industrial and technical processes, WIKA offers a broad selection of pressure switches for different applications. Standard instruments can be ordered easily through…

8. Reddit – Refrigerant Pressure Switches

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Low pressure switch: Used to pump down the unit and shut off the compressor when refrigerant pressure is too low, often due to leaks or improper charge. High pressure switch: Protects the compressor by shutting it off in case of high pressure, which can occur due to a dirty condenser coil or fan failure. It may also activate a condenser fan to maintain proper head pressure.

Strategic Sourcing Conclusion and Outlook for what are pressure switches

Why Is Strategic Sourcing Important for Pressure Switches?

In summary, pressure switches play a critical role in various industrial applications, ensuring safety, efficiency, and system reliability. For B2B buyers, understanding the different types of pressure switches—mechanical and electronic—along with their specific applications, is crucial for making informed purchasing decisions. Strategic sourcing allows businesses to optimize their supply chains, reduce costs, and enhance product quality by selecting the right suppliers who meet their unique operational needs.

As international markets continue to evolve, particularly in regions such as Africa, South America, the Middle East, and Europe, the demand for reliable pressure switches is set to grow. Companies should prioritize partnerships with manufacturers who not only offer competitive pricing but also maintain high standards of quality and innovation.

Looking ahead, now is the time for businesses to reassess their sourcing strategies for pressure switches. By leveraging technological advancements and focusing on supplier relationships, organizations can ensure they remain competitive in their respective industries. Engage with reputable suppliers and explore tailored solutions that meet your operational requirements today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.