Washing Machine Power Supply Board: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for washing machine power supply board

In today’s competitive landscape, sourcing reliable washing machine power supply boards presents a significant challenge for international B2B buyers. The complexity of different models, varying specifications, and fluctuating market prices can make it daunting to identify the right components that ensure operational efficiency. This comprehensive guide is designed to simplify the process, offering insights into the various types of power supply boards available, their applications across different washing machine brands, and essential considerations for supplier vetting.

As businesses in Africa, South America, the Middle East, and Europe (including regions like Saudi Arabia and Vietnam) seek to optimize their supply chains, understanding the nuances of washing machine power supply boards becomes crucial. This guide empowers buyers by providing detailed information on sourcing strategies, cost analysis, and market trends, enabling informed purchasing decisions.

By addressing common challenges and offering practical solutions, this resource aims to enhance your procurement process and ensure that you can confidently secure high-quality components that meet your operational needs. Whether you’re looking to streamline repairs, maintain inventory, or enhance product offerings, this guide serves as an essential tool for navigating the global market effectively.

Understanding washing machine power supply board Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Main Control Board | Centralized control for all washing functions | OEM parts suppliers, appliance manufacturers | Pros: Integrates multiple functions; Cons: Higher cost, complex installation. |

| Motor Control Board | Regulates motor speed and direction | Repair shops, appliance service centers | Pros: Essential for performance; Cons: May require specialized knowledge for repairs. |

| Power Supply Board | Converts AC to DC, supplies power to components | Manufacturers, repair facilities | Pros: Critical for functionality; Cons: Vulnerable to power surges. |

| User Control Board | Interface for user commands and settings | Appliance retailers, service providers | Pros: User-friendly; Cons: Can malfunction, leading to usability issues. |

| Display Board | Visual feedback for user interactions | Retailers, appliance manufacturers | Pros: Enhances user experience; Cons: Fragile, prone to damage. |

What are the characteristics of the Main Control Board?

The Main Control Board is the heart of the washing machine’s electronic system, managing various functions such as washing cycles, water levels, and spin speeds. It typically integrates multiple functions into a single unit, making it essential for the machine’s overall performance. B2B buyers should consider the compatibility with specific washing machine models and brands when purchasing. The investment can be significant, but the efficiency gained often justifies the cost.

How does the Motor Control Board function in washing machines?

The Motor Control Board is responsible for regulating the motor’s speed and direction, ensuring optimal performance during different washing cycles. This board is crucial for the agitation and spinning processes. Buyers in repair shops or service centers should prioritize sourcing genuine OEM parts to maintain reliability. While the Motor Control Board is vital for functionality, it may require specialized knowledge for installation and troubleshooting.

Why is the Power Supply Board critical for washing machines?

The Power Supply Board converts AC power from the outlet into DC power, which is then distributed to various components within the washing machine. This board is essential for the machine’s operation, as it ensures that all parts receive the correct voltage. B2B buyers should be aware of the board’s susceptibility to power surges, which can lead to failures. Investing in high-quality boards can mitigate these risks, ensuring longer operational life.

What role does the User Control Board play in washing machines?

The User Control Board serves as the interface between the user and the washing machine, allowing for the selection of different washing programs and settings. It is designed for user-friendliness, offering an intuitive experience. B2B buyers should consider the ease of replacement and compatibility with existing models when sourcing these boards. While they enhance user experience, they can also be prone to malfunctions, which may impact customer satisfaction.

How does the Display Board enhance user interactions?

The Display Board provides visual feedback to users, showing cycle status, error messages, and other essential information. This component is vital for enhancing the user experience, making it easier for consumers to interact with the machine. B2B buyers should look for durable options, as Display Boards can be fragile and susceptible to damage. Investing in high-quality display boards can significantly improve customer satisfaction and reduce return rates.

Key Industrial Applications of washing machine power supply board

| Industry/Sector | Specific Application of washing machine power supply board | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Home Appliances Manufacturing | Powering and controlling washing machines | Ensures efficiency and reliability in production processes | Quality certifications, compatibility with various models |

| Commercial Laundry Services | Replacement and maintenance of washing machine components | Reduces downtime, enhances service delivery, and customer satisfaction | Availability of OEM parts, warranty, and support services |

| Electronics Retail | Integration in appliance displays | Improves product demonstration and operational reliability | Supplier reputation, delivery timelines, and pricing |

| Appliance Repair Services | Repair and refurbishment of washing machines | Increases customer retention and service offerings | Access to a wide range of parts, technical support |

| E-commerce Platforms | Online sales of washing machine parts | Expands product offerings and caters to DIY repair markets | Product authenticity, return policies, and shipping options |

How is the Washing Machine Power Supply Board Used in Home Appliances Manufacturing?

In the home appliances manufacturing sector, the washing machine power supply board is integral to the functionality and performance of washing machines. It regulates power flow, ensuring that all components operate efficiently. Manufacturers prioritize sourcing high-quality boards to minimize defects and enhance the longevity of their products. For international buyers, especially from regions like Africa and South America, understanding local electrical standards and compatibility with various washing machine models is crucial to avoid operational issues.

What Role Does the Washing Machine Power Supply Board Play in Commercial Laundry Services?

For commercial laundry services, the washing machine power supply board is vital for maintaining operational efficiency. Given the high volume of laundry processed, any malfunction can lead to significant downtime and loss of revenue. Sourcing reliable power supply boards ensures that machines run smoothly, minimizing service interruptions. Buyers in the Middle East and Europe should consider suppliers that offer OEM parts with robust warranties, as this can significantly enhance service reliability and customer satisfaction.

How Does the Washing Machine Power Supply Board Enhance Electronics Retail?

In electronics retail, the washing machine power supply board is used to power display models, allowing potential customers to see the machines in action. This functionality not only showcases the product’s features but also builds consumer trust in its reliability. Retailers must source boards that are not only functional but also compatible with various models to meet diverse customer needs. Buyers from regions like Vietnam should focus on suppliers with a strong reputation for quality to ensure optimal customer experiences.

How is the Washing Machine Power Supply Board Essential for Appliance Repair Services?

Appliance repair services rely heavily on the availability of washing machine power supply boards for repairs and refurbishments. The ability to quickly replace or repair these boards ensures minimal disruption for clients, enhancing customer loyalty. Repair services should prioritize sourcing OEM parts to guarantee compatibility and performance. International buyers must also consider suppliers that provide technical support and a wide range of components to address different appliance models effectively.

Why is the Washing Machine Power Supply Board Important for E-commerce Platforms?

E-commerce platforms benefit from offering a variety of washing machine power supply boards, catering to the DIY repair market. By providing genuine OEM parts, these platforms can attract customers looking for reliable solutions to their appliance issues. Buyers should ensure that the suppliers they work with offer clear return policies and fast shipping options, which are critical for maintaining customer satisfaction. This is particularly important in regions where access to physical stores may be limited.

3 Common User Pain Points for ‘washing machine power supply board’ & Their Solutions

Scenario 1: Difficulty in Sourcing Reliable Power Supply Boards

The Problem: B2B buyers, especially those in regions like Africa and South America, often struggle with sourcing high-quality washing machine power supply boards. Local suppliers may lack the necessary inventory, and imported parts can take significant time to arrive, leading to operational delays. This challenge is compounded by the risk of receiving counterfeit or substandard components that can cause more issues in the long run, affecting customer satisfaction and brand reputation.

The Solution: To address this pain point, buyers should establish relationships with reputable manufacturers and distributors who specialize in washing machine parts. Conduct thorough due diligence by checking certifications, customer reviews, and product warranties. Utilize digital marketplaces that focus on B2B transactions, ensuring they offer detailed specifications and compatibility information. Moreover, consider implementing a just-in-time inventory system that allows for smaller, more frequent orders, reducing the risk of excess stock and ensuring that parts are always available when needed. By prioritizing quality over cost, businesses can enhance their reliability and customer satisfaction.

Scenario 2: Compatibility Issues with Existing Washing Machines

The Problem: Another significant challenge arises when B2B buyers encounter compatibility issues between the power supply boards they procure and the washing machines they service. Different models and brands often use distinct specifications and configurations, which can lead to frustration when trying to integrate new components. This not only results in wasted time and resources but can also disrupt the service workflow, leading to unsatisfied end customers.

The Solution: To mitigate compatibility issues, buyers should invest in comprehensive training for their procurement teams. Understanding the specific requirements for various washing machine brands can greatly reduce errors in purchasing. Additionally, maintaining an updated database of machine models and their compatible parts can streamline the sourcing process. Buyers should also consider utilizing advanced technologies such as 3D modeling and simulation software to visualize compatibility before making purchases. Finally, working closely with suppliers to obtain detailed product specifications and installation guides can prevent misunderstandings and ensure that the right components are chosen every time.

Scenario 3: High Failure Rates and Warranty Claims

The Problem: High failure rates of washing machine power supply boards can lead to increased warranty claims, which can be a significant financial burden for businesses. Buyers may find themselves in a cycle of returning defective parts, managing customer complaints, and incurring additional costs related to service and replacement. This situation is particularly challenging for companies operating in regions with limited access to high-quality components, leading to a negative impact on their bottom line.

The Solution: To combat high failure rates, buyers should focus on selecting OEM (Original Equipment Manufacturer) parts rather than generic alternatives. While OEM parts may have a higher upfront cost, they often provide better reliability and come with extensive warranties. Additionally, implementing a robust quality control process for incoming parts can help identify defects before they reach the customer. Establishing clear communication channels with suppliers regarding performance expectations and warranty terms can also facilitate quicker resolutions to any issues that arise. Finally, investing in after-sales support and customer education can foster loyalty and reduce the frequency of warranty claims, ultimately enhancing profitability.

Strategic Material Selection Guide for washing machine power supply board

What Are the Key Materials Used in Washing Machine Power Supply Boards?

When selecting materials for washing machine power supply boards, several factors must be considered, including electrical performance, durability, cost, and compliance with international standards. Below is an analysis of four common materials used in these applications.

1. FR-4 (Flame Retardant 4)

Key Properties:

FR-4 is a composite material made from woven fiberglass cloth and epoxy resin. It has excellent mechanical strength and thermal stability, with a glass transition temperature of around 130°C. Its flame-retardant properties make it suitable for electrical applications.

Pros & Cons:

The durability of FR-4 is high, making it resistant to moisture and chemicals. However, it can be more expensive than other substrates, and its manufacturing process may require specialized equipment. Additionally, while it offers good electrical insulation, it may not be suitable for extreme thermal conditions.

Impact on Application:

FR-4 is compatible with various electronic components, making it a versatile choice for power supply boards. However, its thermal limitations could affect performance in high-temperature environments.

Considerations for International Buyers:

FR-4 complies with several international standards, including UL 94 for flame resistance. Buyers from regions like Africa and the Middle East should ensure that suppliers meet local compliance regulations.

2. Aluminum

Key Properties:

Aluminum is lightweight, has excellent thermal conductivity, and is resistant to corrosion. It can withstand temperatures up to 600°C, making it suitable for high-performance applications.

Pros & Cons:

Aluminum’s high thermal conductivity is advantageous for heat dissipation, which can enhance the longevity of electronic components. However, it is more susceptible to oxidation, which can lead to performance issues over time. The cost of aluminum can vary, but it is generally more affordable than specialized composites.

Impact on Application:

Aluminum is often used for heat sinks in power supply boards, improving thermal management. Its compatibility with various media makes it a reliable choice for diverse environments.

Considerations for International Buyers:

When sourcing aluminum components, buyers should be aware of the different grades available and their respective corrosion resistance. Compliance with ASTM standards is crucial for ensuring quality.

3. Polyimide

Key Properties:

Polyimide is a high-performance polymer known for its excellent thermal stability and electrical insulation properties. It can operate at temperatures exceeding 300°C and is resistant to various chemicals.

Pros & Cons:

The primary advantage of polyimide is its ability to maintain performance under extreme conditions. However, it tends to be more expensive than other materials, and its manufacturing can be complex, requiring advanced techniques.

Impact on Application:

Polyimide is particularly suitable for applications where high thermal resistance is critical, such as in power supply boards that experience significant heat generation.

Considerations for International Buyers:

Buyers should ensure that polyimide materials meet international standards like JIS or DIN, especially in regions with stringent compliance requirements.

4. Copper

Key Properties:

Copper is renowned for its excellent electrical conductivity and thermal properties. It can withstand high temperatures and has a melting point of around 1,085°C.

Pros & Cons:

Copper’s superior conductivity makes it ideal for power supply applications, ensuring minimal energy loss. However, it is prone to corrosion and can be heavier than alternatives, which may affect design considerations. The cost of copper fluctuates based on market conditions, often making it a medium to high-cost option.

Impact on Application:

Copper is essential for traces and pads on printed circuit boards (PCBs), facilitating efficient electrical connections. Its compatibility with various components enhances overall performance.

Considerations for International Buyers:

International buyers should be aware of the different grades of copper and ensure compliance with relevant standards to avoid issues related to conductivity and corrosion.

Summary Table

| Material | Typical Use Case for washing machine power supply board | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| FR-4 | Substrate for circuit boards | High mechanical strength and thermal stability | Higher cost and specialized manufacturing | Medium |

| Aluminum | Heat sinks and structural components | Excellent thermal conductivity | Susceptible to oxidation | Low |

| Polyimide | Insulation in high-temperature applications | Exceptional thermal stability | Higher cost and complex manufacturing | High |

| Copper | Electrical traces and connections | Superior electrical conductivity | Prone to corrosion and heavier | Medium |

This material selection guide provides a comprehensive overview for international B2B buyers, ensuring informed decisions that align with performance needs and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for washing machine power supply board

What Are the Main Stages of Manufacturing a Washing Machine Power Supply Board?

Manufacturing a washing machine power supply board involves several critical stages, each designed to ensure that the final product meets high standards of quality and reliability. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Washing Machine Power Supply Boards?

Material preparation is the first stage in the manufacturing process. High-quality raw materials, such as printed circuit board (PCB) substrates, copper foil, and electronic components, are sourced from reputable suppliers. These materials undergo rigorous inspection to ensure they meet specified standards. For instance, PCBs are typically evaluated for thickness, dielectric constant, and thermal conductivity, as these properties directly affect the board’s performance.

What Techniques Are Used for Forming Washing Machine Power Supply Boards?

The forming stage includes the fabrication of the PCB. This involves several techniques such as etching, laminating, and drilling. The etching process removes unwanted copper from the board to create the desired circuit pattern. Advanced techniques like laser drilling are often used for creating microvias, which are essential for high-density interconnect (HDI) boards. This stage is critical, as precision in forming ensures that the circuit paths are accurately created, leading to optimal electrical performance.

How Is the Assembly Process Conducted for Power Supply Boards?

The assembly of washing machine power supply boards involves placing various electronic components onto the PCB. This is typically done using surface mount technology (SMT), which allows for the efficient placement of components. Automated pick-and-place machines are commonly employed to ensure accuracy and speed.

Following component placement, soldering is performed to secure the components. Reflow soldering is widely used in this process, where the entire board is heated to melt solder paste and create robust electrical connections. After soldering, boards are often subjected to visual inspections to identify any misalignments or defects.

What Are the Final Finishing Steps in Manufacturing Power Supply Boards?

The finishing stage includes several processes aimed at preparing the board for shipping. This may involve conformal coating, which protects the board from moisture and dust, and final testing to ensure all components function correctly. Boards are typically tested for continuity, resistance, and thermal performance. This step is vital, as it guarantees that the power supply board can reliably operate within the intended washing machine environment.

What Quality Control Standards Should B2B Buyers Expect?

Quality assurance in the manufacturing of washing machine power supply boards is crucial for maintaining product reliability and safety. B2B buyers should look for suppliers who adhere to internationally recognized standards, such as ISO 9001, which focuses on quality management systems. This certification indicates that the supplier has established processes to ensure consistent quality.

In addition to ISO standards, industry-specific certifications like CE marking (indicating compliance with EU safety requirements) are essential. For buyers in regions like Africa, South America, and the Middle East, understanding local regulatory requirements is also important, as they may vary significantly from those in Europe.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process to ensure adherence to standards. These checkpoints typically include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to verify that they meet quality specifications.

- In-Process Quality Control (IPQC): Conducted during the manufacturing process, this includes monitoring critical parameters such as temperature during soldering and component placement accuracy.

- Final Quality Control (FQC): This final inspection assesses the overall functionality of the assembled power supply boards. Common testing methods include electrical testing, thermal imaging, and performance simulation.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify the quality control practices of their suppliers. One of the most effective methods is conducting audits, where buyers can assess the supplier’s manufacturing processes and quality control systems firsthand. During these audits, buyers should review quality documentation, such as inspection reports and compliance certificates.

Additionally, requesting third-party inspection reports can provide an unbiased assessment of the supplier’s quality practices. Many reputable manufacturers will have established relationships with third-party testing organizations, ensuring that their products meet both international and local standards.

What Nuances Should International B2B Buyers Be Aware Of in Quality Control?

For international B2B buyers, particularly those from diverse markets like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is crucial. Variations in regulatory standards, cultural perceptions of quality, and logistical challenges can impact the procurement process.

Buyers should familiarize themselves with local standards that may differ from international norms. For example, while CE marking is crucial in Europe, other regions may have their own certification requirements, such as SASO in Saudi Arabia. Additionally, language barriers and differing business practices can affect communication regarding quality expectations.

Conclusion: Why Quality Assurance is Critical for Washing Machine Power Supply Boards

In summary, the manufacturing processes and quality assurance mechanisms for washing machine power supply boards are intricate and essential for delivering reliable products. B2B buyers must prioritize suppliers who implement rigorous quality control measures and adhere to international standards. By understanding these processes and actively verifying supplier practices, buyers can ensure they are sourcing high-quality power supply boards that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘washing machine power supply board’

Introduction

This practical sourcing guide is designed to assist B2B buyers in efficiently procuring washing machine power supply boards. By following this step-by-step checklist, you will ensure that you select the right components from reputable suppliers, thereby enhancing the reliability and performance of your washing machines.

Step 1: Define Your Technical Specifications

Before beginning your search for power supply boards, it’s vital to clearly outline your technical requirements. Specify the voltage, current ratings, and compatibility with various washing machine models. This clarity will help you communicate effectively with suppliers and ensure you receive components that meet your operational needs.

- Voltage and Current Ratings: Ensure the specifications align with the electrical requirements of the washing machines you are servicing.

- Model Compatibility: Identify the models that the power supply board will support to avoid compatibility issues.

Step 2: Research Potential Suppliers

Start by compiling a list of potential suppliers who specialize in washing machine parts, particularly power supply boards. Look for suppliers with a strong reputation in the industry.

- Online Reviews and Ratings: Utilize platforms like Trustpilot or industry-specific forums to gauge supplier reliability.

- Industry Experience: Prioritize suppliers with extensive experience in the appliance parts sector, as they are more likely to understand your specific needs.

Step 3: Evaluate Supplier Certifications

Before proceeding with a supplier, verify that they hold relevant certifications, such as ISO 9001 or CE marking. These certifications indicate compliance with international quality standards.

- Quality Assurance: Certified suppliers are more likely to provide high-quality components, reducing the risk of defects.

- Regulatory Compliance: Ensure the products meet local regulations, which is particularly important for international transactions.

Step 4: Request Samples or Prototypes

Once you have narrowed down your options, request samples or prototypes of the power supply boards. Testing these samples will allow you to assess their quality and compatibility with your machines.

- Functional Testing: Ensure the samples perform as expected under operational conditions.

- Quality Inspection: Check for any physical defects or discrepancies in specifications.

Step 5: Compare Pricing and Terms

Analyze the pricing structure and payment terms offered by each supplier. While price is important, consider the total cost of ownership, including shipping, duties, and warranties.

- Bulk Discounts: Inquire about discounts for larger orders, which can significantly lower your costs.

- Return Policies: Understand the supplier’s return policy in case the components do not meet your expectations.

Step 6: Negotiate Terms and Place Orders

Once you’ve selected a supplier, negotiate terms that are favorable to your business. This may include pricing, delivery schedules, and warranty terms.

- Clear Communication: Ensure all terms are documented to avoid misunderstandings.

- Lead Times: Confirm lead times for delivery to align with your production schedules.

Step 7: Establish Ongoing Relationships

After the initial purchase, aim to establish a long-term relationship with your supplier. This can lead to better pricing, priority service, and access to new products as they become available.

- Feedback Loop: Provide feedback on product performance to help the supplier improve.

- Regular Check-ins: Schedule periodic reviews to discuss future needs and potential collaborations.

By following this checklist, you can navigate the procurement process for washing machine power supply boards with confidence, ensuring that you make informed decisions that support your business objectives.

Comprehensive Cost and Pricing Analysis for washing machine power supply board Sourcing

What Are the Key Cost Components in Sourcing Washing Machine Power Supply Boards?

When analyzing the costs associated with sourcing washing machine power supply boards, several critical components come into play. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s margin.

-

Materials: The choice of materials directly impacts the price. High-quality components, such as capacitors and resistors, are essential for durability and performance, but they can significantly increase costs. Low-cost materials may reduce initial expenditure but can lead to higher failure rates and warranty claims.

-

Labor: Labor costs vary by region and can be a significant factor, especially if the production is based in areas with high wage standards. Additionally, the complexity of assembly processes can require specialized labor, further influencing the overall cost.

-

Manufacturing Overhead: This includes indirect costs such as utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can lower overhead costs, which is critical for maintaining competitive pricing.

-

Tooling: Initial tooling costs for producing custom boards can be substantial. However, these costs are often amortized over larger production runs, making them less significant per unit in high-volume orders.

-

Quality Control: Implementing stringent QC measures ensures reliability and performance, which can incur additional costs. However, investing in quality can reduce long-term costs associated with returns and repairs.

-

Logistics: Shipping costs, especially for international transactions, can significantly affect the total cost. Factors like distance, mode of transport, and customs duties must be considered.

-

Margin: Suppliers typically add a margin to cover their costs and generate profit. This margin can vary widely based on the supplier’s market positioning and the competitive landscape.

How Do Price Influencers Affect the Cost of Washing Machine Power Supply Boards?

Several factors influence the pricing of washing machine power supply boards, particularly for B2B buyers. Understanding these can lead to more informed purchasing decisions.

-

Volume/MOQ: Manufacturers often have minimum order quantities (MOQs), which can affect pricing. Higher volumes typically lead to lower per-unit costs due to economies of scale.

-

Specifications and Customization: Custom boards designed to meet specific requirements can increase costs due to additional engineering and tooling expenses. Buyers should weigh the benefits of customization against the added costs.

-

Materials Quality and Certifications: Boards that meet international safety and performance certifications may command higher prices. However, these certifications can also be crucial for market acceptance and reducing liability.

-

Supplier Factors: Supplier reputation, reliability, and historical performance can influence pricing. Established suppliers may charge a premium for their proven track record, while newer entrants might offer competitive pricing to gain market share.

-

Incoterms: The choice of Incoterms (International Commercial Terms) can impact the overall cost structure. For example, FOB (Free on Board) can shift some logistics costs to the buyer, affecting the total landed cost.

What Are Effective Buyer Tips for Sourcing Washing Machine Power Supply Boards?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies to enhance cost-efficiency:

-

Negotiation: Engage suppliers in discussions about pricing and terms. Understanding the cost components can provide leverage in negotiations, particularly regarding volume discounts or payment terms.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but the total cost over the product’s lifecycle, including maintenance, potential downtime, and warranty costs. A lower upfront cost may not always equate to a better long-term investment.

-

Research and Compare Suppliers: Conduct thorough research to compare different suppliers based on price, quality, and service. Gathering multiple quotes can provide insights into market pricing and help in making informed decisions.

-

Understand Local Market Dynamics: Different regions may have varying pricing structures due to local economic conditions, tariffs, and shipping costs. Awareness of these factors can lead to better sourcing strategies.

-

Stay Informed on Pricing Trends: Keep abreast of global trends in electronics manufacturing, as fluctuations in material costs or supply chain disruptions can affect pricing. Regularly updating your knowledge can position you better for negotiations.

Disclaimer

The prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and specific buyer requirements. Always confirm current pricing directly with suppliers before making purchasing decisions.

Alternatives Analysis: Comparing washing machine power supply board With Other Solutions

Exploring Alternatives to the Washing Machine Power Supply Board

In the landscape of washing machine components, the power supply board plays a critical role, acting as the nerve center for electrical management. However, various alternatives exist that can either complement or serve as substitutes for traditional power supply boards. This analysis will delve into these alternatives, providing B2B buyers with essential insights to guide their purchasing decisions.

Comparison Table

| Comparison Aspect | Washing Machine Power Supply Board | Smart Power Management System | Integrated Inverter Technology |

|---|---|---|---|

| Performance | Reliable power distribution; regulates voltage and current effectively | Enhanced efficiency with real-time monitoring; optimizes power usage | Provides variable speed control for motors, reducing energy consumption |

| Cost | Moderate initial investment; replacement parts available | Higher initial cost but potential long-term savings | Higher upfront cost; requires specialized installation |

| Ease of Implementation | Straightforward installation; typically requires basic electrical knowledge | More complex; may need professional installation | Installation can be intricate, often requiring expert technicians |

| Maintenance | Regular checks needed for wear and tear; moderate maintenance | Low maintenance; software updates may be required | Requires occasional servicing; components may need replacement over time |

| Best Use Case | Standard washing machines needing reliable power management | High-efficiency machines where power usage data is crucial | Energy-efficient models aiming for reduced operational costs |

Understanding Each Alternative

Smart Power Management System

Smart power management systems leverage advanced technology to monitor and control energy usage in real-time. These systems can optimize power distribution, reduce energy waste, and provide data analytics to improve operational efficiency. The primary advantage of a smart system is its ability to dynamically adjust power consumption based on load requirements. However, the initial investment can be significantly higher than a traditional power supply board, and installation may necessitate professional expertise.

Integrated Inverter Technology

Integrated inverter technology is designed for washing machines that require variable speed control for motors. This technology allows for precise adjustments to the motor speed, resulting in improved energy efficiency and reduced operational costs. The benefits include lower electricity bills and less wear on machine components. However, the installation process can be complex, often requiring skilled technicians, and the initial costs are typically higher compared to conventional power supply boards.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the right solution for washing machine power management, B2B buyers should assess their specific operational requirements and budget constraints. For businesses looking for a cost-effective and straightforward solution, the traditional washing machine power supply board may suffice. However, for those aiming to enhance efficiency and reduce long-term energy costs, investing in a smart power management system or integrated inverter technology may yield significant benefits. Ultimately, the choice will depend on the balance between upfront costs, installation complexity, and the desired performance outcomes.

Essential Technical Properties and Trade Terminology for washing machine power supply board

What Are the Key Technical Properties of a Washing Machine Power Supply Board?

When sourcing washing machine power supply boards, understanding their technical properties is crucial for making informed purchasing decisions. Here are some key specifications to consider:

-

Material Grade

The material grade of a power supply board influences its durability and performance. Common materials include FR-4 (a flame-retardant fiberglass) and polyimide. FR-4 is widely used due to its excellent electrical insulating properties and thermal stability, making it ideal for high-performance applications. Buyers should verify material specifications to ensure compatibility with their washing machines. -

Voltage Rating

This specification indicates the maximum voltage the power supply board can handle without failing. Most washing machine power supply boards operate at voltages ranging from 110V to 240V, depending on regional electrical standards. Understanding the voltage rating is essential for ensuring safety and operational efficiency, particularly in regions with varying power supply conditions. -

Current Rating

The current rating defines the maximum current the board can safely carry, usually measured in amperes (A). A board with a higher current rating can support more powerful washing machines or additional features such as advanced sensors. This specification is crucial for buyers to ensure that the board meets the operational demands of their specific washing machine models. -

Temperature Tolerance

Temperature tolerance refers to the range of temperatures the board can withstand during operation. Boards typically operate efficiently within a range of -40°C to 85°C. This specification is particularly important in regions with extreme climates, as it impacts reliability and lifespan. Buyers should assess whether the boards can handle local environmental conditions. -

Circuit Design Complexity

The complexity of the circuit design can affect both the performance and repairability of the power supply board. More intricate designs may offer advanced functionalities but could complicate repairs. Buyers should consider their technical capabilities for maintenance and whether they have access to compatible replacement parts. -

Compliance Standards

Compliance with international safety and quality standards (such as CE, UL, or RoHS) is essential for ensuring that the power supply board meets regulatory requirements. These certifications provide assurance regarding the safety and environmental impact of the product. Buyers should prioritize boards that comply with relevant standards in their regions.

What Are Common Trade Terms Related to Washing Machine Power Supply Boards?

Understanding industry jargon can facilitate smoother transactions and negotiations. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In the context of washing machine power supply boards, OEM parts are often preferred for their quality assurance and compatibility. B2B buyers should prioritize OEM components to ensure reliability and performance. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is vital for budgeting and inventory planning. Buyers should inquire about MOQs to ensure they can meet purchase requirements without overcommitting to excess inventory. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. It allows buyers to compare offers and negotiate better deals. Crafting a detailed RFQ can help ensure that suppliers understand your needs and provide accurate quotes. -

Incoterms (International Commercial Terms)

Incoterms are standardized shipping terms that define the responsibilities of buyers and sellers in international trade. They clarify who pays for shipping, insurance, and tariffs, which is crucial for cost management. Familiarity with these terms helps buyers avoid misunderstandings and additional costs. -

PCB (Printed Circuit Board)

A PCB is a board used to support and connect electronic components. Understanding PCB specifications is essential when sourcing power supply boards, as it impacts performance and compatibility with washing machines. Buyers should look for detailed PCB information to ensure the right fit for their equipment. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. It is an essential factor in planning and inventory management. Buyers should inquire about lead times when negotiating with suppliers to ensure timely delivery and minimize operational disruptions.

By familiarizing yourself with these technical properties and trade terms, you can make more informed purchasing decisions regarding washing machine power supply boards, ensuring compatibility, reliability, and compliance with industry standards.

Navigating Market Dynamics and Sourcing Trends in the washing machine power supply board Sector

What Are the Current Market Dynamics and Key Trends Influencing the Washing Machine Power Supply Board Sector?

The global washing machine power supply board market is witnessing significant growth driven by various factors including increasing consumer demand for energy-efficient appliances, technological advancements, and a rising focus on sustainability. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek to optimize their product offerings, understanding these dynamics becomes crucial.

One of the most prominent trends is the shift towards smart appliances, which integrate IoT technology to enhance user experience. This trend is reshaping the design and functionality of power supply boards, as manufacturers are focusing on developing more sophisticated control boards that can handle advanced features like remote monitoring and energy management. Additionally, the rise of e-commerce has facilitated easier access to a broader range of suppliers, allowing buyers to compare prices and features more effectively.

Emerging markets are also experiencing rapid urbanization, leading to a surge in household appliance purchases. In regions like Saudi Arabia and Vietnam, consumers are increasingly willing to invest in high-quality, durable products, prompting manufacturers to elevate their standards. This is creating opportunities for international buyers to source premium power supply boards that meet stringent quality benchmarks while also catering to local market preferences.

How Is Sustainability and Ethical Sourcing Shaping the Washing Machine Power Supply Board Market?

In an era of heightened environmental awareness, sustainability has become a critical consideration for B2B buyers in the washing machine power supply board sector. The environmental impact of manufacturing processes, particularly in terms of energy consumption and waste generation, is under scrutiny. Ethical supply chains are gaining prominence as companies strive to meet regulatory requirements and consumer expectations for responsible sourcing.

International buyers are increasingly looking for suppliers who prioritize eco-friendly practices, such as using recycled materials and reducing carbon footprints. Certifications like ISO 14001 and Energy Star are becoming essential criteria for selecting suppliers, as they signify a commitment to environmental management and energy efficiency. Furthermore, the adoption of “green” materials in the production of power supply boards not only minimizes environmental impact but also enhances product appeal in markets where consumers are willing to pay a premium for sustainable options.

As B2B buyers navigate this landscape, they must consider how their sourcing decisions align with sustainability goals. Collaborating with suppliers who share these values can lead to a stronger brand reputation and increased customer loyalty, which are crucial in a competitive market.

What Is the Historical Context Behind the Evolution of the Washing Machine Power Supply Board?

The washing machine power supply board has evolved significantly since the inception of electric washing machines in the early 20th century. Initially, these boards were rudimentary, primarily functioning to control power distribution to the motor and basic washing functions. However, as consumer expectations grew and technology advanced, the design and complexity of these boards transformed dramatically.

By the 1980s, the introduction of microcontrollers marked a pivotal shift, allowing for more sophisticated programming and control of washing cycles. This innovation paved the way for modern features such as programmable settings, load sensing, and energy-saving modes. Today, the power supply board is a crucial component in smart washing machines, enabling connectivity and advanced functionalities that enhance user experience.

This historical perspective underscores the importance of continuous innovation in the sector. For international B2B buyers, understanding the evolution of power supply boards not only provides insight into current product offerings but also helps in forecasting future trends and making informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of washing machine power supply board

-

How do I troubleshoot a washing machine power supply board issue?

Troubleshooting a power supply board issue typically involves checking for visible signs of damage, such as burnt components or loose connections. Begin by disconnecting the washing machine from the power source for safety. Use a multimeter to test the voltage levels at the board’s input and output terminals. If voltage is absent or inconsistent, it may indicate a faulty board. Consult the manufacturer’s guidelines for specific diagnostic procedures or consider hiring a qualified technician for a comprehensive evaluation. -

What is the best power supply board for my washing machine model?

The best power supply board for your washing machine model depends on compatibility and performance requirements. Always refer to your machine’s model number to ensure you select an OEM (Original Equipment Manufacturer) part. OEM boards are designed to meet the manufacturer’s specifications, ensuring reliability and longevity. If you’re considering alternatives, verify that they meet industry standards and have positive reviews from other users. -

What are the key factors to consider when sourcing washing machine power supply boards internationally?

When sourcing power supply boards internationally, consider factors such as product quality, supplier reputation, and compliance with local regulations. Verify that the supplier offers OEM parts or high-quality replacements. Additionally, assess their ability to provide warranties and after-sales support. Understanding import tariffs, shipping times, and logistics costs is crucial for budgeting and ensuring timely delivery. -

How can I vet suppliers for washing machine power supply boards?

Vetting suppliers involves researching their background, customer reviews, and industry certifications. Request references from other businesses that have sourced similar products. Conduct audits or site visits if possible, and evaluate their production processes and quality control measures. A reliable supplier should provide transparent information regarding their sourcing, manufacturing practices, and compliance with international standards. -

What are the minimum order quantities (MOQs) for power supply boards?

Minimum order quantities (MOQs) can vary widely among suppliers, often influenced by manufacturing costs and the specific part being ordered. Typically, MOQs can range from a few pieces to hundreds. It’s advisable to discuss your needs with potential suppliers and negotiate terms that suit your business model. Some suppliers may offer lower MOQs for new partnerships or trial orders. -

What payment terms should I expect when sourcing power supply boards?

Payment terms can differ significantly based on the supplier’s policies and your negotiation skills. Common terms include a deposit upfront (typically 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer credit terms for established businesses. Always clarify payment methods, such as wire transfers or letters of credit, and consider using escrow services for larger orders to mitigate risk. -

How do I ensure quality assurance (QA) for imported power supply boards?

To ensure quality assurance for imported power supply boards, implement a multi-step QA process. Request samples before placing bulk orders and conduct inspections based on predefined criteria. Engage third-party inspection services to evaluate the products during production and before shipment. Establish clear quality standards with your supplier and ensure they are documented in your purchase agreement. -

What logistics considerations are important when importing washing machine parts?

Logistics considerations include understanding shipping methods, lead times, and customs clearance processes. Choose reliable freight forwarders who are experienced with electronic components to minimize risks. Be aware of import duties and taxes that may apply to your shipments. Additionally, consider the impact of logistics on your supply chain and ensure you have contingency plans for delays or disruptions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Washing Machine Power Supply Board Manufacturers & Suppliers List

1. Samsung – Washer Power Supply Control Board

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Samsung Washer Power Supply Control Board”, “Part Number”: “DC94-04157A”, “Condition”: “Used”, “Price”: “$49.99”, “Original Price”: “$99.98”, “Discount”: “50% off”, “Shipping”: “Free USPS First Class”, “Location”: “Davenport, Iowa, United States”, “Estimated Delivery”: “Between Wed, Sep 10 and Sat, Sep 13”, “Returns”: “30 days returns, buyer pays for return shipping”, “Seller”: “…

2. LG – Washing Machine Control Board

Domain: appliancerepair.homedepot.com

Registered: 1992 (33 years)

Introduction: {“products”:[{“name”:”LG Washing Machine Control Board”,”price”:”$243.05″,”status”:”In Stock”,”part_number”:”EBR75857902″},{“name”:”LG Washing Machine Noise Filter”,”price”:”$78.70″,”status”:”In Stock”,”part_number”:”6201EC1006T”},{“name”:”LG Washing Machine Noise Filter”,”price”:”$76.60″,”status”:”In Stock”,”part_number”:”EAM60991301″},{“name”:”LG Washing Machine Noise Filter”,”price”:”$75.55″,”s…

3. Whirlpool – FFB 10469 BV EE

Domain: justanswer.com

Registered: 2004 (21 years)

Introduction: Washing Machine Model: Whirlpool FFB 10469 BV EE; Issue: Won’t power up after programming unit replacement; Troubleshooting Steps: Verify wiring connections, check power button and user interface board, test for power at the control board, inspect noise filter and fuse, try a hard reset.

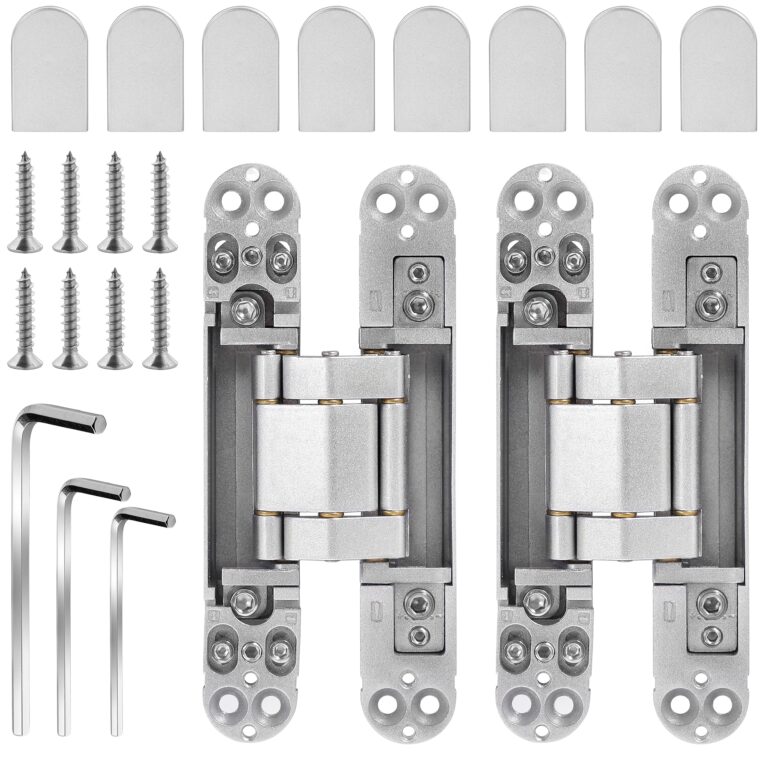

4. Washing Machine – Control Board Components

Domain: forum.allaboutcircuits.com

Registered: 2003 (22 years)

Introduction: Control board for washing machine; Capacitors: 250V, 560uF; Power management chips: LNK624DG, TNY178PN; Related components: LNK305GN, LNK623; Testing equipment: Multimeter; Voltage measurements: 240V, 88V (AC), 110V, 0V (DC); Repair kits available for various brands.

Strategic Sourcing Conclusion and Outlook for washing machine power supply board

The importance of strategic sourcing for washing machine power supply boards cannot be overstated, particularly in the context of global supply chains. By focusing on quality OEM parts, B2B buyers can ensure reliability and performance in their products. Establishing relationships with reputable suppliers not only enhances operational efficiency but also mitigates risks associated with counterfeit parts, which can lead to increased service costs and dissatisfied customers.

In addition, leveraging regional partnerships can facilitate faster delivery times and reduce shipping costs, which is particularly crucial for buyers in Africa, South America, the Middle East, and Europe. The demand for high-quality washing machine components continues to grow, driven by an increase in consumer expectations and the shift towards energy-efficient appliances.

Looking ahead, international buyers should prioritize strategic sourcing initiatives that emphasize sustainability and innovation. Engaging with suppliers who invest in technology and eco-friendly practices will not only enhance product offerings but also align with global sustainability goals. Take proactive steps now to secure your supply chain and position your business for future success in the competitive appliance market.