Vibratory Tumblers: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for vibratory tumblers

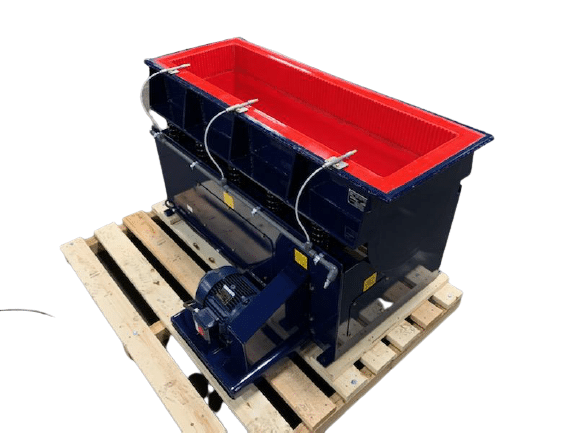

In the competitive landscape of industrial manufacturing, sourcing high-quality vibratory tumblers presents a significant challenge for B2B buyers across various regions, including Africa, South America, the Middle East, and Europe. These essential machines are not only pivotal for metal finishing and rock polishing but also contribute to improving efficiency and reducing operational costs. As international businesses seek to enhance their production capabilities, understanding the diverse types and applications of vibratory tumblers becomes crucial.

This comprehensive guide aims to demystify the vibratory tumbler market by exploring various models, their specific applications, and the nuances of supplier vetting. Buyers will gain insights into key factors such as cost considerations, operational efficiencies, and maintenance requirements, enabling them to make informed purchasing decisions. Additionally, we will address regional market dynamics and supplier reliability, which are vital for successful transactions in countries like Nigeria and Vietnam.

By equipping B2B buyers with actionable knowledge, this guide empowers businesses to navigate the global market effectively. Whether you’re looking to enhance your product quality or streamline your manufacturing processes, understanding vibratory tumblers is an essential step toward achieving your operational goals. Prepare to explore a wealth of information that will help you select the right equipment for your needs while optimizing your investment.

Understanding vibratory tumblers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Vibratory Tumblers | Basic models with a single bowl for small to medium parts | General deburring and polishing | Pros: Cost-effective, versatile. Cons: Limited capacity and speed for larger operations. |

| Industrial Vibratory Tumblers | Larger capacity with enhanced durability and power | Heavy-duty applications, mass production | Pros: High efficiency, suitable for large batches. Cons: Higher initial investment. |

| Rock Polishing Tumblers | Designed specifically for rock tumbling, faster process | Hobbyists, gemstone and jewelry industries | Pros: Quick polishing, less grit usage. Cons: Less effective for non-rock materials. |

| Adjustable Vibratory Tumblers | Customizable settings for various media and parts | Specialized finishing for diverse materials | Pros: Flexibility in operation, tailored results. Cons: Complexity may require training. |

| Tumble-Dump Systems | Large capacity with automated dumping features | High-volume production lines | Pros: Streamlined workflow, reduced manual labor. Cons: Requires significant floor space. |

What Are the Characteristics of Standard Vibratory Tumblers?

Standard vibratory tumblers are often the first choice for businesses looking to enhance their metal finishing processes. These models typically feature a single bowl and are designed for small to medium-sized parts. They are versatile and cost-effective, making them ideal for general deburring and polishing tasks. However, their limited capacity and speed may not meet the demands of larger operations, which can be a consideration for B2B buyers looking to scale their processes.

How Do Industrial Vibratory Tumblers Differ?

Industrial vibratory tumblers stand out due to their enhanced durability and larger capacities. They are engineered for heavy-duty applications and mass production, making them suitable for businesses that require high efficiency and consistent results over large batches. While they come with a higher initial investment, the long-term savings in labor and material costs often justify the expense. B2B buyers should consider their production needs and budget constraints when evaluating these options.

Why Choose Rock Polishing Tumblers?

Rock polishing tumblers are specifically designed for the gemstone and jewelry industries, offering a faster and more efficient polishing process compared to traditional rotary tumblers. These machines consume less grit and electricity, making them an economical choice for hobbyists and small businesses. However, they may not be as effective for non-rock materials, which could limit their versatility in a B2B setting.

What Are the Benefits of Adjustable Vibratory Tumblers?

Adjustable vibratory tumblers allow businesses to customize settings based on the specific media and parts being processed. This flexibility is crucial for specialized finishing applications, enabling companies to achieve tailored results. While they offer numerous advantages, including improved operational efficiency, the complexity of these systems may require additional training for staff, which is an important consideration for B2B buyers.

What Should You Know About Tumble-Dump Systems?

Tumble-dump systems are designed for high-volume production lines, featuring automated dumping capabilities that streamline the workflow. These systems are particularly beneficial for businesses that process large quantities of parts, as they reduce manual labor and increase efficiency. However, they require significant floor space and may not be ideal for smaller operations. B2B buyers should assess their production volume and space availability when considering this option.

Key Industrial Applications of vibratory tumblers

| Industry/Sector | Specific Application of vibratory tumblers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Metal Fabrication | Deburring and polishing metal parts | Enhances surface finish, reduces manual labor costs | Material compatibility, machine capacity, and media type |

| Jewelry Manufacturing | Polishing gemstones and metal settings | Achieves high-quality finishes, saves processing time | Size of tumbler, media type, and energy efficiency |

| Automotive Parts | Cleaning and finishing small components | Improves product quality and consistency | Customization options, batch size, and noise levels |

| Electronics Manufacturing | Deburring and cleaning circuit boards | Ensures precision and reliability in electronic devices | Compatibility with various materials and precision levels |

| Aerospace Components | Surface finishing of turbine blades and other critical parts | Enhances durability and performance of components | Compliance with industry standards, material specifications |

How Are Vibratory Tumblers Used in Metal Fabrication?

In the metal fabrication industry, vibratory tumblers are primarily used for deburring and polishing metal parts. The tumbling action effectively removes sharp edges and surface imperfections, leading to a smoother finish. This process not only enhances the aesthetic appeal of the metal components but also reduces the risk of injury during handling. For international buyers, especially in regions like Africa and South America, it’s crucial to consider the machine’s capacity to handle various metal types and the compatibility of the tumbling media with the materials being processed.

What Role Do Vibratory Tumblers Play in Jewelry Manufacturing?

Vibratory tumblers are essential in jewelry manufacturing for polishing gemstones and metal settings. This equipment allows jewelers to achieve high-quality finishes on intricate designs without extensive manual labor. The efficiency of vibratory tumblers helps reduce processing time, enabling jewelers to increase production rates. For buyers in the Middle East and Europe, sourcing considerations should include the size of the tumbler, the type of polishing media used, and energy efficiency to minimize operational costs.

How Are Vibratory Tumblers Applied in Automotive Parts Production?

In the automotive industry, vibratory tumblers are utilized for cleaning and finishing small components, such as bolts and brackets. The tumbling process enhances product quality by ensuring that all parts are uniformly cleaned and deburred, which is critical for maintaining consistency in automotive assembly. Buyers from regions like Africa must evaluate the customization options available for their specific parts and consider the noise levels of the equipment, as these factors can impact operational efficiency in a manufacturing setting.

Why Are Vibratory Tumblers Important in Electronics Manufacturing?

Vibratory tumblers serve a vital role in the electronics manufacturing sector by deburring and cleaning circuit boards. This process ensures that the components are free from debris, which could compromise the reliability of electronic devices. For international B2B buyers, particularly in regions like Vietnam, it is essential to assess the compatibility of vibratory tumblers with various materials used in electronics, as well as the precision levels required for high-quality production.

How Do Vibratory Tumblers Benefit Aerospace Component Manufacturing?

In aerospace manufacturing, vibratory tumblers are used for surface finishing of critical components such as turbine blades. This application is crucial for enhancing the durability and performance of parts exposed to extreme conditions. Buyers in the aerospace sector must ensure that the tumblers comply with stringent industry standards and specifications. Additionally, understanding the material requirements and the specific finishing processes needed for different aerospace components is vital for successful sourcing.

3 Common User Pain Points for ‘vibratory tumblers’ & Their Solutions

Scenario 1: Struggling with Consistent Finishing Quality

The Problem: Many B2B buyers in industries such as metalworking or jewelry manufacturing face challenges with achieving consistent finishing quality when using vibratory tumblers. Variability in results can stem from improper media selection, inconsistent moisture levels, or incorrect tumbling times. This inconsistency not only affects the aesthetic appeal of finished products but also leads to increased rework costs and dissatisfied customers. Buyers may find themselves frustrated as they attempt to troubleshoot these issues without a clear understanding of the underlying causes.

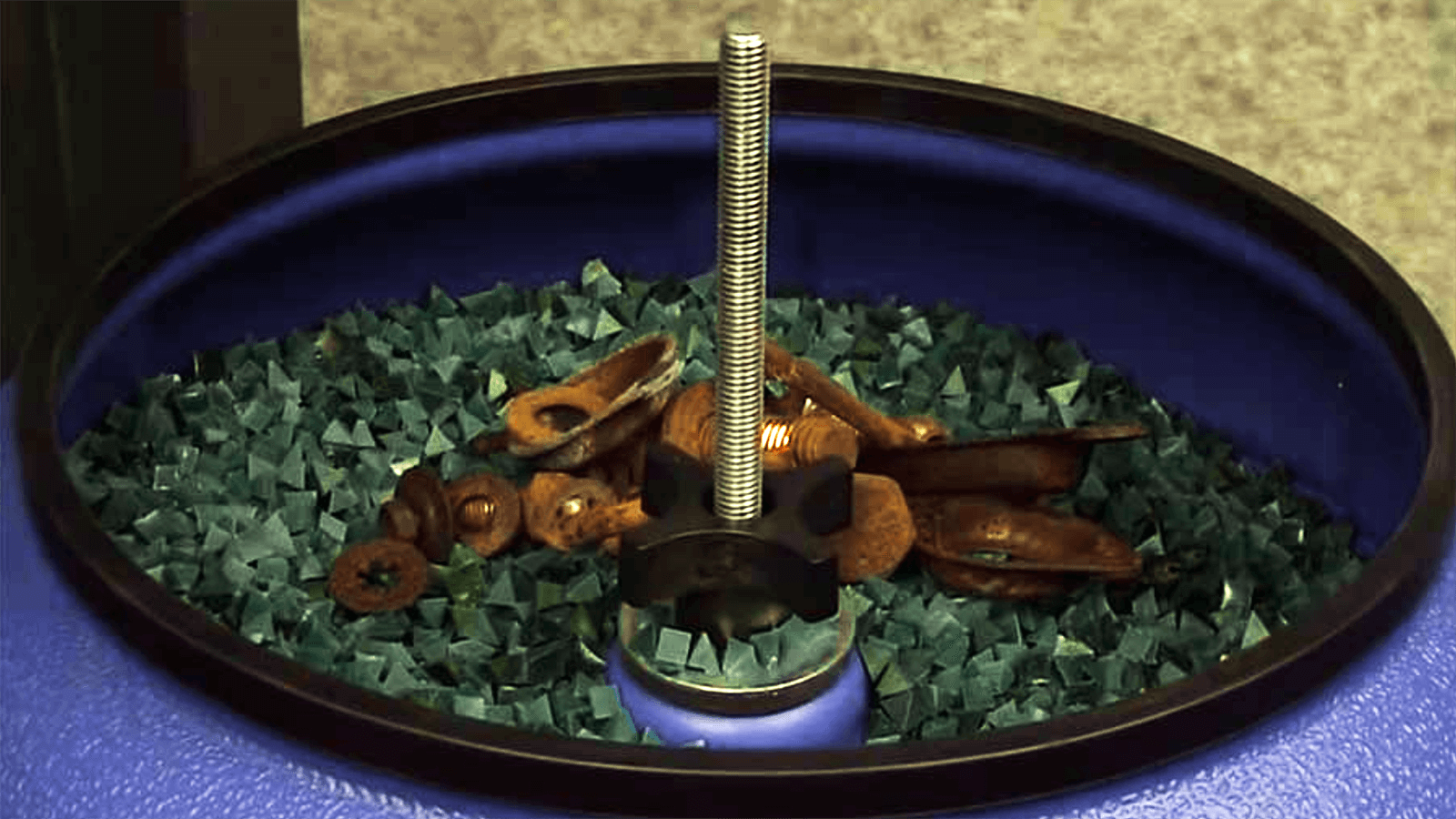

Illustrative image related to vibratory tumblers

The Solution: To ensure consistent finishing quality, B2B buyers should focus on a few key areas: selecting the right media, monitoring moisture levels, and adhering to optimal tumbling cycles. Start by conducting a thorough analysis of the materials being processed and the desired finish. This will guide you in choosing the right media type and size—ceramic, plastic, or even natural media can yield different results. Additionally, regularly check and maintain moisture levels during the tumbling process. A good practice is to implement a daily inspection routine to monitor the condition of the media and adjust water levels as necessary. Finally, establish a standardized tumbling time based on empirical results from previous batches to achieve the desired finish consistently. Documenting these processes will create a reference guide that can be utilized across your operations, reducing variability and improving quality control.

Scenario 2: Overcoming High Operational Costs

The Problem: B2B buyers often encounter high operational costs associated with running vibratory tumblers. These costs can arise from excessive grit and polish consumption, high electricity bills, and the need for frequent maintenance. In regions where operational budgets are tight, such as in developing markets in Africa and South America, these expenses can significantly impact profitability. Buyers need effective strategies to mitigate these costs while maintaining production efficiency.

The Solution: To reduce operational costs, buyers should consider optimizing the use of vibratory tumblers by implementing a few best practices. First, assess and adjust the amount of media used per batch—vibratory tumblers often require less media than rotary tumblers, so be sure to follow manufacturer recommendations closely. Additionally, conduct a cost-benefit analysis to determine whether investing in higher-quality, longer-lasting media could reduce overall grit consumption. Furthermore, it’s essential to maintain the vibratory tumbler properly; regular cleaning and timely replacement of worn components can prevent costly breakdowns and extend the life of the equipment. Finally, evaluate your operational schedule—running tumblers during off-peak electricity hours can lead to significant savings. By implementing these strategies, businesses can lower their operational costs without sacrificing quality.

Scenario 3: Navigating Equipment Noise and Space Constraints

The Problem: Noise generated by vibratory tumblers can be a significant concern for B2B buyers, particularly those operating in urban areas or shared facilities. The loud vibrations can disrupt work environments, leading to complaints from staff and potentially affecting productivity. Additionally, space constraints may limit the size and number of tumblers that can be used effectively. Buyers are often at a loss on how to balance effective operation with maintaining a comfortable workplace atmosphere.

The Solution: Addressing noise and space issues starts with selecting the right equipment and optimizing the workspace layout. Buyers should look for vibratory tumblers designed with sound-dampening features or consider investing in enclosures or noise barriers that can help reduce sound levels. When setting up the workspace, position the tumbler on a solid, vibration-absorbing surface—such as a concrete block or a dedicated workbench—to minimize noise transmission. In terms of space management, consider utilizing smaller, high-capacity vibratory tumblers that can handle larger batches without taking up too much floor space. Additionally, implementing a regular maintenance schedule will ensure that the machinery operates smoothly and quietly. By proactively addressing noise and space constraints, businesses can create a more productive and pleasant working environment while maximizing the effectiveness of their vibratory tumblers.

Illustrative image related to vibratory tumblers

Strategic Material Selection Guide for vibratory tumblers

What Are the Key Materials Used in Vibratory Tumblers?

When selecting materials for vibratory tumblers, understanding the properties and applications of various materials is crucial for optimizing performance and ensuring longevity. Below, we analyze four common materials used in vibratory tumblers, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand a wide range of temperatures. It typically has a high tensile strength, making it suitable for heavy-duty applications.

Pros & Cons:

The durability of stainless steel is a significant advantage, as it resists rust and wear, ensuring a long service life. However, it can be more expensive than other materials, which may impact initial investment costs. Manufacturing complexity is moderate, as stainless steel requires specialized techniques for shaping and welding.

Impact on Application:

Stainless steel is compatible with various media types, including ceramic and plastic, making it versatile for different finishing applications.

Illustrative image related to vibratory tumblers

Considerations for International Buyers:

Buyers should be aware of compliance with international standards such as ASTM and DIN, particularly regarding corrosion resistance and mechanical properties. In regions like Africa and South America, where environmental conditions can vary, selecting the right grade of stainless steel is essential.

2. Polyurethane

Key Properties:

Polyurethane is a synthetic material known for its flexibility, resilience, and resistance to abrasion. It can handle moderate temperatures and is often used in applications requiring impact resistance.

Pros & Cons:

The primary advantage of polyurethane is its cost-effectiveness and lightweight nature, which reduces shipping costs. However, it has a lower temperature tolerance compared to metals, which may limit its use in high-heat applications. Manufacturing is relatively simple, allowing for custom shapes and sizes.

Impact on Application:

Polyurethane is ideal for softer materials and is often used as a lining for tumblers to prevent damage to delicate parts. It may not be suitable for heavy-duty applications involving hard metals.

Considerations for International Buyers:

Buyers should check for compliance with local regulations regarding synthetic materials, especially in regions with strict environmental laws. Understanding the specific polyurethane formulation can also be critical, as different grades may offer varying performance characteristics.

3. Cast Iron

Key Properties:

Cast iron is characterized by its high wear resistance and ability to absorb vibrations, making it suitable for heavy-duty applications. It generally has a high thermal conductivity and can withstand significant pressure.

Pros & Cons:

The durability and strength of cast iron are significant benefits, particularly for industrial applications. However, it is prone to rust if not properly maintained, and its weight can increase shipping costs. Manufacturing cast iron parts can be complex and time-consuming.

Impact on Application:

Cast iron is often used in larger vibratory tumblers designed for bulk processing, where its ability to handle heavy loads is advantageous.

Considerations for International Buyers:

Buyers should consider the availability of cast iron and its compliance with international quality standards. In regions like the Middle East, where humidity can be high, proper maintenance protocols must be established to prevent rust.

4. Plastic

Key Properties:

Plastic materials, such as high-density polyethylene (HDPE), are lightweight, corrosion-resistant, and flexible. They can handle a range of temperatures but are generally less durable than metals.

Illustrative image related to vibratory tumblers

Pros & Cons:

The main advantage of plastic is its low cost and ease of manufacturing, allowing for quick production runs. However, its lower strength and durability compared to metals can limit its applications, particularly in heavy-duty environments.

Impact on Application:

Plastic is suitable for lighter materials and is often used in smaller vibratory tumblers for delicate parts. It is also commonly used for media that requires non-abrasive handling.

Considerations for International Buyers:

Buyers should verify the plastic’s compliance with safety and environmental standards, especially in regions with stringent regulations. The choice of plastic grade can significantly affect performance, so understanding the specific application is crucial.

Summary Table

| Material | Typical Use Case for vibratory tumblers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy-duty applications | Excellent corrosion resistance | Higher initial investment | High |

| Polyurethane | Softer materials and delicate parts | Cost-effective and lightweight | Limited temperature tolerance | Low |

| Cast Iron | Bulk processing in industrial settings | High wear resistance | Prone to rust, heavy weight | Med |

| Plastic | Small tumblers for delicate components | Low cost and easy to manufacture | Lower strength and durability | Low |

This strategic material selection guide provides critical insights for B2B buyers looking to optimize their vibratory tumblers’ performance while considering factors like cost, application suitability, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for vibratory tumblers

What Are the Main Stages of Manufacturing Vibratory Tumblers?

The manufacturing process for vibratory tumblers involves several critical stages, each designed to ensure the final product meets high standards of quality and performance. Understanding these stages can help B2B buyers assess the capabilities and reliability of potential suppliers.

Material Preparation: How Are Components Selected and Prepared?

The first stage in the manufacturing of vibratory tumblers is material preparation. Manufacturers typically use high-quality steel or other durable alloys for the tumbler’s body and components to withstand the rigors of continuous operation. The selection process involves evaluating material properties such as tensile strength, corrosion resistance, and wear resistance.

Once the materials are chosen, they undergo various treatments, including cutting, welding, and heat treatment, to enhance their structural integrity. This preparation ensures that the tumblers can handle heavy loads and intensive usage without compromising performance.

Forming: What Techniques Are Used to Shape Tumblers?

The forming stage employs several techniques, including stamping, bending, and machining, to create the specific shapes needed for the vibratory tumbler’s components. Advanced computer numerical control (CNC) machines are often used for precision machining, allowing for accurate and consistent production of complex parts.

Illustrative image related to vibratory tumblers

In this stage, manufacturers also create the vibratory motor mounts and bowls that facilitate the tumbling action. The design of these components is crucial, as they directly impact the efficiency and effectiveness of the tumbling process.

Assembly: How Are Components Integrated into a Final Product?

After forming, the components move to the assembly stage. This process typically involves the following steps:

- Component Fitting: Each part is fitted together, ensuring that all components align correctly for optimal performance.

- Welding and Fastening: Permanent connections are made through welding, while other parts may be secured with bolts or screws, allowing for easier maintenance and repair.

- Electrical Integration: Motors and control systems are integrated at this stage, ensuring that the electrical components function seamlessly with the mechanical parts.

The assembly process is crucial, as any misalignment or improper fitting can lead to operational inefficiencies and increased wear on the equipment.

Finishing: What Processes Ensure a High-Quality Surface?

The final stage is finishing, where the tumbler undergoes treatments to enhance its surface quality. This may include:

- Deburring: Removing sharp edges and burrs to prevent damage to parts being tumbled.

- Surface Treatment: Applying coatings such as powder coating or galvanization to protect against corrosion and enhance durability.

- Quality Inspection: Each unit is inspected for surface defects, ensuring that the finish meets industry standards.

This finishing process not only enhances the aesthetic appeal of the tumbler but also significantly impacts its longevity and performance.

What Are the Quality Control Standards for Vibratory Tumblers?

Quality control (QC) is an essential aspect of manufacturing vibratory tumblers. B2B buyers should be aware of the relevant international standards and specific industry certifications that ensure product quality.

Which International Standards Are Relevant for Quality Assurance?

Manufacturers of vibratory tumblers often adhere to international standards such as ISO 9001, which focuses on quality management systems. Compliance with this standard indicates that a manufacturer has established a systematic approach to managing its processes, ensuring consistent quality.

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe or API (American Petroleum Institute) standards for equipment used in oil and gas may also apply. These certifications demonstrate compliance with safety and environmental regulations.

Illustrative image related to vibratory tumblers

What Are Common Quality Control Checkpoints?

Quality control checkpoints are integrated at various stages of the manufacturing process, including:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing process to catch defects early.

- Final Quality Control (FQC): The completed vibratory tumblers undergo a thorough inspection before shipment, assessing functionality, safety, and overall quality.

These checkpoints are crucial in maintaining high-quality standards throughout the production process.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential to ensure they receive reliable products.

What Methods Can Buyers Use to Assess Supplier Quality?

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate a supplier’s manufacturing processes, quality control measures, and overall operational efficiency.

-

Quality Reports: Requesting detailed quality reports can provide insight into a supplier’s QC practices, including the results of inspections and any corrective actions taken.

-

Third-Party Inspections: Engaging independent third-party inspection services can offer an unbiased assessment of the supplier’s quality control processes.

What Are the Nuances of Quality Control for International Buyers?

International buyers must also consider the nuances of quality control that may vary by region. For instance, some countries may have stricter regulations regarding environmental impact and product safety. Understanding these regional differences can help buyers make informed decisions and select suppliers who comply with local standards.

Additionally, language barriers and cultural differences may affect communication regarding quality expectations. Therefore, establishing clear guidelines and expectations from the outset is crucial for successful collaboration.

Conclusion

The manufacturing processes and quality assurance practices for vibratory tumblers are intricate and vital for ensuring high-performance equipment. By understanding these aspects, B2B buyers can make informed choices when selecting suppliers, ultimately leading to better operational efficiency and product quality in their own businesses.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vibratory tumblers’

This guide is designed to assist international B2B buyers in effectively sourcing vibratory tumblers, ensuring that the procurement process is streamlined and aligned with business needs. With the growing demand for efficient metal finishing and polishing solutions, understanding the key elements of sourcing vibratory tumblers is crucial for making informed purchasing decisions.

Illustrative image related to vibratory tumblers

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements for the vibratory tumblers. Consider the size of the parts you need to process, the expected throughput, and the type of media you will use.

– Key specifications to consider:

– Capacity (e.g., volume of materials).

– Power requirements (voltage and wattage).

– Material compatibility (ensure the tumbler can handle the materials you intend to process).

Step 2: Research Supplier Reputation

Conduct thorough research on potential suppliers to gauge their reputation in the industry. Look for suppliers with proven track records and positive reviews from other businesses.

– How to assess reputation:

– Check online reviews and testimonials.

– Request references from other customers, especially those in your region or industry.

– Evaluate their presence in trade shows and industry publications.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Key evaluation criteria:

– Years in business and experience with vibratory tumblers.

– Range of products offered (ensure they have the right model for your needs).

– After-sales support and warranty options.

Step 4: Assess Compliance and Certifications

Ensure that the suppliers meet industry standards and possess necessary certifications. This is particularly important for businesses operating in regulated markets.

– Certifications to look for:

– ISO certifications (quality management).

– CE marking (compliance with European safety standards).

– Any relevant local certifications based on your region.

Illustrative image related to vibratory tumblers

Step 5: Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations. This should include pricing, delivery timelines, and terms of service.

– Important elements to include in your request:

– Full breakdown of costs (including shipping and handling).

– Lead times for delivery.

– Payment terms and financing options, if applicable.

Step 6: Evaluate After-Sales Support and Training

After-sales support is crucial for the successful operation of vibratory tumblers. Inquire about the training provided for equipment operation and maintenance.

– Key aspects of support to consider:

– Availability of technical support and spare parts.

– Training programs for staff to ensure proper use and maintenance.

– Return policy and warranty coverage.

Step 7: Negotiate Terms and Finalize Purchase

Once you have all the necessary information, engage in negotiations with your chosen supplier. Aim to finalize terms that are beneficial for both parties.

– Considerations during negotiation:

– Price adjustments based on bulk orders.

– Flexible payment terms or discounts for early payment.

– Clear documentation of delivery schedules and responsibilities.

By following these steps, B2B buyers can confidently navigate the sourcing process for vibratory tumblers, ensuring they select the right equipment that meets their operational needs while establishing a reliable supplier relationship.

Comprehensive Cost and Pricing Analysis for vibratory tumblers Sourcing

What Are the Key Cost Components in Sourcing Vibratory Tumblers?

When sourcing vibratory tumblers for industrial applications, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials significantly influences the cost of vibratory tumblers. High-quality steel and durable plastics are commonly used, which can increase the price but enhance the product’s lifespan. Buyers should evaluate the materials used in the construction of tumblers to ensure they meet their operational requirements.

-

Labor and Manufacturing Overhead: Labor costs can vary based on geographical location and manufacturing processes. Countries with lower labor costs may offer more competitive pricing; however, this can sometimes compromise quality. Manufacturing overhead, including factory maintenance and utilities, also contributes to the overall cost.

-

Tooling: Custom tooling for specific designs or features can add to the initial investment. If a buyer requires customized tumblers, it is crucial to factor in these costs as they can vary significantly based on design complexity.

-

Quality Control (QC): Implementing stringent QC processes can increase production costs but is essential for ensuring product reliability. Buyers should inquire about the QC measures employed by manufacturers to avoid potential issues down the line.

-

Logistics: Shipping costs can vary widely, particularly for international buyers. Factors such as distance, shipping mode, and weight of the equipment play a significant role in logistics expenses. Understanding the Incoterms is vital to clarify responsibilities related to shipping costs and risks.

-

Margin: Supplier margins can fluctuate based on market demand, brand reputation, and the level of customization offered. It’s important for buyers to compare quotes from multiple suppliers to identify competitive pricing.

How Do Price Influencers Affect the Cost of Vibratory Tumblers?

Several factors influence the pricing of vibratory tumblers, particularly for international B2B transactions.

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract discounts due to economies of scale. Buyers should consider their immediate and future needs to negotiate better pricing based on volume.

-

Specifications and Customization: Custom features or specific design requirements can increase costs. Buyers should weigh the benefits of customization against potential price increases.

-

Quality and Certifications: Tumblers that meet industry certifications (e.g., ISO, CE) may command higher prices. Buyers should assess whether the added cost for certified equipment aligns with their operational standards.

-

Supplier Factors: The supplier’s reputation, experience, and service levels can impact pricing. Established suppliers may charge a premium for their reliability and customer support.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers regarding shipping costs, insurance, and risk management. This knowledge can help buyers avoid unexpected costs.

What Are Some Buyer Tips for Cost-Efficiency in Sourcing Vibratory Tumblers?

-

Negotiate Effectively: Engage in discussions with suppliers to negotiate better terms, especially regarding MOQ and payment terms. Leverage competitive quotes to secure favorable pricing.

-

Consider Total Cost of Ownership (TCO): Beyond the initial purchase price, assess the total cost of ownership, including maintenance, operational efficiency, and potential downtime. Investing in higher-quality tumblers may lead to long-term savings.

-

Explore Local Suppliers: For buyers in regions such as Africa or South America, sourcing from local manufacturers may reduce shipping costs and lead times. Additionally, local suppliers may better understand regional needs and offer tailored solutions.

-

Stay Informed on Market Trends: Keep abreast of market trends affecting the vibratory tumbler industry. Changes in material costs, technological advancements, or shifts in demand can impact pricing.

Conclusion

In summary, sourcing vibratory tumblers involves a comprehensive understanding of various cost components and price influencers. By considering these factors and employing strategic purchasing tactics, international B2B buyers can optimize their sourcing efforts and achieve cost-effective solutions tailored to their operational needs.

Alternatives Analysis: Comparing vibratory tumblers With Other Solutions

Understanding Alternative Solutions to Vibratory Tumblers

In the world of metal finishing and rock polishing, vibratory tumblers are a popular choice due to their efficiency and effectiveness. However, several alternative technologies and methods exist that can achieve similar results. This analysis will compare vibratory tumblers with rotary tumblers and barrel tumblers, highlighting their respective strengths and weaknesses to help international B2B buyers make informed purchasing decisions.

Comparison Table

| Comparison Aspect | Vibratory Tumblers | Rotary Tumblers | Barrel Tumblers |

|---|---|---|---|

| Performance | High-speed polishing, less grit usage | Slower, better for rounding shapes | Variable performance, depends on setup |

| Cost | Higher initial investment | Generally lower initial cost | Moderate cost, depending on size |

| Ease of Implementation | Requires learning curve for moisture management | Simple setup, user-friendly | Easy to set up, but may require more space |

| Maintenance | Moderate, occasional media replacement | Low, minimal upkeep | Low, but requires regular checks |

| Best Use Case | Ideal for fine polishing and deburring | Best for shaping and smoothing | Good for bulk processing |

Detailed Breakdown of Alternatives

Rotary Tumblers: Are They a Worthy Alternative?

Rotary tumblers operate on a simple principle of rotation, which helps in rounding and smoothing the edges of materials effectively. They are generally more cost-effective upfront than vibratory tumblers, making them a popular choice for smaller operations or businesses just starting in the polishing sector. However, they are slower and require more grit and polish, leading to higher long-term operational costs. Additionally, rotary tumblers may not achieve the same level of fine polish that vibratory tumblers can provide in a shorter time frame, making them less suitable for intricate polishing tasks.

Barrel Tumblers: What Are Their Advantages?

Barrel tumblers, often used in bulk processing, can accommodate larger quantities of materials, making them efficient for high-volume operations. They are easy to set up and operate, which can be appealing for businesses looking for straightforward solutions. However, their performance can vary significantly based on the setup, and they may not provide the same level of polish as vibratory tumblers. Furthermore, while they are generally low-maintenance, the need for periodic checks to ensure consistent performance can be a drawback for some operations.

Conclusion: How to Choose the Right Solution for Your Business

When selecting the right finishing solution, B2B buyers must consider various factors including performance, cost, and specific use cases. Vibratory tumblers excel in fine polishing and deburring tasks, making them suitable for industries requiring precision. In contrast, rotary tumblers are ideal for shaping, while barrel tumblers cater to bulk processing needs. Each option has its unique benefits and limitations, so buyers should assess their operational requirements, volume needs, and budget constraints to make an informed decision that aligns with their business objectives.

Essential Technical Properties and Trade Terminology for vibratory tumblers

What Are the Key Technical Properties of Vibratory Tumblers?

Understanding the technical properties of vibratory tumblers is crucial for businesses considering investment in these machines. Here are some essential specifications that can impact operational efficiency and product quality:

-

Barrel Capacity

– Definition: The volume of the tumbler’s barrel, typically measured in quarts or gallons.

– B2B Importance: Larger capacities allow for more significant batches, which can enhance productivity. Businesses should assess their production needs to select a tumbler that accommodates the volume of materials they typically process. -

Motor Power

– Definition: The strength of the motor driving the tumbler, usually expressed in horsepower (HP) or watts.

– B2B Importance: A more powerful motor can handle tougher materials and larger loads. This specification is vital for ensuring that the tumbler can meet the demands of high-volume operations without overheating or failing. -

Vibration Frequency

– Definition: The rate at which the tumbler vibrates, typically measured in vibrations per minute (VPM).

– B2B Importance: Different materials and processes require specific vibration frequencies to achieve the desired finishing results. Understanding this property helps businesses optimize their operations for efficiency and effectiveness. -

Material Grade

– Definition: The quality and type of materials used in the construction of the tumbler, including the barrel and frame.

– B2B Importance: Higher-grade materials enhance durability and reduce maintenance costs over time. Investing in robust equipment can lead to longer lifespans and decreased downtime, which is critical for maintaining production schedules. -

Noise Level

– Definition: The sound produced by the tumbler during operation, often measured in decibels (dB).

– B2B Importance: For businesses operating in noise-sensitive environments, understanding the noise level is essential. Selecting a quieter model can improve workplace conditions and compliance with local regulations. -

Cycle Time

– Definition: The duration required to complete a tumbling process, which can vary based on the materials and desired finish.

– B2B Importance: Shorter cycle times can lead to increased throughput, allowing businesses to process more materials in a given timeframe. This efficiency can significantly impact profitability.

What Are Common Trade Terms Associated with Vibratory Tumblers?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B space. Here are some common terms relevant to vibratory tumblers:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Importance: When sourcing vibratory tumblers, understanding OEM relationships can ensure that you are purchasing quality machinery backed by reliable manufacturers. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps businesses manage inventory levels and budget effectively, ensuring they do not overstock or underutilize resources. -

RFQ (Request for Quotation)

– Definition: A standard business process where a company solicits bids from suppliers for specific products or services.

– Importance: Submitting an RFQ can lead to competitive pricing and better terms, making it essential for cost-conscious buyers in the market for vibratory tumblers. -

Incoterms (International Commercial Terms)

– Definition: A set of rules that define the responsibilities of sellers and buyers in international transactions.

– Importance: Understanding Incoterms is crucial for navigating logistics and shipping costs, helping businesses avoid unexpected expenses and ensuring smooth delivery processes. -

Lead Time

– Definition: The time it takes from placing an order to receiving the product.

– Importance: Awareness of lead times helps businesses plan their production schedules effectively, ensuring that they can meet customer demands without delay. -

Deburring

– Definition: The process of removing sharp edges or burrs from a workpiece.

– Importance: For manufacturers using vibratory tumblers for finishing, understanding deburring techniques is vital for achieving the desired surface quality and safety standards.

By grasping these technical properties and trade terms, businesses can make informed decisions that enhance their operational efficiency and product quality when investing in vibratory tumblers.

Navigating Market Dynamics and Sourcing Trends in the vibratory tumblers Sector

What Are the Key Trends Driving the Vibratory Tumblers Market?

The vibratory tumblers market is experiencing robust growth driven by several key factors. Firstly, the increasing demand for efficient metal finishing solutions across various industries—such as automotive, aerospace, and jewelry—has propelled the need for vibratory tumblers that offer faster processing times and reduced operational costs. In regions like Africa and South America, the rise in manufacturing capabilities and investment in industrial sectors is fueling the adoption of advanced tumbling technologies.

Illustrative image related to vibratory tumblers

Emerging B2B tech trends, including automation and smart manufacturing, are also reshaping the vibratory tumblers landscape. Companies are increasingly integrating IoT capabilities into their tumbling systems, allowing for real-time monitoring and data analytics, which enhance operational efficiency. Furthermore, the shift towards sustainability is influencing sourcing trends; buyers are increasingly looking for equipment that minimizes energy consumption and waste generation.

Market dynamics are further influenced by supply chain considerations. Global supply chain disruptions, particularly post-COVID-19, have prompted buyers to diversify their sourcing strategies. This trend is particularly relevant for B2B buyers in regions such as the Middle East and Europe, where geopolitical factors may affect traditional supply routes. As a result, buyers are seeking reliable suppliers who can offer not only quality products but also consistent delivery timelines.

How Important Is Sustainability and Ethical Sourcing in the Vibratory Tumblers Sector?

Sustainability and ethical sourcing have become critical considerations for B2B buyers in the vibratory tumblers sector. Environmental impacts associated with traditional manufacturing processes are prompting companies to seek solutions that are not only effective but also eco-friendly. Vibratory tumblers, known for their lower energy consumption and reduced material waste compared to rotary tumblers, present a more sustainable option for businesses.

Moreover, the importance of ethical supply chains is gaining traction. Buyers are increasingly scrutinizing their suppliers for compliance with environmental regulations and ethical labor practices. Certifications such as ISO 14001 for environmental management and Fair Trade standards are becoming essential criteria for sourcing decisions. These certifications not only enhance a company’s brand reputation but also appeal to a growing segment of environmentally conscious consumers.

In addition, the use of ‘green’ materials in the production of vibratory tumblers is on the rise. This includes sourcing raw materials that are recycled or have minimal environmental impact. For international B2B buyers, particularly in emerging markets, aligning with suppliers who prioritize sustainability can lead to competitive advantages, including access to new markets and improved customer loyalty.

What Is the Brief Evolution and History of Vibratory Tumblers?

The evolution of vibratory tumblers dates back to the mid-20th century, when they were first introduced as a faster alternative to traditional rotary tumblers. Initially, these machines were primarily used in jewelry manufacturing for polishing and finishing delicate items. As industries advanced, the applications of vibratory tumblers expanded to include a variety of sectors, including automotive and aerospace, where precision and efficiency are paramount.

In the 1980s and 1990s, technological advancements led to the development of more sophisticated vibratory systems, integrating features such as variable speed controls and enhanced media options. The introduction of automated systems further revolutionized the industry, allowing for batch processing and improved quality control. Today, vibratory tumblers are considered a staple in industrial finishing processes, with ongoing innovations aimed at improving energy efficiency and reducing environmental impact. As the market continues to evolve, vibratory tumblers remain a vital component for businesses seeking to optimize their production and finishing capabilities.

Frequently Asked Questions (FAQs) for B2B Buyers of vibratory tumblers

-

How do I solve issues with noise from my vibratory tumbler?

To mitigate noise from vibratory tumblers, consider several approaches. First, ensure the tumbler is placed on a stable surface, like a concrete block, to minimize vibrations. Filling the bowl to an appropriate level with media can also reduce noise. Additionally, running the tumbler during hours when noise is less disruptive, such as early morning or late evening, can be beneficial. If noise remains a concern, consider using soundproofing materials in the area where the tumbler operates. -

What is the best vibratory tumbler for polishing delicate parts?

For polishing delicate parts, the best vibratory tumbler is one with adjustable speed settings, allowing for finer control during the polishing process. Models such as the Ultra-Vibe series offer versatility in processing various materials while minimizing potential damage. It’s essential to choose a tumbler with appropriate media that complements the material being polished. Consulting with suppliers about their specific recommendations based on your needs can also enhance the selection process. -

What factors should I consider when vetting suppliers for vibratory tumblers?

When vetting suppliers, prioritize their reputation in the industry, customer reviews, and experience with international shipping. Ensure they have a reliable supply chain and can meet your specific demands, such as customization options and minimum order quantities (MOQ). Request references or case studies from previous clients to assess their service quality. Additionally, inquire about their after-sales support and warranty policies to ensure long-term satisfaction with your purchase. -

How can I customize a vibratory tumbler to fit my specific needs?

Customization options for vibratory tumblers can vary by manufacturer. Common customizations include adjusting the size of the bowl, selecting different media types, and modifying motor speeds. Engage directly with suppliers to discuss your specific requirements, such as batch sizes and types of materials processed. Some manufacturers may offer bespoke solutions that cater to unique applications, so it’s beneficial to communicate your needs clearly to find the best fit. -

What are the typical payment terms when sourcing vibratory tumblers internationally?

Payment terms can vary significantly between suppliers, but common practices include advance payment, letters of credit, or payment upon delivery. Many suppliers may require a deposit, typically ranging from 30% to 50% of the total cost upfront, with the balance due prior to shipping. It’s essential to clarify terms before finalizing the order and ensure they align with your cash flow capabilities. Consider negotiating terms that offer you flexibility, especially when placing large orders. -

What quality assurance measures should I expect from suppliers of vibratory tumblers?

Reputable suppliers should implement stringent quality assurance (QA) protocols throughout the manufacturing process. Look for suppliers who adhere to international quality standards, such as ISO certifications. They should conduct regular inspections and testing of their products before shipment. Additionally, inquire about their warranty policies and return procedures, as these can serve as indicators of their commitment to quality and customer satisfaction. -

How do I ensure timely logistics and delivery of my vibratory tumbler?

To ensure timely logistics, communicate clearly with your supplier about delivery timelines and shipping methods. Verify that they have experience with international shipping and understand customs regulations in your region. Discuss potential delays and how they will be managed. Utilizing freight forwarders who specialize in machinery can also streamline the process, ensuring that your tumbler arrives on schedule and in optimal condition. -

What is the average lifespan of a vibratory tumbler, and how can I extend it?

The average lifespan of a vibratory tumbler ranges from 5 to 10 years, depending on usage and maintenance. To extend its lifespan, ensure regular maintenance, including cleaning the bowl and checking for wear on the motor and components. Operate the tumbler within its specified limits, and avoid overloading it with media. Following manufacturer guidelines for usage and maintenance can significantly enhance durability and performance over time.

Top 6 Vibratory Tumblers Manufacturers & Suppliers List

1. Raytech – Vibratory Tumblers

Domain: raytech-ind.com

Registered: 1997 (28 years)

Introduction: Vibratory Tumblers are used to deburr and finish irregular shapes, processing more complex part configurations than conventional tumblers. They run cleaner with plastic media. Key products include: TV-5 Tumbler ($133.90), TV-5 Rock Polishing Starter Kit ($152.95), DRI-Polisher ($174.95), Tumble-Vibe 10 (with drain) ($244.95), Tumble-Vibe 10 (no drain) ($169.95), TV-10 Professional Rock Polishing K…

2. Rock Tumbler – Lot-O-Tumbler Single

Domain: rocktumbler.com

Registered: 2000 (25 years)

Introduction: Vibratory Rock Tumblers tumble faster than rotary tumblers, using less grit, polish, and electricity per pound of rock. Key products include:

1. Lot-O-Tumbler Single:

– Temporarily Out of Stock

– Tumbles about 4 pounds of rock (pieces up to 2 1/2 inches)

– Tumbles rocks from start to finish in about one week

– Uses about 50% less grit and 25% less electricity than a rotary tumbler…

3. Suvalapidary – Diamond Pacific VT-Series Vibratory Tumblers

Domain: suvalapidary.com

Registered: 2010 (15 years)

Introduction: Diamond Pacific Vibra-Sonic VT-Series Vibratory Tumblers

– Regular Price: $1,455.94

– Models Available: VT-12 (115 V, Sold Out), VT-12 (220 V, Sold Out), VT-14 (115 V, Sold Out), VT-14 (220 V, Sold Out), VT-35 (115 V, Sold Out), VT-35 (220 V, Sold Out)

– Unique rotary and vibratory tumbling action reduces processing time by up to 90% compared to ordinary tumblers.

– Industry standard for over 50 y…

4. Kramer Industries – Vibratory Tumblers

Domain: kramerindustriesonline.com

Registered: 2001 (24 years)

Introduction: Vibratory Tumblers are designed for batch and continuous parts deburring and polishing. They feature rolling action to remove material from delicate parts, accommodating various sizes and shapes. Key features include:

– Available in bench model sizes for small parts and larger tub/bowl systems for big batches.

– High-speed shaking action for effective deburring and polishing.

– Can be fully aut…

5. Raytech – TV5 & Diamond Pacific – Mini-Sonic

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. Raytech TV5 (or TV10) – 5 lb capacity, lowest cost option, decent quality, loudest vibe, picky about water and leveling, low quality bowl but inexpensive to replace. 2. Diamond Pacific mini-sonic – 4 lb capacity, quietest vibe, variable speed, can do coarse step, not widely used. 3. Lot-O – 4.5 lb capacity, relatively quiet, gentle, picky with water, needs to be mounted, had recent quality cont…

6. IQS Directory – Vibratory Tumblers

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Vibratory tumblers are machinery used in the vibratory finishing process for mass finishing applications. They operate by placing workpieces in a container with media pellets, where a motor generates vibrational energy to agitate the contents. This process is effective for cleaning, deburring, deflashing, descaling, and polishing various workpieces, improving adhesion for coatings and maintaining …

Strategic Sourcing Conclusion and Outlook for vibratory tumblers

In the evolving landscape of vibratory tumblers, strategic sourcing remains pivotal for international B2B buyers. By investing in high-quality vibratory tumblers, businesses can significantly enhance their metal finishing, polishing, and deburring processes while reducing operational costs. The efficiency of these machines translates into faster processing times and lower material consumption, which is crucial for maintaining competitiveness in today’s market.

For buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the diverse offerings—from compact models for small-scale operations to industrial-grade systems for large-scale applications—can inform better purchasing decisions. Leveraging local suppliers and manufacturers may also yield advantages in terms of service and support, ensuring that businesses can optimize their operations effectively.

As the demand for vibratory tumblers continues to grow, it is essential for businesses to stay informed about technological advancements and market trends. Embracing these innovations not only enhances productivity but also positions companies for future success. Engage with suppliers today to explore how the right vibratory tumbler can transform your operations and drive sustainable growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to vibratory tumblers