Vibrating Screen: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for vibrating screen

In today’s competitive global market, sourcing the right vibrating screen can be a daunting challenge for B2B buyers, particularly those operating in diverse industries such as mining, food processing, and pharmaceuticals. The need for efficient, reliable, and specialized screening equipment is paramount to ensure operational success and product quality. This guide aims to streamline the purchasing process by providing a comprehensive overview of vibrating screens, covering various types, applications, and the latest technological advancements.

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe—including countries like Nigeria and Germany—will find actionable insights into how to evaluate suppliers, understand cost implications, and navigate the complexities of maintenance and operational efficiency. The guide delves into critical factors influencing the selection of vibrating screens, such as material characteristics, installation layouts, and compliance with industry standards.

With a focus on empowering informed purchasing decisions, this resource equips B2B buyers with the knowledge needed to choose the right vibrating screen for their specific needs. By understanding the diverse options available and leveraging expert insights, businesses can enhance productivity, reduce costs, and ultimately gain a competitive edge in their respective markets.

Understanding vibrating screen Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Inclined Vibrating Screens | Angled design for efficient material flow | Mining, aggregates, and recycling | Pros: High capacity, effective for coarse materials. Cons: May require more space for installation. |

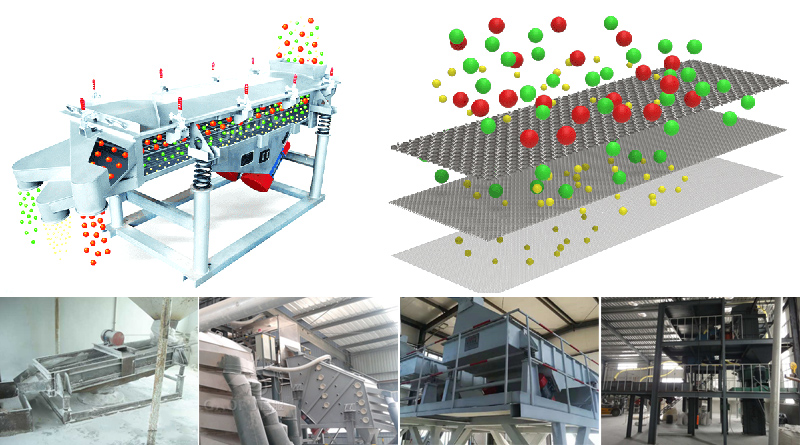

| Linear Vibrating Screens | Straight-line motion for uniform material distribution | Food processing, plastics, and chemicals | Pros: Precise separation, low maintenance. Cons: Limited to specific material types. |

| Circular Vibrating Screens | Circular motion enhances material stratification | Sand, gravel, and coal industries | Pros: Versatile for various materials, good efficiency. Cons: May not handle very fine materials well. |

| Fusion Screens | Integrated design minimizing contamination risk | Food and pharmaceutical industries | Pros: FDA-approved, easy to clean. Cons: Higher initial cost due to advanced technology. |

| Self-Cleaning Screens | Mechanism to reduce blinding using sliders and balls | Recycling and waste management | Pros: Maintains screening efficiency, reduces downtime. Cons: More complex design may require specialized maintenance. |

What Are Inclined Vibrating Screens and Their Applications?

Inclined vibrating screens are designed with an angle that facilitates the flow of materials. This design is particularly effective in applications involving mining, aggregates, and recycling. Buyers should consider the screen’s capacity, the type of materials being processed, and the space available for installation. While they offer high throughput and effective separation of coarse materials, the need for additional space can be a limiting factor in some operations.

How Do Linear Vibrating Screens Function in Various Industries?

Linear vibrating screens utilize a straight-line motion to ensure uniform material distribution across the screening surface. They are commonly used in food processing, plastics, and chemical industries due to their precise separation capabilities. When purchasing, businesses should evaluate the material characteristics and flow rates to select the appropriate model. While they require low maintenance and provide accurate results, their efficiency may be limited to specific material types.

Why Choose Circular Vibrating Screens for Your Operations?

Circular vibrating screens operate with a circular motion that enhances the stratification of materials. This type of screen is widely used in the sand, gravel, and coal industries due to its versatility and efficiency. B2B buyers should assess the types of materials being screened and the desired output sizes when selecting this option. Although circular screens provide good efficiency across various materials, they may struggle with very fine particles, which can affect overall performance.

What Are the Benefits of Fusion Screens in Sanitary Applications?

Fusion screens represent a significant advancement in screen technology, featuring an integrated design that minimizes contamination risks. They are particularly suitable for food and pharmaceutical industries, where cleanliness is paramount. Buyers should consider the benefits of FDA-approved materials and ease of cleaning when evaluating this option. While fusion screens offer a high standard of hygiene and performance, their initial cost may be higher due to the advanced technology involved.

How Do Self-Cleaning Screens Enhance Screening Efficiency?

Self-cleaning screens utilize a unique mechanism of sliders and balls to reduce blinding, thereby maintaining screening efficiency. They are ideal for applications in recycling and waste management, where consistent performance is crucial. When selecting self-cleaning screens, buyers should consider the complexity of the design and the potential need for specialized maintenance. While they effectively minimize downtime and enhance efficiency, their intricate design could require more attention compared to simpler screen types.

Key Industrial Applications of vibrating screen

| Industry/Sector | Specific Application of vibrating screen | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Mining | Screening ores and minerals | Enhances material recovery and reduces processing costs | Durability, size, and capacity to handle coarse materials |

| Food Processing | Separation of food particles | Ensures product quality and compliance with safety standards | FDA approval, ease of cleaning, and material compatibility |

| Construction Materials | Aggregates sorting and grading | Improves efficiency in material handling and reduces waste | Versatility in handling different material sizes and types |

| Chemical Processing | De-dusting and de-watering of chemicals | Increases product purity and operational efficiency | Chemical resistance, maintenance requirements, and capacity |

| Pharmaceuticals | Scalping and sizing of active ingredients | Guarantees precise dosage and enhances product consistency | Compliance with GMP standards and material certifications |

How is Vibrating Screen Used in Mining Applications?

In the mining sector, vibrating screens are crucial for the efficient screening of ores and minerals. They help separate valuable materials from waste, enhancing recovery rates while minimizing processing costs. Buyers in this industry should consider the durability and size of the screens, as they must withstand harsh operating conditions and handle coarse materials. Additionally, the capacity of the vibrating screen to process high volumes is essential for meeting production targets, especially in large-scale mining operations across Africa and South America.

What Role Does Vibrating Screen Play in Food Processing?

Vibrating screens are employed in food processing to separate and classify food particles, ensuring product quality and safety. They help eliminate contaminants and ensure that food products meet regulatory standards. For international buyers, particularly in Europe and the Middle East, sourcing screens with FDA-approved components is vital. Additionally, ease of cleaning and maintenance is critical to maintain hygiene standards, making the choice of material and design an important consideration.

How is Vibrating Screen Applied in Construction Materials?

In the construction materials industry, vibrating screens are used for sorting and grading aggregates. This application is crucial for ensuring that the correct sizes of materials are available for various construction projects, thereby improving operational efficiency and reducing waste. Buyers should look for versatile screens that can handle different material types and sizes. The ability to customize the screening process based on specific project requirements is also a significant factor for buyers in regions like Africa, where construction demands are rapidly evolving.

What Benefits Does Vibrating Screen Provide in Chemical Processing?

Vibrating screens in chemical processing are essential for de-dusting and de-watering processes, which enhance product purity and operational efficiency. By effectively removing unwanted particles and moisture, these screens contribute to higher-quality chemical products. Buyers in the chemical industry should prioritize screens that are resistant to harsh chemicals and easy to maintain. Additionally, understanding the capacity requirements is crucial, as the volume of material processed can significantly impact production efficiency.

How is Vibrating Screen Used in Pharmaceuticals?

In the pharmaceutical industry, vibrating screens are vital for scalping and sizing active ingredients, ensuring precise dosage and consistent product quality. This application is particularly critical in meeting Good Manufacturing Practice (GMP) standards, which are strictly enforced in Europe and other regions. Buyers should focus on sourcing screens that comply with GMP regulations and have the necessary material certifications. Additionally, the ability to handle sensitive materials without degradation is a key requirement for pharmaceutical manufacturers, making the selection process critical.

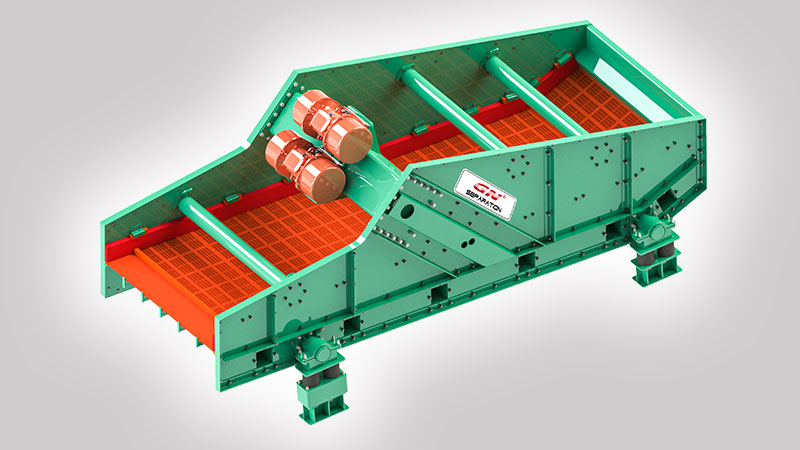

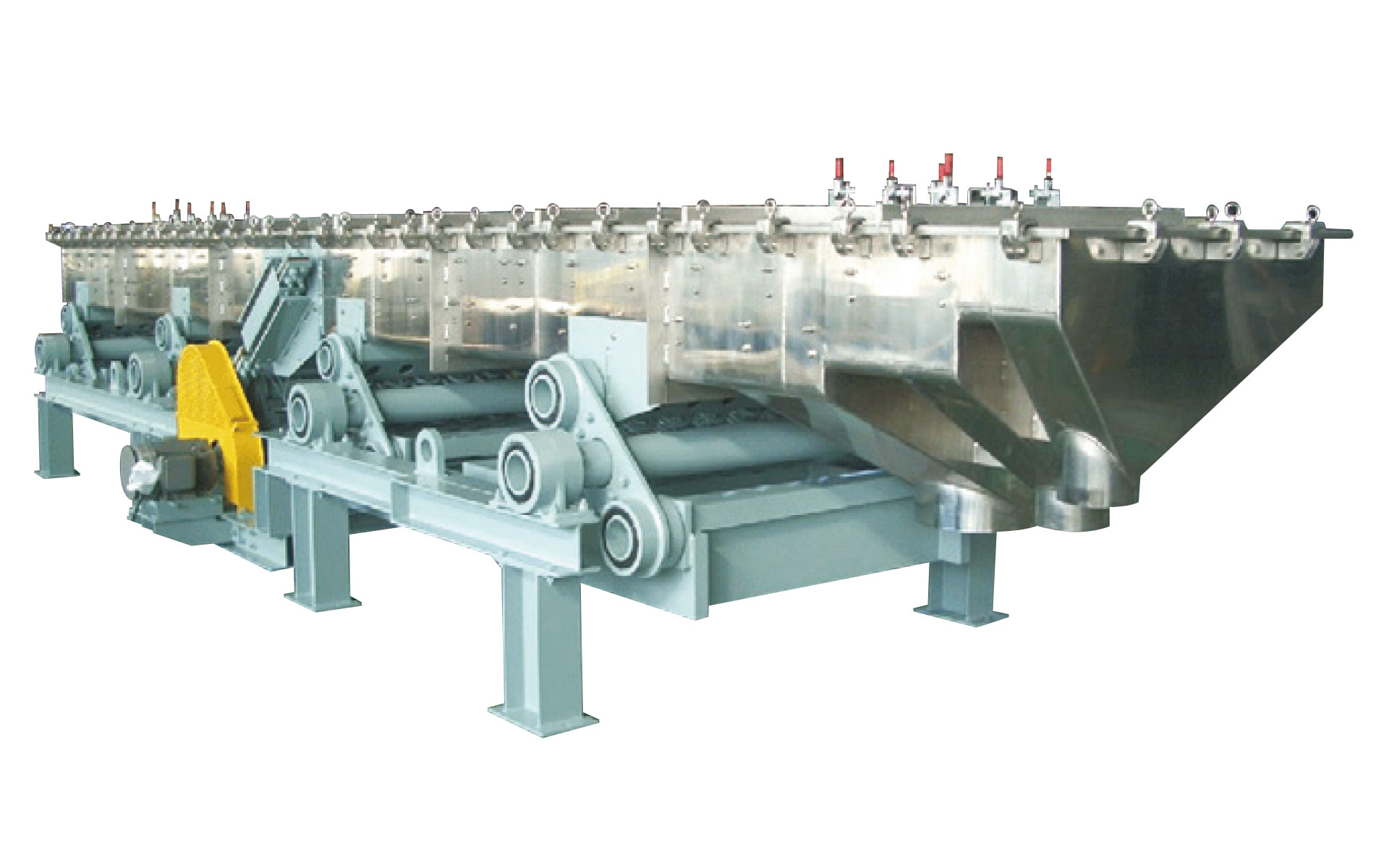

Illustrative image related to vibrating screen

3 Common User Pain Points for ‘vibrating screen’ & Their Solutions

Scenario 1: Inconsistent Screening Performance Leading to Production Delays

The Problem: Many B2B buyers face the challenge of inconsistent screening performance from their vibrating screens, which can lead to significant production delays. This inconsistency may arise from factors such as improper screen selection for the material characteristics, wear and tear on older screens, or inadequate maintenance practices. For instance, a company in the aggregate industry may find that its vibrating screens are not effectively separating materials, resulting in a bottleneck in the production process. This not only affects output but can also compromise product quality, leading to customer dissatisfaction and potential financial losses.

The Solution: To address this pain point, it is crucial to conduct a thorough analysis of the material properties and operational requirements before selecting a vibrating screen. Buyers should engage with manufacturers to ensure they understand the specific screening needs based on factors such as particle size, shape, and moisture content. Investing in modern, performance-engineered vibrating screens, like those designed by Haver & Boecker Niagara or Syntron, can enhance efficiency and consistency. Additionally, establishing a regular maintenance schedule will help in identifying wear early, ensuring that screens are replaced or repaired before they significantly impact production. By taking these proactive steps, companies can reduce downtime and enhance overall operational efficiency.

Scenario 2: High Operating Costs Due to Inefficient Equipment

The Problem: Operating costs can escalate when vibrating screens are not optimized for energy efficiency and material handling. For example, a mining operation may find that its existing screens consume excessive power while failing to achieve the desired throughput. This inefficiency can be attributed to outdated technology or improper screen configuration, leading to increased energy bills and reduced profit margins. Buyers in such scenarios often struggle to balance operational costs with the need for high-quality screening.

The Solution: To mitigate high operating costs, buyers should consider investing in advanced vibrating screen technology that focuses on energy efficiency. For instance, opting for models like SWECO’s Fusion Screens, which integrate FDA-approved components and eliminate adhesives, can enhance durability and reduce maintenance costs. Furthermore, custom-configuring screens to fit specific applications can improve performance and reduce energy consumption. It is also advisable to conduct a cost-benefit analysis when evaluating new equipment versus retrofitting existing screens. This approach allows companies to make informed decisions that align with their financial goals while ensuring optimal screening performance.

Scenario 3: Contamination Risks in Sensitive Applications

The Problem: For industries such as food processing or pharmaceuticals, the risk of contamination during material handling is a critical concern. A B2B buyer in these sectors may experience issues with traditional vibrating screens that use adhesives or non-FDA-approved materials, which can introduce contaminants into the final product. This not only poses health risks but can also result in costly recalls and damage to the company’s reputation.

The Solution: To effectively address contamination risks, buyers should prioritize screens specifically designed for sensitive applications. Implementing screens like SWECO’s Fusion Plus, which eliminates adhesives and uses FDA-approved components, can significantly reduce the risk of contamination. Additionally, it’s important to ensure that the screens are easily cleanable and maintainable to uphold hygiene standards. Regular training for operators on proper cleaning and maintenance practices can further enhance product safety. By selecting the right vibrating screen and fostering a culture of compliance with safety protocols, companies can protect their products and maintain their market integrity.

Strategic Material Selection Guide for vibrating screen

What are the Key Materials Used in Vibrating Screens and Their Properties?

When selecting materials for vibrating screens, it’s essential to consider their properties, advantages, and disadvantages to ensure optimal performance in various applications. Here, we analyze four common materials used in vibrating screens: stainless steel, polyurethane, rubber, and carbon steel.

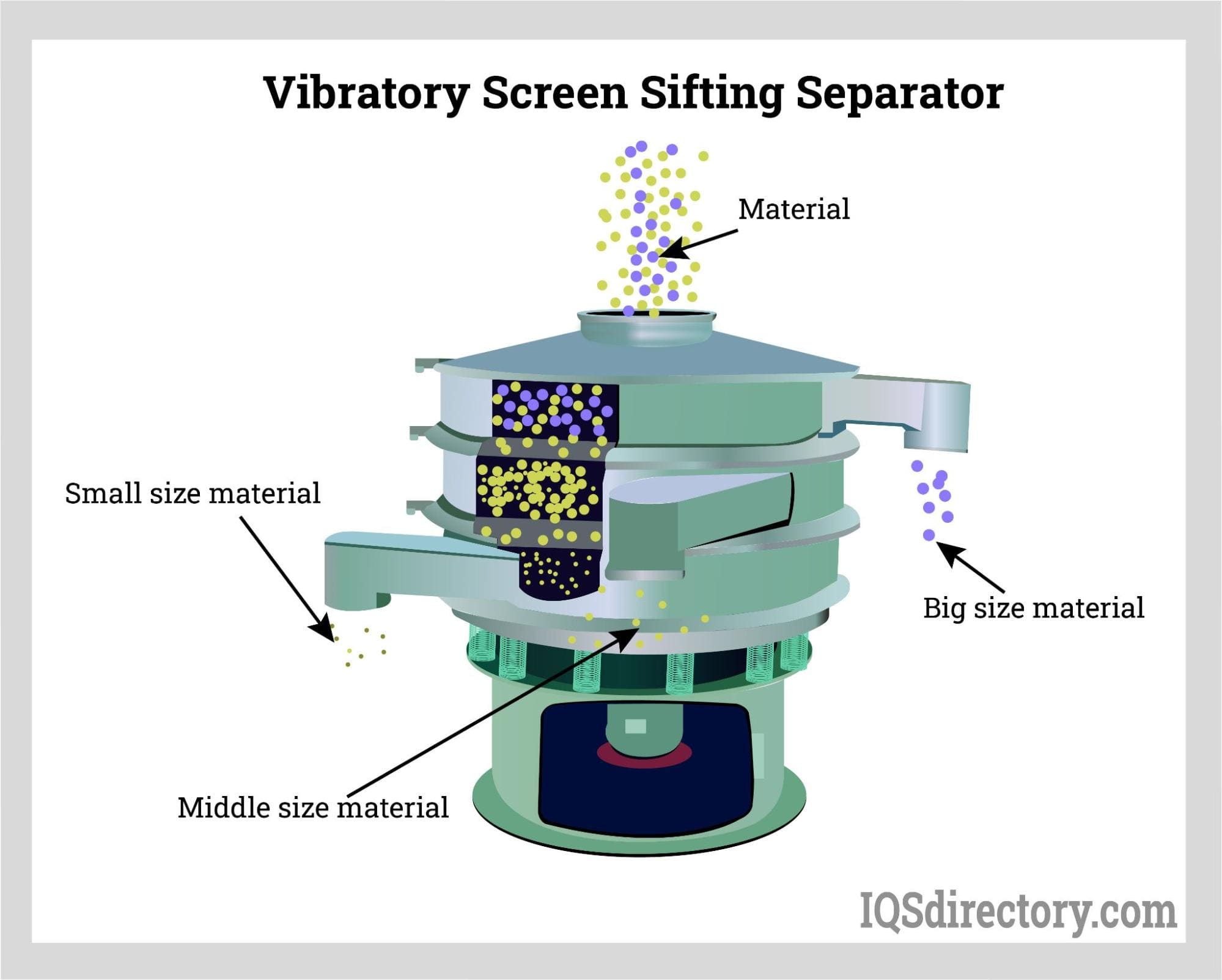

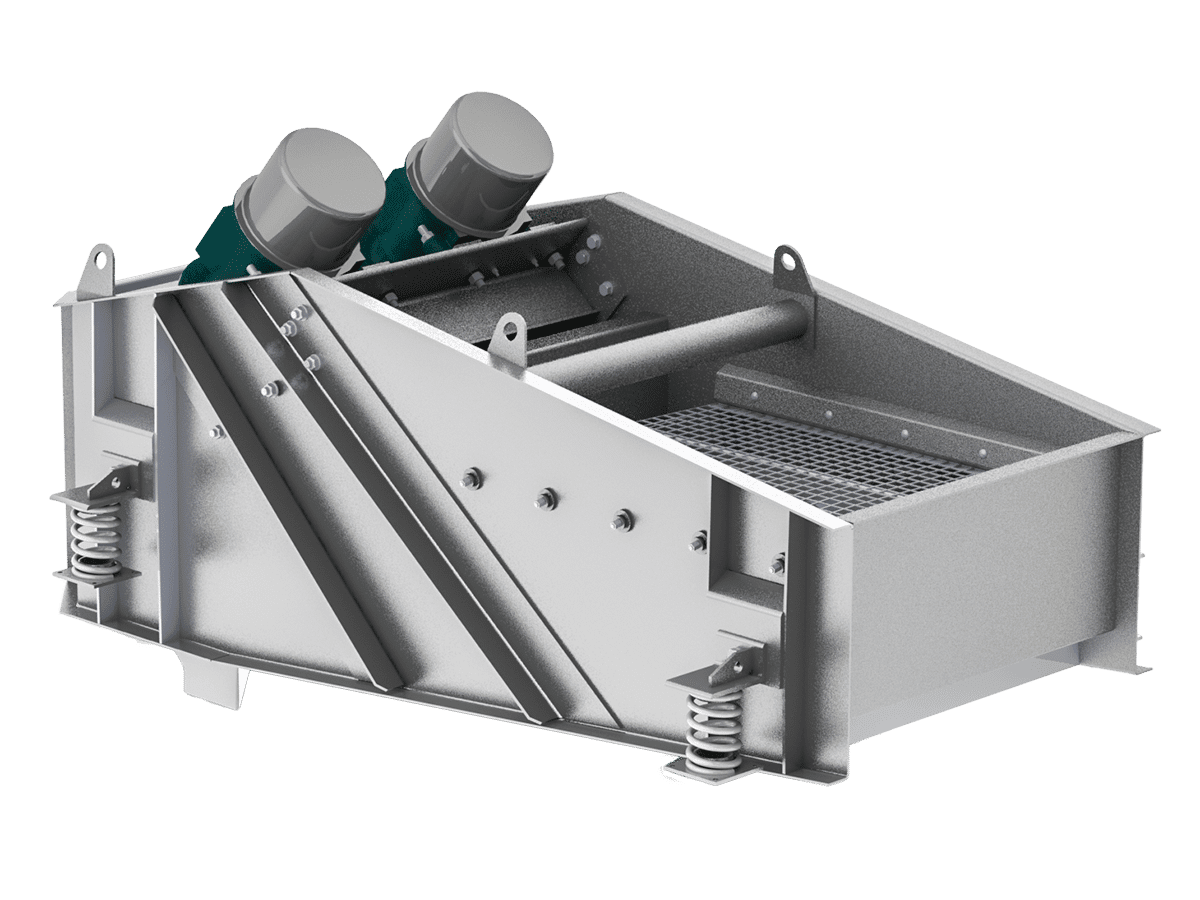

Illustrative image related to vibrating screen

How Does Stainless Steel Perform in Vibrating Screens?

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures. It typically has a temperature rating of up to 800°F (427°C) and can handle pressures exceeding standard operational limits.

Pros & Cons: The durability of stainless steel makes it suitable for a wide range of applications, especially in industries like food processing and pharmaceuticals. However, it tends to be more expensive than other materials, which can increase overall project costs. Additionally, manufacturing stainless steel screens can be complex due to the need for precise fabrication techniques.

Impact on Application: Stainless steel is ideal for applications involving corrosive materials or environments, ensuring longevity and minimal maintenance. Its compatibility with sanitary standards makes it a preferred choice for food-grade applications.

Considerations for International Buyers: Buyers must ensure compliance with international standards such as ASTM and FDA regulations for food applications. In regions like Germany, adherence to DIN standards is crucial, while in Africa and South America, local standards may vary.

What Advantages Does Polyurethane Offer for Vibrating Screens?

Key Properties: Polyurethane is known for its flexibility, abrasion resistance, and lightweight nature. It can operate effectively at temperatures up to 200°F (93°C) and offers good chemical resistance.

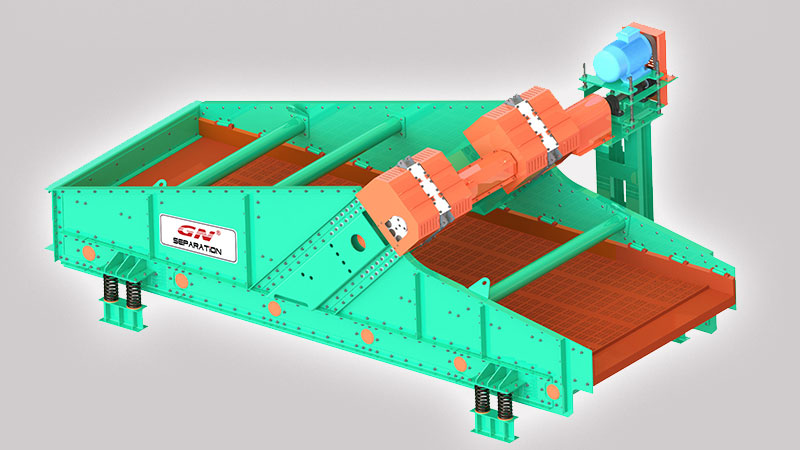

Illustrative image related to vibrating screen

Pros & Cons: The main advantage of polyurethane is its ability to reduce noise during operation, making it suitable for environments where sound levels must be controlled. However, it may not withstand extreme temperatures or heavy loads as effectively as metals, limiting its use in certain heavy-duty applications.

Impact on Application: Polyurethane screens are particularly effective in mineral processing and recycling applications, where fine materials are involved. They also minimize blinding, enhancing screening efficiency.

Considerations for International Buyers: Buyers should verify that the polyurethane used meets local chemical safety standards, particularly in regions with strict environmental regulations. Understanding the material’s compatibility with specific media is also essential.

Illustrative image related to vibrating screen

How Does Rubber Compare in Vibrating Screens?

Key Properties: Rubber is highly elastic and provides excellent shock absorption. It can handle temperatures ranging from -40°F to 180°F (-40°C to 82°C) and offers good resistance to wear and tear.

Pros & Cons: Rubber screens are cost-effective and provide excellent noise reduction. However, they can degrade faster in harsh environmental conditions or when exposed to certain chemicals, limiting their lifespan compared to metal options.

Impact on Application: Rubber is often used in applications requiring impact resistance, such as in mining and aggregate processing. Its flexibility allows it to adapt to various shapes and sizes, making it versatile.

Considerations for International Buyers: Buyers should consider the local climate and environmental conditions when selecting rubber screens. Compliance with local material standards is also necessary to ensure optimal performance.

What Role Does Carbon Steel Play in Vibrating Screens?

Key Properties: Carbon steel is known for its high tensile strength and durability. It can withstand significant loads and is often used in heavy-duty applications. However, it has lower corrosion resistance compared to stainless steel.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness and strength, making it suitable for demanding applications. On the downside, its susceptibility to rust and corrosion requires protective coatings, which can increase maintenance efforts.

Impact on Application: Carbon steel is widely used in industries such as mining and construction, where heavy materials are screened. Its robustness makes it a go-to choice for large-scale operations.

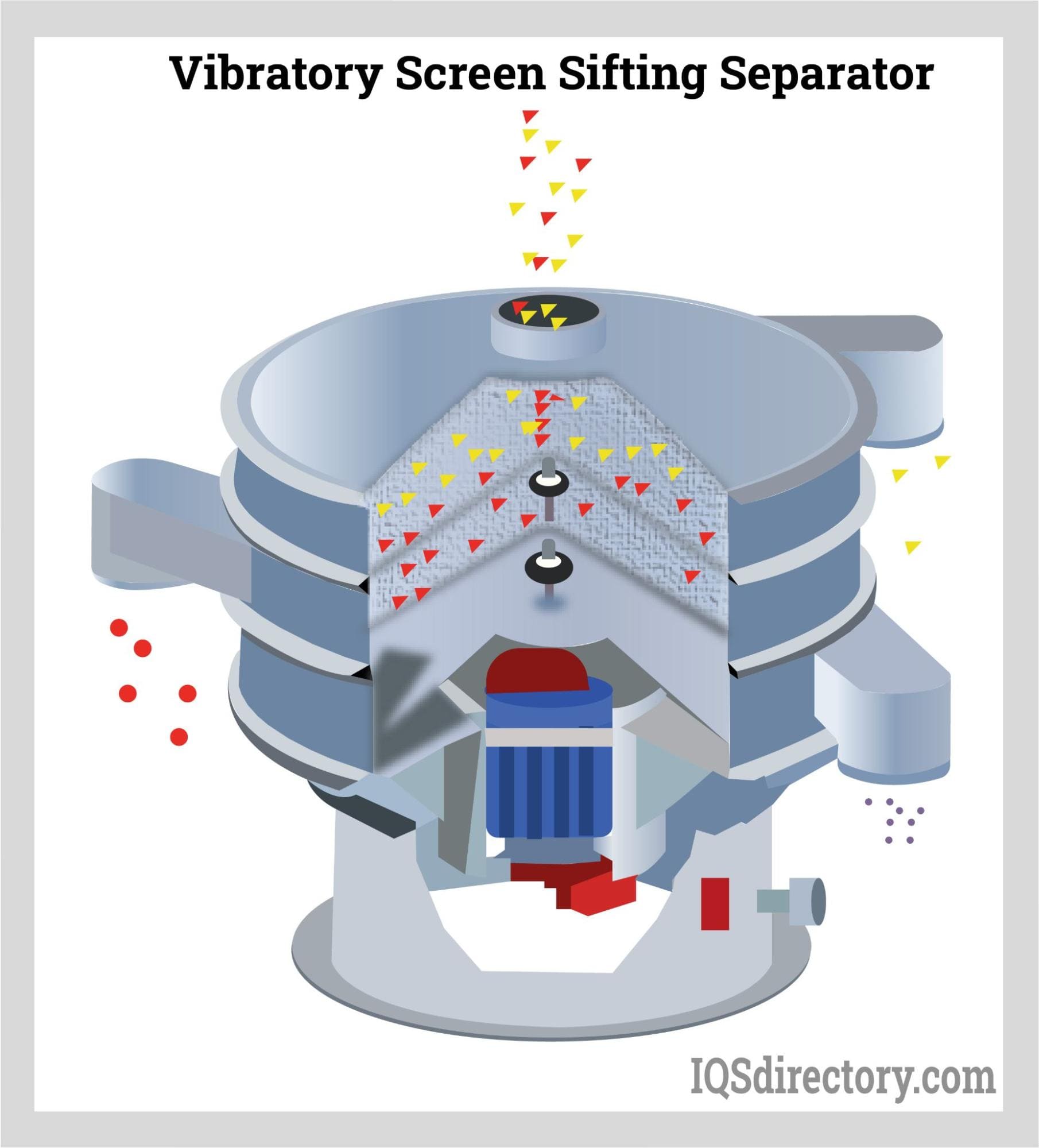

Illustrative image related to vibrating screen

Considerations for International Buyers: Buyers must ensure proper coating and maintenance practices to prevent corrosion, especially in humid or coastal regions. Familiarity with local standards for material strength and safety is also crucial.

Summary Table of Material Selection for Vibrating Screens

| Material | Typical Use Case for vibrating screen | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, pharmaceuticals | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Polyurethane | Mineral processing, recycling | Noise reduction, flexibility | Limited temperature resistance | Medium |

| Rubber | Mining, aggregate processing | Cost-effective, shock absorption | Degrades in harsh conditions | Low |

| Carbon Steel | Heavy-duty applications in mining | High strength, cost-effective | Susceptible to corrosion | Medium |

This strategic material selection guide provides valuable insights for B2B buyers in diverse regions, helping them make informed decisions based on their specific application needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for vibrating screen

What Are the Key Stages in the Manufacturing Process of Vibrating Screens?

The manufacturing process of vibrating screens involves several critical stages, each designed to ensure the final product meets both performance standards and customer expectations. Below are the main stages of the manufacturing process:

Illustrative image related to vibrating screen

1. Material Preparation

The first step involves selecting the right materials suitable for the specific application of the vibrating screen. Common materials include high-strength steel for the frame and various types of mesh for the screening surface. Quality assurance begins at this stage, as the selected materials must meet industry standards for durability and performance. Suppliers should provide material certifications to verify compliance with specifications.

2. Forming

After the materials are prepared, the next step is forming. This involves cutting, bending, and shaping the steel to create the frame and other components of the vibrating screen. Advanced techniques such as laser cutting and CNC machining are often employed to ensure precision and consistency. The use of robotic systems in forming can enhance efficiency while reducing human error, which is critical for maintaining quality.

3. Assembly

During the assembly phase, all components are brought together. This includes attaching the screen mesh to the frame and installing any additional features such as vibration motors or springs. Quality control checkpoints are essential during assembly. Each component must be checked for proper fit and function to ensure the unit operates smoothly. Some manufacturers employ modular designs, allowing for easier assembly and maintenance.

Illustrative image related to vibrating screen

4. Finishing

The finishing stage involves surface treatment processes such as painting or galvanizing to protect the vibrating screen from corrosion and wear. This is particularly important for equipment used in harsh environments, such as mining or heavy industrial applications. After finishing, screens undergo a final quality inspection to ensure that all specifications have been met, including dimensions, surface finish, and functionality.

What Quality Assurance Practices Are Essential for Vibrating Screens?

Quality assurance (QA) is critical in the manufacturing of vibrating screens, ensuring that the final product meets international standards and customer requirements. Here are some key QA practices:

Relevant International and Industry-Specific Standards

To maintain high-quality production, manufacturers often adhere to international standards such as ISO 9001, which focuses on quality management systems. Additionally, industry-specific certifications like CE marking (for products sold in the European Economic Area) and API (American Petroleum Institute) standards for equipment used in oil and gas applications may also apply. These certifications provide assurance that the products meet safety, health, and environmental protection requirements.

Illustrative image related to vibrating screen

Quality Control Checkpoints

Quality control is integrated throughout the manufacturing process, with specific checkpoints such as:

-

Incoming Quality Control (IQC): This involves inspecting materials upon arrival to ensure they meet predefined specifications.

-

In-Process Quality Control (IPQC): Regular checks during the manufacturing process help identify issues early, minimizing defects and rework.

-

Final Quality Control (FQC): A thorough inspection of the finished product ensures it meets all quality standards before shipment.

Common Testing Methods

Various testing methods are employed to validate the quality and performance of vibrating screens. These may include:

-

Vibration Testing: To ensure the screen operates efficiently under load without excessive wear or failure.

-

Load Testing: Verifying that the screen can handle the specified weight and material flow without deformation.

-

Material Testing: Checking the tensile strength and fatigue resistance of materials used in the screen’s construction.

How Can B2B Buyers Verify Supplier Quality Control?

When sourcing vibrating screens, particularly for international markets like Africa, South America, the Middle East, and Europe, it’s essential for B2B buyers to verify the quality control practices of potential suppliers. Here are some actionable strategies:

Conducting Supplier Audits

B2B buyers should consider performing onsite audits of potential suppliers. This allows them to assess the manufacturing process, quality control measures, and overall operational efficiency. During the audit, buyers can verify compliance with international standards and evaluate the supplier’s commitment to quality.

Requesting Quality Assurance Reports

Suppliers should provide documentation that outlines their quality assurance processes, including results from IQC, IPQC, and FQC. This documentation can offer insights into the supplier’s quality management systems and highlight any certifications they hold.

Engaging Third-Party Inspection Services

To ensure an unbiased assessment, buyers can engage third-party inspection services. These organizations can conduct independent evaluations of the manufacturing process, material quality, and final product specifications, providing an added layer of assurance.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate specific quality control nuances when sourcing vibrating screens. Here are some considerations:

Understanding Regional Standards

Different regions may have varying standards and regulations governing manufacturing and quality assurance. For example, European buyers must ensure compliance with CE marking, while buyers in the Middle East may need to consider local certifications. Understanding these requirements is crucial for successful procurement.

Language and Documentation Barriers

Buyers may encounter language barriers or discrepancies in documentation when dealing with international suppliers. It’s important to ensure that all quality documentation is clear and comprehensible, potentially requiring translation services for critical documents.

Cultural Differences in Business Practices

Cultural differences can influence how quality is perceived and managed. Buyers should be aware of these differences and establish clear communication regarding quality expectations and standards from the outset.

By understanding the manufacturing processes and quality assurance practices relevant to vibrating screens, B2B buyers can make informed decisions, ensuring they select reliable suppliers that meet their operational needs and maintain high-quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vibrating screen’

To effectively procure a vibrating screen, B2B buyers must navigate a series of critical steps to ensure they select the most suitable equipment for their specific needs. This guide provides a structured checklist to facilitate a smooth sourcing process.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for selecting the right vibrating screen. Consider factors such as the type of material being screened, desired particle size, flow rate, and operational environment. For example, if dealing with abrasive materials, look for screens constructed from durable materials to withstand wear and tear.

Step 2: Assess Your Application Requirements

Different applications require different types of vibrating screens. Identify whether your needs are for scalping, sizing, dewatering, or rinsing. For instance, if you’re in the food processing industry, you may require FDA-approved screens to meet safety standards.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. Request detailed company profiles, case studies, and references from buyers in similar industries or regions. Pay attention to the supplier’s experience with specific applications to ensure they can meet your unique requirements.

Step 4: Check Product Quality and Certifications

Quality assurance is paramount when selecting vibrating screens. Verify that the products meet international standards and certifications relevant to your industry. Look for certifications such as ISO or FDA compliance, which can indicate a commitment to quality and safety.

Step 5: Request Customization Options

Many suppliers offer customizable vibrating screens to better suit specific applications. Inquire about options for screen size, mesh type, and frame material. Customization can enhance performance and efficiency, ensuring that the equipment aligns perfectly with your operational needs.

Illustrative image related to vibrating screen

Step 6: Analyze Total Cost of Ownership

Consider the total cost of ownership (TCO) rather than just the initial purchase price. Evaluate factors such as maintenance costs, energy consumption, and expected lifespan of the equipment. A lower upfront cost may lead to higher expenses over time if the equipment requires frequent repairs or consumes excessive energy.

Step 7: Negotiate Terms and Conditions

Once you’ve selected a supplier, engage in negotiations to secure favorable terms. Discuss warranties, delivery timelines, and after-sales support. Clear agreements on these aspects can help mitigate risks and ensure a smooth procurement process.

By following this checklist, B2B buyers can make informed decisions when sourcing vibrating screens, ultimately leading to improved operational efficiency and product quality.

Comprehensive Cost and Pricing Analysis for vibrating screen Sourcing

What Are the Key Cost Components in Vibrating Screen Manufacturing?

When analyzing the cost structure of vibrating screens, several components play a crucial role in determining the final price. Key cost components include:

-

Materials: The choice of materials significantly impacts costs. High-quality steel and specialized components for durability and performance can increase material expenses. For instance, FDA-approved materials for food processing applications may also come at a premium.

-

Labor: Skilled labor is essential in the assembly and quality control of vibrating screens. Labor costs can vary by region, with countries in Africa and South America often experiencing lower labor costs compared to Europe, which may influence overall pricing.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient production processes can help reduce overhead, but advanced technology and automation may require a higher initial investment.

-

Tooling: Custom tooling for specific screen designs can add to costs. For buyers requiring unique specifications, it’s important to factor in these additional expenses.

-

Quality Control (QC): Implementing stringent QC processes ensures reliability and performance, which can increase costs but also reduce long-term failure rates.

-

Logistics: Transportation and shipping costs can vary widely based on location, particularly for international buyers. Incoterms will dictate who bears the shipping costs, affecting the total price.

-

Margin: Suppliers will add a profit margin based on their operational costs, market demand, and competition. Understanding the market landscape can provide insight into reasonable margins.

What Influences the Price of Vibrating Screens for B2B Buyers?

Several factors influence the pricing of vibrating screens, particularly for international buyers:

-

Volume/MOQ: Bulk orders often attract discounts due to economies of scale. Understanding minimum order quantities (MOQ) can help buyers negotiate better prices.

-

Specifications and Customization: Custom-designed screens tailored to specific applications can incur higher costs. Buyers should assess whether standard models meet their needs before pursuing custom solutions.

-

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., ISO, FDA) can increase costs. However, investing in quality often results in better performance and longevity.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities will affect pricing. Established suppliers with proven reliability may charge more due to their experience and track record.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly impact the total cost.

What Tips Can Help Buyers Negotiate Better Prices on Vibrating Screens?

For international B2B buyers, especially from regions like Africa and South America, negotiating better prices involves several strategies:

-

Leverage Volume Discounts: If feasible, consolidate orders to meet or exceed MOQs. This can lead to significant savings.

-

Engage Multiple Suppliers: Obtaining quotes from various suppliers can provide leverage in negotiations. It also helps in understanding the market price range.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, operational efficiency, and potential downtime costs. A lower-priced unit may not always be the most cost-effective in the long run.

-

Be Aware of Pricing Nuances: Different regions may have varying price expectations and practices. Understanding local market conditions can aid in negotiations.

-

Explore Payment Terms: Negotiating favorable payment terms can ease cash flow challenges. Consider options like staggered payments or discounts for early payments.

Conclusion: Why Understanding Cost and Pricing is Essential for B2B Buyers

In summary, a comprehensive understanding of the cost structure and pricing influences of vibrating screens is critical for B2B buyers. By being informed about the various components, price influencers, and effective negotiation strategies, buyers can make more informed purchasing decisions that align with their operational needs and budget constraints. Keep in mind that prices can vary widely based on specifications and market conditions; thus, it’s essential to conduct thorough research and seek multiple quotes to ensure a competitive deal.

Alternatives Analysis: Comparing vibrating screen With Other Solutions

Understanding Alternatives to Vibrating Screens for Screening Solutions

In the industrial sector, selecting the right screening technology is crucial for optimizing productivity and ensuring product quality. Vibrating screens are widely used for separating materials based on size, but several alternatives may also provide effective solutions depending on specific needs and operational contexts. This analysis compares vibrating screens with other viable methods, helping B2B buyers make informed decisions.

| Comparison Aspect | Vibrating Screen | Air Classifier | Trommel Screen |

|---|---|---|---|

| Performance | Highly efficient for various materials; can handle heavy loads. | Excellent for fine particle separation; limited capacity for large volumes. | Effective for large and bulky materials; can separate based on size and shape. |

| Cost | Moderate initial investment; low operating costs due to minimal maintenance. | Higher initial costs; energy-intensive operation can lead to higher long-term expenses. | Variable costs depending on size; often economical for large-scale operations. |

| Ease of Implementation | Generally straightforward installation; requires minimal setup. | More complex installation; may need specialized infrastructure. | Simple to set up; often used in mobile operations for flexibility. |

| Maintenance | Low maintenance due to fewer moving parts; regular inspections needed. | Requires periodic maintenance; potential for wear on components. | Moderate maintenance; may need regular cleaning and repairs due to wear. |

| Best Use Case | Ideal for aggregate, coal, and food processing applications. | Best for separating fine powders in mineral processing and recycling. | Suitable for waste management and composting, as well as mining operations. |

What Are the Pros and Cons of Using an Air Classifier?

Air classifiers are specialized machines that utilize air flow to separate materials based on size and density. One of their main advantages is their ability to efficiently separate fine particles without the need for mechanical agitation. This method is particularly beneficial in industries such as mining and recycling, where precision is critical. However, air classifiers can have a higher initial investment and ongoing energy costs, making them less economical for operations requiring high throughput.

Illustrative image related to vibrating screen

How Does a Trommel Screen Compare to Vibrating Screens?

Trommel screens, cylindrical in shape, rotate to separate materials based on size and shape. They are particularly effective for large or bulky materials and are commonly used in waste management and composting. Trommel screens can handle a wide variety of materials, making them versatile for different applications. However, they may not be as efficient as vibrating screens for fine particle separation and could require more maintenance due to their mechanical components.

Conclusion: How to Choose the Right Screening Solution for Your Business

When selecting a screening solution, B2B buyers should consider their specific operational needs, including material types, required throughput, and budget constraints. Vibrating screens offer a reliable and cost-effective solution for a range of applications, particularly in aggregate and food processing. In contrast, air classifiers excel in fine particle separation but come with higher operational costs, while trommel screens provide versatility for larger materials. By evaluating these factors, businesses can make informed decisions that align with their operational goals and financial constraints.

Essential Technical Properties and Trade Terminology for vibrating screen

What Are the Key Technical Properties of Vibrating Screens?

When selecting a vibrating screen for industrial applications, understanding its technical properties is crucial for ensuring optimal performance and longevity. Here are some of the most critical specifications to consider:

Illustrative image related to vibrating screen

1. Material Grade

The material grade of the vibrating screen, typically stainless steel or carbon steel, significantly affects its durability and resistance to corrosion. Stainless steel is preferred for applications in food processing and pharmaceuticals due to its resistance to contamination and ease of cleaning. In contrast, carbon steel is often used in heavy-duty applications, such as mining, where cost and strength are prioritized. Selecting the right material grade ensures compliance with industry standards and enhances the lifespan of the equipment.

2. Screen Mesh Size

The mesh size defines the particle size that can pass through the screen. A smaller mesh size is essential for fine materials, while larger sizes are suitable for coarse applications. Understanding the required mesh size is vital for achieving the desired product purity and efficiency in separation processes. Incorrect mesh selection can lead to product losses or increased operational costs due to inefficiencies.

3. Tolerance and Precision

Tolerance refers to the allowable deviation in the dimensions of the vibrating screen components, which affects the fit and function of the equipment. High precision in manufacturing tolerances ensures that screens operate effectively without vibration-related issues, such as premature wear or structural failure. This is particularly important in high-capacity operations where even minor discrepancies can lead to significant productivity losses.

4. Capacity and Throughput

Capacity indicates the volume of material a vibrating screen can handle within a specific timeframe. It is essential to match the screen’s capacity with the operational requirements to avoid bottlenecks in production. A screen that cannot handle the required throughput will lead to increased wear and maintenance costs, potentially impacting overall efficiency and profitability.

5. Frequency and Amplitude of Vibration

The frequency and amplitude at which the screen vibrates can be adjusted to optimize performance for different materials. Higher frequencies are typically used for fine screening, while lower frequencies with greater amplitude are suitable for larger, heavier materials. Understanding these parameters allows buyers to customize the vibrating screen to specific applications, enhancing both effectiveness and efficiency.

What Are Common Trade Terms Associated with Vibrating Screens?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some commonly used terms in the context of vibrating screens:

Illustrative image related to vibrating screen

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the vibrating screen industry, this term signifies the original manufacturer of the screening equipment, ensuring that buyers receive authentic parts for maintenance or replacement.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory levels and costs, especially when dealing with specialized equipment like vibrating screens that may require bulk purchases for cost-effectiveness.

3. RFQ (Request for Quotation)

An RFQ is a formal process where a buyer requests price quotes from suppliers for specific products or services. Including detailed specifications for vibrating screens in an RFQ helps ensure that suppliers provide accurate and competitive pricing, facilitating better decision-making.

Illustrative image related to vibrating screen

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in the shipping process. Familiarity with these terms helps buyers understand their obligations regarding shipping, insurance, and tariffs when importing vibrating screens from different regions.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. Understanding lead times is vital for planning and ensuring that operations are not disrupted due to delays in the supply chain, particularly for critical equipment like vibrating screens.

In summary, grasping both the essential technical properties and trade terminology related to vibrating screens empowers B2B buyers to make informed purchasing decisions, optimize their operations, and enhance overall productivity.

Illustrative image related to vibrating screen

Navigating Market Dynamics and Sourcing Trends in the vibrating screen Sector

What Are the Current Market Dynamics and Key Trends in the Vibrating Screen Sector?

The global vibrating screen market is experiencing significant growth, driven by the increasing demand for materials across various industries, including mining, construction, and food processing. In regions like Africa and South America, the push for infrastructure development is propelling the need for efficient separation and screening technologies. Emerging markets are also seeing a rise in the adoption of advanced screening technologies that enhance productivity and reduce operational costs.

Technological advancements are shaping the sector, with innovations such as modular screen designs and smart monitoring systems becoming prevalent. These technologies not only optimize performance but also enable predictive maintenance, reducing downtime and operational inefficiencies. Additionally, the integration of automation and data analytics into vibrating screen operations is allowing companies to enhance their decision-making processes, thereby improving overall productivity and resource allocation.

Moreover, the growing focus on sustainability and environmental responsibility is influencing sourcing trends. B2B buyers are increasingly seeking suppliers who can provide eco-friendly materials and energy-efficient equipment. This trend is particularly pronounced in Europe, where regulatory frameworks are pushing for greener practices across industries. International buyers must remain vigilant about these trends to ensure they are sourcing equipment that meets both performance and environmental standards.

How Can Sustainability and Ethical Sourcing Impact the Vibrating Screen Industry?

Sustainability is becoming a central theme in the vibrating screen sector, with companies recognizing the environmental impact of their operations. The extraction and processing of materials for vibrating screens can lead to significant ecological footprints, prompting manufacturers and buyers alike to consider more sustainable practices. As a result, buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their environmental impact through sustainable sourcing and manufacturing processes.

Ethical supply chains are also gaining traction, as B2B buyers look for partners who adhere to fair labor practices and responsible sourcing of materials. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming important benchmarks for assessing suppliers. Furthermore, the use of recycled materials and sustainable production methods is not only beneficial for the environment but can also enhance brand reputation and customer loyalty.

Illustrative image related to vibrating screen

As sustainability becomes a key differentiator, buyers should prioritize partnerships with suppliers who can provide documentation and certifications that validate their commitment to green practices. This focus on ethical sourcing can lead to improved operational efficiencies, reduced risks, and enhanced corporate social responsibility, which are increasingly important to stakeholders across the globe.

What Is the Evolution and Historical Context of the Vibrating Screen Industry?

The vibrating screen industry has evolved significantly since its inception, with the earliest models emerging in the late 19th century. Initially, vibrating screens were simplistic devices used primarily in mining and aggregate industries for basic separation tasks. Over the decades, technological advancements have led to the development of more sophisticated designs that incorporate various types of motion, such as linear and circular vibrations, enhancing the efficiency of material separation.

The introduction of new materials and manufacturing techniques has also played a crucial role in this evolution. Modern vibrating screens are designed to handle a wide range of materials, from fine powders to coarse aggregates, and are increasingly tailored to meet specific application needs. This evolution reflects the industry’s response to growing demands for efficiency, reliability, and sustainability, positioning vibrating screens as essential equipment across diverse sectors today.

As the market continues to grow and adapt, understanding these historical trends can provide valuable insights for B2B buyers looking to make informed sourcing decisions in the ever-evolving landscape of the vibrating screen industry.

Frequently Asked Questions (FAQs) for B2B Buyers of vibrating screen

-

How do I solve screening inefficiencies in my production line?

To address screening inefficiencies, start by analyzing the specific characteristics of your materials, such as size, shape, and moisture content. Selecting the right type of vibrating screen, whether inclined or linear, can significantly improve performance. Consider models with advanced features like self-cleaning screens or those designed for heavy-duty applications. Collaborating with suppliers who offer customization options can help tailor the equipment to your unique process requirements, ensuring optimal throughput and minimal downtime. -

What is the best vibrating screen for coal processing?

For coal processing, the F-Class or T-Class inclined vibrating screens are often the best choices due to their robust design and ability to handle heavy loads. These screens offer consistent performance and can be configured for various applications, including scalping and dewatering. Additionally, look for features like high-frequency vibrations and durable construction to withstand the abrasive nature of coal. Consulting with a manufacturer who specializes in mining equipment can provide further insights into the most suitable models for your needs. -

What customization options are available for vibrating screens?

Many manufacturers offer a range of customization options for vibrating screens, including screen size, mesh type, and frame material. You can choose from various configurations, such as multi-deck designs for increased separation efficiency or specific coatings for enhanced durability. Additionally, some suppliers provide tailored solutions for unique materials or application requirements. Engaging directly with manufacturers can facilitate a better understanding of available options and lead to a screen that precisely meets your operational needs. -

What are the minimum order quantities (MOQs) for vibrating screens?

Minimum order quantities for vibrating screens can vary significantly depending on the manufacturer and the complexity of the equipment. For standard models, MOQs may range from one to several units, while custom designs often require higher quantities. It’s advisable to discuss your specific needs with potential suppliers to understand their MOQs and whether they offer flexibility, especially for smaller operations or new projects. This can help in budgeting and planning your procurement strategy effectively. -

What payment terms should I expect when sourcing vibrating screens internationally?

Payment terms for international purchases of vibrating screens typically include options such as upfront deposits, letters of credit, or payment upon delivery. Many suppliers may require a deposit of 30-50% before production, with the balance due upon shipment or delivery. Always clarify the terms upfront and consider using secure payment methods to mitigate risks. Familiarizing yourself with international trade regulations and currency exchange implications can also help in negotiating favorable payment terms with suppliers. -

How can I vet suppliers of vibrating screens effectively?

To vet suppliers effectively, start by researching their industry reputation, certifications, and experience. Look for customer reviews, case studies, or testimonials that reflect their performance in similar applications. Request references and inquire about their after-sales support, warranty terms, and maintenance services. Additionally, visiting their manufacturing facility, if feasible, can provide insights into their quality control processes and production capabilities, ensuring you partner with a reliable supplier. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers of vibrating screens should have robust quality assurance measures in place, including adherence to international standards and certifications. Look for suppliers that conduct thorough testing of their products, such as performance evaluations and durability assessments. Additionally, inquire about their quality control processes during manufacturing and their policies for handling defects or issues post-sale. A strong commitment to quality assurance will ensure you receive equipment that meets your operational demands and reduces downtime. -

What logistics considerations should I keep in mind when importing vibrating screens?

When importing vibrating screens, consider factors such as shipping methods, customs regulations, and delivery timelines. Engage with logistics partners experienced in handling industrial equipment to ensure compliance with local regulations. Be aware of the potential for delays in customs and plan accordingly to avoid disruptions in your supply chain. Additionally, consider the total landed cost, including tariffs and duties, to ensure your procurement aligns with your budget and operational timelines.

Top 9 Vibrating Screen Manufacturers & Suppliers List

1. Syntron – Vibrating Screens

Domain: syntronmh.com

Registered: 2014 (11 years)

Introduction: Syntron vibrating screens are designed for various applications including aggregates, coal, plastics, food processing, and pharmaceuticals. They are used to scalp, separate, size, de-dust, and de-water bulk products. Key features include:

– Powered by efficient electromagnetic drives for gentle handling and minimal product degradation.

– No moving parts, requiring no lubrication and minimal mainte…

2. Sweco – Key Separation and Milling Products

Domain: sweco.com

Registered: 1997 (28 years)

Introduction: Key Products: 1. Round Separator 2. Rectangular Separator 3. Gyratory Sifter 4. Pharmaceutical Separator 5. Decanter Centrifuge 6. Other Separation Equipment 7. Grinding Mill 8. Finishing Mill 9. Fusion Screens – FDA approved, eliminates adhesives, available in Fusion and Fusion Plus. 10. Supertaut Plus Screens – FDA approved, durable, withstands caustic and steam cleaning. 11. Magnum Screens – cu…

3. Haver & Boecker Niagara – Vibrating Screens

Domain: haverniagara.com

Registered: 2012 (13 years)

Introduction: Haver & Boecker Niagara offers a range of vibrating screens categorized into five classes: XL-Class, N-Class, F-Class, T-Class, and L-Class. Each class is designed for specific applications and performance requirements. The F-Class Inclined Vibrating Screen is known for consistent performance and load independence. The Niagara F-Class Portable Plant is designed for easy maneuverability. The L-Clas…

4. Sinfonia Technology – Vibrating Screens

Domain: sinfo-t.com

Registered: 2008 (17 years)

Introduction: Sinfonia Technology manufactures a variety of vibrating screens designed to enhance productivity and quality through unique vibration technology. Key features include:

1. **Types of Screens**:

– SF Type Electromagnetic Screen: High-efficiency model for fine powders and resin pellets.

– RVS Type Rotary Vibrating Screen: Suitable for middle-sized materials, direct vibration transmission.

-…

5. SBM – S5X Vibrating Screen

Domain: m.sbmchina.com

Registered: 2007 (18 years)

Introduction: The S5X vibrating screen is a widely used design in mining, aggregate, and industrial mineral processing applications. It addresses common issues faced by traditional models through innovation and extensive industry experience. The S5X is suitable for heavy and medium-duty operations, including fine screening, primary and secondary crushing, and material classification. Its modular design incorpor…

6. Sandvik – Vibrating Screens

Domain: rockprocessing.sandvik

Registered: 2021 (4 years)

Introduction: Vibrating screens optimized for comminution and material handling operations. Throughput rates from 1 to 8000 tonnes per hour. Product types include SK Range, S Range, and SM Range screens, featuring various designs such as linear flat screens, multislope screens, grizzly screens, dewatering screens, and inclined screens. Supported by digital tools, high-quality OEM spare parts, consumables, and l…

7. Eversun Equipment – Rotary Vibrating Screen

Domain: eversunequipment.com

Registered: 2023 (2 years)

Introduction: Rotary vibrating screen for material screening and filtration. Features include:

1. Small size, light weight, easy to move.

2. Adjustable discharge port direction for automatic or manual operation.

3. High screening accuracy and efficiency for powders, granules, slurries, or liquids.

4. Sieve can be as fine as 500 mesh (28 microns) for filtration down to 5 microns.

5. Unique grid design for l…

8. Conn-Weld – Customizable Vibrating Screens

Domain: conn-weld.com

Registered: 1998 (27 years)

Introduction: Vibrating Screens: Customizable Pan Feeder, Elliptical Horizontal Screen, Dewatering Screen, Extreme Duty Scalping Screens, Incline Screens, Horizontal Screens, Banana Style Screens, Sieve Units, Curved Sieves, Fixed Flat Sieves, Hydro Sieves, Uprising Sieves, Screen Baskets, Screen Media & Hold-Down Systems. Key features include adjustable feed rates, low maintenance, wear protection options, hig…

9. Propel – MVS Series Vibrating Screen

Domain: propelind.com

Registered: 2009 (16 years)

Introduction: Product Name: MVS Series Vibrating Screen

Key Features:

– Versatile for primary, secondary, and tertiary screening.

– Standard slope angle of 18°, adjustable for special applications.

– Suitable for wet screening with spray pipes.

– High screening capacity and excellent performance.

– Circular motion modular vibrators with two bearings per vibrator, interconnected by cardan shaft.

– Unique angle …

Strategic Sourcing Conclusion and Outlook for vibrating screen

As the vibrating screen market continues to evolve, strategic sourcing emerges as a critical factor for international B2B buyers seeking to enhance operational efficiency and product quality. By understanding the diverse range of vibrating screen technologies, including innovations such as Fusion Screens and self-cleaning designs, businesses can tailor their procurement strategies to meet specific application needs while minimizing maintenance costs. The importance of selecting the right equipment based on material characteristics and operational requirements cannot be overstated, as this directly impacts productivity and overall performance.

Looking ahead, the increasing demand for advanced screening solutions across sectors such as mining, food processing, and pharmaceuticals presents significant opportunities for savvy buyers. As markets in Africa, South America, the Middle East, and Europe continue to expand, there is a growing imperative to invest in high-quality, reliable vibrating screens that can withstand diverse environmental conditions.

Take the initiative now to evaluate your current screening processes and explore the latest technologies available. By leveraging strategic sourcing, you can ensure your operations remain competitive and responsive to market demands. Embrace this opportunity to partner with leading manufacturers and elevate your screening capabilities to new heights.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.