Unlocking Value: A Strategic Analysis of the Worm Motor Gear Market

Introduction: Navigating the Global Market for worm motor gear

In the fast-evolving landscape of industrial machinery, sourcing reliable worm motor gear solutions can be a daunting challenge for B2B buyers. The need for efficient, high-torque applications across various sectors—from food processing to logistics—demands a deep understanding of the specifications and capabilities of worm gear motors. This comprehensive guide serves as an essential resource for international buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, including major markets like Brazil and Germany.

Throughout this guide, we will explore the diverse types of worm motor gears available, their specific applications, and the critical factors to consider when vetting suppliers. Understanding the nuances of cost, performance, and compatibility will empower buyers to make informed purchasing decisions that align with their operational needs. Additionally, we will delve into best practices for maintenance and lubrication, which are crucial for maximizing the lifespan and efficiency of these essential components.

By equipping B2B buyers with the knowledge and insights needed to navigate the global market for worm motor gears, this guide aims to streamline your sourcing process, mitigate risks, and ultimately enhance the performance of your machinery.

Understanding worm motor gear Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| UNICASE Worm Gear Units | One-piece housing for compact design, high torque capacity | Intralogistics, automotive, material handling | Pros: Compact, efficient, high load capacity. Cons: Limited customization options. |

| UNIVERSAL SI Worm Gear | Modular components for flexible configurations | Food processing, packaging, pharmaceuticals | Pros: Highly customizable, robust. Cons: Longer assembly time for custom setups. |

| SMI Series Worm Gear | Smooth surface for easy cleaning, hygienic design | Food and beverage, pharmaceutical industries | Pros: Easy to clean, corrosion-resistant. Cons: Potentially higher initial costs. |

| Standard Worm Gear | Traditional design with high reduction ratios | General machinery, conveyor systems | Pros: Simple design, effective torque conversion. Cons: Difficult lubrication management. |

| Dual Worm Gear | Two worms for enhanced torque and efficiency | Heavy-duty applications, industrial machinery | Pros: Increased torque, improved efficiency. Cons: Higher complexity and cost. |

What Are UNICASE Worm Gear Units and Their Benefits for B2B Buyers?

UNICASE Worm Gear Units feature a one-piece housing design that enhances compactness while maximizing torque capacity. This design is particularly advantageous in applications requiring significant power in limited spaces, such as intralogistics and automotive sectors. B2B buyers should consider these units for their robust performance and reliability, although they may face limitations in customization options compared to modular systems.

How Do UNIVERSAL SI Worm Gears Offer Flexibility for Diverse Applications?

The UNIVERSAL SI Worm Gear is characterized by its modular components, allowing for extensive customization to suit various applications, including food processing and packaging. This flexibility enables businesses to configure the gear motor according to specific operational needs, enhancing efficiency. However, potential buyers should be aware that the assembly time may increase when opting for a customized solution, which could impact project timelines.

Why Choose the SMI Series Worm Gear for Hygienically Sensitive Industries?

SMI Series Worm Gears are designed with smooth surfaces that facilitate easy cleaning, making them ideal for industries such as food and beverage and pharmaceuticals, where hygiene is paramount. The corrosion-resistant properties of these gears further enhance their suitability for such applications. While the initial investment may be higher, the long-term benefits of reduced maintenance and compliance with hygiene standards can justify the cost.

What Are the Advantages and Disadvantages of Standard Worm Gears?

Standard Worm Gears provide a traditional approach to gear design, offering significant reduction ratios that allow for effective torque conversion. They are widely used in general machinery and conveyor systems. However, buyers should consider the challenges associated with lubrication management due to the sliding friction inherent in their operation, which can lead to increased wear and maintenance requirements.

How Do Dual Worm Gears Improve Performance in Heavy-Duty Applications?

Dual Worm Gears utilize two worms to enhance torque and efficiency, making them suitable for heavy-duty applications in industrial machinery. This design allows for improved power delivery and can accommodate higher loads without compromising performance. However, potential buyers should evaluate the increased complexity and costs associated with these systems, ensuring they align with their operational requirements and budget constraints.

Key Industrial Applications of worm motor gear

| Industry/Sector | Specific Application of worm motor gear | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Conveyor systems for food processing | High torque output with compact design | Hygiene compliance, wash-down capabilities, corrosion resistance |

| Intralogistics | Automated storage and retrieval systems | Efficient space utilization and high gear ratios | Customizability, modular components, overload capacity |

| Packaging | Packaging machinery for bottling and canning | Reliability in high-speed operations | Material compatibility, ease of maintenance, lubrication needs |

| Pharmaceutical | Equipment in sterile environments for drug manufacturing | Smooth operation and easy cleaning | Hygienic design, corrosion protection, compliance with regulations |

| Agriculture | Feed and grain handling systems | Enhanced torque for heavy loads | Durability, adaptability to varying environmental conditions, sourcing local suppliers |

What Are the Key Applications of Worm Motor Gears in the Food and Beverage Industry?

In the food and beverage sector, worm motor gears are extensively used in conveyor systems that transport products through various stages of processing. Their compact design allows for high torque output in tight spaces, which is crucial for efficient operation. Buyers in this sector must prioritize hygiene compliance, ensuring that the gear systems can withstand wash-down processes and are resistant to corrosion. Additionally, suppliers should provide options that meet food safety standards to avoid contamination.

How Are Worm Motor Gears Beneficial in Intralogistics?

Worm motor gears play a vital role in automated storage and retrieval systems in intralogistics. These systems benefit from the high gear ratios that worm gears provide, facilitating efficient space utilization within warehouses. For international buyers, particularly in regions with varying infrastructure, sourcing customizable and modular components is essential. Moreover, the high overload capacity of worm gears can enhance reliability in demanding environments, reducing downtime and maintenance costs.

Why Are Worm Motor Gears Essential for Packaging Machinery?

In the packaging industry, worm motor gears are integral to machinery used for bottling and canning processes. They ensure reliability during high-speed operations, which is critical for maintaining production efficiency. Buyers should consider the material compatibility of worm gears with various packaging substances and the ease of maintenance required for their lubrication needs. Selecting a supplier that understands the specific operational challenges of packaging machinery can enhance overall productivity.

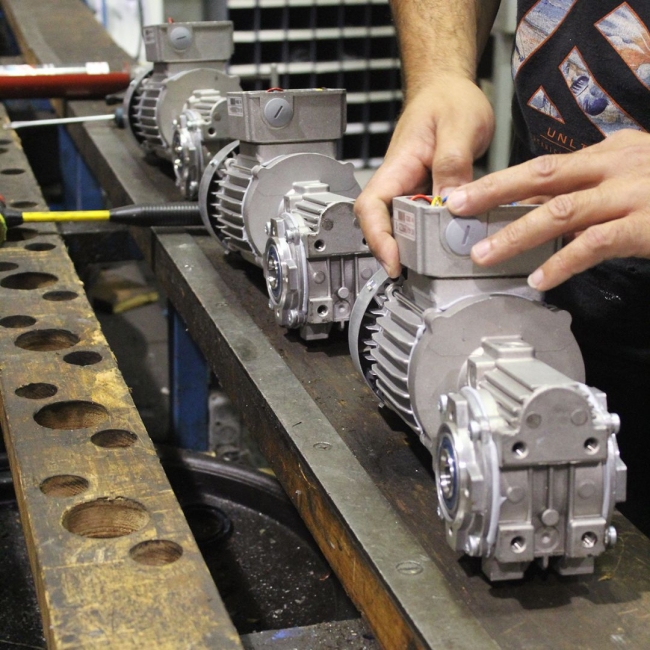

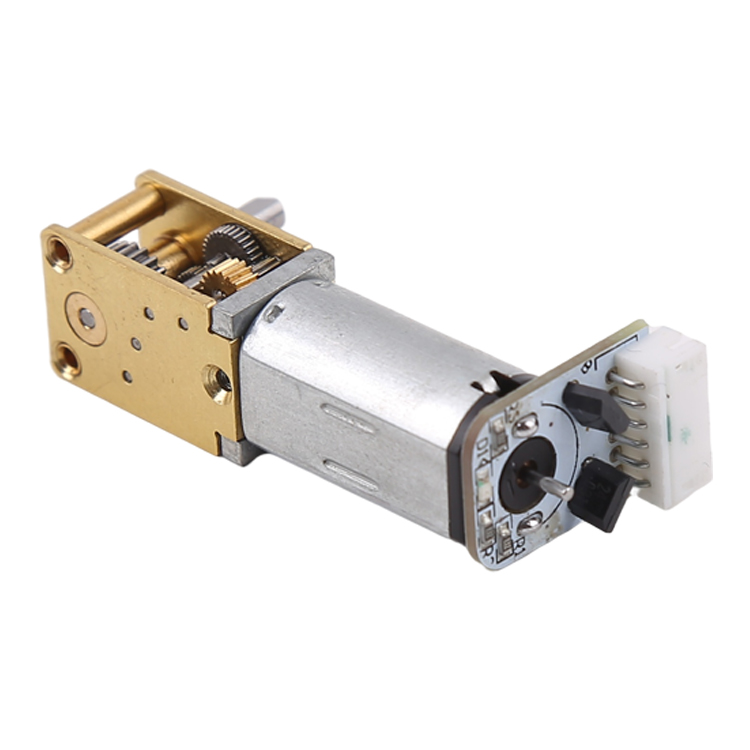

Illustrative image related to worm motor gear

What Role Do Worm Motor Gears Play in Pharmaceutical Manufacturing?

Worm motor gears are crucial in pharmaceutical manufacturing, particularly in equipment used in sterile environments. Their smooth operation minimizes contamination risks, and their design allows for easy cleaning, which is necessary for compliance with stringent regulations. Buyers in this sector should focus on suppliers that offer corrosion-resistant options and can ensure that their products meet industry-specific standards. The ability to customize gear systems for specific applications is also a key consideration.

How Are Worm Motor Gears Used in Agriculture?

In the agricultural sector, worm motor gears are commonly found in feed and grain handling systems. Their ability to provide enhanced torque for heavy loads makes them ideal for transporting bulk materials. For buyers, durability and adaptability to varying environmental conditions are crucial factors when sourcing these components. Engaging with local suppliers can also help mitigate logistics challenges and ensure timely availability of parts, particularly in remote areas.

3 Common User Pain Points for ‘worm motor gear’ & Their Solutions

Scenario 1: High Lubrication Requirements Leading to Increased Maintenance Costs

The Problem:

B2B buyers often face challenges with the high lubrication requirements of worm motor gears. Due to the unique sliding motion between the worm and wheel, traditional lubrication methods may not suffice, leading to increased wear and tear. This can result in frequent breakdowns, unexpected maintenance costs, and extended downtime, which can be particularly detrimental in industries like manufacturing and logistics where operational efficiency is crucial. Buyers may find themselves at a crossroads: either invest in specialized lubricants and filtration systems or risk the longevity and reliability of their equipment.

The Solution:

To mitigate these challenges, buyers should consider investing in high-quality, specialized lubricants designed for worm gear applications. Look for lubricants with high viscosity ratings (ISO 460 to ISO 1000) that can handle the extreme conditions of worm gear operation. Additionally, implementing a proactive maintenance schedule that includes regular oil analysis can help monitor lubricant effectiveness and wear metal levels, ensuring optimal performance. Partnering with suppliers who offer guidance on proper lubrication techniques and maintenance practices can further streamline operations. Consider also integrating advanced lubrication systems that automate oil delivery, reducing the risk of human error and ensuring consistent lubrication without excessive manual intervention.

Scenario 2: Space Constraints in Equipment Design

The Problem:

Another common pain point for B2B buyers is the challenge of integrating worm motor gears into compact equipment designs. Many industries, such as packaging and food processing, require efficient use of space while maintaining high torque output. However, the bulky nature of traditional gear systems can lead to design limitations, complicating installation and reducing overall equipment efficiency. Buyers often struggle to find solutions that balance performance with the need for compactness.

Illustrative image related to worm motor gear

The Solution:

To address space constraints, buyers should explore compact worm gear motor options, such as those featuring a UNICASE design. This design integrates all components into a single housing, significantly reducing the footprint while enhancing torque and load capacity. When sourcing worm gear motors, prioritize suppliers that offer modular systems allowing for customized configurations to fit specific space requirements. Additionally, consider working with engineers to optimize the layout of the motor within the equipment, ensuring that all components are efficiently aligned. This approach not only maximizes space but also improves overall system performance.

Scenario 3: Difficulty in Achieving Desired Speed and Torque Ratios

The Problem:

B2B buyers often encounter difficulties when trying to achieve the desired speed and torque ratios using worm motor gears. The unique design of worm gears allows for high reduction ratios, but achieving specific operational parameters can be complex. Buyers may find that standard configurations do not meet their needs, leading to inefficiencies and performance issues in critical applications such as conveyor systems or automation.

The Solution:

To effectively achieve desired speed and torque ratios, it is essential to work closely with manufacturers who can provide customized solutions. Buyers should specify their exact requirements, including load conditions, expected speeds, and operational environments, to ensure the right gear ratios are achieved. Utilizing simulation software during the design phase can also help in visualizing performance outcomes and adjusting specifications accordingly. Additionally, selecting suppliers that offer a range of gear ratios and the flexibility to create tailored solutions will empower buyers to optimize their systems for maximum efficiency and effectiveness. Regular testing and performance assessments should be implemented post-installation to make any necessary adjustments swiftly.

Strategic Material Selection Guide for worm motor gear

What Are the Key Materials Used in Worm Motor Gear Manufacturing?

When selecting materials for worm motor gears, several factors must be considered to ensure optimal performance and longevity in various applications. The choice of material impacts not only the mechanical properties but also the overall cost and suitability for specific environments. Below, we analyze four common materials used in the manufacturing of worm motor gears: steel, brass, aluminum, and plastic.

How Does Steel Perform in Worm Motor Gear Applications?

Steel is the most commonly used material for worm gears due to its excellent mechanical properties. It typically offers high tensile strength, good wear resistance, and the ability to withstand high temperatures and pressures.

Pros: Steel’s durability makes it suitable for heavy-duty applications, while its availability and ease of machining contribute to lower manufacturing costs. Additionally, heat treatment processes can enhance its hardness and wear resistance.

Cons: However, steel is prone to corrosion if not properly treated, which can be a significant drawback in humid or corrosive environments. The weight of steel can also be a disadvantage in applications where weight savings are critical.

Impact on Application: Steel is compatible with a wide range of lubricants, making it versatile across various media. However, buyers must ensure that the specific grade of steel used meets local compliance standards, such as ASTM in the U.S. or DIN in Europe.

What Are the Advantages of Using Brass for Worm Gears?

Brass is another popular choice for worm gears, particularly in applications requiring lower friction and good corrosion resistance. Its natural lubricity reduces wear, making it ideal for applications with frequent start-stop cycles.

Pros: Brass gears are lightweight and have excellent machinability, allowing for intricate designs. They also resist corrosion, which is advantageous in moist environments.

Cons: The primary limitation of brass is its lower strength compared to steel, making it unsuitable for high-load applications. Furthermore, brass can be more expensive than steel, impacting overall project budgets.

Impact on Application: Brass is commonly used in applications such as small machinery and consumer products. Compliance with standards such as JIS in Japan may be necessary for international buyers.

How Does Aluminum Compare as a Material for Worm Gears?

Aluminum is increasingly being used in worm gear applications due to its lightweight nature and good corrosion resistance. It offers a favorable strength-to-weight ratio, making it ideal for applications where weight is a concern.

Pros: Aluminum is easy to machine and can be anodized for additional corrosion protection. Its lightweight nature can lead to energy savings in applications requiring frequent motion.

Cons: However, aluminum may not withstand high temperatures and pressures as effectively as steel, limiting its use in heavy-duty applications. It can also be more expensive than steel, depending on the alloy used.

Impact on Application: Aluminum is suitable for applications in the automotive and aerospace industries. Buyers must consider local compliance standards, such as EN standards in Europe, to ensure material suitability.

What Role Does Plastic Play in Worm Gear Manufacturing?

Plastic worm gears are often used in applications where noise reduction and weight savings are critical. Materials such as nylon or acetal provide good wear resistance and are often self-lubricating.

Pros: The primary advantage of plastic gears is their ability to operate quietly and with minimal lubrication. They are also resistant to corrosion and can be produced at a lower cost than metal gears.

Cons: The main limitation is their lower strength and thermal stability compared to metals, making them unsuitable for high-load or high-temperature applications.

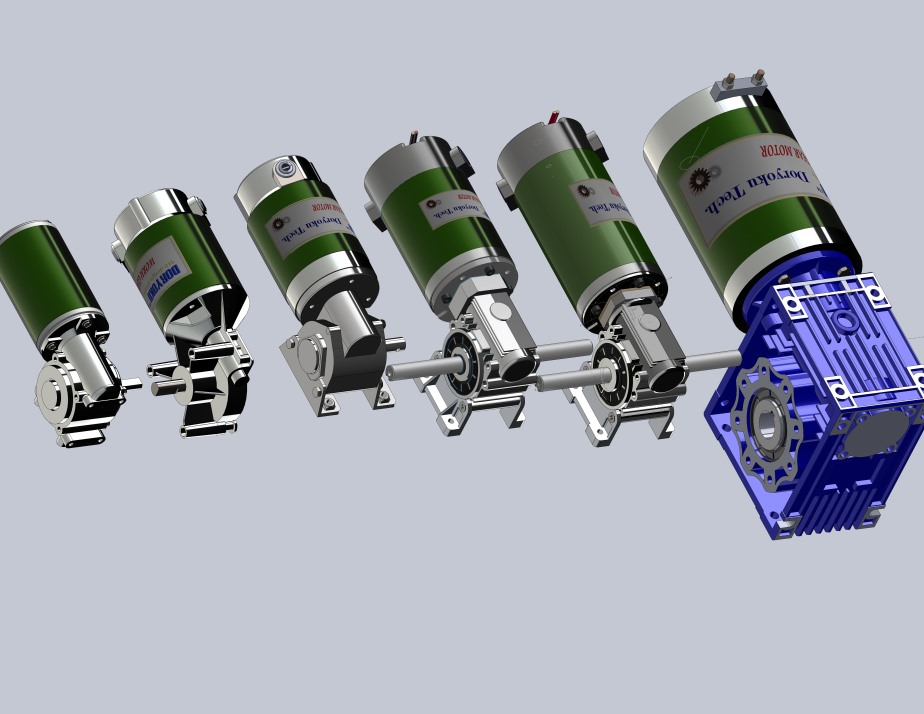

Illustrative image related to worm motor gear

Impact on Application: Plastic gears are commonly used in consumer electronics and household appliances. International buyers should ensure that the selected plastic complies with relevant safety and environmental standards.

Summary Table of Material Selection for Worm Motor Gears

| Material | Typical Use Case for worm motor gear | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty applications requiring high strength | Excellent durability and wear resistance | Prone to corrosion if untreated | Medium |

| Brass | Small machinery and consumer products | Natural lubricity and corrosion resistance | Lower strength compared to steel | High |

| Aluminum | Automotive and aerospace applications | Lightweight and good corrosion resistance | Limited high-temperature performance | Medium |

| Plastic | Consumer electronics and household appliances | Quiet operation and low cost | Lower strength and thermal stability | Low |

This material selection guide provides essential insights for B2B buyers in various regions, enabling them to make informed decisions based on application requirements, compliance standards, and overall cost considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for worm motor gear

What Are the Key Manufacturing Processes for Worm Motor Gear?

The manufacturing of worm motor gears involves a series of well-defined processes that ensure efficiency, precision, and durability. The main stages include material preparation, forming, assembly, and finishing, each critical to the overall performance of the worm gear.

How is Material Prepared for Worm Motor Gear Production?

The first step in manufacturing worm motor gears is material preparation, which typically involves selecting high-quality metals such as steel or brass. The choice of material is crucial as it influences the gear’s strength, wear resistance, and overall longevity. Materials are often subjected to heat treatment processes to enhance their mechanical properties, ensuring they can withstand the high loads and stresses they will encounter in operation.

After selecting the appropriate material, it is cut into manageable sizes and shapes, ready for further processing. This preparation phase may also include surface treatments to improve corrosion resistance, especially important in applications such as food processing or pharmaceuticals.

What Techniques Are Used in the Forming Stage of Worm Gear Manufacturing?

The forming stage is where the raw material is shaped into the components of the worm motor gear. This process typically employs techniques such as:

-

Machining: Precision machining is employed to create the worm and wheel profiles. CNC (Computer Numerical Control) machining is often utilized for its accuracy and ability to produce complex geometries.

-

Hobbing: A specialized gear-cutting process used to produce the worm gear’s teeth. This technique ensures that the teeth are cut to the precise angles necessary for efficient meshing with the worm.

-

Forging: In some cases, forging may be employed to enhance the material’s properties by improving its grain structure. This is particularly relevant for high-load applications where strength is critical.

The combination of these techniques allows manufacturers to produce gears that meet stringent performance criteria, ensuring reliability in demanding applications.

How Are Worm Motor Gears Assembled?

Once the individual components are formed, the next step is assembly. This process involves fitting the worm into the gear wheel and securing them within a housing. Key considerations during assembly include:

-

Alignment: Proper alignment of the worm and wheel is essential to prevent premature wear and ensure smooth operation.

-

Lubrication: The assembly stage also includes the application of appropriate lubricants, which are critical for reducing friction and heat generation during operation. High-viscosity lubricants are often required to accommodate the sliding contact between the worm and the wheel.

-

Sealing: Effective sealing solutions are implemented to protect the internal components from dust and moisture, enhancing the gear’s operational lifespan.

What Finishing Processes Are Necessary for Worm Motor Gears?

Finishing processes play a significant role in the final quality of worm motor gears. These processes may include:

-

Surface Treatment: Techniques such as anodizing or plating can be applied to improve corrosion resistance. In hygienically sensitive applications, smooth surfaces that can be easily cleaned are essential.

-

Quality Inspection: Final inspections are conducted to verify that the gears meet all design specifications and quality standards. This may include dimensional checks and surface quality assessments.

-

Packaging: The final step involves careful packaging to protect the gears during transit. Proper packaging also serves to communicate key information such as handling instructions and compliance certifications.

What Quality Assurance Measures Are Implemented in Worm Motor Gear Manufacturing?

Quality assurance is integral to the manufacturing process of worm motor gears, ensuring that products meet international and industry-specific standards.

Illustrative image related to worm motor gear

Which International Standards Should B2B Buyers Be Aware Of?

Quality control in worm motor gear manufacturing often adheres to international standards such as ISO 9001, which sets forth requirements for a quality management system. Compliance with these standards is essential for ensuring consistent quality and customer satisfaction.

Industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may also be applicable, depending on the intended application of the gears.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are established at various stages of the manufacturing process, including:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials for compliance with specifications before they enter the production line.

-

In-Process Quality Control (IPQC): During production, ongoing inspections are conducted to monitor manufacturing processes and identify any deviations from standards.

-

Final Quality Control (FQC): At the end of the production process, a comprehensive inspection is performed to ensure that the finished gears meet all required specifications and performance standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those sourcing from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are actionable steps:

-

Conduct Audits: Regular audits of the manufacturing facilities can provide insights into the supplier’s adherence to quality standards and operational practices.

-

Request Quality Reports: Buyers should request detailed quality reports, including inspection results and compliance certifications, to assess the supplier’s commitment to quality.

-

Engage Third-Party Inspectors: Utilizing independent third-party inspection services can help verify the quality of products before shipment, providing an additional layer of assurance.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

International buyers should be aware of specific nuances in quality control that may differ by region. For example, regulatory requirements and standards may vary significantly between countries. Understanding these differences is essential to ensure compliance and avoid potential delays or issues in the supply chain.

Additionally, language barriers and cultural differences may affect communication regarding quality expectations. It is advisable to establish clear communication channels and possibly engage local representatives who understand the regional market dynamics.

By thoroughly understanding the manufacturing processes and quality assurance measures in place for worm motor gears, B2B buyers can make informed decisions, ensuring that they source products that meet their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘worm motor gear’

Introduction

Sourcing worm motor gears for your industrial applications is a critical decision that can significantly impact operational efficiency and product reliability. This guide provides a practical checklist to help B2B buyers navigate the procurement process, ensuring that you make informed choices tailored to your specific needs.

Step 1: Define Your Technical Specifications

Understanding your technical requirements is the first step in sourcing worm motor gears. Consider factors such as torque, speed, and the type of load the motor will handle. Additionally, identify the environment in which the motor will operate, such as exposure to moisture or chemicals, which can dictate the materials and protective features required.

Step 2: Research Different Types of Worm Gear Motors

Not all worm gear motors are created equal; they come in various configurations and materials. Research options like UNICASE designs for compactness and high torque, or wash-down versions for hygienic applications in food processing. Knowing the distinctions helps you select a motor that aligns perfectly with your operational needs.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers who specialize in worm gear technology and have a proven track record of reliability and quality.

Step 4: Verify Supplier Certifications

Ensure that potential suppliers hold relevant industry certifications, such as ISO 9001 or specific quality assurance standards. Certifications indicate a commitment to quality and can provide assurance that the products meet international standards. This step is particularly important when sourcing from regions with varying manufacturing practices.

Step 5: Assess Customization Options

Customization can be key to achieving the best performance from your worm gear motors. Inquire whether suppliers offer modular components or tailored solutions that allow for flexibility in design. This can include options for different motor types, gear ratios, or housing configurations, which can be critical for meeting specific application needs.

Step 6: Review Lubrication and Maintenance Requirements

Worm gear motors often have unique lubrication needs due to their sliding contact mechanism. Verify that the supplier provides detailed information on the required lubricants, maintenance schedules, and any specialized equipment needed for upkeep. Understanding these requirements upfront can help you avoid operational disruptions later.

Step 7: Request Samples or Prototypes

Whenever possible, request samples or prototypes to evaluate the quality and performance of the worm motor gears. Testing in your operational environment can reveal compatibility issues or performance limitations that may not be apparent from specifications alone. This step allows you to make data-driven decisions based on real-world performance.

By following this checklist, you can ensure a comprehensive approach to sourcing worm motor gears, ultimately leading to a successful procurement process that meets your operational needs.

Comprehensive Cost and Pricing Analysis for worm motor gear Sourcing

What Are the Key Cost Components of Worm Motor Gear Sourcing?

When sourcing worm motor gears, understanding the cost structure is vital for effective budgeting and procurement. The primary cost components include:

-

Materials: The quality of materials significantly impacts the cost. Common materials for worm gears include steel for the worm and brass or bronze for the wheel. Higher-grade materials enhance durability and performance but increase costs.

-

Labor: Labor costs vary by region and manufacturing processes. Skilled workers are essential for precision machining and assembly, particularly for custom gear solutions.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, directly affecting pricing.

-

Tooling: Custom tooling may be required for specialized gear designs, which can add to the initial costs. However, investing in quality tooling can lead to better long-term efficiencies.

-

Quality Control (QC): Implementing rigorous QC measures is crucial, especially in sectors like food and pharmaceuticals. Enhanced QC processes may increase costs, but they also ensure compliance with industry standards and reduce the risk of product failure.

-

Logistics: Shipping and handling costs can vary dramatically based on the destination, shipment size, and chosen logistics partner. Additionally, customs duties and tariffs can add unforeseen expenses for international buyers.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure business viability. Understanding the supplier’s pricing model can provide insights into potential negotiation points.

What Factors Influence Pricing for Worm Motor Gears?

Several factors can influence the pricing of worm motor gears, particularly in an international B2B context:

-

Volume/MOQ: Purchasing in larger volumes often leads to discounted pricing. Suppliers may have minimum order quantities (MOQ) that affect overall cost; negotiating these can lead to better pricing.

-

Specifications/Customization: Custom gears tailored to specific applications may incur additional costs. Buyers should weigh the need for customization against the potential benefits of off-the-shelf solutions.

-

Materials: The choice of materials directly affects pricing. Premium materials may offer longer lifespans and better performance but come at higher initial costs.

-

Quality and Certifications: Gears that meet international quality standards (such as ISO or CE certifications) may command higher prices. However, they also provide assurance of reliability, which can reduce total ownership costs.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while new entrants may offer lower prices to gain market share.

-

Incoterms: Understanding shipping terms and conditions is crucial. Incoterms dictate who bears the cost of shipping, insurance, and tariffs, which can affect the overall budget significantly.

What Tips Can Help Buyers Negotiate Better Pricing?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, strategic negotiation and cost-awareness are key:

Illustrative image related to worm motor gear

-

Negotiate Terms: Engage in discussions regarding payment terms, delivery timelines, and MOQs. Flexibility on both sides can lead to mutually beneficial agreements.

-

Focus on Total Cost of Ownership (TCO): Instead of solely focusing on the initial purchase price, consider the long-term costs associated with maintenance, durability, and potential downtime. This approach can justify higher upfront costs for more reliable products.

-

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing, preferential treatment, and insights into future pricing trends.

-

Research Market Pricing: Understanding the market landscape can empower buyers during negotiations. Keeping abreast of trends and pricing benchmarks helps in making informed purchasing decisions.

Disclaimer on Indicative Prices

Prices for worm motor gears can vary significantly based on the aforementioned factors. It is essential for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing and to account for local economic conditions, regulatory requirements, and logistical considerations.

Alternatives Analysis: Comparing worm motor gear With Other Solutions

Exploring Alternatives to Worm Motor Gears in Industrial Applications

In the quest for optimal drive solutions, businesses often evaluate various gear technologies to determine the best fit for their operational needs. Worm motor gears, known for their high reduction ratios and compact design, are a popular choice. However, other alternatives also exist, each offering unique advantages and disadvantages. This section will delve into how worm motor gears compare with two viable alternatives: helical gear systems and planetary gear systems.

| Comparison Aspect | Worm Motor Gear | Helical Gear System | Planetary Gear System |

|---|---|---|---|

| Performance | High torque with compact design | Good load handling and efficiency | Excellent torque density and compactness |

| Cost | Moderate to high initial cost | Moderate initial investment | Higher initial cost, but very efficient |

| Ease of Implementation | Requires careful lubrication | Easier to implement with standard setups | More complex installation and alignment |

| Maintenance | Regular lubrication needed | Low maintenance, high durability | Moderate maintenance, depends on load |

| Best Use Case | Intralogistics, food industry | General machinery, automotive | Robotics, aerospace, and high torque applications |

What Are the Pros and Cons of Helical Gear Systems Compared to Worm Motor Gears?

Helical gear systems are an alternative that offers smooth operation and high efficiency. They are characterized by angled teeth that engage gradually, leading to reduced noise and vibration. The primary advantage of helical gears is their ability to handle high loads while maintaining efficiency. They are easier to implement in standard machinery setups, making them a popular choice across various industries. However, they can be less compact than worm gears and may require additional components for load distribution. Additionally, they typically involve higher manufacturing costs due to their complex design.

Illustrative image related to worm motor gear

How Do Planetary Gear Systems Stack Up Against Worm Motor Gears?

Planetary gear systems, also known as epicyclic gears, consist of a central sun gear, planet gears, and a ring gear. They are designed for high torque density in a compact form factor, making them ideal for applications requiring significant power in limited space. Planetary systems excel in providing high efficiency and durability, suitable for demanding environments like robotics and aerospace. However, their complexity can pose challenges during installation and maintenance. Furthermore, the initial investment is usually higher than that for worm motor gears, which might deter some buyers.

How Should B2B Buyers Choose the Right Gear Solution for Their Needs?

When selecting a gear solution, B2B buyers should consider specific operational requirements, including load capacity, available space, and cost constraints. Worm motor gears are ideal for applications requiring high reduction ratios and compactness, particularly in industries like intralogistics and food processing. In contrast, helical gears may serve better in general machinery applications where efficiency is paramount. For applications demanding high torque in confined spaces, planetary gears could be the optimal choice despite their higher cost. Ultimately, a thorough analysis of operational needs, budget, and long-term maintenance considerations will guide buyers to the most suitable gear technology.

Essential Technical Properties and Trade Terminology for worm motor gear

What Are the Key Technical Properties of Worm Motor Gears?

Understanding the technical specifications of worm motor gears is crucial for B2B buyers who are looking for reliable and efficient drive solutions. Here are some essential properties to consider:

1. Material Grade

Worm gears are typically made from materials such as steel, bronze, or aluminum. The choice of material affects strength, durability, and corrosion resistance. For instance, steel offers high strength and is ideal for heavy-duty applications, while bronze provides excellent wear resistance and is often used in applications with higher corrosion potential. Selecting the appropriate material grade ensures that the gear can withstand operational demands and environmental conditions.

2. Gear Ratio

The gear ratio defines the relationship between the input and output speeds of the motor. Worm gears are known for their high reduction ratios, which can range from 5:1 to over 100:1. This feature allows for significant torque multiplication and speed reduction in a compact design. For B2B buyers, understanding the gear ratio is essential to ensure the motor meets the specific performance requirements of their applications.

3. Load Capacity

Load capacity indicates the maximum load that a worm gear can handle without failure. This property is critical for applications involving heavy loads, such as in industrial machinery and automation systems. Buyers must evaluate load capacity to ensure that the selected gear can operate safely and efficiently under expected conditions, preventing premature wear or breakdown.

4. Efficiency

Efficiency refers to the ratio of output power to input power, often expressed as a percentage. Worm gears typically exhibit lower efficiency (around 50-90%) compared to other gear types due to sliding friction. Understanding efficiency is vital for B2B buyers, as it impacts energy consumption, operational costs, and overall system performance.

5. Lubrication Requirements

Worm gears require specific lubricants to minimize sliding friction and wear. High-viscosity lubricants (ISO 460 or higher) are often necessary due to the unique sliding action between the worm and the wheel. Buyers must be aware of lubrication needs to maintain optimal performance and extend the lifespan of the gear.

What Are the Common Trade Terms Associated with Worm Motor Gears?

Familiarity with industry jargon can enhance communication and facilitate smoother transactions. Here are some key terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are sold under another company’s brand. In the context of worm gears, understanding OEM relationships can help buyers ensure they are sourcing quality components that meet industry standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers as it affects inventory management and purchasing decisions. Knowing the MOQ helps in planning procurement strategies and budgeting.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. For buyers of worm motor gears, issuing an RFQ can streamline the procurement process, allowing for comparative analysis of prices and terms from different suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that define the responsibilities of buyers and sellers in the shipping process. Understanding Incoterms is essential for B2B transactions, as they clarify who is responsible for costs, risks, and logistics, ensuring smooth international trade.

5. Lead Time

Lead time is the amount of time it takes from placing an order to receiving the product. For worm motor gears, knowing the lead time helps buyers plan their projects and manage schedules effectively, ensuring that they have the necessary components when needed.

In summary, being knowledgeable about the technical properties and trade terminology related to worm motor gears can significantly enhance the decision-making process for B2B buyers, leading to more informed purchases and successful applications.

Navigating Market Dynamics and Sourcing Trends in the worm motor gear Sector

What Are the Current Market Dynamics and Key Trends Impacting the Worm Motor Gear Sector?

The worm motor gear market is witnessing significant transformations driven by technological advancements and evolving customer needs. One of the primary global drivers is the demand for high-efficiency, compact drive systems, particularly in industries such as intralogistics, packaging, and food processing. As businesses aim to optimize performance while minimizing space, worm gear motors are increasingly favored for their high torque output and compact designs.

Emerging B2B technologies such as Industry 4.0 and IoT are reshaping sourcing strategies as companies seek integrated solutions that enhance operational efficiency and predictive maintenance capabilities. For international B2B buyers in regions like Africa, South America, the Middle East, and Europe, this means sourcing from manufacturers who not only provide high-quality products but also leverage smart technology to ensure reliability and efficiency.

Moreover, sustainability is becoming a pivotal consideration in the sourcing process. Buyers are increasingly prioritizing suppliers that incorporate eco-friendly practices in their manufacturing processes, including energy-efficient designs and recyclable materials. For instance, the use of modular components in worm gear motors allows for tailored solutions that can adapt to changing operational needs, reducing waste and improving resource utilization.

How Important Is Sustainability and Ethical Sourcing in the Worm Motor Gear Sector?

Sustainability and ethical sourcing are no longer optional considerations for B2B buyers in the worm motor gear market; they are essential components of a competitive sourcing strategy. The environmental impact of manufacturing processes and product life cycles is under scrutiny, compelling companies to adopt greener practices. This includes the use of eco-friendly materials, energy-efficient production methods, and a commitment to reducing carbon footprints throughout the supply chain.

Buyers are increasingly seeking suppliers who can provide ‘green’ certifications and demonstrate compliance with international environmental standards. For example, materials that are recyclable or sourced from sustainable practices are becoming more sought after. Additionally, ethical labor practices and transparency in supply chains are critical. Buyers are now more inclined to partner with manufacturers who can guarantee fair labor practices and responsible sourcing of raw materials.

Incorporating sustainability into sourcing decisions not only enhances brand reputation but also aligns with the growing consumer preference for environmentally responsible products. As a result, companies that prioritize ethical sourcing can differentiate themselves in a competitive marketplace while contributing positively to global sustainability efforts.

Illustrative image related to worm motor gear

What Is the Historical Context of Worm Motor Gears in B2B Applications?

Worm motor gears have a rich history that dates back to their invention in ancient mechanical devices. Initially utilized for simple applications, their design evolved significantly over the centuries, leading to the modern variants we see today. The introduction of electric motors in the 19th century propelled the use of worm gears into new industrial applications, enabling efficient power transmission in machinery.

By the late 20th century, advancements in materials and manufacturing technologies facilitated the development of robust and compact worm gear units. These innovations have made them indispensable in various sectors, from food processing to robotics. The modularity and versatility of contemporary worm gear systems allow for tailored solutions that cater to specific operational requirements, reflecting the ongoing evolution of this technology to meet modern industrial challenges.

In summary, the worm motor gear market is shaped by significant technological advancements, a shift towards sustainability, and an increasing emphasis on ethical sourcing. For international B2B buyers, understanding these dynamics is critical to making informed sourcing decisions that align with both operational needs and corporate values.

Frequently Asked Questions (FAQs) for B2B Buyers of worm motor gear

-

How do I choose the right worm motor gear for my application?

Selecting the appropriate worm motor gear requires understanding your specific application needs, such as load capacity, speed reduction requirements, and space constraints. Consider the torque and power density specifications to ensure the motor can handle your application. Additionally, evaluate the environment—whether it’s exposed to harsh conditions or requires hygienic standards—and choose models with suitable features like corrosion protection or easy cleaning. Consulting with manufacturers or suppliers can also provide insights into the best options tailored for your application. -

What are the advantages of using worm gear motors in industrial applications?

Worm gear motors offer several benefits, including high gear ratios and compact designs that save space. They are particularly effective for applications requiring significant torque reduction without the complexity of multiple gear sets. Additionally, worm gears provide a unidirectional drive, preventing back-driving, which enhances safety in applications like conveyors. Their robust construction and ability to handle high overloads make them ideal for demanding industries such as packaging, logistics, and food processing. -

What customization options are available for worm motor gears?

Many manufacturers provide customization options for worm motor gears to meet specific operational requirements. Customizations may include variations in gear ratios, housing designs, and materials to enhance durability or corrosion resistance. You can also specify features like flange or foot-mounted configurations and select from different motor types (e.g., IEC or NEMA). Engaging with suppliers early in the design process can help ensure the final product aligns with your operational needs. -

What are the typical minimum order quantities (MOQ) for worm gear motors?

Minimum order quantities for worm gear motors can vary significantly depending on the supplier and the specific motor configuration. Some manufacturers may have a MOQ of 10 units, while others might require larger orders for custom designs. It’s crucial to discuss your needs with suppliers, as they may offer flexibility for first-time buyers or small businesses. Understanding the MOQ can help you plan your procurement strategy effectively and avoid excess inventory. -

How do I ensure quality assurance when sourcing worm gear motors?

To ensure quality assurance, start by vetting potential suppliers through their certifications, production processes, and industry reputation. Request samples or prototypes to assess performance and reliability. Additionally, inquire about their quality control measures, such as testing standards and inspection procedures. Establishing clear specifications and expectations in your purchase agreement can also help mitigate risks associated with product quality. -

What payment terms should I expect when sourcing internationally?

Payment terms for international orders can vary widely based on the supplier and the nature of the transaction. Common options include advance payment, letters of credit, or payment upon delivery. It’s advisable to negotiate favorable terms that align with your cash flow and risk tolerance. Additionally, consider using escrow services for large transactions to ensure that both parties meet their contractual obligations before funds are released. -

What logistics considerations should I keep in mind when importing worm gear motors?

When importing worm gear motors, logistics considerations include shipping methods, lead times, and customs regulations. Evaluate the best shipping options (air vs. sea) based on urgency and budget. Ensure compliance with local import regulations and tariffs, which can affect total costs. Working with a logistics partner experienced in international shipping can streamline the process and help navigate any challenges that arise during transportation. -

How can I evaluate the technical support offered by worm gear motor suppliers?

Evaluating technical support from suppliers involves assessing their responsiveness, expertise, and resources. Inquire about their customer service channels, such as phone, email, or live chat, and their availability for troubleshooting issues. Request information about technical documentation, installation guides, and warranty policies. A supplier that offers comprehensive support can be invaluable, especially for complex applications that may require ongoing assistance and maintenance.

Top 4 Worm Motor Gear Manufacturers & Suppliers List

1. Machinery Lubrication – Worm Gears

Domain: machinerylubrication.com

Registered: 2001 (24 years)

Introduction: Worm gears consist of a shaft with a spiral thread that engages with a toothed wheel, typically made of steel (worm) and brass (wheel). They change rotational movement by 90 degrees and are known for high reduction ratios, allowing for increased torque or reduced speed with fewer moving parts. However, they require specialized high-viscosity lubricants (ISO 320 and greater) due to sliding friction…

2. RobotShop – High Torque Self-Locking Worm Gear Motor

Domain: robotshop.com

Registered: 2004 (21 years)

Introduction: High Torque Gearmotor Self-Locking Worm Gear Motor with Encoder, 12V, 450RPM

3. OMC – Worm Drive Gearbox

Domain: omc-stepperonline.com

Registered: 2013 (12 years)

Introduction: This company, OMC – Worm Drive Gearbox, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Maedler – Small Worm Geared DC-Motors

Domain: maedlernorthamerica.com

Registered: 2020 (5 years)

Introduction: Small Worm Geared DC-Motors SFS Size 2, available in 12 V and 24 V, with a torque capacity of up to 5 Nm. Various models include: 1. 12V, i=62:1, idle speed 25/min, PN: 43047012, price: $180.48. 2. 24V, i=62:1, idle speed 35/min, PN: 43047024, price: $179.78. 3. 24V, i=62:1, idle speed 50/min, PN: 43047124, price: $152.89. 4. 24V, i=62:1, idle speed 95/min, PN: 43047224, price: $164.98. 5. 24V, i=…

Strategic Sourcing Conclusion and Outlook for worm motor gear

In conclusion, the strategic sourcing of worm motor gears offers significant advantages for businesses aiming to enhance operational efficiency and reliability. By understanding the unique attributes of worm gear systems—such as their high torque capabilities, compact design, and low maintenance requirements—international buyers can make informed decisions that align with their specific application needs.

The flexibility provided by modular designs and the robustness of these systems ensure they can meet the diverse demands of industries ranging from packaging to food processing. Moreover, investing in high-quality worm gear motors not only reduces the risk of failure due to fewer moving parts but also enhances overall productivity.

As the global market continues to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, leveraging strategic sourcing practices will be essential for staying competitive. Buyers are encouraged to explore partnerships with reputable manufacturers who offer tailored solutions to their unique challenges. Embrace the future of drive technology by investing in worm motor gears that can propel your operations to new heights. Take the next step toward optimization and reach out to suppliers today to discuss how these innovative solutions can benefit your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.