Unlocking Value: A Strategic Analysis of the Wire Rope Making Market

Introduction: Navigating the Global Market for wire rope making

In an increasingly interconnected world, sourcing high-quality wire rope is a critical challenge for B2B buyers across various industries. From construction and mining to maritime and logistics, the demand for durable and reliable wire ropes is paramount. This comprehensive guide on wire rope making addresses the complexities of navigating the global market, offering insights into the various types of wire ropes, their specific applications, and the factors influencing their costs.

International buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Germany and Vietnam, will find valuable information on how to vet suppliers effectively. The guide delves into the nuances of wire rope construction, including different materials, core types, and protective finishes, enabling buyers to make informed decisions tailored to their operational needs. Additionally, we explore the significance of compliance with international standards and certifications, ensuring that the selected products meet stringent safety and quality benchmarks.

By equipping B2B buyers with actionable insights and practical knowledge, this guide serves as a crucial resource for optimizing procurement strategies. Empowering businesses to navigate the complexities of wire rope sourcing will not only enhance operational efficiency but also contribute to the long-term success of their projects. Whether you are seeking specific rope configurations or evaluating supplier reliability, this guide is designed to facilitate informed purchasing decisions in a competitive global marketplace.

Understanding wire rope making Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Ordinary Lay | All wires are of the same size; resistant to kinking. | Construction, mining, and general lifting. | Pros: Good resistance to crushing; easy handling. Cons: Less torque resistance compared to Lang’s lay. |

| Lang’s Lay | Outer layer wires twisted in the same direction as strands. | Heavy lifting, marine applications. | Pros: Longer lifespan; better wearing surface. Cons: Can twist under load; not ideal for free-rotating ends. |

| Rotation Resistant | Constructed with alternating layer directions to prevent rotation. | Cranes, elevators, and other high-lift applications. | Pros: Minimizes rotation; enhances stability. Cons: More complex construction may increase costs. |

| Compacted Strand | Increased fill factor with compacted wire arrangement. | Heavy-duty applications requiring durability. | Pros: Higher strength; improved fatigue resistance. Cons: Higher manufacturing costs. |

| Stainless Steel Rope | Corrosion-resistant material, often encapsulated in plastic. | Marine, chemical industries, and outdoor use. | Pros: Excellent corrosion resistance; longevity. Cons: Higher upfront cost; may not be necessary for all applications. |

What are the characteristics and suitability of Ordinary Lay wire ropes for B2B buyers?

Ordinary Lay wire ropes feature strands where all wires are of uniform size, creating a robust structure that is particularly resistant to kinking. This type is widely used in construction, mining, and general lifting applications due to its straightforward design and handling ease. Buyers should consider the operational environment; while Ordinary Lay ropes are strong, they may lack the torque resistance needed for applications where rotation is unavoidable.

How does Lang’s Lay wire rope differ, and what are its key applications?

Lang’s Lay wire ropes have their outer layer of wires twisted in the same direction as the strands, enhancing their surface wear resistance. This design is particularly advantageous in heavy lifting and marine applications, where durability is critical. While Lang’s Lay ropes often last longer than Ordinary Lay counterparts, buyers must be cautious of their tendency to twist under load, making them less suitable for applications where one end is free to rotate.

Illustrative image related to wire rope making

What makes Rotation Resistant wire ropes a preferred choice in specific applications?

Rotation Resistant wire ropes are engineered with multiple layers of strands, each twisted in the opposite direction to counteract torque. This feature makes them ideal for cranes, elevators, and other high-lift applications where stability is paramount. Although they may come at a higher cost due to their complex construction, the benefits of reduced rotation and enhanced stability make them a worthwhile investment for businesses prioritizing safety and efficiency.

Why should buyers consider Compacted Strand wire ropes for heavy-duty needs?

Compacted Strand wire ropes are designed to maximize the fill factor by compacting the wires, resulting in a stronger rope suitable for heavy-duty applications. Their enhanced fatigue resistance makes them ideal for industries that require durability under extreme conditions. While the manufacturing costs may be higher, the long-term performance and strength benefits can justify the investment for B2B buyers focused on reliability and safety in demanding environments.

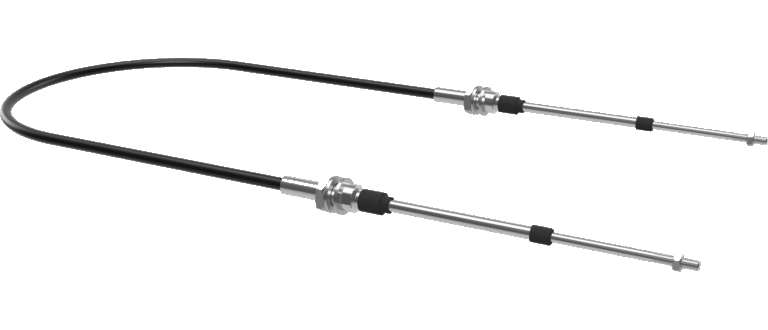

What are the advantages and considerations for Stainless Steel Rope in B2B applications?

Stainless Steel Ropes are known for their exceptional corrosion resistance, often encapsulated in plastic for added protection. They are widely used in marine, chemical, and outdoor applications where exposure to harsh environments is common. Buyers should weigh the higher upfront costs against the longevity and reduced maintenance needs of stainless steel options, as these ropes can provide significant long-term savings and reliability in challenging conditions.

Illustrative image related to wire rope making

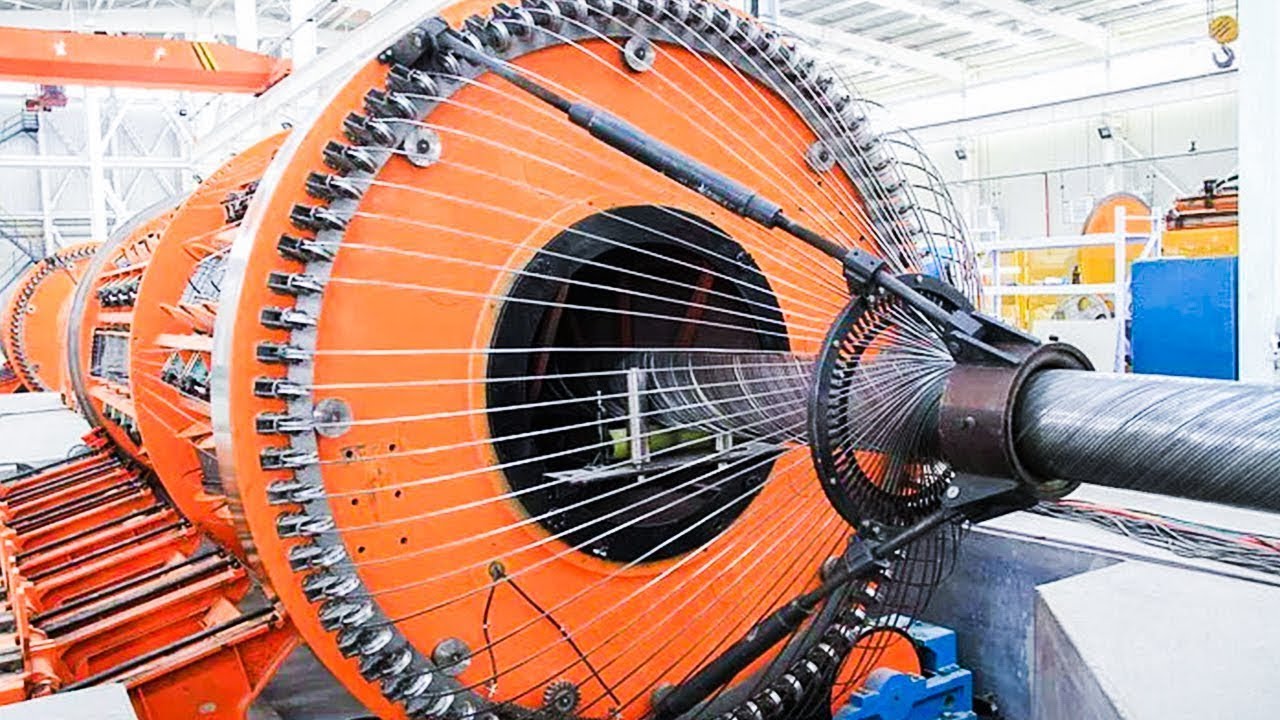

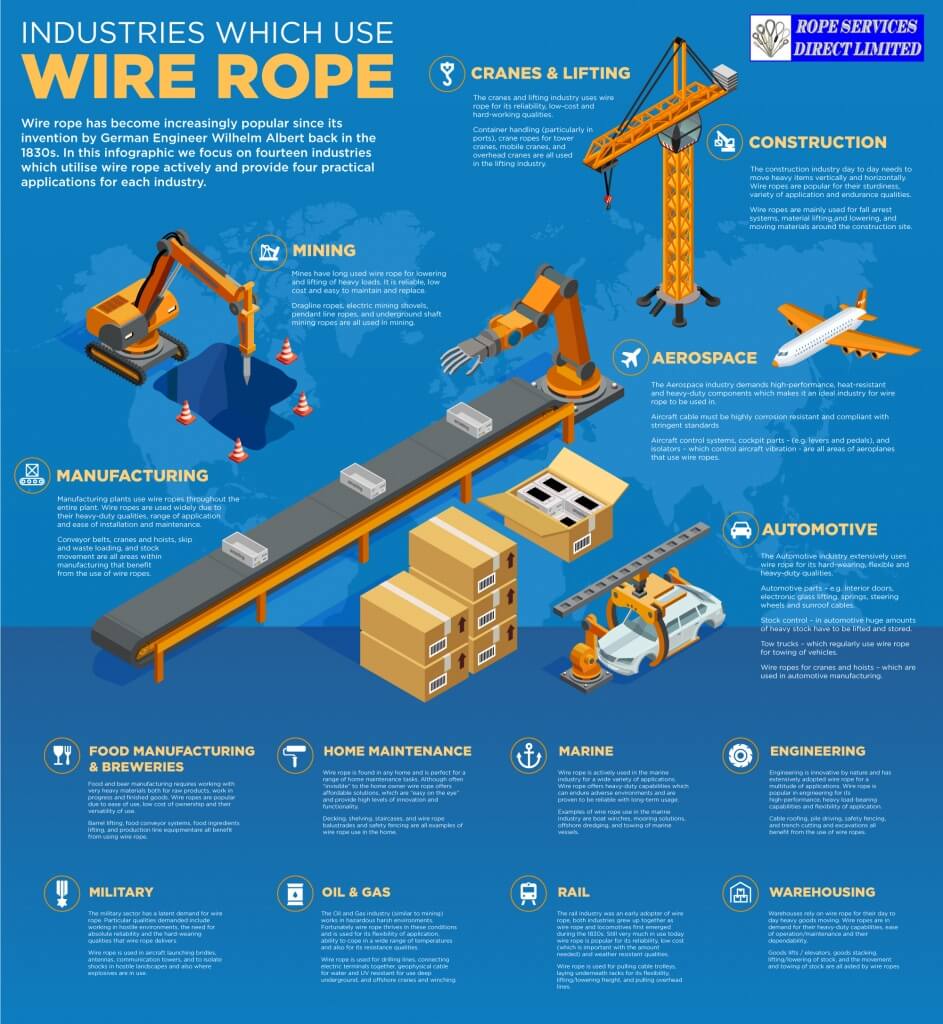

Key Industrial Applications of wire rope making

| Industry/Sector | Specific Application of Wire Rope Making | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Hoisting and Rigging Systems | Enhanced safety and efficiency in lifting operations | Compliance with local regulations and safety standards |

| Mining | Cable for Hoisting Equipment | Increased durability and load capacity | Material grade and environmental resistance |

| Marine and Shipping | Mooring Lines and Towing Cables | Improved safety and reliability under harsh conditions | Corrosion resistance and flexibility |

| Oil and Gas | Drilling and Lifting Operations | High tensile strength to withstand extreme conditions | Customized lengths and specific construction types |

| Transportation and Logistics | Load Securing and Lifting Gear | Effective handling of heavy loads, reducing downtime | Weight capacity and compatibility with existing systems |

How is Wire Rope Used in Construction?

In the construction sector, wire ropes are crucial for hoisting and rigging systems. These ropes facilitate the lifting of heavy materials and equipment, ensuring safety and efficiency on construction sites. International buyers should prioritize ropes that comply with local regulations and safety standards, as this not only enhances operational safety but also mitigates legal risks. Additionally, selecting ropes with high abrasion and corrosion resistance is essential for long-term use in varying weather conditions.

What Role Does Wire Rope Play in Mining?

Wire ropes are extensively used in mining for hoisting equipment, such as lifts and skips. Their construction allows for high tensile strength and flexibility, which are vital for navigating vertical shafts and heavy loads. Buyers from regions with rugged mining environments, like South America and Africa, must consider the material grade and environmental resistance of wire ropes to ensure longevity and reliability under extreme conditions.

How is Wire Rope Essential in Marine and Shipping Industries?

In the marine sector, wire ropes are employed for mooring lines and towing cables. Their ability to withstand harsh marine environments makes them indispensable for ensuring the safety and reliability of vessels. Buyers in this industry should focus on ropes that offer superior corrosion resistance and flexibility, as these features are critical for maintaining performance over time. Additionally, the rope’s compatibility with existing mooring systems is a key consideration for effective procurement.

Why is Wire Rope Important in Oil and Gas Operations?

The oil and gas industry relies on wire ropes for drilling and lifting operations, where high tensile strength is essential to withstand extreme conditions. These ropes must be capable of supporting heavy loads while maintaining performance integrity. Buyers should seek customized lengths and specific construction types tailored to their operational needs, ensuring that the ropes meet the rigorous demands of the sector. Furthermore, understanding the local supply chain can optimize sourcing strategies.

How is Wire Rope Used in Transportation and Logistics?

In transportation and logistics, wire ropes are integral for load securing and lifting gear, enabling effective handling of heavy loads. This application minimizes downtime and enhances operational efficiency. International buyers should evaluate the weight capacity of the wire ropes and ensure compatibility with their existing systems. Moreover, selecting ropes that provide adequate safety margins and durability can significantly reduce operational risks and improve overall productivity.

3 Common User Pain Points for ‘wire rope making’ & Their Solutions

Scenario 1: Inconsistent Quality of Wire Rope Affecting Operations

The Problem: One of the most pressing challenges faced by B2B buyers in the wire rope industry is the inconsistency in quality among different suppliers. This inconsistency can lead to operational inefficiencies, safety risks, and increased costs due to frequent rope failures or premature replacements. Buyers often struggle to find a supplier who meets their specific quality standards, particularly when dealing with high-stress applications such as construction, mining, or heavy lifting. The stakes are high; a subpar wire rope can lead to catastrophic failures, endangering workers and causing significant financial losses.

The Solution: To mitigate these risks, buyers should prioritize sourcing wire ropes from manufacturers with established reputations for quality and reliability. Conducting thorough due diligence is critical; this includes requesting certifications, inspecting quality assurance processes, and evaluating third-party testing results. Additionally, buyers can specify their requirements more clearly, ensuring that suppliers understand the exact standards they must meet. Utilizing a detailed technical specification document that outlines the required tensile strength, corrosion resistance, and construction type can also help in narrowing down potential suppliers. Regular audits and performance reviews of suppliers can further ensure ongoing compliance with quality standards.

Scenario 2: Difficulty in Selecting the Right Wire Rope for Specific Applications

The Problem: Many B2B buyers find it challenging to select the appropriate wire rope for their unique applications, leading to inefficiencies and operational risks. Wire ropes come in various constructions, materials, and finishes, each designed for specific use cases. Buyers may be overwhelmed by options such as galvanized vs. stainless steel, different lay types, and core configurations. This lack of clarity can result in the wrong choice, impacting performance and safety during operations.

Illustrative image related to wire rope making

The Solution: To streamline the selection process, buyers should invest time in understanding the specific requirements of their applications, including load capacities, environmental conditions, and required flexibility. Engaging with manufacturers for technical support can provide valuable insights. It’s beneficial to create a checklist that includes the application’s load requirements, environmental factors (like exposure to saltwater or chemicals), and the frequency of use. Furthermore, utilizing simulation tools or software that can model the performance of different wire rope types under various conditions can aid in making informed decisions. Buyers can also consider trialing a limited quantity of different wire rope types before making bulk purchases to evaluate their performance in real-world conditions.

Scenario 3: High Costs Associated with Wire Rope Maintenance and Replacement

The Problem: The maintenance and replacement costs of wire ropes can significantly impact a company’s bottom line. Frequent wear and tear, coupled with the need for regular inspections and replacements, can lead to unplanned downtime and operational delays. B2B buyers often express frustration over the financial burden that comes with maintaining wire ropes, particularly in industries with rigorous safety standards where compliance is non-negotiable.

The Solution: To effectively manage costs, buyers should focus on implementing a proactive maintenance program that includes regular inspections, proper lubrication, and training for operators on correct handling practices. Establishing a clear maintenance schedule can help identify wear early, preventing unexpected failures. Additionally, investing in high-quality wire ropes designed for durability can reduce the frequency of replacements. Buyers might also consider predictive maintenance technologies, such as sensors that monitor wire rope condition in real-time, enabling timely interventions before issues escalate. Collaborating with suppliers to receive ongoing support and training in wire rope management can also lead to long-term savings and improved safety outcomes.

Strategic Material Selection Guide for wire rope making

When selecting materials for wire rope manufacturing, it is essential to understand the properties, advantages, and limitations of various materials. This analysis focuses on four common materials used in wire rope making: carbon steel, stainless steel, galvanized steel, and synthetic fibers. Each material has unique characteristics that make it suitable for specific applications, particularly in diverse international markets.

What are the Key Properties of Carbon Steel for Wire Rope Making?

Carbon steel is the most widely used material in wire rope production due to its excellent strength-to-weight ratio. It typically exhibits high tensile strength and durability, making it suitable for heavy-duty applications. However, its performance can be affected by environmental factors, as it is prone to corrosion without protective coatings.

Illustrative image related to wire rope making

Pros: Carbon steel is relatively inexpensive and easy to manufacture, allowing for cost-effective production. It offers high load-bearing capabilities, making it ideal for construction and mining applications.

Cons: The primary limitation is its susceptibility to rust and corrosion, which can significantly reduce its lifespan in harsh environments. This necessitates additional protective measures, such as galvanization or coating.

Impact on Application: Carbon steel wire ropes are commonly used in construction, mining, and heavy lifting. However, in regions with high humidity or corrosive conditions, buyers must consider protective coatings to enhance longevity.

Illustrative image related to wire rope making

How Does Stainless Steel Compare in Wire Rope Manufacturing?

Stainless steel is known for its superior corrosion resistance, making it an excellent choice for applications exposed to harsh environments, such as marine or chemical industries. It maintains its strength and integrity even at elevated temperatures.

Pros: The primary advantage of stainless steel is its resistance to rust and corrosion, which significantly extends the service life of the wire rope. It also has a polished finish, which is aesthetically pleasing and easy to clean.

Cons: The main drawback is the higher cost compared to carbon steel. Manufacturing processes for stainless steel can also be more complex, leading to increased production costs.

Impact on Application: Stainless steel wire ropes are ideal for applications in coastal regions or industries where exposure to chemicals is common. Buyers should ensure compliance with international standards such as ASTM and DIN for quality assurance.

Illustrative image related to wire rope making

What Role Does Galvanized Steel Play in Wire Rope Applications?

Galvanized steel wire ropes are carbon steel ropes that have been coated with zinc to enhance corrosion resistance. This treatment allows them to perform well in moderately corrosive environments.

Pros: The galvanization process is relatively cost-effective, providing a balance between durability and affordability. Galvanized wire ropes are widely used in construction and agricultural applications due to their enhanced lifespan.

Cons: While galvanized steel offers better corrosion resistance than untreated carbon steel, it may not perform well in highly corrosive environments, such as saltwater. The zinc coating can also wear off over time, requiring periodic inspection and maintenance.

Impact on Application: Galvanized wire ropes are suitable for a variety of applications, including lifting and rigging. For buyers in humid regions, it is crucial to assess the level of exposure to corrosive elements to determine suitability.

How Do Synthetic Fibers Compare to Traditional Materials in Wire Rope Making?

Synthetic fibers, such as nylon or polyester, are increasingly being used in wire rope manufacturing due to their lightweight and high tensile strength. They are particularly advantageous in applications where weight reduction is critical.

Pros: Synthetic fiber ropes are resistant to corrosion, UV rays, and chemicals, making them suitable for a wide range of environments. They also exhibit excellent flexibility and ease of handling.

Cons: The primary limitation is their lower heat resistance compared to steel, which may restrict their use in high-temperature applications. Additionally, synthetic ropes may not have the same load-bearing capacity as steel ropes.

Impact on Application: Synthetic fiber ropes are ideal for marine applications, recreational activities, and situations where weight is a concern. International buyers should consider the specific environmental conditions and compliance with relevant standards.

Summary Table of Material Selection for Wire Rope Making

| Material | Typical Use Case for wire rope making | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Construction, mining | High strength and durability | Prone to corrosion | Low |

| Stainless Steel | Marine, chemical industries | Superior corrosion resistance | Higher cost and complex manufacturing | High |

| Galvanized Steel | Lifting, rigging | Cost-effective corrosion protection | Limited in highly corrosive environments | Medium |

| Synthetic Fibers | Marine, recreational | Lightweight and flexible | Lower heat resistance | Medium |

This guide provides essential insights into material selection for wire rope manufacturing, helping international B2B buyers make informed decisions that align with their specific application needs and environmental conditions.

Illustrative image related to wire rope making

In-depth Look: Manufacturing Processes and Quality Assurance for wire rope making

What Are the Main Stages in the Manufacturing Process of Wire Rope?

The manufacturing process of wire rope is intricate, involving several stages that ensure the final product meets stringent performance and safety standards. Understanding these stages is crucial for B2B buyers looking to source high-quality wire ropes.

How Is Material Prepared for Wire Rope Production?

The journey of wire rope begins with the selection of raw materials, primarily wire rods made from high-carbon steel. These rods undergo a series of processes including:

-

Wire Drawing: The wire rods are cold-drawn through a series of dies to achieve the desired diameter and tensile strength. This process not only reduces the diameter but also enhances the material’s mechanical properties.

-

Heat Treatment: Depending on the intended application, the drawn wire may undergo heat treatment to improve its hardness and flexibility. This is a critical step for achieving the required performance specifications.

-

Surface Treatment: The wire can be left untreated, galvanized, or made from stainless steel. Galvanization provides corrosion resistance, while stainless steel offers additional protection in extreme environments. Buyers should specify their requirements based on environmental conditions.

What Techniques Are Used for Forming Wire Rope?

Once the wire is prepared, it undergoes forming, where individual wires are twisted into strands:

-

Strand Formation: Wires are twisted together in a specific configuration to form strands. Common constructions include ordinary lay, Seale, and Warrington, each offering different benefits in terms of flexibility and load-bearing capacity.

-

Core Selection: The strands are then laid around a core, which can be made of fiber, steel, or plastic. The choice of core influences the rope’s strength, resistance to crushing, and overall performance under load.

-

Rope Closing: In this final forming step, the strands are twisted together to create the finished wire rope. The lay direction (right or left hand) is carefully chosen to minimize kinking and enhance performance.

How Is Quality Assurance Implemented in Wire Rope Manufacturing?

Quality assurance is paramount in wire rope manufacturing, ensuring that products meet international safety and performance standards. B2B buyers should be aware of the various checkpoints and certifications involved.

What Are the Relevant International Standards for Wire Rope Quality?

Manufacturers of wire ropes must adhere to various international standards to ensure product quality and safety:

Illustrative image related to wire rope making

- ISO 9001: This quality management standard outlines the requirements for consistent quality in manufacturing processes.

- CE Marking: Indicates compliance with European safety standards, essential for products sold in European markets.

- API Specifications: The American Petroleum Institute (API) provides standards that are particularly relevant for wire ropes used in oil and gas industries.

Buyers should ensure that their suppliers are certified to these standards, which can often be verified through documentation provided by the manufacturer.

What Are the Key Quality Control Checkpoints in Wire Rope Production?

Quality control (QC) checkpoints are integral to the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials for compliance with specifications before they enter the production process. This helps catch any defects early.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor processes and ensure that each stage adheres to quality standards. This includes checking dimensions, tensile strength, and surface finish.

-

Final Quality Control (FQC): After the wire rope is completed, it undergoes a final inspection to ensure that it meets all required specifications before shipping. This may include load testing to verify the minimum breaking load.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For B2B buyers, verifying the quality control measures of suppliers is essential for ensuring product reliability. Here are some strategies:

-

Supplier Audits: Conducting on-site audits of the manufacturing facility can provide insights into the production processes and quality control practices. This is particularly important for buyers from regions like Africa and South America, where local suppliers may vary in adherence to international standards.

-

Reviewing Quality Reports: Requesting detailed QC reports from suppliers can help assess their compliance with relevant standards. These reports should outline the results of IQC, IPQC, and FQC checks.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control processes. This is especially valuable for buyers operating in highly regulated industries.

What Testing Methods Are Commonly Used in Wire Rope Quality Assurance?

Various testing methods are employed to ensure that wire ropes meet the necessary performance criteria:

-

Tensile Testing: This tests the maximum load the wire rope can withstand before breaking. It is a fundamental measure of strength and is often required for certification.

-

Bending and Fatigue Testing: These tests simulate the conditions under which the rope will operate, helping to determine its longevity and performance in real-world applications.

-

Corrosion Resistance Testing: For ropes intended for use in harsh environments, tests are conducted to assess how well the materials resist corrosion over time.

How Do Certification Nuances Affect International B2B Buyers?

International buyers must navigate various certification nuances when sourcing wire ropes. For example:

Illustrative image related to wire rope making

-

Regional Standards: Different regions may have specific requirements that impact the certification process. For instance, European buyers may prioritize CE marking, while those in the Middle East may look for compliance with local standards.

-

Documentation Requirements: Buyers should ensure that their suppliers can provide all necessary documentation, including certificates of compliance and test reports. This is crucial for customs clearance and regulatory compliance.

-

Cultural Considerations: Understanding the cultural context of suppliers can facilitate better communication and compliance with quality standards. For example, buyers from Europe may have different expectations compared to those from Africa or South America regarding transparency and documentation.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing wire ropes, ensuring they receive products that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wire rope making’

To successfully procure wire rope making, B2B buyers must navigate a complex landscape of technical specifications and supplier evaluations. This practical guide outlines essential steps to streamline the sourcing process, ensuring that you obtain high-quality wire rope that meets your operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the wire rope meets your project’s requirements. Consider factors such as diameter, tensile strength, and construction type (e.g., 6×19, 6×36). Additionally, identify the environmental conditions the rope will face, such as exposure to corrosive substances or extreme temperatures, which can influence material choice.

Step 2: Research Industry Standards and Certifications

Understanding the relevant industry standards is vital for compliance and safety. Look for certifications such as ISO 9001 or EN standards that assure quality and reliability. Ensure that the products you are considering adhere to these standards, as this can significantly impact performance and safety in your applications.

Step 3: Evaluate Potential Suppliers

Thorough evaluation of suppliers is key to finding a reliable partner. Request detailed company profiles, including their manufacturing capabilities and experience in the wire rope sector. Seek references from other businesses in your industry to gauge their reliability and service quality.

- Check for production capacity: Ensure the supplier can meet your volume requirements.

- Assess lead times: Understand their delivery timelines to align with your project schedules.

Step 4: Request Product Samples

Before making a bulk purchase, request samples of the wire rope you are considering. Testing samples allows you to assess the quality, flexibility, and durability of the rope under real-world conditions. This step is essential to verify that the product meets your specifications and operational demands.

Step 5: Understand Pricing Structures

Explore the pricing models offered by different suppliers. Prices can vary significantly based on material quality, construction complexity, and order volume. Ensure you understand what factors contribute to the pricing and whether bulk discounts or long-term contracts are available.

- Negotiate terms: Don’t hesitate to discuss pricing, especially if you foresee a long-term partnership.

- Consider total cost of ownership: Evaluate not just the upfront costs but also maintenance and replacement costs over time.

Step 6: Review After-Sales Support and Warranty Policies

After-sales support is critical for long-term satisfaction with your wire rope purchase. Investigate the warranty terms and what support services the supplier provides, such as installation assistance or maintenance guidelines. A strong after-sales program can save you time and money in case of issues.

Illustrative image related to wire rope making

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier, ensure that all terms are clearly documented in a purchase agreement. This should include pricing, delivery schedules, quality standards, and support commitments. A well-defined agreement minimizes misunderstandings and lays the groundwork for a successful partnership.

By following these steps, B2B buyers can effectively navigate the wire rope procurement process, ensuring they make informed decisions that align with their operational needs and business goals.

Comprehensive Cost and Pricing Analysis for wire rope making Sourcing

What Are the Key Cost Components in Wire Rope Making?

Understanding the cost structure of wire rope production is essential for B2B buyers seeking effective sourcing strategies. The primary cost components include:

-

Materials: The foundation of wire rope is high-quality steel wire, often cold-drawn from wire rod. Prices can fluctuate based on market demand and the quality of steel (e.g., galvanized vs. stainless steel). Raw materials can account for 50-70% of the total production cost, making it critical to select suppliers who offer competitive pricing without sacrificing quality.

-

Labor: Labor costs can vary significantly by region. In countries with higher wage standards, such as Germany and parts of Europe, labor costs may represent 20-30% of the total manufacturing expenses. Conversely, countries in Africa or South America may offer lower labor costs, impacting overall pricing.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, and equipment maintenance. Overhead can add an additional 10-15% to the production costs. Efficient manufacturing processes can help mitigate these costs, so assessing a supplier’s operational efficiency is advisable.

-

Tooling: Initial tooling costs can be significant, especially for custom wire rope specifications. These costs can be amortized over larger production runs, which means buyers should consider their volume requirements when negotiating tooling fees.

-

Quality Control (QC): Stringent QC processes ensure that the wire ropes meet safety and performance standards. Investing in robust QC can add 5-10% to manufacturing costs, but it ultimately protects buyers from the risks associated with substandard products.

-

Logistics: Shipping costs are influenced by distance, transportation mode, and Incoterms used in the contract. International shipments may incur additional customs duties and tariffs, particularly when sourcing from outside the EU or the Americas. Logistics can contribute significantly to the total cost, often ranging from 5-15%.

-

Margin: Suppliers typically mark up their costs to establish a profit margin, which can vary widely based on the supplier’s market positioning, brand reputation, and the degree of customization required.

How Do Price Influencers Affect Wire Rope Costs?

Several factors can influence the pricing of wire ropes, making it imperative for buyers to understand these dynamics:

Illustrative image related to wire rope making

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide better pricing for larger orders due to economies of scale. Understanding MOQ requirements can help buyers negotiate better terms.

-

Specifications and Customization: Custom specifications, such as unique construction types or special coatings, can drive costs higher. Buyers should clearly define their requirements upfront to avoid unexpected expenses.

-

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., ISO, EN standards) typically come at a premium. Buyers should weigh the benefits of these certifications against their budget constraints.

-

Supplier Factors: Supplier reputation, reliability, and location can significantly impact pricing. Engaging with established suppliers with a proven track record may incur higher costs, but it can also reduce risks associated with quality and delivery.

-

Incoterms: The choice of Incoterms affects the division of costs and responsibilities between buyers and sellers. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for accurate cost estimations.

What Are Effective Buyer Tips for Sourcing Wire Rope?

For international B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe, here are some actionable tips:

-

Negotiate Wisely: Leverage volume commitments and long-term contracts to negotiate better pricing. Suppliers may be more flexible on price if they see the potential for ongoing business.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and operational costs. Sometimes, higher upfront costs can lead to lower long-term expenses.

-

Understand Pricing Nuances: Be aware of market conditions that may affect pricing, such as fluctuations in raw material costs or changes in international trade policies. Keeping abreast of these factors can give buyers leverage in negotiations.

-

Conduct Supplier Audits: For larger orders or critical applications, conducting supplier audits can help ensure quality standards are met and can provide insights into potential cost-saving measures.

Disclaimer

The prices and cost structures mentioned are indicative and can vary based on numerous factors, including market conditions, specific product requirements, and supplier negotiations. Always conduct thorough market research and supplier assessments to obtain accurate pricing.

Alternatives Analysis: Comparing wire rope making With Other Solutions

In the landscape of industrial applications, wire rope making stands as a pivotal solution for lifting, hoisting, and securing heavy loads. However, there are alternative solutions available that can also meet similar operational needs. This section explores these alternatives, providing B2B buyers with a comprehensive understanding of their options.

Illustrative image related to wire rope making

| Comparison Aspect | Wire Rope Making | Synthetic Rope Making | Chain Systems |

|---|---|---|---|

| Performance | High tensile strength, abrasion-resistant, flexible | Lightweight, high strength-to-weight ratio, UV resistant | Extremely strong, durable, and reliable under heavy loads |

| Cost | Moderate to high initial investment | Generally lower initial cost, but varying quality affects longevity | Higher upfront cost, but low long-term maintenance |

| Ease of Implementation | Requires specialized equipment and expertise | Easier to handle and install, often user-friendly | Complex installation requiring specialized tools |

| Maintenance | Regular inspection and lubrication required | Minimal maintenance needed, but susceptible to wear | Requires periodic inspection, rust prevention measures |

| Best Use Case | Heavy lifting in construction, mining, and maritime applications | Marine, recreational, and industrial lifting | Heavy-duty lifting where strength and durability are paramount |

What Are the Advantages and Disadvantages of Synthetic Rope Making?

Synthetic rope making utilizes materials such as nylon or polyester to create lightweight, flexible ropes. One of its primary advantages is the high strength-to-weight ratio, allowing for easier handling and transport. Additionally, synthetic ropes are often UV resistant, making them suitable for outdoor applications. However, they may not match the durability and abrasion resistance of traditional wire ropes, especially in demanding environments. Over time, synthetic ropes can degrade, requiring more frequent replacement.

How Do Chain Systems Compare to Wire Rope Making?

Chain systems provide an alternative to wire rope that is known for its robustness and reliability. They excel in heavy-duty lifting applications, especially where extreme strength is required. Chains are less susceptible to kinking and can handle high loads without stretching. However, their weight can be a disadvantage, making them less portable. Installation can also be more complex compared to wire ropes, necessitating specialized tools and expertise. Chains require regular maintenance to prevent rust and other forms of degradation.

Conclusion: How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the appropriate solution among wire rope making, synthetic ropes, and chain systems requires careful consideration of specific operational needs. B2B buyers should assess factors such as load capacity, environmental conditions, maintenance requirements, and budget constraints. Understanding the unique advantages and limitations of each alternative will empower buyers to make informed decisions that align with their operational goals and enhance their overall efficiency.

Essential Technical Properties and Trade Terminology for wire rope making

What Are the Essential Technical Properties of Wire Rope?

In the wire rope manufacturing industry, understanding key technical properties is critical for ensuring product quality and suitability for specific applications. Here are some essential specifications to consider:

-

Material Grade

Wire ropes are typically made from various grades of steel, which determine their strength and durability. Common grades include:

– IPS (Improved Plow Steel): Offers a balance of strength and flexibility.

– EIPS (Extra Improved Plow Steel): Provides higher tensile strength, making it ideal for heavy-duty applications.

– EEIPS (Extra Extra Improved Plow Steel): The highest strength grade, suitable for extreme conditions.

For B2B buyers, selecting the correct material grade is vital to meet load requirements and ensure long-term performance in harsh environments. -

Breaking Load

The breaking load is the maximum load a wire rope can withstand before failure. It is expressed in kilonewtons (kN) and calculated based on the total metallic area of the wires and their tensile strength.

Understanding the breaking load is crucial for ensuring safety and compliance with industry standards, particularly in sectors like construction and mining where heavy lifting is common. -

Lay Length

Lay length refers to the length of one complete helix of the wire or strand. This specification affects the rope’s flexibility and fatigue resistance.

For buyers, knowing the lay length is essential for application compatibility, as improper lay lengths can lead to premature wear or failure. -

Core Type

Wire ropes can have different core types, including:

– Fiber Core (FC): Provides flexibility and shock absorption but less strength.

– Steel Core (IWRC): Enhances strength and is suitable for high-load applications.

The core type chosen impacts the rope’s performance characteristics, which is critical for selecting the right rope for specific industrial tasks. -

Finish Type

Wire ropes can be finished as untreated (bright), galvanized, or stainless steel. Galvanization provides corrosion resistance, while stainless steel offers superior durability in harsh environments.

Buyers should consider the environmental conditions of their operations when selecting a finish type to ensure longevity and reduce maintenance costs.

What Are Common Trade Terms in Wire Rope Manufacturing?

Understanding industry jargon is essential for effective communication and negotiation in the wire rope market. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In wire rope, OEMs are critical for ensuring that the ropes meet specific standards and requirements for various machinery. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest number of units a supplier is willing to sell. This is important for buyers to understand as it affects inventory levels and costs.

Knowing the MOQ helps in budgeting and planning procurement strategies effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. It is a vital part of the procurement process, enabling buyers to compare options and negotiate better terms. -

Incoterms (International Commercial Terms)

These are standardized terms that define the responsibilities of buyers and sellers in international trade, covering aspects like shipping, insurance, and tariffs.

Familiarity with Incoterms helps buyers avoid misunderstandings regarding delivery terms and costs. -

Torque

Torque refers to the rotational force applied to the wire rope, which is particularly relevant in applications where the rope is subject to twisting.

Understanding torque is essential for ensuring the correct rope type is used, as excessive torque can lead to rope failure.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and safety in their industries.

Navigating Market Dynamics and Sourcing Trends in the wire rope making Sector

What Are the Key Trends Shaping the Global Wire Rope Market?

The wire rope market is experiencing notable growth, driven by several global factors. The construction and mining sectors are primary contributors, as they increasingly demand high-strength and durable wire ropes for heavy lifting and hoisting applications. Additionally, advancements in technology, such as the integration of smart sensors in wire rope systems, are revolutionizing maintenance practices and enhancing operational safety. These smart technologies allow for real-time monitoring, reducing downtime and improving efficiency, which is particularly appealing to international B2B buyers from diverse markets, including Africa, South America, the Middle East, and Europe.

Sourcing trends are also evolving, with a noticeable shift towards local procurement to mitigate risks associated with supply chain disruptions. Buyers are increasingly prioritizing suppliers that can offer just-in-time delivery and flexible manufacturing options to accommodate fluctuating demand. Furthermore, the push for customization is gaining momentum, as businesses seek wire ropes tailored to specific applications, such as marine, oil and gas, and construction industries.

Illustrative image related to wire rope making

In regions like Europe and the Middle East, regulatory compliance regarding safety and quality standards is becoming more stringent. This trend necessitates that suppliers not only adhere to international certifications but also demonstrate their commitment to innovation and sustainability. Consequently, B2B buyers are encouraged to seek partnerships with manufacturers that exhibit a robust understanding of these market dynamics and can provide solutions that align with their strategic objectives.

How Is Sustainability and Ethical Sourcing Impacting Wire Rope Manufacturing?

In the wire rope making sector, sustainability and ethical sourcing are increasingly becoming focal points for B2B buyers. The environmental impact of production processes is under scrutiny, prompting manufacturers to adopt greener practices. This includes utilizing recycled materials in wire rope production and implementing energy-efficient manufacturing techniques. Buyers are now more inclined to partner with suppliers who can demonstrate a commitment to reducing their carbon footprint and minimizing waste.

Moreover, ethical sourcing is essential in building trust and credibility. B2B buyers are seeking suppliers who ensure fair labor practices throughout their supply chains. This can be achieved by requiring transparency in sourcing materials and adherence to international labor standards. Certifications such as ISO 14001 for environmental management and the Fair Trade certification for labor practices are becoming vital in the selection process for suppliers.

Green certifications and materials, such as eco-friendly lubricants and coatings, are also gaining traction. These not only enhance the performance and longevity of wire ropes but also appeal to environmentally conscious buyers. By prioritizing sustainability, businesses can differentiate themselves in a competitive market and cater to the growing demand for responsible sourcing.

Illustrative image related to wire rope making

What Is the Historical Context of Wire Rope Development Relevant to Today’s Market?

The evolution of wire rope technology dates back to the 1830s, with early developments in Europe laying the foundation for modern applications. Initially, wire ropes were crafted by hand, utilizing wrought iron wires twisted together. This rudimentary method was refined through the 19th century, leading to innovations in wire rope design and manufacturing processes, particularly in the United States.

The introduction of steel wire ropes in the late 1800s significantly enhanced the strength and flexibility of ropes, making them indispensable in mining, construction, and maritime industries. Understanding this historical context is crucial for B2B buyers today, as it highlights the ongoing advancements in material science and engineering that continue to shape the wire rope sector. The legacy of innovation not only underscores the importance of quality and reliability in wire rope products but also informs current trends in customization and technology integration, which are essential considerations for international buyers seeking competitive advantages in their respective markets.

Frequently Asked Questions (FAQs) for B2B Buyers of wire rope making

-

How do I choose the right wire rope for my application?

Choosing the right wire rope involves considering several factors such as load capacity, environment, and flexibility. Assess the tensile strength required for your application, keeping in mind the rope construction (e.g., 6×36-FC or 6×19-IWRC) that best suits your needs. Additionally, consider factors like corrosion resistance (e.g., galvanized vs. stainless steel) and the type of core (fiber, steel, or plastic) to ensure optimal performance in your specific working conditions. -

What are the key specifications to look for in wire rope?

Key specifications include the rope’s diameter, construction type, breaking load, and tensile strength. Understand the meaning of terms like Minimum Breaking Load (MBL) and calculated breaking load, as these will inform you of the rope’s performance under stress. It’s also essential to consider the lay type (ordinary or Lang’s) and the number of strands and wires, as these factors influence the rope’s durability and handling characteristics. -

What is the minimum order quantity (MOQ) when sourcing wire rope?

Minimum order quantities can vary significantly by supplier and product type. Typically, MOQs for wire rope can range from a few hundred meters to several tons, depending on the specifications and the supplier’s manufacturing capabilities. It’s advisable to discuss your specific needs with suppliers to find flexible options or negotiate MOQs that suit your purchasing strategy, especially when sourcing from international markets. -

How do I vet potential wire rope suppliers?

To vet potential suppliers, start by checking their certifications and compliance with international standards (e.g., ISO, API). Assess their production capacity, lead times, and quality assurance processes. Request references from other customers, and consider visiting their facilities if possible. Additionally, evaluate their responsiveness and customer service, as these factors can be critical in establishing a long-term partnership. -

What payment terms should I expect when ordering wire rope internationally?

Payment terms can vary widely among suppliers. Common practices include full payment upfront, a 30% deposit with the balance due before shipment, or payment on delivery. It’s advisable to clarify payment methods (e.g., wire transfer, letter of credit) and any associated fees. Ensure that you understand the implications of currency fluctuations and international transaction fees, which can affect the overall cost of your order. -

What logistics considerations should I keep in mind for wire rope shipments?

When arranging logistics, consider the shipping method (air, sea, or land) based on your urgency and budget. Understand the customs regulations and import duties in your destination country, as these can impact delivery times and costs. Collaborate with logistics providers experienced in handling heavy and bulky items like wire rope to ensure safe and efficient transportation. Additionally, factor in potential delays due to port congestion or regulatory inspections. -

How can I ensure quality assurance for my wire rope orders?

To ensure quality assurance, request detailed product specifications and test certificates from suppliers before shipment. Implement a quality control process that includes pre-shipment inspections and random sampling of products. Consider working with third-party inspection agencies to verify compliance with industry standards. Establish a clear communication channel with your supplier for addressing any quality concerns post-delivery. -

What customization options are available for wire rope?

Customization options for wire rope can include specific lengths, diameters, and constructions tailored to your application. Some manufacturers offer specialized coatings for enhanced corrosion resistance or unique core configurations to improve performance. Discuss your specific requirements with potential suppliers to understand what customization capabilities they have and any associated costs or lead times involved in producing tailored wire ropes.

Top 3 Wire Rope Making Manufacturers & Suppliers List

1. Facebook – Durable Rope

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Rope this strong can only be made like this.

2. Industrial Rope – Wire Rope Solutions

Domain: industrialrope.com

Registered: 1997 (28 years)

Introduction: Wire Rope – Industrial Wire Rope Supply Company, Inc. offers a variety of wire ropes including 6×19 & 6×36 Class Ropes, 8×19 & 8×25 Resistwist ropes, 19×7 ropes, Flex-X, XLT4, 7 Flex & 7 flex PFV. The company provides wire rope slings, inspections, testing, training services, and custom fabrication. Key products include:

– Wire Rope Chokers with Standard Eyes Each End ($17.25 – $167.75)

– Vinyl Co…

3. Expometals – Tubular Stranding Machine DIN630

Domain: expometals.net

Registered: 2010 (15 years)

Introduction: Tubular stranding machine DIN630 with 48 bobbins, Mod. MS63/48. Used for making ropes and wire strands by twisting together thinner cords or wires. Applications include construction, elevators, mining, energy supply, agriculture, and logistics. The machine consists of pay-off, rotor and bearing assembly, stranding section, haul-off, and take-up. It allows for the creation of strands by helically w…

Strategic Sourcing Conclusion and Outlook for wire rope making

What Are the Key Takeaways for Strategic Sourcing in Wire Rope Manufacturing?

In the competitive landscape of wire rope manufacturing, strategic sourcing plays a pivotal role in ensuring quality, cost-effectiveness, and supply chain efficiency. By understanding the intricate details of wire rope construction—from the choice of materials like steel grades to the specific configurations of strands and cores—buyers can make informed decisions that enhance their operational performance.

Moreover, leveraging insights into global supply chain dynamics allows buyers from Africa, South America, the Middle East, and Europe to identify reliable suppliers who meet their unique needs. Establishing relationships with manufacturers who prioritize innovation and sustainability can also lead to long-term partnerships that drive mutual growth.

Illustrative image related to wire rope making

How Can International Buyers Prepare for Future Trends?

Looking ahead, the wire rope market is poised for growth driven by advancements in technology and increasing demand across various sectors, including construction, mining, and maritime industries. B2B buyers should remain proactive in exploring new sourcing strategies, such as incorporating advanced materials and sustainability practices into their procurement processes.

Investing in quality wire rope solutions today not only ensures safety and reliability but also positions businesses to thrive in tomorrow’s market. Engage with trusted suppliers to discuss how tailored wire rope solutions can meet your operational challenges and contribute to your success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to wire rope making

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.