Unlocking Value: A Strategic Analysis of the What Is Shock Cord Market

Introduction: Navigating the Global Market for what is shock cord

In today’s competitive global marketplace, sourcing shock cord can pose significant challenges for B2B buyers. Understanding the nuances of this versatile product—often referred to as bungee cord or elastic rope—is essential for making informed purchasing decisions. This guide offers a comprehensive overview of shock cord, exploring its various types, applications across industries, and critical factors for supplier vetting. With insights into pricing structures and quality differentiators, international buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Brazil and Saudi Arabia—will find actionable information tailored to their unique needs.

Shock cord serves a multitude of purposes, from securing cargo in transit to acting as shock absorbers in mechanical systems. Its elastic properties allow for easy application in diverse settings, making it indispensable in sectors ranging from aerospace to outdoor recreation. However, with a plethora of options available in the market, choosing the right shock cord can be daunting. This guide aims to demystify the selection process, empowering buyers with the knowledge to navigate the complexities of sourcing shock cord effectively. By leveraging this information, businesses can enhance their operational efficiency, reduce costs, and ultimately secure the right solutions for their specific applications.

Understanding what is shock cord Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Shock Cord | Elastic rubber core with a polyester outer sheath | Cargo securing, outdoor gear, marine applications | Pros: High elasticity, durable. Cons: Limited UV resistance compared to other materials. |

| Bungee Cord | Typically has hooks on both ends for easy attachment | General-purpose utility, outdoor sports | Pros: Versatile, easy to use. Cons: May stretch too much under heavy loads. |

| Marine Shock Cord | Marine-grade polyester for enhanced UV and abrasion resistance | Boating, water sports, outdoor equipment | Pros: Superior durability in harsh conditions. Cons: Higher cost due to specialized materials. |

| Tarp Straps | Rubber or EPDM with S-hooks for securing tarps | Cargo transport, trailer use | Pros: Excellent for heavy-duty applications. Cons: Limited stretch compared to shock cords. |

| Custom Shock Cord | Made to specific lengths and specifications | Industrial applications, custom projects | Pros: Tailored to specific needs. Cons: Longer lead times for production. |

What Are the Key Characteristics of Standard Shock Cord?

Standard shock cords feature a robust elastic rubber core encased in a braided polyester sheath. This design allows for significant stretch, typically between 100-125% under load, making them suitable for a variety of applications, from securing cargo to outdoor gear. When purchasing, buyers should consider the diameter and length needed for their specific tasks, as these factors can significantly impact performance. While they are durable, it’s essential to note that their UV resistance is not as high as some other materials, potentially limiting outdoor applications.

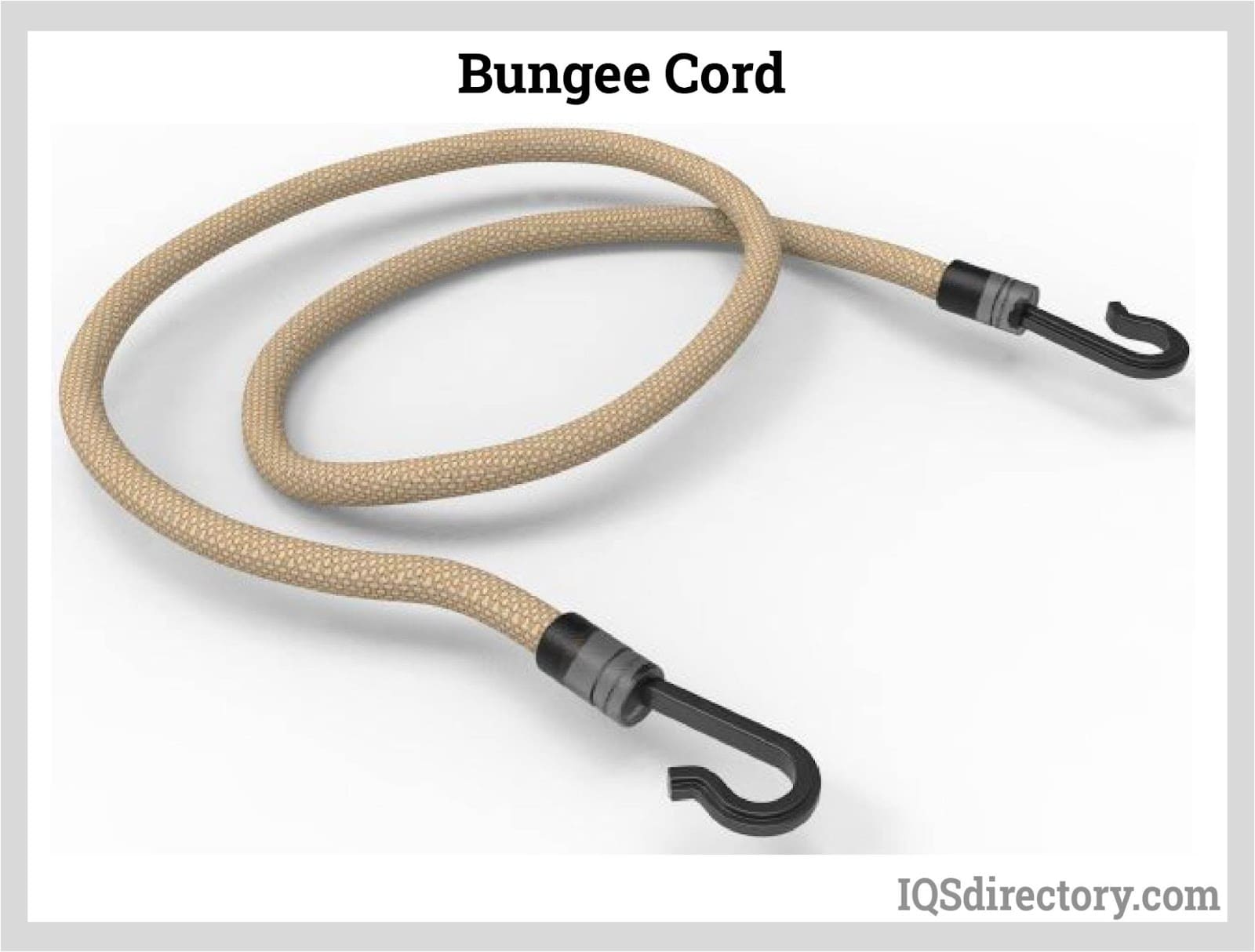

How Do Bungee Cords Differ from Other Shock Cords?

Bungee cords, a common variation of shock cords, are characterized by their pre-attached hooks, making them easy to use for quick securing solutions. They are ideal for general-purpose utility, such as fastening outdoor sports equipment or securing items during transport. While their versatility is a significant advantage, buyers should be cautious of their stretch capabilities, as excessive loads can lead to overstretching, which may compromise their effectiveness. When selecting bungee cords, it’s important to assess the load requirements and the environment in which they will be used.

Why Choose Marine Shock Cord for Outdoor Applications?

Marine shock cords are specifically designed with marine-grade polyester, providing enhanced UV and abrasion resistance. This makes them particularly suitable for boating and other water-based activities, where durability against harsh conditions is crucial. Buyers in industries such as marine transport should prioritize these cords for their reliability and longevity in outdoor environments. While they may come at a higher price point, the investment is often justified by their superior performance and reduced need for frequent replacements.

Illustrative image related to what is shock cord

What Are the Advantages of Using Tarp Straps?

Tarp straps are designed with rubber or EPDM material and equipped with S-hooks, making them an excellent choice for securing tarps on trailers or during cargo transport. They excel in heavy-duty applications due to their robust construction, providing reliable tension without excessive stretching. Buyers should consider the specific needs of their cargo securing applications when choosing tarp straps, as they offer limited stretch compared to traditional shock cords. However, their strength and reliability make them a go-to choice for many businesses.

How Can Custom Shock Cords Benefit Your Business?

Custom shock cords can be tailored to specific lengths and applications, making them ideal for businesses with unique requirements. Industries that need specialized solutions, such as manufacturing or construction, can benefit from custom shock cords that meet their exact specifications. While they offer the advantage of being perfectly suited to a particular task, buyers should be aware of longer lead times associated with production. Evaluating the cost-effectiveness of custom solutions against standard options is crucial for making informed purchasing decisions.

Key Industrial Applications of what is shock cord

| Industry/Sector | Specific Application of what is shock cord | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Shock absorbers in aircraft landing gear | Enhances safety and performance of aircraft landings | Compliance with aviation standards and certifications |

| Marine | Securing cargo on boats and trailers | Prevents cargo movement, ensuring safety and efficiency | UV resistance and marine-grade materials required |

| Construction | Temporary securing of tarps and equipment | Reduces delays and improves site safety | Durable and weather-resistant options preferred |

| Sports and Recreation | Tent setup and securing outdoor gear | Ensures stability and ease of setup in outdoor events | Lightweight and high-elasticity options needed |

| Military | Equipment and weapon securing in transport | Increases operational efficiency and safety | High tensile strength and durability for rugged use |

How is Shock Cord Used in the Aerospace Industry?

In the aerospace sector, shock cords are primarily utilized as shock absorbers in aircraft landing gear. Their ability to absorb and dissipate energy is crucial during landings, enhancing the safety and performance of aircraft. For international buyers, particularly in regions like Africa and the Middle East, it is essential to source shock cords that comply with stringent aviation standards and certifications to ensure reliability and safety in operations.

Illustrative image related to what is shock cord

What Role Does Shock Cord Play in Marine Applications?

In marine applications, shock cords are invaluable for securing cargo on boats and trailers, preventing movement during transport. This is particularly important in regions such as South America, where cargo transportation can involve rough waters. Buyers must prioritize sourcing shock cords that are UV resistant and made from marine-grade materials to withstand harsh environmental conditions, ensuring the safety of both cargo and crew.

How is Shock Cord Beneficial in Construction Projects?

In the construction industry, shock cords are frequently employed for temporarily securing tarps and equipment. This application helps reduce delays caused by weather conditions and enhances site safety by preventing accidents related to loose materials. Buyers from Europe and similar markets should consider durable, weather-resistant shock cords that can endure the rigors of outdoor construction environments.

Why is Shock Cord Important for Sports and Recreation?

For sports and recreational activities, shock cords are often used in the setup of tents and to secure outdoor gear. Their elasticity allows for quick and easy adjustments, ensuring stability during events. International buyers, especially from Brazil and other outdoor-centric regions, should seek lightweight shock cords that offer high elasticity and durability, facilitating seamless outdoor experiences.

How Does the Military Utilize Shock Cord for Equipment Transport?

The military sector utilizes shock cords extensively for securing equipment and weapons during transport. Their stretchability and strength contribute to increased operational efficiency and safety in challenging environments. Buyers in this sector must focus on high tensile strength and durable materials that can withstand rugged use, ensuring reliability in critical situations across various terrains and climates.

3 Common User Pain Points for ‘what is shock cord’ & Their Solutions

Scenario 1: Difficulty in Choosing the Right Shock Cord for Specific Applications

The Problem: B2B buyers often encounter challenges when selecting the appropriate shock cord for their specific needs, particularly when dealing with diverse applications like marine transport, outdoor equipment, or cargo securing. The confusion can arise from the myriad of options available, including different materials, diameters, and stretch factors. A buyer may inadvertently choose a shock cord that does not provide sufficient elasticity or durability for their intended use, leading to potential safety hazards and financial losses. For instance, using a shock cord with inadequate UV resistance in outdoor applications can result in premature wear and tear, ultimately affecting the integrity of the cargo being secured.

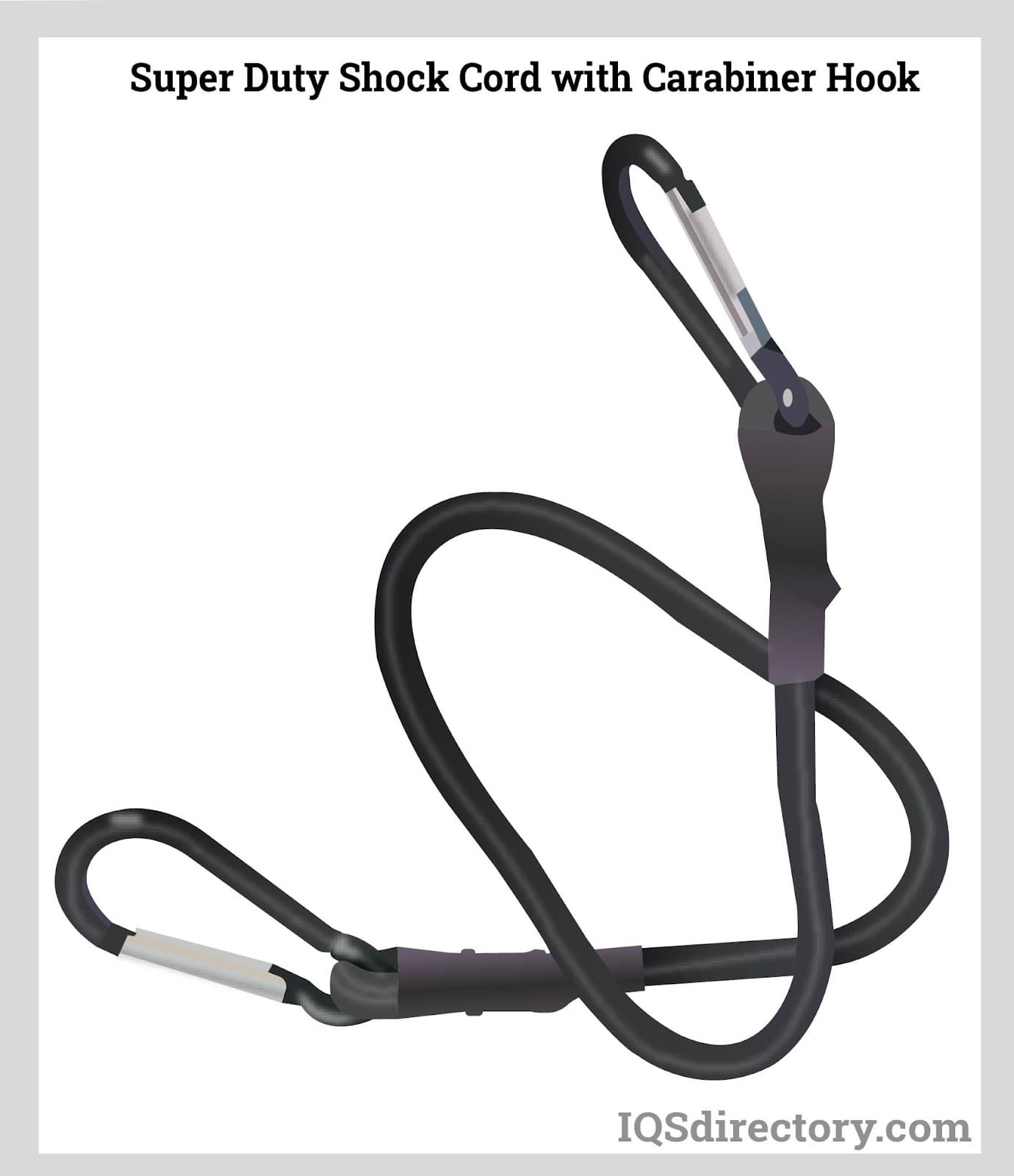

Illustrative image related to what is shock cord

The Solution: To effectively choose the right shock cord, B2B buyers should begin by thoroughly assessing the specific application requirements. This includes considering the material composition—polyester is recommended for outdoor use due to its UV resistance and durability, while rubber may be more suitable for indoor applications. Next, evaluating the required stretch factor is crucial; a shock cord with a stretch capacity of 100-125% under load is ideal for most applications, but buyers should consider their unique needs. It’s advisable to consult manufacturers’ specifications and seek expert advice when necessary. Furthermore, ordering samples for testing before making bulk purchases can help ensure that the selected shock cord meets performance expectations.

Scenario 2: Concerns Over Shock Cord Durability and Longevity

The Problem: Many B2B buyers are concerned about the longevity and performance of shock cords, especially in demanding environments such as construction sites or marine applications. The risk of material degradation over time—due to factors like UV exposure, environmental conditions, or heavy usage—can lead to failure during critical operations, jeopardizing safety and resulting in costly downtime. Buyers may struggle to find reliable information on the expected lifespan of different shock cord types, making it difficult to justify their investment.

The Solution: To address durability concerns, buyers should prioritize sourcing shock cords that are explicitly designed for their intended environment. For instance, marine-grade shock cords with a robust polyester jacket offer enhanced UV and abrasion resistance, making them ideal for outdoor and water-related uses. Buyers should also inquire about the manufacturer’s testing methods and certification processes that demonstrate the shock cord’s resistance to wear and tear. Implementing regular maintenance checks and replacing shock cords based on usage metrics can prevent unexpected failures. Furthermore, establishing a relationship with reputable suppliers can provide access to expert insights on the best products for specific applications, helping buyers make informed decisions.

Scenario 3: Inefficiencies in Shock Cord Customization for Unique Applications

The Problem: B2B buyers often face challenges in customizing shock cords for unique applications, such as creating specific lengths or incorporating hooks and attachments. This can be particularly frustrating when standard lengths do not meet their requirements, leading to wasted materials and increased costs. Additionally, without proper customization, the shock cords may not perform optimally, which can affect the efficiency of operations. Buyers may find themselves spending excessive time and resources trying to adapt existing products to fit their needs.

The Solution: To streamline the customization process, buyers should consider purchasing shock cords in bulk spools, allowing for easy cutting to desired lengths. Suppliers often provide various diameters and materials, enabling buyers to create tailored solutions without compromising quality. Furthermore, integrating bungee hooks and other attachments can enhance functionality; suppliers typically offer these accessories as part of their inventory, simplifying the customization process. Buyers are encouraged to collaborate with their suppliers to explore custom solutions and bulk order options, which can lead to significant cost savings and operational efficiency. Additionally, leveraging technology such as CAD software for designing custom applications can facilitate better planning and execution in shock cord usage.

Illustrative image related to what is shock cord

Strategic Material Selection Guide for what is shock cord

What Materials Are Commonly Used in Shock Cord Manufacturing?

Shock cords are made from various materials, each offering unique properties that influence their performance in different applications. Understanding these materials can help B2B buyers select the right shock cord for their specific needs.

How Does Natural Rubber Perform in Shock Cords?

Natural rubber is one of the most common materials used in shock cord manufacturing. It boasts excellent elasticity and a high stretch factor, typically around 100-125%. This material performs well in a wide range of temperatures but can degrade when exposed to UV light and ozone, which limits its outdoor applications.

Pros and Cons: Natural rubber is durable and cost-effective, making it a popular choice for many applications. However, its susceptibility to environmental factors can lead to a shorter lifespan, particularly in harsh conditions. Additionally, the manufacturing process can be complex due to the need for specific formulations to enhance UV resistance.

Impact on Application: Natural rubber shock cords are ideal for indoor use or in shaded environments but may not be suitable for outdoor applications in regions with high UV exposure, such as parts of Africa and the Middle East.

What Role Does Polyester Play in Shock Cord Durability?

Polyester is often used as a protective sheath over the elastic core of shock cords. It enhances the durability and UV resistance of the cord, making it suitable for outdoor applications. Polyester’s temperature tolerance is moderate, typically performing well in both hot and cold environments.

Pros and Cons: The primary advantage of polyester is its resistance to abrasion and UV degradation, which significantly extends the lifespan of shock cords used outdoors. However, polyester can be more expensive than other materials, which may impact overall product cost for bulk buyers.

Impact on Application: Shock cords with a polyester sheath are ideal for marine and outdoor applications, such as securing cargo on boats or trailers. Buyers from regions like Europe and South America may prioritize these materials for their enhanced durability in various weather conditions.

Illustrative image related to what is shock cord

How Do Synthetic Elastomers Compare in Shock Cord Applications?

Synthetic elastomers, such as EPDM (ethylene propylene diene monomer), are increasingly used in shock cords due to their superior resistance to UV light, ozone, and extreme temperatures. They provide excellent elasticity and a longer lifespan compared to natural rubber.

Pros and Cons: The key advantage of synthetic elastomers is their versatility and durability, making them suitable for a wide range of applications, including automotive and industrial uses. However, they can be more expensive to produce, which may affect pricing for B2B buyers looking for cost-effective solutions.

Impact on Application: Synthetic elastomer shock cords are particularly beneficial in regions with extreme weather conditions, such as the Middle East, where high temperatures and UV exposure can degrade other materials.

Illustrative image related to what is shock cord

What Is the Importance of Polypropylene in Shock Cord Manufacturing?

Polypropylene is another material used in shock cords, often chosen for its lightweight and cost-effective properties. While it offers decent elasticity, its stretch factor is generally lower than that of rubber-based materials.

Pros and Cons: Polypropylene shock cords are affordable and lightweight, making them suitable for applications where weight is a concern. However, they lack the durability and UV resistance of polyester or synthetic elastomers, limiting their use in harsh environments.

Impact on Application: Buyers in regions with milder climates, such as parts of South America, may find polypropylene shock cords adequate for their needs, particularly for lightweight applications like securing lightweight cargo.

Summary of Material Selection for Shock Cords

| Material | Typical Use Case for what is shock cord | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Rubber | Indoor applications, low UV exposure | Excellent elasticity and stretch | Degrades under UV exposure | Low |

| Polyester | Marine and outdoor applications | High durability and UV resistance | Higher cost compared to others | Med |

| Synthetic Elastomers | Automotive, industrial applications | Superior UV and temperature resistance | Higher manufacturing costs | High |

| Polypropylene | Lightweight cargo securing | Cost-effective and lightweight | Lower durability and UV resistance | Low |

This table provides a concise overview of the materials used in shock cord manufacturing, helping B2B buyers make informed decisions based on their specific application needs and regional considerations.

Illustrative image related to what is shock cord

In-depth Look: Manufacturing Processes and Quality Assurance for what is shock cord

What Are the Key Stages in the Manufacturing Process of Shock Cord?

The manufacturing process of shock cord involves several critical stages, each designed to ensure the final product meets the necessary performance standards for various applications. Understanding these stages is essential for B2B buyers, as it can inform their purchasing decisions and help them identify reliable suppliers.

How Is Material Prepared for Shock Cord Production?

The first step in manufacturing shock cord is material preparation. This involves sourcing high-quality raw materials, which typically include an elastic rubber core and a durable outer sheath, often made from polyester or polypropylene. The rubber is chosen for its elasticity, while the outer material is selected for its strength and resistance to environmental factors like UV rays and moisture.

Once the materials are sourced, they undergo quality checks to ensure they meet industry specifications. This includes testing for elasticity, tensile strength, and environmental resistance. Suppliers often provide certificates of analysis for these materials, which B2B buyers should request to verify quality.

What Techniques Are Used for Forming Shock Cord?

The forming process is where the elastic core and the outer sheath are combined. This is typically achieved through a technique known as extrusion. During this process, the rubber core is fed into an extruder, where it is heated and forced through a die to create a continuous length of elastic cord. The outer sheath is then applied through a co-extrusion process or by braiding, ensuring a tight fit that enhances durability.

Illustrative image related to what is shock cord

In some cases, the production may also involve twisting or braiding techniques to improve the mechanical properties of the shock cord. These processes not only enhance the strength of the product but also provide additional elasticity, which is crucial for applications requiring shock absorption.

How Is Assembly Completed in Shock Cord Manufacturing?

After the forming stage, the shock cord is cut to the desired lengths, which may vary based on customer specifications. This assembly stage can also include adding end fittings or hooks, particularly if the cord is intended for use as a bungee cord. The quality of these fittings is critical, as they must withstand the forces exerted during use.

Quality assurance checks are performed at this stage to ensure that the lengths are accurate and that the fittings are securely attached. It is essential for B2B buyers to understand the assembly process, as any weaknesses in this stage can lead to product failures.

Illustrative image related to what is shock cord

What Finishing Processes Are Involved in Shock Cord Production?

Finishing processes include applying protective coatings or treatments to the shock cord to enhance its resistance to environmental factors. For instance, cords may undergo UV treatment to prevent degradation from sun exposure or be coated for additional abrasion resistance.

Final inspections are conducted to ensure that the shock cord meets all quality standards before packaging. B2B buyers should inquire about the specific finishing techniques used, as these can significantly impact the performance and longevity of the shock cord in various applications.

What Quality Control Measures Are Essential for Shock Cord Production?

Quality control (QC) is paramount in the manufacturing of shock cord, particularly given its wide range of applications across various industries. Understanding the QC measures that suppliers implement can help B2B buyers ensure they are purchasing high-quality products.

What International Standards Are Relevant for Shock Cord Quality?

Manufacturers of shock cord are often required to adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards indicates that a manufacturer has established processes to ensure consistent quality and continuous improvement.

In addition to ISO standards, industry-specific certifications may also apply. For example, products intended for marine use may need to meet CE certification standards, while those used in aerospace applications may require compliance with API (American Petroleum Institute) standards.

What Are the Key Quality Control Checkpoints in Shock Cord Manufacturing?

Quality control checkpoints are critical throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified requirements before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify any deviations from quality standards in real-time.

- Final Quality Control (FQC): This final inspection ensures that the finished product meets all specifications and is free from defects before shipping.

B2B buyers should ask suppliers about their specific QC checkpoints and any documentation they provide as proof of compliance.

What Testing Methods Are Commonly Used to Ensure Shock Cord Quality?

Various testing methods are employed to evaluate the performance characteristics of shock cords. These may include:

Illustrative image related to what is shock cord

- Tensile Strength Testing: Measures the maximum load the shock cord can handle before breaking.

- Elongation Testing: Assesses how much the cord can stretch under load and return to its original shape.

- Abrasion Resistance Testing: Evaluates how well the cord withstands wear and tear.

- UV Resistance Testing: Determines how effectively the cord can resist degradation from sun exposure.

B2B buyers should seek suppliers who conduct these tests and provide detailed reports as part of their quality assurance documentation.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is crucial to ensuring product reliability. There are several methods to achieve this:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures directly.

- Quality Reports: Requesting detailed quality reports and certifications can provide insights into the supplier’s compliance with international standards.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control practices and the products being manufactured.

What Nuances Should International B2B Buyers Consider Regarding QC?

International buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of specific nuances when dealing with QC. These include:

- Cultural Differences: Understanding how different cultures approach quality and compliance can impact negotiations and expectations.

- Logistics and Shipping: Consideration of how quality may be affected during shipping, especially for products requiring careful handling.

- Regulatory Compliance: Familiarity with local regulations and standards in the buyer’s region can help ensure that imported products meet necessary legal requirements.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices for shock cord is essential for B2B buyers. By being informed about these aspects, buyers can make better decisions, ensuring they select reliable suppliers who provide high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is shock cord’

Introduction

This sourcing guide is designed to assist B2B buyers in procuring shock cord, a versatile elastic material widely used across various industries. Understanding the specifications, applications, and supplier capabilities is essential to ensure that the shock cord meets your operational needs and quality standards. This checklist will provide actionable steps to streamline your sourcing process effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial before sourcing shock cord. Consider factors such as diameter, stretchability, material composition, and intended applications. For example, a shock cord with a marine-grade polyester jacket offers superior UV and abrasion resistance, making it ideal for outdoor or marine uses.

- Diameter Options: Determine the appropriate thickness based on the load it will bear.

- Elasticity Requirements: Assess the stretch factor needed for your applications, typically ranging from 100% to 125% under load.

Step 2: Research and Identify Reputable Suppliers

Identifying reliable suppliers is key to ensuring product quality and timely delivery. Look for suppliers with a solid reputation in the industry and a history of providing high-quality shock cords.

- Supplier Reviews: Check customer feedback and ratings to gauge reliability.

- Industry Experience: Preference should be given to suppliers with experience in your specific market sector, such as marine, aerospace, or automotive.

Step 3: Verify Supplier Certifications and Compliance

Before finalizing a supplier, ensure that they comply with international quality standards and certifications. This can significantly impact the quality and reliability of the shock cord you purchase.

Illustrative image related to what is shock cord

- ISO Certifications: Look for suppliers with ISO 9001 certification or other relevant standards.

- Material Compliance: Ensure materials used in shock cords meet regional safety and environmental regulations, especially for markets in Africa or South America.

Step 4: Request Product Samples

Before placing a bulk order, request samples of the shock cord to evaluate its quality and performance. This step allows you to test the material under actual working conditions.

- Testing for Durability: Assess factors such as stretchability, abrasion resistance, and overall elasticity.

- Application Fit: Ensure the sample meets the specific needs of your projects or products.

Step 5: Negotiate Pricing and Terms

Once you have identified potential suppliers and validated their products, it’s time to negotiate pricing and payment terms. This is a vital step to ensure you get the best value for your investment.

- Bulk Order Discounts: Inquire about pricing structures for larger orders, which can lead to significant savings.

- Payment Terms: Discuss favorable payment terms that can help with cash flow, especially for large purchases.

Step 6: Establish Logistics and Delivery Timelines

Planning for logistics and delivery timelines is essential to ensure that your supply chain remains uninterrupted. Confirm lead times and shipping options with your chosen supplier.

- Shipping Options: Evaluate various shipping methods based on urgency and cost-effectiveness.

- Delivery Timelines: Set clear expectations for delivery dates to align with your project schedules.

Step 7: Assess After-Sales Support

Finally, consider the level of after-sales support offered by the supplier. This can be particularly important for resolving any issues that may arise after the purchase.

Illustrative image related to what is shock cord

- Warranty Information: Understand the warranty terms for the shock cord.

- Customer Service: Evaluate the supplier’s responsiveness and willingness to assist with any post-purchase inquiries or issues.

By following this checklist, B2B buyers can confidently navigate the sourcing process for shock cord, ensuring they select the right product and supplier for their needs.

Comprehensive Cost and Pricing Analysis for what is shock cord Sourcing

What Are the Cost Components Involved in Sourcing Shock Cord?

When sourcing shock cord, understanding the cost structure is crucial for B2B buyers. The total cost is influenced by several components, including materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The primary component is the raw materials used in shock cord production, which typically include an elastic rubber core and a durable outer sheath made from materials like polyester or polypropylene. The choice of materials significantly impacts cost; for instance, marine-grade polyester offers superior durability and UV resistance but comes at a higher price compared to standard options.

-

Labor: Labor costs vary based on the region and the complexity of the manufacturing process. In regions with lower labor costs, such as certain parts of Africa or South America, manufacturing might be more economical, but it’s essential to consider the trade-off with quality and consistency.

-

Manufacturing Overhead: This includes costs associated with utilities, facility maintenance, and administrative expenses. Efficient manufacturers often manage these costs effectively, which can lead to competitive pricing for buyers.

-

Tooling: Tooling costs involve the initial investment in molds and machines necessary for production. These costs are amortized over production runs, meaning larger orders can dilute the tooling expense per unit.

-

Quality Control (QC): Ensuring product quality is vital, particularly in industries like aerospace and marine. QC processes may add to the cost but are essential for maintaining standards and certifications that can influence buyer decisions.

-

Logistics: Shipping and handling costs can vary widely based on the supplier’s location, shipping method, and final destination. For international buyers, understanding Incoterms is crucial as they dictate who bears the cost and risk during transport.

-

Margin: Suppliers will add a profit margin to cover their costs and ensure profitability. This margin can vary based on market demand, competition, and product uniqueness.

What Influences the Pricing of Shock Cord for International Buyers?

Several factors influence pricing in the shock cord market, particularly for international B2B buyers from regions like Africa, South America, the Middle East, and Europe.

-

Volume and Minimum Order Quantity (MOQ): Larger orders often come with significant discounts, making it essential for buyers to assess their needs and negotiate MOQs that align with their budget.

-

Specifications and Customization: Customized shock cords, whether in terms of length, diameter, or material, can incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., ISO, CE) typically drive up costs but are necessary for applications that demand reliability and safety. Buyers should weigh the importance of these factors against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge a premium for their proven quality and service, while emerging suppliers may offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is crucial for international transactions. Terms like FOB (Free on Board) and CIF (Cost, Insurance, Freight) can significantly influence total costs and responsibilities for both parties.

What Tips Can Help Buyers Achieve Cost-Efficiency in Sourcing Shock Cord?

B2B buyers can employ several strategies to enhance cost-efficiency when sourcing shock cord:

-

Negotiate Effectively: Building strong relationships with suppliers can lead to better pricing and terms. Engage in open discussions about your needs and explore possibilities for bulk discounts or long-term contracts.

-

Consider Total Cost of Ownership (TCO): Rather than focusing solely on the purchase price, evaluate the TCO, which includes shipping, handling, and potential costs associated with product failure or replacements. Investing in higher-quality shock cord may lead to lower long-term costs.

-

Stay Informed About Market Trends: Understanding market dynamics, such as raw material price fluctuations and supply chain disruptions, can help buyers anticipate price changes and make informed purchasing decisions.

-

Leverage Local Suppliers: Where possible, consider sourcing from local suppliers to minimize logistics costs and lead times. This can also support regional economies and reduce carbon footprints.

-

Be Aware of Pricing Nuances: International buyers must be cognizant of currency fluctuations, tariffs, and import duties that can impact the overall cost of sourcing shock cord.

Disclaimer: The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough market research and supplier assessments before finalizing any purchasing decisions.

Illustrative image related to what is shock cord

Alternatives Analysis: Comparing what is shock cord With Other Solutions

Exploring Alternatives to Shock Cord: What Are the Best Options?

When evaluating solutions for securing cargo, absorbing shock, or providing tension, it’s essential to consider various alternatives to shock cord. Each option has unique characteristics, advantages, and limitations that can influence a B2B buyer’s decision based on specific needs and applications. Below is a detailed comparison of shock cord against two viable alternatives: bungee cords and tie-down straps.

Comparison Table of Shock Cord and Alternatives

| Comparison Aspect | What Is Shock Cord | Bungee Cords | Tie-Down Straps |

|---|---|---|---|

| Performance | High elasticity and durability; ideal for shock absorption and tension. | Good elasticity; suitable for general use but may not hold under extreme loads. | Very strong; designed for heavy-duty securing of loads without stretch. |

| Cost | Moderate cost; bulk options available, making it economical. | Generally lower cost; available in various sizes and quantities. | Higher upfront cost, especially for quality options with ratchets. |

| Ease of Implementation | Simple to use; no knots required, just stretch and secure. | Easy to use; quick securing method, but hooks can be cumbersome. | Requires more effort to set up; involves threading and tightening. |

| Maintenance | Low maintenance; durable polyester cover resists UV and abrasion. | Minimal maintenance; inspect for wear but generally durable. | Low to moderate; ratchet mechanisms may require occasional lubrication. |

| Best Use Case | Excellent for light to medium loads, securing items in transit, and recreational use. | Suitable for quick, lightweight applications like securing bicycles or camping gear. | Best for heavy loads in transportation, such as securing cargo on trucks or trailers. |

Detailed Breakdown of Alternatives

Bungee Cords

Bungee cords are often seen as a more affordable alternative to shock cords. They consist of elastic strands covered in fabric and typically feature hooks at both ends. While they are easy to use and great for quick fixes, bungee cords are less robust than shock cords and can struggle under heavy loads. Their elasticity makes them suitable for securing lightweight items but may not provide the same level of reliability for more demanding applications, especially in rugged conditions.

Tie-Down Straps

Tie-down straps, particularly those with ratchet mechanisms, offer a high-performance alternative to shock cord. They are designed for heavy-duty use, providing a strong and secure hold on cargo. However, they require more time and effort to set up compared to shock cords. While they excel in securing large or heavy items during transport, they lack the elasticity and shock absorption qualities of shock cords, making them less versatile for applications requiring flexibility.

Conclusion: How to Choose the Right Solution for Your Needs

In selecting the appropriate solution for securing cargo or absorbing shock, B2B buyers should consider their specific requirements, including load weight, environmental conditions, and ease of use. Shock cords are a versatile choice for many applications, particularly where elasticity and shock absorption are crucial. In contrast, bungee cords may be more suitable for lightweight tasks, while tie-down straps are ideal for heavy-duty securing. Understanding these distinctions can help buyers make informed decisions that align with their operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for what is shock cord

What are the Essential Technical Properties of Shock Cord?

Understanding the technical specifications of shock cord is crucial for B2B buyers who need reliable and efficient solutions for various applications. Here are some key properties to consider:

1. Material Composition

Shock cords typically consist of an elastic rubber core encased in a durable outer sheath, commonly made from materials like polyester or polypropylene. The choice of material influences the cord’s strength, elasticity, and resistance to environmental factors such as UV exposure and abrasion. For example, polyester offers superior UV resistance, making it ideal for outdoor applications.

2. Diameter and Stretch Factor

Shock cords are available in various diameters, ranging from 1/8 inch to 1/2 inch. The diameter directly affects the load capacity and stretch characteristics. Generally, shock cords can stretch between 100-125% under full load. Knowing the appropriate diameter and stretch factor is essential for ensuring that the cord meets specific application requirements, such as securing cargo without risk of breakage.

3. Working Load Limit (WLL)

The Working Load Limit is the maximum weight that a shock cord can safely handle during normal use. This specification is critical for B2B buyers, as exceeding the WLL can lead to failure and potential safety hazards. Understanding the WLL helps in selecting the right shock cord for applications such as transporting goods or securing equipment.

4. Tensile Strength

Tensile strength refers to the maximum amount of tensile (pulling) stress that the shock cord can withstand before breaking. This property is crucial in applications where significant forces are applied, such as in marine or industrial settings. A higher tensile strength indicates a more robust product, making it suitable for demanding environments.

5. Environmental Resistance

Shock cords may be designed to withstand specific environmental conditions, including temperature variations and exposure to chemicals. For instance, EPDM rubber is known for its resistance to UV rays and ozone, making it suitable for prolonged outdoor use. Evaluating environmental resistance ensures that the selected shock cord will perform reliably over time.

What are Common Trade Terminology Used in Shock Cord Procurement?

Familiarity with industry jargon is vital for effective communication and negotiation in the procurement process. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of shock cords, understanding OEM specifications ensures that the products meet the required standards for various applications.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is important for B2B buyers to manage inventory levels and cost-effectiveness, particularly when purchasing shock cords in bulk.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. For shock cords, submitting an RFQ allows buyers to compare prices and terms from different suppliers, facilitating better purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that define the responsibilities of buyers and sellers in shipping agreements. Understanding these terms is crucial for B2B buyers, as they dictate who is responsible for transportation costs, insurance, and risk during shipping.

5. Lead Time

Lead time refers to the duration between placing an order and receiving the goods. For shock cords, knowing the lead time helps businesses plan their operations and manage inventory effectively, ensuring that they have the necessary materials when needed.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing shock cords, optimizing their procurement strategies to meet specific operational needs.

Navigating Market Dynamics and Sourcing Trends in the what is shock cord Sector

What Are the Global Drivers Influencing the Shock Cord Market?

The shock cord market is experiencing robust growth driven by several global factors. The increasing demand for versatile and durable materials across various sectors such as transportation, marine, and recreational activities is a primary driver. As international trade expands, the need for secure cargo handling solutions is paramount, making shock cords indispensable for logistics and freight companies. Furthermore, the rise of outdoor recreational activities in regions like Africa and South America has spurred demand for shock cords in camping, boating, and sports equipment.

Emerging technologies in materials science are also shaping the market. Innovative manufacturing processes are enabling the production of shock cords with enhanced durability and performance, appealing to quality-conscious B2B buyers. Digitalization in sourcing is another trend, with platforms facilitating international procurement, allowing businesses in regions like Brazil and Saudi Arabia to connect with suppliers efficiently. The emphasis on bulk purchasing and custom solutions is becoming prevalent as companies seek to optimize their supply chain and reduce costs.

How Are Sustainability and Ethical Sourcing Shaping the Shock Cord Sector?

Sustainability is increasingly influencing the shock cord market, with buyers seeking eco-friendly materials and ethical production practices. The environmental impact of traditional rubber production has prompted many manufacturers to explore sustainable alternatives, such as recycled materials or bio-based elastomers. This shift aligns with the growing consumer and corporate demand for products that minimize ecological footprints.

Ethical sourcing practices are crucial for B2B buyers, especially in regions where supply chain transparency is under scrutiny. Companies that prioritize responsible sourcing not only enhance their brand reputation but also mitigate risks associated with labor practices and environmental regulations. Certifications like ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainable practices. By opting for suppliers with green certifications, businesses can ensure that their procurement aligns with global sustainability goals, appealing to an environmentally conscious clientele.

Illustrative image related to what is shock cord

What Is the Historical Context of Shock Cord Development?

The evolution of shock cords dates back to the early 20th century, initially developed for aviation applications. Their primary function was to absorb shocks on aircraft landing gear, a necessity for safe landings on short carrier decks during World War II. As the technology matured, shock cords found applications in civilian sectors, including outdoor gear and cargo securing solutions.

By the mid-20th century, the versatility of shock cords led to widespread adoption across various industries. From military to recreational use, their ability to provide tension and shock absorption made them essential in securing goods and enhancing safety. Today, shock cords are a staple in B2B supply chains, reflecting their enduring significance in both industrial and consumer markets. The historical context of their development underscores the importance of adapting to market needs while maintaining a focus on innovation and quality.

Frequently Asked Questions (FAQs) for B2B Buyers of what is shock cord

-

How do I choose the right shock cord for my application?

Choosing the right shock cord depends on your specific needs, such as load capacity, environmental conditions, and application type. For instance, select a shock cord with a higher diameter for heavy-duty applications, while smaller diameters are suitable for lightweight tasks. Consider the material as well; polyester offers UV resistance and durability, making it ideal for outdoor use. If you require customization, consult suppliers about specific lengths or additional features like hooks to ensure the product meets your operational requirements. -

What are the common applications of shock cord in various industries?

Shock cords are versatile and used across many sectors, including marine, aerospace, and logistics. Common applications include securing cargo, creating tension in tarps, and even in military settings for equipment stabilization. They are also employed in outdoor gear, such as tents and canopies, where flexibility and shock absorption are critical. Understanding the specific requirements of your industry can help you leverage shock cords effectively for various applications. -

What should I consider when vetting suppliers for shock cords?

When vetting suppliers for shock cords, assess their manufacturing capabilities, quality assurance processes, and industry certifications. Check their experience in producing shock cords suitable for your specific application, and request samples to evaluate quality. Additionally, inquire about their customer service, lead times, and the ability to meet your quantity requirements. It’s also advisable to read reviews or case studies from other clients to ensure their reliability and performance history. -

What are the minimum order quantities (MOQs) for shock cords?

Minimum order quantities (MOQs) for shock cords can vary significantly between suppliers. Typically, MOQs may range from a few hundred meters to several thousand, depending on the supplier’s production capacity and your specific requirements. Discussing your needs with potential suppliers can often lead to more flexible arrangements, particularly if you are willing to enter a long-term purchasing agreement or if you are ordering multiple products. -

How do I ensure quality assurance for shock cords?

To ensure quality assurance for shock cords, collaborate with suppliers who implement rigorous testing protocols. Inquire about their quality control measures, such as material testing and end-product inspections. Request documentation of compliance with international standards, and consider third-party testing as an additional safeguard. Establishing a clear understanding of your quality expectations upfront can also help mitigate issues later in the procurement process. -

What payment terms are commonly offered by shock cord suppliers?

Payment terms for shock cord purchases can vary widely based on supplier policies and your relationship with them. Common arrangements include upfront payment, net 30/60/90 days, or even payment upon delivery. It’s crucial to discuss and negotiate these terms before finalizing your order, especially for larger quantities. Consider using escrow services for added security in international transactions, ensuring that both parties are protected throughout the payment process. -

How can I customize shock cords for my specific needs?

Customizing shock cords typically involves selecting specific lengths, diameters, and materials to suit your application. Many suppliers offer options to add hooks, clips, or other attachments to enhance functionality. Discuss your requirements with potential suppliers to explore their customization capabilities, including color options or branding. Providing detailed specifications will help suppliers deliver a product that meets your exact operational needs. -

What logistics considerations should I keep in mind when sourcing shock cords internationally?

When sourcing shock cords internationally, consider shipping times, customs regulations, and potential tariffs. Ensure that your supplier can provide documentation required for customs clearance, such as certificates of origin and compliance. It’s also vital to understand the shipping methods available, as air freight may be faster but more expensive than sea freight. Collaborating with logistics partners experienced in international shipping can facilitate smoother transactions and minimize delays.

Top 10 What Is Shock Cord Manufacturers & Suppliers List

1. Reddit – Shock Cord

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Shock cord is a type of elastic cord that is similar to bungee cord but smaller in diameter. It is commonly used in outdoor gear such as backpacks and pouches for rifle magazines. Shock cord stretches significantly and is often made with a rubber core and a braided nylon outer layer. It can be found in fabric stores under the name ‘elastic cord’ and is also available online or at outdoor retailers…

2. US Cargo Control – Shock Cord and Bungee Rope

Domain: uscargocontrol.com

Registered: 2005 (20 years)

Introduction: Shock Cord, Elastic Rope, Bungee Cord Rope; Length options: 50′, 100′, 300′, 500′; Diameter options: 1/8″, 3/16″, 1/4″, 3/8″, 1/2″; Material: Black Polyester; Pricing starts at $13.99; Shipping: Ships today for certain products, others in 2-3 business days.

3. Paracord Planet – Heavy Duty Shock Cord

Domain: paracordplanet.com

Registered: 2011 (14 years)

Introduction: Heavy Duty Shock for Marine and Rugged Use. Variations include 2.5MM Shock Cord, 1/8″ Shock Cord, 3/16″ Shock Cord, 1/4″ Shock Cord, 5/16″ Shock Cord, 3/8″ Shock Cord, 1/2″ Shock Cord, 5/8″ Shock Cord, and Reflective Shock Cord. Prices range from $4.99 to $349.99 with free standard shipping on orders over $8.99 (US only). Shock cord features a braided nylon sheath surrounding a rubber core, suitab…

4. IQS Directory – Bungee Cords

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Bungee cords, also known as shock cords or elastic cords, are composed of numerous elastic strands covered in a woven fabric, typically featuring hooks at each end for attachment. They are primarily made from rubber (natural or synthetic) and encased in a fabric shell made from materials like polypropylene, cotton, or nylon. Bungee cords are used to secure luggage or loads on vehicles and are avai…

5. Merriam-Webster – Rubber Shock Cord

Domain: merriam-webster.com

Registered: 1999 (26 years)

Introduction: This company, Merriam-Webster – Rubber Shock Cord, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

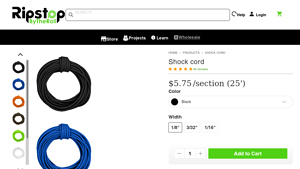

6. Ripstop by the Roll – Elastic Shock Cord

Domain: ripstopbytheroll.com

Registered: 2013 (12 years)

Introduction: {“name”:”Elastic Shock Cord”,”price”:”$5.75″,”length”:”25 feet”,”colors”:[“Black”,”Blue”,”Burnt Orange”,”Dark Olive”,”Neon”,”White”],”widths”:[“1/8 inch”,”3/32 inch”,”1/16 inch”],”material”:”Nylon”,”weights”:{“1/8 inch”:”1.9 oz (54 grams)”,”3/32 inch”:”1.2 oz (34 grams)”,”1/16 inch”:”0.6 oz (17 grams)”},”description”:”High-quality elastic shock cord commonly used as draw cord in applications that …

7. Gear Aid – Shock Cord

Domain: gearaid.com

Registered: 2005 (20 years)

Introduction: {“name”: “Shock Cord”, “description”: “Strong, stretchy cord for versatile repairs. Ideal for replacing worn-out shock cord in tents and gear, customizing bungees, closures, and tie-downs, and stretching and securing lightweight items with durable elasticity.”, “price”: “$6.95”, “sku”: “80650”, “size”: “84” x 1/8””, “includes”: “One elastic shock cord replacement”, “made_in”: “USA”, “features”: …

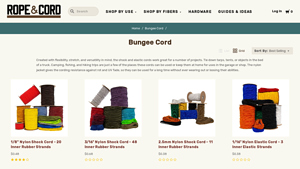

8. Rope and Cord – Bungee Cord

Domain: ropeandcord.com

Registered: 2017 (8 years)

Introduction: Bungee Cord is designed for flexibility, stretch, and versatility, suitable for various projects such as tying down tarps, tents, or objects in a truck. Ideal for camping, fishing, and hiking, it can also be used at home in garages or shops. The nylon jacket provides resistance against rot and UV fade, ensuring durability. Available sizes include: 1/8″ Nylon Shock Cord (20 Inner Rubber Strands) – …

9. TITAN Survival – Elastic Shock Cord

Domain: titansurvival.com

Registered: 2013 (12 years)

Introduction: Shock Cord – TITAN Survival

– Guaranteed for life

– Free shipping on all U.S. orders

– Elastic ShockCord with 100% stretch

– Tensile strength of ~100 LBS

– Ideal for creating bungee cords and securing items

– Available in 1000 foot spools

– Color options: Black, Coyote Brown, Olive Drab

– Price: $114.98 USD (originally $124.98 USD) for each color

– Made in USA

– Veteran-Owned

10. Knot & Rope – Polyethylene Rope

Domain: knotandrope.com

Registered: 2003 (22 years)

Introduction: {“SKU”:”2507-W”,”Weight”:”0.13 lb”,”Original Price”:”$1.78 – $178.00″,”Current Price”:”$1.78″,”Breaking Strength”:”500 lbs.”,”Fiber”:”Polyethylene over Rubber”,”Elongation”:”120% +/- 15%”,”Diameter”:”5/8″”,”Working Load Limit”:”40-100 lbs.”,”Color Options”:[{“Color”:”White”,”Price”:”$1.78 / Per Ft.”,”Spool Price”:”$160.00 / 100′ Spool”},{“Color”:”Black”,”Price”:”$1.78 / Per Ft.”,”Spool Price”:”$16…

Strategic Sourcing Conclusion and Outlook for what is shock cord

As global industries increasingly rely on versatile materials, shock cord stands out as a crucial asset across sectors ranging from transportation to outdoor recreation. Its unique elastic properties and durability make it ideal for securing cargo and absorbing shock, ensuring safe transit and handling of goods. By strategically sourcing high-quality shock cords, businesses can enhance operational efficiency, reduce costs, and improve product reliability.

Illustrative image related to what is shock cord

International buyers, particularly from Africa, South America, the Middle East, and Europe, should prioritize suppliers that offer a diverse range of shock cord specifications. This includes variations in elasticity, material composition, and length, tailored to specific applications within local markets. Establishing partnerships with reputable manufacturers can also facilitate better pricing and quicker delivery times, critical for maintaining competitive advantage.

Looking ahead, the demand for shock cords is poised to grow as industries evolve and new applications are discovered. Now is the time for international B2B buyers to invest in reliable sourcing strategies that leverage this demand. Embrace the potential of shock cords and secure your supply chain for future success—connect with trusted suppliers today to explore tailored solutions for your business needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.