Unlocking Value: A Strategic Analysis of the Washer Agitator Parts Market

Introduction: Navigating the Global Market for washer agitator parts

The global market for washer agitator parts presents a complex landscape for B2B buyers, particularly as they navigate sourcing challenges and quality assurance. With the variety of components—such as agitator assemblies, repair kits, and specific parts for leading brands—buyers must ensure they select reliable, high-quality items that meet their operational needs. This guide serves as a comprehensive resource, addressing various types of washer agitator parts, their applications, and the nuances of supplier vetting to help buyers make informed decisions.

In regions like Africa, South America, the Middle East, and Europe, where appliance maintenance is critical to both residential and commercial sectors, understanding the cost implications and sourcing strategies can significantly impact operational efficiency. The guide delves into essential factors like pricing trends, shipping logistics, and warranty considerations, providing actionable insights tailored to the unique demands of international markets.

By leveraging this knowledge, B2B buyers will be better equipped to navigate procurement processes, mitigate risks, and ultimately enhance their supply chain effectiveness. Whether you are looking to streamline maintenance operations or ensure compliance with local standards, this guide will empower you to make strategic purchasing decisions in the competitive landscape of washer agitator parts.

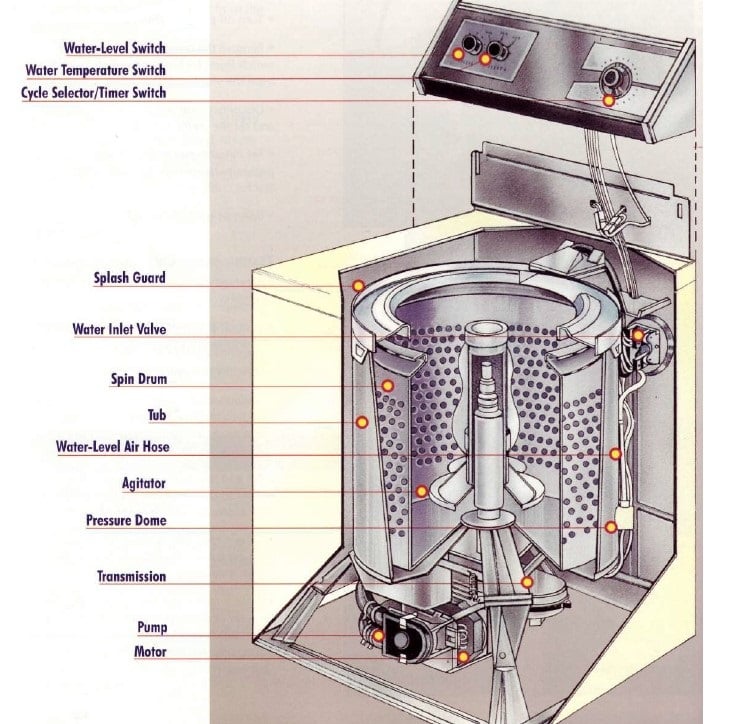

Understanding washer agitator parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Agitator Assembly | Complete unit including both upper and lower agitators | Appliance repair shops, manufacturers | Pros: Easy installation, comprehensive solution. Cons: Higher upfront cost. |

| Agitator Repair Kits | Includes components for fixing specific agitator issues | DIY repair services, small appliance retailers | Pros: Cost-effective, tailored solutions. Cons: Requires technical knowledge for installation. |

| Washplates | Flat disk that replaces traditional agitators in some models | Modern washing machine manufacturers | Pros: More efficient washing, less wear on clothes. Cons: Limited compatibility with older models. |

| Agitator Dogs | Small components that assist in the agitator’s motion | Appliance repair technicians | Pros: Inexpensive, easy to replace. Cons: Wear out frequently, requiring regular maintenance. |

| Agitator Caps | Seals that prevent water leakage and ensure proper function | Parts suppliers, appliance manufacturers | Pros: Essential for functionality, affordable. Cons: Often overlooked, leading to larger issues if not replaced. |

What are the Key Characteristics of Agitator Assemblies for B2B Buyers?

Agitator assemblies are complete units that integrate both the upper and lower sections of the agitator. They are designed for easy installation and provide a comprehensive solution for washing machine repairs. Ideal for appliance repair shops and manufacturers, these assemblies reduce the time needed for repairs, making them a favored choice among B2B buyers. However, the initial investment is higher compared to purchasing individual parts, which may affect budget-conscious buyers.

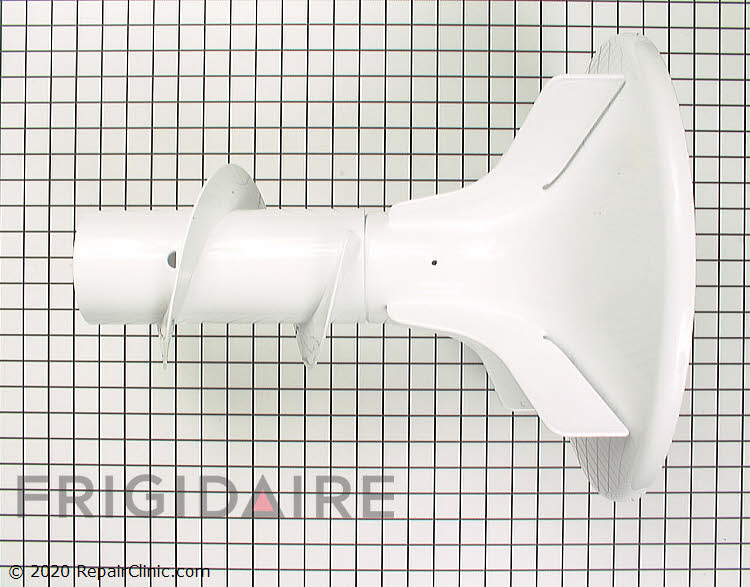

How Do Agitator Repair Kits Cater to Specific Needs?

Agitator repair kits are specifically designed to address common issues such as non-functioning agitators or irregular movement. These kits typically include essential components like cams and dogs, making them a cost-effective option for DIY repair services and small appliance retailers. While they offer tailored solutions, the installation process can be technical, requiring buyers to possess some level of expertise or access to skilled technicians.

Illustrative image related to washer agitator parts

What Advantages Do Washplates Offer in Modern Washing Machines?

Washplates are increasingly used in modern washing machines, replacing traditional agitators with a flat disk design. This innovation enhances washing efficiency and minimizes fabric wear, catering to manufacturers focused on producing high-performance appliances. While washplates are effective, their compatibility is generally limited to newer models, which may pose challenges for businesses servicing older machines.

Why are Agitator Dogs Crucial for Washer Functionality?

Agitator dogs are small yet vital components that facilitate the movement of the agitator. Their low cost and ease of replacement make them appealing to appliance repair technicians. However, they tend to wear out frequently, necessitating regular maintenance to avoid more significant issues. B2B buyers should consider stocking these parts to ensure quick repairs and maintain customer satisfaction.

What Role Do Agitator Caps Play in Washer Maintenance?

Agitator caps are essential for preventing water leakage and ensuring the smooth operation of the agitator. They are relatively inexpensive and play a crucial role in the overall functionality of washing machines. Parts suppliers and appliance manufacturers should prioritize these components to avoid larger repair issues caused by neglect. Despite their affordability, agitator caps are often overlooked, highlighting the need for awareness among B2B buyers about their importance in washer maintenance.

Key Industrial Applications of washer agitator parts

| Industry/Sector | Specific Application of washer agitator parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Home Appliance Manufacturing | Production and assembly of washing machines | Ensures efficient and effective cleaning capabilities | OEM compatibility, bulk purchasing options, quality standards |

| Laundry Services | Maintenance and repair of commercial washing machines | Reduces downtime and operational costs | Availability of spare parts, quick delivery times |

| Retail and E-commerce | Selling replacement parts for home washing machines | Expands product offerings and meets customer demand | Competitive pricing, reliable suppliers, inventory management |

| Appliance Repair Services | Repairing residential and commercial washing machines | Increases customer satisfaction and loyalty | Access to a wide range of parts, technical support |

| Export and Import Businesses | Sourcing and distributing washer agitator parts internationally | Facilitates trade and market expansion | Compliance with international regulations, shipping logistics |

How Are Washer Agitator Parts Used in Home Appliance Manufacturing?

In the home appliance manufacturing sector, washer agitator parts are integral to the assembly of washing machines. These parts, including agitator assemblies and repair kits, ensure that the machines operate efficiently, providing effective cleaning. Manufacturers must focus on sourcing OEM-compatible parts to maintain quality and reliability. For international buyers, understanding local regulations and standards is crucial to ensure compliance and facilitate smooth operations.

Illustrative image related to washer agitator parts

What Role Do Washer Agitator Parts Play in Laundry Services?

Laundry services rely heavily on the efficient functioning of their washing machines, making washer agitator parts essential for maintenance and repairs. Regular replacement of worn-out agitator components minimizes downtime, which is critical for business profitability. International buyers in this sector should prioritize sourcing high-quality parts with swift delivery options to maintain service continuity and customer satisfaction.

How Do Retail and E-commerce Businesses Benefit from Washer Agitator Parts?

Retailers and e-commerce platforms can capitalize on the growing demand for replacement washer agitator parts by expanding their product offerings. By providing a range of parts suitable for different washing machine brands, they can attract a diverse customer base. Key considerations for international sourcing include competitive pricing and ensuring a reliable supply chain to meet customer needs promptly.

Why Are Washer Agitator Parts Important for Appliance Repair Services?

Appliance repair services depend on quick access to a variety of washer agitator parts to effectively service residential and commercial washing machines. The ability to provide timely repairs enhances customer satisfaction and fosters loyalty. For buyers in this sector, having a reliable supplier with a comprehensive inventory and technical support is vital to streamline operations and ensure high service quality.

How Do Export and Import Businesses Utilize Washer Agitator Parts?

Export and import businesses play a crucial role in the global supply chain of washer agitator parts, facilitating international trade. These businesses must navigate compliance with various regulations and ensure efficient shipping logistics. International buyers should focus on establishing relationships with reputable manufacturers to secure quality parts that meet market demands, thereby enhancing their competitive edge in diverse regions.

3 Common User Pain Points for ‘washer agitator parts’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Agitator Parts

The Problem: B2B buyers often face challenges in sourcing high-quality washer agitator parts that meet specific machine requirements. With numerous suppliers in the market, distinguishing between OEM (Original Equipment Manufacturer) parts and generic alternatives can be daunting. Buyers may worry about the reliability and performance of non-OEM parts, which could lead to increased downtime and operational inefficiencies. For businesses that rely on a fleet of washing machines—such as laundromats or textile companies—this can translate into significant financial losses and customer dissatisfaction.

The Solution: To effectively source quality agitator parts, buyers should establish relationships with reputable suppliers who specialize in OEM components. Conduct thorough research on potential vendors, checking for certifications and customer reviews. When placing orders, always specify the model and part numbers to ensure compatibility. Utilizing a centralized procurement system can streamline the ordering process and maintain a record of past purchases, making it easier to reorder the correct parts in the future. Additionally, consider participating in industry trade shows or online forums where suppliers showcase their products, allowing for direct comparisons and personal interactions that can foster trust.

Scenario 2: Managing Inventory for Washer Agitator Parts

The Problem: Many B2B buyers struggle with managing inventory for washer agitator parts, which can lead to either overstocking or stockouts. Overstocking can tie up capital and increase storage costs, while stockouts can delay repairs and negatively impact service levels. This balancing act is particularly challenging for businesses operating in regions with fluctuating demand or unreliable supply chains, such as parts of Africa or South America, where logistics can be unpredictable.

The Solution: Implementing an inventory management system that utilizes just-in-time (JIT) principles can help optimize stock levels. This system should track the usage rates of various parts and predict future demand based on historical data. Buyers can establish minimum stock thresholds for critical parts, such as agitator dogs and repair kits, and automate reorder notifications. Additionally, developing a strategic partnership with suppliers who offer drop-shipping services can mitigate inventory risks by allowing businesses to maintain lower stock levels while ensuring timely delivery of parts when needed. Regular audits of inventory can also help identify slow-moving items, allowing for better allocation of resources.

Scenario 3: Addressing Performance Issues with Agitator Components

The Problem: Performance issues with washer agitator parts, such as excessive noise or poor agitation, can lead to operational disruptions and customer complaints. These issues often stem from wear and tear on agitator components, which can be exacerbated by using subpar replacement parts. For businesses that pride themselves on quality service, ensuring that washing machines operate smoothly is critical to maintaining their reputation and customer trust.

The Solution: Regular maintenance schedules should be established to inspect and replace agitator parts before they fail. Training staff on the signs of wear—such as unusual noises or ineffective washing—can help in early detection of potential problems. When replacements are necessary, investing in high-quality, compatible agitator parts is crucial. It’s beneficial to consult technical specifications and performance ratings for each component. Additionally, consider implementing a feedback loop where technicians report performance issues back to management, allowing for data-driven decisions on parts procurement. Engaging with suppliers for training on proper installation and maintenance techniques can also enhance the longevity and efficiency of agitator components, ultimately leading to better performance and fewer disruptions.

Strategic Material Selection Guide for washer agitator parts

What Are the Key Materials Used in Washer Agitator Parts?

When selecting materials for washer agitator parts, it is crucial to consider their properties, advantages, and limitations. The choice of material directly impacts the performance, durability, and cost-effectiveness of the components. Here, we analyze four common materials used in washer agitator parts: plastic, stainless steel, aluminum, and rubber.

How Does Plastic Perform in Washer Agitator Parts?

Plastic is widely used in various components of washer agitators, particularly for parts like wash plates and agitator caps. Key properties of plastic include lightweight, corrosion resistance, and good insulation against electrical currents. Additionally, plastics can withstand moderate temperatures, making them suitable for typical washing machine operations.

Pros: Plastic is generally low-cost and easy to mold into complex shapes, which simplifies manufacturing. Its lightweight nature can reduce shipping costs and energy consumption during operation.

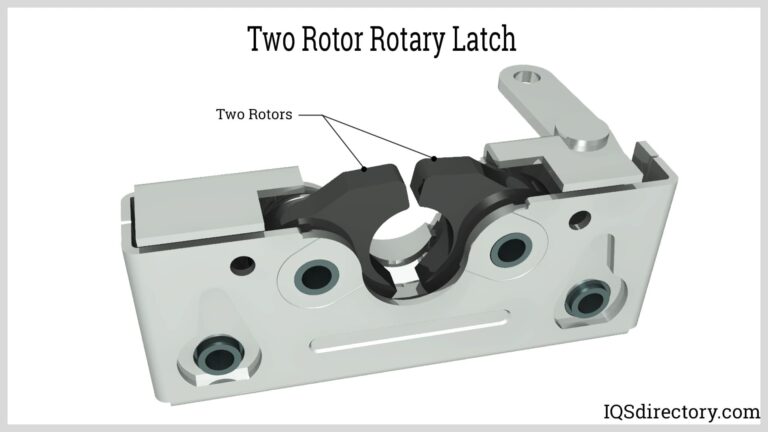

Illustrative image related to washer agitator parts

Cons: However, plastic may not be as durable as metals, particularly under high-stress conditions or extreme temperatures. It can also degrade over time due to UV exposure or chemical interactions with detergents.

Impact on Application: Plastic parts are compatible with most washing media but may not perform well in environments with high temperatures or aggressive chemicals.

International Considerations: Buyers from regions like Africa and South America should ensure that the plastics used comply with local regulations regarding recyclability and chemical safety. Standards such as ASTM D638 for tensile strength may also be relevant.

What Role Does Stainless Steel Play in Washer Agitator Parts?

Stainless steel is another popular choice for washer agitator components, particularly for structural parts like the agitator shaft and couplings. Its key properties include high tensile strength, excellent corrosion resistance, and the ability to withstand high temperatures and pressures.

Pros: The durability of stainless steel makes it ideal for long-term use, reducing the need for frequent replacements. It also provides a premium feel and performance, which can be a selling point in competitive markets.

Cons: The main drawback is its higher cost compared to plastic and aluminum, which may deter budget-conscious buyers. Manufacturing processes for stainless steel can also be more complex and time-consuming.

Impact on Application: Stainless steel’s compatibility with various washing media is excellent, making it suitable for both residential and commercial applications.

International Considerations: Compliance with international standards like ASTM A240 for stainless steel is essential, especially for buyers in Europe and the Middle East. Understanding local corrosion rates and environmental factors is also crucial for ensuring longevity.

How Does Aluminum Compare in Washer Agitator Parts?

Aluminum is often used for lighter components of washer agitators, such as certain types of wash plates and structural supports. Its key properties include lightweight, good corrosion resistance, and decent thermal conductivity.

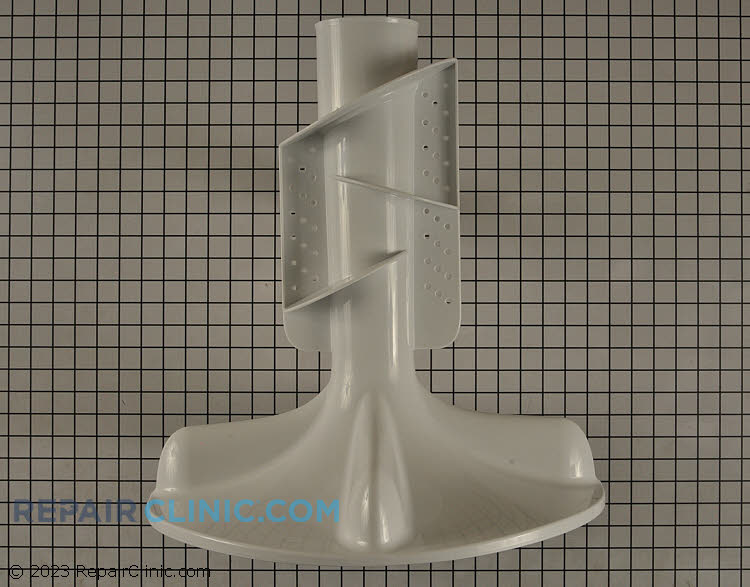

Illustrative image related to washer agitator parts

Pros: Aluminum is cost-effective and easy to machine, allowing for rapid production. Its lightweight nature contributes to lower shipping costs and energy efficiency during operation.

Cons: However, aluminum is less durable than stainless steel and may deform under high stress. It can also be more susceptible to corrosion in certain environments, especially if not properly treated.

Impact on Application: Aluminum parts are suitable for most washing environments but may require careful consideration in areas with high humidity or exposure to corrosive substances.

International Considerations: Buyers should ensure that aluminum parts meet standards such as ASTM B221 for structural aluminum. Additionally, understanding local preferences for aluminum alloys can enhance compatibility and performance.

What Is the Role of Rubber in Washer Agitator Parts?

Rubber is commonly used for seals and gaskets in washer agitators. Its key properties include flexibility, excellent water resistance, and good vibration dampening capabilities.

Pros: Rubber components are crucial for preventing leaks and ensuring smooth operation, contributing to overall appliance efficiency. They are also relatively inexpensive and easy to replace.

Cons: Rubber can degrade over time due to exposure to heat and chemicals, leading to potential failures. Its performance can be compromised in extreme temperatures.

Impact on Application: Rubber is compatible with water and most detergents but may not withstand high temperatures or aggressive cleaning agents.

International Considerations: Compliance with standards like ASTM D2000 for rubber materials is important for international buyers, particularly in regions with strict manufacturing regulations.

Summary Table of Material Selection for Washer Agitator Parts

| Material | Typical Use Case for washer agitator parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Wash plates, agitator caps | Low cost, easy to mold | Less durable under stress | Low |

| Stainless Steel | Agitator shafts, couplings | High durability, corrosion-resistant | Higher cost, complex manufacturing | High |

| Aluminum | Lightweight structural supports | Cost-effective, lightweight | Less durable, susceptible to corrosion | Medium |

| Rubber | Seals and gaskets | Excellent water resistance | Degrades over time | Low |

This analysis provides a comprehensive overview of the materials used in washer agitator parts, enabling international B2B buyers to make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for washer agitator parts

What Are the Main Stages in the Manufacturing Process of Washer Agitator Parts?

The manufacturing of washer agitator parts involves several critical stages, each designed to ensure high-quality output that meets international standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation:

The process begins with the selection of raw materials, typically high-grade plastics and metals that are resistant to wear and corrosion. Suppliers must ensure that materials comply with international standards, such as ASTM or ISO specifications. Once the materials are sourced, they undergo a series of tests to check for quality and durability. -

Forming:

Forming techniques vary depending on the specific parts being produced. Injection molding is often used for plastic components, while stamping or machining is utilized for metal parts. Advanced technologies, such as CNC machining, ensure precision and consistency in forming. The choice of technique is crucial, as it affects the part’s overall performance and longevity. -

Assembly:

After individual components are formed, they are assembled into complete agitator units. This stage requires skilled labor and often involves automated systems to ensure efficiency and accuracy. During assembly, parts are checked for compatibility and fit to prevent issues during the operational phase. -

Finishing:

The final stage involves surface treatments, such as painting or coating, to enhance the part’s resistance to environmental factors and improve aesthetics. Quality control checks are performed at this stage to ensure that the finishing meets the desired specifications.

How Is Quality Assurance Implemented in Manufacturing Washer Agitator Parts?

Quality assurance is a critical component of the manufacturing process, ensuring that all products meet predefined standards. Key international standards relevant to this industry include ISO 9001, which focuses on quality management systems, and CE marking, which indicates compliance with EU safety, health, and environmental protection standards.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This involves assessing the quality of raw materials upon arrival. Suppliers must provide documentation proving that materials meet specified standards.

– In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to ensure that parts are being produced according to design specifications. This may involve dimensional checks and functional tests.

– Final Quality Control (FQC): Once the manufacturing process is complete, a comprehensive inspection is performed to ensure that the final product meets all quality requirements before shipping. -

Common Testing Methods:

Various testing methods are employed to validate the performance and durability of washer agitator parts. These include mechanical testing (tensile and compression tests), thermal analysis, and environmental testing to simulate real-world conditions.

How Can B2B Buyers Verify the Quality Assurance of Suppliers?

For international buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance processes is crucial. Here are actionable steps to ensure compliance:

-

Conduct Supplier Audits:

Regular audits of suppliers can help assess their manufacturing processes and quality control measures. During an audit, buyers can evaluate the adherence to international standards and the effectiveness of their quality management systems. -

Request Quality Reports:

Buyers should ask for detailed quality assurance reports from suppliers, including documentation of tests performed, certifications obtained, and any corrective actions taken in response to quality issues. -

Engage Third-Party Inspection Services:

Utilizing third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control processes. These agencies can conduct inspections at various stages of production and provide certification that the products meet required standards. -

Understand Certification Nuances:

Different regions may have specific quality certifications that are critical for compliance. For example, CE marking is essential for products sold in the European market, while ISO certifications are recognized globally. Buyers should ensure that their suppliers possess the necessary certifications relevant to their target markets.

What Are the Challenges and Considerations for International B2B Buyers?

International B2B buyers face several challenges when sourcing washer agitator parts, particularly regarding quality assurance and compliance. Here are some considerations:

-

Cultural and Regulatory Differences:

Different countries have varying regulations governing manufacturing standards. Buyers must familiarize themselves with local laws and compliance requirements in the regions they operate in. -

Supply Chain Transparency:

Ensuring transparency in the supply chain is crucial for maintaining quality standards. Buyers should establish clear communication channels with suppliers and encourage transparency regarding sourcing and manufacturing processes. -

Risk Management:

Identifying potential risks in the supply chain, such as disruptions due to political instability or natural disasters, is essential. Buyers should develop contingency plans to mitigate these risks and maintain a steady supply of quality parts. -

Sustainability Practices:

Increasingly, buyers are prioritizing suppliers that adhere to sustainable practices in their manufacturing processes. This includes using eco-friendly materials and minimizing waste. Suppliers that can demonstrate commitment to sustainability may have a competitive advantage in the marketplace.

By understanding the intricacies of manufacturing processes and quality assurance for washer agitator parts, B2B buyers can make informed decisions that enhance their procurement strategies and ensure the reliability of their products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘washer agitator parts’

The following guide is designed to assist B2B buyers in effectively sourcing washer agitator parts. It outlines critical steps to ensure a smooth procurement process, helping you select the right components while minimizing risks associated with supplier selection and product quality.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential before initiating the sourcing process. Identify the specific types of agitator parts required, such as repair kits, assembly components, or individual parts like caps and seals. Include details such as OEM part numbers and compatibility with various washer models to streamline your procurement efforts.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers in the market. Use platforms like industry directories, trade shows, and online marketplaces to compile a list. Pay attention to suppliers that specialize in washer agitator parts, as they are more likely to understand your specific needs and offer tailored solutions.

Step 3: Evaluate Supplier Certifications

Before moving forward, it’s crucial to verify supplier certifications and compliance with industry standards. Look for certifications such as ISO 9001, which indicates a commitment to quality management. This step helps ensure that the supplier adheres to international quality standards, reducing the risk of defective parts.

Step 4: Request Product Samples

Always request product samples before placing a bulk order. This allows you to assess the quality, compatibility, and performance of the agitator parts. Evaluate the samples based on materials used, fit, and functionality to ensure they meet your technical specifications.

Step 5: Check Customer Reviews and References

Investigate customer reviews and seek references from other businesses that have purchased from the supplier. This feedback can provide valuable insights into the supplier’s reliability, product quality, and customer service. Aim for suppliers with a strong track record, particularly in your target markets.

Step 6: Negotiate Pricing and Terms

Once you have shortlisted potential suppliers, engage in negotiations regarding pricing, minimum order quantities, and payment terms. Ensure that you understand the total cost of ownership, which includes shipping, duties, and any additional fees. Establishing favorable terms can lead to long-term partnerships and cost savings.

Step 7: Plan for Logistics and Delivery

Consider the logistics involved in shipping and delivery of the washer agitator parts. Confirm the supplier’s ability to meet your delivery timelines and understand their shipping policies. Additionally, ensure that they can provide tracking information and support in case of any issues during transit.

Following this checklist will equip you with a structured approach to sourcing washer agitator parts, ultimately leading to successful procurement outcomes and enhanced operational efficiency.

Comprehensive Cost and Pricing Analysis for washer agitator parts Sourcing

What Are the Key Cost Components in Washer Agitator Parts Sourcing?

When sourcing washer agitator parts, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

- Materials: The type of materials used significantly impacts the cost. High-quality plastics or metals can increase the price of components like agitator assemblies and repair kits.

- Labor: Labor costs vary based on geographic location and the skill level required for production. Countries with lower labor costs may offer competitive pricing, but this can affect quality.

- Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce overhead, leading to better pricing for buyers.

- Tooling: Initial tooling costs for custom parts can be substantial. These costs are typically amortized over production runs, influencing the pricing of larger orders.

- Quality Control (QC): Ensuring that parts meet specifications can add to the overall cost. Buyers should consider the implications of QC on long-term reliability and warranty claims.

- Logistics: Shipping and handling costs are particularly important for international buyers. Factors such as distance, transport mode, and customs duties can substantially affect total costs.

- Margin: Suppliers will incorporate a profit margin that varies based on their market positioning, competition, and perceived value of the parts.

How Do Price Influencers Affect Washer Agitator Parts Sourcing?

Several factors influence the pricing of washer agitator parts, particularly for international buyers.

Illustrative image related to washer agitator parts

- Volume/MOQ: Larger orders often result in lower per-unit costs due to economies of scale. Establishing a Minimum Order Quantity (MOQ) can help buyers negotiate better pricing.

- Specifications/Customization: Customized parts typically incur higher costs due to additional design and production complexities. Buyers should weigh the necessity of customization against potential cost increases.

- Materials and Quality Certifications: The choice of materials and whether parts meet industry certifications can affect pricing. Higher-quality materials and certifications often lead to higher costs but can enhance durability and performance.

- Supplier Factors: The supplier’s reputation, production capacity, and reliability can influence pricing. Established suppliers may charge a premium for their experience and quality assurance.

- Incoterms: Understanding Incoterms is vital for international transactions. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting the total landed cost.

What Buyer Tips Can Help Optimize Costs in Sourcing Washer Agitator Parts?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, strategic sourcing can optimize costs. Here are some essential tips:

- Negotiation: Engage suppliers in discussions about pricing, especially if you can commit to larger orders or establish a long-term relationship. Leverage multiple quotes to foster competitive pricing.

- Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), which includes acquisition costs, maintenance, and operational costs over the product’s lifespan. Sometimes, a higher initial price can lead to lower long-term costs if the part is more durable or efficient.

- Pricing Nuances for International Buyers: Be aware of potential additional costs such as import duties, taxes, and shipping fees when sourcing from different regions. Understanding local market conditions can also provide leverage in negotiations.

Disclaimer on Indicative Prices

Prices for washer agitator parts can vary widely based on the aforementioned factors. The indicative prices provided in various sources are subject to change based on market conditions, supplier pricing strategies, and geopolitical factors. It is advisable for buyers to conduct thorough market research and obtain updated quotes prior to making purchasing decisions.

Alternatives Analysis: Comparing washer agitator parts With Other Solutions

Understanding Alternatives to Washer Agitator Parts

In the competitive landscape of appliance repair and maintenance, understanding the alternatives to washer agitator parts is crucial for B2B buyers. As the demand for efficient, cost-effective solutions continues to grow, businesses must evaluate various options that can meet their operational needs while maintaining performance standards. This section compares traditional washer agitator parts with two viable alternatives: wash plates and high-efficiency washing machine systems.

| Comparison Aspect | Washer Agitator Parts | Wash Plates | High-Efficiency Washing Systems |

|---|---|---|---|

| Performance | Effective in stain removal through mechanical agitation | Provides a gentler wash, reducing fabric wear | Advanced technology minimizes water usage and energy consumption |

| Cost | Generally lower initial costs; ongoing replacement needed | Moderate costs; durable with less frequent replacement | Higher upfront investment; long-term savings on utilities |

| Ease of Implementation | Simple to replace; DIY-friendly | Installation requires some technical knowledge | Professional installation often necessary |

| Maintenance | Regular maintenance needed; parts wear over time | Minimal maintenance; robust design | Requires periodic servicing; technology updates may be needed |

| Best Use Case | Suitable for various washing machine models | Best for delicate fabrics and energy-efficient washing | Ideal for large-scale operations focused on sustainability |

What Are the Advantages and Disadvantages of Wash Plates?

Wash plates serve as a significant alternative to traditional agitators. They operate on a pulsating motion that can be gentler on fabrics while still effectively cleaning. The advantages of wash plates include their reduced wear on clothing, making them ideal for delicate items. Additionally, they often require less water and energy, contributing to lower utility bills. However, they may not be as effective in heavy-duty cleaning scenarios, making them less suitable for commercial operations dealing with heavily soiled items.

How Do High-Efficiency Washing Systems Compare?

High-efficiency washing systems represent a more advanced alternative, utilizing innovative technologies to clean clothes with minimal water and energy. These systems often incorporate features like smart sensors and automated settings, enhancing user experience and operational efficiency. The primary advantage is their long-term cost savings through reduced utility bills and less frequent maintenance. However, the initial investment can be substantial, and they may require professional installation and occasional servicing, which could deter some businesses from adopting this technology.

Conclusion: How Can B2B Buyers Choose the Right Solution?

For international B2B buyers, the decision to select between washer agitator parts, wash plates, or high-efficiency washing systems hinges on a careful assessment of their specific needs. Factors such as the types of fabrics being washed, budget constraints, and long-term operational goals should guide this decision. Businesses focused on cost-effectiveness and ease of maintenance may find traditional agitator parts more suitable, while those prioritizing fabric care and sustainability may lean towards wash plates or high-efficiency systems. Ultimately, understanding the nuances of each option will empower buyers to make informed choices that align with their operational objectives.

Essential Technical Properties and Trade Terminology for washer agitator parts

What Are the Essential Technical Properties of Washer Agitator Parts?

When sourcing washer agitator parts, understanding the critical technical specifications is paramount for ensuring compatibility, durability, and performance. Here are some key properties:

-

Material Grade

Washer agitator parts are typically made from materials such as high-grade plastics or metals like stainless steel. The material grade directly impacts durability, resistance to corrosion, and overall performance. For instance, using high-grade plastics can reduce the weight of the part, leading to less strain on the motor while maintaining effective agitation. -

Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension of a part. In washer agitator components, maintaining precise tolerances is crucial for ensuring proper fit and function. Poorly manufactured parts with excessive tolerances may lead to vibrations, noise, and ultimately, premature failure, impacting the overall washing machine performance. -

Compatibility

Compatibility indicates whether a part can work with specific models or brands of washing machines. Parts are often labeled with OEM (Original Equipment Manufacturer) numbers, which are essential for B2B buyers to ensure they are purchasing the correct part for their intended application. Compatibility reduces the risk of returns and enhances customer satisfaction. -

Weight

The weight of agitator parts can affect shipping costs and handling, particularly for bulk orders. Lighter parts may incur lower shipping fees and are easier to manage during installation. Understanding the weight specifications helps businesses estimate logistics costs accurately. -

Performance Ratings

Performance ratings such as load capacity and operational speed are essential for evaluating how well a part will function under specific conditions. These ratings guide buyers in selecting parts that meet their operational requirements, ensuring optimal washing machine performance.

What Are Common Trade Terminology and Jargon Related to Washer Agitator Parts?

Familiarity with industry terminology is crucial for effective communication and negotiation. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to parts made by the manufacturer of the original product. OEM parts are typically regarded as higher quality and are recommended for repairs to maintain the integrity of the washing machine. Buyers should prioritize OEM parts to ensure reliability and compatibility. -

MOQ (Minimum Order Quantity)

MOQ is the minimum quantity of units that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to manage inventory costs effectively. Buyers must negotiate terms that align with their purchasing capabilities while ensuring they do not overstock. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific parts. This process is crucial for comparing costs and ensuring that buyers receive competitive pricing and favorable terms. An RFQ can help businesses make informed decisions based on comprehensive market analysis. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps businesses navigate global trade efficiently, minimizing risks associated with international shipping. -

Aftermarket Parts

Aftermarket parts are components made by manufacturers other than the original equipment manufacturer. While they can be less expensive, buyers should evaluate their quality and compatibility carefully. Understanding the difference between OEM and aftermarket parts can significantly impact the long-term performance of washing machines. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. In the B2B context, understanding lead times is critical for inventory management and ensuring that repair operations run smoothly. Buyers should negotiate lead times that align with their operational needs to avoid downtime.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions that enhance their supply chain efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the washer agitator parts Sector

What Are the Key Trends and Market Dynamics in the Washer Agitator Parts Sector?

The washer agitator parts sector is experiencing significant transformation, driven by several global factors. Increasing consumer demand for energy-efficient appliances is prompting manufacturers to innovate and enhance the design of agitator components. Buyers from regions like Africa, South America, the Middle East, and Europe are particularly focused on sourcing parts that not only meet operational efficiency but also comply with various international standards. The rise of e-commerce platforms has also streamlined the procurement process, enabling international buyers to access a wider range of products and suppliers with ease.

Emerging technologies, such as advanced supply chain management software and data analytics, are reshaping the sourcing landscape. Buyers are increasingly leveraging these technologies to assess supplier reliability, track shipments, and manage inventory effectively. Additionally, the trend towards digital marketplaces is facilitating better price comparisons and enabling buyers to make informed decisions.

Another noteworthy trend is the growing importance of localization in sourcing strategies. Buyers are looking to partner with local suppliers to reduce lead times and transportation costs, particularly in markets like Saudi Arabia and Vietnam. This shift not only fosters economic growth within local communities but also enhances the overall responsiveness of supply chains.

How Does Sustainability and Ethical Sourcing Impact B2B Relationships in the Washer Agitator Parts Industry?

Sustainability has become a pivotal consideration for international B2B buyers in the washer agitator parts sector. The environmental impact of manufacturing processes and the lifecycle of products are under increasing scrutiny. Buyers are now prioritizing suppliers that demonstrate commitment to sustainable practices, such as reducing carbon footprints and minimizing waste. This focus on sustainability extends to the sourcing of raw materials, with an emphasis on using recycled or eco-friendly materials in the production of washer agitator parts.

Moreover, ethical sourcing is gaining traction as businesses recognize the importance of transparent supply chains. Buyers are keen to partner with manufacturers that uphold labor rights and comply with ethical standards, ensuring that the production of parts does not exploit workers or harm communities. Certifications like ISO 14001 for environmental management or Fair Trade can play a significant role in the decision-making process, providing assurance to buyers that their suppliers align with ethical values.

By prioritizing sustainability and ethical sourcing, B2B buyers not only enhance their brand reputation but also meet the growing consumer demand for responsible products, thereby driving long-term growth.

What Is the Evolution of the Washer Agitator Parts Industry?

The evolution of the washer agitator parts industry can be traced back to the development of washing machines in the early 20th century. Initially, these machines relied on simple mechanical systems to agitate laundry, which led to the invention of the agitator design. Over the decades, advancements in materials and technology have resulted in more efficient and durable agitator components, significantly improving washing performance and appliance longevity.

The introduction of electronic controls in the late 20th century further revolutionized the sector. Modern washing machines now feature sophisticated agitation patterns that optimize cleaning while conserving water and energy. As consumer preferences have shifted towards convenience and efficiency, the washer agitator parts industry has adapted, focusing on producing high-quality, reliable components that meet the evolving needs of both manufacturers and end-users.

In conclusion, understanding the market dynamics, sourcing trends, and the historical context of washer agitator parts is essential for B2B buyers looking to navigate this sector effectively. By leveraging insights on sustainability and ethical sourcing, buyers can make informed decisions that align with their business objectives and values.

Frequently Asked Questions (FAQs) for B2B Buyers of washer agitator parts

-

1. How do I solve issues with my washing machine agitator?

To address problems with a washing machine agitator, first identify the specific issue, such as loud noises, failure to agitate, or damage to clothes. Common solutions include replacing worn parts like agitator dogs, clutches, or the entire agitator assembly. Ensure you have the correct OEM part numbers for compatibility. For persistent issues, consider consulting a professional technician who can diagnose underlying mechanical problems. Regular maintenance and timely part replacements can also prolong the life of the agitator. -

2. What is the best agitator part for my washing machine model?

The best agitator part for your washing machine depends on the model and the specific issue you are experiencing. Always refer to your machine’s manual for OEM part numbers. For common brands like Whirlpool, Kenmore, or GE, several reliable options are available, including repair kits and complete assemblies. If unsure, consult a supplier or technician with experience in your brand to ensure you choose the most effective replacement part. -

3. What factors should I consider when vetting suppliers for washer agitator parts?

When vetting suppliers, consider factors such as their reputation, product range, pricing, and delivery times. Check for certifications and compliance with international quality standards. Evaluate their customer service responsiveness and after-sales support, as these aspects can significantly impact your purchasing experience. Additionally, reviewing customer testimonials and case studies can provide insights into their reliability and product quality. -

4. What are the typical minimum order quantities (MOQ) for washer agitator parts?

Minimum order quantities can vary widely among suppliers, typically ranging from 10 to 100 units, depending on the part and manufacturer. Some suppliers may offer lower MOQs for specific items or during promotional periods. It’s advisable to discuss your needs directly with suppliers, as they may accommodate smaller orders for new customers or bulk purchases, thereby allowing for better inventory management. -

5. What payment terms can I expect when purchasing washer agitator parts internationally?

Payment terms often vary by supplier and region, but common options include advance payment, net 30/60 days, or letters of credit. For international transactions, be aware of additional costs such as customs duties and taxes, which can affect your total expenditure. It’s crucial to establish clear payment terms before placing an order to avoid misunderstandings and ensure timely processing. -

6. How can I ensure the quality of the washer agitator parts I purchase?

To ensure quality, source parts from reputable suppliers who offer OEM or high-quality aftermarket components. Request product specifications, certifications, and warranty information before purchase. Conduct thorough research on supplier reviews and performance history. Implementing a quality assurance process, including inspection upon receipt, can also help maintain standards and avoid defective parts. -

7. What logistics considerations should I keep in mind when sourcing washer agitator parts?

When sourcing parts internationally, consider logistics factors such as shipping times, customs clearance, and potential delays. Understand the shipping options available, including express versus standard delivery, and factor in the associated costs. Ensure your supplier provides tracking information and has a reliable logistics partner. It’s also wise to plan for potential disruptions in the supply chain and establish backup suppliers as needed. -

8. Can I customize washer agitator parts for my specific needs?

Many suppliers offer customization options for washer agitator parts, especially for bulk orders. Customization can include specific dimensions, materials, or functional modifications to meet unique operational requirements. Discuss your specifications with potential suppliers to assess their capabilities and willingness to accommodate your needs. Keep in mind that custom orders may have longer lead times and higher costs compared to standard parts.

Top 3 Washer Agitator Parts Manufacturers & Suppliers List

1. McCombs Supply – Agitator Parts

Domain: mccombssupply.com

Registered: 2001 (24 years)

Introduction: This company, McCombs Supply – Agitator Parts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. PartSelect – Washer Agitator Directional Cogs

Domain: partselect.com

Registered: 1999 (26 years)

Introduction: Washer Agitators | OEM Replacement Parts – PartSelect.com

1. Washer Agitator Directional Cogs

– Price: $7.31

– In Stock

– PartSelect Number: PS388034

– Manufacturer Part Number: 80040

– Description: Used for replacing the agitator directional cogs (Agitator Dogs, Agitator Repair Kit, Washer Agitator Dogs, Agitator Dog Ears). The agitator creates the thrusting motion in the washer t…

3. GE – WH43X10034 Washer Lid Lock Assembly

Domain: geapplianceparts.com

Registered: 1999 (26 years)

Introduction: WH43X10034 is a washer lid lock assembly compatible with various GE washing machines. It ensures the lid remains locked during operation for safety. The part is designed to fit specific models, and it is essential for proper functioning of the washer. Installation requires basic tools and knowledge of appliance repair.

Strategic Sourcing Conclusion and Outlook for washer agitator parts

As the demand for efficient and reliable washing machines continues to rise globally, strategic sourcing of washer agitator parts emerges as a crucial component for businesses aiming to enhance their service offerings. By prioritizing high-quality, OEM replacement parts, international B2B buyers can ensure optimal performance and longevity of washing machines, addressing common issues such as ineffective agitation and noise disturbances. This proactive approach not only improves customer satisfaction but also reduces the frequency of repairs, ultimately leading to cost savings.

In regions like Africa, South America, the Middle East, and Europe, establishing robust supplier relationships can facilitate access to a diverse range of agitator parts, tailored to various washing machine brands. Leveraging local suppliers can also help navigate logistical challenges, ensuring timely delivery and compliance with regional regulations.

Looking ahead, businesses should embrace innovation in their sourcing strategies, exploring partnerships with manufacturers who prioritize sustainability and advanced technology in their products. This forward-thinking approach will not only enhance operational efficiency but also align with the growing consumer demand for environmentally friendly solutions. International B2B buyers are encouraged to assess their sourcing strategies now to stay competitive and responsive in a rapidly evolving market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.