Unlocking Value: A Strategic Analysis of the Vinil Para Carros Market

Introduction: Navigating the Global Market for vinil para carros

Navigating the global market for vinil para carros presents a significant challenge for international B2B buyers, especially when sourcing high-quality materials that meet diverse regional standards and preferences. With a booming automotive aftermarket, businesses must navigate a myriad of options, from glossy and matte finishes to specialized carbon fiber designs. This guide offers a comprehensive overview of the various types of vinyl wraps available, their applications across different vehicle segments, and essential supplier vetting processes.

Buyers will gain insights into cost considerations, ensuring they make informed purchasing decisions that align with their budget and quality expectations. We delve into the importance of understanding local market trends, which vary significantly across regions such as Africa, South America, the Middle East, and Europe, including specific insights for countries like Vietnam and Nigeria.

By equipping B2B buyers with actionable information on sourcing, product specifications, and supplier relationships, this guide empowers them to confidently navigate the complexities of the vinyl wrap market. Whether looking to enhance a vehicle’s aesthetic appeal or protect its surface, understanding the nuances of vinil para carros can transform a business’s offerings and customer satisfaction levels. This resource aims to facilitate a smoother procurement process, driving success in a competitive landscape.

Understanding vinil para carros Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Glossy Vinyl Wrap | High shine finish, vibrant colors, and smooth texture. | Vehicle customization, advertising | Pros: Eye-catching appearance; Cons: Prone to scratches. |

| Matte Vinyl Wrap | Non-reflective finish with a sophisticated look. | Luxury vehicle wraps, branding | Pros: Unique aesthetic; Cons: More susceptible to stains. |

| Carbon Fiber Vinyl Wrap | Textured finish mimicking real carbon fiber, lightweight. | Performance vehicles, aesthetic upgrades | Pros: Lightweight; Cons: Higher cost compared to other wraps. |

| Satin Vinyl Wrap | Semi-gloss finish that combines both matte and glossy looks. | Commercial fleets, luxury vehicles | Pros: Versatile appearance; Cons: Less durable than glossy wraps. |

| Paint Protection Film | Clear vinyl that protects the original paint from damage. | Protective applications, resale value | Pros: Preserves original paint; Cons: Can be more expensive. |

What Are the Characteristics of Glossy Vinyl Wraps?

Glossy vinyl wraps are characterized by their high shine and vibrant color options. This type of wrap is popular for vehicle customization and advertising due to its ability to attract attention. It offers a smooth texture that enhances the overall aesthetic of the vehicle, making it an ideal choice for businesses aiming to stand out. When purchasing, B2B buyers should consider factors such as the durability of the finish and the potential for scratches, which may affect the long-term appearance of the wrap.

Illustrative image related to vinil para carros

How Does Matte Vinyl Wrap Differ from Other Options?

Matte vinyl wraps feature a non-reflective finish that provides a sophisticated and modern look. This type is often used for luxury vehicle wraps and branding, appealing to businesses that want to convey a premium image. B2B buyers should be aware that while matte wraps offer a unique aesthetic, they are also more susceptible to stains and may require more careful maintenance compared to glossy options.

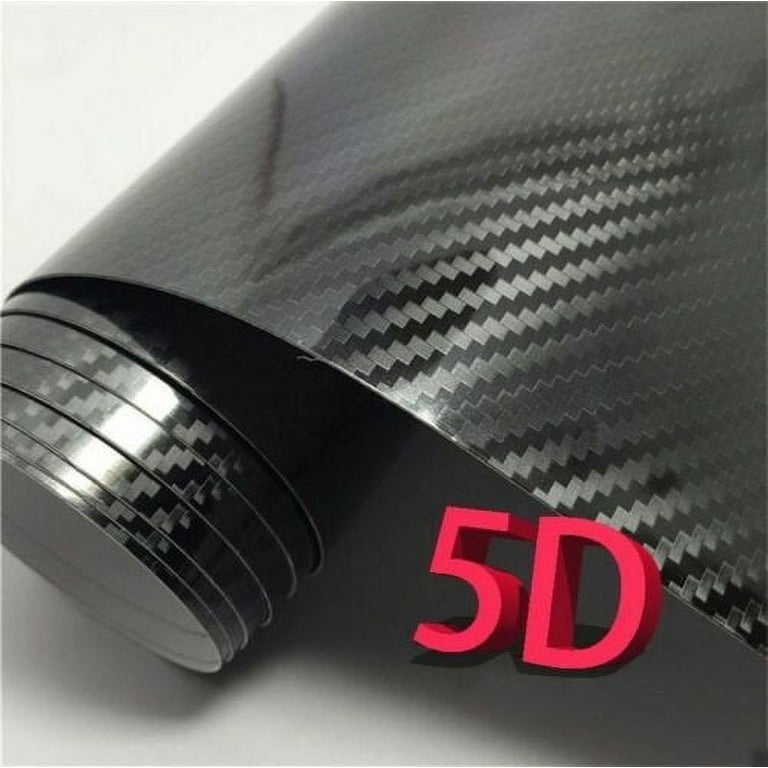

Why Choose Carbon Fiber Vinyl Wraps for Performance Vehicles?

Carbon fiber vinyl wraps are designed to mimic the appearance of real carbon fiber, offering a textured finish that is lightweight and visually striking. This type is commonly used in performance vehicles and aesthetic upgrades, making it a popular choice among automotive enthusiasts. B2B buyers should consider the higher cost associated with carbon fiber wraps, as well as their application suitability for specific vehicle types.

What Are the Benefits of Satin Vinyl Wraps?

Satin vinyl wraps provide a semi-gloss finish that combines elements of both matte and glossy wraps, making them versatile for various applications. They are frequently used in commercial fleets and luxury vehicles, appealing to businesses that want a refined look without the high maintenance of a full gloss. Buyers should evaluate the durability of satin wraps, as they may not be as resilient as glossy options.

How Does Paint Protection Film Enhance Vehicle Value?

Paint protection film (PPF) is a clear vinyl wrap that safeguards the original paint from scratches, chips, and environmental damage. This type is particularly valuable for protective applications and can significantly enhance a vehicle’s resale value. B2B buyers should assess the cost-effectiveness of PPF, as it may represent a higher initial investment but can save money on repairs and maintenance in the long run.

Key Industrial Applications of vinil para carros

| Industry/Sector | Specific Application of vinil para carros | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Customization | Vehicle wraps for branding and aesthetics | Enhances brand visibility and provides a unique vehicle appearance | Quality of vinyl, durability, color options, and ease of application |

| Public Transport | Fleet branding for buses and taxis | Cost-effective advertising that can be easily updated or changed | Compliance with local regulations, adhesive strength, and longevity |

| Events and Promotions | Temporary vehicle advertising for events | Flexible marketing solution with high visibility during events | Customizability, turnaround time, and material quality |

| Delivery Services | Branding for delivery vans and trucks | Builds brand recognition while on the road, enhancing customer trust | Weather resistance, ease of removal, and maintenance needs |

| Automotive Repair Shops | Protective vinyl for vehicle surfaces | Protects original paintwork and enhances resale value | Compatibility with various vehicle models and surface types |

How is ‘vinil para carros’ Used in Automotive Customization?

In the automotive customization sector, ‘vinil para carros’ is primarily utilized for vehicle wraps that serve both aesthetic and branding purposes. Businesses can transform their vehicles into eye-catching advertisements or unique designs that stand out on the road. The flexibility of vinyl allows for easy application and removal, making it an ideal choice for companies looking to refresh their branding. For international buyers, particularly in regions like Africa and South America, sourcing high-quality vinyl that can withstand diverse climates is crucial. Buyers should consider durability, color range, and application methods to ensure a successful wrap.

Illustrative image related to vinil para carros

What Role Does Vinyl Play in Public Transport Branding?

Public transport systems, such as buses and taxis, leverage ‘vinil para carros’ for fleet branding. This approach offers a cost-effective method for advertising that can be easily updated as marketing campaigns change. Vinyl wraps can cover large surfaces, making them highly visible to commuters and passersby. For B2B buyers in the Middle East and Europe, it’s essential to ensure compliance with local regulations regarding advertising on public vehicles. Additionally, buyers should prioritize the adhesive strength and longevity of the vinyl to withstand varying weather conditions.

How Can Temporary Vehicle Advertising Benefit Events?

Temporary vehicle advertising using ‘vinil para carros’ is an effective strategy for events and promotions. Companies can wrap vehicles to promote specific events, campaigns, or product launches, gaining high visibility in crowded areas. The temporary nature of these wraps allows for quick changes to marketing messages. For international B2B buyers, understanding local market trends and preferences is vital for selecting the right design and messaging. Buyers should also look for vinyl that is easy to apply and remove, minimizing downtime for the vehicles involved.

In What Ways Do Delivery Services Utilize Vinyl Branding?

Delivery services frequently utilize ‘vinil para carros’ to brand their vans and trucks, establishing brand recognition while on the move. This type of branding not only reinforces the company’s image but also builds customer trust as the vehicles become familiar sight in the community. For B2B buyers, especially in regions like Vietnam and Nigeria, factors such as weather resistance and the ease of maintenance of the vinyl are important considerations. Ensuring that the vinyl can endure the rigors of daily use without fading or peeling is essential for long-term effectiveness.

Illustrative image related to vinil para carros

Why is Protective Vinyl Important for Automotive Repair Shops?

Automotive repair shops often employ ‘vinil para carros’ as a protective layer for vehicle surfaces. This application helps shield the original paintwork from scratches, UV damage, and environmental factors, thereby enhancing the vehicle’s resale value. For B2B buyers in the automotive repair industry, compatibility with various vehicle models and surface types is crucial. They should also consider the ease of application and removal, as well as the vinyl’s ability to maintain its appearance over time, ensuring customer satisfaction and repeat business.

3 Common User Pain Points for ‘vinil para carros’ & Their Solutions

Scenario 1: Sourcing High-Quality Vinyl Wraps for Diverse Markets

The Problem: B2B buyers often struggle with sourcing high-quality vinyl wraps that meet the diverse needs of their customer base. In regions like Africa and South America, where environmental conditions vary significantly, buyers face challenges in ensuring that the vinyl wraps are durable and suitable for local climates. Additionally, the risk of receiving subpar products can lead to dissatisfaction among end customers, tarnishing the buyer’s reputation.

The Solution: To effectively source high-quality vinyl wraps, buyers should prioritize suppliers that offer transparent product specifications and quality certifications. Look for manufacturers that provide detailed information on the materials used, including thickness and UV resistance, which are crucial for durability in harsh climates. Engaging in direct communication with suppliers can help clarify these specifications. Additionally, requesting samples before placing bulk orders allows buyers to assess the quality and performance of the vinyl in real-world applications. Establishing relationships with reputable suppliers who have experience in the local market can further enhance product reliability and customer satisfaction.

Illustrative image related to vinil para carros

Scenario 2: Installation Challenges Leading to Increased Costs

The Problem: Many B2B buyers encounter difficulties during the installation of vinyl wraps, which can lead to increased labor costs and project delays. Inconsistent application techniques often result in bubbles, wrinkles, or misalignment, which not only affect the aesthetics but also the longevity of the wrap. This issue is particularly pressing for businesses that rely on quick turnaround times and high-quality finishes to maintain client satisfaction.

The Solution: To mitigate installation challenges, buyers should invest in comprehensive training programs for their installation teams. Providing hands-on workshops or online training sessions focusing on best practices for vinyl application can significantly improve the skill level of installers. Additionally, sourcing high-quality installation tools, such as heat guns and specialized squeegees, can make the application process more efficient. Encouraging installers to familiarize themselves with the specific properties of the vinyl wrap being used, such as stretchability and heat responsiveness, will also enhance the final outcome. Collaborating with suppliers who offer installation support or tutorials can provide further assistance in ensuring a flawless application.

Scenario 3: Dealing with Customer Complaints About Vinyl Durability

The Problem: After investing in vinyl wraps, B2B buyers may face customer complaints regarding the durability and performance of the product. Issues like fading, peeling, or damage from environmental factors can lead to a loss of trust and repeat business. This is particularly concerning in regions where extreme weather conditions are prevalent, as customers expect their investment to withstand such challenges.

The Solution: To address concerns about vinyl durability, buyers should focus on sourcing products that come with warranties or performance guarantees. Prioritize suppliers who utilize advanced technologies in their vinyl manufacturing, such as protective coatings that enhance resistance to UV rays, scratches, and moisture. Additionally, educating end customers on proper care and maintenance of vinyl wraps can help extend the life of the product. Providing clear guidelines on cleaning methods and avoiding exposure to harsh conditions will empower customers to take better care of their wraps. Regular follow-ups with clients to assess satisfaction and address any issues can also help in building long-term relationships and trust.

Illustrative image related to vinil para carros

Strategic Material Selection Guide for vinil para carros

What Are the Common Materials Used in Vinyl for Cars?

When selecting vinyl for automotive applications, understanding the properties, advantages, and limitations of various materials is crucial for B2B buyers. Below, we analyze four common materials used in car vinyl, focusing on their performance characteristics, pros and cons, and specific considerations for international buyers.

1. Polyvinyl Chloride (PVC)

Key Properties: PVC is a versatile plastic known for its durability and resistance to weathering, chemicals, and UV radiation. It performs well in a temperature range of -10°C to 60°C, making it suitable for various climates.

Pros & Cons: PVC is relatively inexpensive and easy to manufacture, which makes it a popular choice for car wraps. However, it can be less flexible than other materials, which may lead to cracking in extreme temperatures. Additionally, while PVC is durable, it may not be as long-lasting as other premium materials.

Impact on Application: PVC vinyl is compatible with a wide range of adhesives and can be printed on easily, making it ideal for custom graphics. However, its rigidity can limit its application on curved surfaces.

Considerations for International Buyers: Buyers should ensure compliance with local environmental regulations, as PVC can be subject to restrictions in some regions. Standards such as ASTM D1238 for flow characteristics may also be relevant.

Illustrative image related to vinil para carros

2. Cast Vinyl

Key Properties: Cast vinyl is made by pouring liquid vinyl into a mold, resulting in a thinner and more conformable product. It offers excellent temperature resistance and can endure high-pressure applications.

Pros & Cons: The primary advantage of cast vinyl is its superior conformability, allowing it to adhere to complex surfaces without bubbling. However, it is typically more expensive than PVC and may require specialized installation techniques.

Impact on Application: Cast vinyl is ideal for detailed graphics and wraps on vehicles, providing a smooth finish that enhances aesthetic appeal. Its flexibility allows for application on both flat and curved surfaces.

Considerations for International Buyers: Buyers should look for products that meet international standards such as ISO 14001 for environmental management. The higher cost may be justified by the longevity and performance of cast vinyl in challenging environments.

3. Polyurethane (PU)

Key Properties: PU vinyl is known for its exceptional durability and resistance to abrasions and chemicals. It can withstand a temperature range of -30°C to 80°C, making it suitable for various climates and conditions.

Pros & Cons: PU vinyl is highly flexible and offers excellent adhesion, making it ideal for intricate designs. However, it is generally more expensive than both PVC and cast vinyl, which may deter some buyers.

Impact on Application: This material is particularly effective in high-wear areas, such as car wraps that experience frequent contact with other surfaces. Its durability ensures that graphics remain intact over time.

Considerations for International Buyers: Compliance with JIS standards for quality assurance is crucial for PU vinyl. Buyers should also consider the potential for higher import duties due to the material’s cost.

4. Carbon Fiber Vinyl

Key Properties: Carbon fiber vinyl mimics the appearance of real carbon fiber but is made from PVC or PU. It is lightweight, strong, and resistant to UV rays and chemicals.

Pros & Cons: The aesthetic appeal of carbon fiber vinyl is a significant advantage, making it popular for luxury and performance vehicles. However, it can be more expensive than standard vinyl options and may require careful installation to avoid misalignment.

Impact on Application: Carbon fiber vinyl is suitable for both interior and exterior applications, enhancing the vehicle’s visual appeal. Its unique texture can also provide a non-slip surface.

Illustrative image related to vinil para carros

Considerations for International Buyers: Buyers should verify that the carbon fiber vinyl meets international quality standards, such as ASTM D4956 for reflective sheeting. The higher cost may be offset by the premium look and feel it provides.

Summary Table of Vinyl Materials for Cars

| Material | Typical Use Case for vinil para carros | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | General wraps and graphics | Cost-effective and widely available | Less flexible, prone to cracking | Low |

| Cast Vinyl | Detailed graphics and custom wraps | Superior conformability | Higher cost, requires skilled installation | Medium |

| Polyurethane (PU) | High-wear areas and intricate designs | Excellent durability and flexibility | More expensive than other options | High |

| Carbon Fiber Vinyl | Aesthetic enhancements for luxury cars | Premium look and lightweight | Higher cost, careful installation needed | High |

This guide provides essential insights for B2B buyers considering vinyl for automotive applications. By understanding the properties and implications of each material, buyers can make informed decisions that align with their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for vinil para carros

What Are the Main Stages in the Manufacturing Process of Car Vinyl?

The manufacturing of car vinyl, commonly used for vehicle wraps, involves several critical stages that ensure the final product meets quality and performance standards.

-

Material Preparation: The process begins with selecting high-quality polymer materials, primarily PVC (polyvinyl chloride) and other additives. These materials are sourced from reliable suppliers to ensure consistency. The PVC is then mixed with color pigments, plasticizers, and stabilizers to achieve the desired properties, such as flexibility and durability.

-

Forming: Once the materials are prepared, they undergo extrusion. This involves melting the PVC mixture and forcing it through a die to form a continuous sheet of vinyl. This sheet is cooled and cut to size for further processing. During this stage, manufacturers may also incorporate specific features such as air channels for easier application and bubble-free finishes.

-

Assembly: Depending on the product specifications, additional components, such as adhesives or protective layers, may be applied during assembly. The adhesive backing is critical, as it ensures the vinyl adheres properly to various surfaces without damaging the paint underneath. Some manufacturers may utilize advanced adhesive technologies, such as repositionable adhesives, to enhance usability.

-

Finishing: The final stage involves cutting the vinyl into specified dimensions and applying protective coatings if necessary. This may include UV protection to enhance longevity and prevent fading. Quality checks are performed at this stage to ensure that the vinyl meets the required standards in terms of color, texture, and thickness.

How Is Quality Assurance Implemented in Car Vinyl Production?

Quality assurance (QA) is an integral part of the manufacturing process to ensure that car vinyl products are reliable and meet international standards. Here are the key components of QA in vinyl production:

-

International Standards Compliance: Manufacturers often adhere to ISO 9001 standards, which outline criteria for a quality management system. This certification is crucial for B2B buyers as it indicates that the supplier maintains consistent quality in their products and processes. Additionally, regional standards such as CE marking in Europe or other relevant certifications may be required depending on the target market.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified criteria. Any non-compliant materials are rejected.

– In-Process Quality Control (IPQC): During manufacturing, samples are taken at various stages to monitor quality. This includes checking for consistency in thickness, color, and adhesion properties.

– Final Quality Control (FQC): Before shipment, finished products undergo rigorous testing for performance metrics such as durability, flexibility, and resistance to environmental factors. This is the last line of defense to catch any potential issues. -

Testing Methods: Common testing methods include:

– Adhesion Tests: To evaluate how well the vinyl adheres to different surfaces.

– Weathering Tests: To assess the vinyl’s resistance to UV light, temperature fluctuations, and moisture.

– Tensile Strength Tests: To measure the vinyl’s durability and resistance to tearing.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring product reliability. Here are actionable steps to consider:

-

Supplier Audits: Conduct regular audits of potential suppliers to assess their manufacturing processes, quality control measures, and compliance with international standards. This can include reviewing their quality management systems and certifications.

-

Requesting Quality Reports: Ask suppliers for detailed quality reports that outline their manufacturing processes, quality checks, and any third-party testing results. This transparency can help build trust and ensure that the products meet the necessary standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s production processes and the quality of the products. This can be particularly beneficial for buyers unfamiliar with local suppliers’ manufacturing practices.

-

Understanding Quality Control Nuances: Different regions may have varying quality control expectations and standards. Buyers should familiarize themselves with local regulations and industry norms, particularly when sourcing from emerging markets. This understanding can help in negotiating quality assurance terms and setting expectations with suppliers.

What Challenges Do B2B Buyers Face with Quality Assurance in Car Vinyl?

B2B buyers, especially those from diverse markets, may encounter several challenges regarding quality assurance in car vinyl procurement:

-

Variability in Manufacturing Standards: Suppliers in different regions may not adhere to the same quality standards, leading to inconsistencies in product quality. This can pose risks for businesses that depend on reliable vinyl for branding or vehicle modifications.

-

Supply Chain Disruptions: Global supply chain issues can affect the availability of high-quality raw materials, impacting the overall quality of the finished product. Buyers should consider diversifying their supplier base to mitigate this risk.

-

Limited Access to Testing Facilities: In some regions, access to advanced testing facilities may be limited, making it challenging to verify product quality independently. Buyers should factor this into their sourcing strategy and consider suppliers that provide comprehensive testing documentation.

-

Cultural and Communication Barriers: Differences in business practices and communication styles can complicate negotiations and quality assurance discussions. Establishing clear communication channels and expectations upfront can help bridge these gaps.

Conclusion

In summary, understanding the manufacturing processes and quality assurance measures for car vinyl is crucial for B2B buyers. By familiarizing themselves with the various stages of production, quality control practices, and verification methods, buyers can make informed decisions that align with their business needs. Emphasizing quality assurance not only enhances product reliability but also fosters long-term partnerships with suppliers across diverse global markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vinil para carros’

To successfully procure ‘vinil para carros’ for your business, it is essential to follow a structured approach. This guide provides a checklist of steps to ensure you select the right products and suppliers for your needs.

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the vinyl you intend to source. This includes the type of vinyl (e.g., gloss, matte, carbon fiber), thickness, adhesive properties, and UV resistance. Having defined specifications helps streamline communication with suppliers and ensures that you receive products that meet your quality standards.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers in the market. Look for companies with a strong reputation, positive customer reviews, and a history of reliability. Utilize industry trade shows, online marketplaces, and business directories to gather a list of potential candidates.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that potential suppliers hold relevant certifications. Certifications such as ISO 9001 or industry-specific quality standards demonstrate a commitment to quality and can significantly reduce risk. Ensure that they can provide documentation to back up their claims.

Step 4: Request Samples for Quality Assessment

Always request samples of the vinyl products before placing a bulk order. Inspect the samples for color accuracy, texture, and adhesive performance. This step is crucial as it allows you to evaluate the quality firsthand and ensure it aligns with your specifications and expectations.

Step 5: Inquire About Customization Options

If your project requires specific branding or unique designs, inquire about customization capabilities. Many suppliers offer options for custom colors, patterns, or finishes. Understanding these options upfront will help you determine if the supplier can meet your specific branding needs.

Illustrative image related to vinil para carros

Step 6: Assess Pricing and Payment Terms

Once you have shortlisted potential suppliers, compare their pricing structures and payment terms. Look for competitive pricing but also consider the value offered, including product quality and customer support. Negotiate favorable payment terms, especially for large orders, to enhance your cash flow management.

Step 7: Establish Logistics and Shipping Arrangements

Discuss logistics with your chosen supplier to understand shipping options, costs, and delivery timelines. Ensuring that the supplier can meet your delivery requirements is critical to maintaining your production schedules. Consider potential tariffs and import regulations, especially if sourcing from international suppliers.

Following this checklist will help you navigate the complexities of sourcing ‘vinil para carros’ effectively, ensuring you secure high-quality products that meet your business needs.

Comprehensive Cost and Pricing Analysis for vinil para carros Sourcing

In the competitive landscape of sourcing ‘vinil para carros’ (car vinyl), understanding the cost structure and pricing dynamics is essential for international B2B buyers. This analysis delves into the key components that influence pricing, the factors affecting cost, and practical tips for buyers seeking to optimize their purchasing strategies.

What Are the Key Cost Components in Car Vinyl Sourcing?

The cost structure for sourcing car vinyl typically encompasses several key components:

-

Materials: The primary raw materials used in vinyl production include PVC (polyvinyl chloride) and various additives that enhance durability and flexibility. The quality of these materials significantly impacts the overall price. High-quality vinyl with UV resistance and enhanced adhesion properties will command higher costs.

-

Labor: Labor costs are incurred during the manufacturing process, including skilled workers who handle production and quality control. Regions with lower labor costs can offer competitive pricing, which is particularly relevant for buyers from developing markets.

-

Manufacturing Overhead: This includes expenses related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can reduce overhead, allowing suppliers to offer more competitive pricing.

-

Tooling: Customization often requires specialized tooling, which can add to the initial costs. Buyers should consider whether the need for unique designs justifies the tooling investment.

-

Quality Control (QC): Ensuring that the vinyl meets industry standards involves rigorous testing and quality assurance processes. This can add to the overall cost but is crucial for maintaining product integrity, especially for buyers requiring certifications.

-

Logistics: Transportation and shipping costs are significant, especially for international orders. Factors such as distance, shipping method, and Incoterms (International Commercial Terms) can all influence logistics expenses.

-

Margin: Suppliers will add a profit margin to their costs, which varies based on market competition, brand positioning, and perceived value of the product.

What Influences Pricing for Car Vinyl?

Several factors play a critical role in determining the final price of car vinyl:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to better pricing due to economies of scale. Buyers should negotiate for volume discounts, especially when sourcing for multiple projects.

-

Specifications and Customization: Customized vinyl, whether in color, finish, or size, can increase costs. Buyers should weigh the benefits of customization against potential price increases.

-

Material Quality and Certifications: Vinyl products that come with certifications (e.g., ISO, ASTM) may carry a premium but offer assurance regarding performance and safety. Buyers should evaluate whether these certifications align with their needs.

-

Supplier Factors: The reputation, reliability, and financial health of the supplier can affect pricing. Established suppliers may charge more but often provide better service and quality assurance.

-

Incoterms: Understanding the shipping terms (e.g., FOB, CIF) is crucial for calculating total landed costs. Different Incoterms can significantly affect the final price depending on who bears the transportation costs.

How Can Buyers Negotiate Effectively for Car Vinyl?

To ensure cost-efficiency, buyers should adopt several strategies:

-

Leverage Total Cost of Ownership (TCO): Rather than focusing solely on the purchase price, consider the long-term costs associated with installation, maintenance, and potential replacements. Higher-quality vinyl may have a higher upfront cost but lower replacement rates.

-

Negotiate Terms: Engage suppliers in discussions about pricing, lead times, and payment terms. Building a relationship can lead to better deals over time.

-

Conduct Market Research: Understanding market rates and competitor pricing can empower buyers during negotiations. Knowing what others pay for similar products can provide leverage.

-

Explore Local Suppliers: For buyers in regions like Africa or South America, sourcing from local manufacturers can reduce shipping costs and lead times, potentially offering better overall value.

Conclusion: Pricing Nuances for International Buyers

International B2B buyers must navigate a complex landscape when sourcing car vinyl. By understanding the cost components, influencing factors, and effective negotiation strategies, buyers can make informed decisions that enhance their sourcing strategies. It is essential to approach negotiations with a clear understanding of the total cost of ownership while considering both quality and supplier reliability. Prices can vary significantly, so conducting thorough market research and establishing strong supplier relationships can yield substantial benefits.

Illustrative image related to vinil para carros

Disclaimer: Prices mentioned are indicative and may vary based on supplier, order volume, and market conditions. Always consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing vinil para carros With Other Solutions

In the evolving landscape of vehicle customization, businesses are often faced with a variety of options for enhancing the aesthetics and protection of their vehicles. Among these, ‘vinil para carros’ (vinyl wraps for cars) stands out as a popular choice. However, several alternative solutions are available, each with its unique benefits and drawbacks. This section will explore these alternatives, helping B2B buyers make informed decisions.

| Comparison Aspect | Vinil Para Carros | Paint (Traditional) | Plasti Dip |

|---|---|---|---|

| Performance | Durable, weather-resistant, and versatile | Long-lasting but can chip and fade | Good for temporary applications, easy to remove |

| Cost | Moderate, typically $70-$120 per roll | Higher initial cost, $300-$1,000+ per car | Lower cost, $50-$150 for a DIY project |

| Ease of Implementation | Requires skill for proper installation | Professional application needed | DIY-friendly, easy to apply |

| Maintenance | Low maintenance, easy to clean | Requires regular waxing and care | May require touch-ups, not as durable |

| Best Use Case | Customization and branding | Permanent color change | Temporary color change and protection |

What are the Pros and Cons of Using Traditional Paint as an Alternative to Vinil Para Carros?

Traditional paint is a long-standing method for vehicle customization, offering a permanent color change. Its primary advantage is its durability; when applied correctly, it can last many years. However, it is often more expensive than vinyl wraps and requires professional application to ensure a flawless finish. Additionally, paint can chip and fade over time, necessitating regular maintenance and care, including waxing and polishing to maintain its appearance.

How Does Plasti Dip Compare to Vinil Para Carros in Terms of Application and Longevity?

Plasti Dip is a rubberized coating that allows for color customization and protection. One of its significant advantages is its ease of application, making it a popular choice for DIY enthusiasts. It can be applied directly to the vehicle’s surface, and when the owner wants to change the color or remove it, Plasti Dip can be peeled off easily. However, it is not as durable as vinyl wraps and may require more frequent touch-ups, especially in high-wear areas. Plasti Dip is best suited for temporary applications or for those wanting to experiment with different colors.

How Should B2B Buyers Decide Between These Options?

When choosing the right solution for vehicle customization, B2B buyers should consider their specific needs and budget. For businesses looking for a durable and visually appealing option, ‘vinil para carros’ provides a balance of performance and aesthetics, making it ideal for branding and long-term use. On the other hand, if the goal is a permanent change with a high-quality finish, traditional paint may be more appropriate despite its higher cost and maintenance demands. For those seeking flexibility and cost-effectiveness, Plasti Dip presents an attractive alternative, especially for temporary projects or experimental designs.

Ultimately, understanding the unique characteristics of each option will empower businesses to make the best decision for their vehicle customization needs. By weighing factors such as performance, cost, ease of implementation, maintenance, and the intended use case, B2B buyers can align their choices with their operational goals.

Illustrative image related to vinil para carros

Essential Technical Properties and Trade Terminology for vinil para carros

What Are the Essential Technical Properties of ‘vinil para carros’?

When sourcing ‘vinil para carros’ for vehicle wrapping, understanding the technical properties is crucial for making informed purchasing decisions. Here are some of the key specifications to consider:

-

Material Grade

Vinyl wraps are typically made from polyvinyl chloride (PVC), which varies in thickness and flexibility. High-quality material grades, such as polymeric vinyl, offer superior conformability and durability compared to monomeric vinyl. For B2B buyers, selecting the right material grade ensures longevity and reduces the likelihood of premature wear, thus protecting investment. -

Thickness

The thickness of vinyl wraps is usually measured in mils (thousandths of an inch). A standard thickness ranges from 2 to 4 mils, with thicker options providing better durability and resistance to scratches and tears. For businesses, thicker vinyl can lead to fewer replacements and lower long-term costs. -

Adhesive Technology

Advanced adhesives, like High Mach® and Air Drain® technologies, enhance the installation process. High Mach® ensures a strong bond without damaging the surface upon removal, while Air Drain® allows for bubble-free application. This technology is vital for installers, as it reduces time spent correcting installation errors and improves the final appearance. -

UV Resistance

UV resistance is critical for maintaining color vibrancy and preventing fading over time. Quality vinyl wraps should offer protection against sun damage, which is particularly important in regions with high UV exposure. B2B buyers should prioritize UV-resistant options to ensure that the product retains its aesthetic appeal and functionality for longer periods. -

Finish Options

Vinyl wraps come in various finishes, including glossy, matte, satin, and textured. Each finish affects the visual impact and maintenance of the wrap. Understanding these options allows businesses to cater to specific customer preferences, enhancing marketability. -

Warranty Period

A warranty period typically indicates the expected lifespan of the vinyl wrap. Higher-quality products often come with longer warranties, providing assurance of durability and performance. B2B buyers should consider warranty terms when assessing value, as they reflect manufacturer confidence in their product.

What Are the Common Trade Terms in the ‘vinil para carros’ Industry?

Familiarity with industry jargon can significantly enhance communication and negotiation in B2B transactions. Here are some essential terms to know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of vinyl wraps, OEM products ensure compatibility and quality, making them a preferred choice for many businesses. -

MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell. Understanding MOQ is essential for B2B buyers as it affects inventory management and cost efficiency. Suppliers often set MOQs to ensure profitability, so negotiating favorable terms can lead to better pricing. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It includes specifications, quantities, and other details. For B2B transactions, issuing an RFQ allows buyers to compare options and ensure they receive competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) clarify who is responsible for shipping costs and risk at various stages. Understanding these terms is vital for avoiding unexpected expenses in the supply chain. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to delivery. Knowing the lead time is crucial for effective project planning and inventory management, helping businesses avoid delays in customer fulfillment. -

Color Matching

This term refers to the process of ensuring that the vinyl wrap matches the desired color specifications. For B2B buyers, color matching is essential to meet client expectations, particularly for custom vehicle wraps.

Understanding these technical properties and trade terms will empower B2B buyers in the ‘vinil para carros’ market to make informed decisions, ensuring successful partnerships and optimal product selection.

Illustrative image related to vinil para carros

Navigating Market Dynamics and Sourcing Trends in the vinil para carros Sector

What are the Current Market Dynamics and Key Trends in the vinil para carros Sector?

The global market for ‘vinil para carros’ is experiencing significant growth, driven by various factors including increasing consumer demand for vehicle customization and aesthetic enhancement. The rise of social media and automotive influencers has fueled interest in vehicle wraps as a means of personal expression. Additionally, the automotive aftermarket is expanding, particularly in regions like Africa, South America, and the Middle East, where vehicle ownership is on the rise. B2B buyers should note that the demand for high-quality vinyl wraps, such as those offering glossy, matte, and carbon fiber finishes, is peaking as businesses seek to differentiate themselves in a crowded market.

Emerging technologies, such as advanced adhesive systems and digital printing capabilities, are transforming the sourcing landscape. Buyers are increasingly looking for suppliers who can offer innovative solutions that simplify application processes, reduce waste, and enhance durability. Moreover, the integration of e-commerce platforms is streamlining sourcing, allowing international buyers to access a wider range of products and suppliers efficiently. The trend towards customization is also evident as manufacturers introduce limited edition colors and finishes, appealing to niche markets.

How is Sustainability and Ethical Sourcing Shaping the vinil para carros Market?

The importance of sustainability and ethical sourcing in the ‘vinil para carros’ sector cannot be overstated. With growing environmental concerns, B2B buyers are increasingly prioritizing suppliers that adhere to sustainable practices. This includes sourcing materials that have a lower environmental impact, such as eco-friendly vinyl options that are free from harmful chemicals and produced using renewable energy sources.

Illustrative image related to vinil para carros

Additionally, certifications like ISO 14001 (Environmental Management) and the use of recycled materials are becoming critical factors in supplier selection. Buyers should seek out manufacturers that provide transparency regarding their supply chains and environmental policies. The trend towards sustainability not only meets regulatory requirements but also resonates with environmentally conscious consumers, enhancing brand reputation and customer loyalty.

What is the Brief Evolution of the vinil para carros Sector?

The ‘vinil para carros’ sector has evolved significantly over the last few decades. Initially, vinyl wraps were primarily used for commercial purposes, such as advertising and branding on fleet vehicles. However, as technology advanced, the use of vinyl for personal vehicle customization gained traction. The introduction of high-quality polymeric vinyl, which offers better durability and conformability, revolutionized the market, allowing for a wide array of colors and finishes.

Today, vinyl wraps are not just about aesthetics; they also serve functional purposes, including paint protection and vehicle preservation. The continuous development of new materials and techniques has positioned vinyl wraps as a viable alternative to traditional paint, appealing to a broader demographic of consumers and businesses alike. This evolution is crucial for B2B buyers to understand, as it highlights the versatility and potential profitability of investing in high-quality vinyl products.

Illustrative image related to vinil para carros

Frequently Asked Questions (FAQs) for B2B Buyers of vinil para carros

-

How do I select the right vinyl wrap for my business needs?

Choosing the right vinyl wrap involves considering factors such as the type of finish (glossy, matte, or metallic), durability, and intended application. Assess the specific requirements of your projects, including the vehicles you will be wrapping and the environmental conditions they will face. It’s also essential to evaluate the adhesive quality to ensure easy application and removal without damaging the vehicle’s surface. Consulting with suppliers who offer samples can help you make an informed decision. -

What are the most popular types of vinyl wraps available for vehicles?

The most popular types of vinyl wraps include glossy metallic, matte finishes, and carbon fiber wraps. Glossy metallic wraps offer a vibrant and shiny appearance, while matte wraps provide a sleek, modern look. Carbon fiber wraps are favored for their high-tech appearance and durability. When selecting, consider your target market’s preferences and the branding needs of your clients, as this can significantly influence your purchasing decisions. -

What minimum order quantities (MOQ) should I expect from suppliers?

Minimum order quantities can vary widely depending on the supplier and the specific type of vinyl wrap. Typically, MOQs range from 10 to 50 rolls, but some suppliers may offer smaller quantities for custom orders. It’s crucial to discuss your needs with potential suppliers to negotiate favorable terms, especially if you’re testing a new product or entering a new market. Understanding MOQs can help you manage inventory effectively and control costs. -

How can I ensure quality when sourcing vinyl wraps internationally?

To ensure quality, conduct thorough research on potential suppliers, including checking certifications and industry standards. Request samples to evaluate the material’s durability, color accuracy, and adhesive properties. Additionally, consider visiting manufacturing facilities or utilizing third-party quality assurance services to oversee production. Establishing clear communication regarding quality expectations and specifications upfront can help mitigate risks. -

What payment terms are commonly offered in international B2B transactions for vinyl wraps?

Payment terms for international transactions typically include options such as upfront payment, letters of credit, or payment upon delivery. Many suppliers may offer a partial payment upfront with the balance due upon completion or delivery. It’s essential to clarify payment terms early in the negotiation process and ensure they align with your cash flow needs. Utilizing secure payment methods can also protect both parties in the transaction. -

What logistics considerations should I keep in mind when importing vinyl wraps?

Logistics considerations include shipping methods, customs regulations, and potential tariffs or taxes. Determine the best shipping option based on cost and delivery time, considering air freight for urgent shipments and sea freight for larger orders. Familiarize yourself with customs documentation required for importation to avoid delays. Collaborating with a logistics partner experienced in international trade can streamline the process and ensure compliance. -

Can I customize vinyl wraps for specific branding needs?

Yes, many suppliers offer customization options for vinyl wraps, including bespoke colors, finishes, and sizes tailored to your branding requirements. When discussing customization, provide detailed specifications and examples of desired designs. Be aware that custom orders may involve higher MOQs and longer lead times, so plan accordingly to meet your project timelines. -

What are the best practices for applying and maintaining vinyl wraps?

Best practices for applying vinyl wraps include ensuring the vehicle surface is clean and free from debris, using proper tools for application, and allowing for adequate curing time. For maintenance, regular cleaning with non-abrasive products is recommended to preserve the wrap’s appearance. Additionally, avoid exposing wrapped vehicles to extreme weather conditions for prolonged periods, as this can affect the wrap’s longevity and finish. Training your team on proper application and care can enhance the overall quality of your projects.

Top 3 Vinil Para Carros Manufacturers & Suppliers List

1. WrapWorkers® – Discos de Vinil para Carros

Domain: audioledcar.com

Registered: 2010 (15 years)

Introduction: Categoria: Discos de vinil para carros

Marca: WrapWorkers®

Características:

– Alta qualidade e longa duração

– Tecnologia High Mach® para máxima aderência sem danificar a superfície

– Sistema Air Drain® para remoção de bolhas de ar

– Resistência a condições climáticas adversas (frio, calor, chuva, sol, neve)

– Duração média de 4 anos

Aplicações:

– Superfícies de metal ou plástico

– Interior e exte…

2. Vpeliculas – Car Wrapping Solutions

Domain: vpeliculas.pt

Introduction: Películas Car Wrapping é o processo de transformar a aparência do carro com grandes folhas de vinil colorido ou texturizado. Vantagens incluem proteção da pintura original, durabilidade de 1-10 anos, fácil manutenção (apenas limpeza com água e produto), e possibilidade de remoção sem danificar a pintura. Áreas comuns para embrulhar incluem capô, tejadilho e bagageira. O investimento varia conforme…

3. Antalis – Vinil Autocolante para Carros

Domain: antalis.pt

Introduction: Vinil autocolante para carros de alta qualidade; Marcas: Arlon, Legend; Cores disponíveis: Gloss Red, Gloss White, Gloss Black, Gloss Black Metallic, Gloss Pearl White; Formatos: 1520 x 25.00, 1524 x 15.24, 1524 x 25.00; Comprimento da bobine: 15.24m, 25.00m; Espessura: 76µ, 80µ, 84µ; Material: Cast Vinyl; Técnicas de impressão: LFP inkjet; Acabamentos: brilho, mate, silk; Tipo de adesivo: FLITE T…

Strategic Sourcing Conclusion and Outlook for vinil para carros

In the rapidly evolving landscape of automotive customization, strategic sourcing of high-quality vinyl wraps is essential for businesses aiming to enhance their product offerings. Key takeaways for B2B buyers include the importance of selecting suppliers who provide a diverse range of colors and finishes, such as glossy, matte, and metallic options. Leveraging advanced technologies, such as air drainage systems and high adhesion properties, can significantly improve the installation experience and customer satisfaction.

Moreover, as markets in Africa, South America, the Middle East, and Europe continue to expand, there is a growing demand for durable and visually appealing vinyl solutions that cater to diverse automotive aesthetics. By establishing strong supplier partnerships and staying attuned to emerging trends, businesses can position themselves as leaders in this competitive sector.

Looking ahead, international buyers are encouraged to explore innovative vinyl products that not only meet current market demands but also anticipate future trends. This proactive approach will enable businesses to thrive and adapt to the evolving needs of customers. Engage with trusted suppliers today to enhance your offerings and drive growth in the vinyl wrap market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.