Unlocking Value: A Strategic Analysis of the Us Composites Market

Introduction: Navigating the Global Market for us composites

Navigating the global market for U.S. composites presents a unique challenge for international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, such as Brazil and Vietnam. Sourcing high-quality composite materials—ranging from fiberglass to advanced carbon fiber—requires not only an understanding of product specifications but also a keen awareness of supply chain dynamics and cost implications. This guide aims to demystify the complexities of the composites market, providing a comprehensive overview of various types, applications, and the nuances involved in supplier vetting.

Through this resource, buyers will gain valuable insights into the diverse applications of U.S. composites, from marine and automotive industries to aerospace and artistic endeavors. We will delve into critical factors such as cost analysis, inventory management, and the impact of raw material shortages, which are particularly relevant in today’s fluctuating market landscape. Additionally, this guide will equip you with strategic approaches to assess suppliers effectively, ensuring that your purchasing decisions are informed and aligned with your business needs.

By the end of this guide, international buyers will be empowered to navigate the U.S. composites market with confidence, enabling them to make sound investment choices that enhance their operational efficiency and product quality.

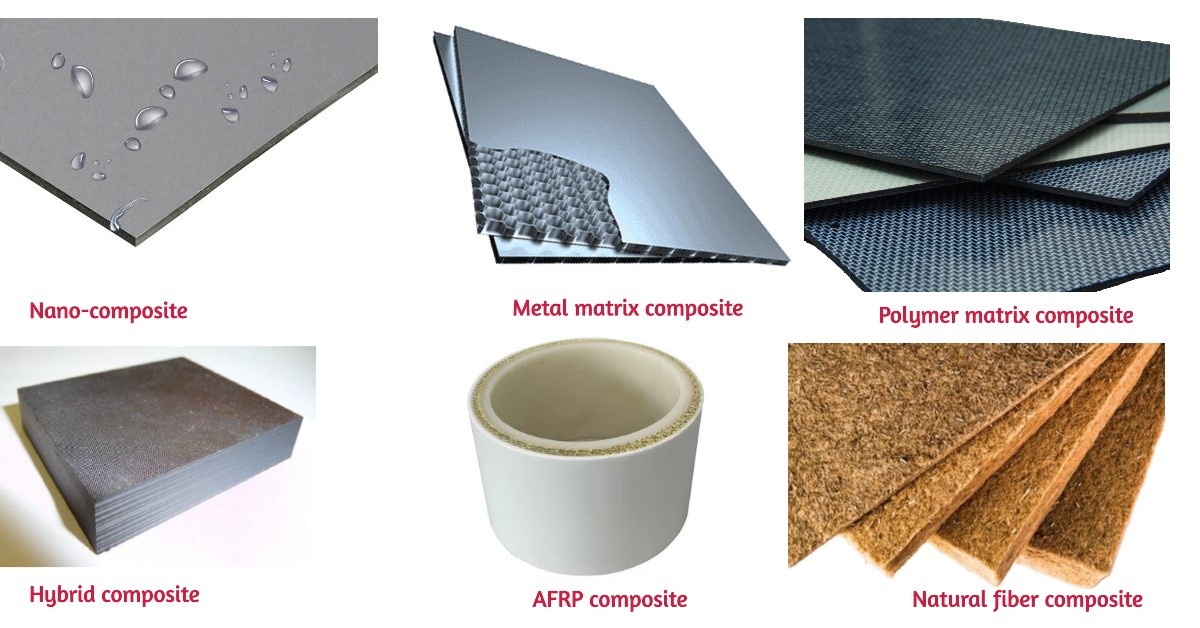

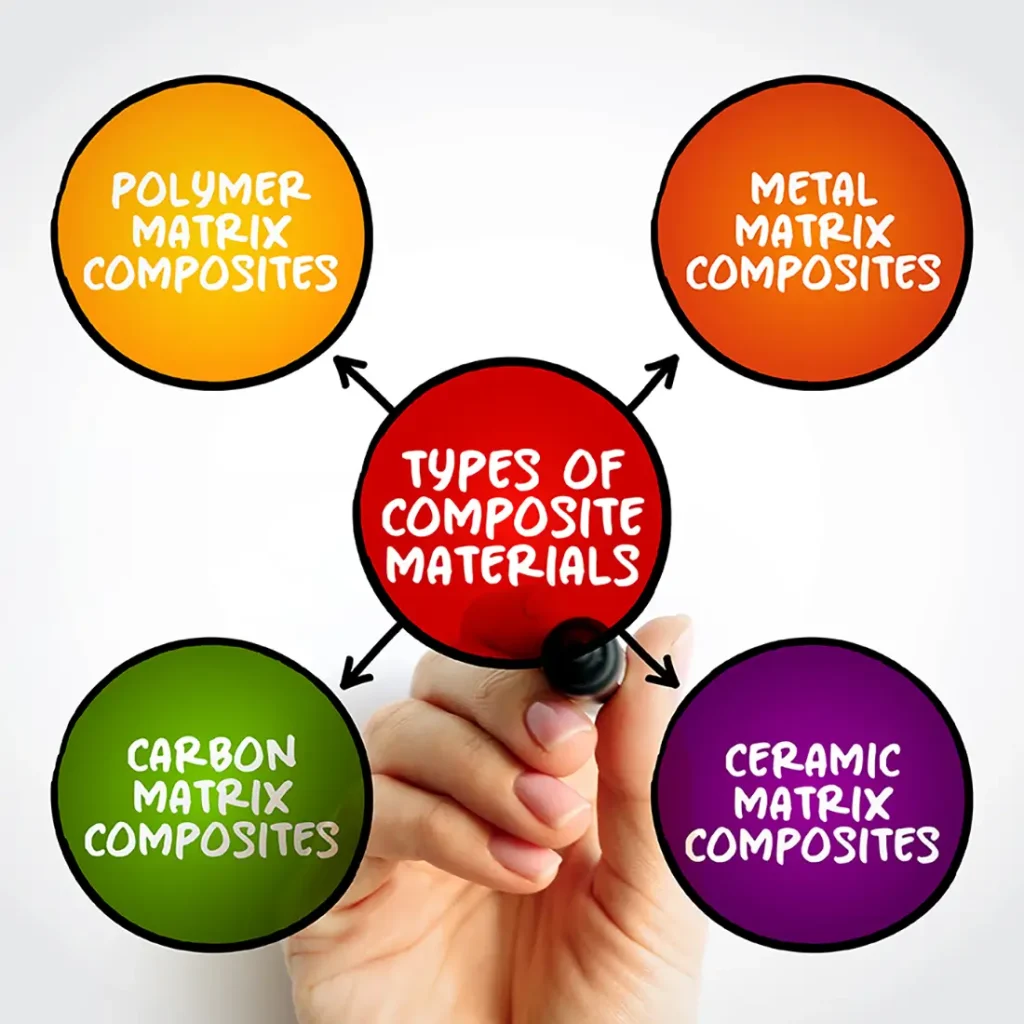

Understanding us composites Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fiberglass Composites | Lightweight, high strength-to-weight ratio, corrosion-resistant | Marine, automotive, construction | Pros: Cost-effective, versatile. Cons: Lower stiffness than carbon fiber. |

| Carbon Fiber Composites | Exceptional strength, rigidity, and lightweight | Aerospace, high-performance automotive | Pros: High performance, low weight. Cons: Higher cost, requires specialized handling. |

| Epoxy Resins | Excellent adhesive properties, chemical resistance | Coatings, adhesives, structural applications | Pros: Strong bonding, durable. Cons: Longer curing times, can be more expensive. |

| Urethane Foams | Versatile, lightweight, good thermal insulation | Insulation, cushioning, marine applications | Pros: Lightweight, good insulation. Cons: Limited structural strength. |

| KEVLAR® Composites | High tensile strength, impact resistance | Defense, aerospace, automotive safety | Pros: Superior impact resistance. Cons: More expensive, requires specialized processing. |

What Are the Characteristics of Fiberglass Composites for B2B Buyers?

Fiberglass composites are widely recognized for their lightweight nature and high strength-to-weight ratio, making them a popular choice in various industries such as marine, automotive, and construction. They are resistant to corrosion, which enhances their durability in harsh environments. B2B buyers should consider the cost-effectiveness of fiberglass composites, especially for applications where weight savings are essential. However, it’s important to note that while they offer versatility, they may not provide the same level of stiffness as carbon fiber options.

How Do Carbon Fiber Composites Stand Out in Performance?

Carbon fiber composites are known for their exceptional strength and rigidity, making them ideal for high-performance applications, particularly in the aerospace and automotive sectors. Their lightweight characteristics contribute to improved fuel efficiency and performance in vehicles and aircraft. For B2B buyers, the primary consideration when choosing carbon fiber is its higher cost compared to other materials. Additionally, specialized handling and processing may be required, which could affect procurement timelines.

Why Are Epoxy Resins Crucial for Industrial Applications?

Epoxy resins are vital in the composites industry due to their excellent adhesive properties and chemical resistance. They are commonly used in coatings, adhesives, and structural applications, providing strong bonding capabilities that enhance the durability of composite products. B2B buyers should weigh the benefits of epoxy’s durability against its longer curing times and potentially higher costs. Understanding the specific requirements of the application will help in selecting the right epoxy formulation.

What Makes Urethane Foams a Versatile Choice?

Urethane foams are valued for their versatility, lightweight nature, and excellent thermal insulation properties. They are utilized across various applications, including insulation and cushioning in marine environments. For B2B buyers, the primary advantages of urethane foams are their lightweight characteristics and insulation capabilities. However, they may have limitations in structural strength, which should be considered when evaluating their use in load-bearing applications.

How Do KEVLAR® Composites Provide Impact Resistance?

KEVLAR® composites are distinguished by their high tensile strength and superior impact resistance, making them essential in industries such as defense, aerospace, and automotive safety. B2B buyers will find that KEVLAR® composites offer significant protection against impacts and abrasions, which is critical in safety applications. However, the cost of KEVLAR® materials is generally higher, and they require specialized processing techniques, which can influence overall project budgets and timelines.

Key Industrial Applications of us composites

| Industry/Sector | Specific Application of us composites | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine | Boat Hulls and Structures | Enhanced durability and reduced weight | Ensure compliance with marine standards and regulations |

| Aerospace | Aircraft Components | High strength-to-weight ratio for fuel efficiency | Look for certifications and industry-specific specifications |

| Automotive | Body Panels and Chassis Parts | Improved fuel efficiency and crash performance | Consider local regulations for material use and recycling |

| Construction | Structural Reinforcements | Increased lifespan and reduced maintenance costs | Evaluate compatibility with local building codes |

| Wind Energy | Turbine Blades and Components | Lightweight materials for enhanced energy output | Source materials that can withstand extreme weather conditions |

How Are U.S. Composites Used in the Marine Industry?

In the marine sector, U.S. composites are extensively utilized in the fabrication of boat hulls and structural components. Their lightweight nature significantly enhances fuel efficiency and speed while providing exceptional resistance to corrosion and water damage. For international buyers, especially those in Africa and South America, it is crucial to ensure that the materials comply with local maritime safety standards and regulations. Additionally, sourcing from a supplier with a robust inventory can mitigate delays due to raw material shortages.

What Role Do U.S. Composites Play in Aerospace Applications?

In aerospace, U.S. composites are vital for manufacturing aircraft components, including wings and fuselage sections. These materials offer a high strength-to-weight ratio, which is essential for improving fuel efficiency and overall performance. Buyers in this sector must prioritize suppliers that can provide certified materials and adhere to stringent aviation regulations. Understanding the specific requirements for temperature and pressure resistance is also crucial for ensuring the longevity and safety of aerospace applications.

How Are U.S. Composites Beneficial in the Automotive Sector?

The automotive industry leverages U.S. composites for body panels and chassis parts, enhancing vehicle performance while reducing overall weight. This results in improved fuel efficiency and better crash performance, which are critical factors for modern automotive design. International buyers should consider sourcing from suppliers that offer materials compatible with local environmental regulations and recycling initiatives. Additionally, the availability of a diverse range of composite options can facilitate customized solutions for specific automotive applications.

What Advantages Do U.S. Composites Offer in Construction?

In construction, U.S. composites are increasingly used for structural reinforcements, providing enhanced durability and reduced maintenance costs. These materials can withstand harsh environmental conditions, making them ideal for various building applications. Buyers should assess the compatibility of these composites with local building codes and standards to ensure compliance. Furthermore, sourcing from suppliers that offer technical support can aid in the effective integration of composites into construction projects.

How Are U.S. Composites Utilized in Wind Energy Applications?

U.S. composites are essential in the wind energy sector, particularly in the production of turbine blades and other components. Their lightweight characteristics enable better energy output and efficiency, essential for maximizing renewable energy production. Buyers in regions prone to extreme weather conditions, such as the Middle East and Europe, should prioritize sourcing durable composites that can withstand such challenges. Additionally, understanding the lifecycle and recyclability of these materials can support sustainability initiatives in wind energy projects.

3 Common User Pain Points for ‘us composites’ & Their Solutions

Scenario 1: Navigating Raw Material Shortages

The Problem:

B2B buyers in regions like Africa and South America often face challenges related to the unpredictability of raw material availability for composites. A significant issue is the scattered shortages of materials such as fiberglass and epoxy resins, which can lead to extended lead times and project delays. For instance, a manufacturer in Brazil might find that the specific type of carbon fiber they need is temporarily unavailable, disrupting their production schedule and affecting their ability to meet client deadlines.

The Solution:

To effectively navigate raw material shortages, buyers should establish relationships with multiple suppliers, including U.S. Composites. This diversification ensures that if one source encounters a shortage, alternatives are available. Additionally, consider placing orders well in advance of project timelines and maintaining a buffer stock of essential materials. Buyers can also benefit from staying updated on market trends and potential shortages through industry newsletters or direct communication with suppliers. Engaging in strategic partnerships can also provide access to exclusive inventory or early notice of stock replenishments, minimizing disruption to production schedules.

Scenario 2: Managing Shipping Costs and Logistics

The Problem:

International shipping can present a myriad of challenges for B2B buyers sourcing composites from U.S. suppliers. High shipping costs, unexpected fees, and complicated logistics can add significant expenses and complexities to the procurement process. For instance, a construction company in the Middle East may find themselves paying exorbitant shipping fees for composite materials, which can significantly impact their project budgets and profitability.

The Solution:

Buyers should proactively manage shipping costs by comparing rates from various logistics providers and negotiating terms with suppliers like U.S. Composites. Utilizing freight forwarders can also streamline the shipping process, ensuring that buyers get the best rates and services tailored to their needs. Additionally, consolidating shipments to maximize container space can lead to substantial savings. Buyers should also inquire about any potential hazardous materials charges for specific products, as these can significantly impact overall shipping costs. By staying informed and employing strategic shipping practices, companies can effectively manage their logistics costs.

Scenario 3: Understanding Product Specifications and Applications

The Problem:

Another common challenge for B2B buyers is the complexity surrounding the specifications and applications of composite materials. Different industries have unique requirements; for example, the aerospace sector demands high-performance materials that can withstand extreme conditions, while marine applications may prioritize corrosion resistance. A buyer from a European automotive company might struggle to determine which type of resin or fabric is best suited for their specific application, potentially leading to poor material choices and subpar product performance.

The Solution:

To address this issue, buyers should invest time in thoroughly researching product specifications and applications through resources provided by suppliers like U.S. Composites. This includes consulting technical data sheets, application guidelines, and case studies that illustrate successful implementations. Engaging with supplier representatives for expert advice can provide invaluable insights into selecting the right materials. Additionally, participating in industry workshops or training sessions can enhance understanding of material properties and best practices. Creating a robust internal knowledge base or resource library can also empower teams to make informed decisions about composite materials, ultimately leading to improved project outcomes and product quality.

Strategic Material Selection Guide for us composites

What Are the Key Properties of Fiberglass in U.S. Composites?

Fiberglass is a widely used composite material known for its excellent strength-to-weight ratio and versatility. It can withstand temperatures up to 150°C (302°F) and offers good corrosion resistance, making it suitable for various applications in marine, automotive, and construction industries. Fiberglass is also resistant to UV light, which is crucial for outdoor applications.

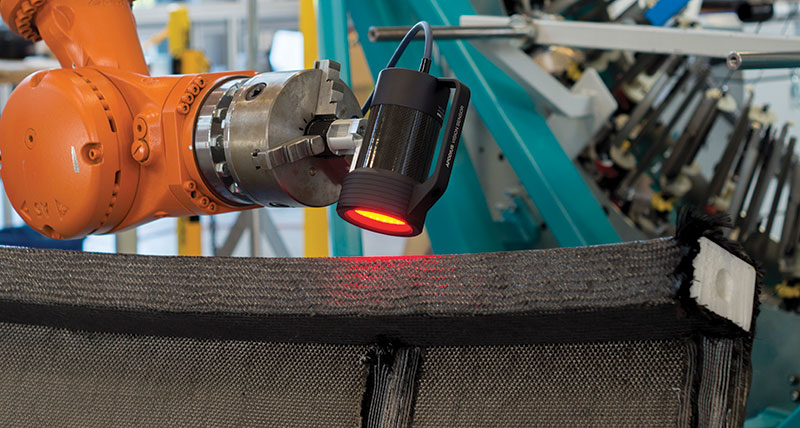

Illustrative image related to us composites

What Are the Advantages and Disadvantages of Using Fiberglass?

The primary advantage of fiberglass is its durability and lightweight nature, which enhances performance without adding significant weight to the end product. Additionally, it is relatively cost-effective compared to other composite materials. However, manufacturing complexity can increase with intricate designs, and the material may not perform as well under high-temperature conditions compared to carbon fiber or certain thermoplastics.

How Does Fiberglass Impact Specific Applications?

In terms of media compatibility, fiberglass is suitable for applications involving water, chemicals, and various solvents. Its resistance to moisture makes it an ideal choice for marine applications, while its lightweight nature benefits automotive designs. However, buyers should be cautious about the specific resin used, as some may not be compatible with certain chemicals.

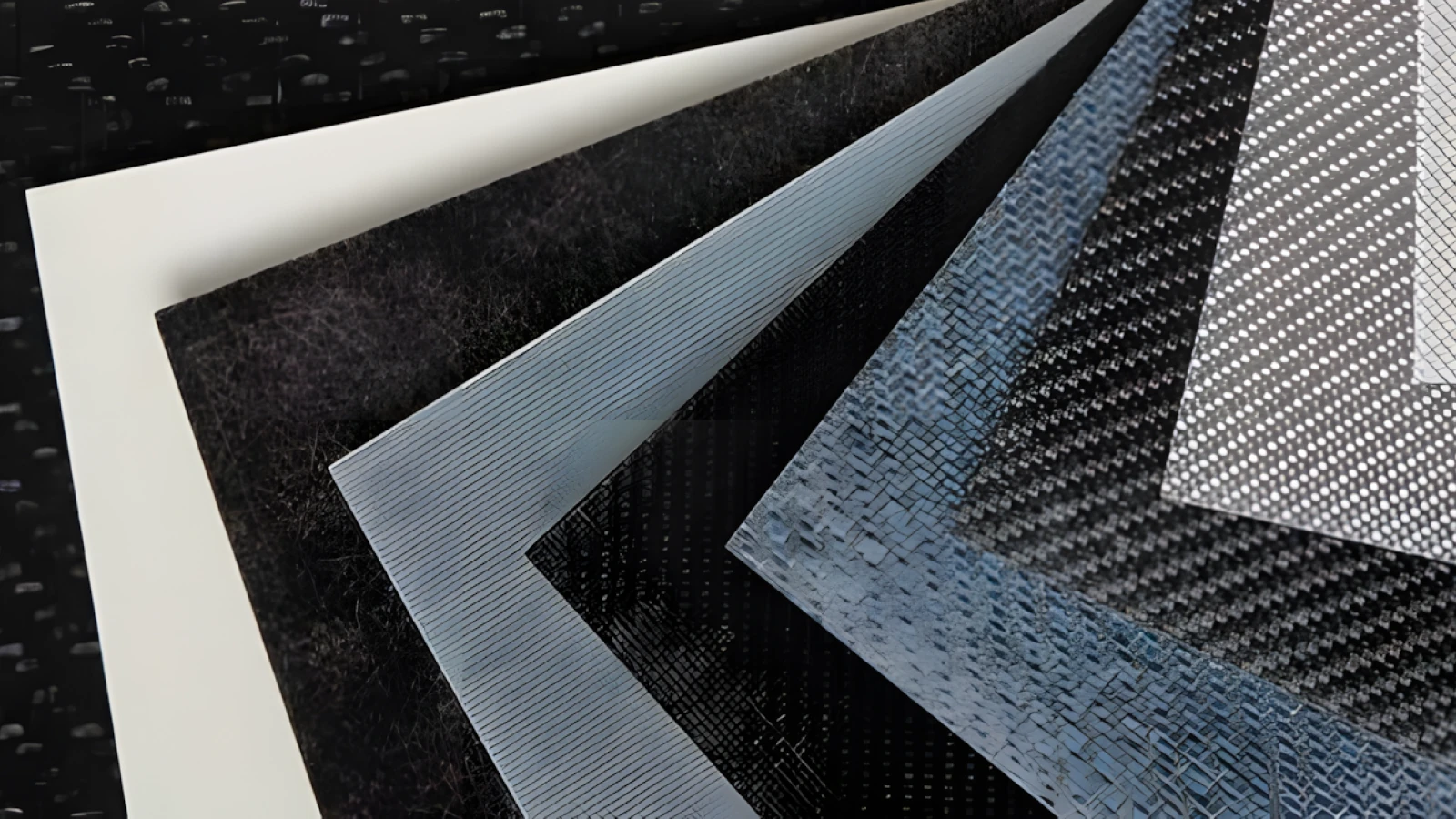

What Are the Key Properties of Carbon Fiber in U.S. Composites?

Carbon fiber is renowned for its exceptional strength and rigidity, with a temperature tolerance often exceeding 200°C (392°F). It also exhibits low thermal expansion, making it ideal for precision applications. Its lightweight nature combined with high tensile strength makes it a preferred choice in aerospace and high-performance automotive sectors.

What Are the Advantages and Disadvantages of Using Carbon Fiber?

The key advantage of carbon fiber is its superior strength-to-weight ratio, allowing for the creation of lightweight structures without compromising performance. However, the material is significantly more expensive than fiberglass and requires specialized manufacturing processes, which can increase production times and costs. Additionally, carbon fiber is prone to brittleness, which may limit its application in certain environments.

How Does Carbon Fiber Impact Specific Applications?

Carbon fiber is highly suitable for applications requiring high-performance materials, such as aerospace components and high-end sports equipment. It is compatible with various media, including fuels and oils, but care must be taken in environments with high impact, as it can fracture under stress.

Illustrative image related to us composites

What Are the Key Properties of Epoxy Resins in U.S. Composites?

Epoxy resins are known for their excellent adhesion, chemical resistance, and mechanical properties. They typically withstand temperatures up to 120°C (248°F) and provide strong bonding capabilities, making them ideal for composite applications. Their versatility allows them to be used in various sectors, including automotive, aerospace, and construction.

What Are the Advantages and Disadvantages of Using Epoxy Resins?

The primary advantage of epoxy resins is their superior bonding strength and durability, which enhances the overall performance of composite materials. However, they can be more expensive than polyester resins and may require precise mixing and curing conditions, adding complexity to the manufacturing process. Additionally, their sensitivity to moisture during curing can impact performance.

How Do Epoxy Resins Impact Specific Applications?

Epoxy resins are compatible with a wide range of media, including chemicals and solvents, making them suitable for various industrial applications. Their excellent adhesion properties make them ideal for bonding dissimilar materials, but buyers should ensure that the chosen epoxy is appropriate for their specific environmental conditions.

What Are the Key Properties of Polyester Resins in U.S. Composites?

Polyester resins are popular for their cost-effectiveness and ease of use. They typically withstand temperatures up to 80°C (176°F) and are known for good mechanical properties and resistance to UV degradation. Polyester resins are commonly used in marine, automotive, and construction applications.

Illustrative image related to us composites

What Are the Advantages and Disadvantages of Using Polyester Resins?

The main advantage of polyester resins is their lower cost compared to epoxy resins, making them an attractive option for large-scale applications. However, they have lower mechanical properties and chemical resistance than epoxies and can be more susceptible to environmental degradation. Additionally, they may not bond as effectively to certain substrates.

How Do Polyester Resins Impact Specific Applications?

Polyester resins are suitable for applications where cost is a significant factor, such as in boat hulls and automotive parts. However, their lower temperature resistance may limit their use in high-performance applications, and buyers should consider compatibility with specific chemicals and environmental conditions.

| Material | Typical Use Case for us composites | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Fiberglass | Marine applications | Lightweight and durable | Manufacturing complexity in intricate designs | Medium |

| Carbon Fiber | Aerospace components | Superior strength-to-weight ratio | High cost and brittleness | High |

| Epoxy Resins | Automotive and construction | Excellent adhesion and durability | Higher cost and curing sensitivity | Medium |

| Polyester Resins | Boat hulls and automotive parts | Cost-effective and easy to use | Lower mechanical properties than epoxy | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for us composites

What Are the Main Stages of Manufacturing Processes for U.S. Composites?

The manufacturing process of U.S. composites involves several critical stages, including material preparation, forming, assembly, and finishing.

Material Preparation

The initial stage focuses on sourcing and preparing raw materials, which are essential for creating high-performance composite products. For U.S. composites, this includes fiberglass, carbon fiber, epoxy, and polyester resins. Suppliers must ensure that materials meet specific standards to guarantee quality. This often involves checking for impurities and verifying specifications through documentation.

How Are Composites Formed?

The forming stage employs various techniques such as hand lay-up, vacuum infusion, and compression molding. Hand lay-up is a popular method where layers of fiber are manually placed into a mold, followed by the application of resin. Vacuum infusion is a more automated process, which allows for a more uniform distribution of resin and better fiber wet-out, reducing the risk of voids. Compression molding is used for producing complex shapes and high-volume parts, ensuring consistent quality across large batches.

What Happens During the Assembly Stage?

In the assembly stage, components are brought together to create the final product. This may involve bonding, fastening, or other joining techniques. Quality checks are crucial here to ensure that all parts fit correctly and that there are no defects. The assembly process may also include the application of additional materials like adhesives or sealants to enhance the durability of the composite.

How Is the Finishing Process Conducted?

Finishing involves surface preparation and treatment, which can include sanding, painting, or applying protective coatings. This stage is vital for both aesthetic appeal and functional performance. It often requires specialized equipment and skilled labor to achieve the desired finish and to ensure the long-term durability of the product.

What Quality Assurance Standards Are Relevant for U.S. Composites?

Quality assurance is a fundamental aspect of the manufacturing process for U.S. composites, particularly for B2B buyers. Various international standards, such as ISO 9001, guide quality management systems. Compliance with these standards assures buyers of the manufacturer’s commitment to maintaining high-quality processes and products.

How Are Industry-Specific Standards Applied?

In addition to general quality standards, specific certifications such as CE marking for European markets or API specifications for the oil and gas sector may apply. These certifications indicate that products meet stringent safety and performance requirements, which can be especially important for industries like aerospace and automotive.

What Are the Key Quality Control Checkpoints in Composite Manufacturing?

Quality control (QC) checkpoints are implemented throughout the manufacturing process to catch defects early.

Illustrative image related to us composites

What Is Incoming Quality Control (IQC)?

Incoming Quality Control (IQC) involves inspecting raw materials upon arrival at the manufacturing facility. This step ensures that materials meet the specified quality criteria before they are used in production. For international buyers, it is essential to verify that suppliers have robust IQC processes to avoid issues later in the production cycle.

How Is In-Process Quality Control (IPQC) Conducted?

In-Process Quality Control (IPQC) monitors the manufacturing process in real-time. This can involve regular sampling and testing of products at various stages, allowing manufacturers to identify and rectify any issues immediately. Techniques such as non-destructive testing (NDT) and visual inspections are commonly used.

What Is Final Quality Control (FQC)?

Final Quality Control (FQC) occurs before the product is shipped to the customer. This stage verifies that the finished product meets all specifications and quality standards. FQC may include functional testing, dimensional checks, and surface inspections to ensure that the product is ready for use.

Illustrative image related to us composites

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, understanding how to verify a supplier’s quality control processes is crucial.

What Audit Procedures Should Be Followed?

Buyers should consider conducting audits of potential suppliers. These audits can assess the effectiveness of the supplier’s quality management system, including their adherence to ISO standards and industry-specific certifications.

How Can Buyers Request Quality Reports?

Requesting detailed quality reports from suppliers can provide insights into their QC processes. These reports should include information on testing methods, results, and any corrective actions taken in response to identified issues. Transparent reporting is a good indicator of a reliable supplier.

Illustrative image related to us composites

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can further validate a supplier’s claims about their quality control processes. These independent assessments can provide an unbiased view of the supplier’s capabilities and adherence to required standards, giving buyers added confidence in their purchasing decisions.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate specific nuances related to quality control and certification.

How Do Regional Standards Affect Quality Assurance?

Different regions may have varying standards and requirements for composites. For instance, European buyers may require CE marking, while those in the Middle East may need to comply with local regulations. Understanding these regional standards is essential for ensuring compliance and acceptance in the target market.

Illustrative image related to us composites

What Challenges Can Arise in Global Supply Chains?

Global supply chains can introduce challenges, such as discrepancies in quality standards and variations in raw material quality. Buyers should be aware of these potential issues and work closely with suppliers to establish clear expectations and quality benchmarks.

Conclusion: Ensuring Quality in U.S. Composites Manufacturing

Understanding the manufacturing processes and quality assurance practices for U.S. composites is essential for B2B buyers looking to ensure product reliability and performance. By focusing on the key stages of manufacturing, relevant quality standards, and effective verification methods, buyers can make informed decisions and build strong partnerships with suppliers in the composites industry.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘us composites’

In the dynamic world of composite materials, sourcing effectively is crucial for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. This guide provides a structured approach to procuring U.S. composites, ensuring you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Before engaging suppliers, clearly outline the technical requirements for your composite materials. This includes the type of composites needed (e.g., fiberglass, carbon fiber), specific performance metrics, and intended applications (marine, automotive, aerospace). Having well-defined specifications helps in communicating your needs accurately and enables suppliers to provide tailored solutions.

Illustrative image related to us composites

Step 2: Conduct Market Research

Research potential suppliers and their offerings in the U.S. composites market. Utilize online resources, industry publications, and trade shows to gather information. Focus on understanding the range of products available, pricing structures, and any unique selling propositions. This knowledge will empower you to make informed comparisons between different suppliers.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a proven track record in delivering quality materials and excellent customer service, as this will mitigate risks in your procurement process.

Step 4: Verify Supplier Certifications and Compliance

Ensure that the suppliers you are considering meet industry standards and certifications relevant to composites. Look for certifications such as ISO 9001 or specific compliance with aerospace or automotive industry regulations. This step is vital for ensuring product quality and reliability, especially when working in highly regulated sectors.

Step 5: Request Samples and Conduct Testing

Once you have shortlisted potential suppliers, request samples of the composites you intend to purchase. Perform thorough testing to evaluate the materials against your specifications. This hands-on evaluation is critical for assessing the quality and performance of the composites before making a larger investment.

Step 6: Discuss Pricing and Payment Terms

Engage in discussions about pricing structures, payment terms, and potential discounts for bulk orders. Understanding the total cost of ownership, including shipping and any import duties, is essential for accurate budgeting. Negotiate terms that align with your financial strategy while ensuring you maintain a good relationship with the supplier.

Step 7: Establish a Logistics Plan

Finally, develop a logistics plan for the procurement process. Consider shipping options, lead times, and inventory management strategies. A well-thought-out logistics plan can help you avoid delays and ensure that materials arrive when needed, ultimately supporting your production schedules.

Illustrative image related to us composites

By following these steps, you can navigate the complexities of sourcing U.S. composites more effectively, ensuring that you secure high-quality materials that meet your business needs.

Comprehensive Cost and Pricing Analysis for us composites Sourcing

What Are the Key Cost Components in Sourcing U.S. Composites?

When evaluating the cost structure of U.S. composites, several critical components must be considered. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The primary cost driver is the raw materials, including fiberglass, carbon fiber, and epoxy resins. Prices can fluctuate based on market demand, availability, and specific material properties required for high-performance applications.

-

Labor: Skilled labor is essential for the production of composite materials, particularly in areas requiring specialized knowledge such as aerospace or marine applications. Labor costs can vary significantly based on geographic location and the complexity of the manufacturing process.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can help in minimizing overhead, thus impacting overall pricing.

-

Tooling: The initial investment in tooling can be significant, especially for custom parts. Buyers should consider these costs as part of the total investment when ordering specialized composites.

-

Quality Control (QC): Ensuring compliance with industry standards and certifications adds to the cost. Rigorous QC processes help maintain product integrity and can affect pricing, especially for high-stakes industries like aerospace.

-

Logistics: Shipping and handling costs are crucial, especially for international orders. These can vary widely depending on distance, weight, and the complexity of the items being shipped.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. Understanding the supplier’s pricing strategy can aid in negotiation.

What Influences Prices for U.S. Composites in International Markets?

Several factors can influence pricing when sourcing U.S. composites, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs. Buyers should negotiate MOQs to optimize cost efficiency.

-

Specifications and Customization: Custom specifications can significantly impact pricing. Buyers should clearly define their needs to avoid unexpected costs.

-

Material Quality and Certifications: Higher-quality materials or those with specific certifications (e.g., aerospace-grade) may command premium prices. Understanding the quality requirements can help in budgeting.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may offer better service but at higher costs.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can influence total costs. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for calculating landed costs.

How Can Buyers Negotiate Effectively for U.S. Composites?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant cost savings. Here are some strategies:

Illustrative image related to us composites

-

Research Market Prices: Knowledge of market prices for specific composite materials can empower buyers during negotiations.

-

Build Relationships: Establishing a strong relationship with suppliers can lead to better terms, including pricing and payment options.

-

Consider Total Cost of Ownership (TCO): Instead of focusing solely on purchase price, evaluate the TCO, which includes shipping, duties, and potential quality issues that could lead to additional costs.

-

Be Flexible with Specifications: If possible, consider alternatives or less stringent specifications that may lower costs while still meeting essential requirements.

-

Leverage Volume Discounts: If your business can project future needs, negotiating larger volume purchases can yield significant discounts.

What Are Pricing Nuances for International Buyers?

International buyers must be aware of pricing nuances that can affect their sourcing decisions. Currency fluctuations can impact costs, so it’s wise to lock in prices when favorable exchange rates are available. Additionally, import duties and taxes can add unforeseen expenses, making it essential to factor these into the overall budget.

Buyers should also be aware of potential delays in shipping, especially in times of raw material shortages, as highlighted in industry updates. These delays can lead to increased costs in production schedules and inventory management.

Conclusion

Understanding the comprehensive cost structure and pricing influences in sourcing U.S. composites is vital for international B2B buyers. By considering all cost components, negotiating effectively, and being mindful of pricing nuances, businesses can achieve better outcomes in their sourcing strategies.

Alternatives Analysis: Comparing us composites With Other Solutions

Understanding Alternatives in Composite Solutions

In the dynamic landscape of composite materials, businesses often seek alternatives to ensure they select the best product for their specific applications. This analysis compares U.S. Composites with two other viable alternatives in the composite materials market: Composites One and Hexcel Corporation. Each of these options offers unique features that can cater to various industry needs, from marine to aerospace applications.

Comparison Table

| Comparison Aspect | Us Composites | Composites One | Hexcel Corporation |

|---|---|---|---|

| Performance | High-performance in diverse applications; specialized in carbon fiber and fiberglass | Comprehensive product range; strong in aerospace and industrial applications | Industry leader in advanced composites; focus on aerospace and automotive |

| Cost | Competitive pricing; often lower than competitors | Moderate pricing; offers bulk discounts | Premium pricing; reflects advanced technology and materials |

| Ease of Implementation | User-friendly website; quick ordering process | Excellent customer support; provides technical assistance | Requires specialized knowledge for optimal use; extensive training available |

| Maintenance | Low maintenance; durable materials | Moderate maintenance; depends on application | High durability but requires specific handling and storage |

| Best Use Case | Ideal for marine, automotive, and artistic applications | Suitable for aerospace, construction, and industrial sectors | Best for aerospace and high-performance automotive applications |

Detailed Breakdown of Alternatives

Composites One

Composites One is a leading distributor of composite materials, offering a wide range of products including resins, reinforcements, and process materials. One of its main advantages is the extensive customer support they provide, which is particularly valuable for companies new to composites. However, the pricing is moderate, and while they do offer bulk discounts, it may not be as competitive as U.S. Composites for smaller orders. Their focus on various sectors, including aerospace and industrial applications, makes them a versatile choice, but they may not have the same specialization in carbon fiber as U.S. Composites.

Illustrative image related to us composites

Hexcel Corporation

Hexcel Corporation stands out as an industry leader in advanced composite materials, particularly in the aerospace and automotive sectors. Their products are known for their high performance and reliability. However, the premium pricing reflects the advanced technology and materials used in their composites. While Hexcel offers extensive training and support, the requirement for specialized knowledge can be a barrier for some businesses. This option is best suited for companies looking for cutting-edge solutions and are willing to invest more for enhanced performance and reliability.

Choosing the Right Composite Solution for Your Needs

When selecting a composite solution, B2B buyers should consider their specific application needs, budget constraints, and the level of support required. U.S. Composites is an excellent option for those seeking affordability and a broad range of materials for diverse applications. Conversely, if your business operates primarily in the aerospace sector and requires advanced materials, Hexcel may be the best fit despite the higher cost. Composites One serves as a balanced choice for those needing solid support and a wide array of products without the premium pricing of Hexcel. Ultimately, assessing performance, cost, ease of implementation, and maintenance will guide buyers to make an informed decision that aligns with their business objectives.

Essential Technical Properties and Trade Terminology for us composites

What Are the Key Technical Properties of U.S. Composites?

Understanding the essential technical properties of U.S. composites is crucial for B2B buyers, especially when making informed purchasing decisions. Here are some critical specifications to consider:

1. Material Grade

Material grade refers to the quality and composition of composite materials, such as fiberglass, carbon fiber, or Kevlar. Different grades offer varying levels of strength, flexibility, and durability. For instance, aerospace-grade composites are designed for high performance and lightweight applications, making them ideal for aircraft manufacturing. B2B buyers must assess material grade to ensure that the composites meet specific project requirements and industry standards.

2. Tolerance

Tolerance is the allowable variation in dimensions and properties of composite materials. It is critical in applications where precise fit and performance are necessary, such as in automotive or aerospace components. Understanding tolerance levels helps buyers select products that will fit seamlessly into their designs, reducing the risk of costly adjustments or failures.

3. Cure Time

Cure time refers to the duration required for a resin to harden and reach its optimal performance characteristics. This property can vary depending on the type of resin used (e.g., epoxy or polyester) and environmental conditions. Knowing the cure time is vital for production planning, as it impacts lead times and overall project timelines.

4. Tensile Strength

Tensile strength measures the maximum amount of tensile (stretching) stress a material can withstand before breaking. For composites, this property is crucial in applications where materials experience significant forces. Buyers need to evaluate tensile strength to ensure that the composites can handle the stresses they will encounter during use, particularly in industries like construction and automotive.

5. Weight-to-Strength Ratio

The weight-to-strength ratio is a critical property that indicates how much strength a material offers relative to its weight. This specification is particularly important in sectors such as aerospace and automotive, where reducing weight can lead to improved fuel efficiency and performance. B2B buyers should consider this ratio to select composites that provide the necessary strength without adding excess weight.

What Are Common Trade Terms in the U.S. Composites Industry?

Familiarity with industry terminology can enhance communication and negotiation processes between buyers and suppliers. Here are some essential trade terms:

Illustrative image related to us composites

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the composites industry, understanding OEM relationships can provide insights into product compatibility and sourcing strategies.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell in a single order. This term is critical for B2B buyers, as it can impact inventory management and cash flow. Buyers should negotiate MOQs to align with their production needs while ensuring cost-effectiveness.

3. RFQ (Request for Quotation)

An RFQ is a document that solicits price proposals from suppliers for specific products or services. In the composites sector, submitting an RFQ can help buyers obtain competitive pricing and terms, facilitating better purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international shipping terms that outline the responsibilities of buyers and sellers in a transaction. Understanding these terms is vital for B2B buyers to clarify shipping costs, risks, and delivery responsibilities, ensuring smooth international transactions.

5. Lead Time

Lead time is the period between placing an order and receiving the goods. In the composites industry, lead times can vary based on material availability and production schedules. Buyers should factor in lead times when planning projects to avoid delays.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions that align with their operational goals and project requirements.

Navigating Market Dynamics and Sourcing Trends in the us composites Sector

What Are the Key Market Dynamics and Sourcing Trends in the US Composites Sector?

The US composites market is experiencing robust growth driven by several global factors, including increasing demand for lightweight materials in the aerospace, automotive, and marine industries. The push for energy efficiency and lower emissions is prompting manufacturers to seek advanced materials that enhance performance while reducing overall weight. Emerging technologies such as automation in manufacturing processes and digital supply chain management are revolutionizing sourcing strategies, making them more efficient and transparent. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, this means access to high-quality composite materials with improved lead times and competitive pricing.

Moreover, the market is witnessing a shift toward hybrid composites that combine the benefits of various materials, such as carbon fiber and fiberglass. This trend is particularly relevant for sectors like renewable energy and construction, where durability and sustainability are paramount. Buyers should be proactive in understanding regional variations in demand, as economic growth and infrastructure development in emerging markets can create unique opportunities for sourcing composite materials. Additionally, navigating potential raw material shortages, as indicated by recent updates in the industry, is crucial for maintaining supply chain stability and ensuring timely delivery of products.

How Does Sustainability Impact Sourcing in the US Composites Sector?

Sustainability is becoming a central focus in the composites industry, driven by regulatory pressures and increasing consumer awareness of environmental issues. B2B buyers are now prioritizing suppliers that demonstrate a commitment to sustainable practices. This includes sourcing raw materials that are renewable or recycled, as well as adopting manufacturing processes that minimize waste and energy consumption. The environmental impact of composites, particularly in terms of lifecycle analysis, is a critical consideration for international buyers seeking to align with global sustainability goals.

Ethical sourcing is equally important, as buyers are keen to ensure that their supply chains are free from human rights abuses and environmental degradation. Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) can provide assurance that suppliers adhere to stringent environmental standards. By prioritizing suppliers with these certifications, B2B buyers can enhance their corporate social responsibility profiles and cater to an increasingly eco-conscious market.

What Is the Historical Context of the US Composites Sector?

The evolution of the US composites sector has been marked by significant technological advancements and market adaptations since its inception in the mid-20th century. Initially, composites were primarily used in aerospace applications due to their strength-to-weight ratio and resistance to corrosion. Over the decades, the industry expanded to include a diverse range of applications across various sectors, including automotive, construction, and consumer goods.

The introduction of advanced materials such as carbon fiber and innovations in resin systems have further propelled the sector forward, allowing for the development of high-performance products. As global competition intensifies, the focus has shifted toward cost-effective production methods and the integration of sustainable practices, setting the stage for the current market dynamics. Understanding this historical context is essential for international buyers, as it highlights the evolution of product offerings and the increasing importance of sustainability in sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of us composites

-

How do I solve issues related to raw material shortages in composites?

To address raw material shortages, it’s essential to establish a proactive relationship with your suppliers. Regularly communicate with them to receive updates on inventory and potential delays. Diversifying your supplier base can also mitigate risks; consider sourcing from multiple distributors. Additionally, maintaining a buffer stock of critical materials can help ensure continuity in production, especially if lead times are extended due to global supply chain disruptions. -

What is the best composite material for marine applications?

For marine applications, fiberglass and epoxy composites are often the most suitable due to their excellent resistance to water, corrosion, and UV degradation. Fiberglass provides strength and durability, while epoxy resins enhance the bonding and overall structural integrity of the composite. When considering specific requirements, such as weight or flexibility, carbon fiber might also be an option, although it typically comes at a higher cost. -

How can I ensure the quality of the composites I am sourcing?

To ensure quality, request material certifications and test reports from your supplier, verifying that the composites meet industry standards. Conducting third-party testing on samples before committing to large orders can also be beneficial. Establishing a clear quality assurance process, including inspections and testing during production, helps maintain product integrity and meets your specifications. -

What are the typical minimum order quantities (MOQs) for composite materials?

Minimum order quantities for composite materials can vary significantly based on the supplier and the specific product. Generally, MOQs can range from 10 to 500 units or more, depending on the type of composite and the supplier’s policies. It’s advisable to discuss your specific needs with suppliers to negotiate MOQs that align with your project requirements while considering potential cost savings on larger orders. -

What payment terms should I expect when purchasing composites internationally?

Payment terms can vary widely among suppliers, but common practices include payment in advance, net 30, or letter of credit. For international transactions, it’s essential to clarify these terms upfront to avoid any misunderstandings. Additionally, consider the currency exchange rates and any potential transaction fees that might apply. Establishing a good rapport with your supplier can also facilitate more favorable payment arrangements. -

How do I vet a composite supplier for international trade?

Vetting a composite supplier involves several steps: check their industry reputation through reviews and testimonials, verify their certifications and compliance with international standards, and evaluate their production capabilities. Conducting a site visit, if possible, or requesting references from other international clients can provide additional insights. Additionally, consider their responsiveness to inquiries and their ability to communicate effectively across time zones. -

What logistics considerations should I keep in mind when importing composites?

When importing composites, consider the shipping methods and associated costs, including customs duties and taxes. Work with logistics providers experienced in handling composite materials, as they may require special handling. Ensure that all documentation, including import permits and invoices, is accurate and complete to avoid delays at customs. Planning for lead times and potential disruptions in the supply chain is crucial to ensure timely delivery. -

Can I customize composite materials to meet my specific requirements?

Yes, many suppliers offer customization options for composite materials, including variations in resin type, fabric weave, and thickness. To initiate the customization process, communicate your specific requirements clearly to the supplier. They can provide recommendations based on your needs and may offer samples for testing. Keep in mind that customization might affect lead times and pricing, so it’s essential to discuss these factors upfront.

Top 8 Us Composites Manufacturers & Suppliers List

1. U.S. Composites – Composite Materials and Resins

Domain: uscomposites.com

Registered: 2000 (25 years)

Introduction: U.S. Composites, Inc. offers a wide range of composite materials including Fiberglass, Epoxy, Composites, Urethane Molding Rubbers, Carbon Fiber, and Urethane Foam. They specialize in carbon fiber, fiberglass, and KEVLAR® woven fabrics, as well as high-performance epoxy and polyester resins. Key products include Carbon & KEVLAR® Cloths, Table Top Epoxy for clear coating, Expanding Urethane Foam, E…

2. U.S. Composites – Composite Materials

Domain: uscomposites.net

Registered: 2004 (21 years)

Introduction: U.S. Composites, Inc. offers a variety of composite materials including:

– Fiberglass & Reinforcements

– Epoxy & Polyester Resins

– Polyurethane Expanding Foams

– Accessories & Equipment

– Adhesives & Sealants

– Chemicals

– Fillers & Sanding Additives

– Molding Rubbers & Materials

Specific products include:

1. Quart 150 Thick Epoxy Resin + Quart 1:1 Hardener – Price: $28.25

2. Quart 635 Thin Epox…

3. U.S. Composites – Composite Materials

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: U.S. Composites, Inc. specializes in manufacturing and distributing a wide range of composite materials including fiberglass cloth, carbon fiber fabric, Kevlar, and various resins, hardeners, and additives. They offer custom fabrication services for unique project requirements.

4. Grand View Research – U.S. Composites Market Insights

Domain: grandviewresearch.com

Registered: 2013 (12 years)

Introduction: The U.S. composites market includes key products such as glass fiber and carbon fiber. The glass fiber segment accounted for the largest market share of 58.01% in 2023, driven by demand in construction, wind energy, electrical & electronics, and automotive & transportation sectors. Glass fibers are preferred for applications like deck lids, engine covers, air ducts, underbody systems, and front-en…

5. US Composites – 635 Epoxy

Domain: rcgroups.com

Registered: 2001 (24 years)

Introduction: US Composites 635 epoxy; smallest size available costs $20.45; shipping via UPS ground was $19.92; upgraded to 2-day air shipping for the same cost; hazardous materials charge of $37.00 applies only to 5-gallon pails of polyester resins and gelcoats; epoxy resins, urethane rubbers, and urethane foams are not subject to this charge; weight of the pint of epoxy and hardener is 2 lbs; shipping rates …

6. US Composites – Fiberglass & Epoxy Resins

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, US Composites – Fiberglass & Epoxy Resins, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Easy Composites – Structural Epoxy Adhesives & Silicone Intensifier

Domain: easycomposites.us

Registered: 2024 (1 years)

Introduction: NEW PRODUCTS: 1. ET5428 Fast Composites Structural Epoxy Adhesive (Off White) – From $17.95 2. INTENSIL™ 40 Heat-Cure Silicone Intensifier Compound – From $12.68 / lb 3. ET5428-B Fast Composites Structural Epoxy Adhesive (Black) – From $17.95 4. FANTOM CLEAR™ CX Carbon Fiber Clearcoat – From $24.95 5. 130UV Instant UV Cure Clear Cyanoacrylate Adhesive 20g (0.7oz) – From $49.60 6. FUSIONFIX™ EP Epo…

8. US Composites – Epoxy 150 Slow

Domain: boatdesign.net

Registered: 1999 (26 years)

Introduction: US Composites Epoxy 150 Slow; Price is very good; Used for structural adhesive for wood on wood and wood on plywood; Users report long-term blush with slow hardener; Medium hardener has serious blush problems; Alternatives mentioned include RAKA 127 resin and 350 non-blush hardener; Concerns about water absorption and additives like alcohol and nonylphenol affecting performance.

Strategic Sourcing Conclusion and Outlook for us composites

How Can Strategic Sourcing Enhance Your Supply Chain for U.S. Composites?

In the rapidly evolving landscape of composite materials, strategic sourcing is vital for international B2B buyers aiming to optimize their supply chains. Key takeaways highlight the importance of maintaining robust relationships with suppliers to mitigate risks associated with raw material shortages, which have been reported intermittently across the industry. Buyers should prioritize suppliers who offer not only competitive pricing but also transparency in inventory management, ensuring timely access to essential materials like carbon fiber, fiberglass, and high-performance resins.

Illustrative image related to us composites

Furthermore, as industries such as aerospace, automotive, and marine continue to grow, leveraging strategic sourcing can lead to significant cost savings and improved product quality. Collaborating with U.S. Composites and similar distributors allows businesses to tap into a diverse range of materials tailored to specific applications, fostering innovation and enhancing competitive advantage.

Looking ahead, we encourage international buyers from Africa, South America, the Middle East, and Europe to explore partnerships with U.S. composite suppliers. By investing in strategic sourcing now, you position your business for future growth and resilience in a competitive market. Engage with suppliers to understand their offerings and capabilities, ensuring you stay ahead in this dynamic industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to us composites

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.