Unlocking Value: A Strategic Analysis of the Types Of Centrifugal Blower Market

Introduction: Navigating the Global Market for types of centrifugal blower

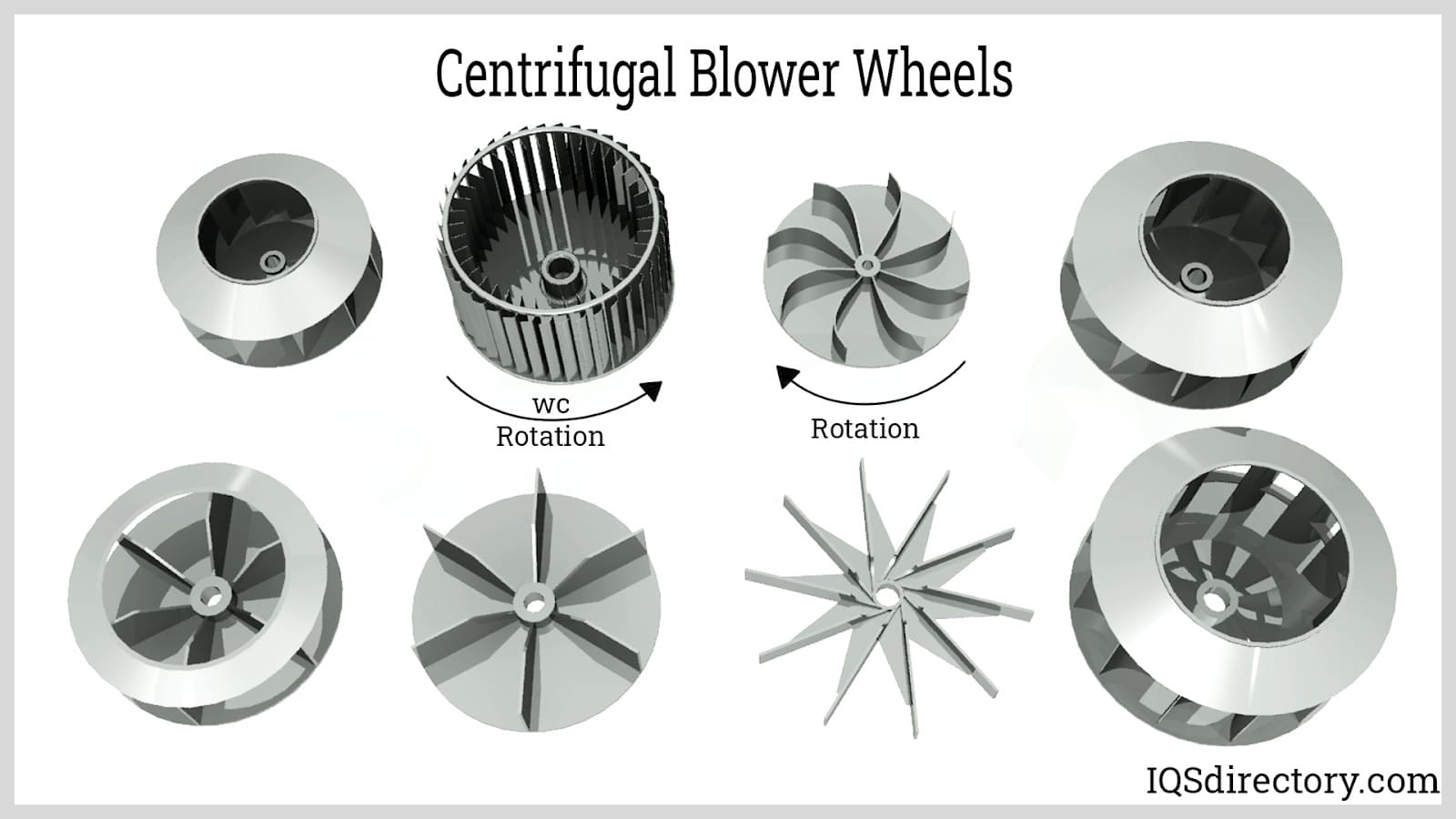

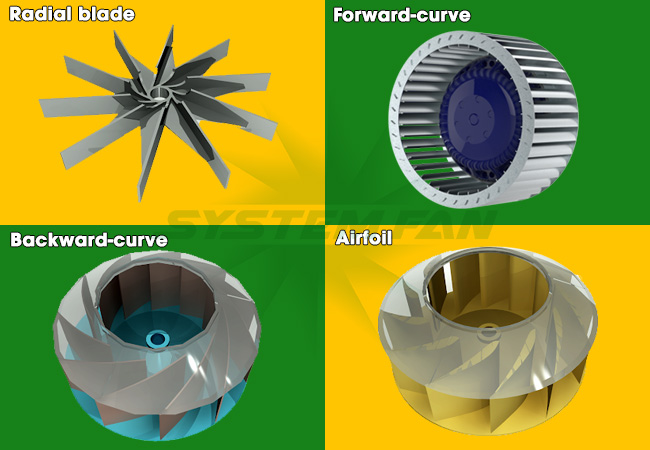

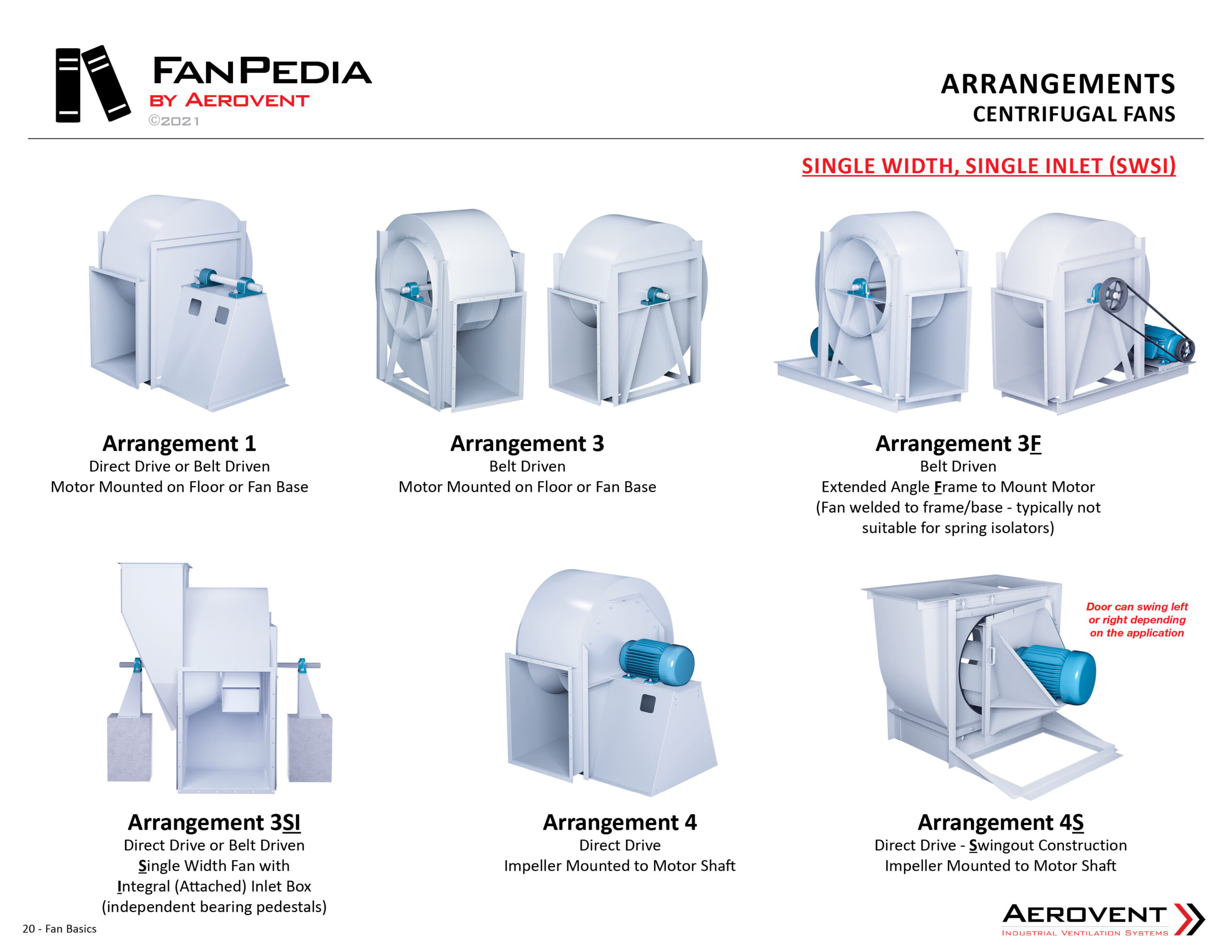

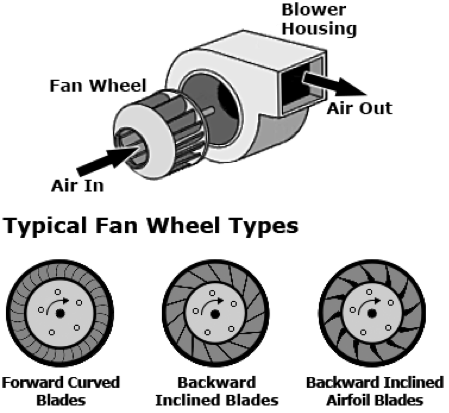

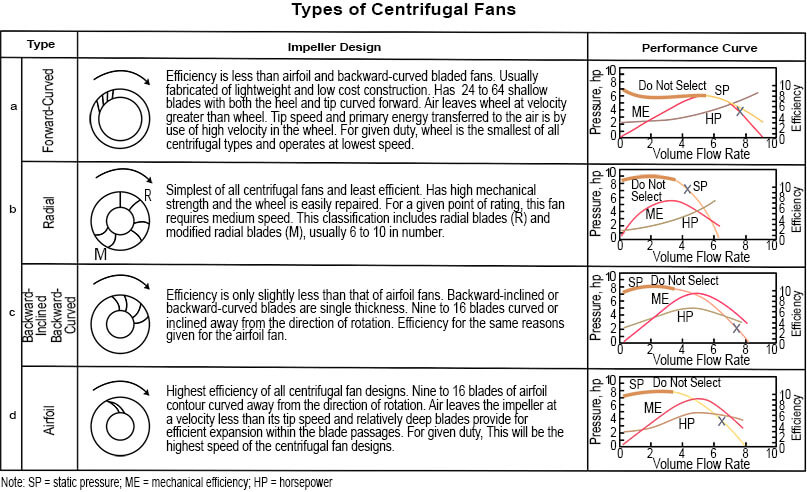

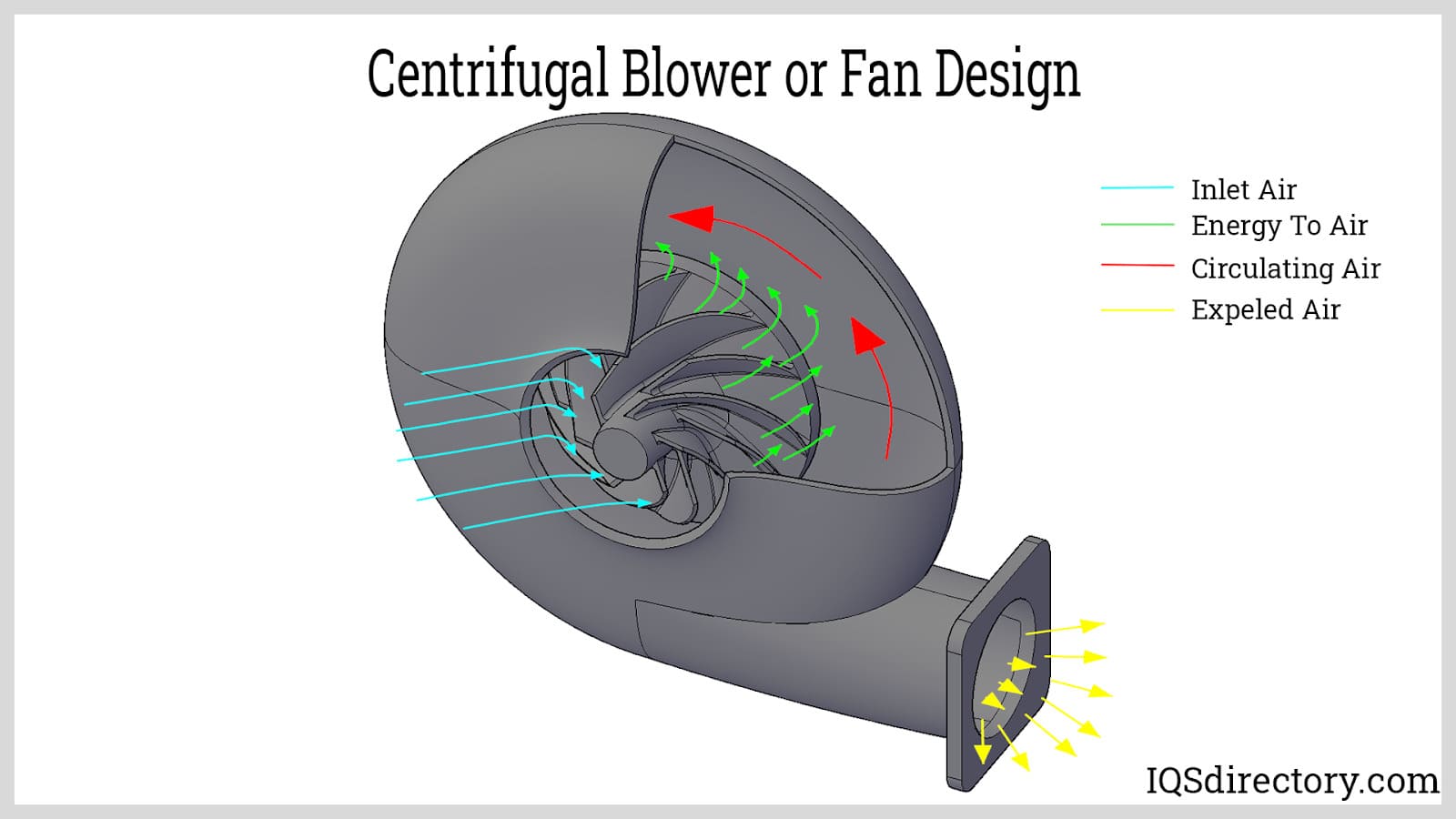

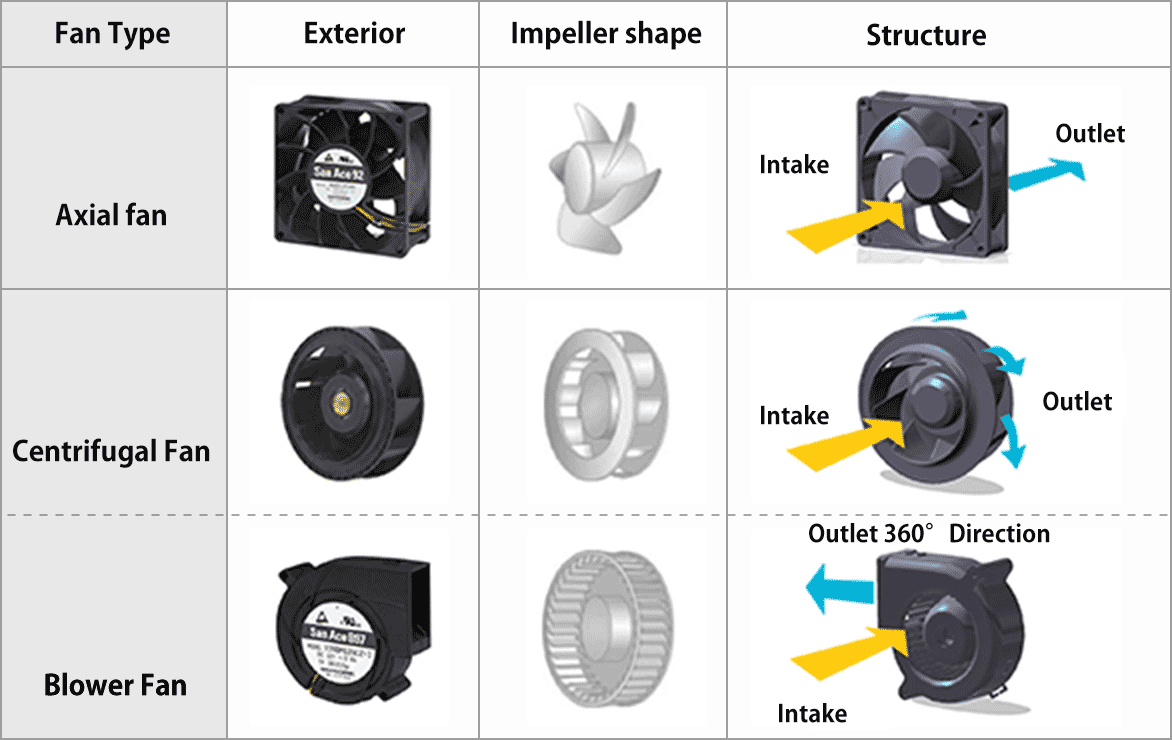

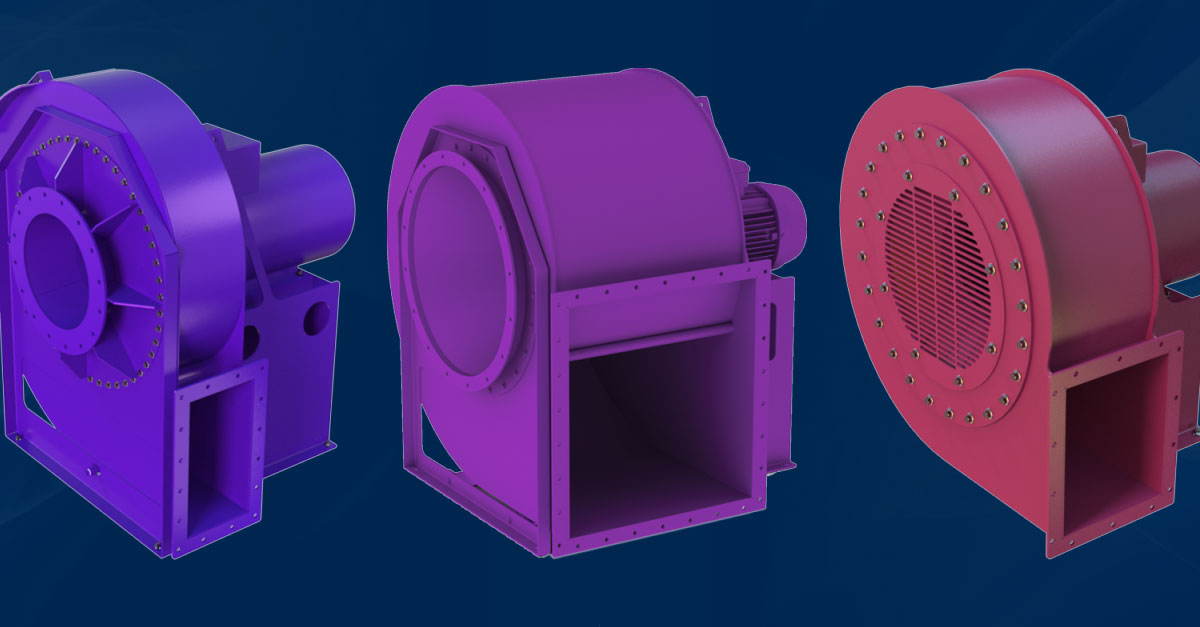

In today’s fast-paced industrial environment, sourcing the right types of centrifugal blowers can be a daunting task for international B2B buyers. The challenge lies not only in understanding the diverse range of centrifugal fans available but also in aligning them with specific operational needs. This guide serves as a comprehensive resource, delving into the various centrifugal blower types—including forward-curved, backward-curved, radial, and aerofoil fans—alongside their optimal applications across different industries.

We will also explore key factors such as performance characteristics, space considerations, noise levels, and air quality management, which are critical in making informed purchasing decisions. Additionally, we will provide insights on supplier vetting and cost analysis, ensuring that buyers can navigate the complexities of the global market with confidence.

Whether you’re based in Africa, South America, the Middle East, or Europe, including key markets like Brazil and Germany, this guide equips you with the knowledge to select the right centrifugal blower for your operations. By understanding the nuances of these fans and their applications, you’ll be empowered to make strategic decisions that enhance efficiency and productivity in your business.

Understanding types of centrifugal blower Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Forward-Curved Centrifugal Fan | Compact design, high airflow at low pressure | HVAC systems, small-scale ventilation | Pros: Space-efficient, cost-effective. Cons: Lower efficiency, can overload in high-pressure situations. |

| Backward-Curved Centrifugal Fan | Fewer, longer blades; energy-efficient, low noise levels | Industrial air management, dust collection | Pros: High efficiency, quieter operation. Cons: Larger footprint, potentially higher initial cost. |

| Radial Centrifugal Fan | Air enters at a 90-degree angle; robust and versatile | Pollution control, material handling | Pros: Handles high resistance, effective for dirty air. Cons: Can be noisier than other types. |

| Aerofoil Centrifugal Fan | Specialized blades for optimal airflow and pressure management | High-performance HVAC, industrial processes | Pros: High efficiency and airflow control. Cons: More complex design, higher maintenance. |

What Are the Characteristics of Forward-Curved Centrifugal Fans?

Forward-curved centrifugal fans are designed with blades that curve in the direction of rotation, allowing for a compact and lightweight structure. They are particularly suited for applications requiring large volumes of air at low pressure, such as in HVAC systems and small-scale ventilation projects. When purchasing, buyers should consider the fan’s airflow capacity and potential for motor overload in high-pressure environments, as this can impact operational efficiency.

How Do Backward-Curved Centrifugal Fans Stand Out?

Backward-curved centrifugal fans feature longer blades that curve away from the direction of rotation. This design enhances energy efficiency and reduces noise, making them ideal for industrial air management and dust collection applications. Buyers should assess the fan’s size and energy consumption, as these fans tend to occupy more space but offer significant operational savings over time due to their efficient performance.

What Makes Radial Centrifugal Fans Suitable for Industrial Applications?

Radial centrifugal fans are characterized by their ability to intake air at a right angle and expel it radially, making them robust and versatile for applications like pollution control and material handling. They can effectively manage high resistance and are well-suited for environments with particulate matter. Buyers should consider the fan’s noise levels and maintenance requirements, as radial fans can be noisier compared to others but excel in demanding conditions.

Why Consider Aerofoil Centrifugal Fans for High-Performance Needs?

Aerofoil centrifugal fans utilize specialized blade designs to maximize airflow and pressure management, making them suitable for high-performance HVAC systems and industrial processes. Their advanced design allows for superior efficiency and control over air movement. However, buyers should be aware that these fans may require more complex maintenance and could have a higher upfront cost, which should be balanced against their long-term operational benefits.

Key Industrial Applications of types of centrifugal blower

| Industry/Sector | Specific Application of types of centrifugal blower | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Air handling in production lines | Improved efficiency and productivity in air movement | Size, noise level, and energy efficiency of the blower |

| Waste Management | Odor control and dust collection | Enhanced air quality and compliance with regulations | Resistance to abrasive particles and ease of maintenance |

| Food Processing | Cooling and drying processes | Consistent product quality and reduced spoilage | Temperature tolerance and hygiene standards |

| HVAC Systems | Ventilation and climate control | Optimized energy usage and comfort for occupants | Compatibility with existing systems and noise levels |

| Chemical Processing | Fume extraction and gas handling | Safety and compliance with health standards | Material compatibility and explosion-proof features |

How Are Centrifugal Blowers Used in Manufacturing?

In manufacturing, centrifugal blowers are crucial for air handling in production lines, ensuring efficient airflow to maintain optimal operating conditions. They help manage temperature and humidity, which can affect product quality and worker comfort. Buyers need to consider the size of the blower to fit into existing setups, as well as its noise level and energy efficiency to minimize operational costs. For international buyers, especially in regions like Africa and South America, understanding local energy regulations and availability is vital for sourcing suitable blowers.

What Role Do Centrifugal Blowers Play in Waste Management?

Centrifugal blowers are employed in waste management for effective odor control and dust collection. By improving air quality, these blowers help facilities comply with environmental regulations, thereby avoiding fines and enhancing community relations. Buyers should focus on blowers that can handle abrasive particles and are easy to maintain, as these factors significantly influence long-term operational efficiency. For buyers in the Middle East and Europe, the emphasis on sustainable practices makes sourcing high-quality, durable blowers essential.

How Do Centrifugal Blowers Benefit Food Processing?

In the food processing industry, centrifugal blowers are used for cooling and drying processes, which are critical to maintaining product quality and preventing spoilage. The right blower ensures that air is delivered at the correct temperature and volume, which is vital for food safety. Buyers must ensure that the blowers meet hygiene standards and can withstand high temperatures. Sourcing from reputable manufacturers who understand the specific requirements of the food sector is particularly important for buyers in Europe, where food safety regulations are stringent.

Why Are Centrifugal Blowers Important in HVAC Systems?

Centrifugal blowers play a significant role in HVAC systems by providing effective ventilation and climate control, which enhance energy efficiency and occupant comfort. Properly selected blowers can lead to significant energy savings and improved indoor air quality. Buyers should consider compatibility with existing HVAC infrastructure and the noise levels produced by the blowers. International buyers, particularly in regions with varying climate conditions like Africa and the Middle East, must also account for local environmental factors when sourcing.

How Are Centrifugal Blowers Used in Chemical Processing?

In chemical processing, centrifugal blowers are vital for fume extraction and gas handling, ensuring safety and compliance with health standards. The ability to manage hazardous materials effectively protects workers and the environment. Buyers need to focus on blowers with appropriate material compatibility and features such as explosion-proof designs, especially in regions with strict safety regulations, like Germany. Understanding local compliance requirements is crucial for sourcing the right equipment.

3 Common User Pain Points for ‘types of centrifugal blower’ & Their Solutions

Scenario 1: Struggling with Space Constraints in Industrial Settings

The Problem: Many businesses face the challenge of limited space within their facilities. As production lines expand, the need for efficient air delivery systems becomes critical. However, traditional centrifugal blowers can be bulky, making it difficult to find a suitable location for installation. This can lead to operational delays and increased costs, as companies may need to redesign their layout to accommodate larger equipment.

The Solution: To address space constraints, buyers should consider compact centrifugal blowers, particularly forward-curved fans, which offer high air output in a smaller footprint. When sourcing equipment, look for manufacturers who specialize in space-saving designs. Additionally, using modular ducting can optimize airflow and reduce the required installation area. It’s also advisable to conduct a thorough site assessment to identify potential locations for installation that maximize efficiency while minimizing disruption. Engaging with suppliers who provide customized solutions can further enhance operational efficiency without compromising on performance.

Illustrative image related to types of centrifugal blower

Scenario 2: Managing High Temperatures in Airflow Applications

The Problem: In industries such as manufacturing and processing, the air that needs to be moved can often be at elevated temperatures. Standard centrifugal blowers may struggle to operate effectively in these conditions, leading to premature motor failure and increased maintenance costs. This not only impacts the reliability of the system but can also halt production, resulting in financial losses.

The Solution: To mitigate the risks associated with high temperatures, businesses should invest in centrifugal blowers specifically designed for thermal resilience. Implementing heat spinners can help dissipate heat away from the motor, extending its lifespan. When selecting a blower, ensure it is rated for the specific temperature range required for your application. Additionally, consider the use of insulated materials in both the blower and ducting to maintain optimal operating temperatures. Regular maintenance checks are crucial; schedule inspections to ensure that all components are functioning correctly and to replace any parts that show signs of wear due to heat exposure.

Scenario 3: Reducing Noise Levels in Operational Environments

The Problem: Noise pollution can be a significant concern in various industrial settings, particularly in locations near residential areas or within facilities where employee comfort is a priority. Forward-curved centrifugal fans are often noisier due to their design, which can lead to complaints from staff and potential regulatory issues. Finding a balance between performance and noise reduction is a common pain point for B2B buyers.

Illustrative image related to types of centrifugal blower

The Solution: For applications where noise reduction is essential, backward-curved centrifugal fans are typically more efficient and quieter due to their design that minimizes turbulence. When specifying fans, look for models that offer sound-dampening features, such as larger impeller diameters and lower rotational speeds. Additionally, consider investing in noise enclosures or sound-absorbing materials around the fan installation to further mitigate noise levels. Conducting a noise assessment prior to installation can also help identify potential hotspots and inform the placement of equipment to optimize sound management. Engaging with suppliers who offer solutions tailored to noise-sensitive applications can provide significant long-term benefits and improve workplace conditions.

Strategic Material Selection Guide for types of centrifugal blower

What Are the Key Materials Used in Centrifugal Blowers?

When selecting materials for centrifugal blowers, several factors influence performance, durability, and suitability for specific applications. Understanding the properties, advantages, and limitations of common materials can help international B2B buyers make informed decisions.

How Does Steel Influence Centrifugal Blower Performance?

Steel, particularly carbon steel and stainless steel, is widely used in centrifugal blower construction due to its strength and durability. Carbon steel offers high tensile strength and is suitable for high-pressure applications, while stainless steel provides excellent corrosion resistance, making it ideal for environments where moisture or chemicals are present.

Pros: Steel is robust and can withstand high temperatures and pressures, making it suitable for various industrial applications. It is also relatively cost-effective compared to other materials.

Cons: While carbon steel is strong, it is prone to rusting if not properly coated or maintained. Stainless steel, although more resistant to corrosion, is significantly more expensive and may require specialized manufacturing processes.

Illustrative image related to types of centrifugal blower

Impact on Application: Steel centrifugal blowers are well-suited for heavy-duty applications such as material handling and dust collection, especially in industries like mining and agriculture.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider local environmental conditions that may affect steel durability. Compliance with local standards, such as ASTM for the U.S. or DIN for Europe, is crucial when sourcing materials.

What Role Does Aluminum Play in Centrifugal Blowers?

Aluminum is another common material used in centrifugal blowers, particularly for applications requiring lightweight and corrosion-resistant solutions. Its low density makes it easier to handle and install.

Pros: Aluminum offers excellent corrosion resistance and is lightweight, which can reduce transportation and installation costs. It is also relatively easy to machine, allowing for complex designs.

Cons: While aluminum is effective in low-pressure applications, it may not withstand high temperatures as well as steel. Its strength is lower compared to steel, which can limit its use in heavy-duty applications.

Illustrative image related to types of centrifugal blower

Impact on Application: Aluminum centrifugal blowers are ideal for applications where weight is a critical factor, such as in HVAC systems and portable equipment.

Considerations for International Buyers: Buyers should ensure that aluminum components meet relevant standards for strength and corrosion resistance, especially in humid or coastal regions.

How Does Composite Material Affect Centrifugal Blower Efficiency?

Composite materials, such as fiberglass-reinforced plastics, are increasingly used in centrifugal blowers due to their lightweight and corrosion-resistant properties. These materials can be tailored to meet specific performance requirements.

Pros: Composites are highly resistant to corrosion and can be engineered for specific applications, providing versatility. They are also lightweight, which can lead to lower shipping and installation costs.

Illustrative image related to types of centrifugal blower

Cons: The manufacturing process for composites can be more complex and costly than traditional materials. Additionally, they may not perform as well under high temperatures or pressures compared to metals.

Impact on Application: Composite centrifugal blowers are suitable for applications in chemical processing and waste treatment, where resistance to corrosive media is essential.

Considerations for International Buyers: B2B buyers should verify the compliance of composite materials with international standards, as well as their suitability for specific environmental conditions.

What Are the Advantages of Using Plastic in Centrifugal Blowers?

Plastic materials, such as polypropylene and polycarbonate, are often used in centrifugal blowers for specific applications requiring lightweight and chemical resistance.

Illustrative image related to types of centrifugal blower

Pros: Plastics are resistant to many chemicals and are lightweight, making them easy to handle and install. They also offer good insulation properties, which can be beneficial in certain applications.

Cons: Plastics generally have lower strength and temperature resistance compared to metals, which can limit their use in high-pressure or high-temperature environments.

Impact on Application: Plastic centrifugal blowers are ideal for applications in the food industry or clean rooms, where hygiene and resistance to chemicals are critical.

Illustrative image related to types of centrifugal blower

Considerations for International Buyers: Buyers should ensure that plastic materials meet relevant food safety standards and chemical resistance requirements, particularly in regions with strict regulations.

Summary of Material Selection for Centrifugal Blowers

| Material | Typical Use Case for types of centrifugal blower | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty applications (mining, agriculture) | High strength and durability | Prone to rust; higher cost for stainless steel | Medium |

| Aluminum | HVAC systems, portable equipment | Lightweight and corrosion-resistant | Lower strength under high pressure | Medium |

| Composite | Chemical processing, waste treatment | Corrosion-resistant and versatile | Higher manufacturing complexity | High |

| Plastic | Food industry, clean rooms | Chemical resistance and lightweight | Lower strength and temperature resistance | Low |

This comprehensive analysis of materials used in centrifugal blowers provides B2B buyers with critical insights to guide their purchasing decisions, ensuring optimal performance and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for types of centrifugal blower

Centrifugal blowers play a crucial role in various industrial applications, and understanding their manufacturing processes and quality assurance protocols is essential for B2B buyers. This section delves into the key stages of manufacturing centrifugal blowers, the quality control measures in place, and how international buyers can ensure the reliability of their suppliers.

Illustrative image related to types of centrifugal blower

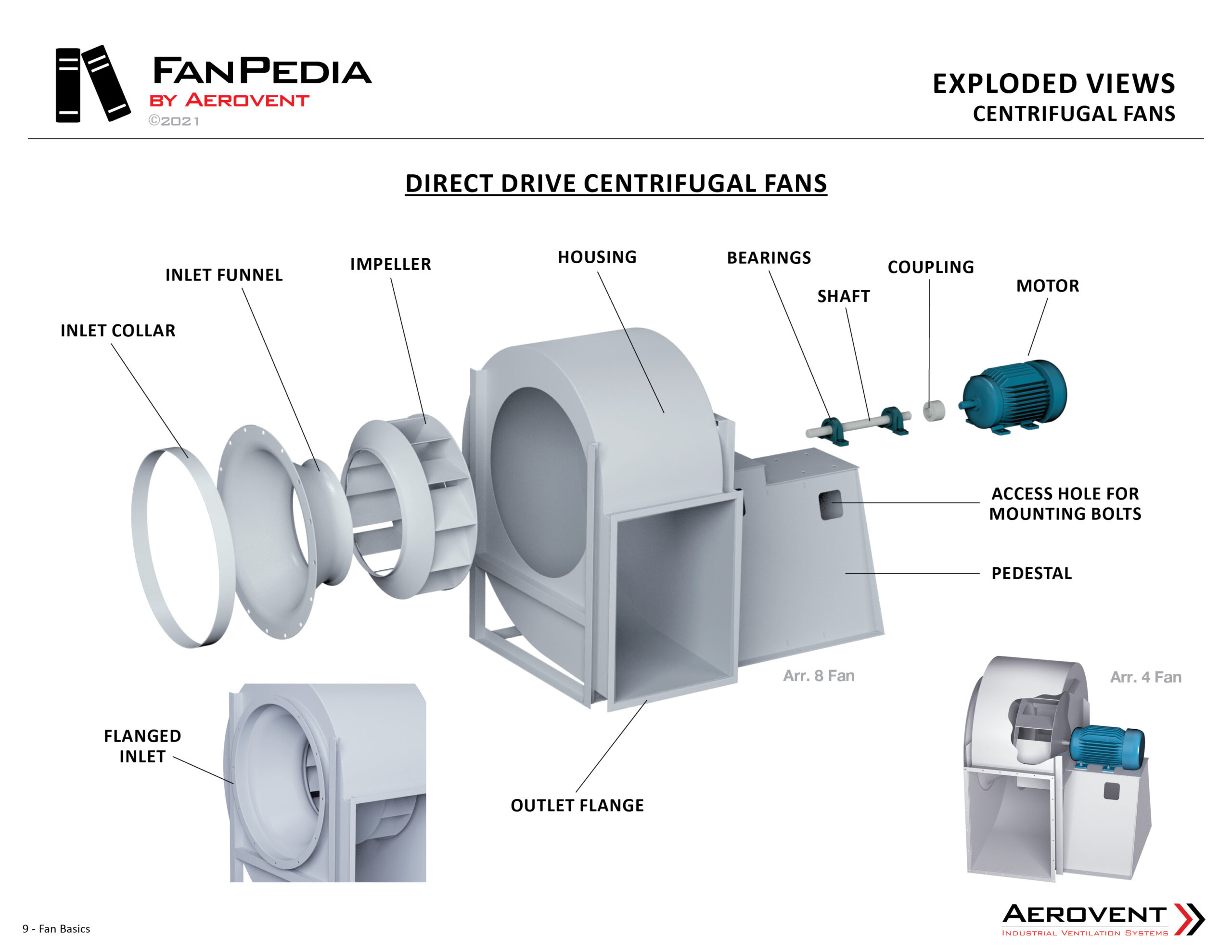

What Are the Main Stages in the Manufacturing Process of Centrifugal Blowers?

The manufacturing process of centrifugal blowers typically involves several critical stages: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Centrifugal Blowers?

Material preparation involves selecting and sourcing high-quality materials that meet industry standards for durability and performance. Common materials include carbon steel, stainless steel, and various alloys, depending on the specific application and environmental conditions.

The preparation stage often includes cutting raw materials to size and treating them to enhance their properties. For example, metal components may undergo processes such as galvanization or powder coating to improve corrosion resistance.

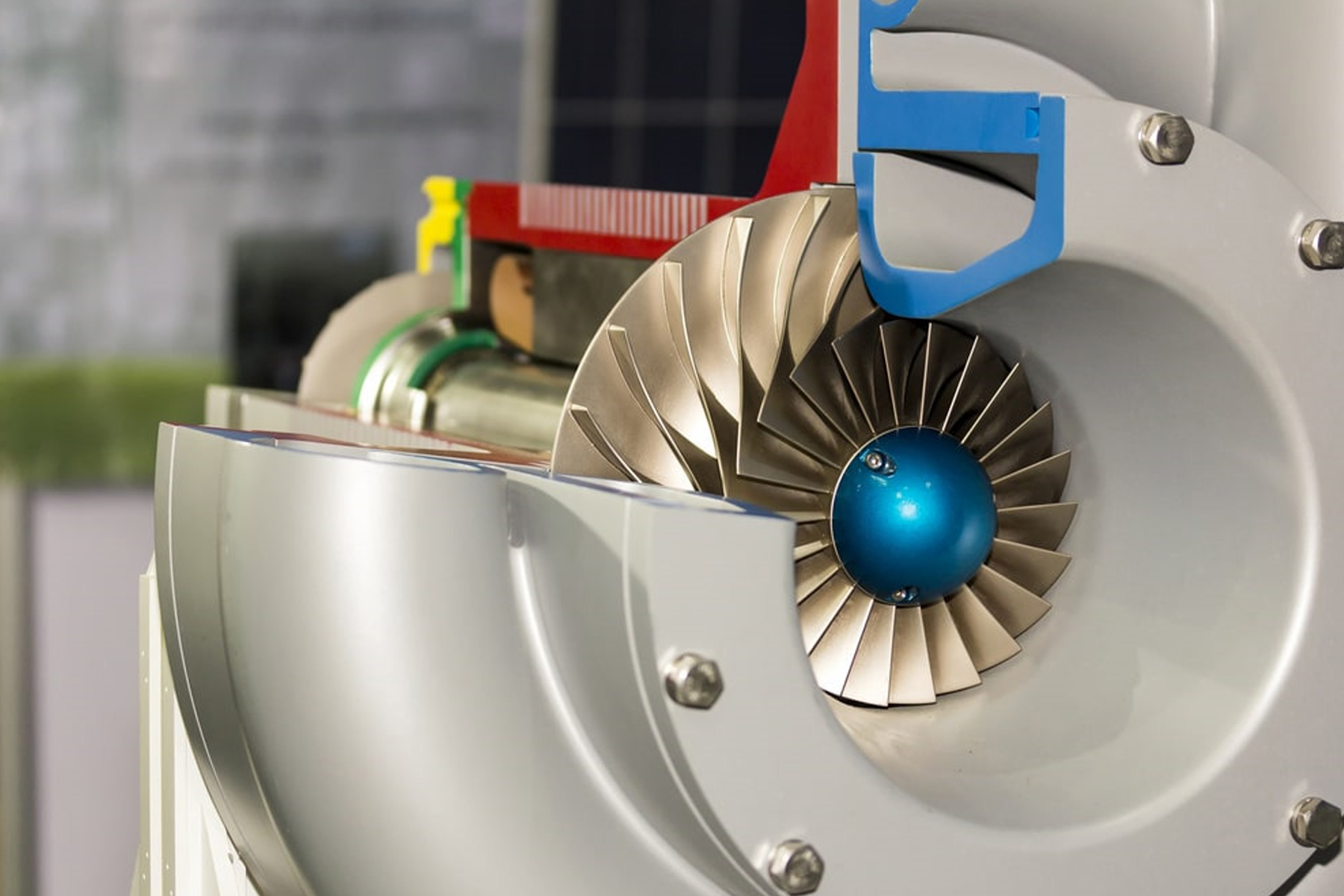

What Techniques Are Used in Forming Components?

Forming is a vital stage where the prepped materials are shaped into the required components of the blower. Key techniques include:

- Casting: Used for creating complex shapes, such as impellers and housings. The metal is poured into molds, allowing for intricate designs that enhance airflow efficiency.

- Machining: This includes processes like milling and turning, where components are finely shaped to meet precise specifications. This step is crucial for ensuring that parts fit together seamlessly during assembly.

- Welding: Essential for joining different components, ensuring structural integrity, especially in high-pressure applications. Welding techniques must be carefully selected based on material compatibility and the intended application.

How Are Centrifugal Blowers Assembled?

Assembly is where the various components come together to form the complete centrifugal blower. This stage typically involves:

- Component Fitting: Parts are fitted together based on design specifications. This includes aligning the impeller with the motor and ensuring proper sealing to prevent air leaks.

- Balancing: Impellers must be dynamically balanced to minimize vibrations during operation. This is crucial for prolonging the life of the blower and ensuring smooth operation.

- Electrical Integration: For electric blowers, motors and control systems are integrated at this stage, ensuring proper functionality and efficiency.

What Finishing Processes Are Commonly Employed?

Finishing processes enhance the performance and appearance of centrifugal blowers. These may include:

- Surface Treatment: Processes such as anodizing or powder coating improve aesthetics and corrosion resistance.

- Quality Testing: Before the final product is shipped, blowers undergo rigorous testing to ensure they meet performance specifications.

How Is Quality Assurance Implemented in Centrifugal Blower Manufacturing?

Quality assurance (QA) is a critical aspect of manufacturing centrifugal blowers, ensuring that products meet both international and industry-specific standards.

Illustrative image related to types of centrifugal blower

Which International Standards Are Relevant for Quality Assurance?

One of the most recognized international standards is ISO 9001, which outlines criteria for a quality management system. Compliance with this standard indicates that a manufacturer maintains consistent quality in their processes and products.

Additionally, industry-specific certifications such as CE for European markets and API for petroleum and natural gas industries are vital. These certifications ensure that products meet rigorous safety and performance standards.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints throughout the manufacturing process typically include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards. This is the first line of defense against defects.

- In-Process Quality Control (IPQC): During the manufacturing stages, continuous monitoring is conducted to ensure that processes are operating within defined parameters. This includes measuring dimensions, weight, and performance characteristics.

- Final Quality Control (FQC): Before shipment, the finished blowers undergo comprehensive testing. This may involve performance tests, noise level assessments, and safety checks to verify compliance with specifications.

What Testing Methods Are Commonly Used for Centrifugal Blowers?

Testing methods can vary but typically include:

- Performance Testing: Assessing airflow, pressure, and energy consumption to ensure the blower operates efficiently under specified conditions.

- Vibration Analysis: This helps identify any imbalances or issues that could lead to premature failure.

- Noise Testing: Ensuring that the blower operates within acceptable noise levels is crucial for applications where sound is a concern.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to ensure product reliability and performance.

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request access to supplier audits and quality reports. An effective audit will reveal the supplier’s adherence to ISO standards and any other relevant certifications. Look for:

- Documentation of Quality Processes: Details on how the supplier implements quality control at each stage of production.

- Performance Metrics: Information on defect rates, customer complaints, and corrective actions taken.

- Third-Party Inspections: Independent assessments can provide additional assurance of quality.

Are There Specific QC Nuances for International Transactions?

When dealing with international suppliers, buyers should be aware of potential regulatory differences that might affect quality standards. It’s crucial to ensure that the supplier’s certifications are recognized in the buyer’s country.

Additionally, buyers may want to consider the following:

- Cultural Differences: Understanding local manufacturing practices and how they may affect quality.

- Logistical Challenges: Assessing how transportation and shipping conditions can impact product integrity.

Conclusion

Understanding the manufacturing processes and quality assurance measures for centrifugal blowers is vital for B2B buyers seeking reliable and efficient solutions. By familiarizing themselves with the key stages of production, quality control standards, and verification methods, buyers can make informed decisions that will benefit their operations and ensure long-term satisfaction with their equipment.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘types of centrifugal blower’

Introduction

This practical sourcing guide is designed to assist B2B buyers in procuring various types of centrifugal blowers, ensuring that your purchasing decisions are informed and strategic. By following this checklist, you can streamline your selection process and align your operational requirements with the right equipment.

Step 1: Define Your Technical Specifications

Understanding your technical requirements is fundamental to selecting the appropriate centrifugal blower. Consider factors such as airflow rate, pressure requirements, and operational temperature. Clearly outlining these specifications will help you narrow down your options and ensure compatibility with your existing systems.

- Airflow Rate: Determine the volume of air you need to move.

- Pressure Requirements: Assess the static pressure your application demands.

Step 2: Identify the Right Type of Centrifugal Blower

There are three main types of centrifugal blowers: forward-curved, backward-curved, and radial. Each type has distinct advantages depending on your application needs.

- Forward-Curved Fans: Best for compact spaces where high airflow at low pressure is required.

- Backward-Curved Fans: More efficient and quieter, ideal for high-pressure environments.

- Radial Fans: Suitable for high resistance situations where robust performance is necessary.

Step 3: Evaluate Supplier Capabilities

Thoroughly assess potential suppliers to ensure they meet your quality and performance standards. Review their company profiles, certifications, and case studies to gauge their expertise in manufacturing centrifugal blowers.

- Certifications: Look for ISO or other relevant certifications that indicate quality assurance.

- Industry Experience: Consider suppliers with a proven track record in your specific industry.

Step 4: Request Detailed Proposals

Solicit detailed proposals from shortlisted suppliers that include pricing, lead times, and warranty terms. A comprehensive proposal will provide insights into the cost-effectiveness and reliability of the centrifugal blowers you are considering.

- Pricing Structure: Understand if the pricing is competitive and what factors may influence costs.

- Lead Times: Confirm delivery timelines to align with your project schedules.

Step 5: Assess Maintenance and Support Services

Evaluate the level of after-sales support and maintenance services offered by your suppliers. Reliable support can significantly enhance the longevity and performance of your centrifugal blowers.

- Technical Support: Ensure that technical assistance is readily available.

- Maintenance Plans: Inquire about routine maintenance services and replacement parts availability.

Step 6: Conduct Performance Testing

Before finalizing your purchase, request performance testing data or trials to verify the blower’s capabilities. Testing can help validate the supplier’s claims and ensure the product meets your operational needs.

- Testing Conditions: Ensure tests are conducted under conditions similar to your operational environment.

- Documentation: Request detailed reports on performance metrics.

Step 7: Finalize Contractual Terms

Once you have selected a supplier, carefully review and finalize the contractual terms. Ensure that all aspects of the agreement, including delivery, warranties, and payment terms, are clearly defined to avoid any future disputes.

Illustrative image related to types of centrifugal blower

- Delivery Schedule: Specify exact dates for delivery and installation.

- Warranty Coverage: Clarify what is included in the warranty and the process for claims.

By following this checklist, you can make a well-informed decision when sourcing centrifugal blowers that meet your business requirements, ensuring optimal performance and efficiency in your operations.

Comprehensive Cost and Pricing Analysis for types of centrifugal blower Sourcing

What Are the Key Cost Components in Centrifugal Blower Sourcing?

When sourcing centrifugal blowers, understanding the cost structure is vital for effective budgeting and decision-making. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The choice of materials significantly impacts the cost. For instance, blowers made from high-grade steel or specialized alloys will generally cost more but offer better durability and performance. Suppliers often provide options that balance cost with quality, so it’s crucial to evaluate material specifications against your application’s demands.

-

Labor: Labor costs can vary based on geographic location and the complexity of manufacturing processes. Skilled labor is often required for assembly and quality checks, influencing the overall price of the blower.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and indirect labor. Manufacturers with efficient operations may offer lower overhead costs, translating to more competitive pricing.

-

Tooling: The cost of tooling can be substantial, especially for custom designs. If you require specialized components, be prepared for higher upfront costs due to the investment in molds and dies.

-

Quality Control (QC): Implementing rigorous QC processes can add to the cost, but it ensures that the blowers meet the required specifications and certifications, which is crucial for reliability and safety.

-

Logistics: Shipping costs vary significantly based on distance, mode of transportation, and the size of the order. For international buyers, understanding Incoterms can help clarify who bears the costs and risks during shipping.

-

Margin: Supplier margins can vary widely based on their market position and the value-added services they provide. Established suppliers with a strong reputation may command higher prices, but this often comes with enhanced reliability and support.

How Do Price Influencers Affect Centrifugal Blower Costs?

Several factors can influence the pricing of centrifugal blowers, including volume, specifications, materials, and supplier characteristics.

-

Volume/MOQ: Larger orders can lead to significant discounts, as suppliers often have minimum order quantities (MOQs). Negotiating for bulk purchasing can yield lower per-unit costs.

-

Specifications and Customization: Custom designs or specialized features typically come with added costs. Buyers should weigh the necessity of these customizations against the potential impact on performance and operational efficiency.

-

Material Quality and Certifications: High-quality materials and industry certifications (such as ISO standards) can increase costs but also ensure better performance and longevity. It’s essential to align these aspects with your operational requirements.

-

Supplier Factors: The reputation, location, and service offerings of a supplier can impact pricing. Suppliers who provide comprehensive support and after-sales service might charge more, but this can lead to lower Total Cost of Ownership (TCO) over time.

-

Incoterms: Understanding Incoterms is crucial for international transactions as they define the responsibilities of buyers and sellers in shipping. Properly negotiated terms can help mitigate unexpected costs.

What Are the Best Practices for Negotiating Centrifugal Blower Prices?

For B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant savings.

-

Conduct Market Research: Understanding the average pricing for centrifugal blowers in your region can provide a solid foundation for negotiations. This knowledge helps in identifying reasonable price ranges and supplier benchmarks.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the upfront cost, but also maintenance, energy consumption, and potential downtime. A more expensive blower may offer lower TCO through better efficiency and reliability.

-

Leverage Volume Discounts: If you anticipate repeat purchases, negotiate terms that benefit from volume discounts. Suppliers may be more willing to reduce prices for larger commitments.

-

Be Transparent About Your Needs: Clearly communicate your requirements and constraints to suppliers. This openness can foster trust and lead to better pricing and service agreements.

-

Request Multiple Quotes: Obtaining quotes from various suppliers allows for comparison and can provide leverage in negotiations. It also helps identify the best fit for your specific needs.

What Should International Buyers Keep in Mind Regarding Pricing Nuances?

International buyers need to navigate various pricing nuances that can affect their overall procurement strategy. Currency fluctuations, import duties, and local regulations can significantly impact costs. Additionally, understanding the supply chain dynamics in your specific region can help in anticipating delays and additional fees.

While indicative prices can provide a reference point, it’s essential to engage directly with suppliers for the most accurate and tailored pricing. Factors such as local market conditions and supplier capabilities can lead to variations that are not immediately evident from generic price lists.

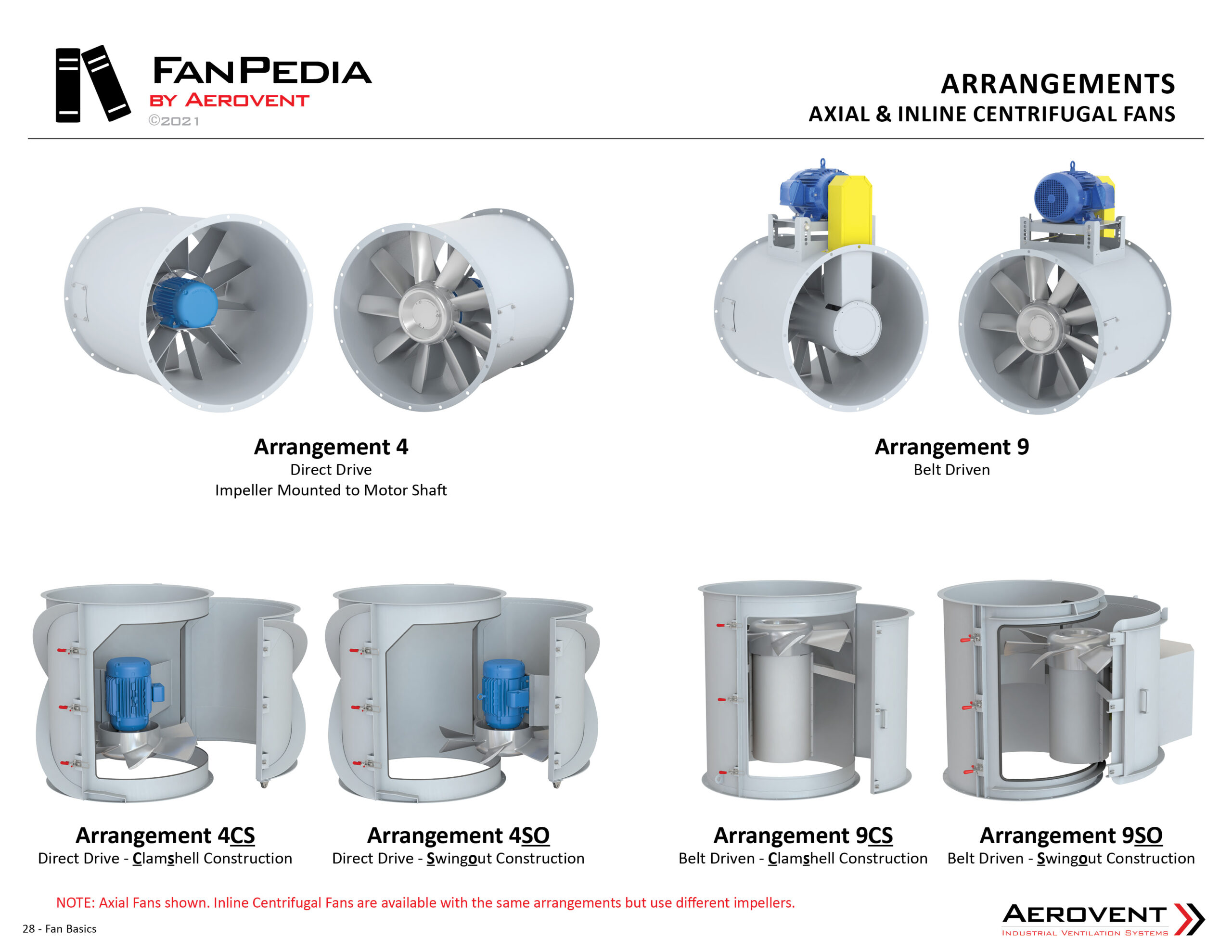

Alternatives Analysis: Comparing types of centrifugal blower With Other Solutions

Introduction

When considering air movement solutions for industrial applications, centrifugal blowers often stand out due to their efficiency and versatility. However, there are alternative technologies available that can achieve similar goals. This section compares various types of centrifugal blowers with other viable solutions, such as axial fans and positive displacement blowers, allowing B2B buyers to make informed decisions based on their specific requirements.

Comparison Table

| Comparison Aspect | Types Of Centrifugal Blower | Axial Fans | Positive Displacement Blowers |

|---|---|---|---|

| Performance | High pressure, moderate volume | High volume, low pressure | Steady flow, high volume |

| Cost | Moderate to high initial investment | Generally lower initial cost | Higher cost due to complexity |

| Ease of Implementation | Requires specific installation | Easy to install | Complex installation |

| Maintenance | Moderate, periodic checks needed | Low, less frequent maintenance | High, regular maintenance required |

| Best Use Case | Dust collection, air management | Ventilation, cooling | Material handling, pneumatic conveying |

Detailed Breakdown

Axial Fans: What Are Their Advantages and Disadvantages?

Axial fans are a popular alternative to centrifugal blowers, especially in applications requiring high volume and low-pressure airflow. They operate by moving air parallel to the axis of the fan, making them effective for general ventilation and cooling applications. The advantages of axial fans include lower initial costs and simpler installation procedures. However, they may not perform as well in applications requiring high static pressure or where space is constrained. Additionally, they can be less efficient than centrifugal blowers in certain scenarios, such as dust collection, where consistent airflow and pressure are critical.

Positive Displacement Blowers: When Are They the Best Choice?

Positive displacement blowers are designed to provide a consistent flow of air or gas by trapping a fixed volume and displacing it into the discharge pipe. They excel in applications requiring high volumes of air with a steady pressure, making them ideal for material handling and pneumatic conveying. While they offer a reliable airflow, their complexity results in higher costs and more intensive maintenance requirements compared to centrifugal blowers. Buyers should consider positive displacement blowers when their processes demand precise air movement and high reliability, despite the increased investment in both initial costs and maintenance.

Conclusion

Choosing the right air movement solution involves a careful analysis of specific operational needs, budget constraints, and maintenance capabilities. Centrifugal blowers offer robust performance in applications requiring high pressure and efficiency, making them suitable for dust collection and air management. However, alternatives like axial fans and positive displacement blowers can provide effective solutions based on different requirements, such as cost-effectiveness, ease of installation, or the need for steady airflow. B2B buyers should assess their unique operational requirements, including airflow volume, pressure needs, and maintenance capabilities, to select the most suitable technology for their applications.

Essential Technical Properties and Trade Terminology for types of centrifugal blower

What Are the Essential Technical Properties of Centrifugal Blowers?

When selecting centrifugal blowers for industrial applications, understanding their technical properties is crucial. Here are several key specifications that can significantly impact performance and efficiency.

1. Airflow Rate (CFM)

The airflow rate, measured in Cubic Feet per Minute (CFM), indicates the volume of air that the blower can move. This specification is vital for determining whether the blower meets the demands of your specific application. A higher CFM is essential in environments where large volumes of air need to be circulated, such as in ventilation systems or dust collection applications.

2. Static Pressure (Inches of Water Gauge)

Static pressure measures the resistance the blower can overcome to move air through ducts and other obstructions. It is expressed in inches of water gauge (in. wg). Understanding the static pressure is critical for applications that involve long duct runs or complex airflow paths, as inadequate pressure can lead to reduced efficiency and increased energy costs.

3. Motor Power (HP)

The motor power, typically measured in horsepower (HP), reflects the energy required to operate the blower. Selecting the appropriate motor power is essential for ensuring reliable performance without overloading the system. Inadequate power can lead to motor burnout, while excessive power may result in unnecessary energy consumption.

4. Material Grade

The material grade of the blower components, such as the impeller and housing, influences durability and resistance to corrosion or wear. Common materials include galvanized steel, stainless steel, and composite materials. Choosing the right material is crucial for applications exposed to harsh environments or abrasive particles, as it directly affects the longevity and maintenance costs of the blower.

5. Noise Level (Decibels)

Noise level is often a significant consideration, especially in environments where quiet operation is necessary. Measured in decibels (dB), centrifugal blowers vary in noise output based on design. Backward-curved fans tend to be quieter, making them suitable for applications in residential areas or noise-sensitive environments.

What Are Common Trade Terms Related to Centrifugal Blowers?

Familiarity with industry jargon can enhance communication and decision-making in the purchasing process for centrifugal blowers. Here are several essential trade terms.

Illustrative image related to types of centrifugal blower

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. Understanding OEM specifications is crucial for ensuring compatibility with existing systems and for maintaining the quality of components.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for B2B buyers, as it can impact inventory management and cost efficiency. Knowing the MOQ helps in budgeting and planning purchases.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price offers from suppliers for specific products or services. This process is essential for comparing pricing and terms among different suppliers, enabling informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that outline the responsibilities of buyers and sellers. They clarify aspects such as shipping costs, insurance, and delivery points, which can significantly influence the total cost of acquiring centrifugal blowers.

5. Static Pressure vs. Dynamic Pressure

Static pressure refers to the pressure exerted by a fluid at rest, while dynamic pressure is associated with the fluid’s motion. Understanding the difference is vital for selecting the right blower for specific applications, as it affects airflow and efficiency.

By grasping these technical properties and trade terminologies, international B2B buyers can make more informed decisions when selecting centrifugal blowers, ultimately enhancing operational efficiency and cost-effectiveness in their applications.

Navigating Market Dynamics and Sourcing Trends in the types of centrifugal blower Sector

What Are the Current Market Dynamics and Key Trends in the Centrifugal Blower Sector?

The centrifugal blower market is experiencing significant growth, driven by increasing industrialization and the demand for efficient air management solutions. Key trends influencing the sector include the rise of energy-efficient designs and the integration of smart technology. As businesses worldwide strive for operational efficiency, forward-curved and backward-curved centrifugal blowers are gaining traction due to their compact designs and energy-saving capabilities. Notably, companies in Africa, South America, the Middle East, and Europe are prioritizing solutions that not only meet their air delivery requirements but also align with sustainability goals.

Emerging technologies, such as IoT-enabled monitoring systems, are transforming how businesses manage their blower operations. These advancements allow for real-time performance tracking, predictive maintenance, and optimization of airflow, leading to reduced operational costs and improved system reliability. In regions like Brazil and Germany, where regulatory pressures for energy efficiency are high, these technologies are becoming essential for compliance and competitive advantage.

Additionally, the increasing focus on air quality and health standards is prompting industries to invest in advanced filtration systems integrated with centrifugal blowers. This trend is particularly relevant in sectors such as food processing, pharmaceuticals, and manufacturing, where clean air is paramount. As a result, international B2B buyers must stay informed about these technological advancements and consider them when sourcing centrifugal blowers to enhance their operational efficiency and maintain compliance with evolving regulations.

How Can Sustainability and Ethical Sourcing Affect Your Choice of Centrifugal Blowers?

Sustainability is becoming a cornerstone of procurement strategies in the centrifugal blower sector. As environmental concerns escalate, businesses are increasingly scrutinizing their supply chains, seeking suppliers who demonstrate a commitment to sustainability and ethical practices. The environmental impact of centrifugal blowers primarily revolves around energy consumption and waste generation during production. Buyers are encouraged to select manufacturers that utilize energy-efficient designs and sustainable materials, thus minimizing their carbon footprint.

Ethical sourcing practices are also gaining prominence, with a focus on transparency in the supply chain. This includes ensuring that materials are sourced responsibly and that labor practices adhere to ethical standards. Certifications such as ISO 14001 for environmental management and Green Seal for sustainability can be indicators of a supplier’s commitment to ethical practices. By choosing suppliers with these certifications, B2B buyers can not only enhance their corporate social responsibility (CSR) profiles but also align with the growing consumer demand for environmentally friendly products.

Illustrative image related to types of centrifugal blower

Moreover, the use of recyclable and biodegradable materials in the manufacturing of centrifugal blowers is becoming a significant consideration for buyers. This trend not only addresses environmental concerns but also resonates with the increasing regulatory pressure for sustainable practices across various regions. By prioritizing sustainable and ethically sourced centrifugal blowers, businesses can improve their operational efficiencies while contributing positively to environmental conservation.

What Is the Evolution of Centrifugal Blowers and Why Is It Relevant for B2B Buyers?

The evolution of centrifugal blowers can be traced back to their origins in the early industrial era, where the need for efficient air movement solutions was first recognized. Initially, designs were rudimentary, with limited applications. However, as industries grew and diversified, so did the technology behind centrifugal blowers. The introduction of advanced materials and precision engineering in the late 20th century significantly improved performance and reliability.

Today, centrifugal blowers are highly specialized, with various designs tailored to meet specific industrial needs, including forward-curved, backward-curved, and radial types. This evolution is particularly relevant for B2B buyers as it underscores the importance of selecting the right type of blower for their applications. Understanding the historical context of these technologies can guide buyers in making informed decisions, ensuring they choose solutions that not only meet their current requirements but also anticipate future needs in an increasingly competitive market.

Frequently Asked Questions (FAQs) for B2B Buyers of types of centrifugal blower

-

How do I choose the right centrifugal blower for my application?

Choosing the right centrifugal blower involves assessing your specific application needs, including airflow requirements, pressure, and space constraints. Consider the type of impeller design: forward-curved fans offer compactness and high airflow at low pressure, while backward-curved fans are more energy-efficient and quieter, ideal for high-pressure environments. Additionally, radial fans are suitable for applications requiring high static pressure. Evaluate factors such as temperature tolerance, noise levels, and the nature of the air being moved (clean or containing particles) to ensure optimal performance. -

What is the best centrifugal blower for high-pressure applications?

For high-pressure applications, backward-curved centrifugal blowers are generally the best choice. These fans are designed with fewer, longer blades that efficiently push air out, generating substantial static pressure. They operate quietly and consume less energy, making them ideal for industrial processes that require reliable airflow under significant resistance. Radial fans can also be suitable for high-pressure needs, especially in material handling or pollution control, but may produce more noise than backward-curved options. -

What customization options are available for centrifugal blowers?

Many manufacturers offer customization options for centrifugal blowers to meet specific operational requirements. Customizations can include impeller size, motor specifications, housing materials, and performance characteristics tailored to unique airflow, pressure, or temperature needs. Additionally, features like noise reduction enclosures or specialized coatings for corrosive environments can be implemented. Engaging with suppliers early in the design process allows for a tailored solution that enhances system efficiency and longevity. -

What are the minimum order quantities (MOQ) for centrifugal blowers?

Minimum order quantities (MOQ) for centrifugal blowers can vary significantly between manufacturers and depend on the type of blower, customization levels, and production capabilities. Some suppliers may have a low MOQ for standard models, while customized designs might require higher quantities to justify production costs. When sourcing internationally, it’s advisable to discuss MOQs upfront to ensure alignment with your operational needs and budget. -

What payment terms should I expect when purchasing centrifugal blowers?

Payment terms for centrifugal blowers vary by supplier and can depend on factors such as order size, customization, and buyer-supplier relationships. Common terms include full payment upfront, partial payments with the balance due upon delivery, or net payment terms (e.g., net 30 days). International buyers should also consider currency fluctuations and transaction fees. Always clarify payment terms before finalizing the order to avoid misunderstandings. -

How do I vet suppliers for centrifugal blowers?

Vetting suppliers for centrifugal blowers involves researching their industry reputation, experience, and product quality. Look for certifications (like ISO standards), customer reviews, and case studies that demonstrate reliability. It’s beneficial to request samples or visit manufacturing facilities, if feasible. Additionally, consider suppliers’ responsiveness to inquiries and their ability to provide technical support and after-sales service, which are crucial for long-term partnerships. -

What quality assurance measures should be in place for centrifugal blowers?

Quality assurance measures for centrifugal blowers typically include rigorous testing protocols during manufacturing, such as performance testing for airflow and pressure, noise level assessments, and durability evaluations. Look for suppliers that adhere to international standards and provide certification for their products. It’s also advisable to establish a warranty and return policy that protects your investment and ensures you have recourse should the product not meet specified performance criteria. -

What logistics considerations should I take into account when importing centrifugal blowers?

When importing centrifugal blowers, consider logistics factors such as shipping methods, lead times, and customs clearance procedures. Ensure that the supplier provides detailed shipping terms, including Incoterms, to clarify responsibilities for shipping costs and risks. Additionally, factor in the need for protective packaging to prevent damage during transit and verify that all necessary documentation, such as certificates of origin and compliance, is provided to facilitate smooth customs processing.

Top 7 Types Of Centrifugal Blower Manufacturers & Suppliers List

1. We Sell Fans – Centrifugal Fan Types

Domain: wesellfans.com

Registered: 2006 (19 years)

Introduction: Centrifugal fans are categorized into three basic wheel types: 1) Forward Curved (FC) – Provides large quantities of air at low pressures (3 to 5 inches of static pressure), typically made of riveted or welded stamped sheet metal, intended for clean air applications. 2) Radial Blower – Commonly used in dirty environments, capable of developing static pressures up to 40 inches, designed for materia…

2. Grainger – Centrifugal Fans

Domain: grainger.com

Registered: 1994 (31 years)

Introduction: This company, Grainger – Centrifugal Fans, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. NYB – Centrifugal Fans

Domain: nyb.com

Registered: 1996 (29 years)

Introduction: Centrifugal Fan Types: 1. Backward Inclined Fans: – Orientation: Backwardly inclined blades – Airflow: Medium to high – Pressure: Low to medium – Efficiency: 80-90% – Characteristics: Large inlet/outlet openings, wide casings – Wheel Types: Airfoil (most efficient, for clean airstreams), Single Thickness (better for material/moisture, less efficient), Backward Curved (similar to single thickness, …

4. Aerovent – Centrifugal Fans

Domain: aerovent.com

Registered: 1996 (29 years)

Introduction: Centrifugal fans designed for a wide range of air volumes and pressures. Available impeller types include backward inclined, backward curved, backward inclined airfoil, radial, and forward curved. Most models come in single-wide or double-wide configurations for higher air volumes. Key models include SWSI Centrifugal Fans (CAE-SW, CB-SW), DWDI Centrifugal Fans (CAE-DW, CB-DW), and Utility Sets (BA…

5. Cincinnati Fan – Centrifugal Blowers

Domain: cincinnatifan.com

Registered: 1998 (27 years)

Introduction: Centrifugal Blowers from Cincinnati Fan include various models designed for high pressure and volume air movement. Key models include:

– Model PB: Cast Aluminum Pressure Blower, up to 4,500 CFM, up to 20 in. wg

– Model PBS: Fabricated Steel Pressure Blower, up to 4,462 CFM, up to 20 in. wg

– Model SPB: Die-Formed Steel Pressure Blower, up to 4,075 CFM, up to 18 in. wg

– Model HP-I: High Pressu…

6. Longwell Fans – Centrifugal Fans

Domain: longwellfans.com

Registered: 2021 (4 years)

Introduction: Centrifugal fans are adaptable fans used in homes, businesses, and industrial applications. They utilize a spinning impeller to pull air in and push it out to the side, creating higher air pressure suitable for ventilation, cooling, and material handling. The fans operate based on centrifugal force, where the impeller spins to pull air in through the inlet, which is then accelerated and directed o…

7. Dynamic Fan – Industrial Centrifugal Fans

Domain: dynamicfan.com

Registered: 1999 (26 years)

Introduction: Dynamic Fan offers industrial centrifugal fans and blowers suitable for various applications, including HVAC systems, filtration, drying, dust elimination, and exhaust. Key features include customizable motor sizes, fan blade shapes, and rotation directions. Types of centrifugal fans available include airfoil, forward curved impellers, backward inclined impellers, flat paddle wheel style impellers…

Strategic Sourcing Conclusion and Outlook for types of centrifugal blower

In conclusion, understanding the diverse types of centrifugal blowers is critical for international B2B buyers aiming to optimize industrial processes. Each blower type—forward-curved, backward-curved, and radial—offers unique benefits tailored to specific applications, from energy efficiency and noise reduction to handling high-pressure environments. Strategic sourcing of these blowers ensures that organizations can enhance performance, reduce operational costs, and improve air quality in their facilities.

As businesses across Africa, South America, the Middle East, and Europe face increasing demands for productivity and sustainability, selecting the right centrifugal blower becomes a pivotal investment decision. Buyers should prioritize suppliers who provide robust technical support and tailored solutions that align with their operational requirements.

Looking ahead, the centrifugal fan market is poised for innovation, with advancements in technology promising even greater efficiencies and eco-friendly designs. By engaging with trusted manufacturers and distributors, international buyers can position themselves to capitalize on these developments, ensuring their operations remain competitive in a rapidly evolving industrial landscape. Take the next step towards enhancing your air management systems—connect with industry experts today to explore the best centrifugal blower solutions for your needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to types of centrifugal blower

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.