Unlocking Value: A Strategic Analysis of the Type Of Hinges Market

Introduction: Navigating the Global Market for type of hinges

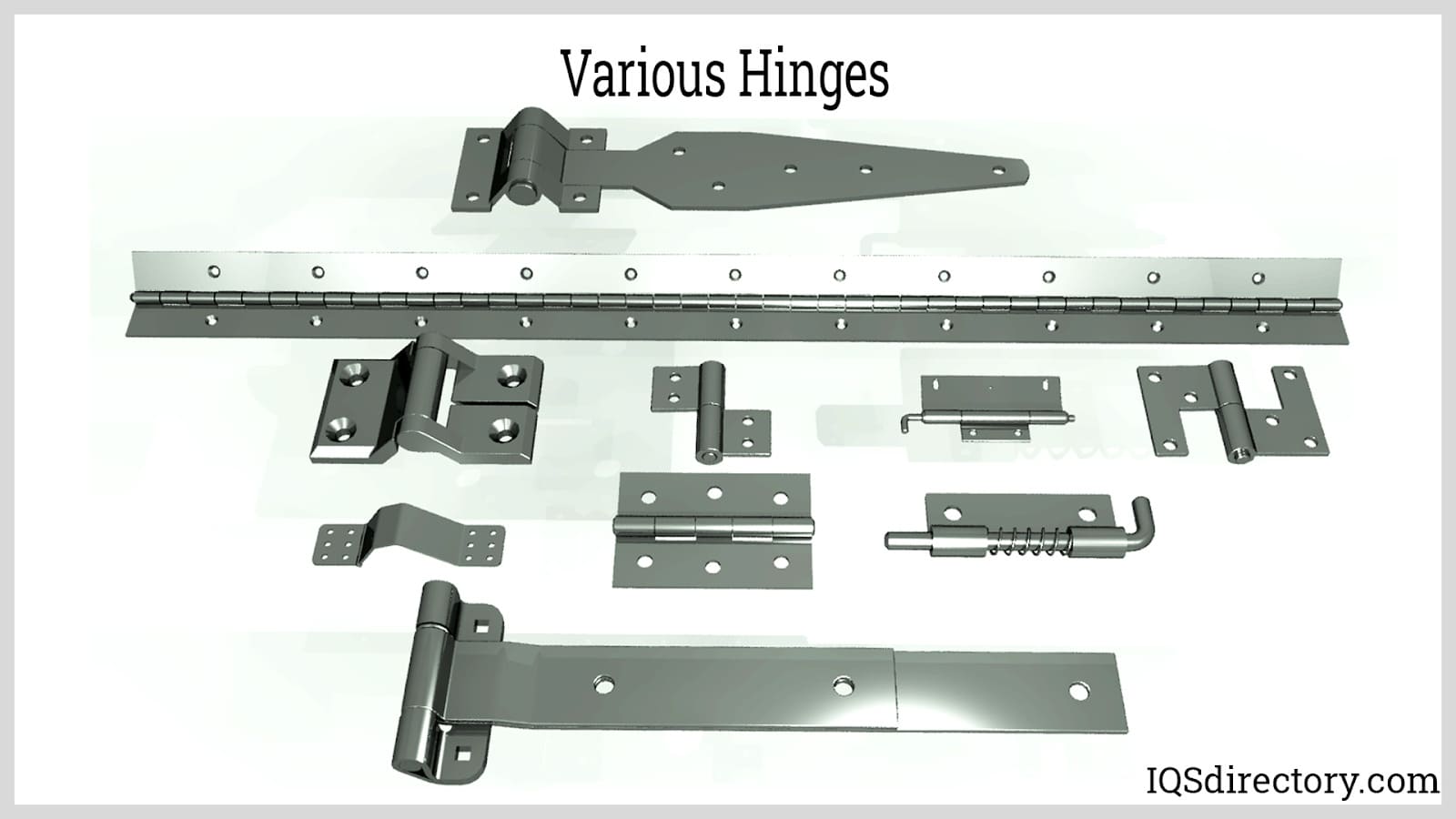

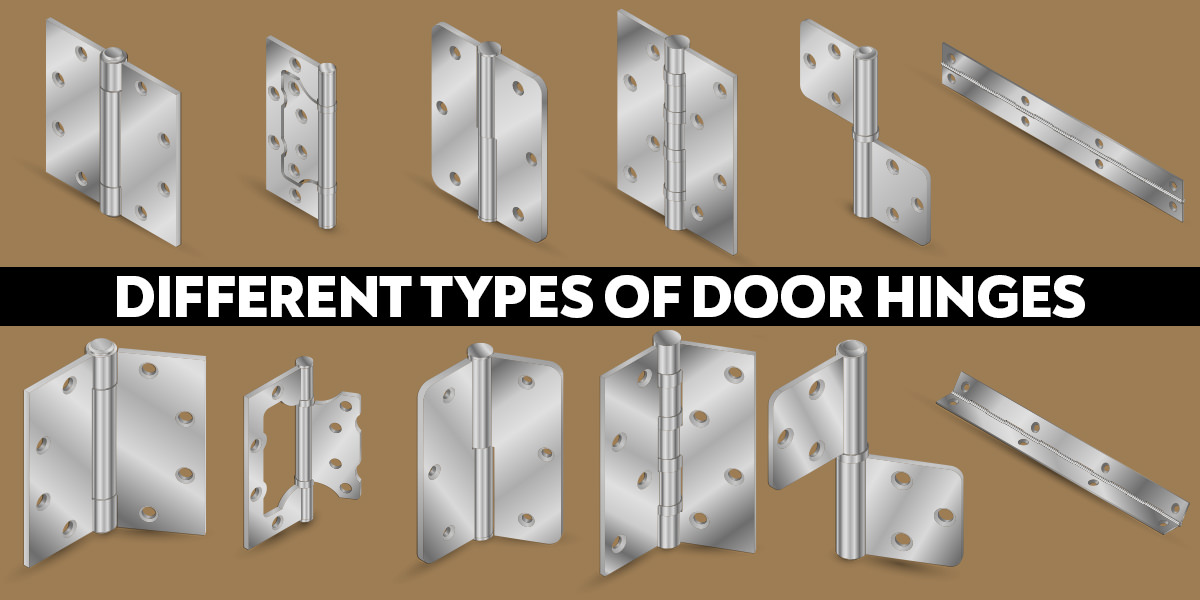

In today’s competitive landscape, sourcing the right type of hinges can be a daunting task for international B2B buyers. With a myriad of options available, understanding the nuances of different hinge types is essential for ensuring functionality, durability, and cost-effectiveness in various applications. This comprehensive guide delves into the diverse world of hinges, exploring over 24 different types, their specific applications, and the critical factors to consider when making a purchase decision.

From butt hinges and butterfly hinges to concealed and rising butt hinges, each type serves unique purposes, tailored to meet the demands of various industries and environments. As buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Vietnam and Saudi Arabia—navigate the global market, this guide equips them with essential insights for vetting suppliers, understanding pricing structures, and identifying the best hinge solutions for their needs.

By providing detailed information on hinge characteristics, applications, and best practices for installation, this guide empowers B2B buyers to make informed purchasing decisions that enhance their product offerings and operational efficiency. With a focus on quality and reliability, you can confidently select the right hinges that will stand the test of time and meet the specific requirements of your projects.

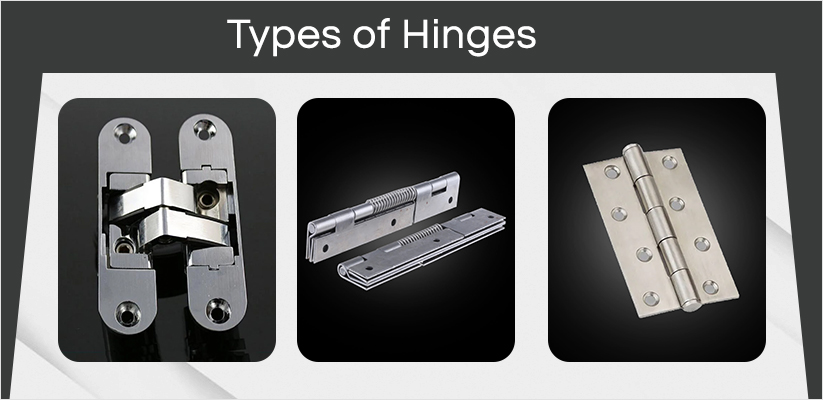

Understanding type of hinges Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Butt Hinge | Simple design, easily mounted, available in various sizes | Doors, cabinets | Pros: Versatile, easy to install. Cons: Limited adjustability. |

| Continuous Hinge | Long, continuous support, distributes weight evenly | Heavy doors, lids, cabinets | Pros: Strong, stable, suitable for heavy use. Cons: Requires precise installation. |

| Pivot Hinge | Allows doors to pivot on a single point | Commercial doors, large openings | Pros: Space-efficient, permits wide openings. Cons: Can be complex to install. |

| Concealed Hinge | Hidden when door is closed, adjustable | Cabinet doors, furniture | Pros: Aesthetic appeal, adjustable. Cons: More complex installation, potentially higher cost. |

| Rising Butt Hinge | Allows door to rise as it opens | Doors over carpets or uneven floors | Pros: Prevents damage to flooring. Cons: May require specific installation conditions. |

What are the Key Characteristics of Butt Hinges?

Butt hinges are among the most commonly used hinges in various applications, especially for doors and cabinets. Characterized by their straightforward design, they are easy to install and come in various sizes, making them versatile for both residential and commercial use. Buyers should consider the weight capacity and the type of material used to ensure longevity and performance. While butt hinges are reliable, they lack adjustability, which may be a consideration for applications requiring precise alignment.

Why Choose Continuous Hinges for Heavy Applications?

Continuous hinges, also known as piano hinges, provide a long, uninterrupted support mechanism, distributing weight evenly along the entire length. This feature makes them ideal for heavy doors, lids, and cabinets, especially in commercial settings. When purchasing continuous hinges, consider the material and finish, as these factors will affect durability and aesthetics. Although they offer exceptional strength, precise installation is crucial to ensure functionality and alignment.

How Do Pivot Hinges Enhance Space Efficiency?

Pivot hinges are designed to allow doors to pivot around a single point, making them an excellent choice for large openings and commercial applications. They enable doors to swing open wider than traditional hinges, which is particularly beneficial in high-traffic areas. Buyers should evaluate the weight capacity and installation requirements, as pivot hinges can be more complex to install compared to standard hinges. Their space-efficient design offers functional advantages, but may necessitate additional adjustments during installation.

Illustrative image related to type of hinges

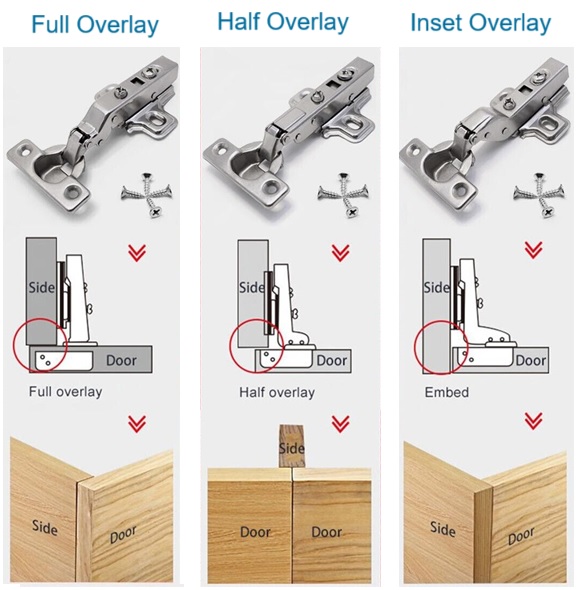

What Makes Concealed Hinges an Aesthetic Choice?

Concealed hinges are hidden from view when the door is closed, providing a clean and modern aesthetic. These hinges are adjustable, making them suitable for cabinet doors and furniture where appearance matters. When considering concealed hinges, buyers should pay attention to the installation complexity and potential costs, as they can be more expensive than traditional options. Their design not only enhances visual appeal but also allows for easy adjustments, making them a popular choice in upscale applications.

When Should You Use Rising Butt Hinges?

Rising butt hinges are specifically designed to lift the door as it opens, preventing it from scraping against uneven floors or thick carpets. This feature is particularly useful in residential and commercial settings where flooring conditions may vary. Buyers should consider the installation environment and ensure that these hinges are compatible with their door types. While they effectively solve clearance issues, rising butt hinges may require specific installation conditions to function optimally.

Key Industrial Applications of type of hinges

| Industry/Sector | Specific Application of type of hinges | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Heavy-duty doors in commercial buildings | Ensures durability and security in high-traffic areas | Material strength, load-bearing capacity, corrosion resistance |

| Furniture Manufacturing | Cabinet doors and furniture assembly | Enhances aesthetic appeal while ensuring functionality | Design compatibility, weight capacity, ease of installation |

| Automotive | Car doors and hoods | Provides reliable operation and safety for users | Weight tolerance, resistance to wear, environmental factors |

| Aerospace | Access panels and aircraft doors | Ensures safety and compliance with strict regulations | Lightweight materials, durability under extreme conditions |

| Retail & Hospitality | Entrance doors and display cases | Facilitates customer access while enhancing design | Security features, ease of use, aesthetic matching with branding |

How Are Type of Hinges Used in the Construction Industry?

In the construction sector, heavy-duty hinges are essential for doors in commercial buildings. These hinges must withstand frequent use and high loads, ensuring that doors operate smoothly without compromising security. Buyers in this industry should consider the material strength and load-bearing capacity, particularly in regions with harsh weather conditions, such as parts of Africa and the Middle East. Corrosion-resistant options are crucial to prolong the lifespan of the hinges, especially in coastal areas.

What Role Do Type of Hinges Play in Furniture Manufacturing?

In furniture manufacturing, hinges are vital for the assembly and functionality of cabinets and various furniture pieces. The right hinge can enhance aesthetic appeal while ensuring that doors and lids operate smoothly. Buyers should focus on design compatibility and weight capacity when sourcing hinges for furniture, especially in markets like South America, where unique styles may demand specific hinge designs. Ease of installation is also a key consideration to minimize production time and costs.

How Are Type of Hinges Essential in the Automotive Industry?

In the automotive sector, hinges are critical components for car doors and hoods, providing reliable operation and ensuring safety for users. The selection of hinges must consider weight tolerance and resistance to wear, particularly in regions with varying climates such as Europe and the Middle East. Additionally, environmental factors, such as exposure to moisture and temperature fluctuations, should influence the choice of materials to guarantee longevity and performance.

Why Are Type of Hinges Important in Aerospace Applications?

The aerospace industry relies on specialized hinges for access panels and aircraft doors, where safety and compliance with strict regulations are paramount. Lightweight materials are essential to minimize the overall weight of aircraft, while durability under extreme conditions is a must. Buyers need to ensure that the hinges meet industry standards and can withstand high-stress environments, particularly for international suppliers serving global aerospace manufacturers.

How Do Type of Hinges Benefit Retail and Hospitality Sectors?

In retail and hospitality, hinges are crucial for entrance doors and display cases, facilitating customer access while enhancing design. Sourcing hinges with security features is vital to protect merchandise and ensure customer safety. Additionally, hinges should align aesthetically with the branding of the establishment, making design compatibility a key factor for buyers. Ease of use and maintenance considerations also play a significant role in the selection process, particularly in high-traffic environments.

3 Common User Pain Points for ‘type of hinges’ & Their Solutions

Scenario 1: Navigating the Complexity of Hinge Selection for Unique Applications

The Problem: B2B buyers often encounter challenges when selecting hinges for specific applications, especially when dealing with unique or custom projects. For instance, a furniture manufacturer might require hinges that can support heavy cabinet doors while remaining concealed for aesthetic purposes. The multitude of hinge types available can overwhelm buyers, leading to the risk of choosing the wrong hinge, which can result in operational inefficiencies, increased costs, and potential project delays.

The Solution: To effectively navigate the hinge selection process, B2B buyers should first conduct a thorough assessment of the specific requirements for their application. This includes evaluating the weight and size of the doors or panels, the desired range of motion, and aesthetic considerations. Once these factors are identified, buyers should consult with manufacturers or suppliers who specialize in hinges. Engaging in technical discussions can yield insights into the best hinge options, such as concealed hinges for aesthetic applications or heavy-duty butt hinges for weight-bearing scenarios. Additionally, buyers should consider ordering samples or prototypes to test in real-world conditions before making bulk purchases, ensuring compatibility and performance.

Scenario 2: Managing Quality Control and Durability Expectations

The Problem: Ensuring the quality and durability of hinges is a significant concern for B2B buyers, particularly in industries where equipment and machinery are subjected to rigorous use. A construction company, for instance, might invest in high-quality doors that require robust hinges to withstand heavy traffic and environmental conditions. Poor quality hinges can lead to frequent replacements, increased maintenance costs, and dissatisfaction among end-users.

The Solution: Buyers should prioritize sourcing hinges from reputable manufacturers with a track record of quality and reliability. This can involve checking for industry certifications, such as ISO standards, which indicate adherence to stringent quality control processes. Furthermore, it is essential to request detailed product specifications, including load ratings and material compositions, to ensure the hinges can endure the specific conditions they will face. Establishing a relationship with suppliers who offer warranties or guarantees on their products can provide an additional layer of assurance. Regular inspections and maintenance of installed hinges can also preemptively identify wear and tear, allowing for timely replacements before failures occur.

Illustrative image related to type of hinges

Scenario 3: Overcoming Installation Challenges with Specific Hinge Types

The Problem: Installation issues can arise when using complex hinge types, particularly those that require precise alignment and adjustments. For example, an architect designing a modern office space may choose pivot hinges to achieve a sleek, minimalist look. However, if the installation process is not executed correctly, it can lead to doors that do not operate smoothly or that misalign over time, compromising both functionality and design integrity.

The Solution: To address installation challenges, it is crucial to provide comprehensive training and resources for installers. Buyers should ensure that their installation teams are familiar with the specific hinge type being used, including any unique requirements or adjustments needed for proper function. Utilizing detailed installation guides provided by manufacturers can help streamline the process and reduce errors. Additionally, investing in high-quality installation tools and equipment can facilitate precise alignment and secure fittings. For particularly complex hinge installations, considering professional installation services might be beneficial, as experienced technicians can ensure optimal performance and longevity of the hinges. Regular follow-ups and maintenance checks post-installation can also help identify any adjustments needed early on, preserving the integrity of the installation.

Strategic Material Selection Guide for type of hinges

What Are the Key Properties of Common Materials Used for Hinges?

When selecting hinges for various applications, the choice of material is crucial for ensuring performance and longevity. Below, we analyze four common materials used in hinge manufacturing: stainless steel, brass, plastic, and aluminum. Each material has distinct properties, advantages, and limitations that can significantly impact the end product’s functionality and suitability for specific applications.

How Does Stainless Steel Perform in Hinge Applications?

Stainless steel is renowned for its exceptional corrosion resistance and strength, making it a popular choice for outdoor and marine applications. It typically withstands high temperatures and pressures, ensuring durability in demanding environments. The primary advantage of stainless steel hinges is their longevity, as they resist rust and wear over time. However, they can be more expensive than other materials, which may be a consideration for budget-conscious buyers. For international B2B buyers, compliance with standards such as ASTM A240 and EN 10088-1 is essential, particularly in regions like Europe and the Middle East where stringent regulations are enforced.

What Are the Benefits and Drawbacks of Using Brass for Hinges?

Brass hinges offer a combination of aesthetic appeal and functional performance. They are resistant to corrosion and tarnishing, making them suitable for indoor applications, particularly in decorative settings such as furniture and cabinetry. The main advantage of brass is its attractive finish, which can enhance the overall design of a product. However, brass is softer than stainless steel, which may limit its use in heavy-duty applications. Additionally, brass hinges can be more expensive due to the cost of raw materials and manufacturing processes. Buyers in regions like South America and Africa should consider local preferences for aesthetics and durability when selecting brass hinges.

How Do Plastic Hinges Compare in Terms of Performance and Cost?

Plastic hinges, often made from high-density polyethylene or polypropylene, are lightweight and resistant to moisture and chemicals. They are ideal for applications where weight reduction is critical, such as in portable or foldable products. The primary advantages of plastic hinges include their low cost and ease of manufacturing, making them suitable for high-volume production. However, plastic hinges may not withstand high temperatures or heavy loads, limiting their applicability in industrial settings. For international buyers, understanding the specific chemical compatibility and temperature ratings of the plastic used is vital, especially in regions with extreme climates.

Illustrative image related to type of hinges

What Advantages Does Aluminum Offer for Hinge Manufacturing?

Aluminum hinges are lightweight yet strong, making them suitable for a variety of applications, including automotive and aerospace. They offer good corrosion resistance, particularly when anodized, and can be manufactured to precise specifications. The key advantages of aluminum hinges include their strength-to-weight ratio and cost-effectiveness in large-scale production. However, they may not be as durable as stainless steel in high-stress environments. Buyers should be aware of compliance with standards such as ASTM B221 and the potential need for protective coatings in harsh environments, particularly in regions like the Middle East where sand and humidity can be challenging.

Summary Table of Material Selection for Hinges

| Material | Typical Use Case for type of hinges | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Outdoor and marine applications | Exceptional corrosion resistance | Higher cost compared to other materials | High |

| Brass | Decorative furniture and cabinetry | Aesthetic appeal and corrosion resistance | Softer, limiting heavy-duty use | Med |

| Plastic | Portable and foldable products | Lightweight and low cost | Limited temperature and load resistance | Low |

| Aluminum | Automotive and aerospace applications | Strong yet lightweight | May require protective coatings | Med |

This strategic material selection guide provides valuable insights for international B2B buyers, allowing them to make informed decisions based on the specific requirements of their applications and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for type of hinges

What Are the Key Stages in the Manufacturing Process of Hinges?

The manufacturing process of hinges involves several critical stages, each contributing to the final product’s quality and functionality. The main stages include material preparation, forming, assembly, and finishing.

Illustrative image related to type of hinges

Material Preparation

The first step in hinge production is selecting the appropriate materials. Common materials for hinges include various metals such as stainless steel, brass, and aluminum, as well as engineered plastics for specific applications. Once the materials are chosen, they undergo processes like cutting and machining to prepare them for forming. This step may involve slicing metal sheets or extruding plastic to the required dimensions.

Forming Techniques

The forming stage is where the raw materials are shaped into hinge components. Techniques such as stamping, forging, and casting are commonly employed. Stamping is particularly popular for producing flat hinges and involves pressing the material into a die to create the desired shape. Forging is used for stronger components and involves shaping the metal while it’s hot, which enhances its structural integrity. For complex designs, casting may be used, allowing for intricate shapes that would be difficult to achieve through other methods.

Assembly Process

After forming, hinge parts are assembled. This stage may involve welding, riveting, or using fasteners like screws and bolts to join different components. The assembly must ensure that all moving parts function smoothly and that the hinge can withstand its intended load. Precision is crucial here, as any misalignment can lead to operational failures.

Finishing Touches

The final stage of manufacturing involves finishing processes such as polishing, coating, or painting. Finishing not only enhances the aesthetic appeal but also improves corrosion resistance and durability. Common finishes include anodizing for aluminum hinges and powder coating for steel hinges. This stage is vital for ensuring the hinge is suitable for its environment, especially in regions with high humidity or salt exposure.

How Do Quality Assurance Processes Enhance Hinge Manufacturing?

Quality assurance (QA) is essential in hinge manufacturing to ensure products meet specific standards and customer expectations. Key international standards, such as ISO 9001, set the framework for effective quality management systems, while industry-specific certifications like CE and API may apply depending on the hinge’s application.

Quality Control Checkpoints

To maintain high quality, manufacturers implement several quality control checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This initial step involves inspecting raw materials to ensure they meet specified standards before production begins. This may include checking the material’s chemical composition, dimensions, and surface quality.

-

In-Process Quality Control (IPQC): During the manufacturing process, periodic inspections are conducted to monitor the production parameters. This includes measuring critical dimensions and checking the functionality of the hinge components.

-

Final Quality Control (FQC): Once production is complete, a final inspection is carried out. This step verifies that the finished hinges meet all specifications and quality standards. Testing methods such as load testing, corrosion resistance testing, and cycle testing are commonly used to assess performance.

What International Standards Should B2B Buyers Look For?

For B2B buyers, understanding international standards and certifications is crucial in selecting reliable hinge suppliers. Compliance with ISO 9001 indicates that the manufacturer adheres to a recognized quality management system, ensuring consistent product quality and customer satisfaction.

In addition to ISO standards, industry-specific certifications may be relevant depending on the application of the hinges:

-

CE Marking: This certification is mandatory for products sold in the European Economic Area (EEA) and indicates compliance with safety, health, and environmental protection standards.

-

API Certification: Relevant for hinges used in the oil and gas industry, API standards ensure that products meet stringent safety and performance requirements.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure they are partnering with reputable hinge manufacturers, B2B buyers should engage in thorough supplier evaluations. Here are actionable steps to verify a supplier’s quality control processes:

-

Conduct Audits: Regular audits of suppliers can provide insight into their manufacturing processes and quality assurance systems. This can be done through onsite visits or third-party audits.

-

Request Quality Reports: Suppliers should provide documentation of their quality control measures, including inspection reports and testing results. This transparency helps buyers assess the reliability of the supplier’s quality assurance practices.

-

Utilize Third-Party Inspection Services: Engaging third-party inspection services can add an extra layer of assurance. These organizations can conduct independent assessments of the manufacturing processes and final products, ensuring they meet the required standards.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, must consider various nuances in quality control when sourcing hinges. Differences in regional standards, regulations, and cultural expectations can influence the quality assurance processes.

Understanding Regional Standards

Buyers should familiarize themselves with the specific standards and certifications relevant to their region. For example, while CE marking is crucial for products sold in Europe, other regions may have different requirements. Buyers must ensure that suppliers are compliant with local regulations to avoid legal issues and ensure product acceptance.

Cultural Expectations and Communication

Effective communication is vital when dealing with international suppliers. Buyers should establish clear quality expectations and specifications upfront. Language barriers can lead to misunderstandings, so employing bilingual professionals or using translation services can help mitigate risks.

Flexibility in Negotiations

Lastly, international buyers may need to be flexible in negotiations concerning quality standards and delivery timelines. Different manufacturing capabilities and supply chain constraints can impact a supplier’s ability to meet certain quality benchmarks. Understanding these factors can help buyers make informed decisions and foster strong supplier relationships.

Conclusion

In conclusion, the manufacturing processes and quality assurance for hinges are intricate and multifaceted. By understanding these processes, B2B buyers can make informed decisions, ensuring they procure high-quality products that meet their specific needs. With a focus on quality control, adherence to international standards, and thorough supplier evaluation, buyers can confidently navigate the global hinge market and establish successful partnerships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘type of hinges’

In the fast-paced world of B2B procurement, sourcing the right type of hinges is critical for ensuring operational efficiency and product quality. This practical guide offers a step-by-step checklist tailored for international buyers, focusing on essential actions to streamline your hinge procurement process.

Step 1: Define Your Technical Specifications

Before diving into sourcing, it’s vital to clearly outline the technical requirements for the hinges you need. Consider factors such as load capacity, material (e.g., stainless steel, brass, or plastic), and specific applications (e.g., doors, cabinets, or machinery). Detailed specifications help avoid misunderstandings with suppliers and ensure you acquire hinges that meet your operational needs.

Step 2: Research Different Types of Hinges

Understanding the various types of hinges available on the market is essential. Familiarize yourself with options like butt hinges, pivot hinges, and concealed hinges, each serving distinct functions. This knowledge will enable you to select the best hinge type based on your project requirements and aesthetic preferences.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers who have a proven track record of quality and reliability, as this can significantly impact your project’s success.

Illustrative image related to type of hinges

- Check Certifications: Ensure that the suppliers adhere to international quality standards, such as ISO certifications, which indicate a commitment to quality management.

- Assess Production Capacity: Verify that the supplier can meet your order volume without compromising quality or delivery timelines.

Step 4: Request Samples

Once you have shortlisted potential suppliers, request samples of the hinges you intend to purchase. Testing samples allows you to evaluate the quality, functionality, and compatibility with your existing systems. This step is crucial in identifying any potential issues before making a bulk order.

Step 5: Negotiate Terms and Conditions

Engage in discussions with your selected suppliers to negotiate favorable terms. This includes pricing, payment terms, delivery schedules, and warranty provisions. Clear agreements on these aspects can prevent future disputes and foster long-term partnerships.

- Consider Bulk Discounts: Inquire about pricing structures for large orders, as many suppliers offer discounts that can significantly reduce your costs.

- Establish a Return Policy: Ensure there is a clear return policy in case the hinges do not meet your specifications upon delivery.

Step 6: Finalize Your Order

Once all terms are agreed upon, finalize your order with a purchase agreement. Confirm all details, including quantities, specifications, and shipping arrangements. This documentation serves as a reference point for both parties and helps mitigate misunderstandings.

Step 7: Monitor Delivery and Quality Control

Upon receiving your order, conduct a thorough inspection of the hinges. Check for any damages or discrepancies from your order specifications. Establishing a quality control process ensures that the hinges meet your requirements and are ready for immediate use.

Illustrative image related to type of hinges

By following this checklist, B2B buyers can streamline the sourcing process for hinges, ensuring that they make informed decisions that support their business objectives.

Comprehensive Cost and Pricing Analysis for type of hinges Sourcing

When sourcing hinges for B2B applications, understanding the comprehensive cost structure and pricing dynamics is crucial for making informed purchasing decisions. This analysis will break down the essential components of costs, price influencers, and provide actionable tips for buyers, particularly in international markets.

What Are the Key Cost Components in Hinge Manufacturing?

The cost structure of hinges typically consists of several main components:

-

Materials: The choice of materials significantly impacts the cost. Common materials include stainless steel, brass, and engineered plastics. Specialty materials or finishes can increase costs due to their rarity and processing requirements.

-

Labor: Labor costs vary depending on the location of manufacturing. Countries with lower labor costs (e.g., Vietnam) may offer competitive pricing, while regions with higher labor standards may incur additional expenses.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. Efficient manufacturing processes can help minimize overhead.

-

Tooling: Custom tooling for specific hinge designs can be a significant upfront cost. The complexity of the hinge design often determines tooling expenses.

-

Quality Control (QC): Implementing rigorous QC processes is essential for ensuring product reliability. However, this adds to the overall cost due to the need for testing and inspection.

-

Logistics: Shipping costs can vary greatly based on the distance from the manufacturer to the buyer and the chosen shipping method. International logistics can also introduce tariffs and duties.

-

Margin: Suppliers will factor in their profit margin, which can vary depending on the competitiveness of the market and the perceived value of the product.

How Do Price Influencers Impact the Cost of Hinges?

Several factors can influence pricing in the hinge market:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Negotiating MOQs can yield better pricing.

-

Specifications and Customization: Customized hinges or those with specific features can significantly increase costs. Buyers should weigh the benefits of customization against budget constraints.

-

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., ISO, CE) can justify higher prices. Buyers should assess whether the added cost aligns with their quality requirements.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their proven track record.

-

Incoterms: Understanding the terms of shipping and responsibility for costs can affect the overall pricing. Different Incoterms (e.g., FOB, CIF) dictate who bears the costs and risks at various stages of the shipping process.

What Are the Best Tips for Negotiating Hinge Prices?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, here are some negotiation tips:

-

Leverage Volume Discounts: When possible, commit to larger orders to negotiate better pricing. Suppliers are often willing to offer discounts for bulk purchases.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also long-term costs, including maintenance, durability, and replacement frequency. Higher upfront costs may lead to lower TCO if the hinges last longer.

-

Build Relationships: Establishing a good relationship with suppliers can lead to better terms and pricing flexibility. Long-term partnerships often yield benefits in negotiations.

-

Be Aware of Pricing Nuances: Understand local market conditions and currency fluctuations, as these can impact pricing. Additionally, different regions may have varying standards that affect costs.

-

Request Multiple Quotes: Obtaining quotes from multiple suppliers can help you gauge the market rate and negotiate effectively. It also provides leverage in discussions with your preferred supplier.

Conclusion

Understanding the intricate cost structure and pricing dynamics of hinge sourcing is essential for B2B buyers. By considering the various cost components, being aware of price influencers, and employing strategic negotiation tactics, buyers can make informed decisions that lead to cost-effective solutions tailored to their needs. Always remember to seek indicative prices and be flexible to adapt to market changes.

Illustrative image related to type of hinges

Alternatives Analysis: Comparing type of hinges With Other Solutions

Understanding Alternatives to Traditional Hinges in B2B Applications

In the world of mechanical solutions, hinges are essential components that allow for the smooth operation of doors, lids, and various other moving parts. However, there are alternative solutions that can achieve similar functionality. This section explores how traditional hinges compare to these alternatives, providing B2B buyers with valuable insights to make informed purchasing decisions.

Comparison of Hinges and Alternative Solutions

| Comparison Aspect | Type of Hinges | Alternative 1: Sliding Mechanism | Alternative 2: Pivot System |

|---|---|---|---|

| Performance | Reliable for various weights; allows swinging motion; limited by space. | Excellent space-saving; smooth operation; can handle heavy loads. | Offers 360-degree rotation; ideal for unique design applications. |

| Cost | Generally low to moderate; varies by material and design. | Moderate to high; initial installation can be costly. | Moderate; can be economical depending on design complexity. |

| Ease of Implementation | Simple installation; requires basic tools; can be DIY. | More complex; may require professional installation for larger systems. | Moderate complexity; requires precision for accurate alignment. |

| Maintenance | Low maintenance; occasional lubrication needed. | Low maintenance; dependent on track system integrity. | Generally low; may require regular checks for alignment. |

| Best Use Case | Traditional doors, cabinets, and furniture. | Closets, sliding doors, and space-constrained areas. | Specialized applications like rotating displays or unique architectural designs. |

Detailed Breakdown of Alternatives

Sliding Mechanism

Sliding mechanisms, often used in wardrobes and patio doors, offer significant advantages in space conservation. They eliminate the swing arc required by traditional hinges, making them ideal for areas with limited space. However, the initial installation can be more complex and may require specialized tracks or guides. While they are effective for heavy loads, the cost of materials and installation can be higher than standard hinges. B2B buyers should consider this option when designing spaces that prioritize accessibility and functionality.

Pivot System

Pivot systems provide an innovative alternative to traditional hinges by allowing doors or panels to rotate around a fixed point. This system can enable 360-degree movement, making it suitable for unique architectural designs or applications where conventional swinging doors may not fit. While the installation process is moderately complex, it offers a modern aesthetic and can handle heavier doors without the need for extensive structural support. However, precision in installation is crucial to ensure smooth operation, which could necessitate professional assistance.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate hinge or alternative solution depends on various factors, including the specific application, spatial constraints, and budget considerations. Traditional hinges remain a reliable choice for standard applications, while sliding mechanisms and pivot systems may offer enhanced functionality in specialized environments. B2B buyers should evaluate their unique requirements, taking into account performance, cost, and ease of installation, to ensure they choose the right solution that meets their operational needs and enhances efficiency.

Essential Technical Properties and Trade Terminology for type of hinges

What Are the Essential Technical Properties of Hinges for B2B Buyers?

When selecting hinges for various applications, understanding their technical properties is crucial. Here are some key specifications that B2B buyers should consider:

Illustrative image related to type of hinges

-

Material Grade

The material of a hinge affects its strength, durability, and resistance to corrosion. Common materials include stainless steel, brass, and zinc-coated steel. Stainless steel is preferred for outdoor applications due to its corrosion resistance, while brass offers aesthetic appeal and moderate strength. Buyers should ensure that the material grade meets the requirements of their specific application, particularly in harsh environments. -

Load Capacity

Load capacity refers to the maximum weight a hinge can support without failing. This property is vital for applications involving heavy doors or gates. Buyers must calculate the total weight that the hinge will bear, considering factors like the door material and usage frequency. Selecting a hinge with an appropriate load capacity helps prevent failures that could lead to safety hazards and increased maintenance costs. -

Tolerance

Tolerance indicates the allowable variation in dimensions during manufacturing. Precise tolerances ensure proper fitting and functioning of the hinge. A hinge that does not fit correctly can lead to operational issues, misalignment, and premature wear. B2B buyers should verify tolerance specifications to ensure compatibility with their door frames and other components. -

Finish

The finish of a hinge not only impacts its aesthetic appeal but also its performance. Options include powder coating, plating, and anodizing, each offering varying levels of resistance to corrosion and wear. Buyers should select a finish that suits the environmental conditions of the application, ensuring longevity and reducing the need for replacements. -

Type of Movement

Different hinges allow for varying degrees of movement. For example, butt hinges typically allow for a 90-degree swing, while pivot hinges can enable 180 degrees or more. Understanding the required range of motion is essential for functionality, especially in spaces with specific design requirements. -

Installation Method

Installation methods can vary significantly between hinge types. Some hinges require mortising, while others can be surface-mounted. The installation method affects labor costs and time, so it is important for buyers to consider which type aligns best with their project capabilities and timelines.

What Are Common Trade Terms Related to Hinges in B2B Transactions?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are several common trade terms relevant to hinge procurement:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. For hinge suppliers, this means providing components that meet the specifications required by other manufacturers for assembly in their products. Understanding OEM relationships is critical for buyers looking to ensure compatibility and quality in their supply chain. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers as it impacts inventory management and cash flow. Buyers should negotiate MOQs that align with their project needs without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request price quotes for specific products. B2B buyers should prepare detailed RFQs that specify technical requirements, quantities, and delivery timelines to receive accurate and competitive offers. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms used in international contracts. They define the responsibilities of buyers and sellers regarding the delivery of goods. Familiarity with these terms helps B2B buyers understand shipping costs, insurance responsibilities, and risk management during transit. -

Lead Time

Lead time refers to the duration between placing an order and receiving the goods. This metric is crucial for project planning and inventory management. Buyers should inquire about lead times when negotiating with suppliers to ensure timely delivery aligns with their operational schedules.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when procuring hinges, ultimately enhancing project efficiency and product performance.

Navigating Market Dynamics and Sourcing Trends in the type of hinges Sector

What Are the Key Market Trends Influencing the Type of Hinges Sector?

The global hinges market is experiencing notable transformations driven by several key factors. Rapid urbanization and infrastructure development in regions such as Africa, South America, and the Middle East are boosting demand for various types of hinges, particularly in construction and furniture manufacturing. Additionally, the rise of e-commerce is reshaping sourcing strategies, allowing international buyers to access a wider array of products and suppliers from different geographical locations, including Europe and Asia.

Illustrative image related to type of hinges

Technological advancements are also influencing the hinges sector. Smart hinges that integrate electronic components for enhanced security and functionality are emerging, particularly in high-end residential and commercial applications. Buyers are increasingly looking for innovative solutions that offer durability, ease of installation, and enhanced performance. Furthermore, the trend towards customization is gaining traction, with manufacturers offering bespoke hinge solutions tailored to specific project requirements.

As sustainability becomes a priority, buyers are seeking products that align with eco-friendly practices. This includes sourcing hinges made from recycled materials or employing energy-efficient manufacturing processes. The overall market dynamics indicate a shift towards a more integrated and technology-driven approach to sourcing hinges, with international buyers needing to adapt to these changes to remain competitive.

How Is Sustainability Shaping Sourcing Practices in the Hinges Market?

Sustainability is no longer a peripheral concern; it has become a core principle driving purchasing decisions in the hinges sector. The environmental impact of hinge manufacturing—ranging from resource extraction to production processes—has prompted buyers to prioritize suppliers who demonstrate commitment to sustainable practices. This includes the use of recycled materials, reduced energy consumption, and responsible waste management.

Ethical sourcing is equally vital, as buyers are increasingly scrutinizing supply chains for transparency and fairness. This trend is particularly significant for international buyers from regions like Africa and South America, where ethical concerns may be more pronounced. Certifications such as ISO 14001 for environmental management and FSC for sustainable sourcing are becoming prerequisites for suppliers aiming to compete in this evolving market.

Moreover, eco-friendly materials, such as those derived from renewable sources or featuring lower carbon footprints, are gaining traction. Buyers are encouraged to look for hinges that incorporate materials like stainless steel or engineered plastics, which offer durability while minimizing environmental impact. By prioritizing sustainability and ethical sourcing, B2B buyers can not only enhance their brand reputation but also meet the growing consumer demand for environmentally responsible products.

How Have Hinges Evolved Over Time to Meet Industry Demands?

The evolution of hinges reflects broader technological and societal changes. Historically, hinges were simple mechanical devices crafted from wood or leather, primarily serving functional purposes. As industrialization progressed, the introduction of metal hinges marked a significant advancement, providing greater durability and versatility.

The 20th century saw the diversification of hinge types, with innovations such as the continuous hinge and pivot hinge emerging to meet specific application needs. Today, the hinges sector is witnessing a surge in smart technology integration, enabling features such as automatic closing mechanisms and security enhancements.

This evolution is not just about materials and functionality; it also encompasses design aesthetics, with decorative hinges gaining popularity in furniture and cabinetry. As the market continues to innovate, understanding this historical context can help B2B buyers appreciate the advancements that cater to modern demands while navigating sourcing decisions effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of type of hinges

-

How do I choose the right hinge type for my application?

Choosing the right hinge type requires understanding the specific application and load requirements. Consider factors such as the weight of the door or panel, the material it’s made from, and the frequency of use. For heavy doors, ball bearing or continuous hinges are ideal, while lighter applications may benefit from flush or butt hinges. Additionally, assess environmental conditions; for instance, stainless steel options are better for coastal areas due to corrosion resistance. Collaborating with suppliers can also provide insights on the best hinge for your needs. -

What is the best hinge for heavy-duty applications?

For heavy-duty applications, continuous or piano hinges are often the best choice as they distribute weight evenly along the entire length, providing stability and support. Ball bearing hinges are also suitable for heavy doors, offering smooth operation and durability. When selecting hinges for heavy-duty use, ensure they are made from high-strength materials, such as stainless steel, to withstand significant wear and stress. Always consult with manufacturers for specifications and load ratings to ensure the chosen hinge meets your project requirements. -

What factors should I consider when sourcing hinges internationally?

When sourcing hinges internationally, consider quality certifications, material standards, and compliance with local regulations. Evaluate the supplier’s reputation through reviews and references, and inquire about their production capabilities and lead times. Understanding the logistics involved, including shipping costs and customs regulations, is crucial for timely delivery. Additionally, ensure that the supplier can provide product samples to assess quality before placing bulk orders, and clarify terms regarding warranties and returns. -

How can I vet suppliers for hinge products?

To vet suppliers for hinge products, start by checking their business credentials, including registration and certifications. Request references from past clients and review their product quality through samples. Utilize platforms that provide supplier ratings or industry certifications to gauge reliability. Conducting site visits can also offer insights into their production processes and quality control measures. Additionally, engage in direct communication to assess their responsiveness and willingness to accommodate your specific needs. -

What is the typical minimum order quantity (MOQ) for hinges?

Minimum order quantities (MOQs) for hinges can vary significantly based on the supplier and the type of hinge. Typically, MOQs can range from 100 to 1,000 units for standard products. However, custom designs may require higher MOQs due to tooling and production setup costs. Always discuss your requirements with potential suppliers to negotiate MOQs that fit your business needs while ensuring you receive competitive pricing. Smaller orders may be possible, but they often come with higher per-unit costs. -

What payment terms should I expect when purchasing hinges?

Payment terms for hinge purchases can vary widely depending on the supplier and the size of the order. Common terms include a deposit upfront (usually 30% to 50%) with the balance due before shipment or upon delivery. Some suppliers may offer credit terms for established businesses. It’s crucial to clarify payment methods accepted, such as wire transfers, letters of credit, or PayPal. Always ensure that you have a clear agreement on payment terms in writing to avoid any misunderstandings. -

How do I ensure quality assurance for my hinge orders?

To ensure quality assurance for your hinge orders, request detailed specifications and certifications from suppliers regarding materials and manufacturing processes. Implement a quality control inspection process that includes checking samples before mass production. Consider third-party inspections or audits to verify compliance with international standards. Establish clear communication channels with your supplier for addressing any quality issues promptly. Additionally, consider setting up a return policy in case the hinges do not meet the agreed-upon specifications. -

What logistics considerations should I keep in mind when importing hinges?

When importing hinges, consider shipping methods, lead times, and customs regulations that apply to your destination country. Ensure that the supplier provides accurate documentation, including invoices and certificates of origin, to facilitate smooth customs clearance. Evaluate shipping options based on cost and delivery speed, and account for potential delays in transit. It’s also wise to partner with logistics providers who have experience in handling your specific type of products to ensure efficient and reliable delivery.

Top 1 Type Of Hinges Manufacturers & Suppliers List

1. Zanda – Types of Hinges

Domain: zanda.com.au

Introduction: Types of Hinges: Butler Tray, Double-action spring, Living, Butterfly, Drop Leaf, Pivot, Butt/mortise, Finial Tip, Rising Butt, Card Table, Floating, Security, Coach, Flush, Self-closing, Concealed, Friction, Soss, Continuous, H Strap, Counter, Flap, HL Tee, Cranked, Lift-off. Commonly used hinges include: Butt hinges (common, simple, loose joint, rising), Butterfly hinge, Flush hinge (fast fix hi…

Strategic Sourcing Conclusion and Outlook for type of hinges

In conclusion, understanding the diverse types of hinges is crucial for international B2B buyers looking to optimize their procurement processes. The right hinge can significantly impact the functionality, durability, and aesthetic appeal of doors and other applications. As highlighted, strategic sourcing involves evaluating hinge types based on specific needs, such as load capacity, environmental conditions, and design requirements. This approach not only ensures the selection of high-quality products but also fosters long-term relationships with reliable suppliers.

For buyers in Africa, South America, the Middle East, and Europe, leveraging local and global markets for hinge procurement can lead to substantial cost savings and enhanced operational efficiency. It is essential to consider both traditional materials and innovative solutions, such as living hinges and concealed designs, to meet varying project specifications.

As we look to the future, embracing technological advancements and sustainable practices in hinge manufacturing will be key. International buyers are encouraged to stay informed about emerging trends and invest in partnerships that prioritize quality and innovation. Taking these steps will position your business favorably in a competitive landscape, ensuring you meet the evolving demands of your customers.

Illustrative image related to type of hinges

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.