Unlocking Value: A Strategic Analysis of the Stainless Steel Conveyor Belts Market

Introduction: Navigating the Global Market for stainless steel conveyor belts

In today’s competitive landscape, sourcing stainless steel conveyor belts presents a critical challenge for international B2B buyers aiming to optimize their operations. As industries across Africa, South America, the Middle East, and Europe increasingly turn to automation, the demand for high-quality, durable conveyor solutions has surged. This guide serves as a comprehensive resource, addressing key considerations such as types of stainless steel conveyor belts, their diverse applications, and effective supplier vetting strategies.

From the food and beverage sector to pharmaceuticals and automotive industries, stainless steel conveyor belts play a pivotal role in enhancing productivity and ensuring compliance with stringent hygiene standards. By navigating the complexities of material selection, cost implications, and performance specifications, this guide empowers businesses to make informed purchasing decisions.

Furthermore, it highlights essential factors like maintenance practices and technological innovations, ensuring that buyers can leverage the latest advancements for maximum ROI. Whether you’re in Saudi Arabia, Nigeria, or elsewhere in the world, understanding these dynamics will enable you to choose the right conveyor solutions tailored to your operational needs. With this knowledge at your fingertips, you can confidently engage with suppliers and enhance your supply chain efficiency.

Understanding stainless steel conveyor belts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Eye-Flex® | Flexible design with high open area for airflow | Food processing, packaging | Pros: Excellent hygiene; adaptable to various products. Cons: May require more maintenance. |

| Flat-Flex® | Flat surface with a unique interlocking design | Baking, freezing, and cooling | Pros: Durable and efficient; minimizes spray deflection. Cons: Limited in heavy-duty applications. |

| Versa-Link® | Modular construction allowing easy repairs | Automotive, electronics | Pros: Quick installation; customizable length. Cons: Higher initial cost compared to traditional belts. |

| Compact-Grid™ | Small mesh openings for enhanced product support | Pharmaceutical, cosmetic | Pros: Great for small items; easy to clean. Cons: Not suitable for heavy loads. |

| Ladder-Track™ | Ladder-like structure for stability and drainage | Environmental services, recycling | Pros: Excellent drainage; robust design. Cons: Limited flexibility in design. |

What are the Characteristics and Benefits of Eye-Flex® Conveyor Belts?

Eye-Flex® conveyor belts are known for their flexibility and high open area, which allows for optimal airflow and cooling during processing. This design is particularly advantageous in food processing and packaging applications, where hygiene is paramount. Buyers should consider the adaptability of Eye-Flex® belts to various products and processes, although it’s important to note that their flexibility may lead to more maintenance requirements over time.

How Does Flat-Flex® Conveyor Belt Design Enhance Performance?

Flat-Flex® conveyor belts feature a unique interlocking design that creates a flat surface ideal for baking, freezing, and cooling applications. The belt’s high durability and efficiency minimize spray deflection, making it a reliable choice for industries that require precision. While Flat-Flex® belts excel in many environments, buyers should be aware that their performance may be limited in heavy-duty applications, which could necessitate alternative solutions.

Why Choose Versa-Link® Conveyor Belts for Modular Needs?

Versa-Link® conveyor belts are designed with modular construction, allowing for easy repairs and customization. This feature is beneficial in automotive and electronics industries, where quick installation and adaptability are vital. Although the initial cost may be higher than traditional belts, the long-term benefits of reduced downtime and enhanced flexibility make Versa-Link® a valuable investment for businesses seeking efficiency.

What Makes Compact-Grid™ Ideal for Sensitive Applications?

Compact-Grid™ conveyor belts are engineered with small mesh openings that provide enhanced support for delicate products, making them suitable for pharmaceutical and cosmetic applications. Their easy-to-clean design ensures compliance with stringent hygiene standards. However, buyers should consider that Compact-Grid™ belts may not be suitable for heavy loads, limiting their use in more robust industrial settings.

How Does Ladder-Track™ Design Support Environmental Applications?

Ladder-Track™ conveyor belts feature a ladder-like structure that enhances stability and drainage, making them ideal for environmental services and recycling applications. Their robust design allows for effective handling of various materials while providing excellent drainage capabilities. However, buyers should be mindful of the limited flexibility in design, which may restrict their application in certain industries.

Key Industrial Applications of stainless steel conveyor belts

| Industry/Sector | Specific Application of Stainless Steel Conveyor Belts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Transporting and handling raw and cooked food products | Ensures hygiene, meets safety standards, and enhances efficiency | Compliance with food safety regulations, corrosion resistance, and easy cleaning features |

| Pharmaceutical | Movement of products in sterile environments | Maintains product integrity and prevents contamination | FDA compliance, material certifications, and design flexibility for integration |

| Automotive Manufacturing | Assembly line operations for vehicle parts | Increases production speed and reduces downtime | Durability under heavy loads, resistance to wear, and customization options |

| Electronics | Transporting components in assembly lines | Minimizes damage to delicate parts and improves workflow | Precision engineering, anti-static properties, and adaptability to various production setups |

| Environmental Services | Waste sorting and recycling processes | Enhances efficiency in material recovery and reduces contamination | Robust design for heavy-duty applications and resistance to various chemicals |

How Are Stainless Steel Conveyor Belts Utilized in Food Processing?

In the food processing industry, stainless steel conveyor belts are essential for the transportation and handling of both raw and cooked food products. They are designed to meet stringent hygiene standards, preventing contamination and ensuring food safety. These belts facilitate various processes, including cooking, freezing, and packaging. For international buyers, particularly in regions like Africa and South America, sourcing belts that comply with local and international food safety regulations is crucial. Additionally, the ability to easily clean and sanitize these belts can significantly enhance operational efficiency.

What Role Do Stainless Steel Conveyor Belts Play in Pharmaceuticals?

Stainless steel conveyor belts are pivotal in pharmaceutical manufacturing, where maintaining a sterile environment is paramount. These belts transport products through various stages of production while preventing contamination, thereby preserving product integrity. Buyers in the Middle East and Europe should prioritize sourcing belts that comply with FDA and other regulatory standards, ensuring they are made from materials that can withstand rigorous cleaning protocols. Flexibility in design also allows for seamless integration into existing production lines, which is a key consideration for optimizing efficiency.

How Are Stainless Steel Conveyor Belts Applied in Automotive Manufacturing?

In the automotive sector, stainless steel conveyor belts are used extensively on assembly lines to transport vehicle parts efficiently. These belts are designed to handle heavy loads and resist wear, which is essential for maintaining production speed and minimizing downtime. B2B buyers in regions such as Saudi Arabia and Nigeria should consider the durability and customization options of conveyor belts to meet specific operational requirements. Investing in high-quality belts can lead to significant long-term savings through reduced maintenance costs and increased productivity.

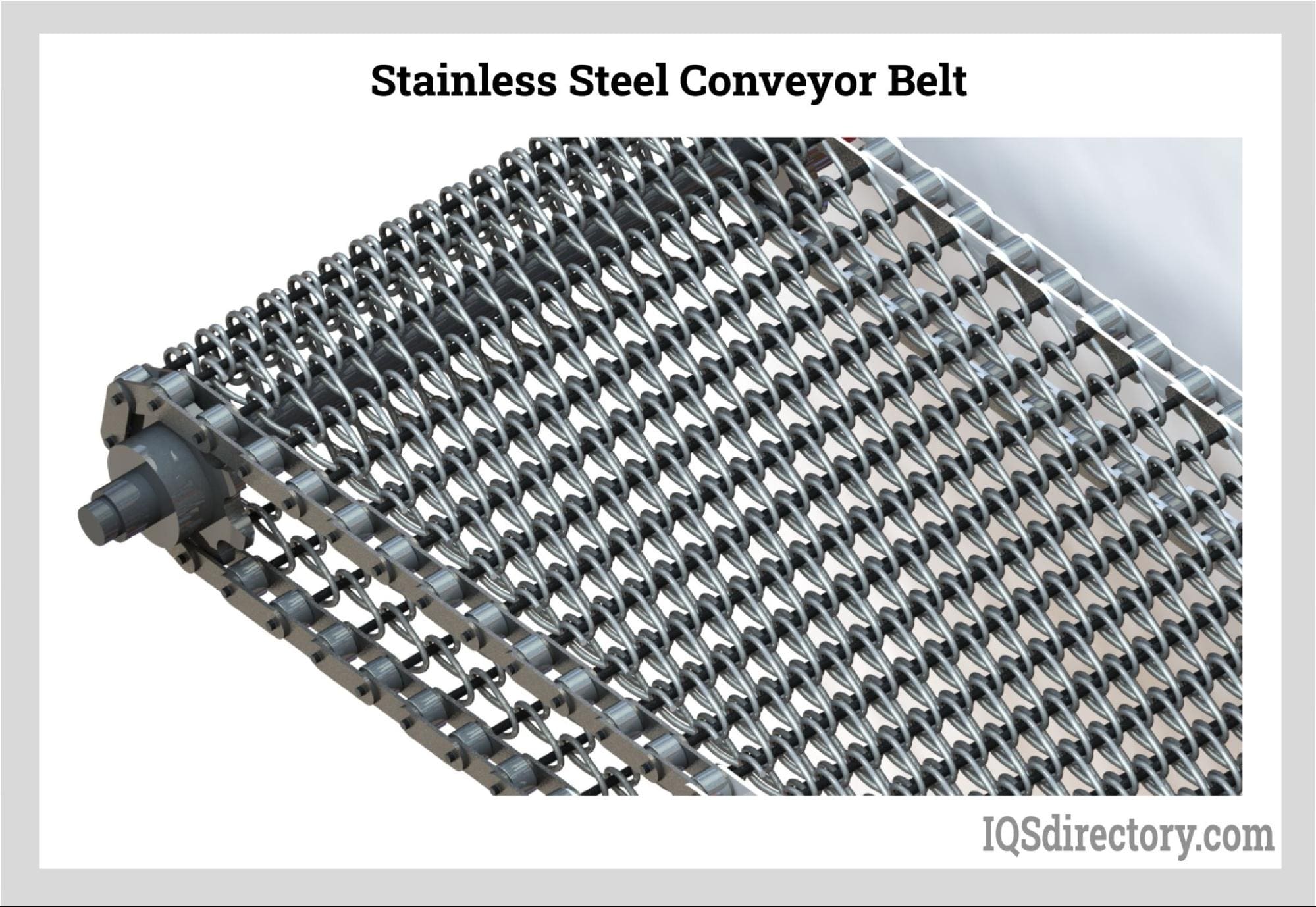

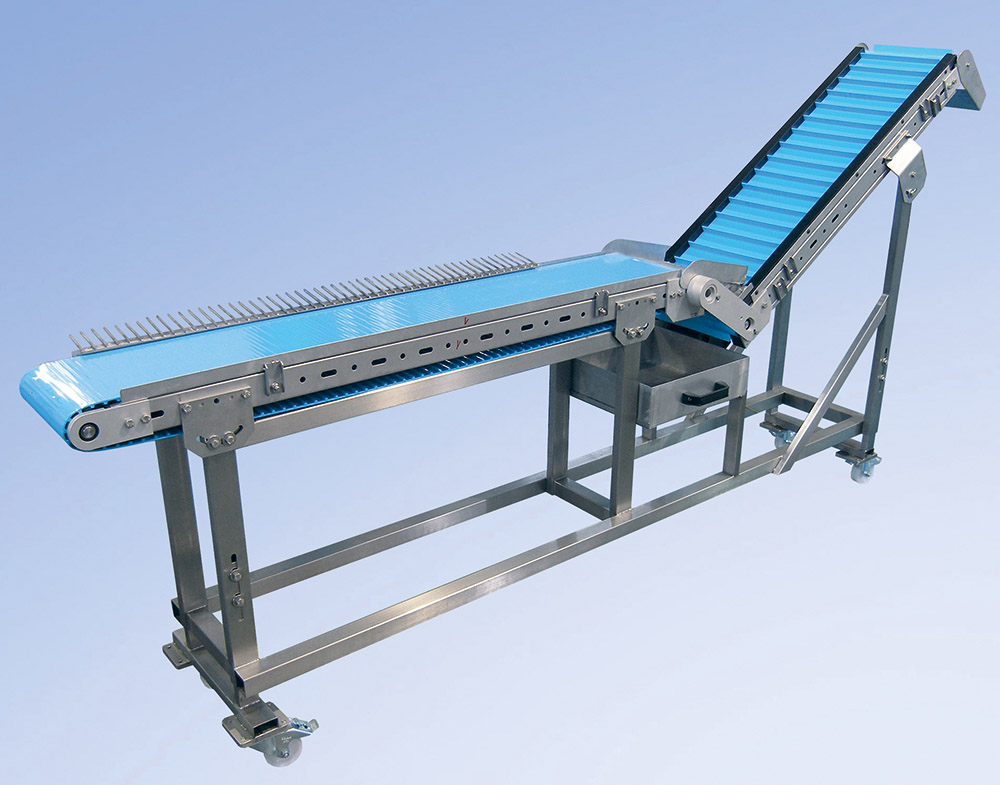

Illustrative image related to stainless steel conveyor belts

Why Are Stainless Steel Conveyor Belts Important in Electronics Manufacturing?

Stainless steel conveyor belts play a critical role in the electronics industry by transporting delicate components through assembly lines. These belts are engineered to minimize the risk of damage while maintaining a smooth workflow. For international buyers, especially in Europe, sourcing belts with anti-static properties is essential to prevent static discharge that can harm sensitive electronic parts. Additionally, the adaptability of these belts to various production setups ensures they can meet the evolving needs of manufacturers in this fast-paced industry.

How Do Stainless Steel Conveyor Belts Contribute to Environmental Services?

In the environmental services sector, stainless steel conveyor belts are utilized for waste sorting and recycling processes. Their robust design enables them to handle heavy materials while maintaining operational efficiency, which is crucial for maximizing material recovery. Buyers from Africa and South America should focus on sourcing belts that are resistant to various chemicals and can withstand harsh conditions. This ensures that the belts remain functional and reliable, ultimately enhancing the sustainability of waste management operations.

3 Common User Pain Points for ‘stainless steel conveyor belts’ & Their Solutions

Scenario 1: Managing Hygiene Standards in Food Processing

The Problem: In the food processing industry, ensuring high hygiene standards is paramount. Buyers of stainless steel conveyor belts often face challenges related to bacterial contamination and compliance with stringent health regulations. Many conveyor systems are not designed with easy cleaning in mind, leading to the accumulation of residues that could compromise food safety. This is particularly concerning for facilities processing meat, dairy, or ready-to-eat foods, where even minor lapses can result in costly recalls or shutdowns.

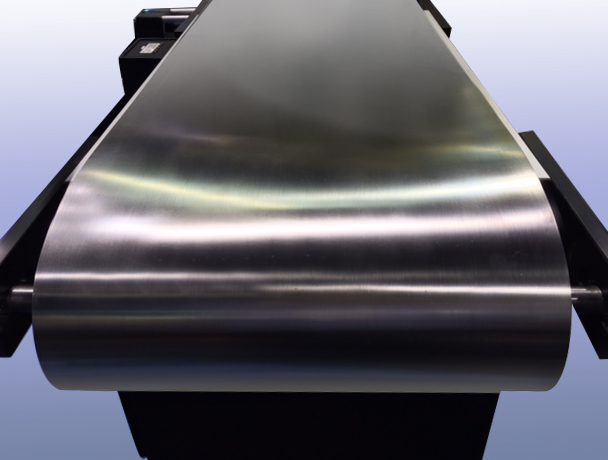

Illustrative image related to stainless steel conveyor belts

The Solution: To address hygiene concerns, it is crucial to select stainless steel conveyor belts specifically designed for sanitary applications. Opt for belts that feature a smooth surface and open mesh designs, which facilitate thorough cleaning and minimize residue buildup. Brands such as Wire Belt Company offer specialized options like PureSteel® belts that are engineered for hygiene and easy maintenance. Additionally, investing in a routine cleaning protocol that includes sanitization and inspection can further enhance safety. Consider integrating automation technologies that streamline the cleaning process, ensuring that your conveyor systems remain compliant with health regulations.

Scenario 2: Overcoming Conveyor Belt Wear and Tear

The Problem: Another common issue faced by buyers is the premature wear and tear of stainless steel conveyor belts. In high-volume operations, such as those in automotive or electronics manufacturing, belts can degrade rapidly due to friction, temperature fluctuations, and exposure to harsh chemicals. This can lead to unexpected downtimes, increased maintenance costs, and ultimately, reduced productivity. Buyers often struggle to find a balance between cost and durability, as lower-quality belts can lead to more frequent replacements.

The Solution: To mitigate wear and tear, it is essential to select stainless steel conveyor belts that match the specific demands of your application. Evaluate factors such as load capacity, operating temperature, and exposure to chemicals when choosing a belt. For example, belts with a higher tensile strength and corrosion resistance, like those made from T316 stainless steel, can withstand harsher environments. Regular maintenance practices, including tension adjustments and lubrication, can extend the lifespan of your conveyor belts. Additionally, implementing a predictive maintenance program can help anticipate wear patterns, allowing for timely replacements before failures occur.

Scenario 3: Customization Challenges in Conveyor Belt Design

The Problem: Many B2B buyers encounter difficulties when trying to customize stainless steel conveyor belts to fit unique operational needs. Standard conveyor belts may not adequately accommodate specific product shapes, sizes, or handling requirements. This lack of customization can lead to inefficiencies, such as bottlenecks or product damage during transport. Buyers often feel frustrated when their existing systems cannot be easily adapted to meet evolving production demands.

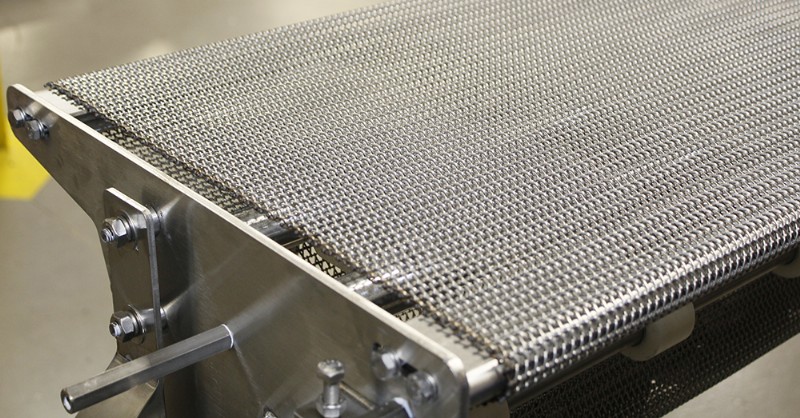

Illustrative image related to stainless steel conveyor belts

The Solution: To effectively address customization challenges, buyers should engage with manufacturers that offer a wide range of design options and engineering support. Companies like Belt Technologies provide tailored solutions, allowing you to specify dimensions, material properties, and belt configurations that align with your production processes. Collaborate closely with engineers to understand how different belt designs can enhance performance and efficiency. Conducting thorough application assessments can also reveal insights into optimal belt features, such as the type of mesh for airflow or the necessary width for product stability. By prioritizing custom solutions, you can ensure that your conveyor systems remain agile and responsive to changing operational needs.

Strategic Material Selection Guide for stainless steel conveyor belts

When selecting materials for stainless steel conveyor belts, several key factors must be considered, including performance properties, application suitability, and regional compliance standards. Below, we analyze four common materials used in the manufacturing of stainless steel conveyor belts, focusing on their characteristics, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of T304 Stainless Steel for Conveyor Belts?

T304 stainless steel is one of the most commonly used materials for conveyor belts due to its excellent corrosion resistance and good mechanical properties. It can withstand temperatures up to 870°C (1600°F) and is suitable for a wide range of applications, from food processing to chemical handling. Its resistance to oxidation makes it ideal for environments where exposure to moisture and corrosive substances is a concern.

Pros: T304 is relatively affordable and easy to fabricate, making it a popular choice for various applications. Its durability ensures a long lifespan, reducing the need for frequent replacements.

Cons: While T304 offers good corrosion resistance, it may not perform well in highly acidic or chloride-rich environments, which can lead to pitting and crevice corrosion.

Illustrative image related to stainless steel conveyor belts

Impact on Application: T304 is suitable for food processing, packaging, and general manufacturing, but its limitations in harsh environments should be considered.

Considerations for International Buyers: Compliance with food safety standards (e.g., FDA, EU regulations) is crucial for buyers in the food industry. Buyers from regions like Saudi Arabia and Nigeria should also be aware of local regulations regarding material safety.

How Does T316 Stainless Steel Compare for Conveyor Belt Applications?

T316 stainless steel is often preferred in applications requiring superior corrosion resistance, particularly in marine and chemical environments. This material can handle temperatures up to 870°C (1600°F) and offers enhanced resistance to pitting and crevice corrosion compared to T304.

Pros: T316’s durability and resistance to harsh chemicals make it ideal for food processing, pharmaceuticals, and marine applications. Its longevity can lead to lower overall costs in the long run.

Cons: T316 is generally more expensive than T304 and may require more complex manufacturing processes, which can increase lead times.

Impact on Application: T316 is particularly suitable for environments involving saltwater or high levels of chlorine, making it an excellent choice for coastal operations or chemical processing facilities.

Considerations for International Buyers: Buyers must ensure compliance with international standards such as ASTM and DIN, especially in regions with strict regulations like Europe.

Illustrative image related to stainless steel conveyor belts

What Are the Benefits of Using T430 Stainless Steel for Conveyor Belts?

T430 stainless steel is a ferritic stainless steel known for its magnetic properties and moderate corrosion resistance. It is typically used in applications where aesthetics are important, such as in food display cases and certain automotive applications.

Pros: T430 is cost-effective and provides good formability, making it suitable for various applications. Its magnetic properties can be beneficial in specific sorting applications.

Cons: Its corrosion resistance is lower than that of T304 and T316, making it less suitable for harsh environments or food processing applications where hygiene is critical.

Impact on Application: T430 is best suited for applications that do not involve exposure to extreme corrosive conditions, such as in dry environments or decorative applications.

Illustrative image related to stainless steel conveyor belts

Considerations for International Buyers: Buyers should consider the specific requirements of their applications and ensure that T430 meets any relevant industry standards.

How Does Alloy 20 Stainless Steel Perform in Conveyor Belt Applications?

Alloy 20, also known as Carpenter 20, is a nickel-chromium-molybdenum stainless steel that offers excellent resistance to corrosive environments, particularly sulfuric acid. It can handle temperatures up to 540°C (1000°F) and is often used in chemical processing applications.

Pros: Alloy 20’s exceptional corrosion resistance makes it ideal for industries dealing with aggressive chemicals. Its durability can lead to significant cost savings over time.

Cons: The high cost of Alloy 20 can be a barrier for some applications, and its fabrication can be more complex compared to standard stainless steels.

Impact on Application: This material is particularly well-suited for chemical processing and pharmaceutical applications where corrosion resistance is paramount.

Considerations for International Buyers: Compliance with chemical handling regulations is essential, especially in regions like South America and the Middle East, where industries may have specific standards for material use.

Summary Table of Material Selection for Stainless Steel Conveyor Belts

| Material | Typical Use Case for stainless steel conveyor belts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| T304 | Food processing, general manufacturing | Good corrosion resistance | Limited in highly acidic environments | Medium |

| T316 | Marine, chemical processing, food industry | Superior corrosion resistance | Higher cost and complexity | High |

| T430 | Decorative applications, dry environments | Cost-effective and formable | Lower corrosion resistance | Low |

| Alloy 20 | Chemical processing, pharmaceuticals | Excellent resistance to corrosives | High cost and complex fabrication | High |

This strategic material selection guide provides essential insights for B2B buyers in various regions, helping them choose the right stainless steel conveyor belt material based on their specific needs and compliance requirements.

Illustrative image related to stainless steel conveyor belts

In-depth Look: Manufacturing Processes and Quality Assurance for stainless steel conveyor belts

Stainless steel conveyor belts play a crucial role in various industries, including food processing, pharmaceuticals, and automotive manufacturing. Understanding the manufacturing processes and quality assurance measures involved in producing these belts is vital for B2B buyers looking to ensure product reliability and compliance with international standards. Below, we delve into the typical manufacturing stages, key quality control measures, and actionable insights for international buyers.

What Are the Main Stages of Manufacturing Stainless Steel Conveyor Belts?

The manufacturing of stainless steel conveyor belts consists of several key stages: material preparation, forming, assembly, and finishing. Each stage is critical to ensuring that the final product meets industry standards for durability and performance.

How Is Material Prepared for Stainless Steel Conveyor Belts?

The first step in the manufacturing process involves selecting high-grade stainless steel, often austenitic grades like 304 or 316, depending on the application requirements. The material is then cut to size and undergoes a thorough cleaning process to remove any contaminants. This preparation phase is crucial as it directly impacts the corrosion resistance and longevity of the conveyor belts.

What Forming Techniques Are Used in Conveyor Belt Manufacturing?

Once the materials are prepared, they are subjected to various forming techniques. Common methods include:

- Welding: This is often used to join sections of the belt together, ensuring a robust structure. Techniques such as TIG (Tungsten Inert Gas) welding are commonly employed for precision and strength.

- Bending and Shaping: The stainless steel is bent and shaped to create the desired belt profile. This may involve the use of specialized machinery that can achieve tight tolerances.

These forming techniques must be executed with precision to maintain the integrity of the belt and ensure it can withstand operational stresses.

Illustrative image related to stainless steel conveyor belts

How Is Assembly Conducted for Stainless Steel Conveyor Belts?

The assembly stage involves integrating various components, such as rollers, sprockets, and support structures, into the conveyor system. This process may require additional welding, riveting, or the use of mechanical fasteners. The assembly must be performed in a controlled environment to prevent contamination, especially for belts used in food processing applications.

What Finishing Techniques Are Applied to Ensure Quality?

Finishing processes such as polishing, passivation, and coating are applied to enhance the surface properties of the belts. Polishing improves aesthetics and reduces friction, while passivation helps to increase corrosion resistance by creating a protective oxide layer on the stainless steel surface. Additional coatings, such as food-safe lubricants, may also be applied depending on the intended application.

What Quality Control Measures Are Essential for Stainless Steel Conveyor Belts?

Quality assurance is a fundamental aspect of manufacturing stainless steel conveyor belts. International buyers should be aware of the standards and checkpoints that ensure product reliability and safety.

Which International Standards Should B2B Buyers Consider?

International standards such as ISO 9001 are crucial for ensuring a consistent quality management system is in place. Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for oil and gas applications are essential. These certifications signal compliance with safety, health, and environmental protection standards.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to verify that they meet specified requirements.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, periodic inspections are conducted to ensure that production methods adhere to established standards and tolerances.

- Final Quality Control (FQC): Before shipment, a thorough inspection is carried out to assess the final product for defects and compliance with specifications.

What Common Testing Methods Are Used in Quality Assurance?

Testing methods for stainless steel conveyor belts can include:

- Visual Inspection: This checks for surface defects and overall construction quality.

- Dimensional Testing: Ensures that the belts meet specified dimensions and tolerances.

- Load Testing: Evaluates the belt’s ability to handle expected loads without failure.

- Corrosion Resistance Testing: Assesses the material’s performance in various environments, particularly for food processing applications.

How Can B2B Buyers Verify Supplier Quality Control?

When sourcing stainless steel conveyor belts, B2B buyers should take proactive steps to verify supplier quality control measures.

Illustrative image related to stainless steel conveyor belts

What Steps Can Buyers Take to Ensure Supplier Compliance?

- Conduct Audits: Regular supplier audits can help assess compliance with quality standards and manufacturing processes.

- Request Quality Reports: Buyers should ask for detailed quality reports that outline inspection results, testing methods, and compliance with international standards.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased evaluation of the manufacturing processes and product quality.

What Are the Quality Control Nuances for International Buyers?

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding regional regulations and standards is crucial. Buyers should familiarize themselves with local import/export regulations and any specific certifications required for their markets. This knowledge can help avoid costly delays and ensure that the conveyor belts meet both local and international compliance standards.

Conclusion: Ensuring Quality in Stainless Steel Conveyor Belts

In conclusion, the manufacturing processes and quality assurance measures for stainless steel conveyor belts are multifaceted and critical to ensuring product reliability and safety. By understanding these processes and taking actionable steps to verify supplier quality control, B2B buyers can make informed decisions that enhance operational efficiency and compliance with industry standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘stainless steel conveyor belts’

To effectively procure stainless steel conveyor belts, following a structured approach can help ensure that you choose the right product and supplier for your business needs. This guide outlines essential steps to streamline your sourcing process, particularly for B2B buyers from diverse international markets.

Step 1: Define Your Technical Specifications

Understanding your operational requirements is crucial before initiating the sourcing process. Define the specific attributes of the conveyor belt you need, such as size, load capacity, and environmental resistance. Consider factors like temperature tolerance and hygienic properties, especially if the belts will be used in food processing or pharmaceutical applications.

Step 2: Conduct Market Research

Investigate the current market landscape for stainless steel conveyor belts. Identify key suppliers and manufacturers known for their reliability and quality. Pay attention to industry trends and technological advancements that could impact your decision-making.

- Look for case studies that demonstrate successful implementations similar to your needs.

- Assess competitors’ choices to gain insights into effective solutions.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to conduct a thorough evaluation. Request detailed company profiles, product specifications, and customer testimonials. Engaging with suppliers through direct communication can provide insights into their expertise and reliability.

- Verify certifications to ensure compliance with industry standards and regulations.

- Ask for references from businesses in similar industries or regions to gauge satisfaction and performance.

Step 4: Request and Analyze Quotations

Once you have shortlisted potential suppliers, request formal quotations. Compare pricing, delivery timelines, and payment terms. Analyzing these quotations will help you understand not just the cost but also the overall value offered.

- Look for transparency in pricing structures, including any hidden fees.

- Evaluate the balance between cost and quality to ensure you’re making a sound investment.

Step 5: Assess After-Sales Support and Warranty

Evaluate the after-sales support offered by suppliers. A robust support system can significantly impact the longevity and efficiency of your conveyor systems. Inquire about warranty terms, maintenance services, and response times for repairs.

- Confirm the availability of spare parts and support in your region.

- Understand the warranty coverage to protect your investment against manufacturing defects.

Step 6: Negotiate Terms and Finalize the Agreement

Once you’ve selected a supplier, engage in negotiations to finalize the terms of purchase. Ensure that all aspects, including delivery schedules, payment terms, and after-sales support, are clearly defined in the contract.

Illustrative image related to stainless steel conveyor belts

- Document everything to avoid misunderstandings later.

- Establish clear communication channels for ongoing correspondence and support.

Step 7: Plan for Installation and Training

After procurement, consider how the installation will be handled. Some suppliers may offer installation services or training for your staff to ensure optimal use of the conveyor systems. This step is vital to minimize downtime and improve productivity.

- Discuss installation timelines and any required modifications to existing systems.

- Arrange for comprehensive training to equip your team with the necessary skills to operate and maintain the equipment effectively.

By following these steps, B2B buyers can ensure a strategic approach to sourcing stainless steel conveyor belts, aligning their procurement decisions with operational needs and market conditions.

Comprehensive Cost and Pricing Analysis for stainless steel conveyor belts Sourcing

What Are the Key Cost Components in Stainless Steel Conveyor Belts Sourcing?

When sourcing stainless steel conveyor belts, it’s essential to understand the various cost components that contribute to the overall price. The primary elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: Stainless steel is the primary raw material, and its price can fluctuate based on market demand, alloy composition, and regional availability. For buyers in regions like Africa or South America, local suppliers may offer competitive pricing, but it’s crucial to assess the quality of the steel to ensure durability and compliance with industry standards.

-

Labor: Labor costs vary significantly depending on the manufacturing location. Regions with higher labor costs may result in increased prices for conveyor belts. For international buyers, consider sourcing from countries with competitive labor markets to reduce overall expenses.

-

Manufacturing Overhead: This includes costs related to utilities, facilities, and equipment maintenance. Manufacturers often factor these expenses into their pricing, so understanding the production environment can help buyers gauge the price’s justification.

-

Tooling: Customization of conveyor belts often requires specialized tooling, which adds to initial costs. Buyers seeking unique specifications should consider the tooling investments necessary to meet their needs.

-

Quality Control (QC): Robust QC processes ensure that the conveyor belts meet safety and operational standards. While this may increase upfront costs, it contributes to the longevity and reliability of the product, ultimately reducing the Total Cost of Ownership (TCO).

-

Logistics: Shipping and handling costs can vary based on the distance from the manufacturing site to the buyer’s location. Factors such as shipping mode, customs duties, and Incoterms (International Commercial Terms) play a significant role in overall logistics expenses.

-

Margin: Suppliers will include a profit margin in their pricing, which can depend on their market position, brand reputation, and the level of service provided. Established brands with a history of quality may command higher prices but can also offer better reliability and support.

How Do Price Influencers Affect the Sourcing of Stainless Steel Conveyor Belts?

Several factors can influence the pricing of stainless steel conveyor belts, impacting the buyer’s final costs.

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically attract discounts, allowing buyers to benefit from economies of scale. Buyers should negotiate MOQs with suppliers to maximize cost-effectiveness.

-

Specifications and Customization: Custom-designed belts may incur additional charges due to the complexity of manufacturing. Buyers should clearly define their requirements to avoid unexpected costs.

-

Material Quality and Certifications: The certification of materials used (e.g., FDA-approved for food processing) can increase costs but is often necessary for compliance with industry regulations. Buyers must weigh the importance of certifications against their budget constraints.

-

Supplier Factors: The supplier’s reputation, service quality, and delivery capabilities can impact pricing. Established suppliers may charge more, but they often provide better support and reliability.

-

Incoterms: Understanding Incoterms is crucial for international buyers as they determine who is responsible for shipping costs, insurance, and risks during transport. This knowledge can help buyers better manage their budgets.

What Tips Can Help Buyers Optimize Costs When Sourcing Stainless Steel Conveyor Belts?

To navigate the complexities of sourcing stainless steel conveyor belts effectively, consider the following strategies:

-

Negotiate Terms: Engage suppliers in discussions about pricing and payment terms. Leverage volume purchasing to negotiate better deals.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the initial price but also long-term costs, including maintenance, downtime, and replacement. Investing in higher-quality belts may yield savings over time.

-

Understand Pricing Nuances for International Buyers: Be aware of currency fluctuations and international shipping costs, which can affect overall pricing. Establishing relationships with local distributors may mitigate some of these risks.

-

Conduct Market Research: Compare multiple suppliers to understand market rates and identify competitive pricing. This information can empower buyers during negotiations.

-

Plan for Future Needs: Anticipate future production demands to avoid frequent reorders, which can lead to higher costs. Consider establishing long-term contracts with suppliers for better pricing stability.

In summary, understanding the cost structure and pricing influencers of stainless steel conveyor belts can help buyers make informed decisions, ensuring they achieve optimal value in their sourcing efforts. Always be mindful of the unique dynamics of your region and industry requirements.

Alternatives Analysis: Comparing stainless steel conveyor belts With Other Solutions

Introduction: Understanding Alternatives in Conveyor Systems

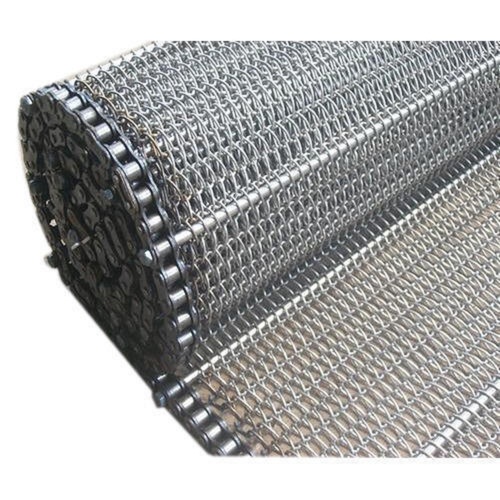

When considering conveyor systems, stainless steel conveyor belts are often a top choice due to their durability, hygiene, and versatility. However, various alternative solutions exist that can also meet specific operational needs. This section aims to provide a comparative analysis of stainless steel conveyor belts against two viable alternatives: plastic modular belts and wire mesh belts. By understanding the strengths and weaknesses of each option, B2B buyers can make informed decisions tailored to their unique requirements.

Comparison Table

| Comparison Aspect | Stainless Steel Conveyor Belts | Plastic Modular Belts | Wire Mesh Belts |

|---|---|---|---|

| Performance | High load capacity, resistant to extreme temperatures and chemicals | Moderate load capacity, versatile but can warp under high heat | Excellent airflow and drainage, suitable for diverse applications |

| Cost | Higher initial investment, longer lifespan reduces total cost | Lower upfront cost, but may require more frequent replacement | Mid-range cost, offers good longevity with proper maintenance |

| Ease of Implementation | Typically requires custom installation and integration | Easier to install with modular designs; can be modified on-site | Can be complex to install depending on design; requires precise alignment |

| Maintenance | Low maintenance due to durability, occasional cleaning needed | Moderate maintenance; parts can be replaced individually | Regular cleaning required, can be prone to rust if not stainless steel |

| Best Use Case | Food processing, pharmaceuticals, heavy-duty industrial applications | Packaging, bottling, and light assembly | Food processing, particularly where airflow is critical (e.g., frying, cooling) |

Detailed Breakdown of Alternatives

Plastic Modular Belts

Plastic modular belts are constructed from interlocking plastic segments, making them adaptable and easy to repair. One of their main advantages is their lower initial cost and modular design, which allows for quick modifications or repairs without the need for complete replacement. However, they typically have a lower load capacity compared to stainless steel belts and may warp under high temperatures or heavy loads, making them less suitable for extreme industrial environments.

Wire Mesh Belts

Wire mesh belts, often made of stainless steel or other metals, are designed for applications requiring excellent drainage and airflow. These belts excel in environments where cooling or heating is critical, such as in frying or drying processes. While they provide good durability and can handle various loads, they require regular maintenance to ensure cleanliness and functionality. Additionally, installation can be complex, especially if not specifically designed for the existing system, leading to potential downtimes during setup.

Conclusion: Choosing the Right Conveyor Solution

Selecting the appropriate conveyor solution hinges on understanding your operational requirements and constraints. Stainless steel conveyor belts are ideal for high-load, hygienic environments, particularly in food and pharmaceutical industries. In contrast, plastic modular belts may be more suited for lighter applications where flexibility and cost-efficiency are prioritized. Wire mesh belts provide unique advantages in processes requiring airflow but may demand more frequent maintenance. By evaluating performance, cost, ease of implementation, maintenance needs, and specific use cases, B2B buyers can confidently choose the conveyor system that best aligns with their operational goals.

Essential Technical Properties and Trade Terminology for stainless steel conveyor belts

What Are the Key Technical Properties of Stainless Steel Conveyor Belts?

When selecting stainless steel conveyor belts, understanding critical technical properties is essential for making informed purchasing decisions. Here are some key specifications that significantly impact performance and suitability for various applications:

Material Grade

Stainless steel conveyor belts are typically made from different grades of stainless steel, such as T303 and T316. T303 is commonly used for general purposes, while T316 offers enhanced corrosion resistance, making it ideal for food processing and pharmaceutical applications. Choosing the right material grade ensures longevity and reliability, especially in environments exposed to moisture or chemicals.

Open Area Percentage

The open area percentage refers to the ratio of the belt’s open space to its total surface area. High open area percentages, such as 68% in flat wire conveyor belts, allow for efficient drainage and airflow, crucial for applications like freezing and drying. This property is particularly important in industries such as food processing, where maintaining hygiene and product quality is paramount.

Tolerance

Tolerance indicates the allowable deviation in the belt’s dimensions and is critical for ensuring proper fit and function within conveyor systems. High precision in tolerances leads to smoother operations and reduces wear and tear on the machinery. This property is vital for B2B buyers looking to minimize downtime and maintenance costs.

Maximum Allowable Tension

This specification defines the maximum force the conveyor belt can handle without failure. Understanding the maximum allowable tension helps businesses select belts that can withstand the operational loads they will encounter. This is especially relevant for heavy-duty applications in industries like automotive and mining, where equipment is often subjected to significant strain.

Edge Treatment

Edge treatment refers to the finishing process applied to the edges of the conveyor belt, such as clinching or welding. Proper edge treatment enhances the belt’s structural integrity and prevents fraying, thereby prolonging its lifespan. For buyers, understanding edge treatments can influence maintenance schedules and overall product durability.

What Are Common Trade Terms Related to Stainless Steel Conveyor Belts?

Navigating the procurement process for stainless steel conveyor belts involves familiarity with specific industry terminology. Here are some essential terms that B2B buyers should understand:

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of conveyor belts, understanding OEM relationships can help buyers identify reliable suppliers who can provide compatible components for their existing systems.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly relevant for businesses looking to balance inventory costs with operational needs. Understanding MOQs can help buyers plan their purchases more effectively, especially in regions with fluctuating demand.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For B2B buyers, issuing RFQs is crucial for comparing offers and ensuring they receive competitive pricing and favorable terms. It streamlines the procurement process by clarifying requirements upfront.

Incoterms (International Commercial Terms)

Incoterms are a set of standardized trade terms used in international contracts to define responsibilities for shipping, insurance, and tariffs. Familiarity with Incoterms helps B2B buyers understand their obligations and rights in transactions, particularly when importing stainless steel conveyor belts from global suppliers.

Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. Understanding lead times is critical for B2B buyers who need to manage production schedules and avoid disruptions. It allows businesses to plan their operations more effectively and maintain a steady workflow.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing stainless steel conveyor belts, ensuring they select the most suitable products for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the stainless steel conveyor belts Sector

What Are the Key Market Dynamics Driving the Stainless Steel Conveyor Belts Sector?

The stainless steel conveyor belts market is experiencing significant growth, driven by an increase in automation across various industries, particularly in food processing, pharmaceuticals, and automotive sectors. The global demand for durable, hygienic, and efficient material handling solutions is propelling manufacturers to innovate and enhance their product offerings. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial.

Illustrative image related to stainless steel conveyor belts

Key trends include the integration of IoT technologies, allowing for real-time monitoring and predictive maintenance, which can significantly reduce downtime and improve operational efficiency. Additionally, the shift towards sustainable manufacturing practices is influencing sourcing decisions, as companies prioritize suppliers who demonstrate environmental responsibility. Buyers should also consider the customization capabilities of manufacturers, as tailored solutions can optimize production processes and meet specific operational requirements.

Emerging markets are witnessing a surge in demand for stainless steel conveyor belts due to industrialization and infrastructure development. Countries like Nigeria and Saudi Arabia are investing heavily in manufacturing sectors, creating opportunities for suppliers who can provide reliable and high-quality conveyor systems. Understanding local market conditions, regulatory frameworks, and cultural considerations will empower B2B buyers to make informed sourcing decisions.

How Is Sustainability and Ethical Sourcing Impacting the Stainless Steel Conveyor Belts Market?

Sustainability has become a focal point for B2B buyers in the stainless steel conveyor belts sector, as environmental considerations increasingly influence purchasing decisions. The production of stainless steel itself can have significant environmental impacts, including high energy consumption and carbon emissions. Thus, manufacturers are adopting more sustainable practices, such as utilizing recycled materials and optimizing energy use in their production processes.

Ethical sourcing is equally important, as buyers are now more aware of the supply chain’s social and environmental implications. Companies are encouraged to partner with suppliers who adhere to ethical labor practices and demonstrate commitment to corporate social responsibility. Certifications like ISO 14001 for environmental management systems and ISO 45001 for occupational health and safety are becoming essential benchmarks for evaluating suppliers.

Moreover, the rise of ‘green’ materials and technologies is reshaping the market landscape. Buyers should actively seek manufacturers that offer eco-friendly conveyor solutions, which can not only enhance their corporate image but also lead to potential cost savings through energy efficiency and reduced waste. This shift towards sustainability and ethical sourcing is not just a trend; it represents a fundamental change in how businesses operate in the global economy.

What Is the Historical Context of Stainless Steel Conveyor Belts in B2B Markets?

The evolution of stainless steel conveyor belts can be traced back to the mid-20th century when industries began to recognize the advantages of stainless steel over traditional materials like rubber or plastic. Its inherent properties—such as corrosion resistance, strength, and hygiene—made it particularly appealing for sectors like food processing and pharmaceuticals, where cleanliness and durability are paramount.

Over the decades, advancements in manufacturing technology have led to the development of various belt designs, including flat wire, modular plastic, and spiral belts, each tailored for specific applications. The introduction of automation in manufacturing processes further accelerated the adoption of stainless steel conveyor systems, as companies sought to enhance efficiency and reduce labor costs.

Today, the market is characterized by a strong emphasis on innovation, with manufacturers continually developing new materials and technologies to meet the evolving needs of industries worldwide. As businesses increasingly focus on automation and sustainability, the stainless steel conveyor belts sector is poised for continued growth, offering numerous opportunities for B2B buyers to enhance their operational capabilities.

Frequently Asked Questions (FAQs) for B2B Buyers of stainless steel conveyor belts

-

1. How do I choose the right stainless steel conveyor belt for my application?

Selecting the appropriate stainless steel conveyor belt involves assessing your specific needs, including the type of materials being handled, the required temperature ranges, and environmental conditions. Consider factors like belt width, load capacity, and the desired level of hygiene, especially for food processing applications. Consulting with a manufacturer or supplier can provide insights into the best options available, ensuring you select a belt that maximizes efficiency and meets industry standards. -

2. What are the benefits of using stainless steel conveyor belts in food processing?

Stainless steel conveyor belts are highly regarded in food processing due to their durability, hygienic properties, and resistance to corrosion. They can withstand high temperatures and harsh cleaning chemicals, making them ideal for applications such as cooking, freezing, and packaging. Their design minimizes contamination risks and facilitates easier cleaning, which is essential for meeting food safety regulations. -

3. What customization options are available for stainless steel conveyor belts?

Many manufacturers offer customization options for stainless steel conveyor belts, allowing businesses to tailor dimensions, surface finishes, and design features to meet specific operational requirements. Customizations can include variations in mesh openings, belt thickness, and edge treatments. Discussing your unique needs with suppliers can help you obtain a belt that enhances your production efficiency and integrates seamlessly with existing systems. -

4. What are the typical minimum order quantities (MOQs) for stainless steel conveyor belts?

Minimum order quantities for stainless steel conveyor belts can vary significantly among manufacturers, often ranging from a few meters to several hundred meters. MOQs may depend on the complexity of the customization required and the specific type of belt. It’s advisable to communicate directly with potential suppliers to understand their MOQs and negotiate terms that align with your production needs. -

5. How do I vet suppliers when sourcing stainless steel conveyor belts internationally?

To effectively vet suppliers, start by checking their industry experience, client testimonials, and certifications. Request detailed product specifications and quality assurance practices to ensure they meet your standards. Conducting background checks and seeking references from other clients can also provide valuable insights. Additionally, consider suppliers who demonstrate a strong commitment to customer service and support, especially in logistics and after-sales care. -

6. What payment terms are common in international transactions for conveyor belt purchases?

Payment terms can vary widely depending on the supplier and the nature of the transaction. Common arrangements include advance payments, letters of credit, or staggered payments based on delivery milestones. It’s crucial to establish clear terms that protect both parties and ensure timely delivery. Discussing payment options upfront can help mitigate risks and foster a smooth transaction process. -

7. How can I ensure quality assurance (QA) for stainless steel conveyor belts?

To ensure quality assurance, request certifications such as ISO or other relevant industry standards from your supplier. Inquire about their QA processes, including testing methods for durability, hygiene, and performance under specified conditions. Establishing a clear inspection process, including pre-shipment checks, can also help guarantee that the belts meet your expectations before they arrive at your facility. -

8. What logistics considerations should I keep in mind when importing stainless steel conveyor belts?

Logistics play a crucial role in the timely delivery of stainless steel conveyor belts. Consider factors such as shipping methods, customs regulations, and potential tariffs or duties that could affect costs and delivery times. Collaborate with logistics providers who have experience in international shipping to ensure smooth transport. Additionally, factor in lead times for production and shipping to avoid delays in your operations.

Top 5 Stainless Steel Conveyor Belts Manufacturers & Suppliers List

1. Ashworth – Flat Wire Conveyor Belts

Domain: ashworth.com

Registered: 1996 (29 years)

Introduction: Flat Wire Conveyor Belts are versatile and economical straight-running belts manufactured by Ashworth since 1951. Key features include: engineered to strict tolerances for longer belt life, maximum open area to minimize spray deflection, available in standard weight and heavy-duty variants, precision manufacturing for increased reliability, and over 75 years of customer satisfaction. Applications …

2. IPCO – Engineered Industrial Processing Solutions

Domain: ipco.com

Registered: 1995 (30 years)

Introduction: IPCO offers engineered industrial processing solutions with a focus on steel belts and conveyor belts. Their solutions cater to various industries including automotive, building materials, chemicals, and energy. Key components include steel belts, Rotoform systems, scattering systems, and double belt presses.

3. ConDrives – Stainless Steel Conveyors

Domain: condrives.com

Registered: 1998 (27 years)

Introduction: Stainless Steel Conveyors designed for frequent washdown and high-corrosive applications. Manufactured of 304 or 316-grade Stainless Steel materials with options for mill finish, polished finish, or sand/glass bead blasted finish. Features include washdown motors and gearboxes, stainless steel frame, rollers, bearings, supports, sprockets, fasteners, corrosion-resistant roller chain, FDA/USDA appr…

4. Keystone MFG – Standard Duty Clinched Selvage Belting

Domain: keystonemfg.com

Registered: 1998 (27 years)

Introduction: {“product_type”:”Conveyor Belting”,”category”:”Standard Duty Clinched Selvage Belting”,”applications”:”Most general conveying applications”,”specifications”:[{“model”:”S1″,”mesh”:”1″ x 1″”,”max_tension”:”240 lbs./ft. of width”,”approx_weight”:”1.85 lbs./sq. ft.”,”widths”:”4.5″ to 240″”},{“model”:”S3″,”mesh”:”½” x 1″”,”max_tension”:”240 lbs./ft. of width”,”approx_weight”:”2.20 lbs./sq. ft.”,”widths…

5. Dorner – 7X Series Sanitary Conveyors

Domain: dornerconveyors.com

Registered: 2007 (18 years)

Introduction: 7X Series – AquaGard and AquaPruf sanitary conveyors designed for food handling. Made of welded stainless steel, plastic chain, and belts. Engineered for fast sanitation and protection from contamination. Meets sanitary standards of BISSC, 3A, USDA, and FDA regulations. Models include AquaGard LP, AquaGard GT, AquaGard 7350, AquaPruf, AquaPruf Ultimate, and AquaPruf VBT. Disassemblable in less tha…

Strategic Sourcing Conclusion and Outlook for stainless steel conveyor belts

Stainless steel conveyor belts represent a vital component in enhancing operational efficiency across various industries, including food processing, pharmaceuticals, and automotive sectors. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the nuances of strategic sourcing for these products can significantly impact your supply chain effectiveness. Prioritizing quality, hygiene standards, and customization capabilities is essential for ensuring that your conveyor systems align with industry requirements and operational goals.

Moreover, leveraging partnerships with trusted manufacturers can lead to improved product longevity and performance, ultimately maximizing your return on investment. The evolving landscape of technology and sustainability in manufacturing further emphasizes the need for proactive sourcing strategies that prioritize innovation and compliance with international standards.

Illustrative image related to stainless steel conveyor belts

Looking ahead, the market for stainless steel conveyor belts is set to expand, driven by increasing demands for automation and hygiene in production processes. As you navigate your sourcing decisions, consider reaching out to reputable suppliers who can offer tailored solutions to meet your specific needs. Embrace the future of manufacturing by investing in high-quality conveyor systems that enhance productivity and uphold the highest standards of safety and efficiency.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to stainless steel conveyor belts