Unlocking Value: A Strategic Analysis of the Sliding Latches Market

Introduction: Navigating the Global Market for sliding latches

In the dynamic landscape of the global market, sourcing reliable sliding latches presents a unique challenge for B2B buyers. As businesses across Africa, South America, the Middle East, and Europe (notably Germany and Saudi Arabia) seek high-quality, secure solutions for their doors, windows, and cabinets, the importance of understanding the diverse types of sliding latches cannot be overstated. This guide is designed to illuminate the complexities of the sliding latch market, offering insights into various types, applications, and the critical factors to consider when vetting suppliers.

From mortise locks and latch locks to pin locks and hasps, each type serves distinct needs within different industries. This comprehensive resource will empower international B2B buyers to make informed purchasing decisions by addressing essential aspects such as material quality, pricing structures, and supplier reliability. In addition, we will explore the regulatory considerations that may impact procurement strategies in different regions.

By delving into this guide, buyers will not only navigate the intricacies of sliding latch options but also enhance their procurement processes, ensuring that they source products that meet both their operational requirements and budget constraints. Ultimately, this knowledge will facilitate strategic partnerships and foster a competitive edge in the marketplace.

Understanding sliding latches Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mortise Lock | Installed within the door, providing a flush finish; typically offers higher security. | Commercial doors, sliding glass doors | Pros: Enhanced security; durable. Cons: Higher installation complexity and cost. |

| Latch Lock | Simple mechanism that allows for easy locking and unlocking; often surface-mounted. | Residential doors, cabinets | Pros: Easy installation; cost-effective. Cons: May offer lower security compared to mortise locks. |

| Step-on Lock | Operated by foot, allowing hands-free locking; ideal for high-traffic areas. | Industrial settings, warehouses | Pros: Convenient for hands-free operation; durable. Cons: Limited aesthetic options. |

| Pin Lock | Utilizes a pin mechanism for locking; compact design suitable for lightweight doors. | Lightweight doors, gates | Pros: Affordable; easy to install. Cons: Less secure for heavy-duty applications. |

| Barrel Slide Bolt | Features a sliding bolt mechanism; surface-mounted, offering a straightforward locking solution. | Gates, outdoor sheds | Pros: Simple design; reliable. Cons: May not provide high security against forced entry. |

What are the Characteristics and Suitability of Mortise Locks?

Mortise locks are embedded within the door itself, allowing for a flush finish that enhances aesthetics and security. They are often preferred in commercial applications where durability and advanced security features are paramount, such as in sliding glass doors or high-traffic entryways. When considering a mortise lock, B2B buyers should evaluate the installation requirements and potential costs, as they typically require professional installation and can be more expensive than other lock types.

How Do Latch Locks Differ from Other Types?

Latch locks are characterized by their straightforward mechanism, which allows for easy locking and unlocking. They are commonly surface-mounted, making installation simpler and more accessible for various applications, including residential doors and cabinets. Buyers should consider the balance between cost-effectiveness and security needs, as latch locks may not provide the same level of protection as mortise locks but are ideal for low-security environments.

What Makes Step-on Locks Ideal for Industrial Settings?

Step-on locks offer a unique hands-free operation that is particularly beneficial in high-traffic industrial environments. These locks are durable and designed to withstand frequent use, making them suitable for warehouses and factories where convenience is crucial. B2B buyers should weigh the practicality of step-on locks against their specific operational needs, keeping in mind that while they are convenient, they may lack aesthetic appeal compared to other lock types.

Why Choose Pin Locks for Lightweight Applications?

Pin locks utilize a compact locking mechanism that is well-suited for lightweight doors and gates. Their affordability and ease of installation make them attractive options for residential and light commercial applications. However, buyers should be cautious about their security limitations, as pin locks may not withstand significant force or tampering, making them less ideal for heavy-duty requirements.

What are the Benefits of Barrel Slide Bolts?

Barrel slide bolts are recognized for their simple sliding mechanism, which provides reliable locking for various applications, including gates and outdoor sheds. Their straightforward design makes them easy to install and operate. However, B2B buyers should consider their security limitations, as barrel slide bolts may not offer robust protection against forced entry, making them more suitable for low-security applications.

Key Industrial Applications of sliding latches

| Industry/Sector | Specific Application of sliding latches | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Securing sliding doors in commercial buildings | Enhances security and access control | Material durability, weather resistance, and compliance with local building codes |

| Automotive | Latching systems for sliding doors in vehicles | Improves user convenience and safety | Compatibility with vehicle design and ease of installation |

| Furniture Manufacturing | Locking mechanisms for sliding cabinets and drawers | Provides enhanced functionality and aesthetics | Design flexibility, weight capacity, and ease of operation |

| Transportation & Logistics | Securing cargo doors on shipping containers | Increases safety and prevents cargo loss | Compliance with international shipping standards and ease of use |

| Agricultural Equipment | Latching systems for sliding gates and equipment doors | Ensures equipment security and operational efficiency | Resistance to corrosion and ease of maintenance |

How Are Sliding Latches Used in Construction Projects?

In the construction industry, sliding latches are essential for securing sliding doors in commercial buildings, such as offices and retail spaces. These latches provide an added layer of security, preventing unauthorized access while allowing for easy operation. Buyers in this sector should prioritize materials that offer durability and weather resistance, particularly in regions with harsh climates. Compliance with local building codes is also critical to ensure safety and reliability in the long term.

What Role Do Sliding Latches Play in Automotive Applications?

In the automotive sector, sliding latches are commonly used in the design of sliding doors for vehicles, enhancing both user convenience and safety. These latches facilitate smooth door operation while ensuring that doors remain securely closed during transit. Buyers in this industry need to consider compatibility with existing vehicle designs and the ease of installation, as these factors can significantly affect production timelines and costs.

How Are Sliding Latches Integrated into Furniture Manufacturing?

In furniture manufacturing, sliding latches serve as locking mechanisms for cabinets and drawers, providing enhanced functionality and aesthetic appeal. These latches allow for smooth operation while securing items inside, making them ideal for residential and commercial furniture alike. Buyers should focus on design flexibility, weight capacity, and ease of operation when sourcing latches to ensure that they meet the specific needs of their products.

Why Are Sliding Latches Important in Transportation and Logistics?

In the transportation and logistics industry, sliding latches are vital for securing cargo doors on shipping containers. They enhance safety by preventing unauthorized access and cargo loss during transit. International buyers should consider compliance with shipping standards and regulations, as well as the ease of use of these latches, to ensure that they meet operational requirements efficiently.

How Do Sliding Latches Benefit Agricultural Equipment?

Sliding latches are also used in agricultural equipment, securing sliding gates and doors to enhance equipment security and operational efficiency. These latches must be resistant to corrosion due to exposure to the elements, which is a common challenge in agricultural settings. Buyers should prioritize durability and ease of maintenance to ensure that the latches can withstand the rigors of agricultural use while providing reliable performance.

3 Common User Pain Points for ‘sliding latches’ & Their Solutions

Scenario 1: Inconsistent Locking Mechanisms Leading to Security Concerns

The Problem: B2B buyers often face challenges with sliding latches that do not engage or disengage consistently. This inconsistency can lead to significant security vulnerabilities, especially in environments where sensitive materials are stored or high-value items are safeguarded. For instance, a manufacturing facility using sliding latches on storage units may find that some latches fail to secure properly after repeated use, risking theft or unauthorized access.

The Solution: To combat this issue, buyers should prioritize sourcing high-quality sliding latches that are specifically designed for durability and reliability. Look for products with robust materials such as stainless steel or heavy-duty zinc plating to ensure they withstand wear and tear. Additionally, consider latches that feature multiple locking positions or additional security features like deadbolts or pin locks. It is also crucial to implement a regular maintenance schedule, including lubrication and inspection of all sliding latches, to ensure they function optimally over time. This proactive approach not only enhances security but also extends the lifespan of the locking mechanisms.

Scenario 2: Difficulty in Installation and Adjustment of Sliding Latches

The Problem: Another common pain point for B2B buyers is the complexity involved in installing and adjusting sliding latches. Misalignment during installation can lead to operational issues, such as doors not closing properly or latches not locking effectively. This is particularly problematic in sectors like construction or facility management, where time and labor costs can escalate due to installation errors.

The Solution: To alleviate installation difficulties, it is essential to invest in latches that come with comprehensive installation guides or video tutorials. Choose sliding latches that offer adjustable mounting options, allowing for easier alignment during installation. Additionally, consider products that include installation tools or templates to streamline the process. For buyers managing multiple installations, training sessions or workshops for maintenance staff can further enhance installation proficiency, ensuring all sliding latches are installed correctly and function as intended.

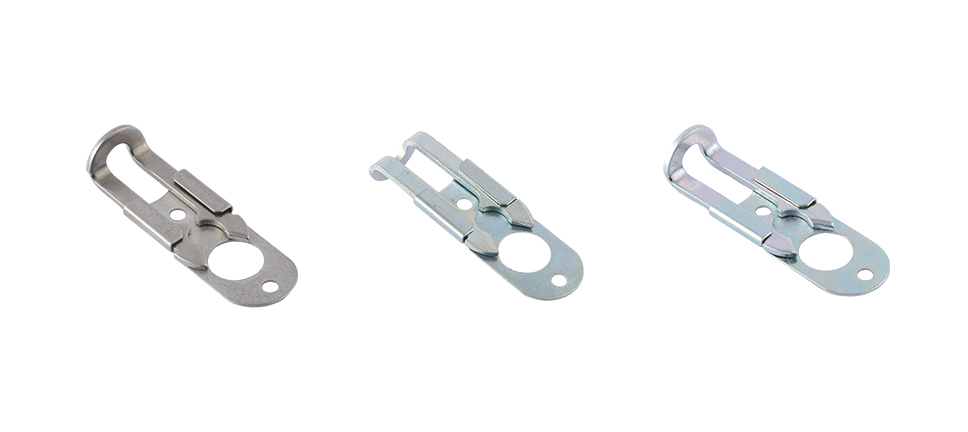

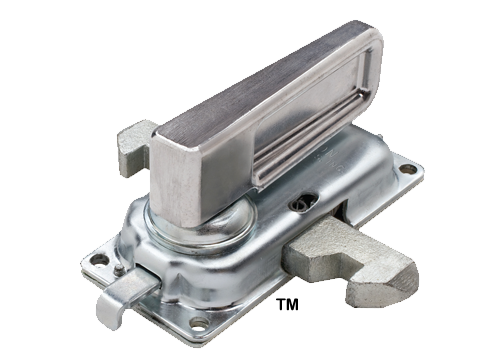

Illustrative image related to sliding latches

Scenario 3: Limited Range of Design Options Causing Compatibility Issues

The Problem: B2B buyers often encounter a limited selection of sliding latch designs that may not be compatible with the aesthetic or functional requirements of their projects. This is especially true for industries like hospitality or retail, where the appearance of fixtures can significantly impact customer experience and brand perception. For example, a hotel looking to upgrade its room security may find sliding latches that are either too industrial-looking or do not match the decor.

The Solution: To address compatibility issues, buyers should work with suppliers that offer a wide range of design options and finishes for sliding latches. It is advisable to select suppliers that specialize in custom solutions or provide a comprehensive catalog of products that cater to diverse design aesthetics. Additionally, engaging in early discussions with design teams can help ensure that the chosen latches meet both functional and aesthetic needs. Leveraging advanced manufacturing technologies, such as CAD modeling, can also assist buyers in visualizing how different latch designs will fit within their specific environments before making a purchase. This strategic approach not only enhances the visual appeal of installations but also ensures that security needs are effectively met.

Strategic Material Selection Guide for sliding latches

What Are the Key Properties of Common Materials Used in Sliding Latches?

When selecting materials for sliding latches, understanding their properties is crucial for ensuring optimal performance. Here, we analyze four common materials: stainless steel, zinc-coated steel, plastic, and brass. Each material has unique characteristics that influence durability, cost, and suitability for specific applications.

How Does Stainless Steel Perform in Sliding Latch Applications?

Stainless steel is a popular choice for sliding latches due to its excellent corrosion resistance and strength. It typically withstands high temperatures and pressures, making it suitable for various environments, including those with exposure to moisture and chemicals.

Illustrative image related to sliding latches

Pros: The durability of stainless steel ensures a long lifespan, reducing the need for frequent replacements. Its aesthetic appeal also makes it a preferred choice for visible applications.

Cons: The primary drawback is the higher cost compared to other materials. Manufacturing complexity can also increase due to the need for specialized tools and processes.

Impact on Application: Stainless steel is compatible with a wide range of media, including water and various chemicals, making it versatile across industries.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers in regions like Europe and the Middle East often prefer stainless steel for its reliability and performance.

What Advantages Does Zinc-Coated Steel Offer for Sliding Latches?

Zinc-coated steel provides a cost-effective solution with decent corrosion resistance due to its protective zinc layer. This material is commonly used in applications where cost is a significant factor, and the environment is not overly harsh.

Illustrative image related to sliding latches

Pros: Its affordability makes it an attractive option for bulk purchasing. Additionally, zinc-coated steel is relatively easy to manufacture and can be produced in various shapes and sizes.

Cons: The corrosion resistance is inferior to stainless steel, particularly if the zinc coating is damaged. This limitation can lead to a shorter lifespan in corrosive environments.

Impact on Application: Zinc-coated steel is suitable for indoor applications or areas with low humidity. However, it may not be ideal for environments with exposure to saltwater or harsh chemicals.

Considerations for International Buyers: Buyers should ensure that the zinc coating meets local standards for corrosion resistance, especially in coastal regions.

Why Choose Plastic for Sliding Latch Applications?

Plastic sliding latches are lightweight and resistant to corrosion, making them suitable for applications where weight is a concern. They can also be manufactured in various colors, providing aesthetic flexibility.

Pros: The low cost and ease of manufacturing make plastic latches an economical choice. They are also non-corrosive, which is advantageous in humid environments.

Cons: Plastic lacks the strength and durability of metal options, making it less suitable for heavy-duty applications. It may also degrade over time when exposed to UV light.

Impact on Application: Plastic latches are best for light-duty applications, such as interior doors or cabinets, but may not hold up under significant stress or outdoor conditions.

Considerations for International Buyers: Compliance with safety standards is crucial, especially in regions with strict regulations regarding materials used in consumer products.

Illustrative image related to sliding latches

What Are the Benefits of Using Brass in Sliding Latches?

Brass is known for its attractive appearance and resistance to corrosion. It is often used in decorative applications where aesthetics are important.

Pros: The natural antimicrobial properties of brass make it suitable for environments requiring hygiene, such as hospitals. Its durability ensures a long service life.

Cons: Brass can be more expensive than other materials and may require more maintenance to retain its appearance. It is also less resistant to mechanical stress compared to stainless steel.

Impact on Application: Brass is ideal for decorative latches in residential applications but may not be suitable for industrial uses where strength is paramount.

Considerations for International Buyers: Buyers should check for compliance with local standards regarding the use of brass, particularly in food-related applications.

Summary Table of Material Selection for Sliding Latches

| Material | Typical Use Case for Sliding Latches | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Industrial and outdoor applications | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Zinc-Coated Steel | Indoor applications | Cost-effective | Limited corrosion resistance | Medium |

| Plastic | Light-duty and interior applications | Lightweight and non-corrosive | Less durable and UV sensitive | Low |

| Brass | Decorative and hygiene-sensitive uses | Aesthetic appeal and antimicrobial | Higher cost and maintenance needs | Medium |

This material selection guide provides B2B buyers with a comprehensive understanding of the materials available for sliding latches, helping them make informed decisions tailored to their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for sliding latches

What Are the Key Stages in the Manufacturing Process for Sliding Latches?

The manufacturing of sliding latches involves several critical stages, each designed to ensure the final product meets specific functional and quality standards. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation:

The first step in manufacturing sliding latches is material selection, which typically involves high-quality metals such as stainless steel, brass, or zinc-coated steel. These materials are chosen for their durability, corrosion resistance, and structural integrity. Once selected, the materials undergo processing, including cutting and shaping to ensure they meet the required specifications. This stage often involves advanced technologies such as laser cutting or CNC machining to achieve precise dimensions.

Forming Techniques:

After preparation, the next stage is forming, where the processed materials are shaped into the desired latch components. This can involve techniques such as stamping, forging, or casting, depending on the design requirements. Stamping is commonly used for high-volume production due to its efficiency and ability to create consistent parts. Forging, on the other hand, enhances the strength of the metal through deformation, making it ideal for latches that require greater durability.

Assembly Process:

Once the components are formed, they are assembled into complete latch systems. This process can be manual or automated, depending on the scale of production. Automated assembly lines are increasingly common, particularly for larger manufacturers, as they enhance efficiency and reduce labor costs. Each component, including bolts, springs, and locking mechanisms, is meticulously fitted to ensure smooth operation and reliability.

Finishing Touches:

The final stage of manufacturing involves finishing processes that enhance the latch’s appearance and functionality. This may include surface treatments such as plating, painting, or powder coating to improve corrosion resistance and aesthetic appeal. Quality assurance measures are also implemented during this stage to ensure that the finishes meet industry standards and customer expectations.

How Is Quality Assurance Implemented in Sliding Latch Manufacturing?

Quality assurance (QA) is a vital component of the manufacturing process, ensuring that sliding latches meet international standards and customer specifications. Various QA practices and standards are employed throughout the manufacturing stages.

International Standards for Quality Assurance:

Most manufacturers adhere to international standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with ISO 9001 demonstrates a commitment to continuous improvement and customer satisfaction. Additionally, industry-specific certifications like CE (Conformité Européenne) for products sold in Europe or API (American Petroleum Institute) certifications for latches used in oil and gas applications may also be relevant, depending on the intended use of the sliding latches.

Quality Control Checkpoints:

Quality control (QC) checkpoints are integrated throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during production helps identify any deviations from quality standards early in the process. This may involve dimensional checks, functional tests, and visual inspections.

- Final Quality Control (FQC): After assembly, the complete latches undergo thorough testing to ensure they function correctly and meet all specifications. This can include load testing, durability assessments, and operational checks.

What Common Testing Methods Are Used for Sliding Latches?

Manufacturers typically employ a range of testing methods to validate the quality and performance of sliding latches. These may include:

- Functional Testing: Assessing the latch’s operational efficiency, including ease of use and locking mechanisms.

- Durability Testing: Subjecting latches to stress tests to evaluate their performance under extreme conditions, simulating wear and tear over time.

- Corrosion Resistance Testing: Exposing latches to corrosive environments to ensure they maintain integrity and appearance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial for ensuring product reliability and compliance with local regulations.

Illustrative image related to sliding latches

Conducting Supplier Audits:

One effective method for verifying quality control is conducting supplier audits. This involves a systematic examination of a supplier’s manufacturing processes, quality management systems, and compliance with international standards. Regular audits can help build trust and ensure that suppliers consistently meet quality requirements.

Requesting Quality Reports:

Buyers should also request detailed quality reports from suppliers, which outline testing methodologies, results, and compliance with relevant standards. These reports provide transparency and insight into the supplier’s commitment to quality.

Utilizing Third-Party Inspections:

Engaging third-party inspection agencies can further validate a supplier’s quality control measures. These organizations conduct independent assessments of manufacturing practices and product quality, providing an unbiased evaluation that can mitigate risks associated with sourcing.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing sliding latches from international suppliers, buyers must consider several quality control nuances:

- Cultural and Regulatory Differences: Understanding local manufacturing practices and regulatory requirements is essential, as these can impact quality control processes. For instance, European standards may differ from those in the Middle East or Africa.

- Communication: Clear communication about quality expectations and specifications is vital. Buyers should ensure that suppliers understand their requirements to avoid misunderstandings that could lead to quality issues.

- Flexibility in Standards: Buyers may need to be flexible with certain quality standards based on the supplier’s capabilities while ensuring that critical safety and operational standards are maintained.

By thoroughly understanding the manufacturing processes and quality assurance measures for sliding latches, B2B buyers can make informed decisions, ensuring they source reliable and high-quality products tailored to their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sliding latches’

In the evolving landscape of B2B procurement, especially for components like sliding latches, having a clear and actionable sourcing guide is vital. This checklist is designed to streamline your purchasing process, ensuring you select the right products from reliable suppliers while meeting your operational requirements.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical specifications for the sliding latches you need. This includes dimensions, material requirements (such as stainless steel or brass), locking mechanisms, and intended applications. Precise specifications help avoid miscommunication with suppliers and ensure that the products meet your performance standards.

- Consider environmental factors: If the latches will be used outdoors, ensure they are corrosion-resistant.

- Review load-bearing requirements: Understand the weight and force the latches must withstand.

Step 2: Research Market Trends and Standards

Understanding the current market trends and industry standards for sliding latches is crucial. This knowledge helps you identify innovative designs, materials, and technologies that could enhance your application.

- Investigate regional regulations: Different countries may have specific safety and quality standards that must be adhered to.

- Look for emerging technologies: Innovations in locking mechanisms or materials can provide better security and durability.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making commitments. Request detailed company profiles, product catalogs, and references from other clients, particularly those in your industry or region.

- Assess their production capabilities: Ensure they can meet your volume requirements and delivery timelines.

- Check for certifications: Look for quality assurance certifications like ISO 9001, which indicate adherence to industry standards.

Step 4: Request Samples for Testing

Before finalizing any orders, request samples of the sliding latches you are considering. Testing samples allows you to evaluate the product’s functionality, durability, and compatibility with your existing systems.

- Conduct real-world tests: Install samples in a controlled environment to assess performance under operational conditions.

- Gather feedback from users: Involve team members who will handle the latches to provide insights on usability and design.

Step 5: Negotiate Pricing and Terms

Once you have identified suitable suppliers and tested their products, it’s time to negotiate pricing and terms. Effective negotiation can lead to better pricing, payment terms, and delivery schedules that fit your needs.

- Consider bulk purchasing discounts: Inquire about volume discounts or loyalty programs that can reduce costs.

- Clarify warranty and return policies: Ensure you understand the terms regarding product warranties and the process for returns or exchanges.

Step 6: Finalize the Order and Monitor Delivery

After reaching an agreement, finalize your order and establish a timeline for delivery. Monitor the shipping process to ensure timely arrival and address any issues that may arise during transit.

- Communicate with suppliers: Maintain open lines of communication to resolve any potential delays or discrepancies.

- Prepare for inspection upon arrival: Have a plan in place to inspect the latches upon delivery to confirm they meet your specifications.

Step 7: Review Supplier Performance Post-Purchase

After the procurement process, evaluate the supplier’s performance based on product quality, delivery adherence, and customer service. This review is vital for future sourcing decisions.

- Gather internal feedback: Involve your team in assessing the latches’ performance in real-world applications.

- Document lessons learned: Use insights from this experience to refine your sourcing process for future purchases.

By following this step-by-step checklist, B2B buyers can effectively navigate the complexities of sourcing sliding latches, ensuring that they secure high-quality products that meet their operational needs.

Illustrative image related to sliding latches

Comprehensive Cost and Pricing Analysis for sliding latches Sourcing

What Are the Key Cost Components of Sliding Latches?

When sourcing sliding latches, understanding the cost structure is essential for B2B buyers. The primary components that contribute to the overall cost include:

-

Materials: The type of materials used significantly affects the price. Common materials include stainless steel, brass, and zinc-plated steel. Higher-quality materials enhance durability and corrosion resistance, which can be crucial depending on the application.

-

Labor: Labor costs vary based on the manufacturing location and the complexity of the latch design. Regions with lower labor costs can offer more competitive pricing, but this may affect quality and production timelines.

-

Manufacturing Overhead: This includes expenses related to facilities, equipment maintenance, and utilities. Efficient production processes can help mitigate these costs, but overhead is an unavoidable factor in pricing.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. This expense is often spread over the production run, making it crucial to consider the volume of latches being ordered.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability but adds to the overall cost. Buyers should assess the supplier’s QC processes to understand how they impact pricing.

-

Logistics: Shipping and handling costs can vary widely based on the supplier’s location and the buyer’s destination. International shipping may incur additional fees such as tariffs or customs duties, which should be factored into the total cost.

-

Margin: Suppliers will typically include a profit margin that reflects their operational costs and market conditions. Understanding the market landscape can help buyers gauge whether the margin is reasonable.

How Do Price Influencers Impact Sliding Latch Costs?

Several factors influence the pricing of sliding latches beyond the basic cost components:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to reduced per-unit costs. Suppliers may offer tiered pricing based on quantity, so negotiating for larger orders can yield significant savings.

-

Specifications and Customization: Custom designs or unique specifications can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-grade materials and compliance with industry standards (e.g., ISO certifications) can increase costs but are essential for applications requiring durability and safety.

-

Supplier Factors: The supplier’s reputation, reliability, and production capacity play a crucial role in pricing. Established suppliers may command higher prices due to their proven track record.

-

Incoterms: Understanding Incoterms is vital for international transactions. These terms dictate the responsibilities of buyers and sellers regarding shipping costs and risk, influencing the overall pricing strategy.

What Buyer Tips Can Help Achieve Cost-Efficiency in Sliding Latch Sourcing?

B2B buyers can employ several strategies to optimize their sourcing process and achieve better pricing:

-

Negotiate Effectively: Engage suppliers in discussions about pricing, especially when committing to larger volumes. Leverage your position as a potential repeat customer to negotiate better terms.

-

Consider Total Cost of Ownership (TCO): While the initial price is important, consider the TCO, which includes maintenance, replacement, and operational costs over the product’s lifespan. Investing in higher-quality latches may reduce long-term expenses.

-

Research Market Prices: Stay informed about market trends and pricing benchmarks for sliding latches. This knowledge empowers buyers during negotiations and helps identify fair pricing.

-

Understand Regional Pricing Nuances: Pricing can vary significantly across different regions. For buyers from Africa, South America, the Middle East, and Europe, understanding local market conditions, tariffs, and shipping challenges can lead to more informed purchasing decisions.

-

Request Samples: Before placing a large order, request samples to assess quality. This step can prevent costly mistakes and ensure the product meets your specifications.

Disclaimer

The prices and cost components discussed are indicative and can vary based on specific supplier agreements, market conditions, and regional factors. Always conduct thorough research and consult with suppliers to obtain accurate pricing tailored to your needs.

Alternatives Analysis: Comparing sliding latches With Other Solutions

In the quest for effective door and gate security solutions, sliding latches are a popular choice among B2B buyers. However, several alternative technologies and methods can achieve similar objectives, each with its own set of advantages and disadvantages. This analysis provides a comparative overview of sliding latches against two viable alternatives: mortise locks and hasp locks.

| Comparison Aspect | Sliding Latches | Mortise Locks | Hasp Locks |

|---|---|---|---|

| Performance | Moderate security; easy to use | High security; robust construction | Basic security; simple design |

| Cost | Low to moderate | Moderate to high | Low |

| Ease of Implementation | Simple installation; user-friendly | Requires professional installation | Easy to install |

| Maintenance | Minimal maintenance required | Low maintenance; durable | Moderate maintenance; prone to rust |

| Best Use Case | Interior doors, light gates | Exterior doors, high-security areas | Sheds, garages, light gates |

What Are the Advantages and Disadvantages of Mortise Locks Compared to Sliding Latches?

Mortise locks offer a higher level of security due to their robust design, making them ideal for exterior doors and high-security applications. They are installed within the door itself, providing a clean look and enhanced durability. However, the installation process can be complex, often requiring professional assistance, which can increase overall costs. Additionally, while mortise locks are low maintenance, they do require more attention than sliding latches, particularly in harsh environments.

How Do Hasp Locks Stack Up Against Sliding Latches?

Hasp locks are a straightforward and cost-effective alternative to sliding latches. They consist of a metal strap that secures a padlock, making them easy to install and replace. Hasp locks are particularly suitable for sheds, garages, and other low-security environments. However, their security level is lower than that of sliding latches and mortise locks, as they can be easily compromised if the padlock is cut. Additionally, they may require more frequent maintenance to prevent rust and ensure smooth operation.

Conclusion: How to Choose the Right Solution for Your Needs

When considering the best locking mechanism for your business needs, it is essential to evaluate the specific application, security requirements, and installation capabilities. Sliding latches are ideal for interior applications where ease of use and low cost are paramount. In contrast, mortise locks provide superior security for external applications but come with a higher price and installation complexity. Hasp locks offer a budget-friendly option for low-security environments but may not suffice for critical applications. By analyzing these alternatives, B2B buyers can make informed decisions that align with their operational needs and security goals.

Essential Technical Properties and Trade Terminology for sliding latches

What Are the Key Technical Properties of Sliding Latches?

When sourcing sliding latches, it’s essential to consider several critical specifications that directly impact performance, durability, and compatibility. Below are key properties to evaluate:

1. Material Grade

Sliding latches are typically manufactured from materials such as stainless steel, brass, or zinc-plated steel. The choice of material affects corrosion resistance, strength, and weight. For example, stainless steel offers superior resistance to rust and can withstand harsh environmental conditions, making it ideal for outdoor applications. Understanding the material grade is crucial for ensuring the latch meets the specific environmental and functional demands of your project.

2. Load Capacity

This specification indicates the maximum weight a latch can securely hold without failure. It is vital for applications involving heavy doors or gates. Buyers should align the load capacity with the intended use case to prevent mechanical failure, which could lead to safety hazards or costly repairs.

Illustrative image related to sliding latches

3. Tolerance

Tolerance refers to the permissible limit of variation in a latch’s dimensions. Tight tolerances are essential for ensuring that the latch fits perfectly into its designated slot, allowing for smooth operation. For B2B buyers, understanding tolerance levels is crucial for ensuring compatibility with existing systems and preventing operational issues.

4. Finish Type

The finish of a sliding latch affects both its aesthetic appeal and its functional longevity. Common finishes include powder coating, galvanization, and polishing. A quality finish not only enhances the latch’s appearance but also increases its resistance to wear and environmental factors. When selecting a latch, consider the finish that best suits the application’s environmental conditions.

5. Mounting Type

Sliding latches can be surface-mounted, mortised, or installed in various configurations. The choice of mounting type affects installation complexity and overall functionality. Knowing the specific mounting requirements is critical for ensuring proper installation and operation.

What Are Common Trade Terms Related to Sliding Latches?

Navigating the B2B landscape involves understanding specific industry jargon that can impact procurement and supply chain decisions. Here are key terms to be familiar with:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of sliding latches, working with OEMs can ensure that the latches meet specific quality and design standards required for integration into larger systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is crucial for budget planning and inventory management. Buyers should evaluate their needs against the MOQ to ensure they are not over-committing resources.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other terms for specific products. When procuring sliding latches, submitting an RFQ can help buyers compare prices and terms across different suppliers, facilitating better purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is vital for international buyers to understand their obligations and reduce risks in cross-border transactions.

5. Lead Time

Lead time refers to the amount of time from placing an order until it is delivered. This term is critical for project planning, especially in industries where timing is essential. Understanding lead times can help buyers coordinate their procurement schedules with project timelines.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing sliding latches, ensuring they meet their specific application needs while optimizing procurement processes.

Navigating Market Dynamics and Sourcing Trends in the sliding latches Sector

What Are the Key Trends Impacting the Sliding Latches Market?

The sliding latches sector is experiencing significant growth, driven by a surge in demand for security solutions across various industries, including construction, furniture, and automotive. As urbanization accelerates, particularly in regions like Africa and South America, the need for reliable and effective locking mechanisms is paramount. In Europe and the Middle East, regulatory requirements for enhanced security in residential and commercial spaces further fuel this demand.

Emerging technologies are reshaping the sourcing landscape, with automation and smart technology integration becoming increasingly prevalent. Buyers are now seeking sliding latches that incorporate electronic locking mechanisms, enabling remote access and enhanced security features. Additionally, manufacturers are leveraging advanced materials to produce more durable and weather-resistant latches, meeting the needs of diverse applications.

International B2B buyers are also gravitating towards suppliers who offer customized solutions, recognizing that tailored products can significantly enhance functionality and aesthetic appeal. The ability to quickly adapt to changing market dynamics and consumer preferences is becoming a critical factor in supplier selection.

How Is Sustainability Influencing B2B Buying Decisions for Sliding Latches?

As sustainability becomes a priority for many organizations, the sliding latches sector is not immune to this shift. The environmental impact of manufacturing processes and materials used in latches is under scrutiny. B2B buyers are increasingly aware of the ecological footprint of their procurement choices and are seeking suppliers who prioritize ethical sourcing and sustainability.

The adoption of ‘green’ certifications, such as ISO 14001 for environmental management, is gaining traction among manufacturers. Buyers are more likely to engage with suppliers who utilize recycled materials or eco-friendly production methods. This trend not only helps reduce waste but also enhances brand reputation among environmentally conscious consumers.

Moreover, the shift towards sustainability is prompting innovation in materials used for sliding latches. Manufacturers are exploring biodegradable and recyclable options, which align with the broader commitment to reducing environmental impact. As a result, buyers looking to establish or maintain a competitive edge are increasingly incorporating sustainability criteria into their sourcing strategies.

What Is the Historical Context of Sliding Latches in B2B Markets?

The evolution of sliding latches can be traced back to ancient civilizations, where simple mechanisms were developed for securing doors and gates. Over the centuries, these devices have transformed significantly, influenced by advancements in materials and manufacturing techniques.

In the 20th century, with the rise of mass production, sliding latches became widely available and affordable, catering to the growing construction and furniture industries. The introduction of new materials, such as stainless steel and plastics, enhanced durability and functionality, allowing for greater design flexibility.

Today, sliding latches are integral to various sectors, from residential security to industrial applications. Their ongoing evolution reflects the changing demands of consumers, particularly in terms of security, aesthetics, and sustainability. As international B2B buyers navigate the current market dynamics, understanding this historical context can provide valuable insights into the future direction of the sliding latches sector.

Frequently Asked Questions (FAQs) for B2B Buyers of sliding latches

-

1. How do I choose the right sliding latch for my application?

Selecting the right sliding latch involves assessing the specific requirements of your application. Consider factors such as the door or gate material, weight capacity, and environmental conditions (e.g., exposure to moisture or chemicals). Additionally, evaluate the level of security needed—some latches offer higher security features, while others prioritize ease of use. It’s also advisable to consult with suppliers who can provide samples or prototypes to test compatibility and functionality before making a bulk purchase. -

2. What are the key features to look for in sliding latches?

When sourcing sliding latches, prioritize features such as material durability, corrosion resistance, and ease of installation. Stainless steel or zinc-plated options are often preferable for their strength and longevity. Additionally, consider the locking mechanism—whether it’s a simple latch or a more complex locking system can impact security. If your application requires frequent use, look for latches with smooth operation and user-friendly designs that facilitate quick access. -

3. What is the typical lead time for sliding latch orders?

Lead times for sliding latch orders can vary significantly based on the supplier and the complexity of the order. Standard products may ship within a few days, while customized latches can take several weeks or even months to manufacture. It’s essential to communicate your timeline clearly with suppliers and inquire about their production capabilities. Planning ahead and ordering well in advance can help mitigate delays, especially for large-scale projects. -

4. What are the minimum order quantities (MOQs) for sliding latches?

Minimum order quantities for sliding latches typically depend on the supplier and the specific product. Many manufacturers set MOQs to ensure cost-effectiveness in production and shipping. While standard items may have lower MOQs, custom designs often require higher quantities. It’s advisable to discuss your needs with potential suppliers to determine if they can accommodate smaller orders or if they offer tiered pricing based on volume. -

5. How can I ensure the quality of sliding latches from international suppliers?

To ensure the quality of sliding latches from international suppliers, conduct thorough due diligence. Request product samples to evaluate materials and workmanship. Look for certifications or compliance with industry standards relevant to your region. Additionally, consider visiting the supplier’s manufacturing facility if possible, or rely on third-party inspection services. Building a strong relationship with your supplier and maintaining open communication can also help ensure consistent quality. -

6. What payment terms are common when sourcing sliding latches internationally?

Payment terms for international orders of sliding latches can vary widely. Common arrangements include upfront payment, partial payments, or payment upon delivery. Letters of credit and escrow services are also frequently used to secure transactions. Discuss payment options with your supplier and clarify any associated fees or currency exchange rates. Establishing clear payment terms upfront can help prevent misunderstandings and ensure a smooth transaction process. -

7. What logistics considerations should I keep in mind when importing sliding latches?

When importing sliding latches, consider logistics factors such as shipping methods, customs regulations, and import duties. Evaluate whether air freight or sea freight is more suitable for your timelines and budget. Familiarize yourself with the import process in your country to ensure compliance with regulations, including any necessary documentation. Partnering with a reliable freight forwarder can help streamline the logistics process and manage any potential challenges. -

8. Can I customize sliding latches for my specific needs?

Yes, many manufacturers offer customization options for sliding latches to meet specific requirements. Customizations may include size, color, material, and locking mechanisms tailored to your application. When discussing customization with suppliers, provide detailed specifications and any necessary design files. Be aware that custom orders may have longer lead times and higher MOQs, so it’s advisable to plan accordingly and discuss all details upfront to ensure your needs are met.

Top 6 Sliding Latches Manufacturers & Suppliers List

1. Sugatsune – Zwei L Knob Latch Indicator

Domain: sugatsune.com

Registered: 1996 (29 years)

Introduction: Zwei L Knob Latch Indicator for Glass Door, ZL-2402-INR-GB

2. Essentra Components – Sliding Snap Latches

Domain: essentracomponents.com

Registered: 2012 (13 years)

Introduction: Sliding Snap Latches are designed for easy operation and secure closure. They are made from durable materials, suitable for various applications. The latches are available in different sizes and styles to accommodate diverse needs. Key features include quick installation, reliable performance, and compatibility with various enclosures.

3. MISUMI – Side Bolts, Hasps & Latches

Domain: us.misumi-ec.com

Registered: 2007 (18 years)

Introduction: Side Bolts, Hasps & Latches include barrel slide bolt latches, slide bar latches, and hasps used for securing doors, gates, and windows. Barrel slide bolt latches are metal fittings that fasten doors with a cylindrical bolt that slides into a support fitting. Slide bar latches function similarly but use a rectangular bolt. Hasps are installed on hinged doors or furniture and secure doors with a T-…

4. Sugatsune – Sliding Door Lock SB

Domain: global.sugatsune.com

Registered: 1996 (29 years)

Introduction: Sliding Door Latches provide high security with simple and effective mechanisms. They come in various types, including options with indicators for occupancy and lock status. Made from high-quality 304 Stainless Steel, they are available in a Satin finish. Key products include: SLIDING DOOR LOCK SB, SBU; SLIDING DOOR LOCK SC, SCU; STAINLESS STEEL LEVER BOLT ZL-2402; LEVER BOLT With Indicator HCZ-80…

5. SWISCO – Window Replacement Latches

Domain: swisco.com

Registered: 1999 (26 years)

Introduction: Hung and Sliding Window Replacement Latches available at SWISCO.com. Customer service hours are 8AM – 4:30PM EST, Mon – Fri. Popular brands include Andersen®, Truth®, and Pella®. All orders are shipped from New Jersey, USA.

6. Ace Hardware – Sliding Door Locks & Latches

Domain: acehardware.com

Registered: 1995 (30 years)

Introduction: Sliding Door Locks & Latches: 94 items available. Key features include: designed for sliding doors which open sideways, compatible with various door types, enhances security compared to traditional locks, made from durable materials like die-cast metal, includes options for indoor and outdoor use, offers night lock systems for added security, easy installation for latch kits, and replacement optio…

Strategic Sourcing Conclusion and Outlook for sliding latches

In today’s dynamic market, strategic sourcing of sliding latches is paramount for international B2B buyers looking to enhance security and functionality in their projects. Understanding the diverse types of sliding latches—such as mortise locks, latch locks, and step-on locks—enables buyers to tailor their selections to specific applications. This strategic approach not only ensures optimal performance but also drives cost efficiencies by leveraging volume discounts and supplier partnerships.

As the demand for high-quality sliding latches continues to rise across Africa, South America, the Middle East, and Europe, businesses must stay ahead of market trends and technological advancements. Engaging with reliable suppliers who offer innovative solutions, such as CAD design capabilities and rapid shipping options, can significantly enhance project timelines and outcomes.

Looking forward, international B2B buyers should prioritize collaboration with manufacturers that align with their quality and security standards. By doing so, they can secure a competitive advantage in their respective markets. Embrace the opportunity to refine your sourcing strategies today, and elevate your operational success through superior sliding latch solutions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.