Unlocking Value: A Strategic Analysis of the Silacone 25Mm Rubber Band Market

Introduction: Navigating the Global Market for silacone 25mm rubber band

In today’s interconnected world, sourcing high-quality silicone 25mm rubber bands presents a significant challenge for international B2B buyers. With a multitude of suppliers and varying product standards, navigating the global market can be daunting. This comprehensive guide aims to demystify the complexities of sourcing silicone rubber bands by covering essential aspects such as types, applications, supplier vetting, and cost considerations. By understanding these elements, businesses can make informed purchasing decisions that align with their operational needs.

The versatility of silicone rubber bands makes them indispensable across various industries, from packaging to manufacturing and even in creative applications. With a focus on regions including Africa, South America, the Middle East, and Europe—particularly Germany and Vietnam—this guide equips buyers with the knowledge to identify reliable suppliers and negotiate favorable terms. It also highlights best practices for assessing product quality and performance, ensuring that the rubber bands sourced meet the specific requirements of their intended applications.

Armed with this information, B2B buyers can streamline their procurement processes, reduce costs, and enhance the efficiency of their operations. Whether you’re looking to secure a steady supply for production lines or seeking innovative solutions for product packaging, this guide serves as your trusted resource in the global market for silicone 25mm rubber bands.

Understanding silacone 25mm rubber band Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Silicone Bands | Made from cooking-grade silicone; UV-resistant | Packaging, bundling, and organizing items | Pros: Durable, versatile; Cons: Limited elasticity for heavy-duty use. |

| Heavy-Duty Silicone Bands | Thicker material for enhanced strength | Industrial use, securing heavy items | Pros: High durability; Cons: May be bulkier, higher cost. |

| Colored Silicone Bands | Available in various colors for easy identification | Retail displays, color-coding applications | Pros: Aesthetic appeal, organizational benefits; Cons: Color may fade over time. |

| Custom Silicone Bands | Tailored sizes and designs based on specifications | Promotional items, specialized applications | Pros: Unique branding opportunities; Cons: Longer lead times for production. |

| Mini Silicone Bands | Smaller dimensions for specific tasks | Crafting, small item organization | Pros: Ideal for niche applications; Cons: Limited load-bearing capacity. |

What Are the Key Characteristics of Standard Silicone Bands?

Standard silicone bands are crafted from cooking-grade silicone, making them suitable for a variety of tasks. Their UV resistance ensures longevity, making them ideal for both indoor and outdoor applications. These bands are commonly used for packaging, bundling, and organizing items in warehouses and retail settings. When purchasing, B2B buyers should consider the size variations available and the specific applications they intend to use the bands for, ensuring they choose the right fit for their needs.

How Do Heavy-Duty Silicone Bands Stand Out?

Heavy-duty silicone bands are designed with thicker material, providing enhanced strength and durability. They are particularly suited for industrial applications where securing heavy items is essential. These bands can withstand significant tension and are often used in manufacturing and logistics. Buyers should assess the weight and type of items they need to secure, as well as the cost implications of choosing a more robust option.

What Advantages Do Colored Silicone Bands Offer?

Colored silicone bands are available in a variety of hues, making them ideal for retail displays or color-coding systems. Their aesthetic appeal enhances product organization and visibility, which can be beneficial in busy environments. However, buyers should be mindful that while the colors can provide an organizational advantage, they may fade over time. When selecting these bands, businesses should consider the branding and visual merchandising aspects.

Why Choose Custom Silicone Bands?

Custom silicone bands allow for tailored sizes and designs, making them a powerful tool for branding and promotional activities. These bands can be designed to meet specific requirements, such as logos or unique sizes for specialized applications. However, longer lead times and potentially higher costs can be a drawback for businesses needing immediate solutions. Companies should weigh the benefits of unique branding against the time and investment required for custom orders.

What Are the Best Uses for Mini Silicone Bands?

Mini silicone bands are designed for small tasks, making them perfect for crafting and organizing small items. Their compact size allows for versatile applications, such as securing cables or organizing small office supplies. While they are excellent for niche applications, buyers should be aware of their limited load-bearing capacity, which restricts their use for heavier items. B2B buyers should evaluate their specific needs to determine if mini bands will effectively meet their organizational goals.

Key Industrial Applications of silacone 25mm rubber band

| Industry/Sector | Specific Application of silicone 25mm rubber band | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Securing components during assembly processes | Enhances efficiency by preventing component loss or damage | Durability, heat resistance, and compliance with safety standards |

| Logistics and Shipping | Bundling packages for shipment | Streamlines packing processes, reducing labor costs | Size consistency, tensile strength, and UV resistance |

| Food and Beverage | Sealing containers and packaging | Ensures product freshness and prevents contamination | Food-grade materials, temperature tolerance, and elasticity |

| Automotive | Organizing wiring and hoses | Improves safety and maintenance by preventing tangling | Resistance to chemicals, UV stability, and flexibility |

| Retail | Creating displays and securing merchandise | Enhances product visibility and reduces theft | Customization options, color variety, and bulk pricing |

How is Silicone 25mm Rubber Band Used in Manufacturing?

In the manufacturing sector, silicone 25mm rubber bands are essential for securing components during assembly processes. They provide a reliable means to keep parts organized, preventing loss or damage during production. Their durability and resistance to various environmental factors, such as temperature fluctuations, make them ideal for manufacturing environments. International buyers, particularly from regions like Africa and South America, should prioritize sourcing bands that meet specific industrial standards to ensure compatibility with their machinery and processes.

What Role Do Silicone Rubber Bands Play in Logistics and Shipping?

In logistics and shipping, silicone 25mm rubber bands are used to bundle packages efficiently. This application enhances the packing process by allowing for quick organization and secure holding of items, thereby reducing labor costs and improving overall efficiency. For B2B buyers in the Middle East and Europe, it is crucial to consider the tensile strength and UV resistance of the bands to ensure they withstand various shipping conditions and maintain integrity throughout transit.

Why are Silicone Rubber Bands Important in the Food and Beverage Industry?

Silicone 25mm rubber bands are increasingly used in the food and beverage industry for sealing containers and packaging. Their food-grade certification ensures that they maintain product freshness and prevent contamination, which is vital for compliance with health regulations. Buyers, especially in European markets like Germany, should focus on sourcing bands that are temperature tolerant and elastic enough to provide a secure seal without compromising the integrity of the packaging.

How Do Automotive Industries Benefit from Silicone Rubber Bands?

In the automotive industry, silicone 25mm rubber bands serve the critical function of organizing wiring and hoses. This application not only enhances safety by preventing tangling but also facilitates easier maintenance and repairs. Buyers in regions such as South America should look for rubber bands that offer resistance to chemicals and UV stability to ensure longevity and reliability in harsh automotive environments.

What Advantages Do Retailers Gain from Using Silicone Rubber Bands?

Retailers utilize silicone 25mm rubber bands for creating displays and securing merchandise. This application enhances product visibility while reducing the risk of theft, ultimately improving sales. For international B2B buyers, especially those in Africa and Europe, the availability of customization options and a variety of colors can significantly enhance marketing strategies and brand identity. Bulk pricing is also a key consideration, allowing for cost-effective procurement.

3 Common User Pain Points for ‘silacone 25mm rubber band’ & Their Solutions

Scenario 1: Limited Durability for Industrial Applications

The Problem: B2B buyers in industries such as manufacturing or logistics often face challenges with the durability of rubber bands, particularly when securing heavy or bulk items. Traditional rubber bands can snap or degrade quickly under stress, leading to operational delays, product damage, and increased costs due to frequent replacements. Buyers are often frustrated with the limited lifespan of conventional bands, especially when exposed to varying temperatures, humidity, or UV light, which can compromise their reliability in outdoor or fluctuating environments.

The Solution: To address these durability concerns, it’s crucial to source silicone 25mm rubber bands specifically designed for industrial use. These bands are made from high-quality silicone that withstands extreme temperatures and environmental conditions without losing elasticity. When purchasing, buyers should look for specifications indicating UV resistance and a broader temperature range to ensure performance under diverse operational circumstances. Additionally, consider bulk purchasing options from reputable suppliers that offer warranties or guarantees on their products. This strategy not only secures the longevity of the bands but also helps in maintaining a consistent supply, reducing the risk of downtime due to material shortages.

Scenario 2: Inconsistent Sizing Leading to Operational Inefficiencies

The Problem: Many B2B buyers encounter issues with inconsistent sizing when ordering rubber bands. This problem can lead to significant operational inefficiencies, particularly in industries that require precise dimensions for packaging or assembly. When the rubber bands do not fit the intended items correctly, it can result in wasted time and resources as employees struggle to find suitable replacements or adjust their processes to accommodate the mismatched sizes.

The Solution: To mitigate sizing issues, it’s essential for buyers to clearly communicate their requirements to suppliers and ensure they are purchasing the correct size of silicone 25mm rubber bands. Creating a detailed specification sheet that outlines the required dimensions and applications can streamline the ordering process. Moreover, establishing a relationship with a supplier that offers customizable options allows for tailored solutions that meet specific operational needs. It’s also advisable to request samples before committing to large orders, enabling buyers to verify the fit and functionality of the bands in their specific applications.

Scenario 3: Environmental Concerns with Traditional Rubber Bands

The Problem: Increasingly, B2B buyers are facing pressure to adopt sustainable practices in their operations. Traditional rubber bands are often made from materials that are not environmentally friendly, leading to concerns about waste and disposal. Companies that prioritize sustainability may struggle to find suitable alternatives that maintain performance while adhering to eco-friendly standards.

The Solution: Switching to silicone 25mm rubber bands can significantly alleviate these environmental concerns. Silicone is a more sustainable material that is durable, reusable, and recyclable, making it an excellent choice for companies looking to reduce their ecological footprint. When sourcing these bands, buyers should look for certifications that demonstrate a commitment to sustainability, such as ISO 14001. Additionally, establishing a recycling program for used bands can enhance a company’s green initiatives and promote responsible waste management. Educating staff on the benefits of using silicone over traditional rubber bands can also foster a culture of sustainability within the organization, aligning with broader corporate responsibility goals.

Strategic Material Selection Guide for silacone 25mm rubber band

When selecting materials for silicone 25mm rubber bands, various options are available, each with distinct properties and implications for performance. Below, we explore four common materials used in the production of silicone rubber bands, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Silicone Rubber Bands?

Silicone Rubber

Silicone rubber is a widely used material for rubber bands due to its excellent elasticity and durability. It can withstand extreme temperatures, ranging from -50°C to 200°C, making it suitable for both indoor and outdoor applications. Silicone also exhibits good UV resistance, which is essential for products exposed to sunlight.

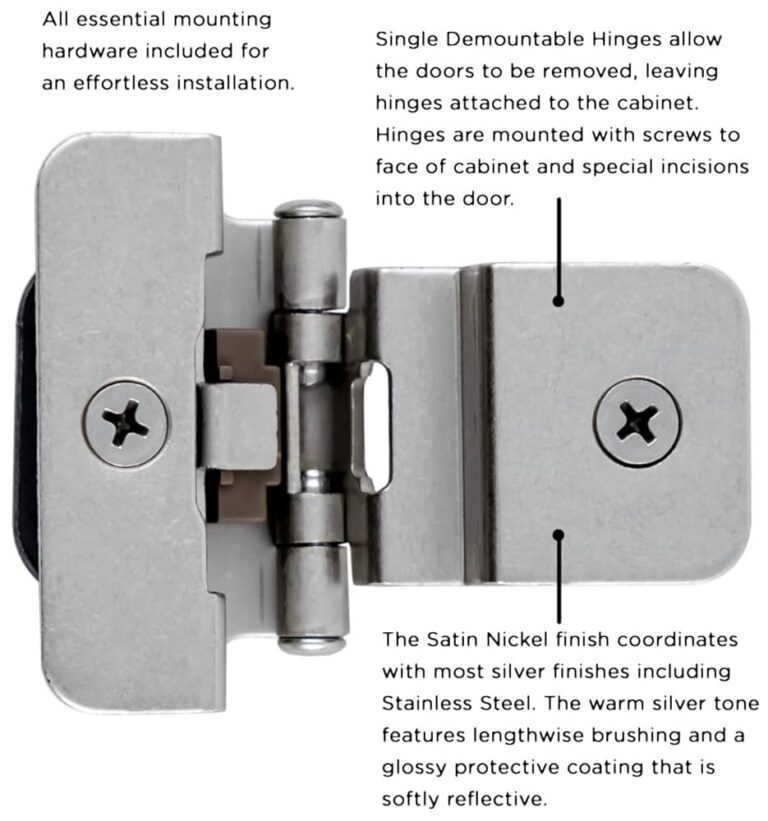

Illustrative image related to silacone 25mm rubber band

- Pros: High flexibility, excellent temperature resistance, and UV stability. It is also non-toxic and food-safe, making it suitable for various applications, including food packaging.

- Cons: Higher manufacturing costs compared to traditional rubber. Silicone rubber bands may also have limited tensile strength compared to other materials.

- Impact on Application: Ideal for applications requiring durability and resistance to environmental factors, such as outdoor use or in industries like food and pharmaceuticals.

- International Considerations: Compliance with food safety standards (e.g., FDA, EU regulations) is crucial for buyers in the food industry. Buyers should also consider certifications like ASTM for quality assurance.

Natural Rubber

Natural rubber is another common material for rubber bands, known for its excellent elasticity and tensile strength. It performs well in a variety of temperatures, although it is less resistant to UV light compared to silicone.

- Pros: Cost-effective, high elasticity, and strong tensile properties.

- Cons: Susceptible to degradation from UV exposure and temperature extremes, leading to a shorter lifespan. It may also cause allergic reactions in some individuals.

- Impact on Application: Suitable for general use where cost is a concern, but less ideal for outdoor applications or environments with high UV exposure.

- International Considerations: Compliance with safety standards varies by region; buyers should check for local regulations regarding allergens and material safety.

EPDM Rubber

Ethylene Propylene Diene Monomer (EPDM) rubber is known for its excellent weather resistance and durability. It can withstand high temperatures and is resistant to ozone and UV radiation.

- Pros: Exceptional weather and UV resistance, making it suitable for outdoor applications. It also has a longer lifespan compared to natural rubber.

- Cons: Higher cost than natural rubber and may be less flexible at low temperatures.

- Impact on Application: Ideal for applications requiring outdoor use, such as gardening or industrial applications where exposure to the elements is a concern.

- International Considerations: Buyers should ensure compliance with industry standards like ASTM for rubber products, especially in automotive or construction sectors.

Nitrile Rubber

Nitrile rubber is characterized by its resistance to oils and chemicals, making it suitable for applications where exposure to such substances is common.

- Pros: Excellent resistance to oils, fuels, and chemicals, along with good mechanical properties.

- Cons: Limited temperature range and less flexibility compared to silicone or natural rubber.

- Impact on Application: Best suited for industrial applications where oil resistance is critical, such as in automotive or manufacturing settings.

- International Considerations: Buyers in specific industries should ensure compliance with relevant chemical resistance standards and certifications.

Summary Table of Material Selection for Silicone 25mm Rubber Bands

| Material | Typical Use Case for silicone 25mm rubber band | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicone Rubber | Food packaging, outdoor applications | High flexibility and UV resistance | Higher manufacturing costs | High |

| Natural Rubber | General use, office supplies | Cost-effective and highly elastic | Degrades under UV exposure | Low |

| EPDM Rubber | Outdoor applications, automotive parts | Exceptional weather resistance | Less flexible at low temperatures | Medium |

| Nitrile Rubber | Industrial applications, automotive | Excellent oil and chemical resistance | Limited temperature range | Medium |

This guide provides a comprehensive overview of the materials suitable for silicone 25mm rubber bands, helping B2B buyers make informed decisions based on their specific needs and regulatory requirements.

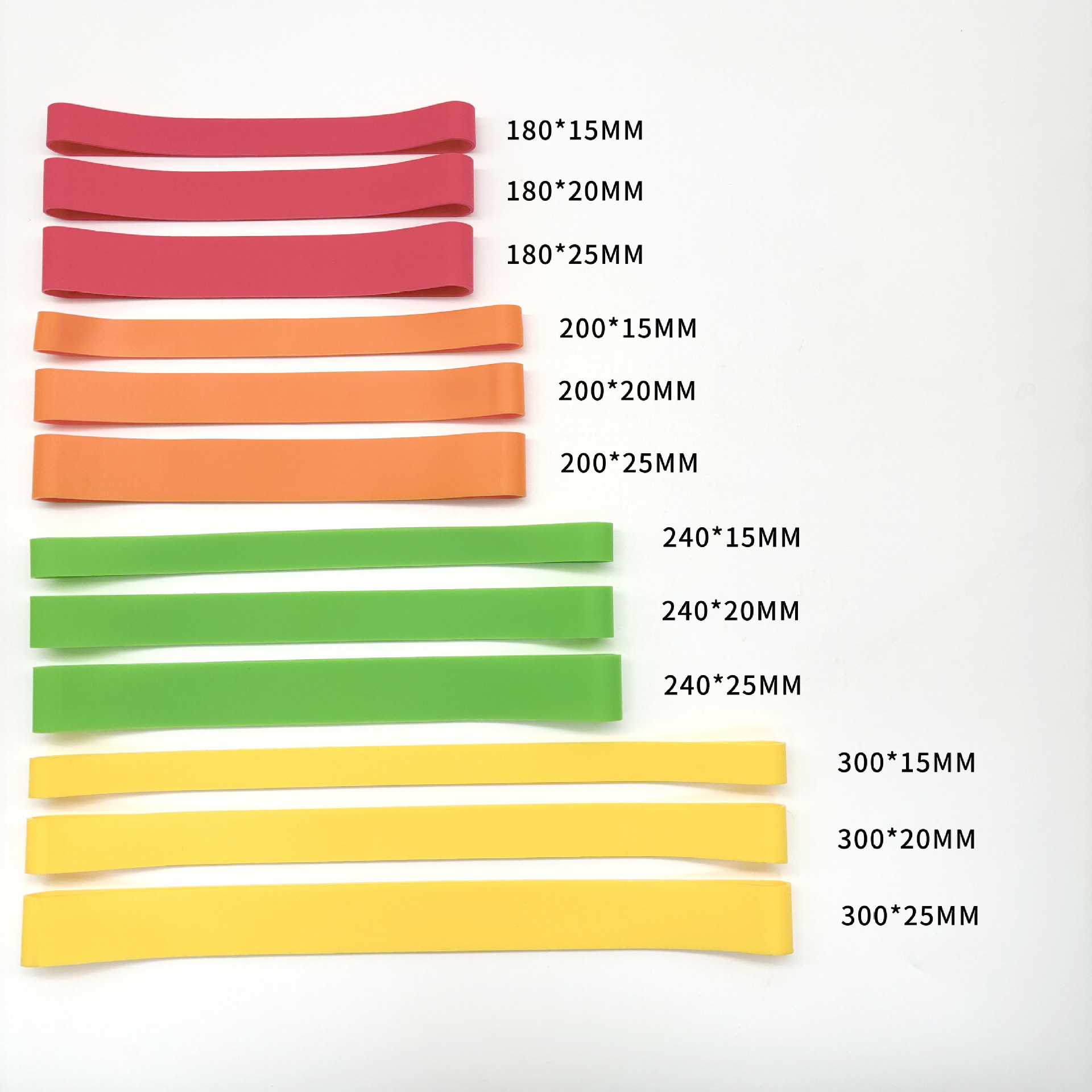

Illustrative image related to silacone 25mm rubber band

In-depth Look: Manufacturing Processes and Quality Assurance for silacone 25mm rubber band

What Are the Key Stages in the Manufacturing Process of Silicone 25mm Rubber Bands?

The manufacturing of silicone rubber bands, particularly the 25mm variety, involves several critical stages that ensure the final product meets quality and performance standards.

Material Preparation: What Materials Are Used?

The first stage in the manufacturing process is material preparation. Silicone rubber is typically synthesized from silicone polymers, which are derived from silica. The raw materials may be mixed with various additives to enhance properties such as flexibility, color, and UV resistance. For high-quality silicone bands, cooking-grade silicone is often preferred as it is designed to withstand extreme temperatures and environmental conditions.

Forming: How Are Silicone Rubber Bands Shaped?

Once the materials are prepared, the next stage is forming. This involves pouring the silicone mixture into molds that are specifically designed for 25mm rubber bands. The molds are usually preheated to ensure proper curing. Two common techniques in this phase are compression molding and injection molding. Compression molding is generally more cost-effective for larger batches, while injection molding allows for more intricate designs and precision.

Assembly: Are There Additional Components?

For simple silicone rubber bands, the assembly stage may be minimal. However, if the product includes additional features—such as grips or custom colors—this stage involves integrating these components. Any additional assembly must be performed under strict quality control measures to ensure consistency.

Finishing: What Final Steps Ensure Quality?

The final stage is finishing, which includes curing, trimming, and surface treatment. The curing process solidifies the rubber, providing it with the necessary strength and elasticity. After curing, any excess material is trimmed, and surface treatments may be applied to enhance durability or aesthetic appeal. This stage is crucial for ensuring that the rubber bands perform well under various conditions.

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is a vital component of the manufacturing process for silicone rubber bands. Implementing a robust QA system helps ensure that products meet international standards and satisfy customer requirements.

What International Standards Are Relevant for Silicone Rubber Bands?

Internationally recognized standards such as ISO 9001 play a crucial role in the manufacturing process. ISO 9001 outlines criteria for a quality management system, which can help manufacturers streamline their processes and improve overall quality. Additionally, industry-specific certifications, such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for industrial applications, may also apply depending on the intended use of the silicone bands.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to catch defects early. These checkpoints typically include:

Illustrative image related to silacone 25mm rubber band

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards before being used in production.

-

In-Process Quality Control (IPQC): During the manufacturing process, samples are taken at various stages to monitor quality and ensure that production remains within specifications.

-

Final Quality Control (FQC): After finishing, each batch of silicone rubber bands undergoes thorough testing to confirm that they meet performance criteria before shipment.

What Common Testing Methods Are Used?

Common testing methods for silicone rubber bands include tensile strength testing, elongation testing, and UV resistance tests. These tests assess the physical properties of the rubber, ensuring it meets the required specifications for durability and flexibility. Other tests may include heat aging and chemical resistance testing, depending on the intended application of the rubber bands.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality control processes of their suppliers. Here are some actionable strategies:

What Audit Practices Should Be Considered?

Conducting supplier audits is a critical step in ensuring quality. Buyers should consider on-site audits to assess the manufacturing processes and quality control systems in place. This allows buyers to gain firsthand knowledge of the supplier’s capabilities and compliance with relevant standards.

What Documentation Should Be Requested?

Buyers should request documentation that outlines the supplier’s quality assurance processes, including ISO certifications and QC reports. These documents provide insights into the supplier’s commitment to quality and adherence to international standards.

How Important Is Third-Party Inspection?

Engaging third-party inspection services can provide an additional layer of assurance. These independent organizations can conduct random inspections and testing of the products before shipment, ensuring that they meet the required quality standards. This practice is particularly beneficial for international transactions where trust and verification are paramount.

Illustrative image related to silacone 25mm rubber band

What Nuances Should International B2B Buyers Be Aware Of?

When sourcing silicone rubber bands internationally, particularly in regions like Africa and South America, buyers should be aware of nuances that may affect quality and delivery.

How Do Regulatory Differences Impact Sourcing?

Different countries have varying regulations regarding material safety and product standards. Buyers should familiarize themselves with local regulations and ensure that their suppliers comply with both international standards and local laws.

What Should Buyers Know About Lead Times and Shipping?

Understanding lead times and shipping logistics is crucial for international transactions. Buyers should consider potential delays due to customs clearance, especially in regions with stringent import regulations. Establishing clear communication with suppliers about expected timelines can help mitigate risks associated with delayed shipments.

Illustrative image related to silacone 25mm rubber band

Conclusion

Understanding the manufacturing processes and quality assurance measures for silicone 25mm rubber bands is essential for B2B buyers looking to source these products internationally. By focusing on material preparation, forming, assembly, and finishing, along with robust quality control practices, buyers can ensure they partner with reliable suppliers that meet their quality standards. Implementing strategic verification methods, including audits and third-party inspections, further enhances confidence in the sourcing process, paving the way for successful international business relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘silacone 25mm rubber band’

In the competitive landscape of B2B procurement, sourcing high-quality silicone 25mm rubber bands requires a strategic approach. This guide provides a structured checklist to streamline your sourcing process, ensuring you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of successful procurement. Determine the exact dimensions, material quality, and performance criteria your silicone rubber bands must meet. Consider factors such as elasticity, temperature resistance, and UV stability, which are critical for durability in various applications.

- Material Quality: Look for cooking-grade silicone that is safe and reliable.

- Performance Metrics: Specify required tensile strength and stretchability.

Step 2: Identify Reliable Suppliers

A thorough search for suppliers is essential to ensure you partner with reputable manufacturers. Utilize industry directories, trade shows, and online platforms to compile a list of potential suppliers specializing in silicone products.

- Reputation Check: Investigate supplier history and customer reviews to gauge reliability.

- Geographical Considerations: Identify suppliers with experience in your target markets, such as Africa, South America, or Europe.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a comprehensive evaluation. Request company profiles, case studies, and references from other buyers in similar industries. This step helps you assess their capacity to meet your specific needs.

- Certifications: Verify that suppliers hold relevant certifications, such as ISO or food safety standards.

- Production Capacity: Ensure they can handle your order volume and timelines.

Step 4: Request Samples for Quality Assurance

Obtaining samples is crucial to verify the quality of the silicone rubber bands. Assess the samples against your specifications to ensure they meet your requirements before placing a bulk order.

- Testing: Conduct tests for elasticity, durability, and resistance to environmental factors.

- Feedback Loop: Share samples with your team for collective evaluation and input.

Step 5: Negotiate Terms and Pricing

Once you have selected a supplier, negotiate favorable terms and pricing. Discuss bulk order discounts, payment terms, and delivery schedules to ensure alignment with your budget and timelines.

- Contract Clarity: Ensure all terms are clearly outlined in the contract to prevent misunderstandings.

- Long-term Relationships: Consider establishing long-term agreements for better pricing and reliability.

Step 6: Confirm Logistics and Delivery Options

Effective logistics planning is vital for timely delivery. Confirm shipping methods, lead times, and any customs considerations relevant to your region.

- Shipping Costs: Get a detailed breakdown of shipping costs and potential delays.

- Tracking Systems: Ensure the supplier provides tracking options for transparency during the shipping process.

Step 7: Monitor Quality Post-Purchase

After receiving your order, implement a quality monitoring system to ensure the silicone rubber bands meet ongoing standards. Regular evaluations can help identify any issues early, allowing for prompt resolution.

- Feedback Mechanism: Establish a communication channel with the supplier for ongoing feedback.

- Quality Control: Conduct periodic assessments of the products in use to ensure they continue to meet specifications.

By following this checklist, B2B buyers can navigate the sourcing process for silicone 25mm rubber bands effectively, ensuring they secure high-quality products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for silacone 25mm rubber band Sourcing

What Are the Key Cost Components for Sourcing Silicone 25mm Rubber Bands?

When sourcing silicone 25mm rubber bands, understanding the cost structure is essential for effective budgeting and procurement. The main cost components include:

-

Materials: The primary expense is the silicone rubber itself, which can vary based on quality and source. High-grade, cooking-grade silicone may incur higher costs but offers better durability and performance.

-

Labor: Labor costs encompass both direct and indirect expenses associated with manufacturing. This includes wages for production staff, quality control inspectors, and packaging teams.

-

Manufacturing Overhead: This includes costs related to factory maintenance, utilities, and equipment depreciation. Overhead can significantly impact pricing, especially in regions with higher operational costs.

-

Tooling: If custom molds or machinery are required for specific designs or sizes, tooling costs can add a substantial upfront investment.

-

Quality Control (QC): Ensuring that the rubber bands meet specified standards requires investment in quality assurance processes, which can affect overall pricing.

-

Logistics: Transportation costs, warehousing, and distribution are critical, especially for international buyers. These costs fluctuate based on shipping methods, distances, and the complexity of the supply chain.

-

Margin: Suppliers typically add a profit margin to cover their expenses and ensure sustainability. This margin can vary widely based on market competition and the supplier’s business model.

How Do Price Influencers Affect the Cost of Silicone Rubber Bands?

Several factors can influence the pricing of silicone rubber bands, including:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Suppliers may offer significant discounts for bulk purchases, making it advantageous for businesses to assess their actual needs and negotiate accordingly.

-

Specifications and Customization: Custom sizes, colors, or formulations can increase costs. Buyers should clearly communicate their requirements to receive accurate quotes.

-

Material Quality and Certifications: Higher quality materials and certifications (like food-grade or medical-grade silicone) typically result in increased costs. Buyers must weigh the benefits of these certifications against their budget constraints.

-

Supplier Factors: The supplier’s reputation, production capacity, and location can influence pricing. Established suppliers with robust quality control may charge more but can provide reliability and consistency.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define responsibilities regarding shipping, insurance, and tariffs, impacting the total cost of ownership.

What Buyer Tips Can Help in Negotiating Costs for Silicone Rubber Bands?

Navigating the procurement landscape for silicone rubber bands requires strategic negotiation and cost management:

-

Negotiate Terms: Don’t hesitate to negotiate payment terms, lead times, and bulk pricing. A well-prepared buyer can leverage multiple quotes to secure better deals.

-

Focus on Cost Efficiency: Assess the Total Cost of Ownership (TCO), which includes not just the purchase price but also logistics, storage, and disposal costs. A lower initial price might lead to higher long-term expenses.

-

Understand Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and shipping times. These factors can significantly affect overall costs.

-

Seek Local Suppliers When Possible: Local sourcing can reduce shipping costs and lead times, offering a competitive edge.

-

Request Samples: Before committing to large orders, request samples to evaluate quality. This can prevent costly mistakes later in the procurement process.

Disclaimer for Indicative Prices

Prices for silicone 25mm rubber bands can vary widely based on the factors discussed above. The information provided is intended for general guidance and should not be construed as definitive pricing. Always consult with suppliers for the most accurate and up-to-date quotes tailored to specific needs and circumstances.

Alternatives Analysis: Comparing silacone 25mm rubber band With Other Solutions

In the realm of industrial applications, selecting the right solution for securing and organizing materials is crucial. While silicone 25mm rubber bands are a popular choice, various alternatives can offer comparable benefits depending on specific use cases and business requirements. This analysis compares silicone rubber bands with two viable alternatives: elastic bands and Velcro straps.

| Comparison Aspect | Silacone 25mm Rubber Band | Elastic Bands | Velcro Straps |

|---|---|---|---|

| Performance | High elasticity and durability; resistant to UV and temperature variations | Moderate elasticity; prone to wear over time | High grip strength; adjustable tension |

| Cost | Moderate, varies by quantity | Low cost, widely available | Moderate, slightly more expensive than elastic bands |

| Ease of Implementation | Simple to use, no tools required | Very easy to apply, no setup needed | Requires some adjustment to fit properly |

| Maintenance | Low maintenance, long-lasting | Higher maintenance, may need replacement frequently | Low maintenance, durable |

| Best Use Case | Organizing and securing items in diverse environments | Temporary binding or light-duty applications | Securing larger items or adjustable configurations |

What are the Pros and Cons of Elastic Bands Compared to Silicone Rubber Bands?

Elastic bands are a common alternative to silicone bands and are widely used due to their low cost and availability. They are suitable for light-duty tasks such as bundling small items or temporary applications. However, they tend to wear out faster and can lose elasticity over time, making them less reliable for long-term use. Additionally, they are not as resistant to environmental factors like UV exposure and temperature fluctuations, limiting their effectiveness in outdoor settings.

How Do Velcro Straps Compare to Silicone Rubber Bands in Performance?

Velcro straps provide a unique alternative, offering adjustable tension and high grip strength. They are particularly useful for securing larger or bulkier items, allowing for flexibility in sizing. Unlike silicone bands, Velcro straps can be reused and adjusted for different applications. However, they may require more time to set up and adjust compared to the simplicity of silicone bands. Furthermore, their bulkiness can be a disadvantage in situations where a slim profile is needed.

Which Solution Should B2B Buyers Choose for Their Needs?

For B2B buyers, the choice between silicone 25mm rubber bands, elastic bands, and Velcro straps ultimately depends on the specific requirements of their operations. Buyers focused on durability and versatility in various environments may find silicone bands to be the superior choice. Conversely, if cost is a significant concern and the application is temporary, elastic bands might suffice. For scenarios requiring adjustable tension and security for larger items, Velcro straps present a compelling option.

In conclusion, understanding the strengths and weaknesses of each solution allows businesses to make informed decisions tailored to their unique operational demands. A thorough assessment of performance, cost, and usability can ensure that the chosen solution meets long-term organizational needs effectively.

Illustrative image related to silacone 25mm rubber band

Essential Technical Properties and Trade Terminology for silacone 25mm rubber band

What Are the Key Technical Properties of Silicone 25mm Rubber Bands?

When evaluating silicone 25mm rubber bands for B2B applications, understanding their technical specifications is crucial for ensuring product quality and suitability for specific uses. Here are some essential properties to consider:

-

Material Grade

Silicone rubber bands are typically made from high-quality, cooking-grade silicone. This material is not only durable but also resistant to heat, cold, and UV exposure. The choice of material affects the band’s longevity and performance in various environments, making it essential for industries such as food packaging, electronics, and outdoor applications. -

Tolerance

Tolerance refers to the allowable variation in the dimensions of the rubber bands. For silicone 25mm rubber bands, maintaining tight tolerances is crucial for ensuring consistent performance, especially in applications requiring precise fit and function. This is particularly important in manufacturing settings where precision affects assembly and operational efficiency. -

Elasticity and Stretch Ratio

The elasticity of silicone bands allows them to stretch significantly without losing their original shape. A higher stretch ratio indicates that the band can accommodate various sizes and shapes, making it versatile for different applications, from bundling products to securing items in transport. Understanding the elasticity helps businesses choose the right band for their specific needs. -

UV Resistance

UV resistance indicates how well the silicone bands can withstand exposure to sunlight without degrading. This property is vital for outdoor applications or products stored in sunny environments. UV-resistant bands maintain their integrity and performance over time, ensuring reliability for long-term use. -

Temperature Range

Silicone bands can often withstand a wide range of temperatures, typically from -60°C to 200°C. This temperature resilience is crucial for industries like food service and manufacturing, where bands may be exposed to extreme conditions. Choosing bands that can handle specific temperature ranges ensures that they will perform effectively in various scenarios.

What Are Common Trade Terms Related to Silicone Rubber Bands?

Familiarity with industry terminology can significantly streamline B2B transactions and enhance communication. Here are some common trade terms relevant to silicone rubber bands:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of silicone bands, businesses often partner with OEMs to create custom products tailored to their specifications, ensuring that the bands meet unique operational needs. -

MOQ (Minimum Order Quantity)

MOQ refers to the minimum quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for businesses to ensure they are making cost-effective purchases while aligning with their inventory management strategies. This term helps buyers avoid overcommitting to inventory they may not need. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers requesting pricing and other details for specific products. For silicone rubber bands, an RFQ can help businesses compare costs and terms from various suppliers, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms helps businesses navigate shipping logistics and costs, ensuring smooth transactions across borders. -

Lead Time

Lead time refers to the amount of time from placing an order until it is delivered. This is especially important in B2B contexts where production schedules depend on timely delivery of materials like silicone bands. Knowing the lead time helps businesses plan their operations and inventory more effectively.

By understanding these technical properties and trade terminologies, international buyers can make more informed decisions when sourcing silicone 25mm rubber bands, ensuring they choose the right products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the silacone 25mm rubber band Sector

What Are the Key Market Dynamics and Trends in the Silicone 25mm Rubber Band Sector?

The global market for silicone rubber bands, particularly the 25mm variety, is experiencing significant growth driven by various factors, including increased demand from multiple sectors such as packaging, automotive, and consumer goods. The rising awareness of the advantages of silicone over traditional rubber—such as greater durability, resistance to environmental factors, and non-toxic properties—has positioned silicone bands as a preferred choice among B2B buyers. Furthermore, the ongoing shift towards sustainable materials is accelerating the adoption of silicone products, as they can be recycled and have a longer lifecycle.

Illustrative image related to silacone 25mm rubber band

Emerging B2B tech trends are also reshaping the sourcing landscape. The integration of e-commerce platforms and digital marketplaces has made it easier for buyers from regions such as Africa, South America, the Middle East, and Europe to access suppliers and compare products efficiently. Real-time data analytics and supply chain visibility tools are now commonplace, enabling companies to make informed decisions regarding inventory management and supplier performance. Additionally, the trend towards customization is gaining traction, with many manufacturers offering tailored silicone bands to meet specific client needs, further enhancing buyer engagement.

How Is Sustainability and Ethical Sourcing Impacting the Silicone 25mm Rubber Band Industry?

Sustainability and ethical sourcing are becoming critical considerations for B2B buyers of silicone rubber bands. The environmental impact of manufacturing processes, including the carbon footprint and waste generation, is under increased scrutiny. Buyers are increasingly seeking suppliers that prioritize eco-friendly practices, such as the use of renewable energy sources and waste minimization strategies.

Certifications such as ISO 14001 for environmental management and OEKO-TEX for sustainable textiles are gaining importance in supplier selection. These certifications not only assure buyers of the supplier’s commitment to sustainability but also enhance brand reputation in increasingly eco-conscious markets. Furthermore, the use of food-grade silicone materials in production aligns with global health standards and caters to industries that require stringent safety regulations, such as food packaging and healthcare.

What Is the Historical Context Behind the Development of Silicone Rubber Bands?

The use of silicone in rubber bands can be traced back to the early 20th century when silicone polymers were first synthesized. Initially, silicone was utilized in industrial applications due to its superior heat resistance and flexibility. Over the decades, advancements in manufacturing technology have enabled the development of silicone rubber bands that are more versatile and resilient than their traditional rubber counterparts.

Illustrative image related to silacone 25mm rubber band

By the late 20th century, the increasing demand for durable and multifunctional materials led to the commercialization of silicone rubber bands, which found applications in various sectors, from consumer goods to industrial uses. Today, the silicone 25mm rubber band has become a staple in many industries, further propelled by the global shift toward sustainable and safe material choices.

In conclusion, understanding the evolving market dynamics, sustainability considerations, and historical context of silicone rubber bands is vital for international B2B buyers. By aligning sourcing strategies with these insights, businesses can better navigate the complexities of this sector and make informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of silacone 25mm rubber band

-

How do I ensure the quality of silicone 25mm rubber bands before purchasing?

To ensure quality, request samples from potential suppliers to evaluate the material, elasticity, and durability. Conduct a thorough review of their quality assurance processes, including certifications like ISO or relevant industry standards. Additionally, consider visiting the supplier’s facility or hiring a third-party inspection service to perform a quality check before shipment. Regular communication regarding quality expectations and testing methods can also help maintain high standards throughout the production process. -

What are the main applications of silicone 25mm rubber bands in various industries?

Silicone 25mm rubber bands are highly versatile and can be used across multiple sectors. Common applications include packaging, organization of materials, binding books, and securing items in manufacturing. They are also popular in the food industry for sealing bags and containers, as silicone is food-safe. Their durability against extreme temperatures and UV exposure makes them suitable for outdoor use, making them an ideal choice for both commercial and industrial applications. -

What customization options are available for silicone 25mm rubber bands?

Many suppliers offer customization options for silicone rubber bands, including color, thickness, and branding. You can request specific dimensions, such as length and width, to meet your unique needs. Additionally, some manufacturers allow for logo printing or embossing to enhance brand visibility. When sourcing, inquire about minimum order quantities (MOQs) for customized products and the associated lead times for production. -

What minimum order quantities (MOQs) should I expect when sourcing silicone 25mm rubber bands?

MOQs can vary significantly between suppliers. Typically, for silicone 25mm rubber bands, MOQs may range from 500 to several thousand units, depending on the manufacturer’s capabilities and your customization requirements. It’s advisable to discuss your needs upfront to negotiate favorable terms. Smaller businesses may look for suppliers who offer lower MOQs or flexible ordering options to accommodate varying demand. -

What payment terms are commonly offered by suppliers of silicone rubber bands?

Payment terms can vary, but many suppliers require a deposit upfront (often 30-50%) with the balance due before shipment. Some may offer flexible terms based on your relationship and order history. It’s essential to clarify payment methods accepted, such as bank transfers, letters of credit, or online payment platforms. Discussing terms early in negotiations can help avoid misunderstandings later in the purchasing process. -

How do I vet suppliers for silicone rubber bands effectively?

To vet suppliers, start by researching their reputation through online reviews and testimonials. Request references from previous clients and evaluate their experience in the industry. Check for relevant certifications and compliance with international standards. Conducting factory audits, if possible, can provide insight into their manufacturing processes and quality control measures. Establishing clear communication and a solid understanding of their capabilities will help ensure a reliable partnership. -

What logistics considerations should I keep in mind when sourcing silicone rubber bands internationally?

When sourcing internationally, consider shipping options, lead times, and import regulations. Work with suppliers who have experience in exporting to your region and can provide guidance on customs processes. Ensure you have a clear agreement on delivery terms, such as Incoterms, to define responsibilities for shipping costs and risks. Additionally, factor in potential delays caused by customs inspections, and plan your inventory accordingly. -

What are the common challenges faced when sourcing silicone rubber bands internationally?

Common challenges include fluctuating shipping costs, language barriers, and differing quality standards. Understanding the local market dynamics and regulations of the supplier’s country is crucial. Additionally, time zone differences can complicate communication. To mitigate these challenges, establish strong relationships with your suppliers, maintain clear communication, and consider working with a local agent or freight forwarder to navigate logistics more efficiently.

Top 6 Silacone 25Mm Rubber Band Manufacturers & Suppliers List

1. Grifiti – Grifiti Band Joes

Domain: grifiti.com

Registered: 2003 (22 years)

Introduction: {“products”:[{“name”:”Grifiti Band Joes 2 x 0.5 and 4\” Circumference, 1.25 Inch Diameter Silicone Bands”,”price”:”$9.99″,”description”:”Versatile Bands for Organizing Small Items and Color-Coding”,”availability”:”In stock (983)”,”colors”:[“Assorted”,”Black”,”Blue”,”+8 more”]},{“name”:”Grifiti Band Joes 1.25 x 0.5 Flat, 2.5\” Circumference, 0.8\” Diameter Mini Silicone Rubber Bands”,”price”:”$10.0…

2. Etsy – 25mm Rubber Bands

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: 25mm Rubber Bands available on Etsy with over 1,000 items listed. Free shipping options available, with delivery within 7 days. Various sellers offer different products including rubber straps for watches, silicone rubber jump rings, and elastic rubber bands in multiple colors. Prices range from $0.71 to $33.02, with some items on sale at discounts of up to 25%. Sellers can use Etsy’s advertising …

3. Citizen – Rubber Watch Bands

Domain: totalwatchrepair.com

Registered: 2008 (17 years)

Introduction: Citizen Rubber Watch Bands & Replacement Straps available at Total Watch Repair. 88 products in total. Features include: 1. Authentic Citizen Rubber watch straps for casual and formal options. 2. Free shipping on orders over $50 (US only). 3. Various colors available: Black, Blue, Dark Blue, Green, Orange, Silver, White. 4. Sizes range from 13mm to 35mm, with multiple options at 20mm, 22mm, and 24…

4. Rubber Bands UK – White Silicone Rubber Bands 250 x 25mm

Domain: rubberbandsuk.com

Registered: 2012 (13 years)

Introduction: {“Product Code”:”PX254″,”Size”:”250 x 25mm”,”Colour”:”White”,”Price”:”£2.35″,”Bulk Pricing”:{“2 or more”:”£2.20″,”5 or more”:”£2.05″,”10 or more”:”£1.75″,”20 or more”:”£1.60″,”50 or more”:”£1.50″},”Material”:”Latex free and food quality, Non marking UV safe silicone rubber”,”Availability”:”In Stock”,”Minimum Quantity”:”2″}

5. Integrity MFG LLC – Sheer Ribbon Embellishments

Domain: integritymfgllc.com

Registered: 2012 (13 years)

Introduction: This company, Integrity MFG LLC – Sheer Ribbon Embellishments, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Decorpanel – Reusable Wire Ties

Domain: decorpanel.se

Registered: 2002 (23 years)

Introduction: This company, Decorpanel – Reusable Wire Ties, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for silacone 25mm rubber band

In navigating the strategic sourcing landscape for silicone 25mm rubber bands, it is crucial to recognize the multifaceted benefits these products offer. Their durability, resistance to environmental factors, and versatility make them invaluable across various industries, from packaging to manufacturing. As international B2B buyers, understanding the importance of sourcing high-quality silicone rubber bands can significantly enhance operational efficiency and product reliability.

Illustrative image related to silacone 25mm rubber band

Engaging with reputable suppliers ensures access to competitive pricing, customization options, and bulk purchasing advantages, which are particularly beneficial for businesses in Africa, South America, the Middle East, and Europe. By prioritizing strategic sourcing, companies can not only optimize their supply chains but also foster long-term partnerships that drive innovation and sustainability.

Looking ahead, the demand for quality silicone products is set to grow, driven by evolving market trends and consumer preferences. International buyers are encouraged to stay proactive in their sourcing strategies, exploring new suppliers and technologies that can elevate their product offerings. The future is bright for those who adapt and innovate—seize the opportunity to enhance your business with reliable silicone solutions today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.