Unlocking Value: A Strategic Analysis of the Shanklin Corporation Market

Introduction: Navigating the Global Market for shanklin corporation

In the fast-evolving landscape of global packaging solutions, sourcing reliable shrink wrap equipment from Shanklin Corporation can present a formidable challenge for international B2B buyers. As businesses strive to enhance product protection, improve presentation, and streamline operations, the demand for high-quality packaging machinery has surged. This guide offers a thorough exploration of Shanklin Corporation’s extensive range of shrink wrap systems, detailing their types, applications, and features.

B2B buyers from diverse regions—including Africa, South America, the Middle East, and Europe—will find invaluable insights into the procurement process, including supplier vetting and cost considerations. By addressing the complexities of sourcing and evaluating packaging solutions, this guide empowers decision-makers to make informed purchasing choices that align with their specific operational needs.

With an emphasis on understanding the unique challenges faced by businesses in markets like Nigeria and Vietnam, we provide actionable strategies for navigating the global market effectively. From identifying the right equipment to understanding maintenance and support options, this comprehensive resource is designed to facilitate seamless transactions and foster long-term partnerships with Shanklin Corporation. Equip yourself with the knowledge to enhance your packaging operations and drive business success in an increasingly competitive environment.

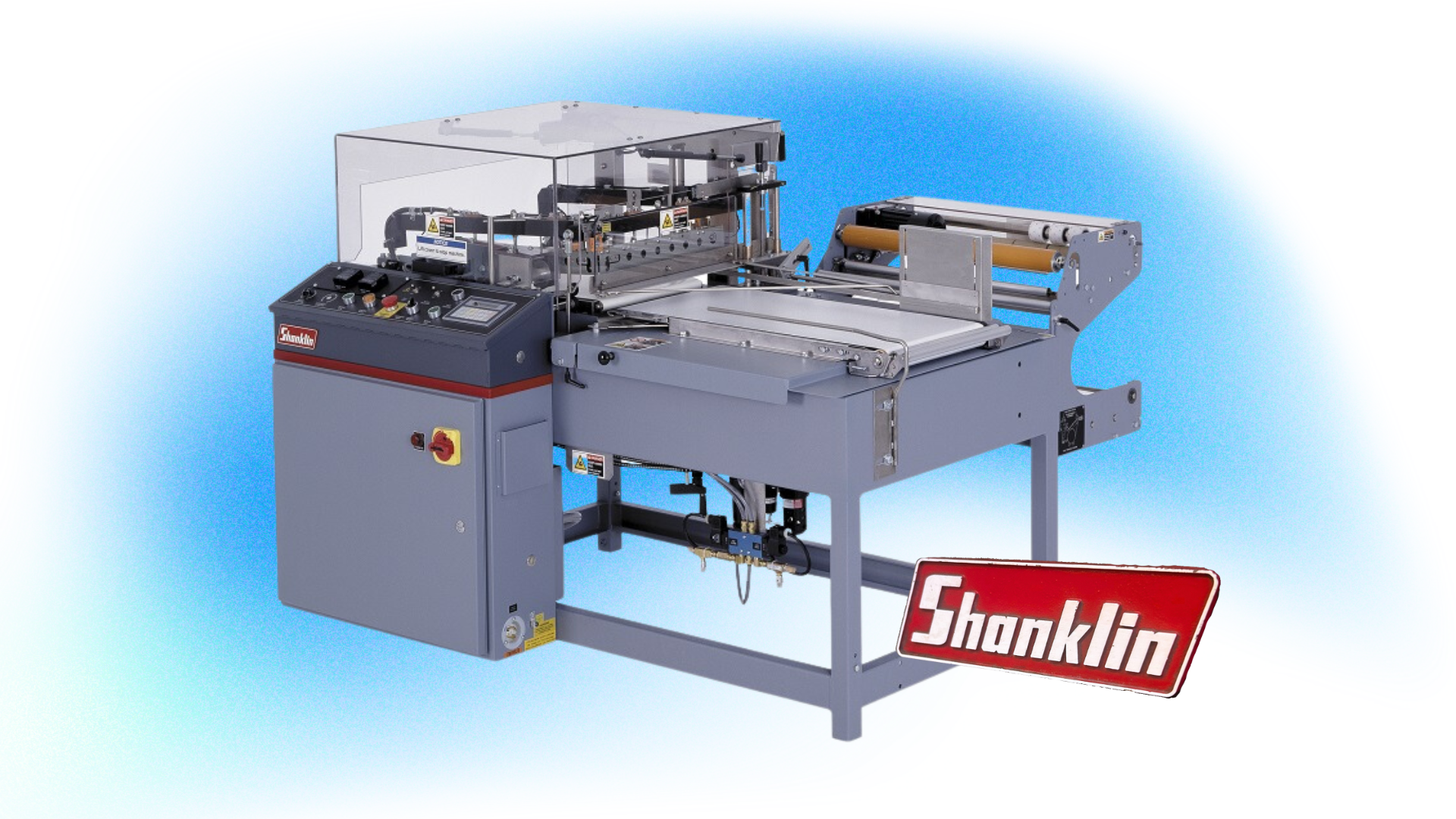

Understanding shanklin corporation Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Shanklin HySpeed Servo Series | High-speed operation (up to 180 packs/min), fully automatic, accommodates various shapes | Food & Beverage, Consumer Products | Pros: High efficiency, versatility; Cons: Higher initial investment. |

| Shanklin F Series Wrapper | Continuous motion, programmable controls, adaptable conveyor speeds | Pharmaceuticals, Cosmetics | Pros: Easy troubleshooting and changeover; Cons: May require operator training. |

| Shanklin Triumph 2 Wrapper | Mid-range features, stores recipes, integrated side sealer | Retail, Packaging Solutions | Pros: Cost-effective, reliable; Cons: Limited speed compared to high-end models. |

| Shanklin L-Bar Sealer | Entry-level, ergonomic design, suitable for smaller operations | Small to Medium Enterprises | Pros: Affordable, user-friendly; Cons: Slower output rates. |

| Shanklin Shrink Tunnels | Designed for high-volume shrink wrapping, compatible with various films | Industrial Applications, Food Industry | Pros: Efficient heat application; Cons: Requires space and setup. |

What are the characteristics of the Shanklin HySpeed Servo Series?

The Shanklin HySpeed Servo Series is designed for businesses requiring rapid packaging solutions. With an output capacity of up to 180 packs per minute, these machines are fully automatic and can handle a diverse range of product shapes and sizes. They are particularly well-suited for high-demand environments, such as food and beverage sectors, where speed and efficiency are paramount. Buyers should consider the higher initial investment against the potential for increased productivity and reduced labor costs.

How does the Shanklin F Series Wrapper stand out for B2B buyers?

The Shanklin F Series Wrapper is known for its continuous motion design and advanced programmable controls, making it ideal for industries like pharmaceuticals and cosmetics. This series allows for seamless changeovers and adjustable conveyor speeds, enhancing operational efficiency. While it offers significant benefits in terms of adaptability and ease of use, potential buyers should factor in the need for operator training to fully leverage its features.

What are the advantages of choosing the Shanklin Triumph 2 Wrapper?

The Shanklin Triumph 2 Wrapper provides a balanced solution for businesses that require more than basic packaging but do not need the full capabilities of high-speed models. It features an integrated side sealer and can store up to 25 product recipes, making it versatile for various applications in retail and packaging. Although it is cost-effective and reliable, its speed may not match that of more advanced systems, which could be a consideration for high-volume operations.

Why might small to medium enterprises opt for the Shanklin L-Bar Sealer?

The Shanklin L-Bar Sealer is designed with entry-level users in mind, offering an ergonomic design that is easy to operate. This model is particularly appealing to small and medium enterprises due to its affordability and user-friendly interface. However, buyers should be aware that while it is suitable for lower volume production, its output rates are slower than more advanced models, which may not meet the needs of faster-paced operations.

What role do Shanklin Shrink Tunnels play in industrial applications?

Shanklin Shrink Tunnels are essential for businesses that require efficient heat application for shrink wrapping. These machines are particularly effective in high-volume environments, such as food packaging and industrial applications, where they can work seamlessly with various shrink films. While they enhance productivity, buyers should consider the space and setup requirements, as these systems can take up significant floor space in a production facility.

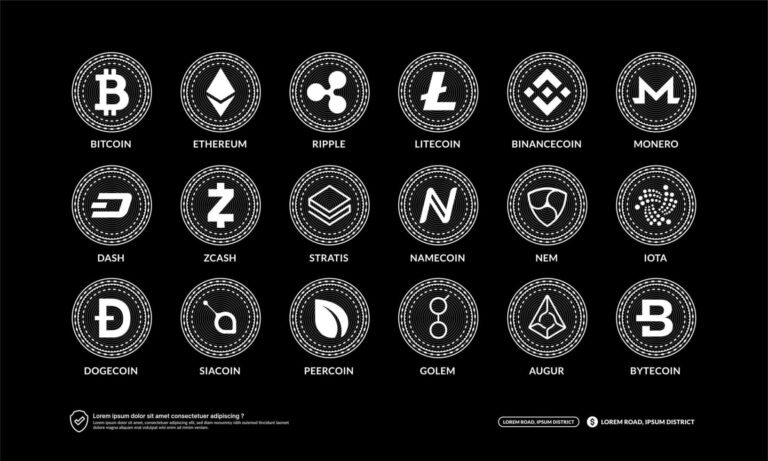

Illustrative image related to shanklin corporation

Key Industrial Applications of shanklin corporation

| Industry/Sector | Specific Application of Shanklin Corporation | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Shrink wrapping of packaged foods | Ensures product freshness and extends shelf life | Need for compliance with food safety regulations and standards |

| Pharmaceutical | Packaging of pharmaceutical products | Provides tamper-evident and secure packaging | Requirement for high-speed operations and sterile conditions |

| Consumer Goods | Bundling and display of retail products | Enhances product presentation and reduces shipping costs | Versatility in handling various product shapes and sizes |

| Cosmetics and Personal Care | Sealing of cosmetic products | Protects product integrity and improves visual appeal | Demand for aesthetic packaging solutions and sustainability |

| Industrial Products | Packaging of machinery parts and components | Ensures safe transport and storage, reducing damage risk | Need for robust, durable packaging solutions for heavy items |

How Does Shanklin Corporation Serve the Food and Beverage Industry?

In the food and beverage sector, Shanklin Corporation’s shrink wrap machines are integral for wrapping packaged foods. These machines help maintain product freshness and extend shelf life by providing a secure barrier against contaminants. For international buyers, particularly in regions like Africa and South America, sourcing equipment that meets local food safety regulations is crucial. Flexibility in handling various packaging sizes and shapes is also a key consideration, as consumer preferences can vary widely.

What Role Does Shanklin Play in Pharmaceutical Packaging?

Shanklin’s equipment is vital for the pharmaceutical industry, where the integrity of products is paramount. Their shrink wrapping solutions offer tamper-evident packaging, which is essential for consumer safety and compliance with stringent regulations. Buyers from the Middle East and Europe should prioritize high-speed operational capabilities and ensure that the machinery can maintain sterile conditions during packaging processes, as these factors significantly impact production efficiency and product safety.

How Is Shanklin Corporation Beneficial for Consumer Goods?

For the consumer goods sector, Shanklin’s bundling and display solutions enhance product visibility on retail shelves. By improving product presentation, businesses can attract more customers and ultimately drive sales. When sourcing these solutions, international buyers should consider the versatility of the machines in accommodating various product shapes and sizes, which is essential for adapting to market trends and consumer demands.

In What Ways Does Shanklin Support the Cosmetics Industry?

In the cosmetics and personal care industry, Shanklin’s packaging solutions not only protect product integrity but also significantly enhance visual appeal. This is crucial in a competitive market where packaging plays a vital role in attracting consumers. Buyers should focus on sourcing equipment that offers aesthetic packaging options while also considering sustainability, as eco-friendly packaging is increasingly becoming a priority for consumers and regulatory bodies alike.

Illustrative image related to shanklin corporation

How Does Shanklin Corporation Address Industrial Product Packaging Needs?

For industrial products, Shanklin’s shrink wrap systems ensure safe transport and storage of machinery parts and components. These systems minimize the risk of damage during shipping, which is vital for maintaining operational efficiency. Buyers should look for robust and durable packaging solutions that can withstand the rigors of transport while also being adaptable to different product sizes, particularly in regions with diverse manufacturing needs, such as Vietnam and Nigeria.

3 Common User Pain Points for ‘shanklin corporation’ & Their Solutions

Scenario 1: Navigating Complex Packaging Needs

The Problem: In the competitive landscape of international trade, businesses often struggle with packaging solutions that can accommodate a wide variety of products. For instance, a food manufacturer in Nigeria might face challenges when trying to package different product sizes and shapes efficiently. When dealing with diverse inventory, the risk of underperformance increases, leading to delays in shipping and potential damage during transit. Furthermore, the inability to adapt quickly to changing packaging requirements can lead to lost sales and dissatisfied customers.

The Solution: To address these challenges, businesses should consider investing in Shanklin Corporation’s versatile shrink wrap systems. The Shanklin HySpeed Servo Series, for example, offers impressive adaptability, allowing users to accommodate various product lengths and shapes with fully automatic handling. B2B buyers should engage with Shanklin’s sales team to discuss specific needs, ensuring they select the right model that meets their production demands. Additionally, leveraging features like the picture-based HMI touchscreen can streamline operations by simplifying navigation for operators, thus reducing training time and errors.

Scenario 2: Maintaining Equipment Efficiency

The Problem: As businesses scale their operations, they often experience wear and tear on their packaging machinery, leading to downtime and increased maintenance costs. A company in South America might find that their Shanklin shrink wrap machines are not performing at optimal levels, resulting in slower production rates and higher operational costs. This scenario can be particularly detrimental in fast-paced environments where efficiency is critical for staying competitive.

The Solution: Regular maintenance and timely upgrades are vital for keeping Shanklin equipment running smoothly. Businesses should establish a proactive maintenance schedule that includes routine checks and the replacement of essential parts, which can be sourced directly from Shanklin’s extensive parts inventory. Additionally, leveraging Shanklin’s corrective action screens can provide real-time recommendations for optimizing machine performance, thus preventing potential issues before they escalate. By investing in training for staff on these features, companies can maximize their equipment’s capabilities and minimize unexpected downtime.

Illustrative image related to shanklin corporation

Scenario 3: Understanding Cost-Effective Packaging Solutions

The Problem: Cost management is a significant concern for B2B buyers, especially in regions like the Middle East and Africa, where budget constraints can impact purchasing decisions. Companies often find themselves needing high-quality packaging solutions without the accompanying high costs. For example, a cosmetics manufacturer in Europe may be hesitant to invest in advanced shrink wrap systems due to perceived high upfront costs, despite the long-term savings on materials and shipping.

The Solution: B2B buyers should view the investment in Shanklin’s packaging solutions as a cost-saving opportunity rather than just an expense. The Shanklin F Series, known for its efficiency and adaptability, can handle various shrink films and packaging styles, which can significantly reduce material waste and shipping costs. Buyers should conduct a total cost of ownership analysis that factors in not only the initial purchase price but also the operational savings over time. Engaging with Shanklin’s representatives can provide insights into financing options or potential lease agreements that make these high-quality systems more accessible. Additionally, highlighting the benefits of durable, tamper-evident packaging can reinforce the value proposition when presenting to stakeholders.

By addressing these common pain points with targeted solutions, businesses can leverage Shanklin Corporation’s expertise to enhance their packaging operations and drive overall efficiency.

Strategic Material Selection Guide for shanklin corporation

What Are the Key Materials Used in Shanklin Corporation’s Packaging Solutions?

When selecting materials for packaging equipment, particularly for shrink wrap systems, several factors must be considered to ensure optimal performance and compatibility with various products. Below, we analyze four common materials used in Shanklin Corporation’s equipment, focusing on their properties, pros and cons, and implications for international B2B buyers.

How Does Polyethylene (PE) Perform in Shrink Wrap Applications?

Polyethylene (PE) is a widely used thermoplastic in shrink wrap applications due to its excellent clarity, flexibility, and resistance to moisture. It can withstand temperatures up to 80°C, making it suitable for various packaging environments.

Illustrative image related to shanklin corporation

Pros: PE is cost-effective and offers good impact resistance, which is crucial for protecting products during transport. Its lightweight nature also contributes to reduced shipping costs.

Cons: However, PE has limited resistance to high temperatures and UV light, which can lead to degradation over time. Additionally, it may not be suitable for products requiring a high barrier against gases or odors.

Impact on Application: PE is ideal for packaging food items, consumer goods, and pharmaceuticals, where moisture resistance is essential.

Considerations for International Buyers: Compliance with local regulations, such as FDA standards in the U.S. or EU regulations in Europe, is critical. Buyers in regions like Africa and South America should also be aware of the availability of PE and its recyclability, aligning with sustainability goals.

What Role Does Polyvinyl Chloride (PVC) Play in Shrink Wrap Systems?

Polyvinyl Chloride (PVC) is another common material used in shrink wrapping due to its excellent sealing properties and durability. PVC can withstand temperatures up to 90°C, making it suitable for a variety of packaging applications.

Pros: PVC offers superior clarity and a high gloss finish, enhancing product presentation. It also has good chemical resistance, making it suitable for packaging a wide range of products.

Illustrative image related to shanklin corporation

Cons: The primary drawback of PVC is its environmental impact, as it is less recyclable than other materials. Additionally, it can be more expensive than PE, which may deter cost-sensitive buyers.

Impact on Application: PVC is particularly effective for packaging electronics, cosmetics, and other sensitive items that require a high-quality finish and protection from environmental factors.

Considerations for International Buyers: Buyers should ensure that PVC complies with local environmental regulations, especially in Europe, where stringent rules are in place regarding the use of PVC in packaging.

How Does Polypropylene (PP) Compare in Shrink Wrap Applications?

Polypropylene (PP) is a versatile thermoplastic that offers excellent resistance to moisture and chemicals, making it a popular choice for shrink wrap applications. It can handle temperatures up to 120°C, providing a robust solution for various packaging needs.

Illustrative image related to shanklin corporation

Pros: PP is known for its strength and durability, making it suitable for heavy-duty applications. It also has a lower density than PE and PVC, which can lead to cost savings in shipping.

Cons: However, PP can be more expensive than PE and may require specialized equipment for sealing. Its lower flexibility compared to PE can also be a limitation in certain applications.

Impact on Application: PP is ideal for packaging food products, industrial goods, and pharmaceuticals, where durability and moisture resistance are paramount.

Considerations for International Buyers: Buyers should be aware of the specific standards applicable to PP in their region, such as ASTM or DIN, and ensure compliance with food safety regulations.

What Is the Significance of Ethylene Vinyl Alcohol (EVOH) in Packaging?

Ethylene Vinyl Alcohol (EVOH) is a high-barrier material often used in combination with other plastics to enhance their gas barrier properties. It is particularly effective in applications requiring extended shelf life.

Illustrative image related to shanklin corporation

Pros: EVOH provides excellent oxygen and aroma barrier properties, making it suitable for food packaging. Its compatibility with various sealing technologies also enhances its usability.

Cons: The primary limitation of EVOH is its susceptibility to moisture, which can compromise its barrier properties. It is also more expensive than other materials, which may impact overall packaging costs.

Impact on Application: EVOH is ideal for packaging perishable goods, such as meats and dairy products, where shelf life is critical.

Considerations for International Buyers: Buyers should consider the specific regulations governing food packaging in their regions, particularly in Europe and North America, where EVOH is often used in multilayer films.

Summary Table of Material Selection for Shanklin Corporation

| Material | Typical Use Case for Shanklin Corporation | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene (PE) | Food packaging, consumer goods | Cost-effective and flexible | Limited UV resistance and durability | Low |

| Polyvinyl Chloride (PVC) | Electronics, cosmetics | Superior clarity and gloss | Environmental concerns and cost | Medium |

| Polypropylene (PP) | Heavy-duty applications, food products | Strong and durable | Higher cost and sealing complexity | Medium |

| Ethylene Vinyl Alcohol (EVOH) | Perishable food packaging | Excellent barrier properties | Moisture sensitivity and cost | High |

This strategic material selection guide provides valuable insights for international B2B buyers considering Shanklin Corporation’s packaging solutions, ensuring they make informed decisions that align with their operational needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for shanklin corporation

What Are the Main Stages of Manufacturing for Shanklin Corporation’s Equipment?

Shanklin Corporation, a leader in packaging solutions, employs a comprehensive manufacturing process that ensures the production of high-quality shrink wrap machines and systems. The main stages of manufacturing include material preparation, forming, assembly, and finishing.

Material Preparation: How Does Shanklin Source and Process Materials?

The manufacturing journey begins with the careful selection of raw materials. Shanklin sources high-grade stainless steel and durable plastics to ensure the longevity and reliability of their equipment. Materials undergo rigorous quality checks to eliminate defects before they enter the production line. This initial step is crucial as it sets the foundation for the entire manufacturing process.

What Techniques Are Used in the Forming Stage?

In the forming stage, advanced techniques such as CNC machining and laser cutting are utilized to shape the components with precision. These methods allow for intricate designs and specifications tailored to various applications. The use of automated machinery enhances speed and accuracy, minimizing human error and increasing overall efficiency.

Illustrative image related to shanklin corporation

How Does Assembly Work at Shanklin Corporation?

Once the components are formed, they move to the assembly stage. This process involves skilled technicians who assemble the parts into functional units. Shanklin employs lean manufacturing principles, which focus on reducing waste while maximizing productivity. This approach not only optimizes assembly time but also ensures that each machine meets strict performance standards.

What Finishing Processes Are Critical for Quality?

The finishing stage includes several key processes such as polishing, painting, and applying protective coatings. These steps enhance both the aesthetic appeal and durability of the equipment. Additionally, final inspections are performed to ensure that each unit complies with Shanklin’s high standards of quality before leaving the factory.

How Does Shanklin Ensure Quality Assurance in Manufacturing?

Quality assurance is integral to Shanklin’s manufacturing philosophy. The company adheres to international standards such as ISO 9001, which provides a framework for consistent quality management. Compliance with these standards not only enhances operational efficiency but also builds trust with B2B buyers.

What Are the Key International and Industry-Specific Standards?

In addition to ISO 9001, Shanklin complies with various industry-specific certifications, including CE for European markets and API standards for certain applications. These certifications indicate that Shanklin’s products meet stringent safety and performance criteria, giving international buyers confidence in their investment.

Illustrative image related to shanklin corporation

What Are the Quality Control Checkpoints Used in Production?

Shanklin implements a multi-tiered quality control (QC) system that encompasses several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they are used in production. It includes visual inspections and material testing to ensure compliance with specifications.

-

In-Process Quality Control (IPQC): During assembly, ongoing inspections are conducted to monitor the quality of the work being performed. This includes checking for proper alignment, functionality, and adherence to safety standards.

-

Final Quality Control (FQC): Before shipment, each machine undergoes a comprehensive final inspection. This process includes performance testing and verification against design specifications, ensuring that all units are ready for operational use.

What Common Testing Methods Are Employed?

Shanklin employs various testing methods to validate the performance and safety of their machines. Common tests include:

- Functional Testing: Machines are run through their operational cycles to ensure they perform as intended.

- Stress Testing: Equipment is subjected to extreme conditions to evaluate durability and reliability.

- Safety Testing: Safety features are thoroughly tested to ensure compliance with regulations, particularly for markets in Europe and North America.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Here are actionable steps:

-

Conduct Audits: Engage in regular audits of the supplier’s manufacturing facilities to assess their adherence to quality standards. This can be done independently or through third-party services.

-

Request Quality Reports: Suppliers should provide detailed quality reports that outline their QC processes, testing results, and compliance with international standards.

-

Third-Party Inspections: Consider employing third-party inspection services to perform unbiased assessments of the manufacturing and QC processes.

What Are the QC and Certification Nuances for International Buyers?

International buyers must be aware of the different regulatory environments they operate within. For instance, compliance with CE marking is mandatory for selling products in European markets, while products exported to the U.S. may need to meet specific FDA regulations, especially in the food and beverage sector. Understanding these nuances helps buyers make informed decisions and ensures that the products they purchase meet local regulations.

Conclusion: Why Is Quality Assurance a Priority for Shanklin Corporation?

Quality assurance is not merely a checkbox for Shanklin Corporation; it is a cornerstone of their operational philosophy. By adhering to rigorous manufacturing processes and international standards, Shanklin ensures that their shrink wrap machines deliver exceptional performance and reliability. For B2B buyers, particularly those from diverse international markets, partnering with a company that prioritizes quality can lead to long-term success and satisfaction.

Illustrative image related to shanklin corporation

Practical Sourcing Guide: A Step-by-Step Checklist for ‘shanklin corporation’

This guide serves as a comprehensive checklist for B2B buyers seeking to procure equipment from Shanklin Corporation. By following these steps, buyers can ensure they make informed decisions that align with their operational needs and industry standards.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical specifications needed for your shrink wrap equipment. This includes understanding the types of products you will package, desired speed, and compatibility with existing systems. Having precise specifications will help narrow down the equipment options and facilitate more accurate discussions with suppliers.

Step 2: Research Supplier Capabilities

Thoroughly investigate the capabilities of Shanklin Corporation and its product offerings. Look into their range of shrink wrap machines, such as the HySpeed Servo Series and F Series, to determine which models align with your needs. Pay attention to features like speed, ease of operation, and adaptability to various package sizes, as these will significantly impact your production efficiency.

Step 3: Evaluate Potential Suppliers

Before making a commitment, vet Shanklin Corporation thoroughly. Request company profiles, case studies, and references from current or previous clients within your industry. This step is crucial to ensure that the supplier can deliver on their promises and has a proven track record of reliability and customer satisfaction.

Illustrative image related to shanklin corporation

Step 4: Verify Supplier Certifications

Confirm that Shanklin Corporation holds relevant industry certifications, such as ISO or USDA approvals for food packaging. Certifications ensure that the equipment meets specific safety and quality standards, which is particularly important for industries such as food and pharmaceuticals. A certified supplier can also provide assurances regarding product safety and compliance with regional regulations.

Step 5: Assess After-Sales Support and Service

Inquire about the after-sales support that Shanklin Corporation offers. Efficient maintenance and quick access to spare parts are critical for minimizing downtime in production. Evaluate their service contracts, availability of technical support, and the ease of obtaining replacement parts to ensure your operations can run smoothly long after the initial purchase.

Step 6: Request Demonstrations and Trials

Whenever possible, request product demonstrations or trials to see the equipment in action. This will allow you to assess the machine’s performance, user interface, and suitability for your specific applications. Observing the equipment firsthand can provide invaluable insights into its operational efficiency and help you make a more informed decision.

Step 7: Review Pricing and Payment Terms

Finally, carefully review the pricing structure and payment terms offered by Shanklin Corporation. Ensure that the pricing is competitive and aligns with your budgetary constraints. Clarify any additional costs that may arise, such as shipping, installation, and maintenance, to avoid unexpected expenses later in the procurement process.

By adhering to this checklist, B2B buyers can confidently navigate the sourcing process for Shanklin Corporation, ensuring they select the right equipment that meets their operational needs and industry standards.

Illustrative image related to shanklin corporation

Comprehensive Cost and Pricing Analysis for shanklin corporation Sourcing

What Are the Key Cost Components in Shanklin Corporation’s Pricing Structure?

When evaluating the cost structure of Shanklin Corporation’s shrink wrap machines, several components play a critical role. These include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margin. The materials used, such as high-quality plastics for shrink films and robust metals for machinery, can significantly affect the overall cost. Labor costs encompass skilled technicians and assembly workers who ensure that machines are built to the highest standards. Manufacturing overhead includes utilities, facility maintenance, and administrative expenses, which are essential for smooth operations. Tooling costs involve the investment in specialized equipment necessary for manufacturing processes. Quality control is vital to ensure that each machine meets industry standards, particularly in regulated sectors like food and pharmaceuticals. Finally, logistics costs related to shipping and handling must be factored in, especially for international deliveries.

How Do Price Influencers Affect Shanklin Corporation’s Offerings?

Several price influencers can affect the final pricing of Shanklin’s products. Volume and minimum order quantities (MOQ) often dictate price breaks; larger orders typically result in lower per-unit costs. Customization can also influence pricing; tailored solutions that meet specific client requirements may incur additional costs. The quality of materials used—such as the strength and durability of the shrink wrap films—can lead to variations in price, as can certifications that assure compliance with international standards. Supplier factors, including the reliability and reputation of material suppliers, can also influence costs. Furthermore, understanding Incoterms is essential for international buyers, as they define responsibilities for shipping, insurance, and tariffs.

What Buyer Tips Should International B2B Customers Consider When Sourcing from Shanklin?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should keep several strategies in mind when negotiating with Shanklin Corporation. First, always conduct thorough market research to understand average pricing and competitive offerings. This knowledge can empower negotiations, allowing buyers to advocate for more favorable terms or pricing. Additionally, assess the Total Cost of Ownership (TCO) rather than just the purchase price. TCO includes maintenance, operational costs, and potential downtimes associated with equipment failure.

Another critical aspect is to inquire about volume discounts and the flexibility of MOQs; negotiating larger orders may result in significant savings. Buyers should also consider the implications of customization on lead times and costs—while customized machinery may better fit specific needs, it could also lead to longer wait times and higher prices.

What Are the Pricing Nuances for International B2B Buyers?

When sourcing from Shanklin, international buyers must navigate various pricing nuances, such as currency fluctuations, import duties, and taxes, which can affect the overall cost. It’s crucial to clarify pricing terms upfront, including whether quotes are provided in local currency or USD, and to understand the implications of different shipping terms (FOB, CIF, etc.). Additionally, buyers should inquire about warranty and service agreements, as these can add long-term value to the investment.

Lastly, while indicative prices may be available, they can vary significantly based on the factors discussed above. Thus, requesting a detailed quote that outlines all costs associated with the purchase is advisable for a clearer understanding of the total expenditure involved.

By taking these factors into account, international buyers can make informed decisions and optimize their procurement strategies when sourcing from Shanklin Corporation.

Alternatives Analysis: Comparing shanklin corporation With Other Solutions

Understanding Alternatives in Shrink Packaging Solutions

In the competitive landscape of shrink packaging, selecting the right equipment is crucial for businesses aiming to enhance efficiency, reduce costs, and ensure product integrity. Shanklin Corporation is a well-established player in this market, known for its high-quality shrink wrap machines. However, potential buyers should consider viable alternatives that may better suit their specific operational needs. This analysis compares Shanklin Corporation’s offerings with other solutions in the market, providing a clearer picture for B2B buyers.

| Comparison Aspect | Shanklin Corporation | Sealed Air Shrink Wrap Systems | Aetna Group Shrink Wrap Equipment |

|---|---|---|---|

| Performance | Up to 180 packs per minute | Up to 200 packs per minute | Up to 150 packs per minute |

| Cost | Moderate to High | High | Moderate |

| Ease of Implementation | High, with detailed manuals and support | Moderate, requires training | High, user-friendly design |

| Maintenance | Low, designed for durability | Moderate, requires regular checks | Low, easy access to parts |

| Best Use Case | Food and beverage, consumer goods | High-volume retail packaging | Industrial applications |

What Are the Advantages and Disadvantages of Sealed Air Shrink Wrap Systems?

Sealed Air’s shrink wrap systems are known for their high-speed performance, capable of reaching up to 200 packs per minute. This makes them ideal for high-volume operations, particularly in retail environments where rapid packaging is essential. However, the initial investment is typically higher than that of Shanklin machines, which may deter some buyers. Additionally, the systems can require more training for operators, potentially increasing the implementation timeline.

How Does Aetna Group Compare in the Shrink Wrap Market?

Aetna Group offers a range of shrink wrap equipment that is particularly well-suited for industrial applications. Their machines can efficiently handle varying product sizes and shapes, achieving speeds of up to 150 packs per minute. A key advantage of Aetna equipment is its user-friendly design, which minimizes the learning curve for new operators. The cost is generally moderate, making it an attractive option for businesses that require reliable performance without the premium price tag. Maintenance is also low due to easy access to replacement parts, which can be a significant advantage for operations with tight schedules.

Illustrative image related to shanklin corporation

Conclusion: How Should B2B Buyers Choose the Right Shrink Packaging Solution?

When selecting a shrink packaging solution, B2B buyers must assess their unique operational requirements, including production volume, budget constraints, and ease of use. Shanklin Corporation offers robust performance and reliability, making it a strong contender for industries like food and beverage. However, alternatives like Sealed Air and Aetna Group provide distinct advantages that may align better with specific business goals, such as higher speed or lower upfront costs. Ultimately, the right choice will depend on a careful evaluation of each solution’s features against the buyer’s specific needs and operational context.

Essential Technical Properties and Trade Terminology for shanklin corporation

What Are the Key Technical Properties of Shanklin Corporation’s Packaging Equipment?

When evaluating packaging solutions, understanding the technical properties of equipment is crucial for making informed purchasing decisions. Here are some essential specifications that B2B buyers should consider:

-

Film Width and Type

Shanklin shrink wrap machines accommodate various film widths, typically ranging from 30 inches centerfold to 60 inches single wound. The choice of film can impact the durability and presentation of the packaged products. Buyers should assess their specific packaging needs, as the correct film type can enhance protection and improve visual appeal, which is especially important in competitive markets. -

Output Rate

The output rate is a critical specification, with Shanklin machines capable of processing up to 180 packs per minute depending on the model. This metric is vital for businesses looking to optimize production efficiency. A higher output rate can significantly reduce labor costs and increase throughput, making it an essential factor for scaling operations. -

Power Options

Shanklin equipment offers various power configurations, including 208V, 230V, and 460V, with options for export voltage. Understanding the power requirements is essential for integration into existing facilities, especially for international buyers. Proper voltage selection ensures optimal performance and prevents potential equipment failures. -

Product Size Compatibility

Shanklin machines can handle products up to 14 inches high, 30 inches wide, and lengths exceeding 50 inches, depending on the model. This versatility allows companies to package a wide range of products, from small items to larger bundles. Buyers should evaluate their product dimensions to ensure compatibility with the selected equipment. -

Control System

Many Shanklin machines feature user-friendly interfaces such as picture-based HMI touchscreens, allowing operators to easily navigate settings and troubleshoot issues. A sophisticated control system can enhance operational efficiency by reducing training time and minimizing errors during production. -

Material Grade

The construction materials used in Shanklin machines are critical for durability and maintenance. High-grade stainless steel is often used in key components, providing resistance to corrosion and wear. This is particularly important for industries such as food and pharmaceuticals, where hygiene and equipment longevity are paramount.

What Common Trade Terms Should B2B Buyers Know When Working with Shanklin Corporation?

Understanding industry terminology can streamline the purchasing process and enhance communication between buyers and suppliers. Here are several key terms relevant to Shanklin Corporation:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of Shanklin, buyers should know whether they are purchasing OEM parts for maintenance or replacement to ensure compatibility and performance. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for budget planning and inventory management. Buyers should clarify this with Shanklin to ensure they can meet purchase requirements without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price estimates from suppliers. This is an essential step for B2B transactions, as it allows buyers to compare pricing and terms across different suppliers, including Shanklin. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. Understanding terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is vital for international buyers to clarify shipping costs, risks, and logistics involved in their orders. -

Lead Time

Lead time refers to the period from placing an order to receiving the product. Understanding lead times helps businesses plan their production schedules and manage inventory effectively. -

TCO (Total Cost of Ownership)

TCO encompasses all costs associated with the purchase and operation of equipment over its lifetime, including maintenance, energy consumption, and training. Buyers should evaluate TCO when considering Shanklin equipment to ensure they are making a financially sound investment.

By familiarizing themselves with these technical properties and trade terminologies, international B2B buyers can make more informed decisions when considering Shanklin Corporation’s packaging solutions.

Navigating Market Dynamics and Sourcing Trends in the shanklin corporation Sector

What are the Current Market Dynamics and Key Trends Affecting Shanklin Corporation?

The global packaging industry is witnessing transformative changes driven by technological advancements and evolving consumer preferences. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. The demand for efficient and reliable packaging solutions, such as those provided by Shanklin Corporation, is on the rise. Key trends include the increasing adoption of automation in packaging processes, which enhances efficiency and reduces labor costs. Machines like the Shanklin HySpeed Servo Series exemplify this trend, offering speed and versatility that cater to diverse production requirements.

Illustrative image related to shanklin corporation

Moreover, sustainability is becoming a significant factor in purchasing decisions. Buyers are increasingly looking for suppliers that prioritize eco-friendly practices and materials. The integration of smart technologies into packaging solutions is also emerging, enabling real-time monitoring and data analytics to optimize operations. As international trade continues to expand, compliance with various regulatory standards is essential, making it vital for buyers to partner with manufacturers who can navigate these complexities effectively.

How is Sustainability and Ethical Sourcing Relevant to Shanklin Corporation?

Sustainability and ethical sourcing are paramount in today’s B2B landscape, especially for companies in the packaging sector. The environmental impact of packaging materials is under scrutiny, prompting businesses to seek suppliers that offer sustainable alternatives. Shanklin Corporation recognizes this shift and is committed to developing packaging solutions that minimize waste and utilize recyclable materials. By sourcing ‘green’ certifications and materials, Shanklin not only meets regulatory demands but also aligns with the values of socially conscious buyers.

Ethical supply chains are increasingly important as consumers demand transparency and accountability from brands. For international buyers, selecting a supplier like Shanklin that prioritizes ethical practices can enhance their brand reputation and fulfill consumer expectations. Additionally, adopting sustainable practices can lead to cost savings in the long run, as efficient resource management often results in reduced operational costs. This makes sustainability not just a responsibility but also a strategic advantage in the competitive packaging market.

What is the Brief Evolution and History of Shanklin Corporation in the B2B Context?

Founded in 1962, Shanklin Corporation has evolved into a leading manufacturer of shrink packaging equipment. The company has built a strong reputation for innovation, focusing on high-quality, reliable machinery that caters to various industries, including food and beverage, pharmaceuticals, and consumer goods. Over the decades, Shanklin has adapted to changing market demands by incorporating advanced technologies into its product offerings, such as automated systems and user-friendly interfaces.

This commitment to innovation has allowed Shanklin to remain competitive in the ever-evolving packaging landscape. By continuously enhancing its product lines and expanding its global reach, Shanklin has positioned itself as a trusted partner for international B2B buyers seeking efficient and effective packaging solutions. The company’s long-standing expertise and dedication to quality make it a key player in navigating the complexities of modern packaging needs.

Frequently Asked Questions (FAQs) for B2B Buyers of shanklin corporation

-

How do I choose the right shrink wrap machine for my business needs?

Selecting the right shrink wrap machine involves evaluating your production volume, product types, and packaging requirements. Consider the speed, versatility, and automation features of the machines. Shanklin offers various models, such as the HySpeed Servo Series for high-speed operations and the Triumph 2 for mid-range applications. Additionally, assess the machine’s compatibility with different shrink films and any specific customization options that may enhance your operational efficiency. -

What factors should I consider when vetting a supplier like Shanklin Corporation?

When vetting a supplier, consider their industry reputation, experience, and customer reviews. Look for certifications that demonstrate quality standards, such as ISO certifications. Evaluate their product range to ensure it aligns with your needs. Additionally, inquire about their customer service, technical support, and warranty policies. Engaging with existing clients or industry peers can provide insights into their reliability and responsiveness. -

What are the minimum order quantities (MOQs) for Shanklin Corporation products?

Minimum order quantities can vary based on the specific equipment and customization options you require. Shanklin Corporation typically accommodates both large and small orders, but discussing your specific needs with their sales team is essential. This conversation will clarify MOQs and help you explore potential discounts for bulk orders, ensuring you get the best value for your investment. -

What payment terms can I expect when purchasing from Shanklin Corporation?

Payment terms may vary based on your location and order size. Shanklin Corporation generally offers flexible payment options, including upfront payments, payment upon delivery, or financing arrangements for larger purchases. It is advisable to discuss your payment preferences with their sales team to negotiate terms that work for both parties, especially for international transactions. -

How does Shanklin Corporation ensure quality assurance in their products?

Shanklin Corporation employs stringent quality control measures throughout their manufacturing process. This includes routine inspections, testing of equipment for performance, and compliance with international safety standards. They also offer warranties and service agreements, ensuring that any issues arising post-purchase are addressed promptly, thereby maintaining the integrity and reliability of their shrink wrap machines. -

What logistics considerations should I keep in mind when importing Shanklin products?

When importing Shanklin products, consider shipping costs, customs duties, and the logistics of transporting heavy machinery. Collaborate with a reliable freight forwarder experienced in international shipping to navigate customs regulations effectively. Ensure you have a clear understanding of delivery timelines and any potential delays that could arise during the shipping process, especially for larger orders. -

Can Shanklin Corporation customize their machines to fit specific production needs?

Yes, Shanklin Corporation offers customization options for their shrink wrap machines to meet unique production requirements. This may include modifications in size, speed, or specialized features tailored to specific products. Engaging directly with their sales team will allow you to discuss your needs in detail, ensuring you receive a machine that optimally fits your operational processes. -

What types of support and training does Shanklin Corporation provide post-purchase?

Post-purchase support from Shanklin Corporation includes technical assistance, maintenance services, and operator training. They typically provide manuals and online resources to help your team familiarize themselves with the equipment. Additionally, Shanklin may offer on-site training sessions to ensure your staff can operate and troubleshoot the machines effectively, maximizing productivity and minimizing downtime.

Top 3 Shanklin Corporation Manufacturers & Suppliers List

1. PackWorld – Omni G & Omni S Shrink Packaging Equipment

Domain: packworld.com

Registered: 1995 (30 years)

Introduction: Shrink packaging equipment, specifically Omni G and Omni S shrink packaging equipment.

2. Shanklin Corporation – Shrink Wrap Systems

Domain: mmequip.com

Registered: 1997 (28 years)

Introduction: Shanklin Corporation is a provider of packaging equipment and solutions, established in 1962. They specialize in shrink wrap systems, including shrink tunnels and sealers, used in various industries such as food and beverage, pharmaceutical, cosmetic, and consumer products. Key products include: 1. Shanklin A-26A L Bar Sealer with Shrink Tunnel – speeds up to 25 packages per minute. 2. SHANKLIN 53…

3. Machine Parts Toolbox – Cable Assy Integrated Inf Mtr Pwr Rec

Domain: machinepartstoolbox.com

Registered: 2014 (11 years)

Introduction: [{‘name’: ‘Cable Assy Integrated Inf Mtr Pwr Rec’, ‘sku’: ‘J05-5128-001’, ‘price’: 216.93}, {‘name’: ‘F-1 W/SLC500 Manual’, ‘sku’: ‘MM-0001C’, ‘price’: 398.0}, {‘name’: ‘Gen. Pur. Perf. Ezl-W/Brush’, ‘sku’: ‘S0868’, ‘price’: 1576.58}, {‘name’: ‘Threaded Stud’, ‘sku’: ‘N01-0075-001’, ‘price’: 12.0}, {‘name’: ‘#35 CHAIN CONNECTING LINK’, ‘sku’: ‘SB-0016’, ‘price’: 6.82}, {‘name’: ‘Infeed Drive Rolle…

Strategic Sourcing Conclusion and Outlook for shanklin corporation

How Can International Buyers Benefit from Shanklin Corporation’s Offerings?

In conclusion, Shanklin Corporation stands out as a leader in the shrink packaging industry, delivering innovative and reliable equipment tailored to diverse sectors such as food and beverage, pharmaceuticals, and consumer goods. Their advanced machinery, such as the HySpeed Servo Series and F Series, not only enhances operational efficiency but also adapts seamlessly to changing production needs. This versatility is crucial for international buyers looking to optimize their supply chains and improve packaging processes.

Strategic sourcing from Shanklin Corporation allows companies to leverage high-quality equipment that minimizes downtime and maximizes productivity. As global markets continue to evolve, the importance of selecting the right partners becomes even more significant. By investing in Shanklin’s solutions, businesses can ensure that they remain competitive in their respective industries.

Looking ahead, international B2B buyers from regions like Africa, South America, the Middle East, and Europe are encouraged to explore Shanklin Corporation’s offerings. Engaging with their expert team can provide tailored solutions that meet specific operational challenges. Don’t miss the opportunity to enhance your packaging efficiency—contact Shanklin today to discover how their innovative technologies can drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.