Unlocking Value: A Strategic Analysis of the Roller Helmet With Full Face Shield Market

Introduction: Navigating the Global Market for roller helmet with full face shield

In the fast-evolving landscape of personal protective equipment, sourcing roller helmets with full face shields presents a unique challenge for B2B buyers, particularly in dynamic markets across Africa, South America, the Middle East, and Europe. With rising safety standards and increasing demand for quality protective gear, businesses must navigate a complex array of options to ensure they meet both regulatory requirements and customer expectations. This comprehensive guide addresses these challenges by providing essential insights into the various types of roller helmets available, their applications across different industries, and the importance of supplier vetting to guarantee product quality and compliance.

The guide delves into critical aspects such as cost considerations, safety certifications, and the latest innovations in helmet technology. By empowering buyers with the knowledge needed to make informed purchasing decisions, this resource aims to facilitate smoother procurement processes and enhance safety protocols in their respective markets. Whether you are a retailer looking to expand your inventory or a company seeking to equip your workforce with reliable protective gear, understanding the nuances of roller helmets with full face shields is essential for success in today’s global marketplace.

With actionable insights tailored to the specific needs of international buyers, this guide positions you to confidently navigate the complexities of sourcing and investing in high-quality roller helmets.

Understanding roller helmet with full face shield Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| S1 Lifer Visor Helmet | Lightweight, customizable fit, multiple color options | Skateboarding, roller derby, recreational | Pros: Stylish, certified safety standards. Cons: Higher price point. |

| Certified Sweatsaver Helmet | Anti-fog visor, dual safety certification, sweat-absorbing liners | Roller derby, BMX, skateboarding | Pros: Comfortable, excellent ventilation. Cons: Limited color options. |

| Full Face Skate Helmet | Complete facial protection, robust construction | Extreme sports, professional skating | Pros: Maximum safety, ideal for high-impact activities. Cons: Heavier, less ventilation. |

| Adjustable Visor Helmet | Adjustable visor height, impact-resistant materials | Recreational use, casual skating | Pros: Versatile, adaptable to different conditions. Cons: May require frequent adjustments. |

| Youth-Specific Visor Helmet | Smaller size, vibrant designs, lightweight construction | Youth sports programs, schools | Pros: Tailored for safety and comfort in younger users. Cons: Limited lifespan as children grow. |

What are the characteristics and suitability of the S1 Lifer Visor Helmet?

The S1 Lifer Visor Helmet is designed for versatility and style, making it a popular choice among skaters and roller derby enthusiasts. Its lightweight construction and customizable fit, along with a variety of color options, cater to individual preferences. B2B buyers should consider its safety certifications, which comply with industry standards, ensuring protection for users. The higher price point may be justified by the helmet’s aesthetic appeal and quality, making it suitable for retailers targeting style-conscious customers.

How does the Certified Sweatsaver Helmet stand out in the market?

The Certified Sweatsaver Helmet is known for its innovative anti-fog visor and dual safety certifications, making it a top choice for roller derby and BMX. Its sweat-absorbing liners provide comfort during intense activities, which is crucial for performance. B2B buyers should note the helmet’s excellent ventilation features, enhancing user experience. However, the limited color options may restrict appeal, so it’s essential to assess market demand for this specific style among target demographics.

Illustrative image related to roller helmet with full face shield

What makes the Full Face Skate Helmet a preferred choice for extreme sports?

The Full Face Skate Helmet offers complete facial protection, making it ideal for extreme sports and professional skating environments. Its robust construction ensures maximum safety during high-impact activities, which is a significant consideration for B2B buyers in the sports equipment sector. While the helmet’s weight and reduced ventilation may deter some users, the safety benefits far outweigh these drawbacks. Retailers targeting serious athletes and extreme sports enthusiasts should include this option in their inventory.

Why is the Adjustable Visor Helmet an attractive option for casual skaters?

The Adjustable Visor Helmet features an innovative design that allows users to modify the visor height, enhancing adaptability for different skating conditions. Made from impact-resistant materials, this helmet is suitable for recreational use and casual skating. B2B buyers should consider its versatility, appealing to a broad audience. However, frequent adjustments may be necessary, which could be a downside for users seeking a more straightforward solution.

What are the advantages of Youth-Specific Visor Helmets in B2B markets?

Youth-Specific Visor Helmets are tailored for younger users, featuring smaller sizes and vibrant designs to attract children. Their lightweight construction ensures comfort during use, making them ideal for youth sports programs and schools. B2B buyers should prioritize safety features, as these helmets must meet rigorous standards to protect younger skaters. While their lifespan may be limited due to growth, they represent a significant opportunity for retailers catering to the youth market.

Illustrative image related to roller helmet with full face shield

Key Industrial Applications of roller helmet with full face shield

| Industry/Sector | Specific Application of roller helmet with full face shield | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports & Recreation | Used in roller derby and extreme sports events | Enhances safety for athletes, reducing injury risk | Ensure compliance with safety standards; consider comfort and fit options. |

| Construction & Heavy Industry | Protective headgear for workers in hazardous environments | Protects workers from head and facial injuries | Look for durability, impact resistance, and ventilation features. |

| Emergency Services | Helmets for first responders during rescue operations | Provides critical protection while maintaining visibility | Ensure lightweight design; consider integration with communication devices. |

| Manufacturing & Warehousing | Safety gear for personnel operating machinery | Reduces workplace accidents and liability | Focus on customization options for fit; ensure compliance with local regulations. |

| Transportation & Logistics | Helmets for delivery personnel and warehouse staff | Enhances worker safety in busy environments | Evaluate visibility features and comfort; assess bulk purchasing options. |

How Are Roller Helmets with Full Face Shields Used in Sports and Recreation?

In the sports and recreation sector, roller helmets with full face shields are essential for athletes participating in high-impact sports like roller derby and skateboarding. These helmets provide crucial head and facial protection, minimizing the risk of injuries during intense competitions. For international buyers, especially in regions with active sports communities, sourcing helmets that meet specific safety certifications (like CPSC and ASTM) is vital. Additionally, comfort and fit are critical, as athletes require gear that allows for maximum performance without compromising safety.

What Role Do Roller Helmets Play in Construction and Heavy Industry?

In construction and heavy industry, roller helmets with face shields are utilized to protect workers from falling debris and hazardous materials. These helmets are designed to withstand impacts and provide full facial coverage, which is essential in environments where head injuries are prevalent. For B2B buyers, sourcing helmets that comply with local safety regulations and offer durability is crucial. Key considerations include the helmet’s weight, ventilation capabilities, and the availability of replaceable components, ensuring long-term use and protection.

How Are Roller Helmets Beneficial for Emergency Services?

Emergency services personnel often face unpredictable and hazardous conditions during rescue operations. Roller helmets with full face shields are indispensable for providing protection while ensuring visibility. These helmets are designed to be lightweight, enabling first responders to operate effectively without being hindered by their gear. For international buyers, especially in regions prone to natural disasters, sourcing helmets that integrate communication systems and meet rigorous safety standards is essential to enhance operational efficiency and safety.

In What Ways Are Roller Helmets Used in Manufacturing and Warehousing?

In manufacturing and warehousing settings, roller helmets with face shields safeguard employees against potential hazards, including flying debris and chemical splashes. These helmets contribute to a safer work environment, thereby reducing the risk of accidents and associated liabilities for businesses. When sourcing helmets, B2B buyers should prioritize features such as customization for fit, compliance with occupational safety standards, and the ability to withstand industrial conditions. Ensuring that helmets are comfortable for extended wear can significantly improve worker morale and productivity.

How Do Roller Helmets Enhance Safety in Transportation and Logistics?

In the transportation and logistics sector, roller helmets with full face shields are increasingly used by delivery personnel and warehouse staff to enhance safety. These helmets protect workers from head injuries in busy environments where collisions and accidents are common. B2B buyers should evaluate features such as visibility, comfort, and the possibility of bulk purchasing options when sourcing helmets. Ensuring that the helmets provide adequate protection while being lightweight can help maintain efficiency and safety in operations across diverse geographical regions.

3 Common User Pain Points for ‘roller helmet with full face shield’ & Their Solutions

Scenario 1: Ensuring Proper Fit for Safety Compliance

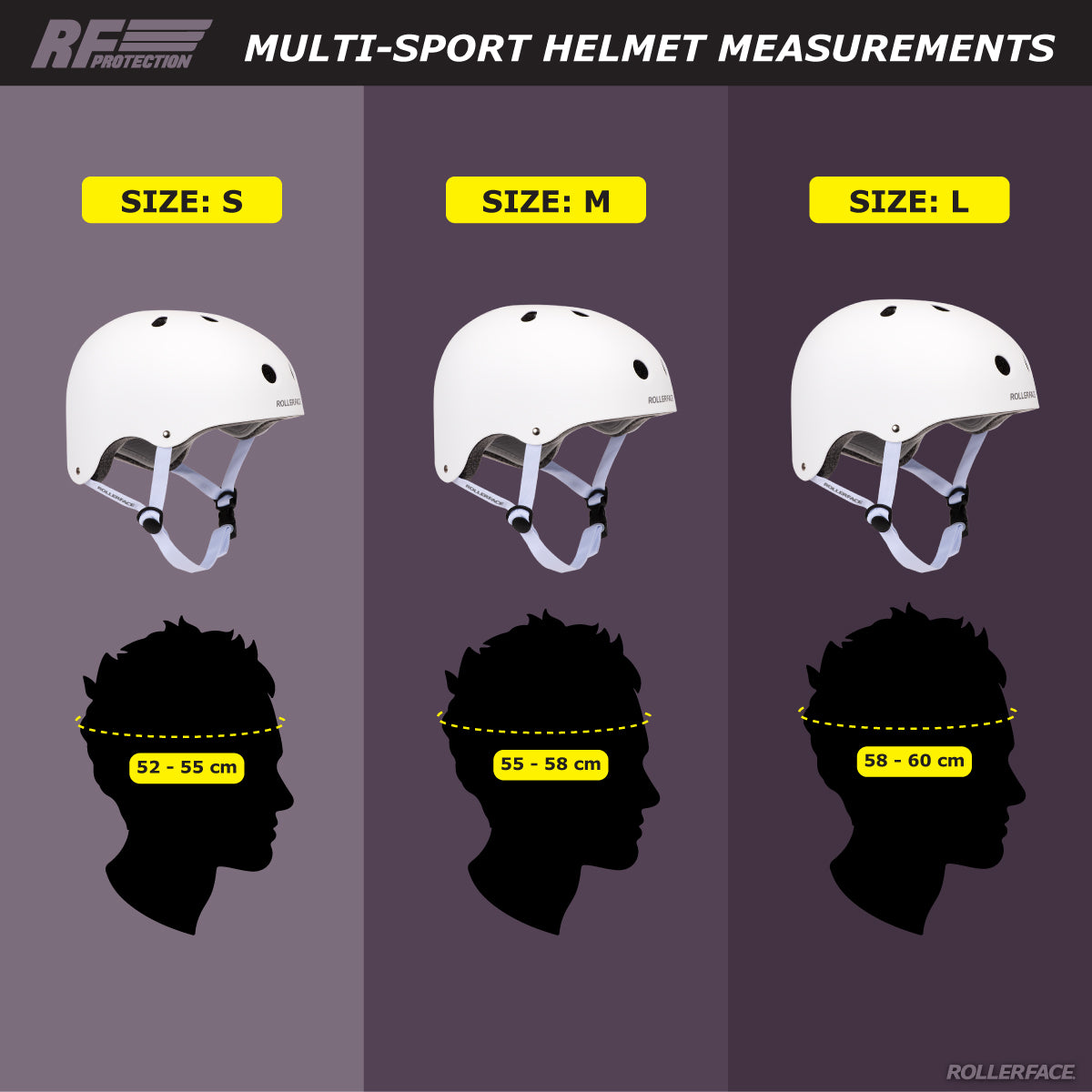

The Problem: B2B buyers often face the challenge of ensuring that the roller helmets with full face shields fit their users correctly. Poor fit can lead to safety risks, as a helmet that is too loose may come off during a fall, while one that is too tight can cause discomfort and distraction. In regions like Africa and South America, where diverse head shapes and sizes are prevalent, finding helmets that cater to a wide range of sizes can be daunting.

The Solution: To address this issue, buyers should look for helmets that come with adjustable sizing options and multiple liner thicknesses. Manufacturers should provide detailed sizing charts and fitting guides, allowing buyers to match the helmet specifications with their user demographics accurately. Additionally, consider sourcing helmets that include interchangeable padding or liner systems, enabling customization for individual users. This approach not only enhances safety compliance by ensuring a snug fit but also promotes user satisfaction and reduces the risk of returns due to sizing issues.

Scenario 2: Managing Visibility and Comfort During Use

The Problem: Another common pain point for B2B buyers is the challenge of ensuring visibility and comfort for users wearing roller helmets with full face shields. The quality of the visor can significantly impact visibility, especially in varying weather conditions. Fogging, scratching, and distortion can obstruct the user’s view, leading to accidents. In hot climates, comfort can also be compromised, causing users to remove their helmets, thus negating safety benefits.

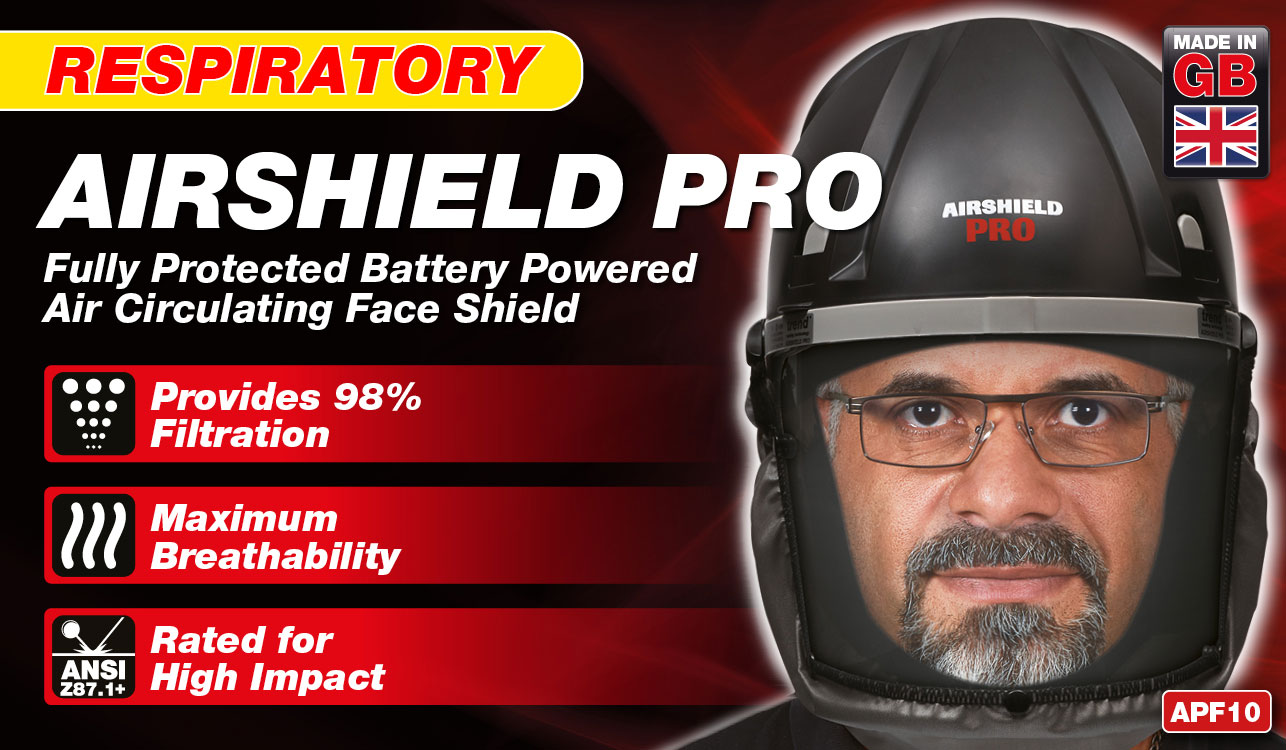

Illustrative image related to roller helmet with full face shield

The Solution: Buyers should prioritize sourcing helmets equipped with high-quality visors that have anti-fog and anti-scratch properties. Helmets with integrated ventilation systems can help reduce fogging by promoting airflow. It’s essential to verify that the visor meets safety standards for impact resistance, ensuring it provides clear optical quality. Additionally, consider purchasing helmets with moisture-wicking liners that enhance comfort during prolonged use. Conducting user trials to gather feedback on visibility and comfort can also guide future purchases and ensure the helmets meet user needs effectively.

Scenario 3: Navigating Budget Constraints While Ensuring Quality

The Problem: B2B buyers often struggle to balance budget constraints with the need for high-quality roller helmets with full face shields. In regions facing economic challenges, such as parts of the Middle East and Africa, finding cost-effective solutions without compromising safety and quality can be a significant hurdle. Buyers may find themselves tempted to choose cheaper options, risking the overall safety of their users.

The Solution: To navigate budget constraints effectively, buyers should focus on sourcing helmets from reputable manufacturers who offer bulk purchasing discounts or loyalty programs. Conducting thorough market research to compare features, certifications, and prices across different brands can lead to better-informed purchasing decisions. Additionally, consider investing in a small number of premium helmets for training or high-risk activities while providing lower-cost alternatives for less intensive use. This strategy ensures that users receive the necessary protection without overstretching the budget. Engaging with suppliers to discuss long-term partnerships can also yield better pricing and ensure a consistent supply of quality helmets.

Strategic Material Selection Guide for roller helmet with full face shield

What Are the Key Materials Used in Roller Helmets with Full Face Shields?

When selecting materials for roller helmets with full face shields, it is essential to consider their properties, advantages, and limitations. The choice of material can significantly impact safety, comfort, and compliance with international standards. Below, we analyze four common materials used in the manufacturing of these helmets.

Polycarbonate: A Popular Choice for Safety and Clarity

Key Properties: Polycarbonate is known for its high impact resistance and optical clarity. It can withstand temperatures up to 120°C and offers excellent UV resistance, making it suitable for outdoor use.

Illustrative image related to roller helmet with full face shield

Pros & Cons: This material is lightweight and provides a good balance between cost and performance. However, polycarbonate can be prone to scratching unless treated with anti-scratch coatings. Additionally, its production process can be complex, potentially increasing manufacturing costs.

Impact on Application: Polycarbonate is particularly effective in environments where visibility is crucial, such as roller derby or skateboarding. It is compatible with various media, including sweat and moisture, which is critical for user comfort.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure that polycarbonate helmets comply with ASTM and CE standards. The demand for lightweight and durable helmets is high in these markets, making polycarbonate a favorable option.

Illustrative image related to roller helmet with full face shield

EPS Foam: The Core of Impact Absorption

Key Properties: Expanded Polystyrene (EPS) foam is a lightweight material that excels in energy absorption. It can withstand significant impact forces, making it ideal for safety applications.

Pros & Cons: EPS is cost-effective and straightforward to manufacture, which contributes to lower overall production costs. However, it is less durable than other materials and can degrade over time, especially under UV exposure.

Impact on Application: EPS foam is critical in protecting the head during falls or collisions, making it essential for roller sports. Its compatibility with various helmet designs allows for customization in fit and comfort.

Considerations for International Buyers: Compliance with safety standards such as CPSC and ASTM is vital for EPS foam helmets. Buyers in Europe may prefer helmets with additional certifications, emphasizing the importance of verifying compliance.

Fiberglass: A Durable and Lightweight Alternative

Key Properties: Fiberglass is known for its high strength-to-weight ratio and resistance to environmental factors. It can withstand high temperatures and offers excellent durability.

Illustrative image related to roller helmet with full face shield

Pros & Cons: While fiberglass helmets provide superior protection, they are typically more expensive to produce. The manufacturing process is complex, which can lead to longer lead times.

Impact on Application: Fiberglass is suitable for high-impact sports where durability is paramount. Its resistance to environmental degradation makes it a preferred choice for outdoor activities.

Considerations for International Buyers: Buyers from South America and Europe often prioritize durability and safety, making fiberglass helmets appealing. Compliance with international standards is crucial, and buyers should verify certifications before procurement.

ABS Plastic: A Cost-Effective Solution

Key Properties: Acrylonitrile Butadiene Styrene (ABS) plastic is known for its toughness and impact resistance. It can withstand temperatures up to 80°C and is resistant to various chemicals.

Pros & Cons: ABS is relatively inexpensive and easy to mold, allowing for versatile helmet designs. However, it may not provide the same level of impact resistance as polycarbonate or fiberglass.

Impact on Application: ABS helmets are suitable for recreational use, where cost is a significant factor. They offer adequate protection for casual roller sports but may not meet the demands of professional athletes.

Considerations for International Buyers: In regions like Nigeria and Saudi Arabia, affordability is often a key consideration. Buyers should ensure that ABS helmets still meet necessary safety standards, as compliance can vary significantly across markets.

Summary Table of Material Selection for Roller Helmets with Full Face Shields

| Material | Typical Use Case for roller helmet with full face shield | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | Roller derby, skateboarding | High impact resistance and optical clarity | Prone to scratching | Medium |

| EPS Foam | Protective core in helmets | Cost-effective and lightweight | Degrades over time | Low |

| Fiberglass | High-impact sports | Superior durability and environmental resistance | Higher production costs | High |

| ABS Plastic | Recreational roller sports | Affordable and easy to mold | Lower impact resistance | Low |

This comprehensive analysis provides B2B buyers with insights into material selection for roller helmets with full face shields, helping them make informed decisions based on safety, cost, and compliance with international standards.

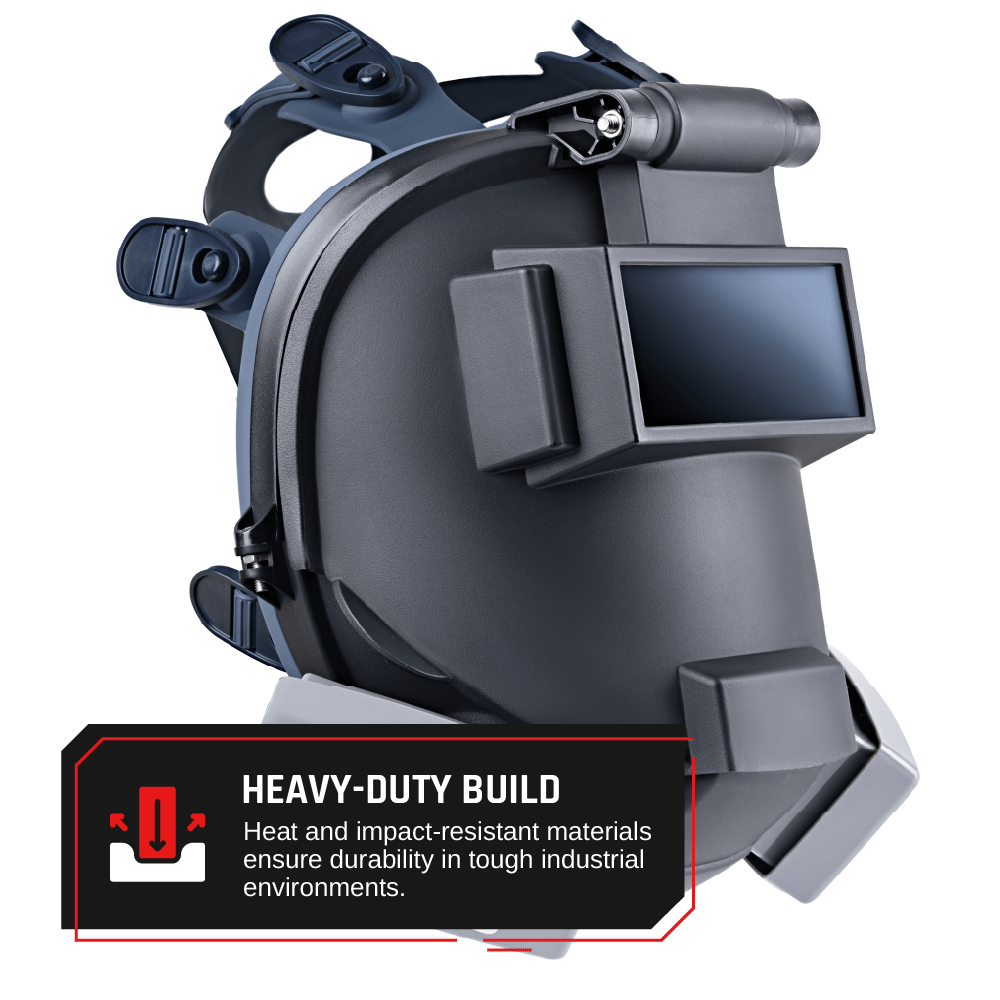

In-depth Look: Manufacturing Processes and Quality Assurance for roller helmet with full face shield

What Are the Main Stages in the Manufacturing Process of Roller Helmets with Full Face Shields?

The manufacturing process of roller helmets with full face shields involves several critical stages, ensuring that the final product meets safety standards and customer expectations.

Illustrative image related to roller helmet with full face shield

Material Preparation

The initial phase begins with the selection of high-quality materials, which typically include expanded polystyrene (EPS) foam for impact absorption, polycarbonate for the face shield, and various fabrics for the interior lining. These materials are sourced from reputable suppliers to ensure durability and compliance with safety regulations.

Once the materials are acquired, they undergo a rigorous inspection to verify their quality. This includes checking for defects, measuring thickness, and ensuring that they meet the specified safety standards. Any materials failing to meet these criteria are discarded to maintain overall product integrity.

Forming and Shaping

Following material preparation, the forming process begins. This involves molding the EPS foam into the desired shape of the helmet shell. Advanced techniques such as injection molding or compression molding are often employed to achieve precise dimensions and structural integrity. During this stage, manufacturers may also incorporate ventilation holes or other design features that enhance user comfort and safety.

Illustrative image related to roller helmet with full face shield

The face shield, made from polycarbonate, is formed through a process called thermoforming, where heat is applied to make the material pliable before shaping it to fit the helmet. This ensures a snug fit that enhances protection without compromising visibility.

Assembly of Components

Once the individual components are shaped, the assembly process commences. The EPS shell is fitted with the inner lining, which is typically made from soft, moisture-wicking materials to improve comfort during use. The face shield is then securely attached, often using a combination of screws and adhesive to ensure it remains firmly in place during use.

During assembly, it’s essential to verify the alignment and fitting of each component to prevent any potential hazards. This is typically done using specialized jigs and fixtures that ensure consistency across all products.

Finishing Touches

The final stage of the manufacturing process involves finishing touches, including painting, applying decals, and quality checks. The helmets are often painted using UV-resistant paints to prevent fading and ensure longevity.

Additionally, any required branding or safety labels are applied at this stage. The helmets then undergo a final inspection to ensure they meet aesthetic and functional standards before packaging for shipment.

Illustrative image related to roller helmet with full face shield

How Is Quality Assurance Implemented in Roller Helmet Production?

Quality assurance (QA) is a critical aspect of manufacturing roller helmets with full face shields. It ensures that products meet international safety standards and are reliable for consumers.

What International Standards Are Relevant for Roller Helmets?

Manufacturers must comply with various international standards to ensure their helmets are safe and effective. Key standards include:

- ISO 9001: This standard outlines the requirements for a quality management system (QMS), ensuring that organizations consistently provide products that meet customer and regulatory requirements.

- CE Marking: This certification indicates that the helmet meets EU safety, health, and environmental protection standards.

- ASTM F-1492: This standard pertains to the safety requirements for helmets used in skateboarding and roller skating, ensuring that products provide adequate protection.

What Are the QC Checkpoints Throughout the Manufacturing Process?

Quality control (QC) checkpoints are integral to maintaining high standards during production. These typically include:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon delivery to ensure they meet specifications.

- In-Process Quality Control (IPQC): During manufacturing, various checkpoints monitor processes like molding and assembly to catch any defects early.

- Final Quality Control (FQC): After assembly, a comprehensive inspection is conducted to ensure that the finished product meets all safety and quality standards. This includes functionality tests, visual inspections, and ensuring compliance with certifications.

What Common Testing Methods Are Used for Roller Helmets?

Manufacturers utilize several testing methods to verify helmet safety and performance, including:

- Impact Testing: Helmets are subjected to drop tests to measure their ability to absorb shock and protect the wearer.

- Penetration Testing: This assesses the helmet’s resistance to sharp objects, ensuring it can withstand potential impacts.

- Retention System Testing: Manufacturers test the chin straps and retention systems to ensure they remain secure during use.

- Visor Testing: The face shield undergoes scratch, fog, and optical clarity tests to ensure it provides unobstructed visibility.

How Can B2B Buyers Verify Supplier Quality Control Practices?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should take several steps to verify the quality control practices of potential suppliers.

Illustrative image related to roller helmet with full face shield

What Should B2B Buyers Look for in Supplier Audits and Reports?

Buyers should request recent audit reports that demonstrate a supplier’s compliance with international standards, including ISO certifications and other relevant safety certifications. These reports should detail the methodologies used during the audits, any non-conformities found, and corrective actions taken.

How Important Are Third-Party Inspections?

Third-party inspections add an additional layer of assurance regarding product quality. Buyers should consider engaging independent organizations to conduct random inspections of the manufacturing facilities and the products. This can help verify that the supplier adheres to the promised quality standards and practices.

What Are the QC and Certification Nuances for International Buyers?

International buyers must be aware of the specific regulations and standards that apply in their regions. For instance, helmets sold in the EU must have CE marking, while those in the US must comply with CPSC standards. Understanding these nuances will help buyers ensure they are sourcing compliant products that meet local regulations.

Conclusion

The manufacturing processes and quality assurance practices for roller helmets with full face shields are complex and multifaceted. By understanding the stages of production, relevant international standards, and effective quality control measures, B2B buyers can make informed decisions. Engaging with suppliers who prioritize quality assurance will not only enhance safety but also build trust and reliability in the products offered to consumers.

Illustrative image related to roller helmet with full face shield

Practical Sourcing Guide: A Step-by-Step Checklist for ‘roller helmet with full face shield’

Introduction

This guide serves as a comprehensive checklist for B2B buyers looking to procure roller helmets with full face shields. These helmets are essential for ensuring safety during roller sports, and selecting the right supplier is critical. By following this structured approach, you can make informed decisions that meet your organization’s safety standards and operational needs.

Step 1: Define Your Technical Specifications

Before approaching suppliers, clearly outline the technical specifications required for the helmets. This includes safety certifications, materials used, weight, and design features such as ventilation and padding.

– Safety Standards: Ensure the helmets comply with relevant safety standards, such as CPSC and ASTM.

– Customization Needs: Determine if you need helmets in specific colors, sizes, or with customizable features.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in roller helmets with full face shields. This step is crucial for finding partners who can meet your specific requirements.

– Market Reputation: Look for suppliers with a strong reputation in the industry, supported by customer reviews and testimonials.

– Product Range: Evaluate their product range to ensure they offer helmets that meet your defined specifications.

Illustrative image related to roller helmet with full face shield

Step 3: Verify Supplier Certifications

Before making any commitments, verify that potential suppliers have the necessary certifications to guarantee the quality and safety of their products.

– Compliance: Ensure they comply with international safety standards relevant to your region, such as CE certification in Europe or ANSI in the U.S.

– Quality Assurance: Check for ISO certifications which indicate a commitment to quality management practices.

Step 4: Request Samples

Request samples of the helmets to assess their quality and suitability for your needs. This step allows you to evaluate the product firsthand and make necessary adjustments before bulk ordering.

– Fit and Comfort: Ensure the helmets fit well and are comfortable for extended wear, as this impacts user safety and satisfaction.

– Material Assessment: Examine the materials used for durability, weight, and resistance to impact.

Step 5: Evaluate Pricing and Payment Terms

Once you have identified a shortlist of suppliers, compare their pricing structures and payment terms. This is vital for budgeting and ensuring financial feasibility.

– Bulk Discounts: Inquire about bulk purchase discounts or long-term contract pricing.

– Payment Flexibility: Understand their payment terms, including deposits, payment plans, and accepted methods.

Illustrative image related to roller helmet with full face shield

Step 6: Assess Customer Support and Warranty

Evaluate the level of customer support and warranty options offered by the suppliers. Good customer service can enhance your purchasing experience and provide peace of mind.

– After-Sales Support: Check if they offer after-sales support and assistance for any issues that may arise post-purchase.

– Warranty Coverage: Understand the warranty terms for repairs or replacements, which can significantly affect your long-term costs.

Step 7: Finalize the Order and Monitor Delivery

After selecting a supplier, finalize your order and establish a timeline for delivery. Monitoring the process ensures that you receive your helmets on time and as specified.

– Order Confirmation: Get a written confirmation detailing the order, including specifications and delivery dates.

– Logistics Coordination: Ensure clear communication regarding shipping methods, tracking, and potential delays.

By following this checklist, B2B buyers can confidently source roller helmets with full face shields that meet their safety and operational requirements.

Illustrative image related to roller helmet with full face shield

Comprehensive Cost and Pricing Analysis for roller helmet with full face shield Sourcing

What Are the Key Cost Components Involved in Sourcing Roller Helmets with Full Face Shields?

When sourcing roller helmets with full face shields, understanding the cost structure is crucial for B2B buyers. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials significantly impacts the overall cost. High-quality polycarbonate for the visor, durable outer shells, and comfortable inner liners can increase the price but offer better protection and comfort.

-

Labor: Skilled labor is essential for assembling helmets and ensuring quality standards. Labor costs can vary by region, affecting the total price.

-

Manufacturing Overhead: This encompasses operational costs such as utilities, rent, and equipment maintenance. Efficient production processes can help mitigate these costs.

-

Tooling: Initial setup costs for molds and specialized tools can be significant, especially for custom designs. Buyers should consider these costs when negotiating.

-

Quality Control: Ensuring helmets meet safety certifications requires thorough testing and inspection processes, which can add to the expense.

-

Logistics: Shipping costs vary based on distance, volume, and chosen Incoterms. Effective logistics planning can help reduce overall costs.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. Buyers should be aware of these margins when evaluating total costs.

How Do Pricing Influencers Affect the Cost of Roller Helmets?

Several factors can influence pricing for roller helmets with full face shields, making it essential for buyers to navigate these effectively.

-

Volume/MOQ: Purchasing in bulk often leads to discounts. Establishing minimum order quantities (MOQs) can also yield better pricing structures.

-

Specifications and Customization: Custom designs or unique specifications may incur additional costs. Buyers should assess the necessity of customization against budget constraints.

-

Material Quality and Certifications: Helmets that comply with international safety standards (like CPSC and ASTM) may be priced higher due to the quality assurance processes involved.

-

Supplier Factors: Supplier reputation and reliability can impact pricing. Established suppliers with a track record of quality may command higher prices but offer better assurance against defects.

-

Incoterms: Understanding Incoterms is vital for calculating total landed costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, Freight) can influence final pricing.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Roller Helmets?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, several strategic approaches can enhance cost-efficiency.

-

Negotiation: Building strong relationships with suppliers can facilitate better negotiation outcomes. Aim for long-term partnerships that may lead to more favorable terms.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Assess factors such as durability, warranty, and replacement parts, which can significantly affect long-term costs.

-

Pricing Nuances for International Buyers: Currency fluctuations and import tariffs can influence overall costs. Staying informed about these factors can aid in budgeting and cost projections.

-

Research and Benchmarking: Conduct thorough market research to understand competitive pricing and features. This knowledge will empower buyers during negotiations.

What Should Buyers Keep in Mind Regarding Indicative Prices?

It is essential to note that indicative prices for roller helmets with full face shields can vary widely based on market conditions, supplier capabilities, and regional demand. Buyers should treat these prices as a starting point for discussions, with the understanding that final costs may differ based on specific requirements and purchasing strategies. Always seek multiple quotes and consider the total value offered by suppliers, including after-sales support and warranty provisions.

Alternatives Analysis: Comparing roller helmet with full face shield With Other Solutions

Exploring Alternatives to Roller Helmets with Full Face Shields

In the realm of protective gear for skating, cycling, and similar activities, the roller helmet with a full face shield stands as a popular choice for enhanced safety. However, various alternative solutions offer unique benefits that may suit different needs, preferences, and environments. This analysis examines these alternatives to help B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | Roller Helmet With Full Face Shield | Certified Sweatsaver Helmet with Visor | S1 Lifer Visor Helmet |

|---|---|---|---|

| Performance | High impact protection, full face coverage | Good impact protection, limited face coverage | Good impact protection, visor for visibility |

| Cost | $150 – $200 | $129.99 | $143.99 |

| Ease of Implementation | Requires proper sizing and adjustments | Easy fit with customizable liners | Easy fit, comes fully assembled |

| Maintenance | Moderate; visor may require cleaning | Low; easy to clean and maintain | Moderate; visor replacement available |

| Best Use Case | High-speed activities requiring full facial protection | Roller derby and similar sports | General skating and biking |

Detailed Breakdown of Alternatives

Certified Sweatsaver Helmet with Visor

The Certified Sweatsaver Helmet with Visor, priced at $129.99, is designed with a focus on comfort and performance. It offers dual certification for both bicycle and skate safety standards, making it a reliable choice for users engaged in high-intensity activities like roller derby. Its lightweight design and moisture-wicking liners enhance user comfort, while the anti-fog visor ensures clear visibility during use. However, it may not provide the same level of full-face protection as a dedicated full face shield helmet, which could be a drawback for those seeking maximum safety.

S1 Lifer Visor Helmet

The S1 Lifer Visor Helmet, available for $143.99, combines style and functionality. This helmet is known for its robust impact protection and aesthetic appeal, featuring various color options. The visor is designed to offer distortion-free visibility while providing essential eye protection. The helmet is easy to fit and adjust, catering to a wide range of head sizes. However, like the Sweatsaver, it lacks the comprehensive facial coverage that a full face shield provides, making it less suitable for activities where face protection is paramount.

Conclusion: How to Choose the Right Protective Gear

When selecting protective gear, B2B buyers should assess the specific needs of their target audience. The roller helmet with a full face shield excels in providing extensive safety for high-speed or high-impact activities. In contrast, alternatives like the Certified Sweatsaver Helmet with Visor and S1 Lifer Visor Helmet offer lighter, more comfortable solutions that may be better suited for environments where full facial coverage is less critical. Ultimately, the decision should hinge on the balance between safety requirements, comfort, and the nature of the activities being performed. By understanding these options, businesses can make strategic purchases that align with their customers’ safety needs and preferences.

Essential Technical Properties and Trade Terminology for roller helmet with full face shield

What Are the Key Technical Properties of Roller Helmets with Full Face Shields?

When evaluating roller helmets with full face shields, several critical specifications must be considered to ensure safety, comfort, and compliance with regulatory standards. Understanding these properties aids B2B buyers in making informed purchasing decisions.

1. Material Composition

Roller helmets are typically constructed from high-impact thermoplastics or polycarbonate materials. These materials are crucial for their lightweight yet durable characteristics, providing both comfort during extended wear and protection against impacts. For B2B buyers, the choice of material directly affects the helmet’s safety rating and marketability.

Illustrative image related to roller helmet with full face shield

2. Safety Certifications

Safety certifications, such as CPSC (Consumer Product Safety Commission) and ASTM (American Society for Testing and Materials), are essential for compliance in various markets. Helmets that meet these standards ensure that they have undergone rigorous testing for impact resistance and other safety features. For international buyers, understanding these certifications can facilitate compliance with local regulations and enhance product credibility.

3. Weight and Balance

The weight of a helmet is a significant factor influencing user comfort and performance. Helmets that are too heavy can lead to neck strain, while those that are well-balanced distribute weight evenly across the head. B2B buyers should prioritize helmets that provide a lightweight design without sacrificing protection, as this can lead to higher customer satisfaction and repeat purchases.

4. Ventilation System

A well-designed ventilation system is vital for maintaining comfort during use. Helmets equipped with integrated vent channels allow for airflow, reducing heat buildup and moisture accumulation. This feature is particularly important in warmer climates, making it a key selling point for B2B buyers targeting regions with high temperatures.

5. Fit and Adjustment Mechanisms

Adjustability features, such as size liners and buckle systems, are crucial for achieving a secure and comfortable fit. Helmets that offer customizable fit options can accommodate a broader range of head sizes, appealing to diverse customer bases. For B2B buyers, this adaptability can enhance product offerings and improve market reach.

What Are Common Trade Terms Used in the Roller Helmet Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are several common terms that every buyer should know.

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of roller helmets, this might refer to manufacturers who provide specific components, such as visors or liners, to helmet brands. Understanding OEM relationships can help buyers source quality components at competitive prices.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell in a single order. This term is critical for B2B buyers as it impacts inventory management and cost-efficiency. Buyers should negotiate MOQs that align with their sales forecasts to avoid overstocking or stockouts.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other terms for specific products. This term is vital for buyers looking to compare multiple suppliers and negotiate the best possible deal. A well-structured RFQ can streamline the procurement process and enhance supplier relationships.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. They cover aspects such as shipping, insurance, and delivery terms. For B2B buyers, understanding Incoterms is essential for managing logistics and minimizing risks in international trade.

Illustrative image related to roller helmet with full face shield

5. Lead Time

Lead time refers to the time taken from placing an order until the product is delivered. This term is significant for B2B buyers who need to plan their inventory and meet customer demands promptly. Clear communication regarding lead times can enhance supply chain efficiency and customer satisfaction.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing roller helmets with full face shields, ultimately leading to better product offerings and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the roller helmet with full face shield Sector

What Are the Current Market Dynamics and Key Trends in the Roller Helmet with Full Face Shield Sector?

The roller helmet with full face shield sector is witnessing significant growth driven by increasing participation in roller sports and heightened awareness of safety standards. Globally, the demand for helmets that provide both comfort and protection is on the rise, influenced by regulations and consumer preferences for high-quality, certified products. Countries in Africa, South America, the Middle East, and Europe are experiencing a surge in roller sports popularity, which is fostering a competitive market landscape.

Emerging B2B technology trends include the integration of advanced materials and smart technologies into helmet designs. For instance, manufacturers are utilizing lighter, impact-resistant materials that enhance safety without compromising comfort. Additionally, features such as anti-fog visors and customizable fit systems are becoming standard, catering to the needs of diverse user demographics. B2B buyers are increasingly focused on suppliers that can provide innovative designs that meet international safety certifications, which are essential for market entry in various regions.

Moreover, the rise of e-commerce platforms is reshaping sourcing dynamics, enabling international buyers to access a broader range of products and manufacturers. This accessibility encourages competitive pricing and fosters a more transparent supply chain, which is particularly beneficial for buyers in emerging markets like Nigeria and Saudi Arabia.

Illustrative image related to roller helmet with full face shield

How Is Sustainability and Ethical Sourcing Impacting the Roller Helmet Market?

Sustainability and ethical sourcing are becoming paramount in the roller helmet with full face shield sector. As environmental concerns grow, B2B buyers are prioritizing suppliers that adopt sustainable practices in their manufacturing processes. The environmental impact of materials used in helmet production is under scrutiny, leading to a shift towards eco-friendly alternatives such as recycled plastics and bio-based materials.

Certifications such as the Global Recycled Standard (GRS) and the Forest Stewardship Council (FSC) are gaining importance, as they assure buyers of a product’s environmental credentials. Furthermore, ethical supply chains that emphasize fair labor practices and transparency are increasingly influencing purchasing decisions. Buyers from regions with strict regulatory frameworks are particularly inclined to partner with manufacturers who can demonstrate compliance with these standards.

Incorporating sustainability into product design not only addresses regulatory requirements but also resonates with a growing consumer base that values eco-conscious brands. By aligning with sustainable practices, B2B buyers can enhance their brand reputation and meet the demands of environmentally aware customers.

How Has the Roller Helmet with Full Face Shield Evolved Over Time?

The evolution of the roller helmet with full face shield reflects broader trends in safety equipment innovation. Initially, helmets were primarily designed for basic head protection, often compromising comfort and style. However, as roller sports gained popularity and awareness of safety increased, manufacturers began to focus on producing helmets that combine functionality with aesthetic appeal.

The introduction of full face shields marked a significant advancement, providing additional protection for the face without obstructing vision. This feature became particularly popular in contact sports and roller derby, where risks of facial injuries are prevalent. Over the years, improvements in materials science have led to the development of lighter and more durable helmets, enhancing user experience.

Today, the roller helmet with full face shield is not only a safety device but also a fashion statement, with various designs and colors catering to diverse consumer preferences. This evolution has established a robust market that continues to grow, driven by innovation and an unwavering commitment to safety.

Frequently Asked Questions (FAQs) for B2B Buyers of roller helmet with full face shield

-

How do I choose the right roller helmet with a full face shield for my business?

Selecting the appropriate roller helmet with a full face shield involves assessing your target market’s needs, safety standards, and style preferences. Consider certifications such as CPSC and ASTM for safety compliance. Evaluate the materials used for durability and comfort, such as lightweight polycarbonate for the visor and moisture-wicking liners. Additionally, consider the aesthetic appeal and customization options to align with your brand. Request samples from suppliers to ensure the product meets your quality expectations before placing a larger order. -

What are the key safety certifications for roller helmets with full face shields?

Roller helmets with full face shields should comply with recognized safety certifications to ensure they provide adequate protection. Look for helmets certified under the U.S. Consumer Product Safety Commission (CPSC) standards and the ASTM F-1492, which is specifically for skate safety. For international markets, check for CE certification in Europe, which verifies that the product meets health, safety, and environmental protection standards. Ensuring these certifications will enhance your product’s credibility and appeal to safety-conscious buyers. -

What is the minimum order quantity (MOQ) for roller helmets with full face shields?

The minimum order quantity (MOQ) for roller helmets can vary significantly based on the manufacturer and the complexity of customization. Typically, MOQs range from 100 to 500 units for standard models. For customized designs, MOQs might be higher due to additional production costs and setup requirements. It’s essential to discuss your specific needs with potential suppliers to negotiate favorable terms that align with your business goals while ensuring sufficient stock for your market. -

What customization options are available for roller helmets with full face shields?

Customization options for roller helmets often include color choices, logo placements, and unique designs tailored to your brand identity. Many manufacturers offer the ability to modify helmet features such as padding, strap designs, and visor types (e.g., tinted, clear, anti-fog). Some suppliers may even allow you to create entirely bespoke models. Be sure to confirm the available options and any associated costs or MOQs for customized orders during your discussions with suppliers. -

How do I vet suppliers for roller helmets with full face shields?

Vetting suppliers is crucial for ensuring product quality and reliability. Start by researching potential suppliers’ reputations through online reviews and industry references. Request samples to assess the quality of their helmets and ensure compliance with safety standards. Additionally, verify their production capabilities, lead times, and quality assurance processes. It’s beneficial to establish clear communication channels and inquire about their experience in exporting to your target markets, particularly in regions like Africa, South America, the Middle East, and Europe. -

What payment terms should I expect when sourcing roller helmets internationally?

Payment terms can vary widely among suppliers, often ranging from 30% upfront deposit and 70% upon shipment to full payment in advance. Many suppliers may offer payment via bank transfers, letters of credit, or platforms like PayPal for smaller orders. It’s important to negotiate terms that protect your investment while maintaining good relationships with suppliers. Be sure to clarify any additional costs such as shipping, customs duties, and taxes that may apply based on your location and the supplier’s terms. -

What are the logistics considerations when importing roller helmets with full face shields?

When importing roller helmets, logistics considerations include shipping methods, customs clearance, and delivery timelines. Choose between air freight for quicker delivery or sea freight for cost-effectiveness, depending on your urgency and budget. Ensure you understand the customs regulations of your destination country to avoid delays or additional fees. Partnering with a reliable freight forwarder can help streamline the process, ensuring that your helmets arrive safely and on time while navigating complex import regulations. -

How can I ensure quality assurance for roller helmets with full face shields?

Implementing a robust quality assurance (QA) process is essential for maintaining product standards. This includes setting clear specifications with your suppliers and requesting regular updates during production. Conduct pre-shipment inspections to verify that the helmets meet safety certifications and quality benchmarks. Establishing a return policy for defective products can also safeguard your business. Consider third-party QA services for additional oversight, especially if sourcing from international suppliers, to ensure compliance with both safety and quality standards.

Top 1 Roller Helmet With Full Face Shield Manufacturers & Suppliers List

1. Eastinear – Children’s Bicycle Helmet

Domain: theraleighbeergarden.com

Registered: 2013 (12 years)

Introduction: This company, Eastinear – Children’s Bicycle Helmet, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for roller helmet with full face shield

In today’s competitive market, the strategic sourcing of roller helmets with full face shields is essential for businesses aiming to enhance safety and meet regulatory standards. By aligning with reliable suppliers that offer certified products, companies can ensure compliance with safety regulations such as CPSC and ASTM standards, critical for building trust with customers. The variety in design, fit, and functionality—from lightweight options to those with advanced anti-fog visors—provides buyers the flexibility to cater to diverse consumer needs.

International buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize establishing strong supplier relationships that not only focus on quality but also on innovation. As the demand for protective gear continues to grow, particularly in sports and recreational activities, leveraging strategic sourcing can yield significant cost savings and improved product offerings.

Illustrative image related to roller helmet with full face shield

Looking forward, businesses must stay ahead of market trends and consumer preferences by continuously evaluating their sourcing strategies. Embrace this opportunity to enhance your product line and strengthen your market presence. Connect with top-tier manufacturers today to secure the best roller helmets with full face shields, ensuring safety and satisfaction for your customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.