Unlocking Value: A Strategic Analysis of the Roller Conveyor Components Market

Introduction: Navigating the Global Market for roller conveyor components

In today’s fast-paced manufacturing and logistics sectors, sourcing roller conveyor components can present a significant challenge for international B2B buyers. As industries increasingly demand efficient material handling solutions, the complexity of selecting the right components—such as rollers, frames, and drive systems—grows. Buyers from regions like Africa, South America, the Middle East, and Europe, including countries like Vietnam and Germany, often face hurdles in ensuring quality, compliance with local standards, and cost-effectiveness. This guide is crafted to equip you with the insights needed to navigate the global market for roller conveyor components effectively.

Within this comprehensive resource, we delve into various types of roller conveyor components, their specific applications across different sectors, and strategies for vetting suppliers. Furthermore, we address crucial considerations such as pricing trends, quality assurance, and logistical challenges associated with international procurement. By providing detailed information and actionable insights, this guide empowers you to make informed purchasing decisions that align with your operational goals. Whether you are looking to enhance productivity, reduce costs, or improve supply chain reliability, understanding the global landscape of roller conveyor components is essential. With the right knowledge, you can confidently select components that will optimize your operations and drive long-term success.

Understanding roller conveyor components Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gravity Roller Conveyor | Uses gravity for product movement; minimal power required | Warehousing, packaging, distribution | Pros: Low maintenance, cost-effective Cons: Limited to downhill or flat applications |

| Powered Roller Conveyor | Utilizes motors for movement; can handle heavier loads | Manufacturing, assembly lines | Pros: Versatile, suitable for various load types Cons: Higher energy consumption, more complex installation |

| Accumulation Roller Conveyor | Allows products to accumulate without stopping the line | Order fulfillment, sorting systems | Pros: Increases efficiency, reduces product damage Cons: Requires more space, can be costly |

| Flexible Roller Conveyor | Adaptable design for various layouts and spaces | Temporary setups, event logistics | Pros: Highly adaptable, easy to reconfigure Cons: May have lower load capacity compared to fixed systems |

| Chain-Driven Roller Conveyor | Uses chains to drive rollers; ideal for heavy loads | Heavy-duty manufacturing, automotive | Pros: Strong and durable, handles heavy weights Cons: More expensive, requires regular maintenance |

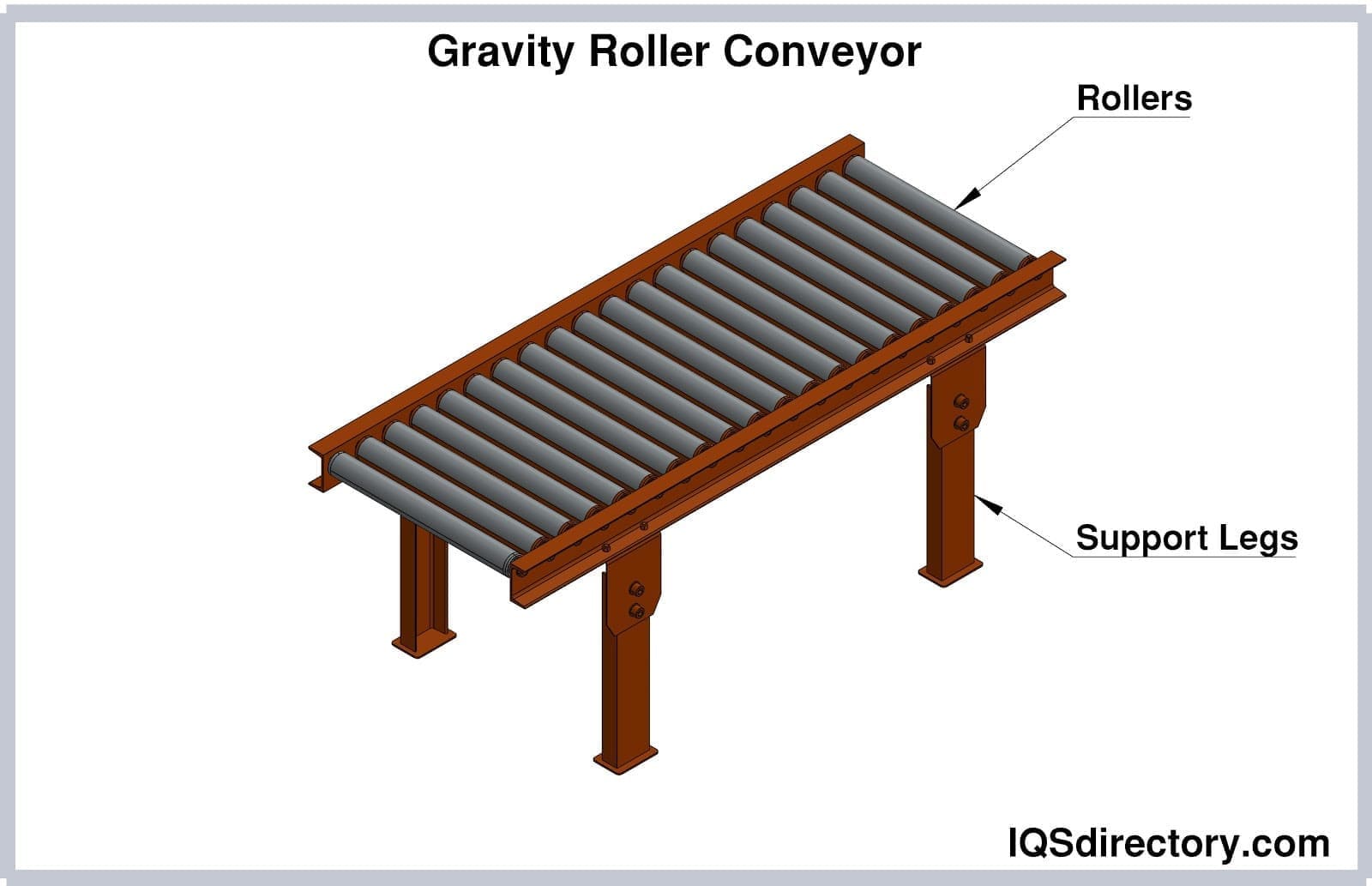

What Are the Key Characteristics of Gravity Roller Conveyors?

Gravity roller conveyors are designed to move products using gravitational force, making them a cost-effective solution for transporting items down inclines or on flat surfaces. They consist of a series of rollers mounted on a frame, allowing items to roll freely. This type is particularly suitable for warehousing and distribution centers where low maintenance and operational costs are essential. Buyers should consider the weight capacity and the incline of the conveyor when making purchasing decisions, as these factors affect efficiency.

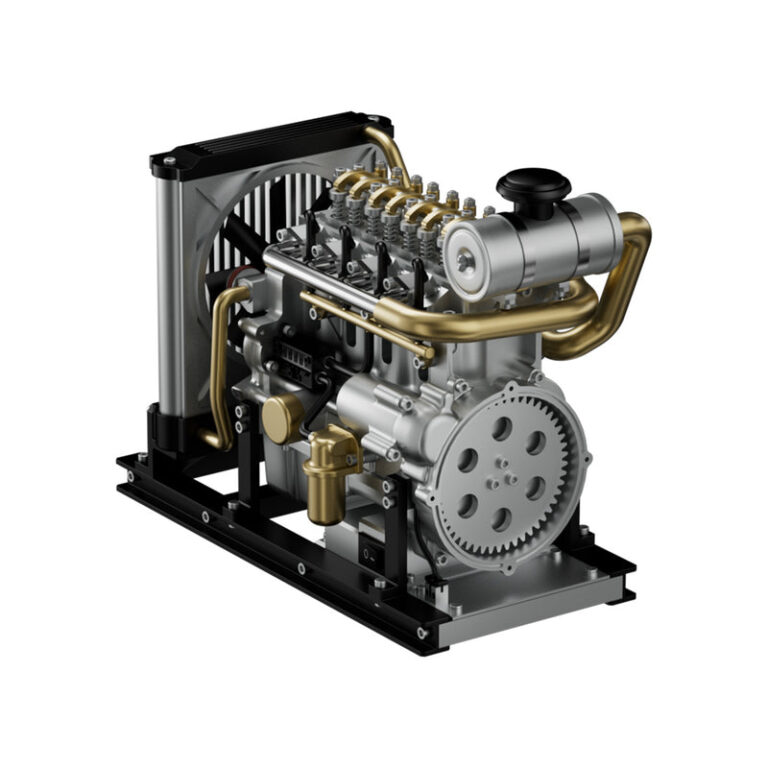

How Do Powered Roller Conveyors Enhance Operational Efficiency?

Powered roller conveyors are equipped with electric motors that drive the rollers, making them ideal for moving heavier loads and more complex operations. They are commonly used in manufacturing and assembly lines where precise control over product movement is necessary. When purchasing powered conveyors, B2B buyers should evaluate the motor specifications, energy consumption, and integration with existing systems to ensure compatibility and efficiency.

What Advantages Do Accumulation Roller Conveyors Offer?

Accumulation roller conveyors are designed to allow products to accumulate without halting the flow of the conveyor system. This feature is particularly beneficial in order fulfillment and sorting systems, where maintaining a steady flow of goods is crucial. Buyers should assess the space requirements and potential costs associated with installation and operation, as these systems may require more room and investment compared to standard conveyors.

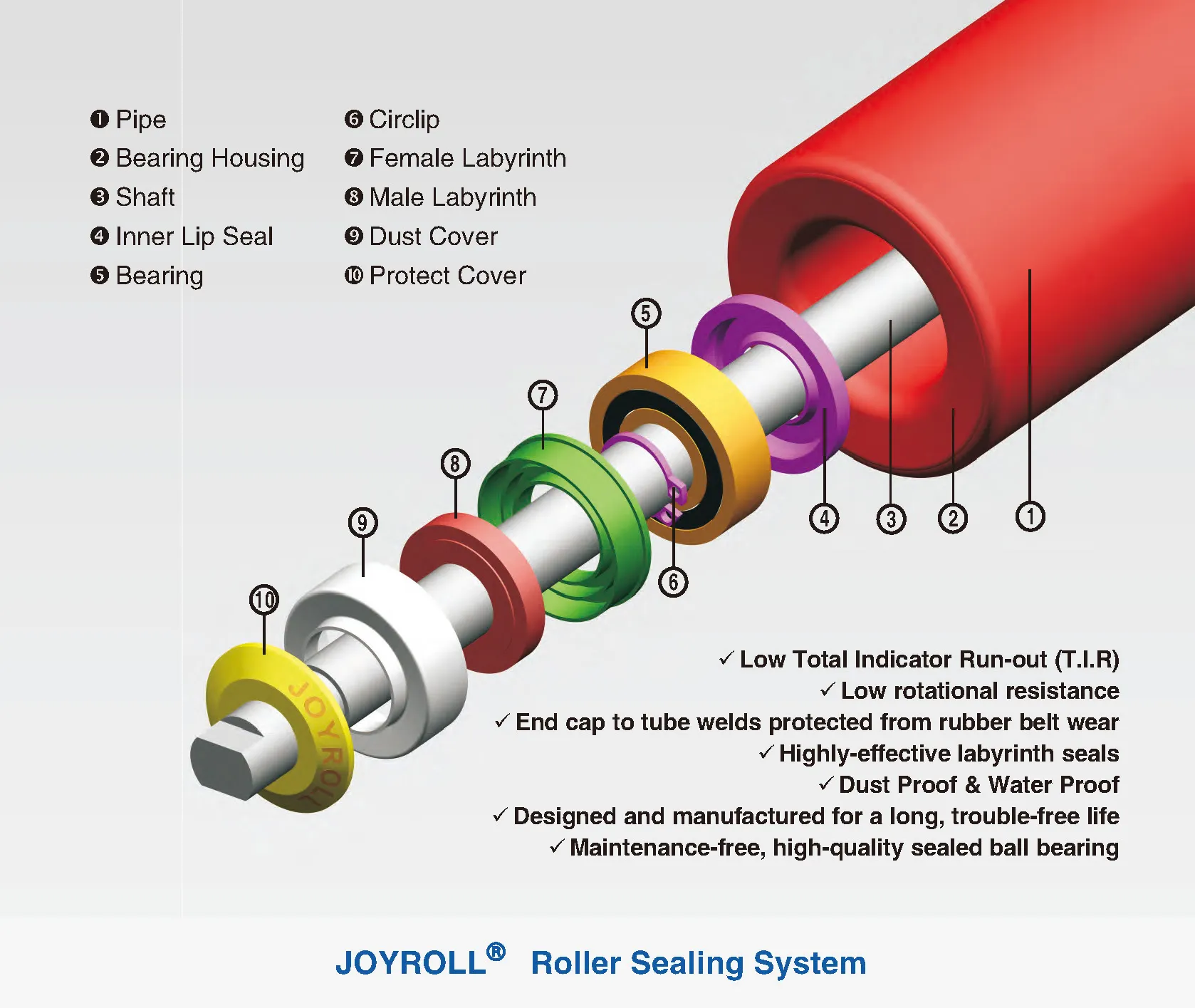

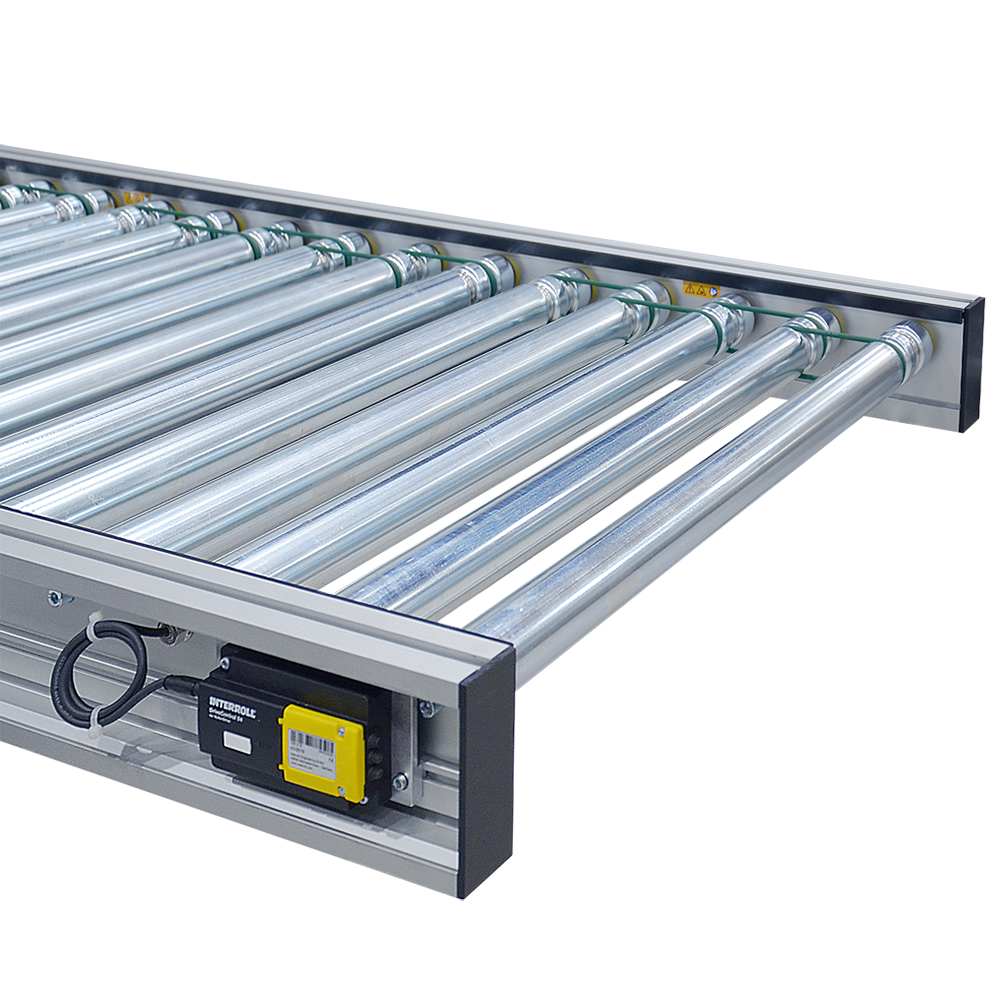

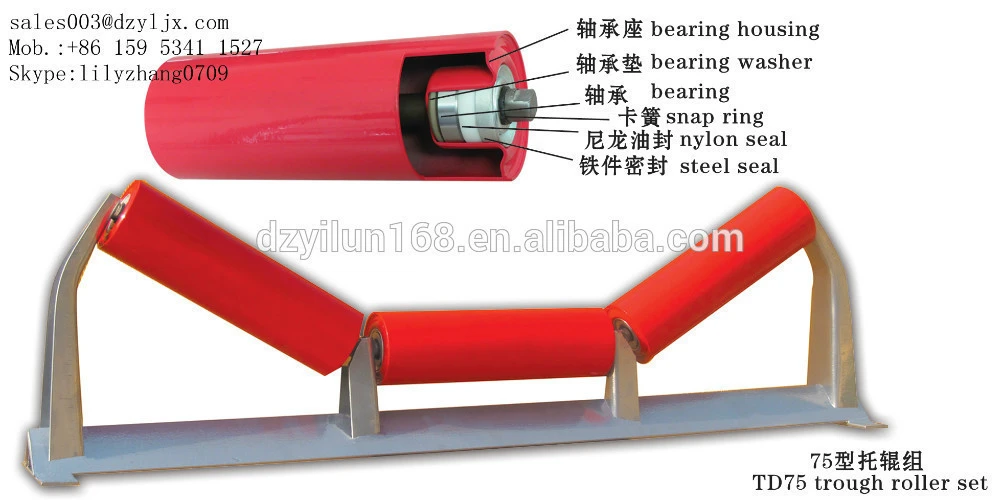

Illustrative image related to roller conveyor components

Why Choose Flexible Roller Conveyors for Dynamic Environments?

Flexible roller conveyors provide adaptability for various layouts and can be easily reconfigured to meet changing operational needs. They are ideal for temporary setups or logistics at events. However, their load capacity may be lower than that of fixed systems. B2B buyers should weigh the benefits of flexibility against the potential limitations in terms of load handling when considering this option.

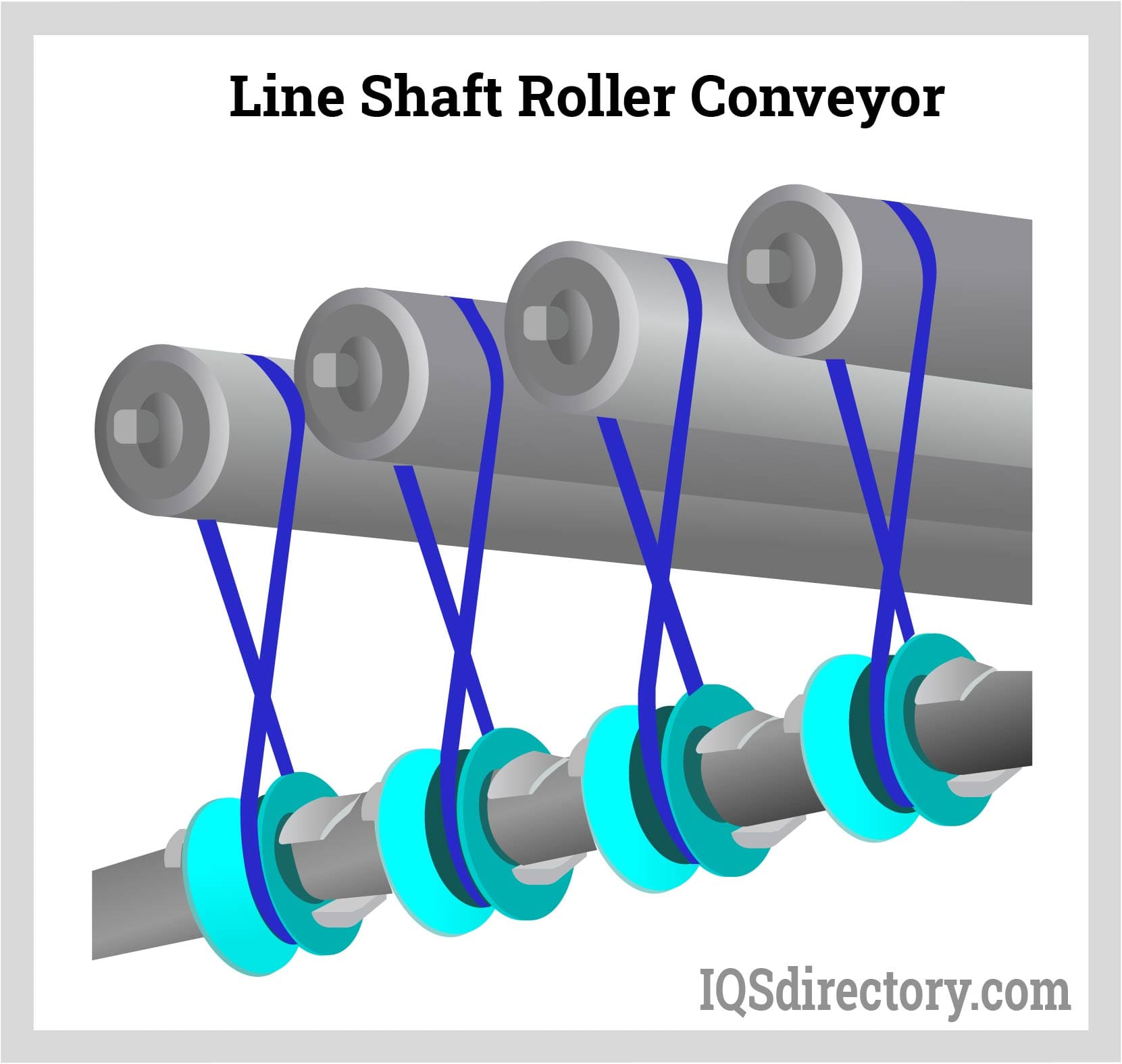

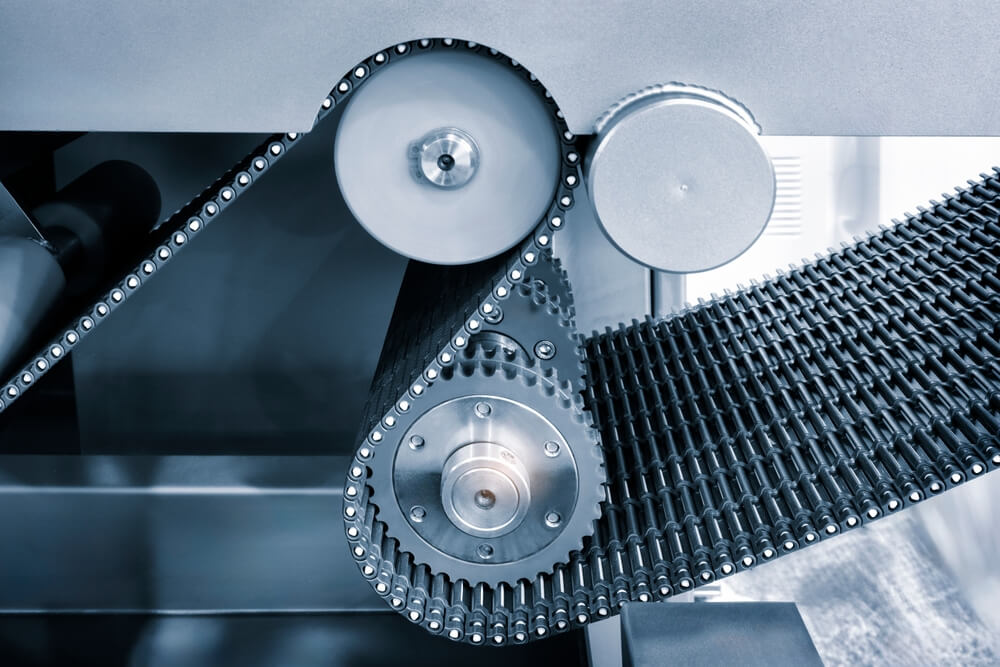

How Do Chain-Driven Roller Conveyors Perform Under Heavy Loads?

Chain-driven roller conveyors are designed for heavy-duty applications, utilizing chains to drive the rollers for enhanced durability. They are often used in automotive and heavy manufacturing sectors. While they provide robust performance for heavy loads, buyers should consider the higher initial costs and maintenance requirements associated with chain-driven systems, ensuring they align with their operational demands.

Key Industrial Applications of roller conveyor components

| Industry/Sector | Specific Application of roller conveyor components | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Assembly line automation | Increased efficiency and reduced labor costs | Durability, load capacity, and compatibility with existing systems |

| Food and Beverage | Packaging and sorting of products | Enhanced hygiene standards and streamlined workflows | Compliance with food safety regulations and material specifications |

| Warehousing and Distribution | Order picking and sorting | Improved inventory management and faster order fulfillment | Customization options and ease of integration with warehouse management systems |

| Automotive | Parts handling and transportation | Reduced downtime and enhanced production speed | Precision engineering and resistance to harsh environments |

| Pharmaceuticals | Automated medication dispensing | Increased accuracy and reduced risk of human error | Compliance with industry standards and reliability under strict regulations |

How Are Roller Conveyor Components Used in Manufacturing?

In the manufacturing sector, roller conveyor components are integral to assembly line automation. They facilitate the smooth movement of materials and products between different stages of production, thereby increasing operational efficiency. This application addresses common challenges such as bottlenecks and labor-intensive processes, allowing businesses to optimize their workforce and reduce overhead costs. Buyers should prioritize sourcing durable components that can handle specific load capacities and are compatible with existing machinery to ensure seamless integration.

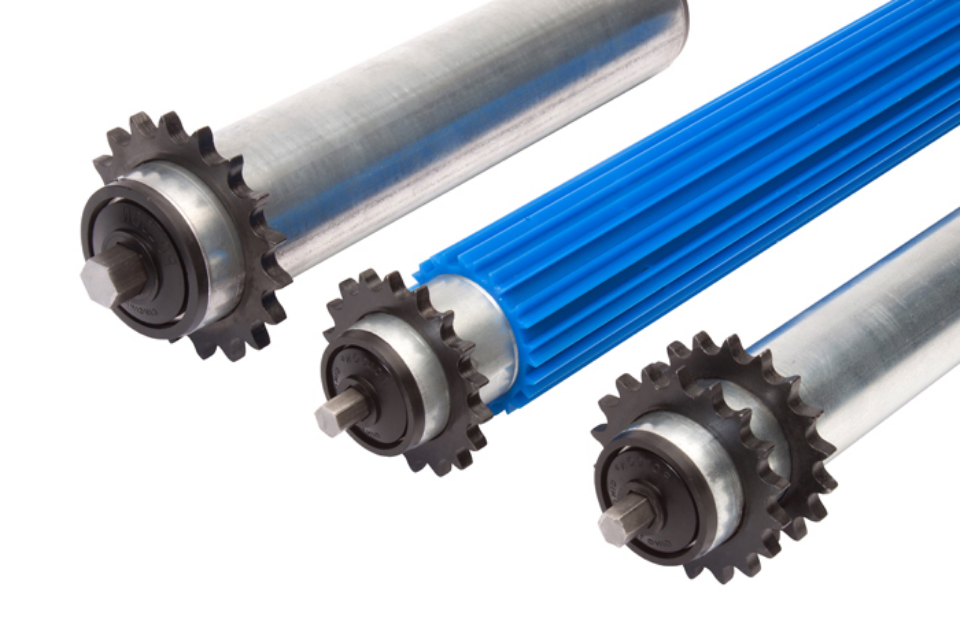

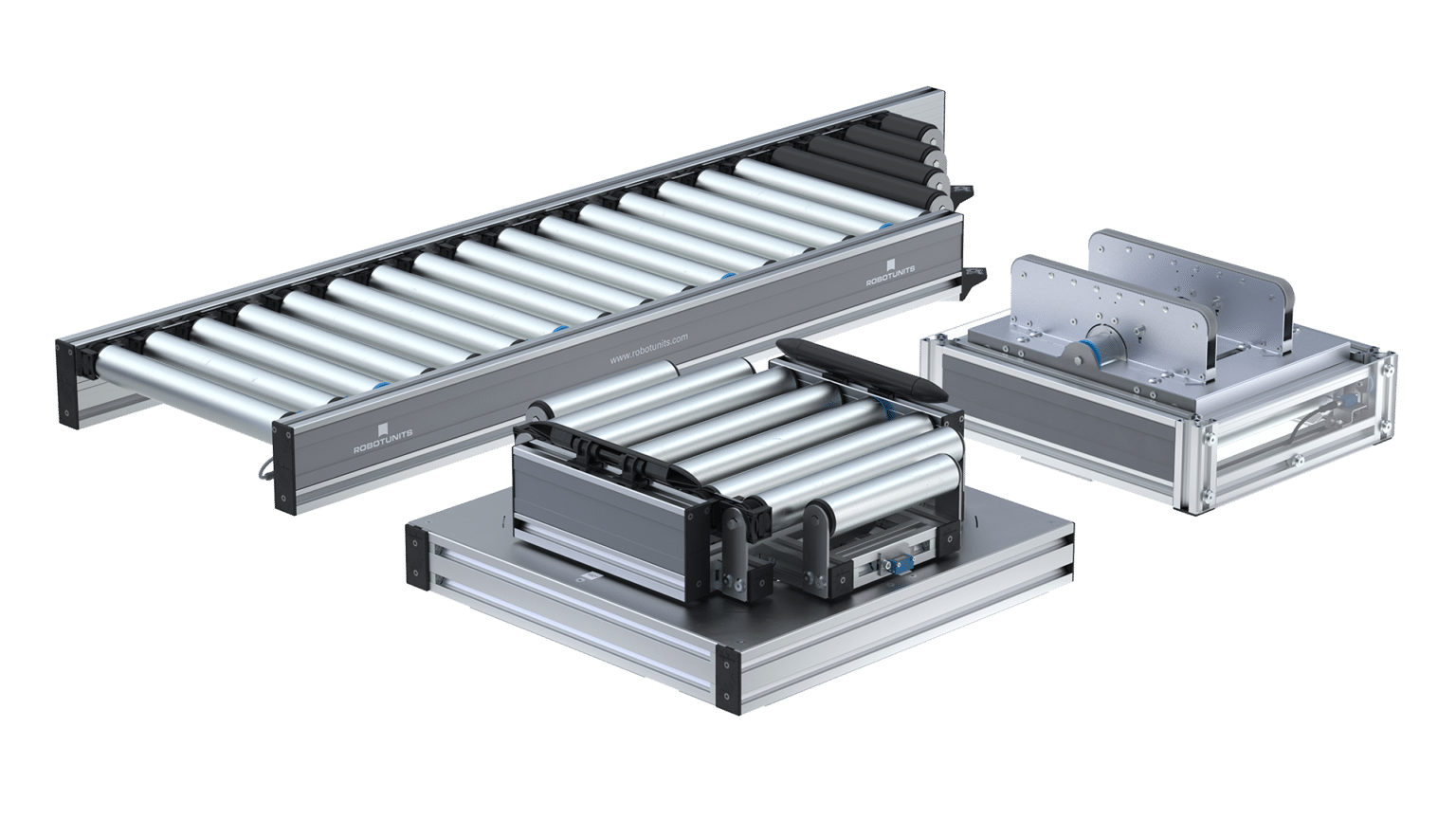

Illustrative image related to roller conveyor components

What Role Do Roller Conveyor Components Play in the Food and Beverage Industry?

In the food and beverage industry, roller conveyor components are essential for the packaging and sorting of products. They help maintain high hygiene standards by allowing for easy cleaning and quick changeovers. This application is crucial for businesses aiming to streamline workflows while adhering to strict food safety regulations. International buyers should consider sourcing materials that meet safety standards and are resistant to corrosion, ensuring longevity and reliability in high-demand environments.

How Do Roller Conveyor Components Enhance Warehousing and Distribution?

Within warehousing and distribution, roller conveyor components are used for order picking and sorting. They facilitate the efficient movement of goods, improving inventory management and enabling faster order fulfillment. This application is vital for businesses looking to reduce lead times and enhance customer satisfaction. Buyers should focus on customization options that cater to their specific operational needs and ensure compatibility with existing warehouse management systems for optimal performance.

In What Ways Are Roller Conveyor Components Utilized in the Automotive Sector?

In the automotive industry, roller conveyor components are critical for parts handling and transportation throughout the manufacturing process. They significantly reduce downtime and enhance production speed by ensuring that parts are delivered precisely where needed without manual intervention. Buyers in this sector should prioritize sourcing precision-engineered components that can withstand harsh environments, ensuring reliable performance and durability throughout the production cycle.

How Are Roller Conveyor Components Essential in the Pharmaceutical Industry?

In the pharmaceutical sector, roller conveyor components are utilized for automated medication dispensing, which enhances accuracy and minimizes the risk of human error. This application is particularly important given the stringent regulatory requirements in this industry. Buyers must ensure that the components they source comply with industry standards and are reliable under strict operational conditions to maintain the integrity of pharmaceutical products.

3 Common User Pain Points for ‘roller conveyor components’ & Their Solutions

Scenario 1: Frequent Downtime Due to Component Failures

The Problem: In many manufacturing and logistics operations, roller conveyor systems are integral to the workflow. However, B2B buyers often face significant challenges when components fail unexpectedly, leading to costly downtime. This can be particularly acute in industries like food processing or automotive, where time is money, and delays can disrupt entire supply chains. Buyers may find that sourcing reliable components is difficult, especially if they are not familiar with the specifications or quality standards required for their specific application.

The Solution: To mitigate the risk of component failures, it is crucial to invest in high-quality roller conveyor components that meet industry standards. Conduct thorough research into suppliers that have a proven track record in your sector, focusing on those who provide detailed specifications, certifications, and performance data. Additionally, implementing a preventive maintenance schedule can help identify potential issues before they lead to failure. This includes regular inspections and timely replacements of wear-prone components. Collaborating with suppliers to establish a reliable inventory of critical spare parts can also ensure that replacements are readily available, minimizing downtime when issues do arise.

Scenario 2: Incompatibility with Existing Systems

The Problem: A common issue faced by B2B buyers is the incompatibility of new roller conveyor components with existing systems. This can occur when upgrading equipment or integrating new technology into established workflows. Buyers may find themselves frustrated when they realize that the new components do not align with the specifications of their current conveyor systems, leading to increased installation costs and extended project timelines.

The Solution: To avoid compatibility issues, it’s essential to conduct a comprehensive assessment of your existing systems before sourcing new components. Engage with engineers or technical experts to analyze the current setup and identify any specific requirements for new components. When selecting roller conveyor components, opt for suppliers that offer customizable solutions or modular components that can easily integrate into various systems. Additionally, request detailed technical documentation and installation support from suppliers to ensure a smooth integration process. This proactive approach not only streamlines installation but also enhances the longevity and performance of your conveyor systems.

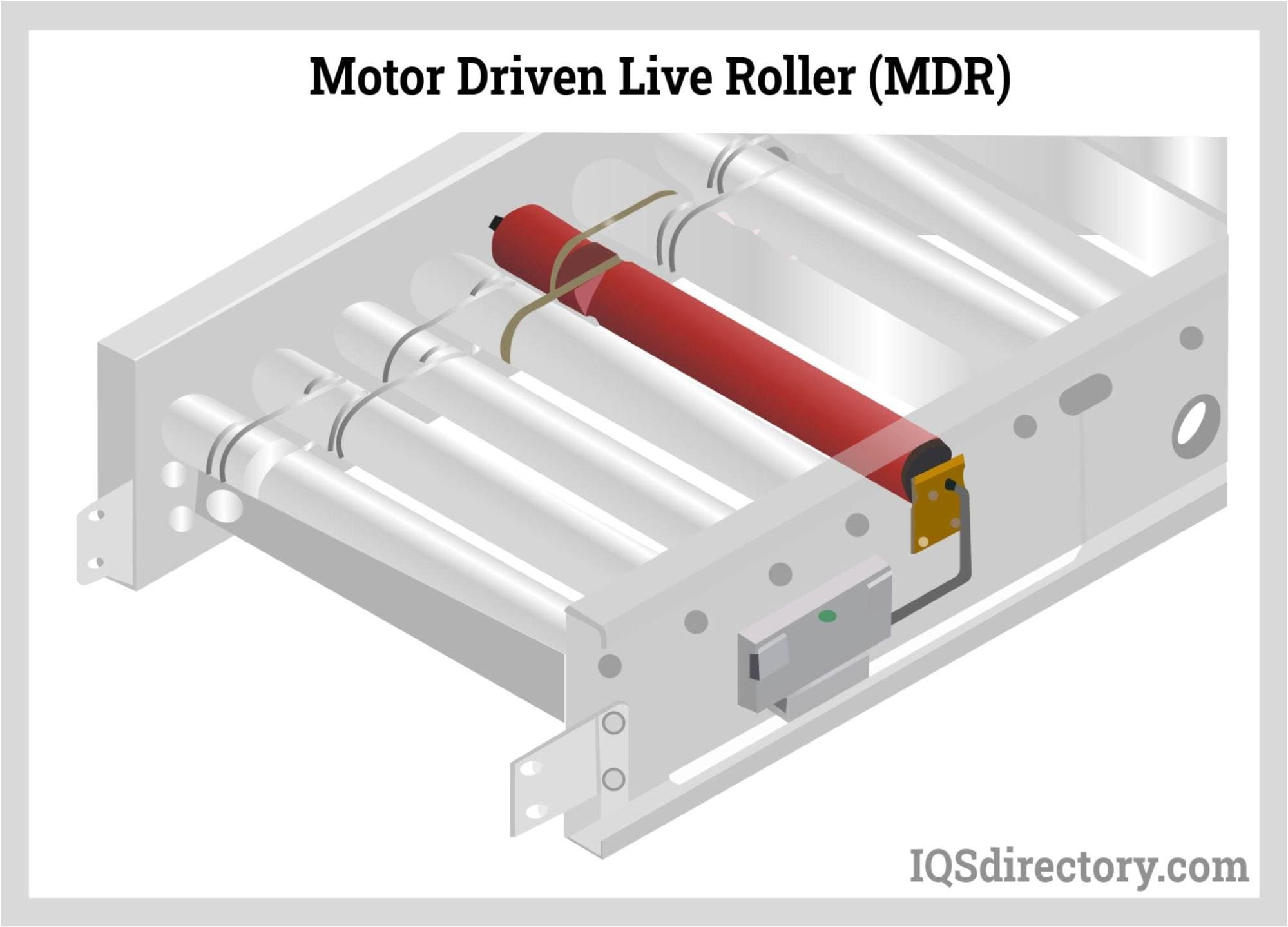

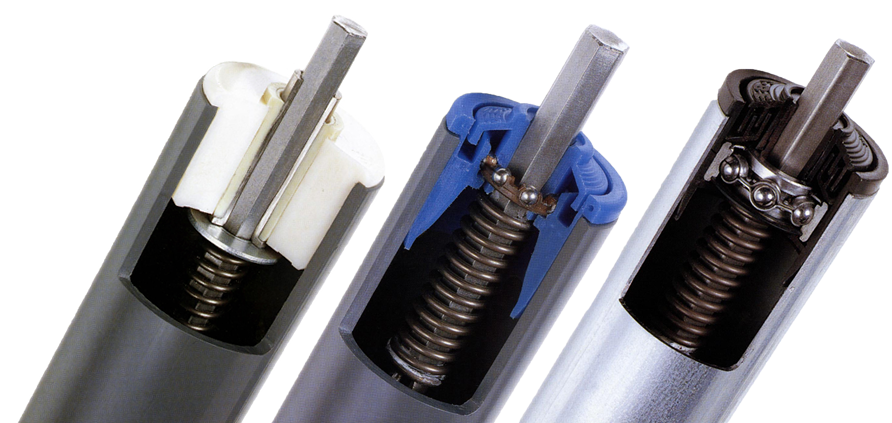

Illustrative image related to roller conveyor components

Scenario 3: High Operational Costs Due to Inefficient Components

The Problem: Many B2B buyers realize that the roller conveyor components they initially selected are not optimized for energy efficiency, leading to inflated operational costs. This is particularly relevant in regions where energy prices are rising, such as in parts of Europe and the Middle East. Inefficient components can lead to higher electricity bills and increased wear and tear on machinery, ultimately impacting profitability.

The Solution: To combat high operational costs, buyers should prioritize energy-efficient roller conveyor components designed with advanced materials and engineering. When sourcing components, look for features such as low-friction bearings, lightweight materials, and designs that minimize energy consumption. Conducting a life-cycle cost analysis can also provide insights into the long-term savings associated with energy-efficient components versus standard options. Additionally, consider working with suppliers who can offer guidance on optimizing conveyor layouts and operational practices to enhance overall system efficiency. By focusing on sustainable and efficient component choices, businesses can significantly reduce operational costs while maintaining productivity.

Strategic Material Selection Guide for roller conveyor components

When selecting materials for roller conveyor components, it is crucial to consider the specific properties, advantages, and limitations of each material in relation to the intended application. This analysis focuses on four common materials: steel, aluminum, plastic, and stainless steel. Each material has distinct characteristics that can significantly impact performance, durability, and cost-effectiveness.

What are the Key Properties of Steel for Roller Conveyor Components?

Steel is a widely used material for roller conveyor components due to its strength and durability. It typically has a high tensile strength, making it suitable for heavy loads and high-pressure applications. Steel can withstand extreme temperatures, although its performance may degrade under prolonged exposure to corrosive environments unless treated.

Pros & Cons: Steel is cost-effective and readily available, making it a popular choice. However, it is susceptible to rust and corrosion, which can lead to increased maintenance costs over time. The manufacturing complexity can also be higher, especially when precision machining is required for specific applications.

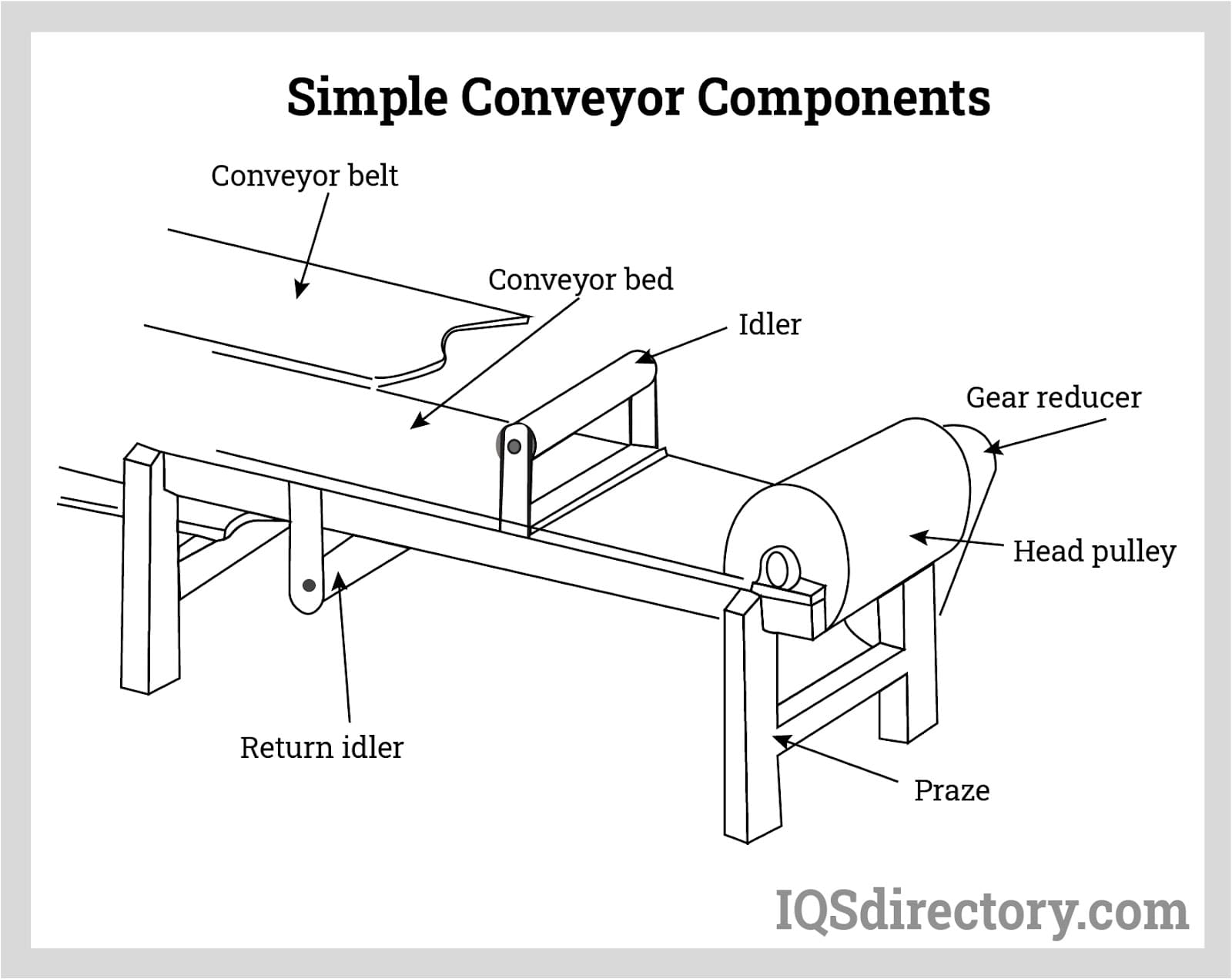

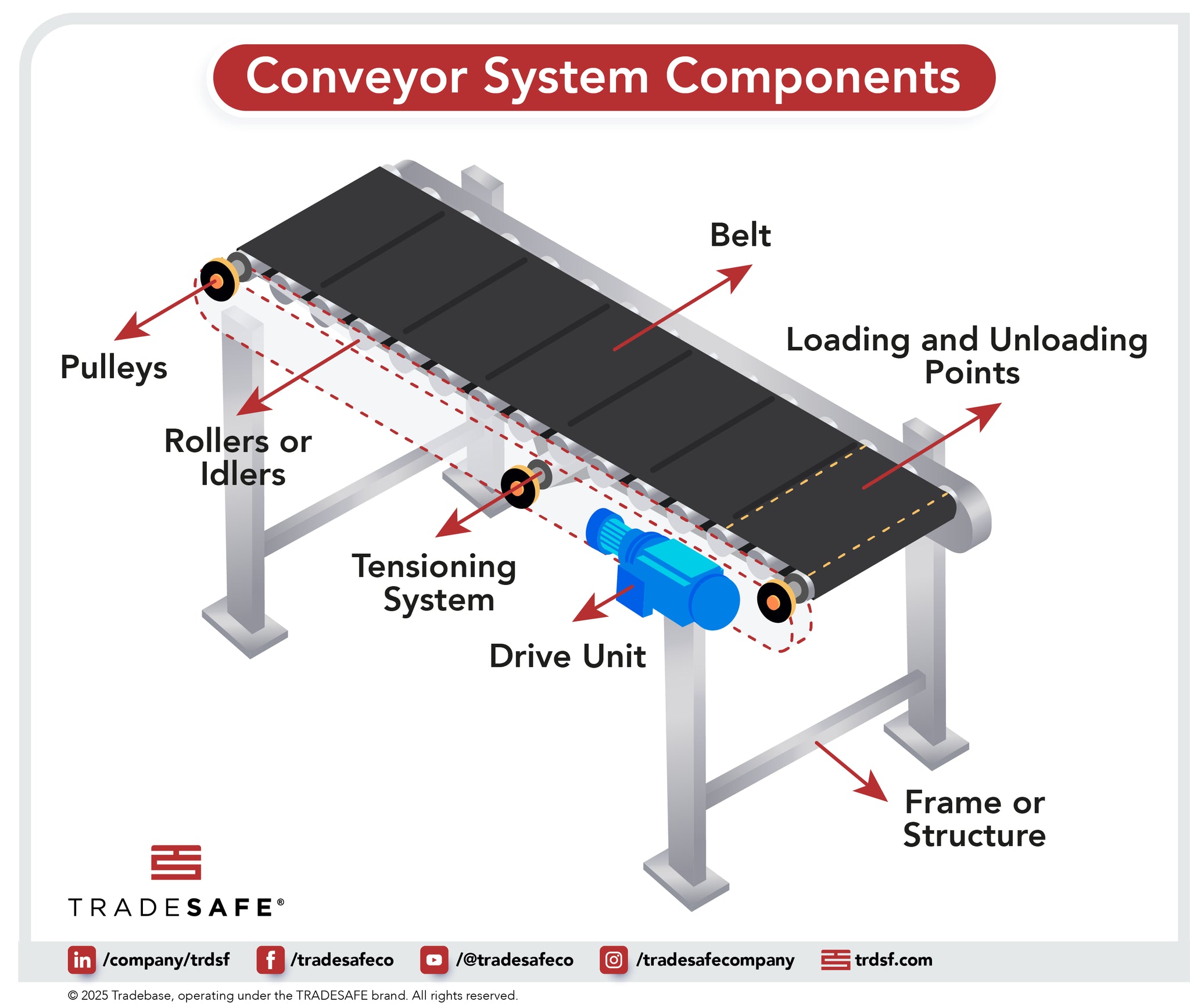

Illustrative image related to roller conveyor components

Impact on Application: Steel is compatible with a wide range of media, including heavy industrial goods. However, its weight may be a disadvantage in applications requiring lightweight components.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN. In regions like Europe and the Middle East, galvanized or coated steel options may be preferred to enhance corrosion resistance.

How Does Aluminum Compare for Roller Conveyor Components?

Aluminum is another popular choice for roller conveyor components due to its lightweight nature and resistance to corrosion. It has a lower density than steel, which makes it easier to handle and install. Aluminum can also withstand moderate temperatures and pressures.

Illustrative image related to roller conveyor components

Pros & Cons: The key advantage of aluminum is its excellent corrosion resistance, which reduces maintenance needs. However, it may not be as strong as steel, making it less suitable for very heavy loads. The cost of aluminum is generally higher than that of steel, which could impact budget-conscious projects.

Impact on Application: Aluminum is ideal for applications where weight savings are critical, such as in packaging or food processing industries. Its compatibility with various media is generally favorable.

Considerations for International Buyers: Buyers should be aware of the different grades of aluminum and their corresponding properties. Compliance with standards such as JIS and ASTM is essential, particularly in regions like South America and Europe where quality assurance is critical.

What are the Advantages of Using Plastic in Roller Conveyor Components?

Plastic materials, such as polycarbonate or polypropylene, are increasingly used in roller conveyor systems due to their lightweight and corrosion-resistant properties. They are often used in applications where hygiene is paramount, such as food and pharmaceutical industries.

Pros & Cons: The main advantage of plastic is its resistance to chemicals and moisture, making it suitable for a variety of environments. However, plastics may not offer the same load-bearing capacity as metals, which limits their use in heavy-duty applications. Additionally, the manufacturing process can be less complex, but the initial cost may still be moderate.

Illustrative image related to roller conveyor components

Impact on Application: Plastic rollers are ideal for transporting lightweight items or in environments where cleanliness is critical. They are not suitable for high-temperature applications.

Considerations for International Buyers: Buyers should verify compliance with food safety standards and regulations, particularly in the food processing sector. Understanding the specific type of plastic and its properties is essential for ensuring compatibility with various media.

Why is Stainless Steel a Preferred Material for Certain Applications?

Stainless steel is renowned for its exceptional corrosion resistance and strength, making it a preferred material for roller conveyor components in harsh environments. It can withstand high temperatures and pressures, making it suitable for heavy-duty applications.

Pros & Cons: The primary advantage of stainless steel is its durability and longevity, reducing the need for frequent replacements. However, it is typically more expensive than other materials like carbon steel and aluminum. The manufacturing complexity can also be higher, requiring specialized processes.

Impact on Application: Stainless steel is ideal for applications in food processing, pharmaceuticals, and chemical industries where hygiene and corrosion resistance are critical.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial, especially for applications in Europe and the Middle East. Buyers should also consider the grade of stainless steel, as different grades offer varying levels of corrosion resistance.

Summary Table of Material Selection for Roller Conveyor Components

| Material | Typical Use Case for roller conveyor components | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy industrial applications | High strength and load-bearing capacity | Susceptible to corrosion | Medium |

| Aluminum | Lightweight and moderate load applications | Excellent corrosion resistance | Lower strength compared to steel | High |

| Plastic | Food processing and lightweight items | Chemical resistance and hygiene | Limited load-bearing capacity | Medium |

| Stainless Steel | Harsh environments and hygiene-critical sectors | Exceptional durability and corrosion resistance | Higher cost and manufacturing complexity | High |

This guide provides a comprehensive overview of material selection for roller conveyor components, enabling international B2B buyers to make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for roller conveyor components

What Are the Main Stages of Manufacturing Roller Conveyor Components?

The manufacturing process of roller conveyor components is a multi-stage operation that ensures the production of high-quality, durable products suitable for various industrial applications. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Illustrative image related to roller conveyor components

How is Material Prepared for Roller Conveyor Manufacturing?

The manufacturing process begins with material preparation, which involves selecting the appropriate raw materials based on the desired properties of the final product. Common materials include steel, aluminum, and plastic, each chosen for its strength, weight, and corrosion resistance.

After material selection, the raw materials undergo cutting and shaping processes. Techniques such as laser cutting and CNC machining are employed to create precise components that meet specifications. Quality during this stage is critical, as any discrepancies can lead to issues in later stages.

What Forming Techniques Are Used in Roller Conveyor Component Manufacturing?

Once the materials are prepared, the next stage is forming. This involves shaping the components into their final forms through processes like stamping, extrusion, or injection molding.

For example, steel rollers may be formed through stamping or rolling, while plastic components are often produced via injection molding. These techniques not only ensure dimensional accuracy but also enhance the mechanical properties of the materials, making them suitable for heavy-duty applications.

How Are Roller Conveyor Components Assembled?

The assembly stage involves combining various components, such as rollers, frames, and bearings, into a complete conveyor system. This process can vary significantly based on the complexity of the system being produced.

Illustrative image related to roller conveyor components

Automated assembly lines are increasingly common, allowing for higher efficiency and consistency. Manual assembly is also utilized, particularly for custom solutions, where skilled technicians ensure that each component fits perfectly and meets quality standards.

What Finishing Processes Are Essential for Roller Conveyor Components?

Finishing processes such as painting, powder coating, or galvanization are crucial for enhancing the durability and aesthetics of roller conveyor components. These processes protect against corrosion and wear, extending the lifespan of the equipment.

Quality control during this stage is vital, as improper finishing can lead to premature failure. Buyers should inquire about the specific finishing techniques employed by suppliers and any relevant certifications that ensure adherence to international standards.

Illustrative image related to roller conveyor components

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is a critical aspect of the manufacturing process for roller conveyor components. International standards such as ISO 9001 provide a framework for quality management systems, ensuring that suppliers consistently meet customer requirements and regulatory standards.

How Do Industry-Specific Certifications Impact Quality Assurance?

In addition to ISO certifications, many suppliers may also hold industry-specific certifications like CE marking for compliance with European safety standards or API certification for products used in the oil and gas sector. These certifications indicate that the products meet stringent safety and quality requirements, which is particularly important for B2B buyers operating in regulated industries.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integral to ensuring that roller conveyor components meet the required specifications throughout the manufacturing process.

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials upon arrival. Suppliers should have robust procedures in place to inspect materials for compliance with specifications, including dimensional checks and material properties.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC involves continuous monitoring of operations to detect any deviations from quality standards. This may include regular inspections and tests at various production stages.

-

Final Quality Control (FQC): The FQC stage involves a thorough inspection of the finished product before it leaves the factory. This includes functional testing, dimensional verification, and visual inspections to ensure that all components meet the established quality criteria.

What Common Testing Methods Are Used in Quality Assurance?

B2B buyers should be aware of common testing methods employed during the QC process, which may include:

- Dimensional Testing: Ensures that components meet specified measurements and tolerances.

- Load Testing: Assesses the strength and durability of rollers under operational conditions.

- Corrosion Resistance Testing: Evaluates the effectiveness of finishing processes in protecting against environmental factors.

- Functional Testing: Confirms that assembled conveyor systems operate as intended.

These tests provide assurance that the components will perform effectively in real-world applications.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control practices is essential for B2B buyers to mitigate risks associated with product failures. Here are several strategies:

-

Supplier Audits: Conducting regular audits of potential suppliers can help assess their quality management systems and adherence to international standards. This may involve on-site visits to evaluate manufacturing processes and quality control measures.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QC processes and the outcomes of various tests conducted on their products.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s quality control practices. These inspections can validate compliance with international standards and provide additional assurance of product quality.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances related to QC and certifications.

For example, different regions may have varying regulatory requirements and standards, impacting how products are certified and tested. Buyers should ensure that suppliers are compliant with both local regulations and international standards relevant to their industry.

Illustrative image related to roller conveyor components

Additionally, understanding the nuances of trade agreements and tariffs can affect procurement strategies. Buyers should consider suppliers who can navigate these complexities and provide documentation that facilitates smoother importation processes.

In summary, a comprehensive understanding of the manufacturing processes and quality assurance practices for roller conveyor components is essential for B2B buyers. By focusing on the details of material preparation, forming, assembly, finishing, and quality control, buyers can make informed decisions and ensure that they are partnering with suppliers committed to delivering high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘roller conveyor components’

This guide serves as a practical checklist for B2B buyers looking to source roller conveyor components efficiently. With the global market expanding, it’s essential to streamline the procurement process to ensure quality, cost-effectiveness, and timely delivery. Follow these steps to navigate the complexities of sourcing roller conveyor components effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the components meet your operational needs. Consider factors such as load capacity, conveyor speed, material type, and environmental conditions. This clarity will help you communicate effectively with suppliers and avoid costly mistakes later.

Step 2: Research Market Trends and Standards

Understanding current market trends and industry standards will guide your sourcing decisions. Investigate the latest technologies in roller conveyor systems, such as energy efficiency and automation. Familiarize yourself with international standards, such as ISO or ANSI, to ensure compliance and compatibility with existing systems.

Step 3: Evaluate Potential Suppliers

Before making any commitments, thoroughly vet potential suppliers. Request company profiles, product catalogs, and case studies to gauge their experience and reliability. Look for suppliers who have worked with clients in similar industries or regions, as they will have a better understanding of your specific needs.

Step 4: Assess Quality Assurance Processes

Quality assurance is paramount in sourcing roller conveyor components. Inquire about the supplier’s quality control measures, including testing procedures and certifications. Look for suppliers that adhere to recognized quality standards, as this will minimize the risk of defects and ensure long-term operational efficiency.

Step 5: Request Samples for Testing

Before finalizing any orders, request samples of the components to evaluate their quality and compatibility with your systems. Testing samples can reveal critical insights into performance and durability under your specific operating conditions. Be proactive in assessing how well the components integrate with your existing equipment.

Step 6: Negotiate Terms and Conditions

Negotiating favorable terms is essential for a successful procurement process. Discuss payment terms, delivery schedules, and warranty options with your chosen supplier. Ensure that all agreements are documented to protect your interests and clarify expectations.

Step 7: Establish a Communication Plan

Clear communication is vital for maintaining a successful supplier relationship. Establish regular check-ins to discuss progress, address concerns, and provide feedback. This proactive approach fosters collaboration and can lead to better service and support from your suppliers.

By following this checklist, B2B buyers can navigate the complexities of sourcing roller conveyor components while ensuring quality and efficiency in their procurement processes.

Illustrative image related to roller conveyor components

Comprehensive Cost and Pricing Analysis for roller conveyor components Sourcing

What Are the Key Cost Components in Roller Conveyor Components Sourcing?

When sourcing roller conveyor components, understanding the cost structure is essential for effective budgeting and strategic procurement. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. Common materials such as steel, aluminum, and polymers vary in cost based on market fluctuations and availability. Sourcing from local suppliers can help mitigate costs related to import tariffs and logistics.

-

Labor: Labor costs differ widely depending on the manufacturing location. Countries with lower labor costs may offer competitive pricing; however, it is crucial to evaluate the skill level and efficiency of the workforce to ensure quality production.

-

Manufacturing Overhead: This encompasses expenses such as utilities, rent, and administrative costs associated with production facilities. Manufacturers often pass these costs onto buyers, making it important to consider the operational efficiency of potential suppliers.

-

Tooling: Custom tooling can be a significant upfront investment. If your project requires specialized components, factor in the costs of designing and producing the necessary molds and tools.

-

Quality Control (QC): Ensuring that components meet specified standards is vital. The costs associated with QC processes, including testing and inspections, should be included in your total pricing analysis.

-

Logistics: Transportation and handling costs can vary dramatically based on the supplier’s location and the chosen shipping method. Consider the implications of Incoterms on logistics costs, as they define the responsibilities of buyers and sellers in the shipping process.

-

Margin: Suppliers will typically include a profit margin in their pricing. Understanding typical margins in the industry can help you gauge the reasonableness of supplier quotes.

How Do Price Influencers Affect Roller Conveyor Components Pricing?

Several factors influence the pricing of roller conveyor components, making it critical for buyers to conduct thorough market research:

-

Volume/MOQ: Purchasing in larger volumes or meeting Minimum Order Quantities (MOQs) can lead to significant discounts. Negotiating bulk orders can enhance cost-effectiveness.

-

Specifications and Customization: Custom-designed components may incur additional costs due to the complexity and time required for production. Clearly defining your specifications upfront can prevent unexpected expenses later.

-

Material Quality and Certifications: High-quality materials often come with a higher price tag. Additionally, certifications for safety and performance can influence pricing, particularly in regions with stringent regulations.

-

Supplier Factors: The reputation and reliability of the supplier play a role in pricing. Established suppliers may charge more for their expertise and proven track record, while emerging manufacturers might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They dictate who bears the cost and risk at different stages of shipping, which can significantly impact the overall price.

What Are the Best Negotiation and Cost-Efficiency Strategies for Buyers?

International B2B buyers should adopt strategic approaches to enhance cost efficiency and optimize negotiations:

Illustrative image related to roller conveyor components

-

Conduct Comprehensive Market Research: Familiarize yourself with prevailing market prices and trends in the regions you are sourcing from. This knowledge will empower you during negotiations and help identify competitive suppliers.

-

Evaluate Total Cost of Ownership (TCO): Instead of solely focusing on the initial purchase price, consider the TCO, which includes maintenance, logistics, and potential downtime. This broader perspective can lead to better long-term investments.

-

Build Relationships with Suppliers: Establishing strong relationships can lead to better pricing agreements and preferential treatment in future transactions. Regular communication and feedback foster trust and collaboration.

-

Leverage Technology: Utilize procurement software and platforms that provide insights into pricing trends and supplier performance. This data can aid in making informed purchasing decisions.

What Should International Buyers Keep in Mind Regarding Pricing Nuances?

When sourcing roller conveyor components from regions such as Africa, South America, the Middle East, and Europe, buyers must be aware of specific pricing nuances:

-

Currency Fluctuations: Exchange rate volatility can affect pricing. Consider negotiating contracts in stable currencies to mitigate risks.

-

Regulatory Compliance: Different regions have varying regulations regarding manufacturing and safety standards, which can influence costs. Ensure that the components sourced comply with local regulations to avoid costly penalties.

-

Cultural Considerations: Understanding cultural nuances in negotiation styles can enhance communication and lead to more favorable outcomes.

Disclaimer on Pricing

The prices discussed in this analysis are indicative and can vary based on numerous factors, including market conditions and supplier negotiations. Buyers should conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing for their specific needs.

Alternatives Analysis: Comparing roller conveyor components With Other Solutions

Understanding the Landscape of Conveyor Solutions

In the realm of material handling, selecting the right solution is crucial for efficiency and productivity. While roller conveyor components are a popular choice for transporting goods, several alternatives also exist that may better suit specific applications. This analysis compares roller conveyor components with two viable alternatives: belt conveyor systems and automated guided vehicles (AGVs). By examining these options, B2B buyers can make informed decisions tailored to their operational needs.

Comparison Table

| Comparison Aspect | Roller Conveyor Components | Belt Conveyor Systems | Automated Guided Vehicles (AGVs) |

|---|---|---|---|

| Performance | High efficiency for heavy loads and continuous movement | Versatile for various materials; adjustable speed | Excellent for flexible routes and autonomous operation |

| Cost | Moderate initial investment; low operational costs | Varies widely; can be high for complex installations | High initial investment; ongoing operational and maintenance costs |

| Ease of Implementation | Relatively straightforward installation | Requires more planning and space; complex setups may need professional help | Requires significant planning, infrastructure, and software integration |

| Maintenance | Low maintenance; occasional roller replacement | Moderate maintenance; belt wear and alignment issues | Regular software updates and battery maintenance; more complex maintenance requirements |

| Best Use Case | Ideal for heavy, stable products in fixed routes | Suitable for diverse materials, inclines, and declines | Best for dynamic environments needing flexibility and real-time adaptability |

In-Depth Analysis of Alternatives

What Are the Benefits and Drawbacks of Belt Conveyor Systems?

Belt conveyor systems are known for their adaptability in transporting various materials, including loose items, packaged goods, and bulk materials. They offer adjustable speeds and incline capabilities, making them versatile for different applications. However, their installation can be complex and may require significant space and planning. While the initial investment can be lower than roller conveyors, ongoing maintenance costs can add up due to belt wear and potential misalignment issues.

How Do Automated Guided Vehicles (AGVs) Compare?

AGVs are revolutionizing material handling by providing automated, flexible solutions for moving goods. They can navigate complex environments and adapt their routes based on real-time data, which enhances efficiency. However, the initial investment for AGVs is considerably high, as it involves not only the vehicles themselves but also the necessary infrastructure and software systems. Maintenance can also be more complex due to the technology involved, including battery management and software updates. AGVs are particularly advantageous in settings where adaptability and automation are paramount.

Illustrative image related to roller conveyor components

How Can B2B Buyers Choose the Right Solution?

When selecting the ideal material handling solution, B2B buyers should consider their specific operational needs, including the type of products being transported, the layout of their facility, and their budget constraints. Roller conveyor components are excellent for consistent, heavy loads in a fixed environment, while belt conveyors offer versatility for various materials. For companies seeking automation and flexibility, AGVs may provide the best long-term investment despite their higher costs. By assessing these factors, businesses can select the solution that best aligns with their goals, ensuring optimal efficiency and return on investment.

Essential Technical Properties and Trade Terminology for roller conveyor components

What Are the Critical Technical Properties of Roller Conveyor Components?

When sourcing roller conveyor components, understanding key technical properties is essential for making informed purchasing decisions. Below are some of the most critical specifications that B2B buyers should consider:

Material Grade

The material grade of roller conveyor components significantly impacts durability, performance, and maintenance. Common materials include steel, stainless steel, and plastic. Steel offers strength and cost-effectiveness, while stainless steel provides corrosion resistance, making it ideal for environments like food processing. Plastic components are lightweight and resistant to chemicals, suitable for specific applications. Selecting the right material grade ensures longevity and reduces the total cost of ownership.

Load Capacity

Load capacity refers to the maximum weight a roller conveyor can handle without compromising performance. This specification is crucial for determining the suitability of the conveyor for specific applications. A thorough understanding of load capacity helps buyers avoid overloading, which can lead to equipment failure, increased maintenance costs, and safety hazards. It is advisable to choose components that exceed the expected load to ensure reliable operation.

Tolerance

Tolerance indicates the permissible limit of variation in a physical dimension, such as roller diameter or length. Tight tolerances are essential for ensuring smooth operation and minimizing wear. Inaccurate tolerances can lead to misalignment, increased friction, and energy loss. For B2B buyers, understanding tolerance specifications helps in selecting components that fit seamlessly into existing systems, enhancing efficiency and reducing downtime.

Surface Finish

The surface finish of roller components affects both aesthetics and functionality. A smooth surface minimizes friction, while specific finishes can enhance corrosion resistance or facilitate easier cleaning. Buyers should consider the application environment—components exposed to harsh conditions may require specialized finishes to prolong lifespan. Selecting the right surface finish can lead to improved operational efficiency and lower maintenance costs.

Roller Diameter

The diameter of rollers is a critical factor influencing the conveyor’s performance. Larger diameters can handle heavier loads and reduce friction, while smaller diameters are more suitable for lighter loads and tighter curves. Understanding the relationship between roller diameter and application requirements ensures that the conveyor operates optimally, avoiding potential bottlenecks in material handling.

What Are Common Trade Terms in Roller Conveyor Procurement?

Navigating the procurement process requires familiarity with industry-specific jargon. Here are some essential trade terms that every B2B buyer should know:

Illustrative image related to roller conveyor components

OEM (Original Equipment Manufacturer)

An OEM produces components that are used in another company’s products. When sourcing roller conveyor components, buyers may seek OEM parts to ensure compatibility and reliability. Understanding OEM specifications helps in selecting high-quality components that meet industry standards.

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers as it impacts inventory management and budgeting. Knowing the MOQ can help companies negotiate better terms and plan their procurement strategy effectively.

RFQ (Request for Quotation)

An RFQ is a formal process where buyers invite suppliers to submit price quotations for specific products. This document outlines the specifications, quantities, and delivery requirements. Utilizing an RFQ can streamline the procurement process, ensuring that buyers receive competitive pricing and comprehensive information from multiple suppliers.

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. Understanding these terms is essential for managing logistics, risk, and costs. Familiarity with Incoterms helps B2B buyers negotiate shipping agreements and avoid misunderstandings regarding delivery and payment responsibilities.

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Knowing the lead time is crucial for project planning and inventory management. Buyers should consider lead times when negotiating with suppliers to ensure that they can meet production schedules and customer demands.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions, ensuring that they procure the right roller conveyor components for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the roller conveyor components Sector

What Are the Current Market Dynamics and Key Trends in Roller Conveyor Components?

The roller conveyor components sector is experiencing significant transformation driven by globalization, technological advancements, and evolving customer demands. International B2B buyers are witnessing a surge in automation, which enhances efficiency and reduces labor costs. In regions such as Africa and South America, the adoption of roller conveyor systems is rapidly increasing as industries seek to streamline operations in manufacturing and logistics. Conversely, Europe, particularly Germany, is leading in innovation, focusing on smart conveyor technologies that integrate IoT and AI for real-time monitoring and predictive maintenance.

Emerging trends also point towards customization and modularity. Buyers are increasingly looking for tailored solutions that can be adapted to specific operational needs, promoting flexibility and scalability. Additionally, the rise of e-commerce and the need for faster delivery times are pushing businesses to optimize their supply chains, making roller conveyor systems indispensable. The focus on reducing lead times and enhancing performance is reshaping sourcing strategies, with a shift towards local suppliers who can offer quicker turnaround and lower transportation costs.

Illustrative image related to roller conveyor components

How Is Sustainability Influencing Sourcing Practices for Roller Conveyor Components?

Sustainability has become a cornerstone of procurement strategies in the roller conveyor components sector. As global awareness of environmental issues rises, B2B buyers are prioritizing suppliers who demonstrate a commitment to ethical sourcing and sustainability. The environmental impact of manufacturing processes, particularly in terms of carbon emissions and resource consumption, is under scrutiny. Thus, businesses are increasingly seeking components made from recycled or eco-friendly materials, which not only reduce the carbon footprint but also appeal to environmentally conscious consumers.

Moreover, certifications such as ISO 14001 and LEED are gaining traction, serving as benchmarks for assessing the sustainability practices of suppliers. Buyers from regions like Europe, which are often ahead in regulatory compliance and green initiatives, are more inclined to partner with manufacturers who meet these standards. By prioritizing ethical supply chains, companies not only enhance their brand reputation but also mitigate risks associated with regulatory penalties and market backlash.

How Has the Roller Conveyor Components Sector Evolved Over Time?

The evolution of roller conveyor components can be traced back to the early 20th century when mechanization began to transform manufacturing processes. Initially, these systems were manually operated and limited in function. However, with advancements in technology and materials science, roller conveyors have evolved to incorporate electric drives, automation, and smart features that enhance operational efficiency.

In recent decades, the focus has shifted towards integration with digital technologies, allowing for more sophisticated systems that provide real-time data analytics and performance monitoring. This evolution reflects broader trends in manufacturing and logistics towards automation and smart solutions, catering to the growing demands for efficiency and productivity. As industries continue to adapt, the roller conveyor components sector is poised for further innovation, driven by both technological advancements and the imperative for sustainable practices.

Illustrative image related to roller conveyor components

Frequently Asked Questions (FAQs) for B2B Buyers of roller conveyor components

-

1. How do I choose the right roller conveyor components for my application?

Selecting the appropriate roller conveyor components requires a thorough understanding of your specific application needs. Consider factors such as the type of material being transported, load capacity, and the environment in which the conveyor will operate. Conducting a needs assessment can help identify the right specifications, including roller diameter, material, and spacing. Engaging with suppliers who offer customized solutions can also ensure that the components meet your operational requirements effectively. -

2. What are the key factors to consider when sourcing roller conveyor components internationally?

When sourcing roller conveyor components internationally, consider the supplier’s reputation, product quality, and compliance with international standards. It’s essential to evaluate logistics capabilities, lead times, and shipping costs, especially for regions like Africa and South America where logistics can be challenging. Additionally, understanding import regulations and tariffs in your country will aid in cost estimation and compliance. Establishing clear communication with suppliers about your expectations is also crucial for a successful partnership. -

3. What is the minimum order quantity (MOQ) for roller conveyor components?

Minimum order quantities (MOQ) for roller conveyor components can vary significantly depending on the supplier and the type of components required. Many suppliers set MOQs to optimize production efficiency, but it’s often negotiable. For smaller businesses or those testing new systems, it’s advisable to discuss flexibility in order quantities with potential suppliers. Some manufacturers may offer lower MOQs for customized components, so exploring various options is beneficial. -

4. How can I ensure the quality of roller conveyor components before making a purchase?

To ensure the quality of roller conveyor components, request product samples and certifications that validate compliance with industry standards. Conducting factory audits can also provide insights into the manufacturing processes and quality control measures in place. Additionally, obtaining references or testimonials from other clients can help gauge the supplier’s reliability and product performance. Establishing clear quality assurance protocols in your purchase agreement can further protect your investment. -

5. What payment terms are common in international transactions for roller conveyor components?

Common payment terms for international transactions can include letters of credit, advance payments, and payment upon delivery. The choice of terms often depends on the buyer-supplier relationship and the perceived risk involved. It’s essential to negotiate terms that provide security for both parties, ensuring that payments are made in accordance with agreed milestones. Familiarity with international payment methods and potential currency fluctuations will also aid in making informed decisions. -

6. How does customization of roller conveyor components impact pricing and lead times?

Customization of roller conveyor components often leads to higher pricing and longer lead times due to the specific requirements and adjustments needed during manufacturing. Factors such as material selection, design modifications, and production processes contribute to the overall cost. However, customized components can enhance efficiency and performance in your specific application, potentially offsetting the initial investment over time. Discussing your needs early with suppliers can help manage expectations regarding both pricing and timelines. -

7. What logistics considerations should I keep in mind when importing roller conveyor components?

When importing roller conveyor components, logistics considerations such as shipping methods, freight costs, and delivery timelines are critical. Understanding the supplier’s logistics capabilities and their partnerships with freight forwarders can streamline the process. Additionally, be aware of customs regulations and documentation required for smooth clearance. Planning for potential delays, especially in regions with complex logistics, will help ensure that your operations remain uninterrupted. -

8. How can I establish a long-term partnership with my roller conveyor component supplier?

To establish a long-term partnership with a roller conveyor component supplier, focus on open communication, reliability, and mutual growth. Regularly provide feedback on product performance and service, which can help improve future transactions. Building trust through timely payments and honoring agreements will strengthen the relationship. Additionally, exploring opportunities for collaboration on future projects can foster loyalty and encourage suppliers to prioritize your needs.

A Look at Roller Conveyor Components Manufacturers & Suppliers

We are currently compiling a detailed list of top roller conveyor components suppliers. Please check back later.

Strategic Sourcing Conclusion and Outlook for roller conveyor components

In today’s competitive landscape, the strategic sourcing of roller conveyor components is essential for optimizing supply chains and enhancing operational efficiency. Key takeaways from our guide emphasize the importance of building strong supplier relationships, leveraging technological advancements, and embracing sustainable practices. By understanding the nuances of sourcing in various regions—including Africa, South America, the Middle East, and Europe—buyers can identify reliable partners who not only meet quality standards but also align with their long-term business goals.

Investing in strategic sourcing not only minimizes costs but also mitigates risks associated with supply chain disruptions. As the global market evolves, the demand for innovative and customizable solutions in roller conveyor systems continues to rise. Therefore, B2B buyers are encouraged to explore diverse sourcing options, including local suppliers and international manufacturers, to enhance their competitive edge.

Looking ahead, the future of roller conveyor components will be shaped by advancements in automation and sustainability. Now is the time for businesses to reevaluate their sourcing strategies, adapt to emerging trends, and engage with suppliers that prioritize innovation. Embrace these opportunities to ensure your operations remain agile and forward-thinking in an ever-changing marketplace.

Illustrative image related to roller conveyor components

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.