Unlocking Value: A Strategic Analysis of the Roll Conveyor Market

Introduction: Navigating the Global Market for roll conveyor

In the ever-evolving landscape of global commerce, sourcing the right roll conveyor systems is a pivotal challenge for B2B buyers. Efficient material handling solutions are essential for optimizing operations across industries, from manufacturing to warehousing. However, the diverse types of roll conveyors available—such as gravity, powered, and flexible systems—can complicate decision-making. This guide aims to demystify the selection process by providing in-depth insights into various conveyor types, their applications, and key factors to consider when evaluating suppliers.

International B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe—including emerging markets like Vietnam and Nigeria—face unique challenges. These include understanding local regulations, navigating supply chain logistics, and managing budget constraints. This comprehensive resource empowers you to make informed purchasing decisions by outlining critical considerations such as cost-effectiveness, supplier vetting, and maintenance needs.

By equipping you with actionable knowledge and expert guidance, this guide seeks to enhance your operational efficiency and ensure that your roll conveyor systems align with your business objectives. Whether you are looking for new installations or exploring used options to maximize budget efficiency, you will find the insights you need to streamline your material handling processes and drive business success.

Understanding roll conveyor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gravity Roller Conveyor | Utilizes gravity for movement; simple design; low maintenance | Warehousing, assembly lines | Pros: Cost-effective, easy to install. Cons: Limited to downhill applications; not suitable for heavy loads. |

| Powered Roller Conveyor | Uses motors to drive rollers; versatile in speed and direction | Package handling, sorting systems | Pros: Efficient for heavy loads, customizable speed. Cons: Higher initial investment; requires power source. |

| Skatewheel Conveyor | Features smaller wheels; ideal for lighter loads and curves | Retail, light assembly | Pros: Space-saving, easy to maneuver. Cons: Limited weight capacity; not suitable for heavy items. |

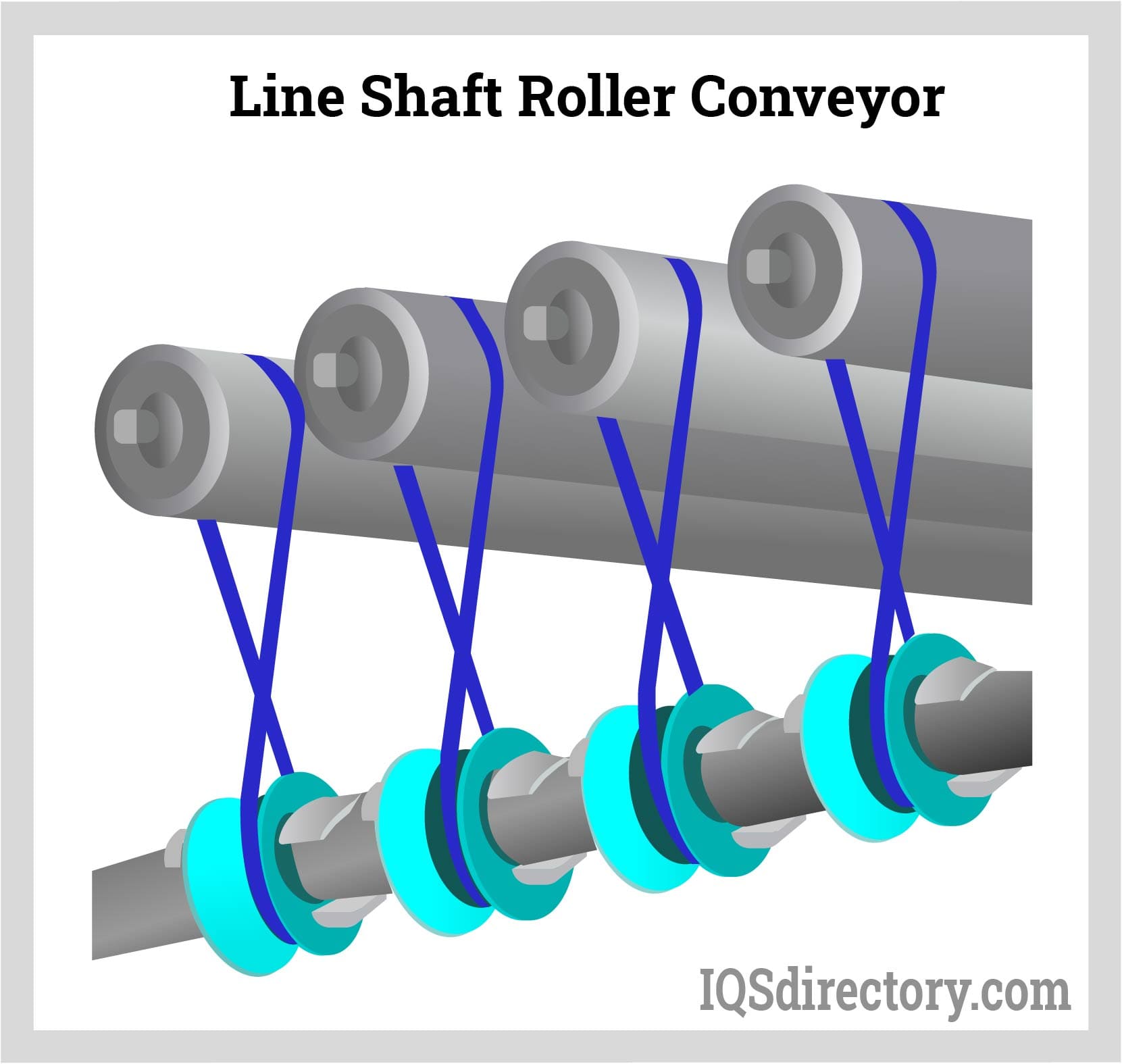

| Line Shaft Conveyor | Uses a central shaft to drive rollers; ideal for accumulation | Distribution centers, manufacturing | Pros: Energy-efficient, flexible layout options. Cons: More complex maintenance; initial setup can be costly. |

| Flexible Conveyor | Adjustable and portable; can be expanded or contracted | Temporary setups, packaging | Pros: Highly adaptable, easy to store. Cons: Less durable; may require frequent adjustments. |

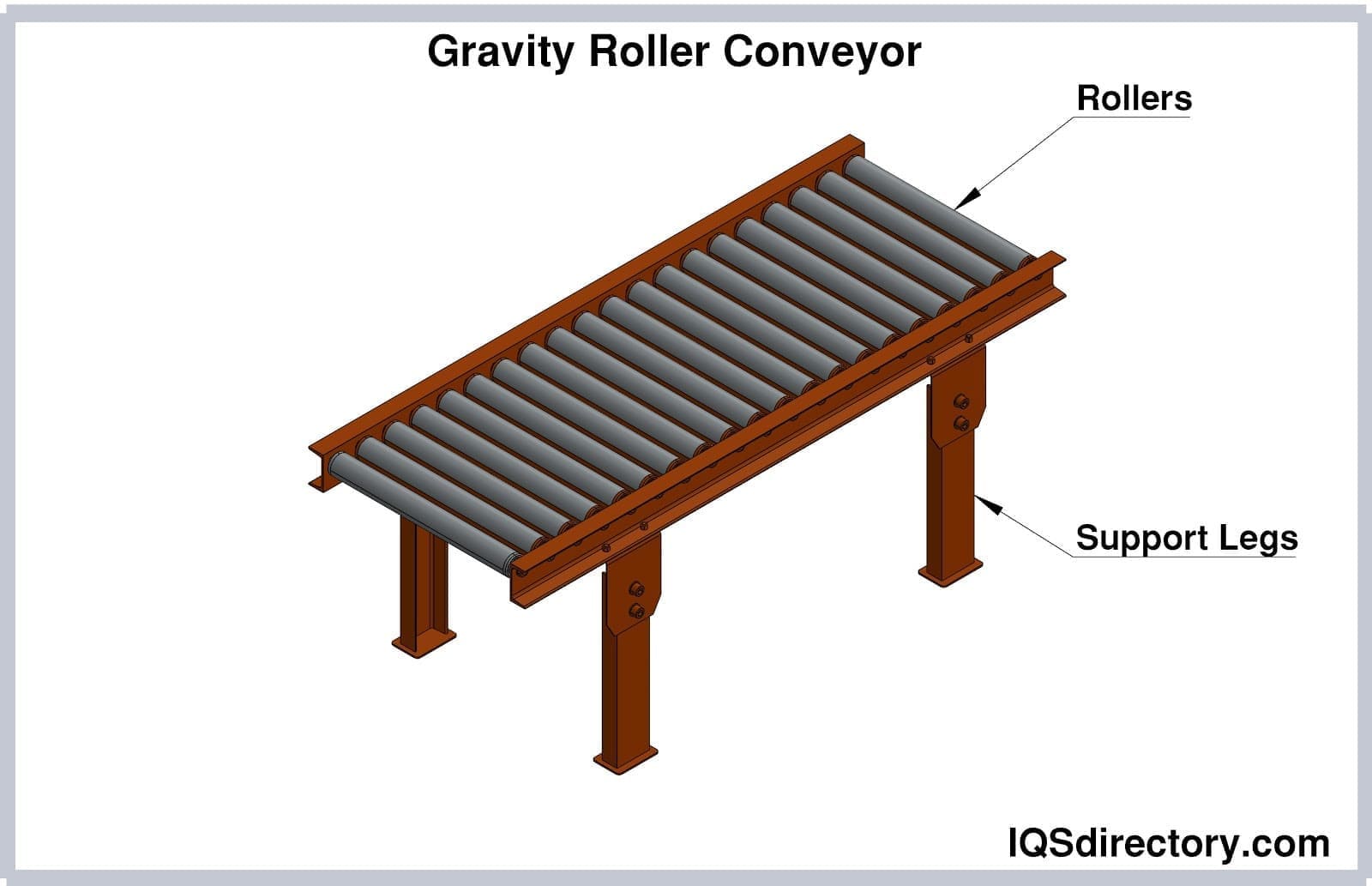

What Are the Characteristics of Gravity Roller Conveyors?

Gravity roller conveyors are designed to move items relying solely on gravitational force, making them a cost-effective solution for various applications. They are typically simple to install and maintain, ideal for light to medium loads, and are often used in warehouses and assembly lines. When purchasing, consider the incline angle and the type of products being transported, as these factors significantly impact performance. Additionally, gravity systems may not be suitable for heavy loads or require powered assistance for horizontal movement.

How Do Powered Roller Conveyors Enhance Efficiency?

Powered roller conveyors integrate motors to drive the rollers, allowing for controlled movement of products across a flat surface. This type of conveyor is versatile, accommodating a range of speeds and directions, making it ideal for package handling and sorting systems. When considering a powered system, evaluate the load capacity, required speed, and energy consumption. While they offer greater efficiency for heavy items, they come with a higher upfront cost and necessitate a reliable power source.

What Makes Skatewheel Conveyors Ideal for Light Loads?

Skatewheel conveyors are characterized by smaller wheels that allow for easy movement of lightweight items. This design is particularly effective in retail environments and light assembly lines where space is a premium. Buyers should assess the weight capacity and the types of products being handled, as skatewheel systems are not suited for heavy loads. Their flexibility and ease of installation make them appealing, but they may require more frequent adjustments compared to heavier-duty options.

Why Choose Line Shaft Conveyors for Accumulation?

Line shaft conveyors utilize a central shaft to drive rollers, allowing for the accumulation of products without the need for extensive power consumption. This makes them particularly useful in distribution centers and manufacturing environments where space and energy efficiency are priorities. When investing in a line shaft system, it is essential to consider the complexity of maintenance and the initial setup costs, as these factors can influence long-term operational efficiency.

How Do Flexible Conveyors Adapt to Various Needs?

Flexible conveyors are designed for adaptability, allowing users to expand or contract the system based on current needs. They are particularly beneficial for temporary setups in packaging or shipping environments. While they offer significant advantages in terms of versatility and storage, potential buyers should be mindful of their durability and the frequency of adjustments required. Assessing the specific operational requirements will help determine if a flexible conveyor is the right fit for your business.

Key Industrial Applications of roll conveyor

| Industry/Sector | Specific Application of Roll Conveyor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Assembly Line Operations | Enhances efficiency and reduces manual handling errors | Durability, load capacity, and adaptability to layout |

| Warehousing | Order Fulfillment and Shipping | Streamlines the movement of goods, reducing lead times | Space optimization, flexibility in configuration |

| Food and Beverage | Packaging and Distribution | Ensures safe and efficient handling of products | Compliance with hygiene standards, material suitability |

| Automotive | Parts Handling and Distribution | Facilitates quick access to components, enhancing productivity | Robustness, compatibility with automated systems |

| E-commerce | Sorting and Processing Returns | Improves handling speed and accuracy of return processes | Modular design, ease of maintenance, and scalability |

How is Roll Conveyor Used in Manufacturing and What Problems Does It Solve?

In manufacturing, roll conveyors are integral to assembly line operations, facilitating the smooth transport of components between workstations. They minimize manual handling, thereby reducing the risk of errors and injuries. Buyers in this sector must consider factors such as the conveyor’s durability and load capacity, ensuring it can withstand the demands of continuous operation. Additionally, adaptability to existing layouts is crucial for maximizing efficiency.

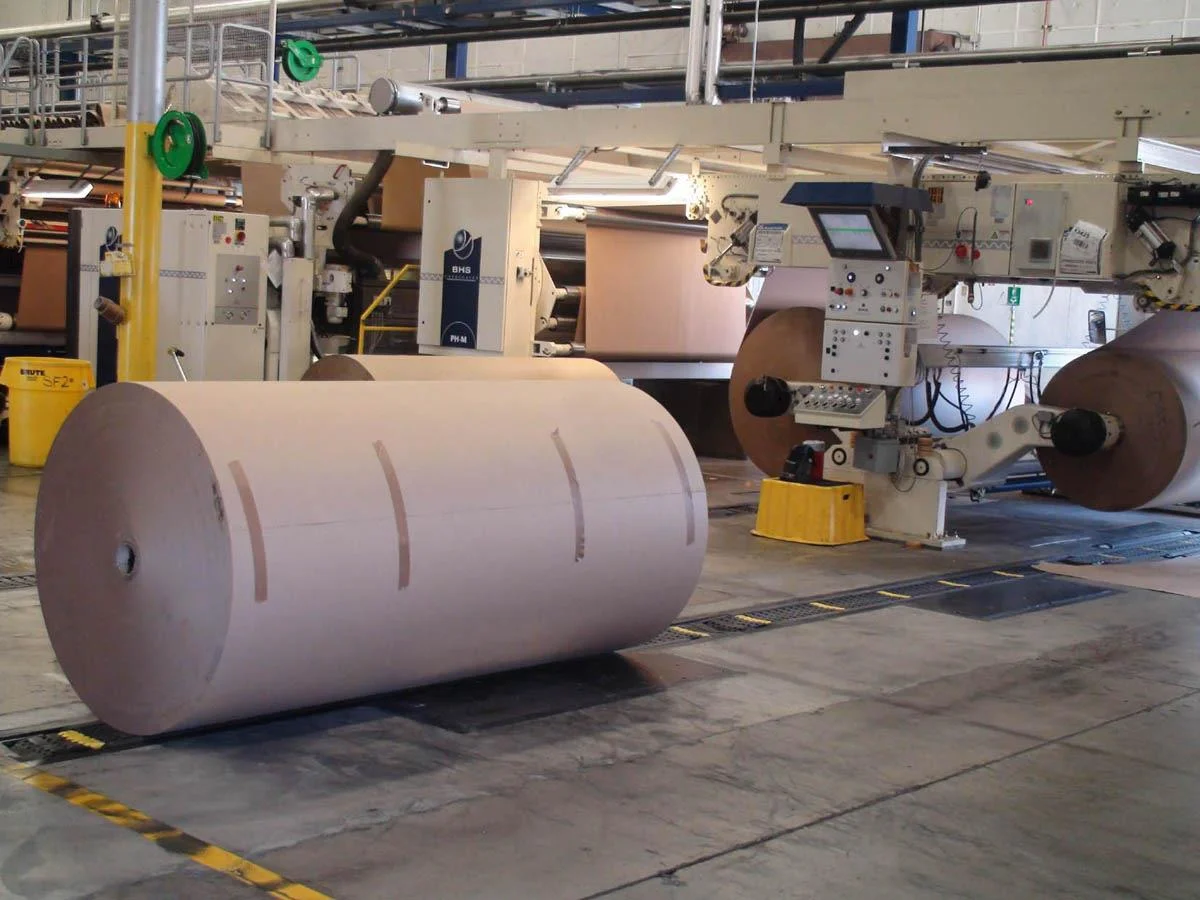

What Role Does Roll Conveyor Play in Warehousing Operations?

In warehousing, roll conveyors are vital for order fulfillment and shipping processes. They enable the efficient movement of goods from storage areas to packing stations, significantly reducing lead times. For international buyers, sourcing conveyors that optimize space and offer flexibility in configuration is essential, especially in facilities with varying product sizes and shapes. The ability to easily modify the conveyor layout can lead to enhanced operational agility.

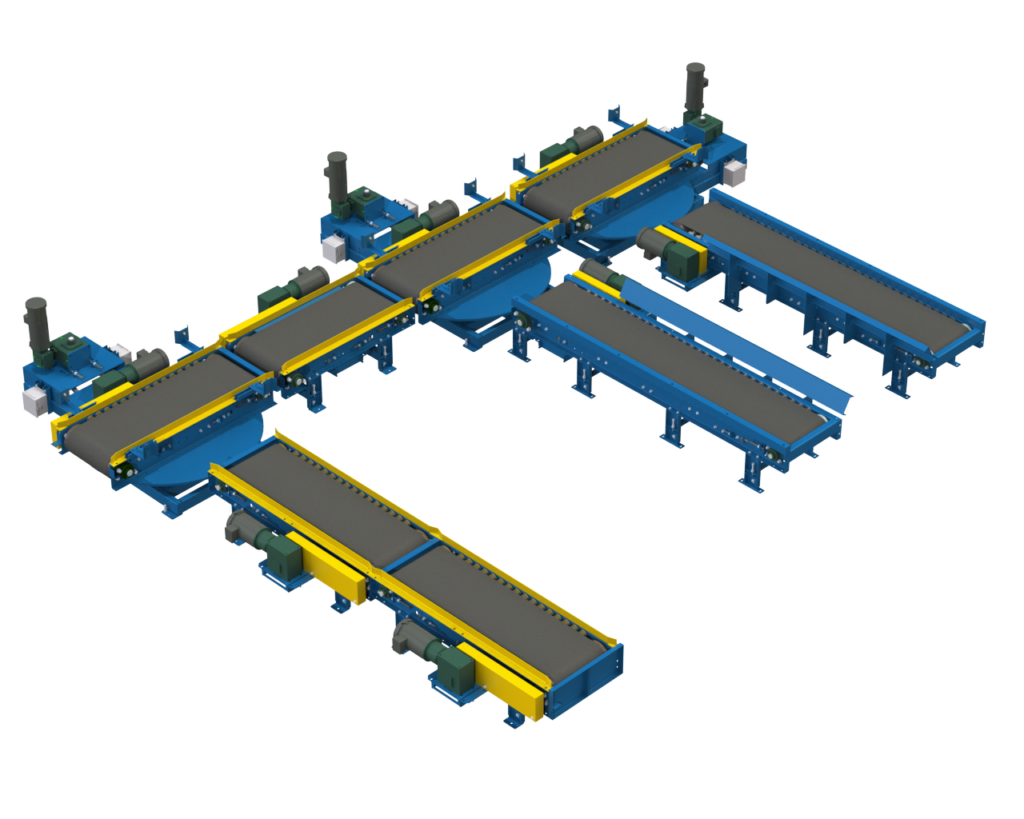

Illustrative image related to roll conveyor

How is Roll Conveyor Beneficial in the Food and Beverage Industry?

In the food and beverage sector, roll conveyors are used for packaging and distribution, ensuring products are handled safely and efficiently. They help maintain hygiene standards while facilitating the rapid movement of goods. Buyers must prioritize compliance with food safety regulations and select materials that are suitable for the environment, such as stainless steel or food-grade plastics. This ensures both safety and longevity in operations.

What Advantages Does Roll Conveyor Offer in Automotive Parts Handling?

Roll conveyors are crucial in the automotive industry for parts handling and distribution. They allow for quick access to components, which enhances overall productivity on the assembly line. When sourcing these conveyors, buyers should focus on robustness and compatibility with automated systems to ensure seamless integration into existing workflows. This is particularly important in high-demand environments where efficiency is paramount.

How Does Roll Conveyor Improve E-commerce Operations?

In e-commerce, roll conveyors play a key role in sorting and processing returns, which has become increasingly important in today’s retail landscape. They enhance the speed and accuracy of handling returns, leading to improved customer satisfaction. Buyers should look for modular designs that allow for easy maintenance and scalability, accommodating fluctuating volumes and varying product types. This adaptability is vital for meeting the dynamic demands of e-commerce operations.

3 Common User Pain Points for ‘roll conveyor’ & Their Solutions

Scenario 1: Inefficient Space Utilization in Warehouse Layouts

The Problem: Many B2B buyers encounter challenges with space efficiency in their warehouses. As operations scale, existing conveyor systems may not optimally fit the changing layout, leading to bottlenecks and wasted space. Buyers often struggle to find a conveyor solution that can adapt to various workflows without significantly disrupting their operations. They may find themselves facing high costs associated with reconfiguring their entire material handling system, which can be especially challenging in tight spaces.

The Solution: To address this issue, consider investing in modular and flexible roller conveyor systems that can be easily reconfigured as business needs change. Look for conveyors that allow adjustable heights and widths, which can accommodate different product sizes and types. Additionally, implementing gravity roller conveyors in areas where electricity is not readily available can provide a cost-effective solution. When sourcing these systems, consult with suppliers about their ability to customize configurations to suit specific space requirements. Conduct a thorough analysis of your warehouse layout to identify areas where conveyors can be integrated seamlessly, maximizing efficiency without requiring extensive modifications.

Illustrative image related to roll conveyor

Scenario 2: High Maintenance Costs and Downtime

The Problem: B2B buyers often face high maintenance costs associated with traditional conveyor systems. Frequent breakdowns and the need for regular servicing can lead to significant operational downtime, negatively impacting productivity and increasing labor costs. Companies may also struggle to find suitable replacement parts, especially if the conveyor system is older or from a less common manufacturer.

The Solution: To mitigate these issues, consider transitioning to modern roller conveyor systems designed for durability and low maintenance. Opt for conveyors with robust materials, such as stainless steel or heavy-duty plastics, which resist wear and corrosion. Additionally, when selecting your system, ensure that it is equipped with readily available components. Partner with suppliers who offer comprehensive support and warranty services, which can significantly reduce maintenance headaches. Regularly scheduled preventative maintenance and training for staff on proper usage can further minimize downtime. Establishing a relationship with a reliable service provider can also ensure quick response times for any unforeseen issues.

Scenario 3: Inadequate Product Handling for Diverse Goods

The Problem: Many businesses deal with a variety of products that require different handling methods. For example, items with irregular shapes or sizes may not move smoothly on standard roller conveyors, leading to jams, damage, or inefficient transport. Buyers often find themselves at a crossroads, unsure whether to invest in multiple conveyor systems or attempt to modify their existing setups.

The Solution: To effectively handle diverse product ranges, consider investing in specialized roller conveyors that cater to specific product needs. For instance, ball transfer tables can be invaluable for moving items in multiple directions, making them ideal for sorting areas. Skatewheel conveyors can also be a great option for lightweight, flat-based products. When specifying your roller conveyor system, work closely with your supplier to evaluate the types of products being transported. Engage in a thorough assessment of your operations to identify potential pain points and tailor solutions that accommodate all product types efficiently. Leveraging advanced technology, such as conveyor systems that integrate sensors for real-time feedback on product flow, can further enhance operational efficiency.

Strategic Material Selection Guide for roll conveyor

What Are the Key Materials Used in Roll Conveyors?

When selecting materials for roll conveyors, it’s essential to consider the specific properties and applications of each material. Below, we analyze four common materials used in roll conveyor systems: steel, aluminum, plastic, and stainless steel.

Illustrative image related to roll conveyor

How Does Steel Perform in Roll Conveyors?

Steel is one of the most widely used materials in roll conveyor systems due to its strength and durability. Key properties include high tensile strength, making it suitable for heavy-duty applications, and good temperature resistance, allowing it to operate effectively in various environments. However, steel is prone to corrosion if not properly treated, which can limit its lifespan in humid or corrosive environments.

Pros: Steel conveyors are durable, can handle heavy loads, and are generally cost-effective compared to other materials. They are also widely available and easy to manufacture.

Cons: The main drawback is their susceptibility to rust and corrosion, which can necessitate additional protective coatings. Steel is also heavier, which may increase shipping costs.

Illustrative image related to roll conveyor

For international buyers, especially in regions like Africa and South America, compliance with local standards (such as ASTM) for material quality is crucial. Buyers should also consider the availability of maintenance services for steel conveyors in their region.

What Advantages Does Aluminum Offer for Roll Conveyors?

Aluminum is another popular choice, particularly for applications requiring lightweight and corrosion-resistant materials. It offers a good strength-to-weight ratio and is resistant to rust, making it ideal for environments where moisture is a concern.

Pros: Aluminum conveyors are lightweight, easy to handle, and resistant to corrosion. They are suitable for applications where weight savings are critical, such as in portable or flexible conveyor systems.

Cons: Aluminum is generally more expensive than steel and may not be suitable for extremely heavy loads. Its lower tensile strength compared to steel can limit its use in heavy-duty applications.

International buyers should be aware of the specific aluminum grades and standards (like JIS) that are suitable for their applications. In regions with high humidity, the corrosion resistance of aluminum can be a significant advantage.

Illustrative image related to roll conveyor

Why Choose Plastic for Roll Conveyors?

Plastic materials, particularly high-density polyethylene (HDPE), are increasingly used in roll conveyors for light to medium-duty applications. They are resistant to chemicals and moisture, making them suitable for various industries, including food processing and pharmaceuticals.

Pros: Plastic conveyors are lightweight, easy to clean, and resistant to a wide range of chemicals. They can also be manufactured in various colors, which can be beneficial for coding and sorting applications.

Cons: The main limitation is their lower load-bearing capacity compared to metal options. They may also be more susceptible to wear and tear under heavy use.

Illustrative image related to roll conveyor

For international buyers, it’s essential to ensure that the plastic materials comply with food safety standards (such as FDA regulations) if used in food-related applications. Understanding local manufacturing capabilities for plastic components is also crucial.

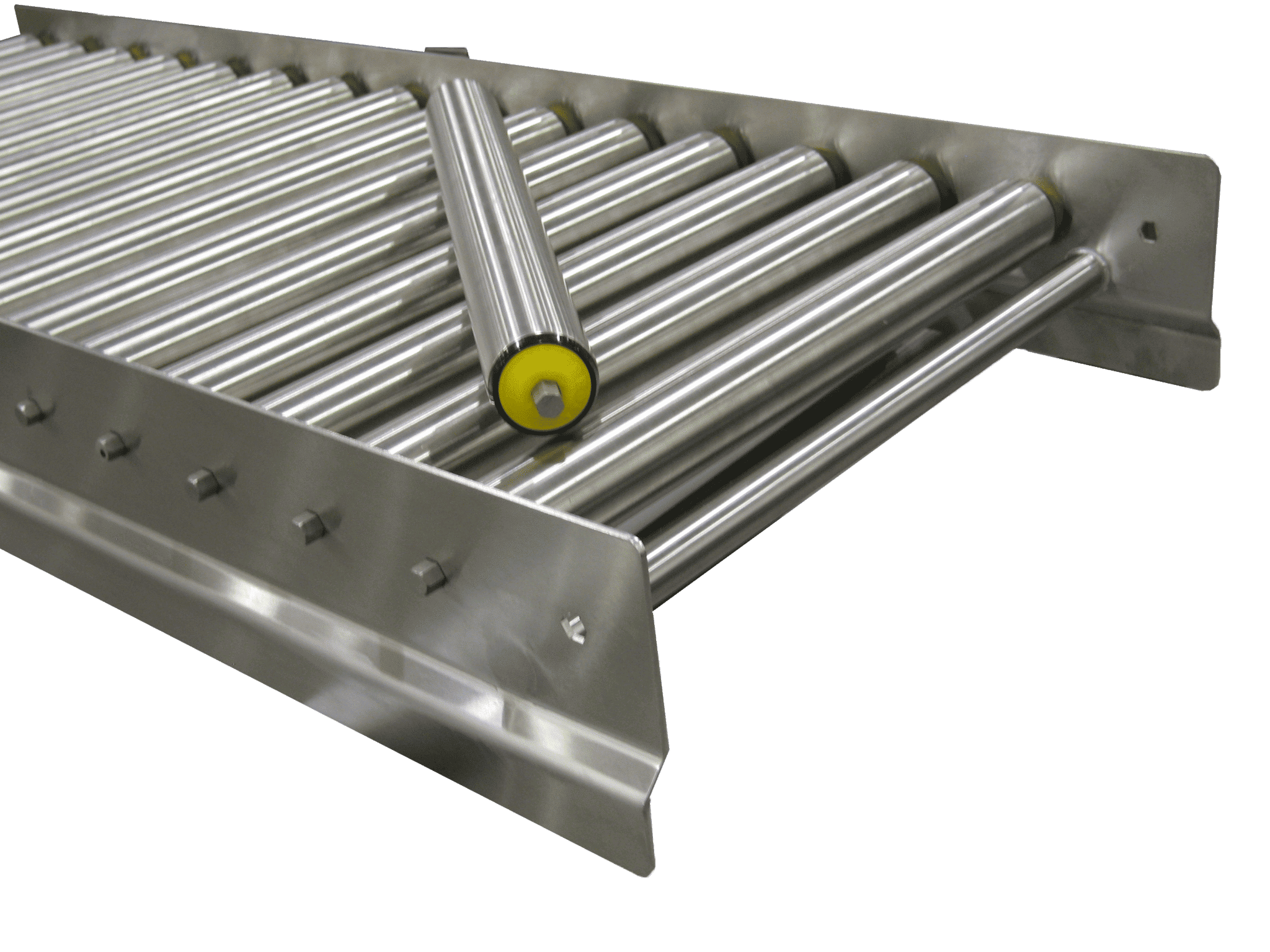

What Role Does Stainless Steel Play in Roll Conveyor Systems?

Stainless steel is often used in environments where hygiene is paramount, such as in food and pharmaceutical industries. Its key properties include excellent corrosion resistance and the ability to withstand high temperatures.

Pros: Stainless steel conveyors are durable, hygienic, and resistant to rust and corrosion. They are easy to clean, making them ideal for applications requiring strict sanitation standards.

Cons: The primary downside is the higher cost compared to other materials, which may limit their use in budget-sensitive projects. Stainless steel is also heavier than aluminum and plastic, which can increase shipping costs.

Illustrative image related to roll conveyor

International buyers must consider compliance with hygiene standards (such as those set by the FDA or EU regulations) when selecting stainless steel conveyors. Understanding the local market for stainless steel and its availability is also essential for timely procurement.

Summary Table of Material Selection for Roll Conveyors

| Material | Typical Use Case for roll conveyor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty applications | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Lightweight and portable systems | Lightweight and corrosion-resistant | Higher cost and lower load capacity | High |

| Plastic | Food processing and light-duty use | Easy to clean and chemical resistant | Lower load capacity and wear | Low |

| Stainless Steel | Hygiene-critical environments | Excellent corrosion resistance | Higher cost and heavier weight | High |

This guide provides a comprehensive overview of material options for roll conveyors, helping international B2B buyers make informed decisions that align with their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for roll conveyor

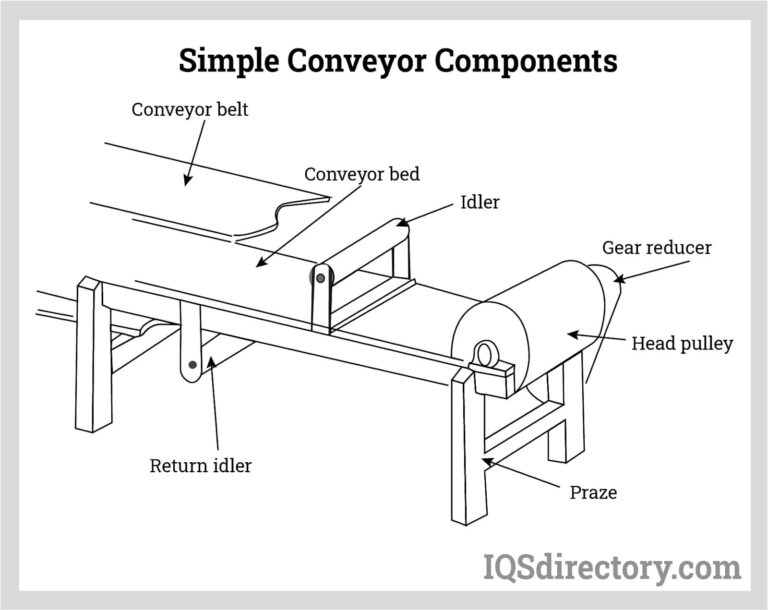

What Are the Main Stages of Manufacturing Roll Conveyors?

The manufacturing of roll conveyors involves several critical stages, each designed to ensure that the final product meets the necessary specifications for durability, efficiency, and safety.

Material Preparation: Selecting the Right Components

The first stage in the manufacturing process is material preparation. High-quality raw materials such as steel, aluminum, and various polymers are selected based on the specific requirements of the conveyor system. For example, heavy-duty applications often utilize high-strength steel to withstand significant loads, while lighter applications may use aluminum for its lightweight properties. The materials undergo rigorous inspection to ensure they meet industry standards before moving on to the next stage.

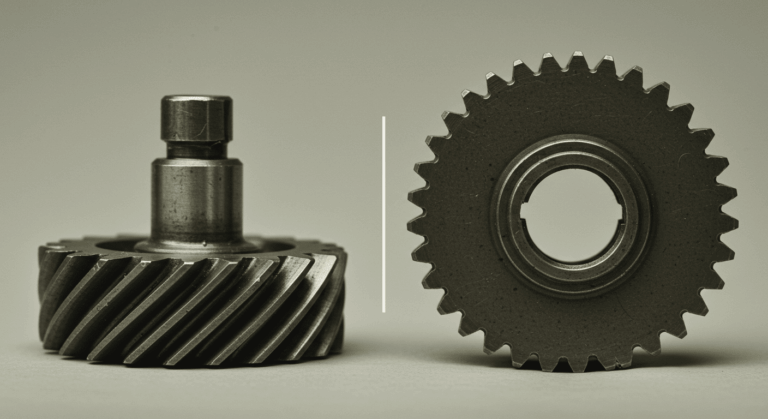

Forming: Shaping Components for Optimal Performance

In the forming stage, raw materials are shaped into the desired components. This often involves processes such as cutting, bending, and welding. Advanced techniques like laser cutting and CNC machining are commonly employed to achieve precise dimensions and tolerances. For example, rollers are typically formed using high-precision machines that ensure uniformity in diameter and surface finish, which is crucial for smooth operation.

Illustrative image related to roll conveyor

Assembly: Integrating Components for Functionality

Once the components are formed, they are assembled into a cohesive system. This stage includes the installation of rollers, frames, and drive mechanisms. Automated assembly lines may be utilized to enhance efficiency and reduce human error. Each conveyor system is designed to meet the specific operational requirements of the end user, whether it’s for heavy-duty material handling or light package movement.

Finishing: Ensuring Durability and Aesthetic Quality

The finishing stage involves surface treatments such as painting, galvanizing, or powder coating to enhance corrosion resistance and aesthetic appeal. This is particularly important for conveyors that will be used in harsh environments or exposed to moisture. Quality control checks are conducted at this stage to ensure that all components meet the required standards for both function and appearance.

What Are the Quality Control Measures in Roll Conveyor Manufacturing?

Quality assurance is paramount in the manufacturing of roll conveyors, ensuring that products meet international and industry-specific standards.

What International Standards Apply to Roll Conveyor Manufacturing?

Manufacturers of roll conveyors typically adhere to several international standards, including ISO 9001, which outlines requirements for a quality management system. Compliance with ISO 9001 ensures that a company consistently meets customer requirements and enhances satisfaction through effective system implementation. In addition, CE marking is crucial for products sold in Europe, signifying compliance with health, safety, and environmental protection standards.

What Are the Key Quality Control Checkpoints?

Quality control (QC) in roll conveyor manufacturing involves several checkpoints:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival. Materials are checked for compliance with specified standards, ensuring that only high-quality components are used in production.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are conducted to monitor the quality of the components being produced. This includes checking tolerances during forming and ensuring proper assembly techniques are followed.

-

Final Quality Control (FQC): After assembly, the completed conveyor systems undergo a thorough inspection. This includes functionality tests, load testing, and visual inspections to verify that the product meets all specified requirements.

What Common Testing Methods Are Used in Quality Control?

Various testing methods are employed to ensure the reliability and performance of roll conveyors:

-

Load Testing: This involves applying weights to the conveyor system to assess its ability to handle specified loads without failure.

-

Functional Testing: Each conveyor is tested to ensure it operates smoothly, checking for issues such as misalignment or excessive noise.

-

Environmental Testing: For conveyors designed for specific environments, tests may include exposure to humidity, temperature variations, or corrosive substances to ensure durability.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential.

What Methods Can Buyers Use to Ensure Supplier Compliance?

-

Supplier Audits: Conducting regular audits of suppliers can provide insight into their manufacturing processes and quality control measures. This includes reviewing documentation related to ISO certifications and quality management systems.

-

Requesting Quality Reports: Buyers should ask suppliers for detailed quality reports that outline their QC processes, testing methods, and results. This documentation can help buyers assess the reliability of the supplier’s products.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing and quality assurance processes. These services can validate compliance with international standards and ensure that the products meet the required specifications.

What Are the Nuances of Quality Control for International B2B Buyers?

Navigating quality control in international trade involves understanding the specific requirements and regulations of different markets.

Are There Regional Compliance Considerations?

For buyers in Africa, South America, the Middle East, and Europe, it is crucial to be aware of local regulations that may affect the importation and use of roll conveyors. For instance, certain countries may require additional certifications or testing for machinery and equipment. Understanding these nuances can help buyers avoid compliance issues and ensure smooth importation.

How Can Buyers Foster Strong Supplier Relationships?

Building strong relationships with suppliers can facilitate better communication regarding quality control measures. Buyers should engage in regular discussions about QC practices and express their expectations clearly. This collaborative approach not only helps in maintaining high-quality standards but also fosters trust and reliability in the long-term partnership.

Conclusion

Understanding the manufacturing processes and quality assurance measures for roll conveyors is essential for B2B buyers looking to make informed purchasing decisions. By focusing on the key stages of manufacturing, adhering to international standards, and implementing robust quality control practices, suppliers can deliver reliable and efficient conveyor systems that meet the diverse needs of businesses across various regions. Buyers must take proactive steps to verify supplier quality, ensuring that their investments yield optimal performance and longevity in their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘roll conveyor’

To assist B2B buyers in sourcing roll conveyors effectively, this guide offers a structured checklist that covers essential steps in the procurement process. By following these actionable items, you can ensure that you select the right conveyor system tailored to your operational needs.

Illustrative image related to roll conveyor

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements of the roll conveyor you need. Consider factors such as load capacity, dimensions, and the types of materials to be transported. This step is critical as it helps you communicate your needs to suppliers and ensures that the equipment can handle your specific applications.

- Load Capacity: Determine the maximum weight the conveyor must support.

- Dimensions: Measure the available space for the installation to ensure a proper fit.

Step 2: Research Different Conveyor Types

Understand the various types of roll conveyors available in the market, such as gravity, powered, and flexible options. Each type serves different purposes and has unique advantages. Knowing the differences helps you choose the right system for your operations.

- Gravity Conveyors: Ideal for light to medium-duty applications where the movement relies on gravity.

- Powered Conveyors: Suitable for heavier loads and longer distances, providing more control over the movement.

Step 3: Evaluate Potential Suppliers

Before making a purchase, thoroughly vet potential suppliers. This includes reviewing their company profiles, case studies, and asking for references from clients in similar industries or regions. A reliable supplier will have a proven track record and be able to provide support after the sale.

- Company Profile: Look for experience in the industry and a solid reputation.

- Customer References: Request testimonials to gauge the supplier’s reliability and service quality.

Step 4: Verify Compliance and Certifications

Ensure that the suppliers you are considering comply with local and international standards for safety and quality. Certifications such as ISO or CE mark can indicate adherence to industry best practices, which is crucial for operational safety and reliability.

- Safety Standards: Check for compliance with relevant safety regulations in your region.

- Quality Assurance: Look for certifications that reflect quality control processes.

Step 5: Request Detailed Quotes

Obtain detailed quotes from multiple suppliers to compare pricing and terms. Ensure that the quotes include all relevant costs, such as shipping, installation, and any additional components required. This transparency helps you make a cost-effective decision.

Illustrative image related to roll conveyor

- Breakdown of Costs: Look for clear itemization of costs to avoid hidden fees.

- Lead Times: Inquire about delivery times to align with your project schedules.

Step 6: Consider After-Sales Support and Warranty

Evaluate the after-sales support and warranty options offered by suppliers. A strong support system can save you time and money in the long run, especially if issues arise post-purchase. Ensure that the warranty covers critical components and that support is readily available.

- Support Services: Confirm the availability of technical support and maintenance services.

- Warranty Coverage: Review warranty terms to understand what is protected and for how long.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier, finalize the purchase agreement. Ensure that all terms discussed are included in the contract, including payment terms, delivery schedules, and service expectations. A well-drafted agreement protects both parties and clarifies responsibilities.

- Contract Terms: Review all terms carefully to avoid misunderstandings.

- Signatures: Ensure that both parties sign the agreement to validate the contract.

Following this checklist will help you navigate the complexities of sourcing roll conveyors, ensuring that you make informed decisions that align with your operational needs and budget.

Comprehensive Cost and Pricing Analysis for roll conveyor Sourcing

What Are the Key Cost Components in Roll Conveyor Sourcing?

When sourcing roll conveyors, understanding the cost structure is essential for effective budgeting and decision-making. The primary components of the cost structure include:

-

Materials: The choice of materials significantly influences costs. Steel and aluminum are common, with variations in quality affecting price. For instance, stainless steel conveyors tend to be more expensive due to their corrosion resistance.

-

Labor: Labor costs encompass assembly, installation, and maintenance. Highly skilled labor may be necessary for custom installations, impacting overall expenses.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment depreciation. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Custom tooling for specific conveyor designs can add to upfront costs. However, investing in high-quality tooling can lead to better precision and lower long-term costs.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the conveyors meet specified standards. While this adds to the cost, it mitigates the risk of defects and associated costs down the line.

-

Logistics: Shipping and handling costs vary based on distance, mode of transport, and packaging requirements. For international buyers, understanding the logistics network is crucial to avoid delays and unexpected expenses.

-

Margin: Supplier margins can vary widely, influenced by market demand, competition, and supplier reputation. Building relationships with suppliers may yield better pricing options.

How Do Price Influencers Affect Roll Conveyor Costs?

Several factors influence the pricing of roll conveyors that buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically qualify for volume discounts, which can significantly reduce the per-unit cost. Understanding MOQ can help buyers plan their procurement effectively.

-

Specifications and Customization: Custom features or specifications can drive up costs. Buyers should weigh the necessity of customization against budget constraints and operational needs.

-

Material Quality and Certifications: Higher-quality materials and industry certifications, such as ISO or CE, can increase costs. However, investing in certified equipment often results in better performance and reliability.

-

Supplier Factors: The supplier’s location, reputation, and financial stability can impact pricing. Established suppliers with a good track record may charge more but offer better service and support.

-

Incoterms: International buyers should be aware of Incoterms as they define the responsibilities of buyers and sellers regarding shipping costs, insurance, and risk. Understanding these terms can prevent unexpected financial burdens.

What Are the Best Buyer Tips for Cost-Efficiency in Roll Conveyor Sourcing?

To maximize cost-efficiency in sourcing roll conveyors, buyers should consider the following strategies:

Illustrative image related to roll conveyor

-

Negotiation: Engage suppliers in discussions regarding pricing, payment terms, and delivery schedules. A collaborative approach can often yield discounts or better terms.

-

Total Cost of Ownership (TCO): Assess the TCO, which includes purchase price, maintenance, operation, and disposal costs. This holistic view enables better budgeting and decision-making over the conveyor’s lifespan.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, the Middle East, and Europe should be mindful of currency fluctuations, tariffs, and import duties that can affect final costs. Conduct thorough market research to anticipate these factors.

-

Supplier Diversification: Engage multiple suppliers to compare pricing and service levels. This practice not only fosters competitive pricing but also mitigates risks associated with supply chain disruptions.

-

Invest in Training: Proper training for staff on conveyor operation and maintenance can minimize downtime and repair costs, ultimately enhancing the return on investment.

Conclusion: What Should International Buyers Keep in Mind?

While indicative prices for roll conveyors can vary significantly based on specifications and suppliers, understanding the cost components, price influencers, and strategic purchasing tips can empower international buyers to make informed decisions. Always conduct thorough research and consider long-term operational costs to ensure a successful procurement process.

Alternatives Analysis: Comparing roll conveyor With Other Solutions

Introduction to Alternative Conveyor Solutions

In the dynamic landscape of material handling, selecting the right conveyor system is crucial for optimizing operational efficiency. While roll conveyors offer significant advantages in moving products, various alternatives can also meet diverse business needs. Understanding these options allows B2B buyers to make informed decisions tailored to their specific operational requirements.

Comparison Table

| Comparison Aspect | Roll Conveyor | Modular Belt Conveyor | Automated Guided Vehicles (AGVs) |

|---|---|---|---|

| Performance | High for light to medium loads; ideal for continuous flow. | Versatile; handles various load types and sizes effectively. | Excellent for complex routing and high-volume transport. |

| Cost | Generally cost-effective; lower upfront costs for gravity models. | Higher initial investment; costs vary based on customization. | High capital expenditure; ongoing operational costs can be significant. |

| Ease of Implementation | Simple installation; minimal training required. | Moderate complexity; may require professional installation. | High complexity; requires integration with existing systems and training. |

| Maintenance | Low maintenance; regular checks needed for rollers. | Moderate maintenance; belt replacement and adjustments required. | Moderate to high; requires routine software and mechanical checks. |

| Best Use Case | Ideal for warehouses and assembly lines with consistent flow needs. | Best for environments with varied product types and sizes. | Suitable for large facilities needing automation and flexibility. |

Detailed Breakdown of Alternatives

Modular Belt Conveyor

Modular belt conveyors consist of interlocking plastic segments, allowing for flexible configurations. They excel in transporting a variety of products, including those with irregular shapes. While their initial costs can be higher than roll conveyors, their adaptability and ability to handle diverse loads make them a valuable investment for businesses with fluctuating inventory needs. However, they require more maintenance due to belt wear and tear, and the complexity of installation can necessitate professional help.

Automated Guided Vehicles (AGVs)

AGVs represent a cutting-edge solution for transporting materials without human intervention. These vehicles navigate predetermined paths using sensors and software, offering high efficiency for high-volume operations. AGVs are particularly advantageous in large facilities where traditional conveyors might be limited by fixed pathways. However, their implementation is often costly, and ongoing maintenance can be complex, requiring specialized knowledge. While they provide significant automation benefits, the initial investment may not be feasible for all companies, especially small to medium-sized enterprises.

Conclusion: Choosing the Right Conveyor Solution for Your Business

Selecting the appropriate conveyor solution hinges on several factors, including operational scale, product types, and budget constraints. Roll conveyors are ideal for businesses seeking a cost-effective and simple solution for consistent product flow. In contrast, modular belt conveyors offer flexibility for varied products, while AGVs provide advanced automation for complex environments. B2B buyers should carefully evaluate their specific needs, considering the long-term implications of each alternative to ensure a strategic investment that enhances productivity and efficiency in their operations.

Illustrative image related to roll conveyor

Essential Technical Properties and Trade Terminology for roll conveyor

What Are the Key Technical Properties of Roll Conveyors?

Understanding the essential technical properties of roll conveyors is critical for B2B buyers looking to optimize their material handling processes. Here are several key specifications to consider:

1. Material Grade

The material used in the construction of roll conveyors significantly affects their durability and performance. Common materials include steel, aluminum, and stainless steel. Steel offers high strength and is ideal for heavy-duty applications, while aluminum is lightweight and corrosion-resistant, making it suitable for environments where weight is a concern. Stainless steel is often used in food processing or pharmaceutical applications due to its hygienic properties. Choosing the right material ensures longevity and reduces maintenance costs.

2. Load Capacity

Load capacity refers to the maximum weight a conveyor can handle. This is typically expressed in pounds per roller or per foot of conveyor. Understanding load capacity is vital for selecting the appropriate conveyor system that meets your operational needs without risking damage to the equipment. Overloading a conveyor can lead to breakdowns, increased maintenance costs, and potential safety hazards.

3. Roller Diameter

The diameter of the rollers impacts both the load capacity and the type of products that can be transported. Common roller diameters range from 1.375 inches to 1.9 inches. A larger diameter roller can typically handle heavier loads and provides better stability for moving products. This specification is crucial for ensuring that the conveyor system aligns with the specific types of goods you intend to transport.

4. Tolerance

Tolerance refers to the allowable deviation from specified dimensions. In roll conveyors, tight tolerances are essential for ensuring smooth operation and efficient product flow. Poor tolerances can result in misalignment, increased wear, and operational inefficiencies. Understanding tolerance specifications helps in selecting equipment that will perform reliably within your specific application.

5. Drive Type

Roll conveyors can be powered or gravity-driven. Powered conveyors use electric motors to move products, making them suitable for longer distances and heavier loads. Gravity conveyors rely on incline or manual push, which can be cost-effective for shorter distances. The choice of drive type affects not only operational efficiency but also energy consumption and overall system cost.

6. Dimensions

The dimensions of the conveyor, including its width and length, must align with the space available in your facility and the size of the products being handled. A well-sized conveyor system improves workflow and reduces the risk of product damage. Understanding the dimensional specifications is crucial for integrating new equipment into existing layouts.

What Are Common Trade Terms in the Roll Conveyor Industry?

Familiarity with industry jargon can enhance communication and negotiation with suppliers. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of roll conveyors, understanding OEM can help buyers identify the source of components and ensure quality standards are met.

Illustrative image related to roll conveyor

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management, as it can affect overall costs and stock levels.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and availability for specific products or services. It’s a critical step in the procurement process that allows buyers to compare options and negotiate better terms.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for managing shipping costs, risks, and logistics when importing or exporting roll conveyors.

5. Lead Time

Lead time is the duration from the placement of an order to the delivery of the goods. It is a key consideration in supply chain management, as longer lead times can impact project timelines and inventory levels.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing roll conveyors, ensuring they select the right equipment to meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the roll conveyor Sector

What Are the Current Market Dynamics and Key Trends in the Roll Conveyor Sector?

The roll conveyor market is experiencing significant growth driven by the global shift towards automation and efficiency in material handling. Industries such as manufacturing, logistics, and e-commerce are increasingly adopting roll conveyor systems to optimize their operations. Key trends include the integration of advanced technologies, such as IoT and AI, which enhance the functionality of conveyor systems by enabling real-time monitoring and predictive maintenance. This technological evolution not only improves operational efficiency but also reduces downtime, making it an attractive investment for international B2B buyers.

Another emerging trend is the demand for customizable conveyor solutions. As businesses strive to meet unique operational needs, suppliers are offering modular and flexible conveyor systems that can be easily adapted or expanded. This flexibility is particularly appealing to buyers from diverse regions, including Africa, South America, the Middle East, and Europe, where varying industrial conditions and operational scales necessitate tailored solutions. Additionally, the rise of e-commerce has amplified the need for efficient order fulfillment systems, further propelling the roll conveyor market.

How Is Sustainability and Ethical Sourcing Impacting the Roll Conveyor Industry?

Sustainability is becoming a core consideration for B2B buyers in the roll conveyor sector, particularly as global awareness of environmental issues rises. Companies are increasingly evaluating the environmental impact of their supply chains, prompting a shift towards ethical sourcing practices. This includes selecting suppliers who prioritize sustainability in their manufacturing processes and materials.

Buyers are now seeking roll conveyors constructed from recycled or sustainably sourced materials, which not only minimize ecological footprints but also enhance brand reputation. Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are becoming essential criteria for suppliers looking to position themselves favorably in the market. Furthermore, innovations in conveyor design, such as energy-efficient motors and low-friction materials, contribute to reduced energy consumption, aligning with the growing demand for green solutions. This focus on sustainability not only meets regulatory requirements but also appeals to environmentally conscious consumers, providing a competitive edge in the market.

How Has the Roll Conveyor Sector Evolved Over Time?

The roll conveyor sector has undergone significant transformation since its inception in the early 20th century. Initially used in manufacturing for simple material transport, advancements in technology have expanded its applications across various industries. The introduction of powered conveyors and automated systems revolutionized material handling, enhancing efficiency and reducing labor costs.

In the latter half of the century, the rise of e-commerce and global trade further propelled the demand for sophisticated conveyor systems capable of handling diverse products and high volumes. Today, the integration of smart technologies is reshaping the industry once again, enabling features like real-time tracking and automated sorting. This evolution reflects the ongoing quest for efficiency and adaptability in a rapidly changing global marketplace, ensuring that roll conveyors remain a vital component in the logistics and manufacturing sectors.

Frequently Asked Questions (FAQs) for B2B Buyers of roll conveyor

-

How do I choose the right roller conveyor for my business?

Selecting the right roller conveyor involves assessing several factors, including the type and weight of products you handle, the layout of your facility, and your specific operational needs. Consider whether you need powered or gravity conveyors, the required speed of operation, and the distance products need to travel. Additionally, evaluate the dimensions of the conveyor, ensuring it can accommodate your largest items with some overhang for safety. Consulting with a supplier’s design expert can provide tailored recommendations based on your unique requirements. -

What are the key specifications to consider when sourcing roller conveyors?

When sourcing roller conveyors, focus on specifications such as roller diameter, load capacity, and material type. The diameter of the rollers affects the weight they can support; for instance, a 1.9-inch diameter roller typically supports heavier loads than a 1.38-inch roller. Additionally, consider the material of the conveyor—steel, aluminum, or plastic—based on your operational environment and product type. It’s also essential to review the conveyor’s speed, power requirements, and the need for additional features like adjustable heights or flexibility. -

What is the minimum order quantity (MOQ) for roller conveyors?

Minimum order quantities for roller conveyors can vary significantly between suppliers, with some offering no minimums while others may require orders of several units. For international buyers, understanding MOQ is crucial for budgeting and logistics. Suppliers may provide discounts for larger orders, so it’s beneficial to discuss your needs with them. If you’re just starting or need a specific configuration, inquire about the possibility of smaller initial orders or demo units to assess their suitability for your operations. -

How can I ensure the quality of roller conveyors from international suppliers?

To ensure quality when sourcing from international suppliers, consider conducting thorough due diligence. Request samples and product specifications, and verify certifications that confirm compliance with international standards. Engage in quality assurance practices such as factory audits or third-party inspections. Establish clear quality benchmarks in your contracts, and maintain open communication with suppliers throughout the manufacturing process to address any concerns promptly. -

What payment terms are typically offered for roller conveyor purchases?

Payment terms for roller conveyor purchases can vary based on the supplier’s policies and the relationship established between the buyer and seller. Common terms include advance payment, net 30, or net 60 days after delivery. For large orders or first-time purchases, negotiating payment terms that allow for a deposit followed by a balance upon delivery can be advantageous. Always clarify payment methods accepted, including wire transfers, letters of credit, or credit cards, and ensure these terms are documented in the purchase agreement. -

What logistics considerations should I keep in mind when importing roller conveyors?

When importing roller conveyors, consider logistics factors such as shipping methods, customs regulations, and lead times. Opt for a reliable freight forwarder familiar with the regulations in your destination country to avoid delays. Factor in potential tariffs and duties that may apply to your shipment, and ensure your supplier provides the necessary documentation for customs clearance. Additionally, plan for storage upon arrival, and consider the installation logistics, including any specialized equipment or personnel needed for setup. -

Can roller conveyors be customized for specific applications?

Yes, many suppliers offer customization options for roller conveyors to meet specific operational needs. Customizations can include modifications in length, width, roller type, and additional features like adjustable heights or integrated controls. When discussing your requirements with suppliers, provide detailed information about your products and operational environment to ensure the conveyor system is tailored to your workflow. Custom solutions can enhance efficiency and safety, making it a worthwhile investment for specialized applications. -

What are the advantages of buying used roller conveyors?

Purchasing used roller conveyors can offer significant cost savings, often ranging from 30% to 50% less than new equipment. This is particularly advantageous for businesses with tight budgets or those looking to scale operations without incurring substantial capital expenses. However, it’s essential to evaluate the condition and functionality of used conveyors thoroughly. Request maintenance records and inspect the equipment to ensure it meets your operational standards. Buying from reputable suppliers who offer warranties can further mitigate risks associated with used equipment.

Top 6 Roll Conveyor Manufacturers & Suppliers List

1. Wh1 – Conveyor Roller Tables

Domain: wh1.com

Registered: 1997 (28 years)

Introduction: New & Used Conveyor Roller Tables for Sale. Key features include: Condition – New (74), Used (19); Stocking location – In Stock @ Wh1 in KC (23), Ships from Factory (70); Styles – Ball Transfer (6), Belt (2), Belt Driven (3), Chain Drive (2), Expanding Conveyors (23), Flat Motor (3), Gravity Roller (16), Gravity Skatewheel (6), Lineshaft Drive (3), Motorized Roller (3), Plastic Belt (3); Heights -…

2. Uline – Heavy Duty Gravity Roller Conveyors

Domain: uline.com

Registered: 1995 (30 years)

Introduction: Heavy Duty Gravity Roller Conveyors with various specifications:

– H-3409: 18″ x 5′, 3,100 lbs capacity, 86 lbs weight, starting at $365.

– H-3411: 18″ x 10′, 1,180 lbs capacity, 166 lbs weight, starting at $665.

– H-3410: 24″ x 5′, 3,100 lbs capacity, 108 lbs weight, starting at $415.

– H-3412: 24″ x 10′, 1,180 lbs capacity, 205 lbs weight, starting at $755.

– H-4070: 30″ x 5′, 3,100 lbs cap…

3. Ultimation Industries – Conveyor Rollers

Domain: ultimationinc.com

Registered: 1998 (27 years)

Introduction: Conveyor Rollers in Various Sizes available from Ultimation Industries LLC. Rollers can be used individually or as part of a gravity roller conveyor system. Compatible with Hytrol, Lewco, and Ashland gravity conveyors. Most models available for same day shipping. Key products include: 1.5″ Dia. Galvanized Steel Replacement Roller (10″ Long) – $4.70, 1.5″ Dia. Galvanized Replacement Roller (16″ Lon…

4. Bastian Solutions – Roller Conveyor Systems

Domain: bastiansolutions.com

Registered: 2005 (20 years)

Introduction: Bastian Solutions offers roller conveyor systems designed for efficient material handling. These systems are ideal for transporting products of various sizes and weights. Key features include customizable configurations, durable construction, and compatibility with other conveyor systems. They are suitable for a range of applications, including packaging, assembly, and distribution. The roller con…

5. Platforms and Ladders – Expandable Roller Conveyor

Domain: platformsandladders.com

Registered: 2014 (11 years)

Introduction: Expandable Roller Conveyor

Price: $2,148.00

Description: An Expandable Roller Conveyor can move light cargo around large work spaces for packaging and distributing facilities. It provides an ergonomically friendly way to transfer goods while minimizing bending and twisting during shipping and handling. Employees can move heavy products across their workspace with ease and efficiency. The conveyor …

6. Glassline – Roll Conveyors

Domain: glassline.com

Registered: 1996 (29 years)

Introduction: Roll Conveyors – Various types and sizes including: Line shaft (round belt) driven, Timing Belt driven rolls, Miter Gear driven rolls. Roll styles available: Vulcanized, tubular, donut, multi-directional. Features include: Rigid Tubular Rollers driven by timing belt, Brush Roll Conveyor, Retracting Trim Conveyor, Fork-Lift Removable Stainless Pivoting Miter Gear (Furnace emergency ejection), High …

Strategic Sourcing Conclusion and Outlook for roll conveyor

In the evolving landscape of material handling, strategic sourcing of roll conveyors plays a pivotal role in enhancing operational efficiency and cost-effectiveness for businesses across diverse sectors. The integration of both new and used conveyor systems provides significant flexibility, enabling companies to optimize their supply chains while managing budget constraints. Notably, opting for used equipment can yield savings of 30-50%, which is essential for organizations seeking to maximize their return on investment.

Illustrative image related to roll conveyor

As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe navigate their sourcing strategies, it is crucial to assess the specific needs of their operations. Factors such as load capacity, conveyor type, and space requirements should guide the selection process. Engaging with experienced suppliers can facilitate informed decisions that align with unique operational goals.

Looking ahead, the demand for efficient and adaptable conveyor solutions will continue to grow. Companies that prioritize strategic sourcing will not only enhance productivity but also position themselves competitively in the global market. To capitalize on these opportunities, buyers are encouraged to connect with trusted suppliers to explore tailored conveyor solutions that meet their evolving material handling needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to roll conveyor

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.