Unlocking Value: A Strategic Analysis of the Push Button Push Button Market

Introduction: Navigating the Global Market for push button push button

In an increasingly interconnected world, sourcing reliable and efficient push button switches is essential for businesses aiming to optimize their operational processes. Whether you are looking for momentary or latching push buttons, the challenge lies in finding high-quality products that meet specific technical requirements while remaining cost-effective. This comprehensive guide on push button switches and their applications is designed to equip international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, with the knowledge necessary for informed purchasing decisions.

The guide delves into various types of push button switches, including their unique features and applications across industries such as automation, machine control, and safety technology. We will also discuss critical factors to consider when vetting suppliers, including certifications, pricing structures, and delivery capabilities. Additionally, we will explore the cost implications of different switch types, providing insights on how to balance quality with budget constraints.

By navigating the complexities of the global market for push button switches, this guide empowers businesses to streamline their sourcing process, minimize risks, and ensure they select the best components for their operational needs. With actionable insights and practical strategies, you will be equipped to make confident decisions that enhance your product offerings and drive business success.

Understanding push button push button Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Momentary Push Buttons | Activates only while pressed; available in various sizes and LED options | Machine control, safety systems | Pros: Easy to use, precise control; Cons: Not suitable for permanent activation. |

| Latching Push Buttons | Maintains its state after being pressed; typically used for ON/OFF functions | Automation systems, lighting control | Pros: Simple operation for toggling states; Cons: May require more complex wiring. |

| Stainless Steel Push Buttons | High durability, often IP67 rated for water and dust resistance | Industrial environments, outdoor applications | Pros: Long-lasting, resistant to harsh conditions; Cons: Higher initial cost. |

| LED Indicator Push Buttons | Integrated LED lighting for status indication; available in multiple colors | Control panels, machinery interfaces | Pros: Visual feedback enhances usability; Cons: Additional cost for LED features. |

| Rotary Push Buttons | Requires rotation to activate; often used for volume or speed control | Audio equipment, machinery adjustment | Pros: Versatile in function; Cons: More complex to install and use than traditional push buttons. |

What Are Momentary Push Buttons and Where Are They Used?

Momentary push buttons are designed to activate a circuit only while being pressed. They are commonly found in applications such as machine control and safety systems, where precise control is essential. B2B buyers should consider their ease of use and reliability, especially in environments where quick responses are critical. However, these buttons may not be suitable for applications requiring a continuous on/off state.

How Do Latching Push Buttons Function in B2B Applications?

Latching push buttons remain in their last activated state until pressed again, making them ideal for toggling functions like lights or machinery. They are widely used in automation systems and lighting control, appealing to B2B buyers looking for simplicity in operation. While they offer straightforward functionality, buyers must be mindful of the potential need for more complex wiring setups.

Why Choose Stainless Steel Push Buttons for Industrial Use?

Stainless steel push buttons are favored in industrial settings due to their durability and resistance to environmental factors, often rated IP67 for water and dust protection. They are suitable for outdoor applications and harsh environments, making them an excellent investment for B2B buyers prioritizing longevity. However, the initial cost may be higher compared to plastic alternatives, which should be factored into purchasing decisions.

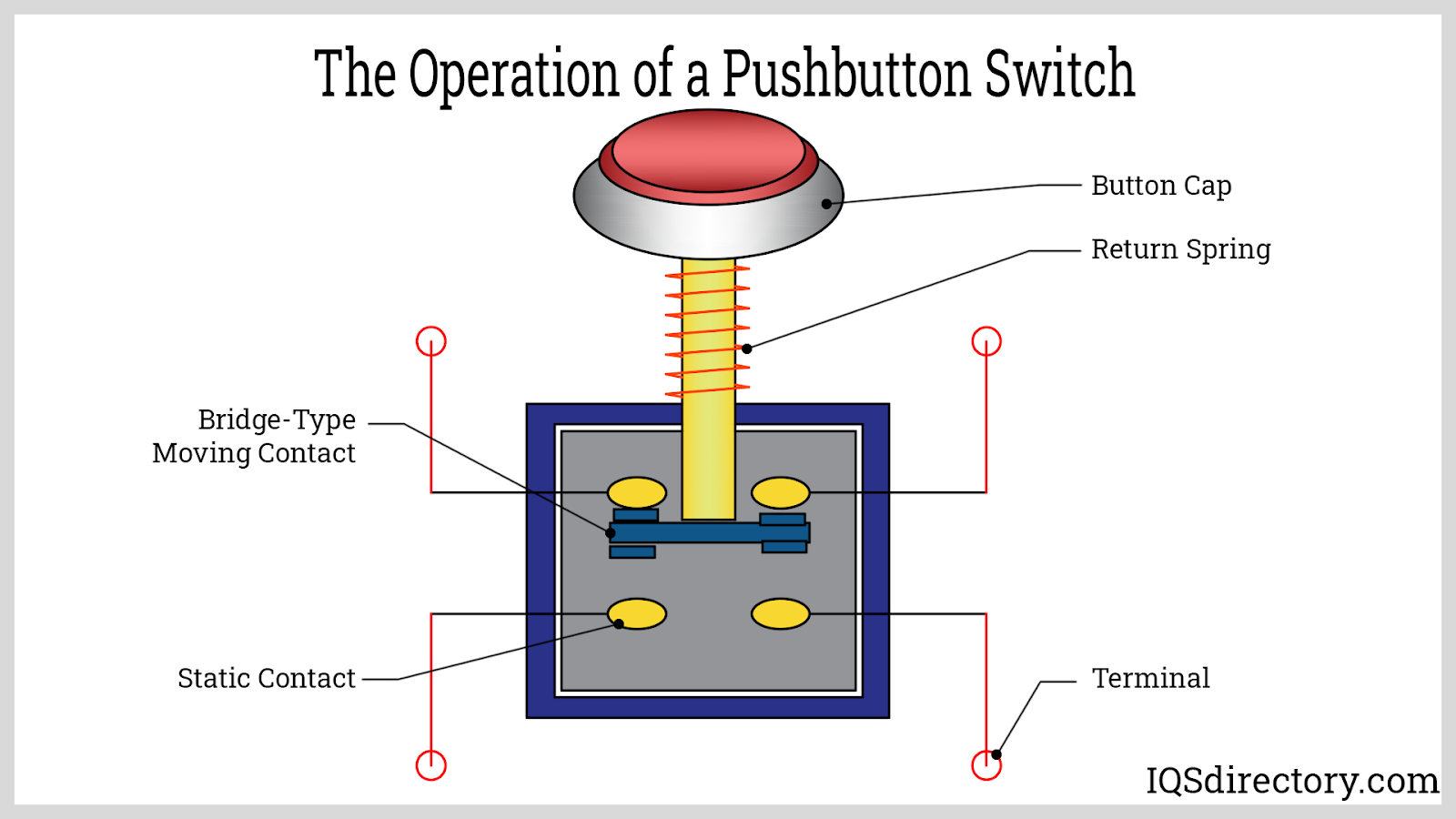

Illustrative image related to push button push button

What Advantages Do LED Indicator Push Buttons Offer?

LED indicator push buttons provide visual feedback through integrated lighting, which can enhance usability in control panels and machinery interfaces. They are particularly beneficial in environments where quick status recognition is necessary. B2B buyers should weigh the benefits of improved operational efficiency against the additional costs associated with LED features when making their selections.

How Are Rotary Push Buttons Used in B2B Settings?

Rotary push buttons require users to rotate the knob to activate functions, such as adjusting volume or speed. They are commonly found in audio equipment and machinery adjustments, appealing to B2B buyers seeking versatile control options. However, their complexity compared to traditional push buttons may pose a challenge in installation and usage, necessitating careful consideration during procurement.

Key Industrial Applications of push button push button

| Industry/Sector | Specific Application of push button push button | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Machine Control Panels | Enhances operational efficiency and safety | Look for durable materials, IP ratings for dust/water resistance, and compatibility with existing systems. |

| Automotive | Vehicle Control Systems | Improves user interface and operational reliability | Ensure compliance with automotive standards and consider LED indicators for clear feedback. |

| Construction & Heavy Equipment | Safety and Emergency Shutdown Systems | Reduces risk of accidents and enhances safety | Prioritize robust designs, quick response times, and compliance with safety regulations. |

| Telecommunications | Network Infrastructure Management | Streamlines system management and maintenance | Seek push buttons that support various voltage levels and environmental ratings for outdoor use. |

| Food Processing | Automated Production Lines | Increases productivity while ensuring safety | Focus on hygiene compliance, ease of cleaning, and durability under harsh conditions. |

How is Push Button Technology Used in Manufacturing Control Panels?

In manufacturing, push button switches are integral to machine control panels, allowing operators to start, stop, or adjust equipment settings easily. These switches enhance operational efficiency by enabling quick responses to machine status changes. For international buyers, especially in regions like Africa and South America, sourcing push buttons with high durability and protection ratings (such as IP65 or higher) is crucial due to varying environmental conditions. Additionally, compatibility with existing control systems is a key consideration.

What Role Do Push Buttons Play in Automotive Systems?

In the automotive sector, push buttons are commonly used in vehicle control systems, including ignition, window controls, and infotainment systems. Their design can significantly impact user experience, providing intuitive control and reliability. Buyers in Europe or the Middle East should prioritize sourcing components that meet stringent automotive industry standards, including certifications for safety and performance. LED indicators can also enhance functionality by providing visual feedback during operation.

How Are Push Buttons Critical in Construction Safety Systems?

Push buttons are vital for safety and emergency shutdown systems in construction and heavy equipment. They allow for immediate response in hazardous situations, thus reducing the risk of accidents. When sourcing for these applications, it is essential to consider robust designs that can withstand harsh environments, quick response times, and compliance with local safety regulations. Buyers from regions with extreme weather conditions, such as the Middle East, should prioritize push buttons with high resistance to temperature fluctuations and moisture.

Why Are Push Buttons Important in Telecommunications Management?

In telecommunications, push buttons facilitate network infrastructure management, allowing technicians to manage and troubleshoot systems efficiently. They can streamline maintenance tasks, reducing downtime and improving service delivery. Buyers, particularly in emerging markets like Vietnam, should look for push buttons that support a wide range of voltage levels and environmental ratings, especially for outdoor applications. Ensuring that the buttons are compatible with existing network equipment is also critical.

How Do Push Buttons Enhance Productivity in Food Processing?

In food processing, push buttons are essential for automating production lines, enabling quick adjustments to processes while ensuring safety standards are met. They help maintain high productivity levels, crucial in a competitive industry. International buyers need to focus on hygiene compliance and ease of cleaning, as well as durability to withstand the harsh conditions typical in food processing environments. Sourcing buttons that meet food safety regulations can also help mitigate compliance risks.

3 Common User Pain Points for ‘push button push button’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Push Button for Specific Applications

The Problem: B2B buyers often face challenges when trying to identify the appropriate push button switches for their specific applications. With a plethora of options available, including momentary and latching buttons, as well as variations in voltage and LED indicators, it can be overwhelming. This can lead to costly mistakes if the incorrect type is selected, resulting in inefficiencies or equipment failures. For companies operating in high-stakes industries like manufacturing or automation, the wrong choice can disrupt operations and lead to significant financial losses.

The Solution: To overcome this challenge, B2B buyers should begin by conducting a thorough assessment of their operational requirements. This includes understanding the environment in which the push buttons will be used, such as temperature ranges, exposure to moisture, or dust levels. Next, buyers should prioritize suppliers that offer detailed product specifications and application guides. Engaging with technical support teams from manufacturers can provide insights into which products have been successfully used in similar applications. Additionally, investing in samples for testing before full-scale purchases can mitigate risk and ensure the selected push buttons meet operational needs.

Illustrative image related to push button push button

Scenario 2: Quality and Durability Concerns in Harsh Environments

The Problem: Many industries, particularly in Africa and the Middle East, operate in harsh environments that can compromise the quality and durability of push button switches. Factors such as extreme temperatures, humidity, dust, and corrosive substances can lead to premature failures of low-quality components. This not only increases maintenance costs but also risks safety and operational integrity, causing delays and potential accidents.

The Solution: B2B buyers should seek push buttons specifically designed for durability in harsh conditions. Look for products with high IP (Ingress Protection) ratings, indicating resistance to dust and water. Additionally, selecting push buttons made from corrosion-resistant materials, such as stainless steel, is crucial for longevity. It is also beneficial to consult with suppliers who can provide case studies or testimonials from similar environments. Establishing a partnership with manufacturers that offer warranties or guarantees on their products can further ensure that the chosen components will withstand the rigors of challenging operational contexts.

Scenario 3: Integration Issues with Existing Systems

The Problem: When integrating new push button technology into existing systems, B2B buyers often encounter compatibility issues. Differences in electrical specifications, connectivity options, or control interfaces can lead to integration failures, resulting in additional costs for modifications or replacements. This is particularly problematic for companies looking to upgrade without a complete system overhaul, leading to frustration and delays in project timelines.

The Solution: To alleviate integration challenges, buyers should prioritize compatibility when selecting push button switches. This involves thoroughly reviewing the technical specifications of existing systems and ensuring that new components match or can be easily adapted. Collaboration with electrical engineers during the selection process can provide valuable insights into potential integration issues. Furthermore, sourcing push buttons from suppliers who offer comprehensive support, including installation guides and troubleshooting assistance, can streamline the integration process. Conducting pilot tests with a limited number of units can also help identify and resolve any issues before a full rollout.

Strategic Material Selection Guide for push button push button

What Are the Key Materials Used in Push Button Switches?

When selecting materials for push button switches, it is essential to consider their properties, advantages, and limitations. The choice of material can significantly impact the performance, durability, and suitability of the push button for specific applications. Below, we analyze four common materials used in push button switches: plastic, stainless steel, aluminum, and rubber.

Illustrative image related to push button push button

How Does Plastic Perform in Push Button Applications?

Plastic is one of the most widely used materials for push button switches due to its versatility and cost-effectiveness. Key properties include lightweight nature, good electrical insulation, and resistance to corrosion. However, plastic can have limitations in terms of temperature resistance, often rated between -20°C to 80°C, which may not be suitable for high-temperature environments.

Pros: Plastic is generally low-cost, easy to mold into various shapes, and can be produced in different colors, making it aesthetically appealing. It also offers good electrical insulation, making it suitable for various electronic applications.

Cons: The main drawback is its susceptibility to wear and tear over time, especially in harsh environments. Additionally, certain plastics may not be compatible with high-stress applications, leading to potential failure.

Illustrative image related to push button push button

Impact on Application: Plastic buttons are ideal for consumer electronics and low-stress environments. However, they may not be suitable for industrial applications where exposure to extreme temperatures or chemicals is common.

Considerations for International Buyers: When sourcing plastic push buttons, ensure compliance with local standards such as ASTM or DIN. Buyers in regions like Africa and South America should also consider the availability of specific plastic types that meet their environmental conditions.

What Advantages Does Stainless Steel Offer for Push Button Switches?

Stainless steel is favored for its strength, durability, and corrosion resistance, making it an excellent choice for industrial applications. Typically, stainless steel push buttons can withstand temperatures ranging from -40°C to 120°C, making them suitable for a wide range of environments.

Pros: The key advantage of stainless steel is its exceptional durability and resistance to corrosion, which extends the lifespan of the product. This material is also easy to clean, making it suitable for applications in food processing or medical environments.

Cons: The main disadvantage is the higher cost compared to plastic. Additionally, stainless steel can be heavier, which may not be ideal for all applications.

Impact on Application: Stainless steel push buttons are well-suited for environments exposed to moisture, dust, and chemicals, such as manufacturing plants and outdoor installations.

Considerations for International Buyers: Buyers should verify that the stainless steel used complies with international standards such as JIS or ASTM. In regions like the Middle East, where humidity can be high, selecting a high-grade stainless steel is crucial to prevent corrosion.

How Does Aluminum Compare as a Material for Push Button Switches?

Aluminum is another popular choice for push button switches, known for its lightweight and good strength-to-weight ratio. It typically offers a temperature range similar to stainless steel, making it versatile for various applications.

Pros: Aluminum is relatively inexpensive compared to stainless steel and can be anodized for added corrosion resistance. It is also lightweight, which can be beneficial for portable devices.

Cons: While aluminum is durable, it is less resistant to corrosion than stainless steel unless treated. It can also be more prone to scratching, which may affect its aesthetic over time.

Impact on Application: Aluminum push buttons are suitable for applications where weight is a concern, such as handheld devices, but may not be ideal in highly corrosive environments without proper treatment.

Considerations for International Buyers: Ensure that aluminum components meet the necessary compliance standards, particularly in regions with strict regulations on materials used in electronics.

Illustrative image related to push button push button

What Role Does Rubber Play in Push Button Switches?

Rubber is often used in push button switches primarily for its flexibility and tactile feedback. It is particularly effective in applications requiring a waterproof or dustproof seal.

Pros: Rubber provides excellent sealing properties, making it ideal for outdoor or industrial applications. It also offers good resistance to shock and vibration, enhancing user experience.

Cons: The main limitation of rubber is its susceptibility to degradation over time, especially when exposed to UV light or extreme temperatures.

Impact on Application: Rubber push buttons are commonly used in consumer electronics and outdoor equipment where moisture and dust ingress are concerns.

Considerations for International Buyers: Buyers should consider the specific rubber compounds used, as not all rubbers are created equal. Compliance with local environmental regulations is also essential.

Summary Table of Material Properties for Push Button Switches

| Material | Typical Use Case for Push Button Switch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Consumer electronics | Low cost and versatile | Susceptible to wear and tear | Low |

| Stainless Steel | Industrial applications | High durability and corrosion resistance | Higher cost and heavier | High |

| Aluminum | Portable devices | Lightweight and cost-effective | Less corrosion-resistant than steel | Medium |

| Rubber | Outdoor equipment | Excellent sealing properties | Degrades over time | Medium |

This analysis provides a comprehensive understanding of the materials used in push button switches, helping international B2B buyers make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for push button push button

What Are the Key Stages in the Manufacturing Process of Push Button Switches?

Manufacturing push button switches involves several critical stages, each essential for ensuring the final product meets quality and performance standards. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step in manufacturing push button switches is selecting high-quality materials, such as stainless steel or durable plastics. These materials are sourced from reputable suppliers who adhere to international standards. Once the materials are procured, they undergo inspections to ensure they meet specified criteria for durability and conductivity.

-

Forming: In this stage, the raw materials are shaped into the desired components of the push button switch. Techniques such as stamping, molding, and machining are commonly employed. For instance, stainless steel buttons are often stamped to create precise shapes, while plastic components may be injection molded for efficiency and consistency. Advanced technologies like CNC machining can also be utilized for high precision in forming complex parts.

-

Assembly: After forming, the individual components are assembled. This process typically involves integrating various elements like the button housing, switch mechanism, LED indicators, and wiring. Automated assembly lines may be used to enhance speed and accuracy, while manual assembly can allow for greater attention to detail in certain applications. Each assembly step is crucial, as it directly impacts the functionality and reliability of the switch.

-

Finishing: The final stage involves finishing touches that enhance the appearance and durability of the push button switches. This may include surface treatments such as polishing, anodizing, or coating to prevent corrosion and improve aesthetic appeal. Quality checks are also conducted during this stage to ensure that the switches meet visual and functional standards.

How Does Quality Assurance Ensure Reliability in Push Button Manufacturing?

Quality assurance (QA) is integral to the manufacturing process of push button switches, ensuring that every unit meets industry standards and customer expectations. Various international and industry-specific standards guide the QA process.

-

International Standards: Compliance with international standards such as ISO 9001 is crucial for manufacturers. This standard outlines requirements for a quality management system (QMS) that ensures products are consistently produced to meet customer and regulatory requirements. Adherence to ISO standards not only enhances product reliability but also boosts the manufacturer’s credibility in international markets.

-

Industry-Specific Certifications: In addition to ISO 9001, push button manufacturers may seek industry-specific certifications such as CE marking for products sold in Europe, or API specifications for applications in the oil and gas sector. These certifications often require rigorous testing and documentation, reflecting the product’s safety and performance characteristics.

What Are the Key Quality Control Checkpoints in Push Button Manufacturing?

Quality control (QC) checkpoints are established throughout the manufacturing process to ensure that defects are caught early and that the final product meets quality standards. The main QC checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint assesses raw materials upon arrival. Incoming materials are inspected for conformity to specifications, which can include dimensional checks, material properties, and visual inspections. Any non-conforming materials are rejected, preventing defects in the final product.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC involves monitoring production lines and conducting tests at various stages, such as after forming and assembly. This real-time monitoring helps identify issues promptly, allowing for corrective actions before the product moves to the next stage.

-

Final Quality Control (FQC): The final checkpoint occurs after the assembly and finishing stages. FQC involves comprehensive testing of the push button switches to evaluate functionality, durability, and safety. Common testing methods include electrical continuity tests, mechanical endurance tests, and environmental testing to assess performance under various conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is vital for ensuring product reliability. Here are several strategies to assess and validate supplier QC processes:

Illustrative image related to push button push button

-

Supplier Audits: Conducting regular audits of potential suppliers allows buyers to evaluate their manufacturing processes, quality control measures, and compliance with international standards. Audits can be performed by the buyer’s internal team or through third-party inspection services.

-

Quality Assurance Reports: Requesting detailed quality assurance reports from suppliers can provide insights into their QC practices. These reports should outline testing methodologies, results, and any corrective actions taken in response to identified issues.

-

Third-Party Inspections: Engaging independent third-party inspection agencies can add an extra layer of assurance. These agencies can perform unbiased evaluations of the manufacturing processes and product quality, ensuring that the supplier adheres to the agreed-upon standards.

What Are the Nuances of Quality Control for International Buyers?

International buyers must navigate various nuances in quality control when sourcing push button switches. Differences in regulatory requirements, cultural expectations, and industry standards can impact the quality assurance landscape.

-

Understanding Local Regulations: Buyers must familiarize themselves with the local regulations and standards applicable in their markets. For example, products sold in the European Union may require CE marking, while products in the Middle East may need to comply with GCC standards. Understanding these requirements helps buyers ensure that the products they source are compliant.

-

Cultural Expectations: Cultural differences can also influence quality perceptions. What is considered acceptable quality in one region may not meet the expectations in another. Buyers should communicate clearly with suppliers about their quality requirements and standards to avoid misunderstandings.

-

Building Relationships: Establishing strong relationships with suppliers can facilitate better quality control. Open communication channels enable buyers to express their quality expectations and collaborate with suppliers to address any potential issues proactively.

By understanding the manufacturing processes and quality assurance practices involved in producing push button switches, B2B buyers can make informed decisions that align with their quality expectations and operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘push button push button’

Introduction

Sourcing push button switches and their accessories effectively is crucial for businesses seeking reliable components for automation, control systems, or other industrial applications. This guide provides a structured checklist to assist international B2B buyers—especially those from Africa, South America, the Middle East, and Europe—in navigating the procurement process efficiently and confidently.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the first step in the sourcing process. This includes determining the type of push button (momentary or latching), voltage ratings, materials (such as stainless steel for durability), and any specific features like LED indicators. A well-defined specification helps in identifying suitable suppliers and ensuring that the products meet your operational needs.

Step 2: Research Potential Suppliers

Begin by identifying suppliers that specialize in push button switches. Utilize online platforms, industry directories, and trade shows to compile a list of potential vendors. Pay close attention to their product range, customer reviews, and case studies that demonstrate their expertise in your specific industry or application.

Step 3: Evaluate Supplier Certifications and Compliance

Verify that potential suppliers hold relevant certifications (such as ISO 9001) and comply with international standards. This step is vital to ensure that the products you source meet safety, quality, and environmental regulations applicable in your region. Look for certifications specific to your industry, as these can greatly influence product reliability.

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples of the push buttons you are considering. Testing samples in your actual operational environment allows you to evaluate their performance, durability, and ease of integration with your systems. This hands-on assessment can prevent costly mistakes and ensure product suitability.

Step 5: Negotiate Pricing and Terms

Once you have shortlisted suppliers, initiate discussions on pricing, payment terms, and delivery timelines. Be prepared to negotiate to achieve favorable terms that align with your budget and operational requirements. Consider bulk purchasing discounts or long-term partnership agreements, which can provide additional savings.

Illustrative image related to push button push button

Step 6: Confirm After-Sales Support and Warranty

Inquire about the after-sales support offered by suppliers, including warranty terms and repair or replacement policies. Reliable support is essential for minimizing downtime in case of product failure. Understanding warranty coverage and support channels will provide peace of mind and foster a long-term relationship with your supplier.

Step 7: Finalize the Order and Monitor Delivery

Once terms are agreed upon, finalize your order with clear documentation. Establish a timeline for delivery and ensure that you have tracking capabilities to monitor the shipment. Stay in close contact with the supplier to address any potential delays or issues proactively, ensuring a smooth procurement process.

Following this checklist will help streamline your sourcing of push button switches and accessories, ultimately supporting your business’s operational efficiency and reliability.

Comprehensive Cost and Pricing Analysis for push button push button Sourcing

What Are the Key Cost Components of Push Button Push Button Sourcing?

When sourcing push button switches, understanding the cost structure is essential for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. The primary cost components include:

-

Materials: The choice of materials significantly impacts cost. High-quality stainless steel, for instance, is often used for durability, especially in industrial applications. The price can vary based on the specific alloy and finish required.

-

Labor: Labor costs can fluctuate based on geographic location and the complexity of manufacturing. In regions with higher labor costs, such as parts of Europe, the price of push buttons will be higher compared to countries with lower labor expenses.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient production processes can help minimize these costs, which ultimately affects the pricing structure.

-

Tooling: The initial investment in tooling for specialized or custom push buttons can be substantial. This cost is often amortized over the production run, so larger orders typically benefit from lower per-unit tooling costs.

-

Quality Control (QC): Implementing stringent quality control measures is essential for ensuring product reliability, particularly for applications in critical environments. QC processes add to the overall cost but are vital for maintaining brand reputation and customer satisfaction.

-

Logistics: Shipping costs can vary widely based on the distance from the supplier, the mode of transportation, and any tariffs or duties applicable to the transaction. Buyers must factor these costs into their total procurement budgets.

-

Margin: Suppliers will typically add a margin to cover their costs and ensure profitability. This margin can vary based on supplier reputation, market demand, and competition.

How Do Price Influencers Impact Push Button Pricing?

Several factors influence the pricing of push button switches, which can vary depending on the buyer’s needs and the supplier’s capabilities:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often receive significant discounts, as suppliers can spread their fixed costs over more units. Buyers should negotiate for favorable terms based on their projected needs.

-

Specifications and Customization: Custom-designed push buttons with specific features (e.g., LED indicators, unique sizes) will generally cost more due to the additional engineering and production efforts involved.

-

Materials and Quality Certifications: Higher-grade materials and certifications (such as IP ratings for water and dust resistance) can increase costs but provide added value in terms of longevity and reliability.

-

Supplier Factors: Established suppliers with a proven track record may command higher prices, reflecting their reliability and quality assurance processes. Conversely, newer or less-known suppliers might offer lower prices to gain market entry.

-

Incoterms: The choice of Incoterms (International Commercial Terms) affects the total cost of procurement. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears shipping costs and risks, which can influence the final price.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Push Buttons?

For international B2B buyers, especially from emerging markets, strategic sourcing of push buttons can lead to significant cost savings:

-

Negotiate Effectively: Engage suppliers in discussions about pricing, especially for larger orders. Use competitive quotes as leverage to negotiate better terms.

-

Consider Total Cost of Ownership (TCO): Evaluate not only the purchase price but also the operational costs, including maintenance, replacement frequency, and energy consumption. A higher upfront cost may lead to lower TCO if the product is more durable.

-

Understand Pricing Nuances: Be aware of how exchange rates and international shipping costs can affect pricing. Building relationships with suppliers can also lead to better pricing and terms over time.

-

Leverage Local Knowledge: Utilize local agents or partners who understand the regional market dynamics, including customs regulations, which can streamline the sourcing process and reduce unforeseen costs.

By considering these insights, B2B buyers can make informed decisions that optimize their sourcing strategies and enhance their competitive positioning in the market.

Alternatives Analysis: Comparing push button push button With Other Solutions

Understanding Alternatives for Push Button Solutions

When considering the implementation of a push button system, it is crucial for B2B buyers to evaluate viable alternatives that can meet their operational needs. While push button switches are popular for their simplicity and efficiency, other technologies may offer enhanced functionalities or cost advantages. This section provides a comparative analysis of push button switches against two alternative solutions: touch-sensitive controls and rotary switches.

Comparison Table

| Comparison Aspect | Push Button Push Button | Touch-Sensitive Controls | Rotary Switches |

|---|---|---|---|

| Performance | Reliable for frequent use and quick response times. | Offers fast activation with a sleek interface. | Allows precise control over multiple settings. |

| Cost | Moderate cost per unit, with additional costs for installation. | Generally higher initial investment but can reduce long-term costs. | Usually lower cost but may require more space for installation. |

| Ease of Implementation | Straightforward installation and integration into existing systems. | May require advanced installation and calibration. | Simple to install but needs more physical space. |

| Maintenance | Low maintenance, with occasional checks needed. | Can be sensitive to environmental factors (e.g., dust, moisture). | Requires regular maintenance to ensure smooth operation. |

| Best Use Case | Ideal for industrial applications needing quick and reliable input. | Best suited for modern interfaces where aesthetics and usability are priorities. | Excellent for applications requiring selection among multiple options. |

Detailed Breakdown of Alternatives

What Are the Benefits and Drawbacks of Touch-Sensitive Controls?

Touch-sensitive controls provide a modern, sleek interface that allows users to activate functions with a simple touch. This technology is often utilized in consumer electronics and high-end industrial applications. The primary advantage is the ease of use, as users can engage with the system without physical buttons, which can be beneficial in environments where cleanliness is critical. However, the initial investment is typically higher than traditional push buttons, and their sensitivity can be affected by environmental factors such as dust or moisture, requiring careful installation and maintenance to ensure longevity.

How Do Rotary Switches Compare to Push Button Solutions?

Rotary switches allow users to select from multiple settings by turning a knob. This can be advantageous in scenarios where multiple functions need to be controlled from a single point, such as in machinery or control panels. The cost of rotary switches is often lower than that of push button systems, making them an attractive option for budget-conscious projects. However, they may require more physical space and can be less intuitive than push buttons, particularly for new users. Regular maintenance is also necessary to ensure smooth operation over time, as mechanical components can wear out.

Illustrative image related to push button push button

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right control solution depends on various factors, including performance requirements, budget constraints, and the specific application environment. For B2B buyers, evaluating the operational needs and the potential trade-offs between push button switches and alternatives like touch-sensitive controls or rotary switches is crucial. Analyzing aspects such as ease of implementation, long-term maintenance costs, and user experience will help in making an informed decision that aligns with both immediate and future operational goals.

Essential Technical Properties and Trade Terminology for push button push button

What Are the Key Technical Properties of Push Button Switches?

When selecting push button switches for industrial applications, several technical properties are crucial for ensuring reliability, safety, and performance. Understanding these properties can help B2B buyers make informed decisions.

1. Material Grade

The material used in the construction of push buttons significantly impacts their durability and suitability for various environments. Common materials include stainless steel, plastic, and aluminum. Stainless steel, particularly V2A and V4A grades, is favored for its corrosion resistance and strength, making it ideal for harsh industrial conditions. Buyers should assess material specifications to ensure they meet the environmental challenges of their specific applications.

2. Ingress Protection (IP) Rating

The IP rating indicates the level of protection provided against dust and moisture. For instance, an IP67 rating means the switch is dust-tight and can withstand immersion in water up to 1 meter for 30 minutes. This property is crucial for applications in outdoor or wet environments, ensuring the longevity of the switch and reducing maintenance costs.

3. Voltage and Current Ratings

Push buttons are designed to operate within specific voltage and current limits. Understanding these ratings is essential for compatibility with the electrical systems in which they will be integrated. For example, some push buttons are rated for 12V or 24V DC, while others can handle up to 230V AC. Selecting the correct ratings ensures optimal functionality and safety.

4. Actuation Type (Momentary vs. Latching)

Push buttons can be momentary (only active while pressed) or latching (maintains state until pressed again). The choice between these types depends on the intended application. Momentary switches are commonly used in applications requiring temporary activation, such as emergency stop buttons, while latching switches are useful for toggling functions on and off, enhancing usability.

5. Size and Mounting Options

The size of the push button and its mounting configuration (e.g., panel mount, surface mount) are essential for compatibility with existing equipment and ease of installation. Buyers should consider the space available in their systems and choose buttons that fit without compromising functionality.

Illustrative image related to push button push button

6. LED Indicators

Many push buttons feature integrated LED indicators, providing visual feedback on their status (e.g., on/off). This functionality is particularly beneficial in complex control panels, as it enhances user experience and operational efficiency.

What Are Common Trade Terms Related to Push Button Switches?

Understanding industry terminology is vital for effective communication and negotiation in B2B transactions. Here are some common terms relevant to push button switches:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In the context of push buttons, OEMs often produce switches that are then integrated into larger systems or machines. B2B buyers should consider sourcing from reputable OEMs to ensure quality and reliability.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers, especially when sourcing components like push buttons, as it can affect inventory management and cash flow.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. For push button switches, an RFQ should detail the required specifications, quantities, and delivery timelines, enabling suppliers to provide accurate pricing and availability.

Illustrative image related to push button push button

4. Incoterms

Incoterms (International Commercial Terms) are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers involved in cross-border purchases of push buttons, as they outline costs, risks, and logistics responsibilities.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. For push button switches, understanding lead times is important for project planning and ensuring that production schedules are met.

6. Certification Standards

Certification standards, such as CE or UL, indicate that a product meets specific safety and performance criteria. For push button switches, ensuring compliance with relevant certification standards is crucial for market acceptance and regulatory compliance.

By familiarizing yourself with these technical properties and trade terms, you can navigate the push button switch market more effectively, making informed decisions that align with your business needs.

Navigating Market Dynamics and Sourcing Trends in the push button push button Sector

What Are the Current Market Trends in the Push Button Sector?

The push button sector is experiencing significant growth driven by advancements in technology, increased automation, and evolving consumer demands. Key trends include the rising adoption of smart technologies, where push buttons are integrated into IoT devices, allowing for enhanced control and user interaction. Additionally, there is a growing demand for customized solutions tailored to specific industry needs, including industrial automation, consumer electronics, and automotive applications.

Illustrative image related to push button push button

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should also be aware of the shift towards digital procurement processes. This trend facilitates faster sourcing and provides access to a broader range of suppliers. The increasing focus on supply chain transparency is prompting buyers to seek out suppliers that can demonstrate reliability and compliance with international standards. Moreover, the demand for robust and high-quality materials, such as stainless steel and specialized plastics, is on the rise, ensuring durability and longevity in challenging environments.

How Can Sustainability and Ethical Sourcing Impact the Push Button Industry?

Sustainability and ethical sourcing are becoming paramount considerations in the push button sector. With growing awareness of environmental issues, B2B buyers are increasingly prioritizing suppliers that adhere to sustainable practices. This includes the use of eco-friendly materials and manufacturing processes that minimize waste and energy consumption. Certifications such as ISO 14001 for environmental management and RoHS compliance for hazardous substances are becoming essential for suppliers aiming to gain a competitive edge.

Furthermore, the importance of ethical supply chains cannot be overstated. Buyers are more inclined to partner with manufacturers who demonstrate a commitment to fair labor practices and community engagement. This not only enhances brand reputation but also fosters trust among consumers and business partners. As the demand for “green” products increases, suppliers that can provide transparent information regarding their sourcing practices and the environmental impact of their products will likely see greater success in the market.

Illustrative image related to push button push button

What Is the Historical Context of the Push Button Sector?

The push button technology has evolved significantly since its inception, transitioning from simple mechanical switches to sophisticated electronic controls. Initially used in basic applications, push buttons have become integral components in various industries, including manufacturing, telecommunications, and consumer electronics. The introduction of momentary and latching push buttons has expanded their functionality, allowing for diverse applications such as machine control and automation systems.

Over the years, advancements in materials and design have enhanced the durability and performance of push buttons. The integration of LED lighting and smart technology has further transformed their usage, catering to modern demands for aesthetic appeal and functionality. As industries continue to evolve, the push button sector is poised for ongoing innovation, driven by the need for efficiency, reliability, and user-centric design.

Frequently Asked Questions (FAQs) for B2B Buyers of push button push button

-

How do I solve issues with the reliability of push button switches?

To enhance the reliability of push button switches, ensure you choose high-quality products from reputable suppliers. Look for switches with certifications such as IP67 for water and dust resistance, which are crucial for industrial environments. Additionally, consider stainless steel options for durability and corrosion resistance. Regular maintenance and inspection can help identify potential failures before they occur, further ensuring consistent performance. -

What is the best type of push button switch for industrial applications?

For industrial applications, momentary push button switches are often preferred due to their reliability and ease of use. Look for switches with robust construction, such as stainless steel, and those rated for high voltage and current. Features like LED indicators can also enhance usability. Select switches that meet your specific operational requirements, including environmental ratings and compatibility with your systems. -

What factors should I consider when sourcing push button switches internationally?

When sourcing push button switches internationally, evaluate the supplier’s reputation, quality certifications, and compliance with international standards. Consider logistics factors, such as shipping times and costs, which can vary significantly by region. Additionally, assess payment terms and currency exchange risks. It’s advisable to request samples before committing to bulk orders to ensure product quality meets your specifications. -

How do I vet suppliers for push button switches?

Vetting suppliers involves several key steps: reviewing their company history, checking references from other clients, and verifying any industry certifications. Requesting product samples is also essential to assess quality. Look for suppliers with established reputations in your target market, and consider their customer service responsiveness. Additionally, evaluate their capacity to meet your order volumes and customization needs. -

What is the typical Minimum Order Quantity (MOQ) for push button switches?

Minimum Order Quantities (MOQs) for push button switches can vary widely based on the supplier and product type. Generally, MOQs can range from as low as 100 units to several thousand. Discuss your specific requirements with potential suppliers to negotiate MOQs that align with your business needs. Some suppliers may offer lower MOQs for standard products, while customized solutions may require higher quantities. -

Can I customize push button switches for my specific application?

Yes, many manufacturers offer customization options for push button switches, including size, color, LED indicators, and functionality (momentary vs. latching). When considering customization, provide detailed specifications to the supplier to ensure the final product meets your operational needs. Keep in mind that customizations may affect lead times and pricing, so plan accordingly. -

What payment terms should I expect when sourcing push button switches?

Payment terms can vary by supplier and region, but common practices include upfront payment, net 30/60 days, or a deposit followed by a balance upon shipment. Establishing clear payment terms in your contract is essential to avoid misunderstandings. Consider using secure payment methods that offer buyer protection, especially for large transactions, to mitigate risks. -

How do I ensure quality assurance for push button switches?

To ensure quality assurance, work with suppliers who implement rigorous testing and quality control processes. Request documentation of their quality management systems, such as ISO certifications. It’s also beneficial to conduct random inspections of products upon receipt and establish a return policy for defective items. Collaborating closely with your supplier on quality expectations can help maintain high standards throughout your supply chain.

Top 7 Push Button Push Button Manufacturers & Suppliers List

1. Waytek – Momentary & Push-Button Switches

Domain: waytekwire.com

Registered: 1998 (27 years)

Introduction: This company, Waytek – Momentary & Push-Button Switches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Securitron – Push Buttons & Egress Devices

Domain: securitron.com

Registered: 1995 (30 years)

Introduction: This company, Securitron – Push Buttons & Egress Devices, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. ProWire USA – Waterproof Push Button Switches

Domain: prowireusa.com

Registered: 2005 (20 years)

Introduction: This company, ProWire USA – Waterproof Push Button Switches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. TE Connectivity – Push Button Switch

Domain: te.com

Registered: 1992 (33 years)

Introduction: This company, TE Connectivity – Push Button Switch, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. DynaLock – Key Push Button Products

Domain: dynalock.com

Registered: 1996 (29 years)

Introduction: [{‘product_code’: ‘6115M’, ‘description’: ‘6000 Series Push Button One Pushbutton’}, {‘product_code’: ‘6115A’, ‘description’: ‘6000 Series Push Button One Pushbutton, 1 Gang, Alternate Action’}, {‘product_code’: ‘6125M’, ‘description’: ‘6001 Series Push Button Two Pushbuttons, 1 Gang Momentary’}, {‘product_code’: ‘6125A’, ‘description’: ‘6000 Series Push Button Two Pushbuttons, 1 Gang Alternate Ac…

6. ITWSwitches™ – Push Buttons

Domain: itwswitches.com

Registered: 1996 (29 years)

Introduction: Push Buttons from ITWSwitches™ are designed for a variety of applications including automation, military/aerospace, and industrial uses. Key features include:

– Sizes range from 12mm to 30mm.

– Options for panel or fully sealed solutions up to IP67.

– Available in maintained, momentary, and reset switch operations.

– Mounting options include PCB, rear mount, screw, snap-in, and threaded bushing.

-…

7. House of Antique Hardware – Antique Push Button Light Switch

Domain: houseofantiquehardware.com

Registered: 1999 (26 years)

Introduction: Antique Push Button Light Switch – Features mother-of-pearl inlay, complies with modern safety standards, works with new or existing home wiring for easy installation. Available products include: 1. Premium Single-Pole Push Button Dimmer with Mother-of-Pearl Inlays – $37.99, UL & CUL listed, suitable for dimmable Incandescent, Halogen & LED bulbs, 300-watt and 600-watt versions available. 2. Premi…

Strategic Sourcing Conclusion and Outlook for push button push button

In today’s competitive landscape, strategic sourcing of push button technologies is crucial for businesses aiming to enhance operational efficiency and product reliability. By prioritizing quality and compatibility, international buyers can ensure that their investments in push button components yield long-term benefits. Key considerations include sourcing durable materials, leveraging local suppliers, and understanding the specific needs of diverse markets across Africa, South America, the Middle East, and Europe.

The diverse applications of push buttons—from industrial automation to consumer electronics—underscore their importance in various sectors. Selecting the right supplier not only fosters innovation but also facilitates adaptability in an ever-evolving market. Buyers should engage in thorough research and build strong relationships with manufacturers who offer customizable solutions tailored to their unique requirements.

Looking ahead, the demand for advanced push button systems is expected to rise, driven by the ongoing trends in automation and smart technology. B2B buyers are encouraged to explore partnerships that prioritize quality, sustainability, and technological advancements. By doing so, they position themselves for success in an increasingly interconnected global market. Take action today—evaluate your sourcing strategies and embrace the future of push button solutions to drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to push button push button

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.