Unlocking Value: A Strategic Analysis of the Power Cord Dc Market

Introduction: Navigating the Global Market for power cord dc

In today’s interconnected world, sourcing reliable power cord DC solutions poses a significant challenge for international B2B buyers. Whether powering industrial machinery or consumer electronics, the demand for high-quality, compatible power cords has never been greater. This guide delves into the complexities of the global market for DC power cords, offering insights into various types, applications, and the critical factors to consider when selecting suppliers. By addressing key concerns such as voltage compatibility, durability, and regulatory compliance, this comprehensive resource equips businesses in regions like Africa, South America, the Middle East, and Europe—including countries like Nigeria and Germany—with the knowledge needed to make informed purchasing decisions.

As you navigate the intricacies of the power cord DC market, you will discover detailed analyses of product specifications, supplier vetting processes, and cost considerations. Additionally, we will explore emerging trends and technologies that influence the industry, helping you stay ahead of market demands. With this guide, you will not only enhance your procurement strategies but also ensure that your operations run smoothly and efficiently, minimizing downtime and maximizing productivity. Empower your business with the right knowledge to source the best DC power cord solutions tailored to your specific needs.

Understanding power cord dc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Universal AC/DC Adapter | Multiple voltage outputs, interchangeable plugs | Consumer electronics, office equipment | Pros: Versatile, cost-effective. Cons: May not be suitable for high-power devices. |

| CCTV DC Power Cable | Typically low voltage, often used with security cameras | Security systems, surveillance equipment | Pros: Easy installation, reliable. Cons: Limited to specific applications. |

| DC Power Splitter Cable | Allows multiple devices to share one power source | Networking equipment, lighting systems | Pros: Efficient power distribution. Cons: Can lead to overload if not rated properly. |

| USB to DC Power Cable | Converts USB power to various DC voltages | Mobile devices, portable electronics | Pros: High compatibility, convenient. Cons: Limited power output for larger devices. |

| DIN-Rail Power Supply | Mounted on DIN rails, supports various voltages | Industrial automation, control systems | Pros: Robust design, high power capacity. Cons: Typically more expensive and complex. |

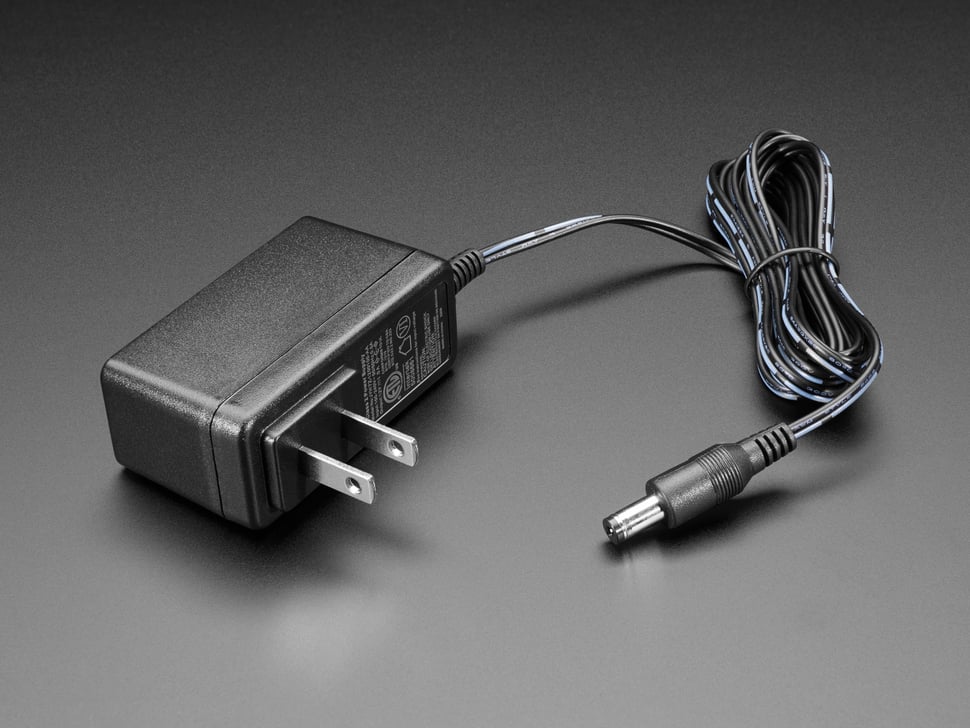

What Are the Key Characteristics of Universal AC/DC Adapters?

Universal AC/DC adapters are designed to provide a range of voltage outputs, making them suitable for various devices. They often come with interchangeable plugs, allowing for flexibility across different regions and device types. For B2B buyers, these adapters are ideal for powering consumer electronics and office equipment, providing a cost-effective solution without the need for multiple dedicated power supplies. However, it is essential to ensure that the adapter’s power rating aligns with the device requirements to prevent damage.

How Do CCTV DC Power Cables Enhance Security Systems?

CCTV DC power cables are specifically designed for low-voltage applications, particularly in security systems. They facilitate the extension of power to surveillance cameras, ensuring consistent performance. For B2B buyers in the security industry, these cables are vital for reliable installation and operation of security equipment. Their straightforward installation process is a significant advantage, though buyers should be aware that these cables are generally limited to specific applications, which may restrict versatility.

What Advantages Do DC Power Splitter Cables Offer?

DC power splitter cables are designed to distribute power from a single source to multiple devices, making them highly efficient for applications like networking equipment and lighting systems. For businesses looking to optimize power usage, these splitters can minimize costs and streamline installations. However, buyers must consider the power ratings to avoid potential overload situations, which can lead to equipment failure or safety hazards.

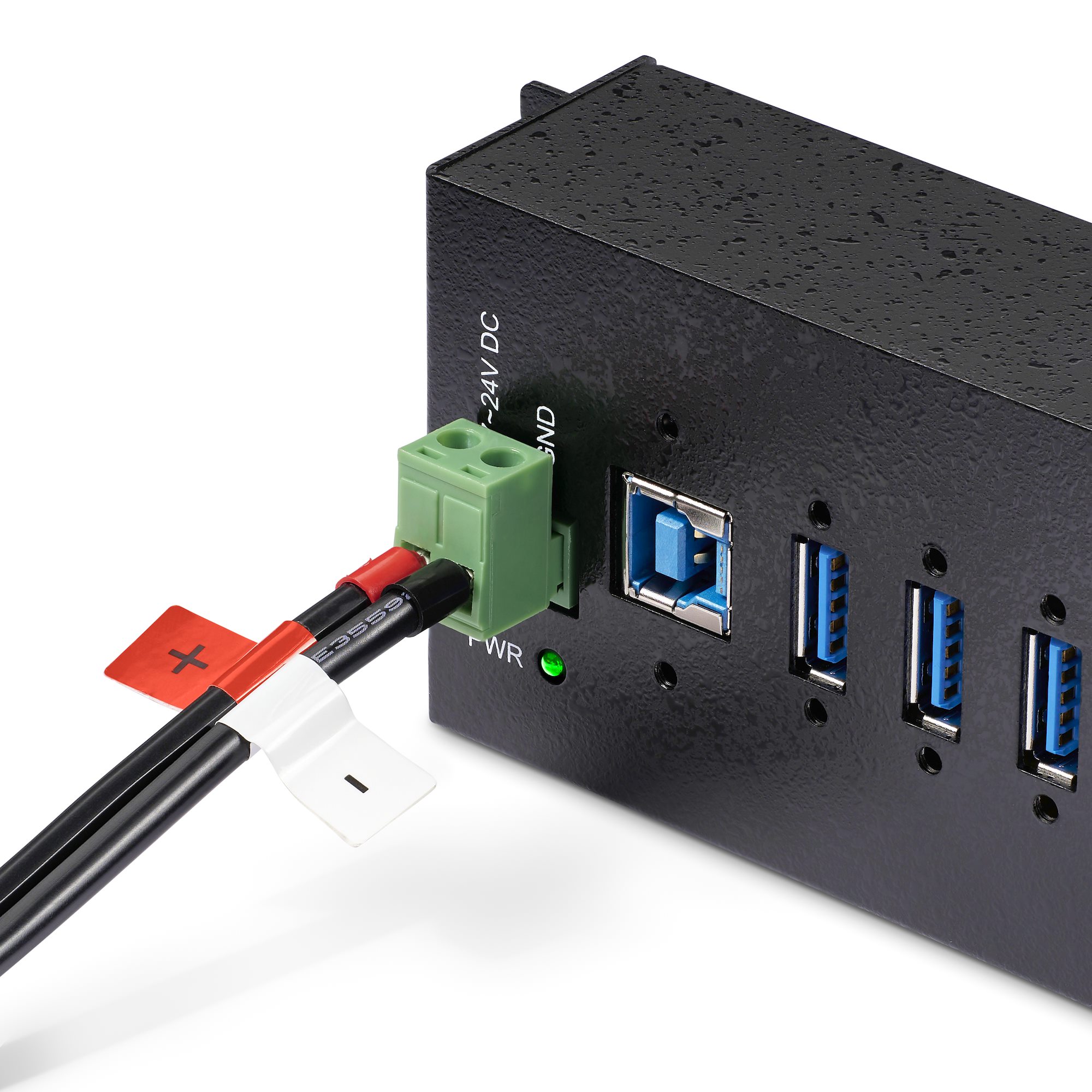

Why Choose USB to DC Power Cables for Portable Devices?

USB to DC power cables are increasingly popular due to their ability to convert USB power into various DC voltages, providing a convenient solution for powering mobile devices and portable electronics. This type of cable is particularly appealing for B2B buyers in sectors requiring flexibility and high compatibility with numerous devices. While they offer significant convenience, it is crucial to note that their power output may not suffice for larger devices, limiting their applicability in some scenarios.

What Makes DIN-Rail Power Supplies Suitable for Industrial Applications?

DIN-rail power supplies are robust solutions designed for mounting on standard DIN rails, widely used in industrial automation and control systems. They support various voltage outputs, making them versatile for different applications. For B2B buyers in industrial sectors, these power supplies provide reliable performance and high power capacity, essential for demanding environments. However, the complexity and higher cost compared to simpler power solutions may require careful consideration during procurement.

Key Industrial Applications of power cord dc

| Industry/Sector | Specific Application of power cord dc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Powering network devices like routers and switches | Ensures reliable connectivity and data transmission | Voltage ratings, compatibility with existing equipment, and durability |

| Security Systems | Supplying power to CCTV cameras and surveillance equipment | Enhances security and monitoring capabilities | Length and gauge of cables, weather resistance, and installation ease |

| Automotive | Charging and powering electronic components in vehicles | Supports advanced functionalities and user convenience | Voltage specifications, connector types, and compliance with safety standards |

| Renewable Energy | Connecting solar panels to inverters and batteries | Facilitates efficient energy conversion and storage | Compatibility with solar systems, insulation type, and environmental ratings |

| Consumer Electronics | Powering devices like laptops, tablets, and other gadgets | Improves device performance and user satisfaction | Plug type, output voltage, and safety certifications |

How is Power Cord DC Used in Telecommunications?

In the telecommunications sector, power cord DC is essential for powering network devices such as routers, switches, and modems. These devices require a stable power supply to ensure uninterrupted connectivity and data transmission. International B2B buyers, particularly from regions like Africa and South America, must ensure that the power cords meet specific voltage ratings and compatibility with existing equipment. Additionally, durability is crucial, as these devices often operate in varying environmental conditions.

What Role Does Power Cord DC Play in Security Systems?

Power cord DC plays a pivotal role in security systems by supplying power to CCTV cameras and other surveillance equipment. This ensures that security measures are consistently operational, enhancing safety and monitoring capabilities for businesses. Buyers in Europe and the Middle East should consider the length and gauge of the cables to ensure they can adequately reach power sources while maintaining performance. Furthermore, weather resistance is a vital factor for outdoor applications.

How is Power Cord DC Beneficial in the Automotive Industry?

In the automotive industry, power cord DC is used to charge and power various electronic components within vehicles, such as infotainment systems and navigation devices. This not only supports advanced functionalities but also enhances user convenience. For B2B buyers, understanding the specific voltage specifications and connector types is essential to ensure compatibility with different vehicle models. Compliance with safety standards is also critical to prevent electrical hazards.

Why is Power Cord DC Important for Renewable Energy Applications?

Power cord DC is crucial in renewable energy applications, particularly in connecting solar panels to inverters and batteries. This facilitates efficient energy conversion and storage, making it a vital component for businesses looking to implement sustainable energy solutions. Buyers should focus on compatibility with their solar systems, as well as insulation types that can withstand environmental factors. Environmental ratings are also important for ensuring long-term performance.

Illustrative image related to power cord dc

How Does Power Cord DC Enhance Consumer Electronics?

In the consumer electronics sector, power cord DC is integral for powering devices like laptops, tablets, and various gadgets. A reliable power supply improves device performance and enhances user satisfaction. When sourcing, buyers should pay attention to plug types and output voltage to ensure compatibility with different devices. Additionally, safety certifications are crucial to protect users and prevent potential hazards.

3 Common User Pain Points for ‘power cord dc’ & Their Solutions

Scenario 1: Compatibility Issues with Diverse Equipment

The Problem: Many B2B buyers often face challenges when trying to source DC power cords that are compatible with a variety of electronic devices. This is particularly common in industries where multiple manufacturers’ equipment is utilized, leading to confusion over specifications like voltage, amperage, and connector types. For instance, a company in Nigeria might purchase a bulk shipment of DC power cords, only to discover that the connectors do not fit their specific devices, resulting in costly delays and operational downtime.

The Solution: To avoid compatibility issues, buyers should conduct thorough research on the specifications required for their devices before purchasing DC power cords. This includes understanding the voltage and amperage needs and identifying the correct connector type, such as 2.1mm or 2.5mm. It’s advisable to create a detailed inventory of devices that will be powered and their respective requirements. Partnering with suppliers who provide a range of universal DC power adapters can also mitigate this issue, as these adapters often come with multiple plug options, allowing for greater flexibility and adaptability in diverse environments.

Scenario 2: Quality and Safety Concerns in Power Supply

The Problem: Quality control is a significant concern for B2B buyers sourcing DC power cords, especially in regions where counterfeit products are prevalent. For instance, a manufacturer in South America may procure low-cost DC cables that fail to meet safety standards, leading to equipment damage or even safety hazards for employees. This not only poses risks to personnel but can also result in financial losses due to equipment repairs and potential liability issues.

The Solution: Buyers should prioritize sourcing DC power cords from reputable manufacturers or distributors that offer certifications such as UL or CE marking, which indicate compliance with safety standards. It is also beneficial to request samples or conduct quality tests before making bulk purchases. Establishing relationships with suppliers who provide transparent information about their products’ origins and quality assurance processes can help in ensuring the reliability of the power cords. Additionally, implementing a vendor evaluation process that includes quality checks can help maintain high standards in power supply equipment.

Illustrative image related to power cord dc

Scenario 3: Difficulty in Finding Custom Lengths and Configurations

The Problem: A frequent pain point for B2B buyers is the inability to find DC power cords in custom lengths or configurations that suit specific installation requirements. For example, a business in Europe may need longer cables to connect devices across a large warehouse but finds that standard lengths are insufficient, leading to makeshift solutions that can compromise performance and safety.

The Solution: To address this challenge, buyers should seek suppliers that offer customizable DC power cords tailored to their specific needs. Many manufacturers provide options for custom lengths, gauge sizes, and connector types, enabling businesses to order exactly what they require. It is advisable to communicate installation needs clearly with suppliers to explore options for bespoke solutions. Furthermore, investing in modular power systems that allow for easy expansion and reconfiguration can provide long-term flexibility, reducing future procurement challenges related to power connectivity.

Strategic Material Selection Guide for power cord dc

What Are the Key Materials Used in Power Cord DC Manufacturing?

When selecting materials for power cord DC applications, several factors come into play, including electrical performance, mechanical strength, and environmental resistance. Below, we analyze four common materials used in the production of power cords, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does PVC (Polyvinyl Chloride) Perform in Power Cord DC Applications?

PVC is one of the most widely used materials for insulation in power cords due to its excellent electrical properties and cost-effectiveness. It has a temperature rating of up to 70°C and offers good resistance to moisture and chemicals.

Pros: PVC is durable, lightweight, and relatively inexpensive, making it suitable for mass production. Its flexibility allows for easy installation in various configurations.

Cons: However, PVC can become brittle over time when exposed to UV light and extreme temperatures, which may lead to cracking. Additionally, it is less environmentally friendly compared to other materials.

Impact on Application: PVC-insulated cords are commonly used in consumer electronics, automotive applications, and household appliances.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers in regions like Europe may prefer PVC alternatives due to environmental regulations regarding plastic usage.

What Role Does Silicone Play in Power Cord DC Manufacturing?

Silicone is another material gaining traction in the power cord market, especially for high-temperature applications. It can withstand temperatures ranging from -60°C to 200°C, making it ideal for environments where heat resistance is critical.

Pros: Silicone is highly flexible, resistant to extreme temperatures, and exhibits excellent electrical insulation properties. It is also resistant to UV light and ozone, enhancing its longevity.

Cons: The main drawback of silicone is its higher cost compared to PVC and other materials. Additionally, its manufacturing process can be more complex, leading to longer lead times.

Impact on Application: Silicone is particularly suitable for industrial applications, automotive wiring, and environments where cords are exposed to high temperatures.

Considerations for International Buyers: Buyers in regions like Africa and South America should consider the higher initial investment in silicone due to its long-term durability and performance benefits. Compliance with local standards is also essential.

How Does TPE (Thermoplastic Elastomer) Compare in Power Cord DC Applications?

TPE is a versatile material that combines the properties of rubber and plastic. It offers a temperature range of -40°C to 105°C, making it suitable for various applications.

Pros: TPE provides excellent flexibility and resilience, is resistant to UV light and chemicals, and is often recyclable, making it an environmentally friendly option.

Cons: While TPE is more durable than PVC, it can be more expensive and may not offer the same high-temperature resistance as silicone.

Impact on Application: TPE is often used in consumer electronics, medical devices, and automotive applications where flexibility and durability are paramount.

Considerations for International Buyers: Buyers in Europe may favor TPE for its environmental benefits, while those in developing regions should weigh the cost against performance and longevity.

What Are the Benefits of Using Rubber in Power Cord DC Manufacturing?

Rubber, particularly EPDM (Ethylene Propylene Diene Monomer), is renowned for its excellent weather resistance and flexibility. It can handle temperatures from -40°C to 120°C.

Pros: Rubber is extremely durable, provides excellent insulation, and is resistant to moisture, making it ideal for outdoor applications.

Illustrative image related to power cord dc

Cons: The primary downside is that rubber can be heavier and more costly to manufacture than PVC. Additionally, it may not be as flexible at lower temperatures.

Impact on Application: Rubber cords are commonly used in outdoor power tools, industrial equipment, and automotive applications where durability is essential.

Considerations for International Buyers: Compliance with international standards is critical, particularly in Europe, where safety regulations are stringent. Buyers should consider the overall performance versus cost when selecting rubber cords.

Summary Table of Material Selection for Power Cord DC

| Material | Typical Use Case for power cord dc | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Consumer electronics, automotive | Cost-effective, lightweight | Becomes brittle under UV exposure | Low |

| Silicone | Industrial, high-temperature applications | Excellent heat resistance | Higher cost, complex manufacturing | High |

| TPE | Medical devices, automotive | Flexible, recyclable | More expensive, lower high-temp resistance | Medium |

| Rubber | Outdoor tools, industrial equipment | Highly durable, moisture resistant | Heavier, higher manufacturing cost | Medium |

This guide provides a comprehensive overview of material selection for power cord DC applications, aiding international B2B buyers in making informed decisions based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for power cord dc

The production of DC power cords involves several meticulous manufacturing processes, each crucial for ensuring the final product meets the quality and safety standards expected by international B2B buyers. This section provides an in-depth look at the typical manufacturing stages, quality control measures, and how buyers can effectively verify the quality of their suppliers.

What Are the Main Stages in the Manufacturing Process of DC Power Cords?

The manufacturing process for DC power cords can be broken down into four primary stages: material preparation, forming, assembly, and finishing.

1. Material Preparation

This initial stage involves sourcing high-quality raw materials, including copper conductors, insulating materials, and connectors. Copper is often chosen for its excellent conductivity, while thermoplastics or rubber compounds are typically used for insulation. Suppliers should ensure that materials comply with international standards, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals), to avoid environmental and health issues.

2. Forming

In this stage, the prepared materials are shaped into the desired configurations. Copper wires are drawn to specific gauges, commonly 18 AWG to 24 AWG for power applications, depending on the current requirements. Insulation is applied through processes such as extrusion, where molten plastic is forced around the wire to create a protective layer. This step is crucial as it affects both the flexibility and durability of the power cord.

3. Assembly

The assembly stage involves connecting the insulated wires to connectors and terminals. This can include soldering, crimping, or other methods to ensure a secure connection. Quality during assembly is critical, as improper connections can lead to electrical failures or safety hazards. Automated machines are often used to enhance precision and speed, but skilled technicians oversee this process to ensure quality.

4. Finishing

The final stage includes testing, labeling, and packaging the finished cords. This may involve applying heat-shrink tubing to provide additional protection and strain relief. Products are then labeled according to specifications, including voltage ratings and safety warnings, before being packaged for shipment.

What Quality Assurance Standards Are Relevant for DC Power Cords?

Quality assurance in the manufacturing of DC power cords is vital for ensuring product reliability and safety. Several international and industry-specific standards apply:

-

ISO 9001: This is a widely recognized quality management standard that outlines requirements for a quality management system (QMS). Compliance with ISO 9001 indicates that the manufacturer has consistent processes for producing quality products.

-

CE Marking: For products sold in the European market, CE marking signifies that the product meets EU safety, health, and environmental protection standards. This is crucial for buyers in Europe, as non-compliance can lead to significant market access issues.

-

UL Certification: In North America, Underwriters Laboratories (UL) certification is essential for safety. It ensures that the power cords have been tested for safety and performance according to established standards.

-

API Standards: For specialized applications, such as those in the oil and gas industry, compliance with American Petroleum Institute (API) standards may be required.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated throughout the manufacturing process, with specific checkpoints at various stages to ensure compliance with standards and specifications.

1. Incoming Quality Control (IQC)

Before production begins, raw materials are inspected to ensure they meet predefined quality standards. This includes checking for defects in insulation materials and verifying the gauge of copper wire. Documentation of these inspections is vital for traceability.

Illustrative image related to power cord dc

2. In-Process Quality Control (IPQC)

During manufacturing, regular checks are performed at different stages. This includes monitoring the extrusion process for proper insulation thickness and inspecting connections during assembly. Statistical process control (SPC) techniques may be applied to detect deviations early.

3. Final Quality Control (FQC)

Once the cords are assembled, final quality checks are conducted. This includes electrical testing to ensure proper functionality, stress testing for durability, and visual inspections for aesthetic quality. Non-conforming products are identified and rejected or reworked.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are several methods to ensure supplier reliability:

-

Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality management systems. This can include both announced and unannounced visits.

-

Quality Reports: Requesting documentation of quality assurance practices, including IQC, IPQC, and FQC reports, helps buyers understand how the supplier maintains quality throughout production.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control processes. This is especially important for buyers who may not have the resources to conduct thorough audits themselves.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate various complexities related to quality control, particularly regarding differing standards and regulations across countries. Here are some key considerations:

Illustrative image related to power cord dc

-

Certification Recognition: Not all certifications are recognized globally. Buyers should ensure that certifications from suppliers are acknowledged in their home markets to avoid compliance issues.

-

Cultural and Regulatory Differences: Understanding the local manufacturing practices and regulations in the supplier’s country can help buyers anticipate potential quality issues. For instance, varying environmental regulations may influence the types of materials used.

-

Language Barriers: Effective communication is crucial for quality assurance. Buyers should ensure that there is a clear understanding of quality expectations, specifications, and standards to avoid misunderstandings.

In conclusion, the manufacturing processes and quality assurance measures for DC power cords are critical to ensuring product reliability and safety. By understanding these processes and actively verifying supplier quality control practices, international B2B buyers can make informed decisions, ultimately leading to successful partnerships and high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘power cord dc’

Introduction

Navigating the procurement of DC power cords can be complex, particularly for international B2B buyers. This guide provides a structured checklist to help you source the right DC power cords effectively, ensuring compatibility, reliability, and compliance with regional standards. By following these steps, you can make informed purchasing decisions that align with your operational needs.

1. Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical specifications required for your DC power cords. This includes voltage, current ratings, and connector types.

- Voltage and Current: Ensure the specifications match the requirements of your devices to avoid damage or inefficiency.

- Connector Types: Identify whether you need standard connectors (like 2.1mm or 5.5mm) or custom designs for unique applications.

2. Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in DC power cords. Look for companies with a solid reputation in your target regions.

Illustrative image related to power cord dc

- Industry Experience: Suppliers with experience in your industry are likely to understand your needs better.

- Product Range: A diverse product range suggests a supplier’s capability to meet various demands, including custom solutions.

3. Verify Supplier Certifications

Ensuring that suppliers hold the necessary certifications is crucial for compliance and quality assurance.

- Quality Certifications: Look for ISO certifications or equivalent, which indicate adherence to international quality standards.

- Safety Standards: Confirm that products meet regional safety standards, such as CE marking in Europe or UL listing in the US.

4. Request Product Samples

Before placing bulk orders, always request samples of the DC power cords. This step allows you to evaluate the product quality firsthand.

- Quality Assessment: Inspect the material, build quality, and overall design to ensure they meet your specifications.

- Testing Compatibility: Test samples with your devices to confirm compatibility and performance under operational conditions.

5. Evaluate Pricing and Payment Terms

Understanding the pricing structure and payment terms is vital for budget management.

- Competitive Pricing: Compare quotes from multiple suppliers, but don’t compromise on quality for lower costs.

- Payment Flexibility: Look for suppliers that offer flexible payment terms, which can ease cash flow management.

6. Consider After-Sales Support and Warranty

After-sales support can significantly impact your operational efficiency. Choose suppliers who provide robust customer service and warranty options.

- Technical Support: Ensure that the supplier offers technical assistance for troubleshooting and installation.

- Warranty Terms: A good warranty policy indicates supplier confidence in their products and offers you security in your investment.

7. Finalize Logistics and Delivery Terms

Once you have selected a supplier, discuss logistics and delivery terms to ensure timely procurement.

- Shipping Options: Evaluate shipping methods that align with your timelines and budget.

- Customs and Duties: Be aware of any customs regulations and duties applicable to your region to avoid unexpected costs.

By following this checklist, B2B buyers can streamline their sourcing process for DC power cords, ensuring they select the best suppliers and products for their specific needs.

Comprehensive Cost and Pricing Analysis for power cord dc Sourcing

What are the Key Cost Components in Power Cord DC Sourcing?

When sourcing power cord DC products, understanding the cost structure is crucial. The primary components include:

-

Materials: The choice of materials significantly influences cost. High-quality copper, insulation, and connectors can enhance performance but may increase the unit price. Buyers should consider the trade-off between cost and reliability, particularly for applications requiring durability.

-

Labor: Labor costs can vary widely based on the manufacturing location. In regions with higher labor costs, such as parts of Europe, manufacturers might pass these expenses onto buyers. Conversely, sourcing from countries with lower labor costs may offer price advantages but could compromise quality.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, rent, and administrative expenses. Efficient manufacturers often have lower overhead costs, allowing them to offer more competitive pricing.

-

Tooling: The initial investment in tooling for custom designs or specifications can be substantial. Buyers should evaluate whether the tooling costs can be amortized over the production run to achieve lower per-unit costs.

-

Quality Control (QC): Stringent QC measures ensure product reliability and compliance with international standards. However, rigorous QC processes can add to the overall cost. Buyers should balance the need for quality with cost considerations, particularly in low-stakes applications.

-

Logistics: Shipping and handling can significantly impact the total cost. Factors such as distance, shipping method, and weight play a crucial role. International buyers should consider logistics in their total cost of ownership calculations.

-

Margin: The manufacturer’s profit margin is a key component of the final price. Buyers should investigate different suppliers to understand their pricing strategies and identify potential negotiation opportunities.

What Influences the Pricing of Power Cord DC Products?

Several factors can influence the pricing of power cord DC products:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically attract volume discounts. Buyers should assess their needs to maximize cost efficiency by negotiating favorable terms based on anticipated demand.

-

Specifications and Customization: Custom specifications can lead to higher costs due to the need for specialized materials or tooling. Buyers should evaluate whether standard products can meet their needs to avoid additional expenses.

-

Material Quality and Certifications: Higher-quality materials and compliance with certifications (like UL, CE, or RoHS) can increase costs. However, such investments often lead to enhanced reliability and performance, which can justify the expense.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with a track record of quality may charge more, but they often provide better support and assurance of product performance.

-

Incoterms: The chosen Incoterms can affect costs significantly. Understanding whether costs include shipping, insurance, and duties can help buyers budget more accurately and avoid unexpected expenses.

How Can Buyers Optimize Costs When Sourcing Power Cord DC Products?

To achieve cost efficiency in sourcing power cord DC products, buyers should consider the following strategies:

-

Negotiation: Engage suppliers in discussions about pricing, especially when ordering in bulk. Establishing a long-term relationship can also lead to better terms and pricing.

-

Total Cost of Ownership (TCO): Evaluate the TCO, which includes purchase price, logistics, quality, and potential failure costs. This holistic view helps buyers make informed decisions that go beyond just the initial price.

-

Understand Pricing Nuances for International Markets: Different regions may have varying pricing structures due to economic conditions, regulations, and logistics. For instance, buyers in Africa or South America may face different challenges compared to European buyers, such as import duties and local regulations.

-

Stay Informed on Market Trends: Keeping abreast of market trends and fluctuations in material costs can provide leverage during negotiations. Being knowledgeable about global supply chain dynamics can also help in securing better deals.

Disclaimer on Indicative Prices

Pricing for power cord DC products can vary significantly based on the aforementioned factors and market conditions. Buyers are encouraged to obtain multiple quotes and conduct thorough market research to ensure they are receiving competitive pricing aligned with their requirements.

Illustrative image related to power cord dc

Alternatives Analysis: Comparing power cord dc With Other Solutions

Introduction: Understanding the Importance of Alternative Solutions

In the realm of powering devices, particularly for industrial and commercial applications, selecting the right power solution is crucial. While power cord DC (direct current) solutions are widely used due to their efficiency and reliability, there are several alternatives that may suit specific needs or applications. This section examines how power cord DC compares to other viable solutions, enabling B2B buyers to make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Power Cord DC | Universal AC/DC Adapter | Battery-Powered Systems |

|---|---|---|---|

| Performance | High efficiency for low-voltage devices | Moderate efficiency, voltage-dependent | High mobility, but variable output |

| Cost | Generally low initial investment | Affordable, but costs vary by wattage | Higher initial investment, ongoing costs for replacement |

| Ease of Implementation | Simple installation, minimal setup | Easy to integrate into existing systems | Requires careful management and setup |

| Maintenance | Low maintenance required | Moderate maintenance, replacement needed | Regular battery maintenance required |

| Best Use Case | Suitable for fixed installations, security systems | Ideal for diverse electronic devices requiring varying voltages | Portable solutions, remote applications where grid power is unavailable |

Detailed Breakdown of Alternatives

Universal AC/DC Adapter

Universal AC/DC adapters serve as versatile power sources for various devices, converting AC to DC voltage. They are typically easy to implement and can support multiple devices with different voltage requirements. However, their efficiency can vary based on the specific device’s needs, and they may require regular replacements or maintenance to ensure optimal performance. The affordability of these adapters makes them an attractive option for businesses with diverse electronic equipment.

Battery-Powered Systems

Battery-powered systems offer a significant advantage in terms of mobility and flexibility, especially in environments where access to a power grid is limited. These systems can power devices without the need for extensive wiring or installation. However, they often come with higher initial costs and require ongoing investment in battery maintenance and replacement. Battery performance can also vary based on load and environmental conditions, which may impact reliability in critical applications.

Conclusion: Choosing the Right Power Solution for Your Needs

When selecting a power solution, B2B buyers should carefully assess their specific requirements. Power cord DC options are ideal for fixed installations where efficiency and low maintenance are paramount. Conversely, universal AC/DC adapters offer flexibility for varied devices but may not match the performance of dedicated DC solutions. Battery-powered systems, while providing unmatched mobility, can lead to higher costs and maintenance challenges. By evaluating these factors against their operational needs, businesses can identify the most suitable power solution, ensuring reliability and efficiency in their operations.

Essential Technical Properties and Trade Terminology for power cord dc

What Are the Essential Technical Properties of DC Power Cords?

When sourcing DC power cords, understanding their technical properties is crucial for ensuring compatibility and reliability. Here are some critical specifications to consider:

Illustrative image related to power cord dc

-

Voltage Rating: This indicates the maximum voltage a power cord can safely handle. Common voltage ratings for DC power cords include 12V, 24V, and 48V. For B2B buyers, selecting a cord with the appropriate voltage rating is essential to avoid equipment damage and ensure operational safety.

-

Current Rating (Amperage): This is the maximum current the power cord can carry without overheating. Ratings are often expressed in milliamperes (mA) or amperes (A). Choosing a cord with an adequate current rating prevents overheating and potential failure, which is vital for maintaining equipment uptime in industrial settings.

-

Wire Gauge (AWG): The American Wire Gauge (AWG) measures the diameter of the wire within the cord. A lower AWG number indicates a thicker wire, which can handle higher current loads. For example, a 20 AWG wire is suitable for lower currents, while a 14 AWG wire is better for higher currents. Understanding AWG is crucial for ensuring that the power cord can efficiently transmit power without significant loss.

-

Connector Type: DC power cords come with various connector types, such as 5.5mm/2.1mm, USB, or custom connectors. The connector type must match the device’s input to ensure compatibility. B2B buyers should verify connector specifications to avoid costly errors in procurement.

-

Material Composition: The material used in the wire insulation and outer sheath affects durability and flexibility. Common materials include PVC (polyvinyl chloride) and rubber. Selecting a cord with high-quality materials enhances longevity, particularly in harsh environments, which is a key consideration for B2B buyers operating in diverse global markets.

-

Temperature Rating: This indicates the maximum and minimum temperatures the cable can withstand. Cords with higher temperature ratings are suitable for environments with extreme heat or cold. Ensuring that the temperature rating matches the operating environment helps prevent cord failure and extends service life.

What Are Common Trade Terms Related to DC Power Cords?

Navigating the procurement of DC power cords also involves understanding industry terminology. Here are some essential terms:

-

OEM (Original Equipment Manufacturer): This refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of DC power cords, knowing whether a supplier is an OEM can provide assurance regarding quality and compatibility with existing systems.

-

MOQ (Minimum Order Quantity): This term specifies the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for B2B buyers, as it impacts inventory management and cost efficiency. Buyers should negotiate MOQs that align with their purchasing strategy.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing for specific products. When sourcing DC power cords, submitting an RFQ allows buyers to compare prices and terms from multiple suppliers, ensuring they secure the best deal.

-

Incoterms (International Commercial Terms): These are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping costs, delivery timelines, and risk management when importing DC power cords from global suppliers.

-

Lead Time: This refers to the time it takes from placing an order until the product is delivered. Knowing the lead time is essential for planning inventory and ensuring timely project execution. B2B buyers should always inquire about lead times to avoid disruptions in their operations.

-

Certification Standards: These are quality assurance protocols that products must meet, such as UL (Underwriters Laboratories) or CE (Conformité Européenne) certifications. Understanding certification standards is vital for B2B buyers to ensure compliance with safety regulations and product reliability.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, ensuring the procurement of DC power cords that meet their operational needs while adhering to industry standards.

Navigating Market Dynamics and Sourcing Trends in the power cord dc Sector

What Are the Current Market Dynamics and Key Trends Affecting the Power Cord DC Sector?

The global market for power cord DC products is witnessing significant growth driven by the surge in electronic devices and renewable energy systems. The increasing demand for connectivity in various sectors, including consumer electronics, telecommunications, and automotive, is propelling the need for reliable power solutions. In regions like Africa and South America, rising urbanization and technological adoption are contributing to a robust market for power supply solutions. Additionally, the Middle East’s focus on infrastructure development and Europe’s push for energy-efficient products further stimulate demand.

Illustrative image related to power cord dc

Emerging B2B tech trends include the rise of smart power adapters and connectors equipped with advanced features such as surge protection, energy monitoring, and compatibility with various device types. The growth of e-commerce platforms is also reshaping sourcing strategies, enabling international buyers to access a broader range of suppliers and products seamlessly. Moreover, the trend towards modular and customizable power solutions is gaining traction as businesses seek to optimize their operations and reduce inventory costs.

International buyers must navigate the complexities of varying regulations and standards across different regions. Understanding local compliance requirements, such as UL, CE, and RoHS certifications, is essential to ensure product safety and reliability. Furthermore, the competitive landscape is characterized by both established manufacturers and emerging players, necessitating thorough market research to identify the best sourcing options.

How Can Sustainability and Ethical Sourcing Be Integrated into B2B Practices for Power Cord DC Products?

Sustainability and ethical sourcing have become paramount in the power cord DC sector, driven by increased consumer awareness and regulatory pressures. The environmental impact of electronic waste and the need for sustainable production processes are key concerns for international buyers. Companies are increasingly held accountable for their supply chain practices, prompting a shift towards eco-friendly materials and processes.

Buyers should prioritize suppliers who demonstrate a commitment to sustainability through certifications such as ISO 14001 (Environmental Management) and adherence to the circular economy principles. Utilizing recyclable materials in the production of power cords, such as PVC-free and halogen-free options, can significantly reduce environmental footprints. Furthermore, transparency in sourcing practices is critical; companies should ensure that their suppliers adhere to ethical labor practices and fair trade principles.

As the demand for ‘green’ certifications grows, manufacturers that invest in sustainable technologies and materials will likely gain a competitive edge. By integrating sustainability into their sourcing strategies, international B2B buyers can not only enhance their brand image but also appeal to environmentally conscious consumers.

What Is the Brief Evolution of Power Cord DC Products in the B2B Sector?

The evolution of power cord DC products can be traced back to the early days of electronics, where basic power connections were made with minimal regulation. As technology advanced, the proliferation of devices requiring specific voltage and current specifications led to the development of more sophisticated power supply solutions. The introduction of standardized connectors, such as the 2.1mm and USB configurations, facilitated compatibility across a wide range of products.

In recent years, the shift towards smart technology has revolutionized the power cord DC sector. Innovations such as intelligent power management systems and modular designs are now prevalent, allowing for greater efficiency and adaptability. This evolution reflects the broader trends of digitalization and sustainability in the global market, positioning power cord DC products as essential components in modern electronic ecosystems.

Frequently Asked Questions (FAQs) for B2B Buyers of power cord dc

-

How do I ensure the quality of DC power cords from suppliers?

To guarantee quality, conduct thorough due diligence on potential suppliers. Look for certifications such as ISO and UL, which indicate adherence to international standards. Request product samples to assess material quality and durability. Additionally, consider suppliers with a solid track record and positive reviews from other international buyers. Establishing a quality assurance protocol, including inspection during production and before shipment, can also mitigate risks associated with defective products. -

What is the best voltage rating for my DC power cords?

The best voltage rating for your DC power cords depends on the specific devices they will power. Common ratings include 5V, 12V, and 24V, which are suitable for various electronics, from small appliances to industrial equipment. Consult the specifications of your devices to ensure compatibility. If you are unsure, seek guidance from the manufacturer or a qualified electrical engineer to determine the optimal voltage that will ensure efficiency and safety. -

What are the typical minimum order quantities (MOQs) for DC power cords?

Minimum order quantities for DC power cords vary widely based on the supplier and the type of cord. Generally, MOQs can range from 100 to 1,000 units. However, many suppliers are willing to negotiate lower quantities for first-time orders or for long-term partnerships. It’s essential to communicate your needs clearly and explore options for bulk discounts, which can significantly lower the per-unit cost and improve your profit margins. -

How do I vet suppliers for international trade of DC power cords?

Vetting suppliers involves several steps: first, research their reputation through online reviews and industry forums. Verify their business credentials, such as registration and compliance with local regulations. Request references from previous international clients to gauge reliability and service quality. Additionally, consider visiting their facilities if feasible or using third-party inspection services to assess production capabilities and quality standards. -

What payment terms are commonly used in international B2B transactions?

Payment terms in international transactions often include options like Letter of Credit (LC), telegraphic transfer (T/T), or PayPal. LC is preferred for large orders as it provides security for both parties. For smaller transactions, T/T is common, requiring a deposit upfront and the balance before shipment. It’s crucial to negotiate terms that protect your interests while ensuring the supplier feels secure. Always document agreed terms in a contract to avoid misunderstandings. -

Can I customize the specifications of DC power cords?

Yes, many suppliers offer customization options for DC power cords, including length, gauge, connectors, and even branding. When discussing customization, be clear about your requirements and any specific certifications needed for your target market. Keep in mind that customized orders may have longer lead times and higher MOQs, so factor this into your planning and budget accordingly. -

What logistics considerations should I keep in mind when sourcing DC power cords?

When sourcing DC power cords, consider shipping methods, costs, and delivery times. Air freight is faster but more expensive, while sea freight is cost-effective for larger orders but takes longer. Assess the reliability of the shipping company and ensure they have experience with international shipments. Additionally, be aware of customs regulations in your country, including any tariffs or taxes that may apply, to avoid unexpected costs and delays. -

How can I handle quality assurance for DC power cords from international suppliers?

Implementing a quality assurance (QA) process is critical when sourcing DC power cords internationally. Begin by establishing clear quality standards and specifications with your supplier. Conduct regular inspections during production and before shipment. You can hire third-party QA companies to perform these checks, ensuring compliance with your standards. Additionally, consider requesting batch testing results or certifications to verify the quality of materials used, which helps mitigate the risk of receiving defective products.

Top 6 Power Cord Dc Manufacturers & Suppliers List

1. SF Cable – AC/DC Adapters & Power Inverters

Domain: sfcable.com

Registered: 2001 (24 years)

Introduction: AC/DC Adapters, Power Inverter & Plugs, Free Standard Shipping on Orders Over $50, Lifetime Warranty on Cables and Non Electronics Products, Same-Day Shipping if ordered before 1pm PST, Customer support available at 1-888-275-8755, Online orders only.

2. ShowMeCables – DC Power Cables

Domain: showmecables.com

Registered: 2002 (23 years)

Introduction: DC Power Cables – Open, 2.1mm, 2.5mm, USB A, Right Angle, Splitter, Straight, 20 & 22 AWG, Male, Female, Adapter Cords

3. CCTV Camera World – DC Power Cables for Security Cameras

Domain: cctvcameraworld.com

Registered: 2013 (12 years)

Introduction: DC Power Cable for low voltage security camera equipment including 12V DC and 24V AC. Essential for extending power source to security cameras, especially wireless ones. Various products available: Male DC Power Terminal, Female DC Power Terminal, Male DC Power Pigtail, 20ft DC Power Pigtail, Female DC Power Pigtail, DC Female to Female Coupler, DC Male to Male Coupler, 1 to 2 Way DC Power Cable S…

4. McMaster – Barrel-Style Power Cords & Connectors

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Barrel-Style Power Cords & Connectors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. LG – 22MN430M-B 22 IPS Monitor

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: LG 22MN430M-B 22″ IPS Monitor, requires a 19V 1.3A power adapter.

6. Vention – USB to DC Power Cable

Domain: ventiontech.com

Registered: 2022 (3 years)

Introduction: DC Power Cord: USB to DC 3.5mm Power Cable, USB A to 3.5 Jack Connector, 5V Power Supply Adapter for Fans, USB HUB DC 5.5mm Charging Cable, Sale price from $1.56.

Strategic Sourcing Conclusion and Outlook for power cord dc

In the evolving landscape of DC power solutions, strategic sourcing remains a cornerstone for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. The diverse range of DC power cords, adapters, and cables available today underscores the importance of aligning sourcing strategies with specific operational needs. Buyers must prioritize quality, compatibility, and supplier reliability to ensure optimal performance and longevity of their electronic devices.

As the demand for efficient power solutions continues to grow, leveraging strategic sourcing can yield significant cost savings and enhance supply chain resilience. Engaging with reputable suppliers who offer comprehensive product ranges and excellent after-sales support can mitigate risks associated with power supply interruptions and device malfunctions.

Looking ahead, the market for DC power solutions is poised for expansion, driven by technological advancements and increasing energy efficiency requirements. Buyers are encouraged to stay informed about emerging trends and innovations in power supply technology, ensuring they are well-positioned to make informed purchasing decisions. By prioritizing strategic sourcing, businesses can not only meet their immediate power needs but also position themselves for sustainable growth in a competitive marketplace.

Illustrative image related to power cord dc

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to power cord dc