Unlocking Value: A Strategic Analysis of the Polymer Tubing Market

Introduction: Navigating the Global Market for polymer tubing

In today’s rapidly evolving industrial landscape, sourcing high-quality polymer tubing presents a significant challenge for B2B buyers across various regions, including Africa, South America, the Middle East, and Europe. As industries diversify and technological advancements accelerate, the demand for reliable and specialized tubing solutions has never been greater. This comprehensive guide on polymer tubing aims to equip international buyers with the critical insights needed to navigate the complex market landscape.

Throughout this guide, we will explore the diverse types of polymer tubing available—ranging from nylon and polyethylene to specialized options like PTFE and polyimide. Each type is tailored for specific applications, ensuring that buyers can select the best fit for their operational needs. Additionally, we will cover essential topics such as supplier vetting processes, cost considerations, and innovative applications across industries from medical to automotive.

By empowering B2B buyers with actionable knowledge, this guide facilitates informed purchasing decisions, helping you to not only meet your operational requirements but also to drive efficiency and innovation within your organization. Whether you are based in Nigeria, Vietnam, or any other part of the globe, understanding the intricacies of polymer tubing will enable you to make strategic choices that align with your business goals and market demands.

Understanding polymer tubing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Nylon Tubing | High durability, excellent chemical resistance, and flexibility. | Aerospace, automotive, and medical applications. | Pros: Strong and versatile. Cons: Higher cost than some alternatives. |

| Polyethylene (HDPE) | Lightweight, tough, and resistant to impact and chemicals. | Packaging, construction, and agriculture. | Pros: Cost-effective and recyclable. Cons: Limited temperature resistance. |

| Polypropylene | High chemical resistance, lightweight, and FDA compliant for food use. | Food processing, medical devices, and consumer goods. | Pros: Versatile and safe for food contact. Cons: Lower heat resistance compared to others. |

| PVC Tubing | Excellent flame, corrosion, and chemical resistance. | Electrical insulation, plumbing, and HVAC systems. | Pros: Affordable and durable. Cons: Less flexible than other options. |

| Polysulfone Tubing | High service temperature and excellent dimensional stability. | Medical devices and high-temperature applications. | Pros: Suitable for sterilization. Cons: More expensive than standard materials. |

What Are the Characteristics of Nylon Tubing for B2B Buyers?

Nylon tubing stands out due to its remarkable durability and flexibility, making it suitable for demanding applications in industries such as aerospace and automotive. Its ability to withstand harsh chemicals and extreme temperatures adds to its appeal. For B2B buyers, considerations include the tubing’s cost relative to its performance benefits, as well as its compliance with industry standards, particularly in sectors like medical where safety is paramount.

How Does Polyethylene (HDPE) Serve Various Industries?

Polyethylene, particularly high-density polyethylene (HDPE), is favored for its lightweight nature and resistance to impact and chemicals. This makes it ideal for applications in packaging, construction, and agriculture. Buyers should consider HDPE’s cost-effectiveness and recyclability, which align with sustainability goals. However, its limited resistance to high temperatures may necessitate careful selection for specific applications.

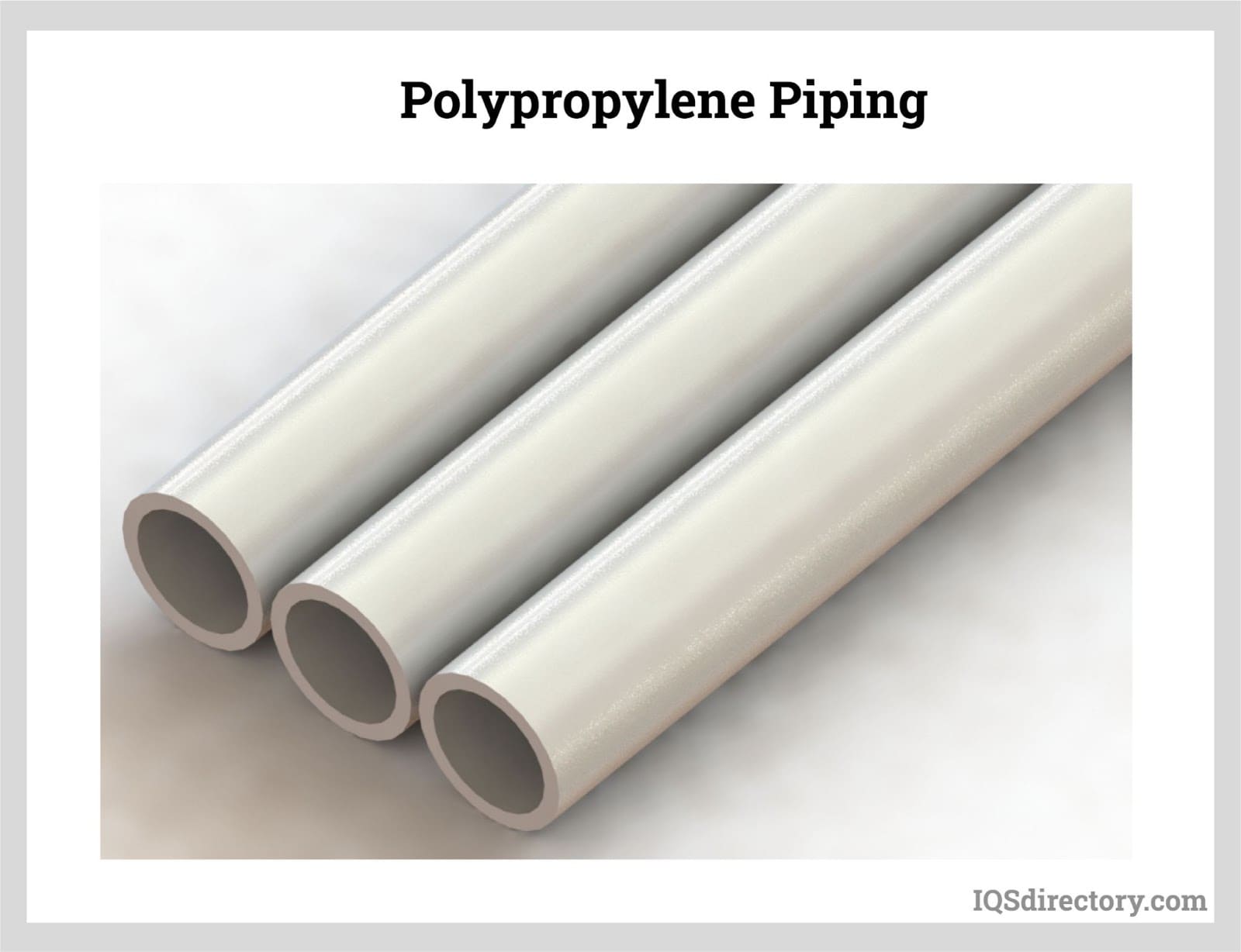

Why Choose Polypropylene Tubing for Your Business Needs?

Polypropylene tubing is known for its high chemical resistance and lightweight properties, making it a go-to choice for food processing and medical devices. Its compliance with FDA regulations for food contact enhances its usability in consumer goods. Buyers should weigh the advantages of versatility and safety against its lower heat resistance, which could limit its application in high-temperature environments.

What Are the Benefits of Using PVC Tubing?

PVC tubing is recognized for its excellent flame, corrosion, and chemical resistance, making it a staple in electrical insulation and plumbing applications. Its affordability and durability make it an attractive option for many businesses. However, buyers should note that PVC’s rigidity may limit flexibility in certain applications, which could be a drawback depending on the intended use.

When Should You Consider Polysulfone Tubing?

Polysulfone tubing is distinguished by its high service temperature and dimensional stability, making it particularly suitable for medical devices and high-temperature applications. Its ability to withstand sterilization processes adds to its value in healthcare settings. While it offers significant performance advantages, B2B buyers must consider the higher costs associated with polysulfone compared to more standard materials, ensuring that the investment aligns with their operational needs.

Key Industrial Applications of polymer tubing

| Industry/Sector | Specific Application of polymer tubing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical Devices | Catheters and minimally invasive surgical instruments | Enhanced patient comfort and improved procedural efficiency | Compliance with medical standards, biocompatibility |

| Food and Beverage | Food-grade tubing for liquid transportation | Ensures safety and quality in food handling | FDA compliance, material durability, temperature resistance |

| Chemical Processing | Tubing for chemical transfer and containment | Reduces risk of contamination and enhances safety | Chemical resistance, pressure ratings, custom sizing |

| Electronics Manufacturing | Insulation for wires and cables in electronic devices | Improves product reliability and performance | Electrical insulation properties, thermal resistance |

| Agriculture | Irrigation systems and fluid transport in farming | Increases efficiency of water usage and crop yield | UV resistance, flexibility, compatibility with various fluids |

How is Polymer Tubing Used in Medical Devices?

In the medical sector, polymer tubing is crucial for the production of catheters and minimally invasive surgical instruments. These tubes are designed to be biocompatible and flexible, enhancing patient comfort while ensuring precise delivery of fluids or medications. Buyers in this sector must prioritize materials that meet stringent medical standards, such as ISO 13485, and ensure that their suppliers can provide documentation for biocompatibility testing. The ability to source custom sizes and configurations is also vital to cater to diverse medical applications.

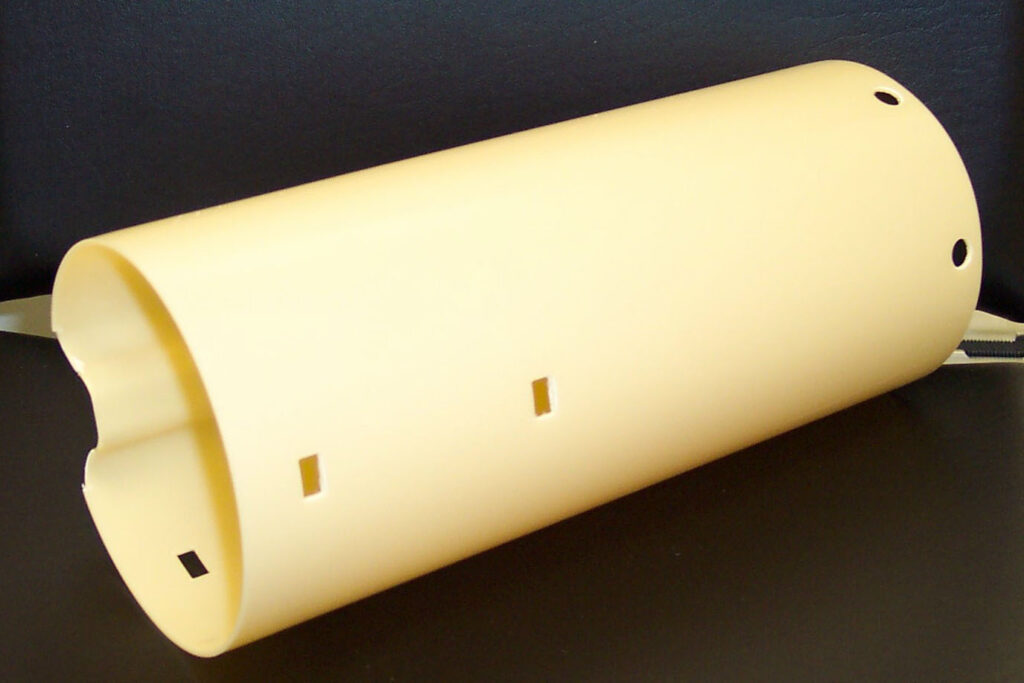

Illustrative image related to polymer tubing

What Role Does Polymer Tubing Play in Food and Beverage Industries?

In the food and beverage industry, polymer tubing is utilized for transporting liquids, ensuring that the materials are safe for food contact. Tubing made from food-grade polymers helps maintain the quality and safety of consumables, thus protecting brand reputation and compliance with regulations. International buyers should focus on sourcing tubing that meets FDA or EU food safety standards, alongside ensuring that the materials can withstand varying temperatures and pressures encountered during processing and transport.

How is Polymer Tubing Essential in Chemical Processing?

Chemical processing relies heavily on polymer tubing for the safe transfer and containment of various chemicals. The right tubing can significantly reduce the risk of leaks and contamination, which is critical for maintaining product integrity and workplace safety. Buyers should consider the chemical resistance of the tubing materials, ensuring they can handle specific substances without degradation. Sourcing from suppliers who offer custom sizing and pressure ratings can further enhance operational efficiency and safety.

In What Ways Does Polymer Tubing Benefit Electronics Manufacturing?

In electronics manufacturing, polymer tubing serves as insulation for wires and cables, which is essential for preventing electrical shorts and enhancing overall product reliability. The use of high-quality polymer tubing ensures that electronics can withstand various environmental conditions, thus improving the longevity of devices. When sourcing for this application, businesses must assess the electrical insulation properties and thermal resistance of the tubing materials to match their specific product requirements.

How is Polymer Tubing Used in Agriculture?

Polymer tubing plays a vital role in agriculture, particularly in irrigation systems and fluid transport for farming applications. The flexibility and UV resistance of these tubes allow for efficient water distribution, ultimately increasing crop yield and resource management. Buyers in the agricultural sector should consider the durability and compatibility of tubing materials with various fluids, ensuring that they can withstand exposure to sunlight and harsh environmental conditions while maintaining performance.

3 Common User Pain Points for ‘polymer tubing’ & Their Solutions

Scenario 1: Sourcing the Right Material for Specific Applications

The Problem: B2B buyers often struggle with selecting the appropriate polymer tubing material that meets specific application requirements. For instance, a buyer in the medical device industry might need tubing that is not only biocompatible but also flexible and resistant to chemicals. The vast array of options—such as Nylon, PVC, and Polyethylene—can lead to confusion and misalignment with project specifications, potentially resulting in product failures or costly redesigns.

Illustrative image related to polymer tubing

The Solution: To effectively source the right polymer tubing, buyers should conduct a thorough needs assessment that includes the application’s environmental conditions, regulatory requirements, and mechanical properties. Engaging with manufacturers who offer custom solutions can be invaluable. Create a detailed specification document that outlines critical attributes such as diameter, wall thickness, chemical resistance, and temperature tolerance. Collaborating with suppliers who have expertise in the specific industry will ensure that the chosen material aligns with both performance expectations and compliance standards. Additionally, consider requesting samples for testing to evaluate their suitability in real-world conditions before making a bulk purchase.

Scenario 2: Ensuring Consistency and Quality in Production

The Problem: Quality control is a significant concern for B2B buyers in industries like automotive or food and beverage, where polymer tubing must meet stringent standards. Inconsistent quality can lead to production delays, increased waste, and even safety hazards. Buyers may find that their chosen supplier does not consistently meet the required specifications, leading to costly rework or product recalls.

The Solution: Establishing a strong partnership with suppliers who adhere to ISO standards can mitigate quality issues. Buyers should prioritize suppliers who provide transparent quality assurance processes, including detailed documentation of production methods, material certifications, and third-party testing results. Implementing a robust quality control plan that includes regular audits of the supplier’s production facilities can help ensure that the tubing remains within specified tolerances. Buyers should also consider using advanced technologies such as real-time monitoring systems to track production metrics, which can help identify deviations from quality standards before they impact the final product.

Scenario 3: Adapting Tubing for Unique Applications

The Problem: Many B2B buyers encounter difficulties when their applications require unique tubing configurations or modifications. For example, a manufacturer may need multi-lumen tubing for a specialized medical device but find that standard offerings do not meet their design requirements. This limitation can lead to delays in product development and increased costs if buyers have to settle for less optimal solutions.

Illustrative image related to polymer tubing

The Solution: To overcome the challenge of adapting tubing for unique applications, buyers should work closely with manufacturers that specialize in custom extrusion services. Begin by outlining your specific application needs, including dimensions, material properties, and any additional features such as reinforcement or flexibility requirements. Utilize the expertise of engineering teams at tubing manufacturers to explore innovative design solutions that can accommodate your specifications. Many suppliers offer prototyping services, which allow buyers to test customized tubing designs before committing to larger production runs. This proactive approach not only ensures that the final product meets the intended use but also enhances overall project efficiency by reducing the risk of redesigns.

Strategic Material Selection Guide for polymer tubing

What Are the Key Properties of Common Polymer Tubing Materials?

When selecting polymer tubing for various applications, understanding the characteristics of different materials is crucial. Here, we analyze four common materials used in polymer tubing: Polyethylene (PE), Polyvinyl Chloride (PVC), Nylon, and Polytetrafluoroethylene (PTFE). Each material has unique properties that can significantly influence product performance and suitability for specific applications.

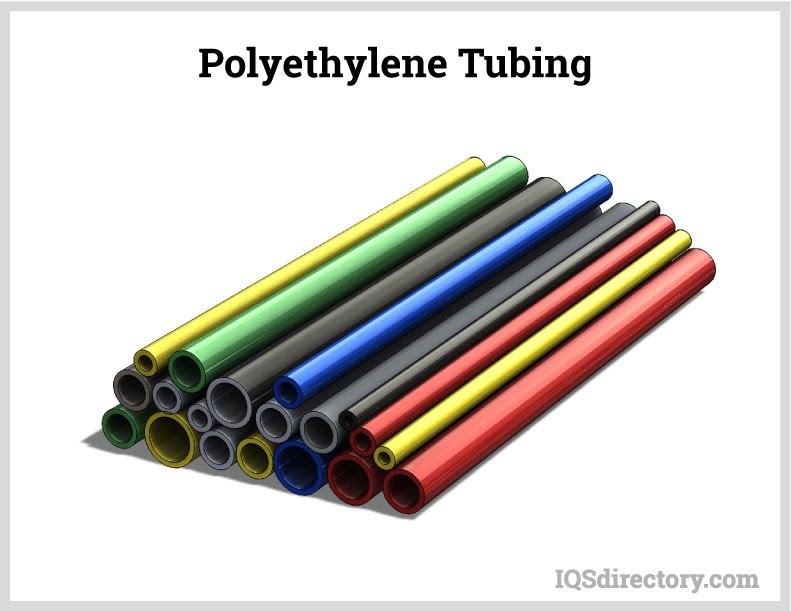

How Does Polyethylene (PE) Perform in Polymer Tubing Applications?

Polyethylene, particularly High-Density Polyethylene (HDPE), is known for its excellent impact resistance and chemical stability. It typically operates effectively in temperatures ranging from -50°C to 60°C and can withstand moderate pressure. PE is non-toxic and resistant to corrosion, making it suitable for transporting various fluids, including potable water.

Pros: The advantages of PE include its lightweight nature, low cost, and ease of manufacturing. It is also highly resistant to moisture and many chemicals, making it versatile for numerous applications.

Cons: However, PE has limitations regarding temperature resistance compared to other materials. It can become brittle at low temperatures and may not perform well under high-pressure conditions.

Illustrative image related to polymer tubing

International Considerations: B2B buyers in regions like Africa and South America should ensure compliance with local regulations regarding food safety and environmental standards, as PE is often used in food and beverage applications.

What Advantages Does Polyvinyl Chloride (PVC) Offer?

PVC is a widely used thermoplastic known for its durability and resistance to environmental factors. It can handle temperatures up to 60°C and is often employed in plumbing and construction applications due to its strength and rigidity.

Pros: PVC’s key advantages include its excellent chemical resistance, low maintenance requirements, and affordability. It is also easy to fabricate and install, making it a popular choice for many industries.

Cons: The main drawback of PVC is its limited flexibility and susceptibility to UV degradation if not properly treated. Additionally, it may release harmful chemicals during manufacturing or disposal, raising environmental concerns.

International Considerations: Buyers in the Middle East and Europe should be aware of compliance with standards such as ASTM and DIN, particularly for construction materials, to ensure safety and reliability.

How Does Nylon Compare as a Polymer Tubing Material?

Nylon tubing is known for its high tensile strength and resistance to abrasion, making it ideal for applications requiring durability. It can operate effectively in temperatures ranging from -40°C to 100°C and can withstand high pressures, making it suitable for hydraulic systems.

Pros: The primary advantages of nylon include its excellent mechanical properties and resistance to wear and tear. It is also lightweight and can be produced in various sizes and configurations.

Illustrative image related to polymer tubing

Cons: On the downside, nylon can absorb moisture, which may affect its dimensional stability and performance in certain environments. It is also generally more expensive than PE and PVC.

International Considerations: B2B buyers should consider local standards and certifications for nylon products, especially in industries like automotive and aerospace, where specific performance criteria must be met.

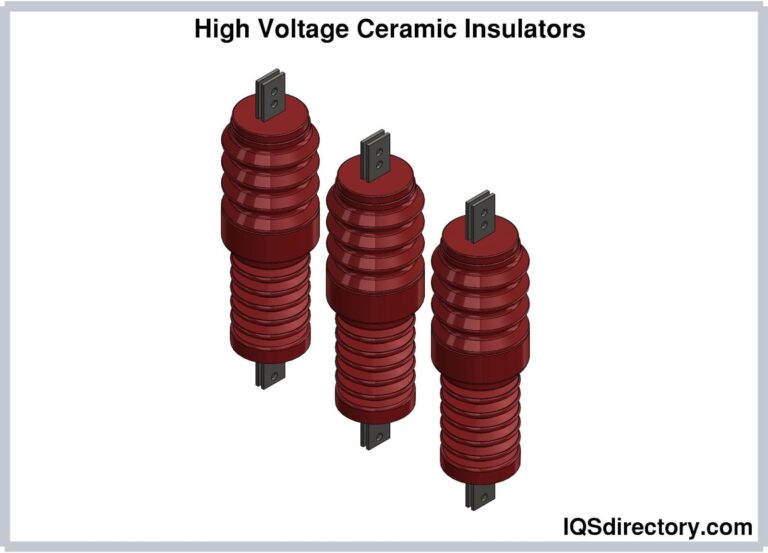

What Makes Polytetrafluoroethylene (PTFE) Unique?

PTFE is renowned for its exceptional chemical resistance and high-temperature tolerance, making it ideal for specialized applications such as medical and food processing tubing. It can withstand temperatures up to 260°C and is non-reactive with most chemicals.

Pros: The key advantages of PTFE include its low friction properties, making it ideal for applications requiring smooth flow, and its durability under extreme conditions. It is also FDA-approved for food contact, enhancing its applicability in the food industry.

Cons: However, PTFE is relatively expensive compared to other polymer materials and can be more complex to manufacture, which may affect lead times and costs.

International Considerations: Buyers in Europe and Asia should ensure compliance with international food safety regulations when using PTFE in food-related applications.

Summary Table of Material Selection for Polymer Tubing

| Material | Typical Use Case for polymer tubing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene (PE) | Water transport, general-purpose tubing | Lightweight and cost-effective | Limited temperature resistance | Low |

| Polyvinyl Chloride (PVC) | Plumbing, construction applications | Excellent chemical resistance | Limited flexibility and UV degradation | Medium |

| Nylon | Hydraulic systems, automotive applications | High tensile strength and durability | Moisture absorption affecting stability | Medium |

| Polytetrafluoroethylene (PTFE) | Medical and food processing tubing | Exceptional chemical resistance and FDA approval | High cost and complex manufacturing | High |

This guide serves as a foundational resource for international B2B buyers, helping them make informed decisions about polymer tubing material selection based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for polymer tubing

What Are the Main Stages of the Manufacturing Process for Polymer Tubing?

The manufacturing of polymer tubing involves several critical stages that ensure the final product meets industry standards and customer specifications. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Polymer Tubing Production?

Material preparation begins with selecting the appropriate polymer based on the desired properties of the tubing. Common materials include polyethylene, nylon, polypropylene, and polyvinyl chloride (PVC). Suppliers often utilize advanced processing techniques such as compounding, where additives are mixed with base polymers to enhance performance characteristics like flexibility, durability, and resistance to chemicals.

Once the material is compounded, it is pelletized for easier handling and feeding into the extrusion machinery. This stage may also involve drying the material to remove moisture, which is crucial for preventing defects during extrusion.

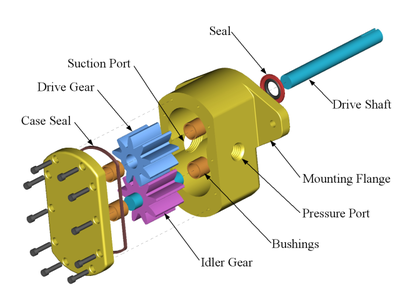

What Techniques Are Used in the Forming Stage of Polymer Tubing?

The forming stage primarily employs extrusion, a process where the prepared polymer pellets are melted and forced through a die to create the desired shape. Depending on the application, manufacturers may use different extrusion techniques, including:

- Single-Screw Extrusion: Commonly used for producing standard tubing, where a single screw transports and melts the polymer.

- Twin-Screw Extrusion: Ideal for more complex formulations, allowing for better mixing and enhanced material properties.

Post-extrusion, the tubing undergoes cooling, which can be achieved through water baths or air cooling systems. This step solidifies the tubing and ensures it retains its shape.

What Assembly Processes Are Common in Polymer Tubing Manufacturing?

In some applications, polymer tubing may require additional components, such as fittings or reinforcements. The assembly stage involves integrating these elements, which can include heat sealing, adhesive bonding, or mechanical fastening. For specialized applications, such as in the medical field, assembly might also involve adding features like lumens or braids for enhanced performance.

Illustrative image related to polymer tubing

How Is the Finishing Process Conducted for Polymer Tubing?

The finishing stage encompasses a range of processes designed to enhance the final product’s appearance and functionality. This may include surface treatments such as polishing, printing, or applying protective coatings. Additionally, manufacturers may conduct dimensional checks to ensure the tubing meets specified tolerances.

What Quality Assurance Standards Are Relevant for Polymer Tubing?

Quality assurance is paramount in the polymer tubing manufacturing process to ensure safety, reliability, and compliance with international standards. B2B buyers should be familiar with several key standards:

- ISO 9001: This international standard sets the criteria for a quality management system, ensuring that manufacturers consistently meet customer and regulatory requirements.

- CE Marking: Particularly important for products sold in the European market, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For tubing used in the oil and gas industry, adherence to American Petroleum Institute (API) standards is crucial for ensuring material integrity and safety.

How Are Quality Control Checkpoints Established in the Manufacturing Process?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to identify and address potential issues early. Key checkpoints include:

- Incoming Quality Control (IQC): This phase involves inspecting raw materials upon arrival to verify compliance with specified standards.

- In-Process Quality Control (IPQC): Conducted during the manufacturing stages, IPQC focuses on monitoring processes such as extrusion and assembly to ensure adherence to quality standards.

- Final Quality Control (FQC): At this stage, finished products undergo thorough testing to ensure they meet all specifications before shipping.

What Common Testing Methods Are Used to Ensure Quality in Polymer Tubing?

Manufacturers employ various testing methods to validate the quality and performance of polymer tubing, including:

- Dimensional Testing: Ensures that the tubing meets specified measurements and tolerances.

- Mechanical Testing: Assesses the strength, flexibility, and durability of the tubing under various conditions.

- Chemical Resistance Testing: Determines how well the tubing withstands exposure to different chemicals, which is critical for applications in the medical and industrial sectors.

- Thermal Testing: Evaluates the tubing’s ability to withstand temperature fluctuations without degrading.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers looking to ensure the quality of polymer tubing should consider several strategies to verify supplier QC measures:

- Conducting Supplier Audits: Regular audits of potential suppliers can provide insights into their manufacturing processes, quality control practices, and adherence to international standards.

- Requesting Quality Reports: Suppliers should be able to provide documentation of their quality control measures, including results from testing and certifications.

- Third-Party Inspections: Engaging independent organizations to conduct inspections can offer an unbiased assessment of the supplier’s quality management system and product quality.

What Are the Specific Quality Control Considerations for International B2B Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. Factors to consider include:

- Regulatory Compliance: Different countries may have varying regulations regarding material safety and performance, requiring buyers to ensure that suppliers can meet local requirements.

- Cultural Differences: Understanding the business practices and quality expectations in different regions can help buyers establish effective communication and collaboration with suppliers.

- Logistics and Transportation: Quality control does not end at manufacturing; buyers should also consider how the tubing will be transported and stored to prevent damage before reaching the end user.

By focusing on these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing polymer tubing, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘polymer tubing’

The following guide provides a structured approach for B2B buyers looking to procure polymer tubing. By following these steps, you can ensure a smooth sourcing process that meets your technical and commercial needs.

Illustrative image related to polymer tubing

Step 1: Define Your Technical Specifications

Clearly outline the specifications required for your polymer tubing. This includes dimensions, material types, and performance characteristics such as flexibility, chemical resistance, and temperature tolerance.

– Material Types: Consider options like nylon, polyethylene, or polystyrene based on your application.

– Dimensions: Specify inner and outer diameters, wall thickness, and any other critical dimensions that affect compatibility with existing systems.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers with a strong reputation in the polymer tubing market. Look for companies that specialize in the specific materials and tubing types you need.

– Supplier Experience: Focus on suppliers with a proven track record in your industry.

– Geographical Considerations: Ensure that suppliers can meet international shipping requirements and timelines relevant to your region.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant industry certifications, such as ISO 9001:2015 or other quality management certifications. This step is essential for ensuring product quality and compliance with international standards.

– Quality Assurance: Certifications indicate a supplier’s commitment to maintaining high-quality production standards.

– Regulatory Compliance: Ensure that products meet specific regulations, especially if they will be used in sensitive applications like food or medical devices.

Step 4: Request Samples for Testing

Before placing a bulk order, request samples of the polymer tubing to evaluate their quality and suitability for your application. Testing samples can reveal important performance characteristics.

– Performance Testing: Assess samples for flexibility, durability, and resistance to chemicals or temperature variations.

– Fit and Compatibility: Ensure the samples fit well with your existing systems and meet your technical requirements.

Step 5: Assess Pricing and Terms of Sale

Compare the pricing structures of different suppliers while considering the total cost of ownership. Look beyond the initial purchase price to include shipping, taxes, and potential tariffs.

– Volume Discounts: Inquire about bulk order discounts or loyalty programs.

– Payment Terms: Understand the payment options available and any financing arrangements that may be beneficial.

Step 6: Check Customer Reviews and References

Seek out reviews and testimonials from other customers in similar industries or regions. This feedback can provide insights into a supplier’s reliability, product quality, and customer service.

– Case Studies: Look for documented case studies that demonstrate successful partnerships and product applications.

– Direct References: Ask suppliers for references and reach out to them to gauge their satisfaction and experiences.

Illustrative image related to polymer tubing

Step 7: Establish a Communication Plan

Once you select a supplier, establish a clear communication plan to facilitate ongoing collaboration. This includes setting expectations for updates on orders, changes in specifications, and handling any issues that may arise.

– Regular Check-Ins: Schedule periodic updates to discuss production timelines, quality control, and any potential challenges.

– Feedback Loop: Create a process for providing feedback on products and services to ensure continuous improvement.

By following this comprehensive checklist, B2B buyers can confidently navigate the procurement process for polymer tubing, ensuring they choose the right products and suppliers for their specific needs.

Comprehensive Cost and Pricing Analysis for polymer tubing Sourcing

What Are the Key Cost Components in Polymer Tubing Manufacturing?

Understanding the cost structure of polymer tubing manufacturing is crucial for B2B buyers. Key cost components include:

-

Materials: The choice of polymer significantly impacts costs. Common materials like PVC, HDPE, and nylon vary in price based on market demand and availability. Specialty materials such as PTFE or polyimide may incur higher costs due to their unique properties and manufacturing complexities.

-

Labor: Skilled labor is essential for the extrusion and manufacturing processes. Labor costs can fluctuate based on geographic location and the level of expertise required.

-

Manufacturing Overhead: This encompasses costs related to facility maintenance, utilities, and equipment depreciation. High-tech extrusion machines, especially those capable of producing specialized tubing, can lead to increased overhead.

-

Tooling: Custom tooling is often necessary for specific applications, contributing significantly to initial costs. The complexity of the tool design affects both the upfront investment and lead times.

-

Quality Control (QC): Rigorous QC processes ensure that the final product meets specifications, adding to the overall cost. Certifications like ISO 9001 can further influence pricing due to the processes involved.

-

Logistics: Transportation and shipping costs are critical, especially for international buyers. Factors such as distance, shipping mode, and customs duties can significantly affect the final price.

-

Margin: Suppliers typically add a margin to cover their risks and profit, which can vary widely depending on the supplier’s market position and the competitiveness of the industry.

How Do Price Influencers Affect Polymer Tubing Costs?

Several factors influence the pricing of polymer tubing beyond basic costs:

-

Volume/MOQ: Bulk orders often lead to reduced per-unit costs. Suppliers may offer tiered pricing based on Minimum Order Quantities (MOQs), encouraging larger purchases.

-

Specifications and Customization: Custom specifications, such as specific dimensions or material grades, can increase costs. Buyers should clearly define requirements to avoid unexpected price hikes.

-

Material Quality and Certifications: Higher-quality materials and additional certifications typically come at a premium. Buyers in regulated industries (e.g., medical, food) must weigh the importance of compliance against costs.

-

Supplier Factors: Supplier reputation, lead times, and reliability can influence pricing. Established suppliers may charge more for their experience and reliability.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for international transactions. They define who bears the cost of shipping, insurance, and duties, which can significantly impact overall costs.

What Are Effective Buyer Tips for Negotiating Polymer Tubing Prices?

B2B buyers can adopt several strategies to optimize their purchasing process:

-

Negotiation: Engage suppliers in discussions about pricing, especially for large orders. Leverage competitive quotes to negotiate better terms.

-

Cost-Efficiency: Focus on Total Cost of Ownership (TCO) rather than just the purchase price. Consider long-term costs, including maintenance, durability, and replacement frequency.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe must consider currency fluctuations and local economic conditions, which can affect pricing. Establishing long-term relationships with suppliers may provide more stable pricing.

-

Explore Multiple Suppliers: Don’t hesitate to source from various suppliers to compare costs and quality. This competitive approach can yield better pricing and terms.

-

Stay Informed on Market Trends: Keep abreast of changes in raw material prices, manufacturing capabilities, and technological advancements that can affect costs. This knowledge can empower negotiation discussions and purchasing decisions.

Conclusion

Understanding the comprehensive cost structure and pricing dynamics of polymer tubing is essential for B2B buyers. By analyzing cost components, recognizing price influencers, and employing effective negotiation strategies, buyers can make informed decisions that enhance their purchasing efficiency and overall value. Always keep in mind that prices can vary significantly based on numerous factors, so it’s wise to approach each purchase with a strategic mindset.

Alternatives Analysis: Comparing polymer tubing With Other Solutions

Understanding Alternatives to Polymer Tubing

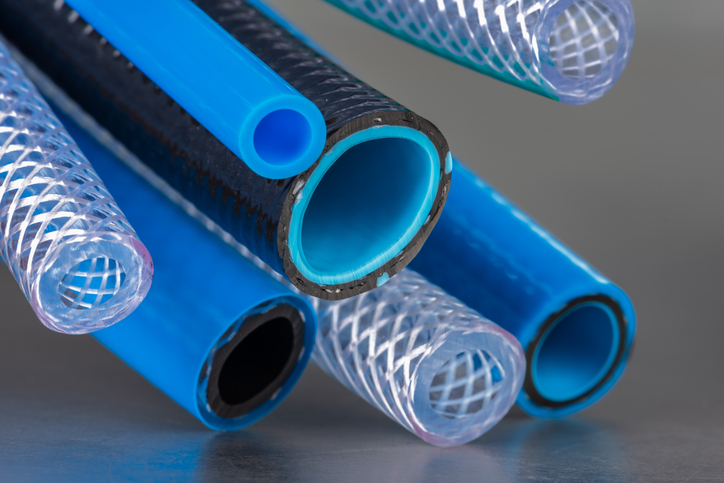

When evaluating solutions for fluid transport and structural applications, polymer tubing presents a reliable option. However, various alternatives may meet specific project requirements more effectively. This analysis compares polymer tubing with two viable alternatives: metal tubing and rubber hoses, enabling B2B buyers to make informed decisions based on their unique needs.

| Comparison Aspect | Polymer Tubing | Metal Tubing | Rubber Hoses |

|---|---|---|---|

| Performance | High flexibility, lightweight, and resistant to corrosion and chemicals | Excellent strength, durability, and heat resistance | Good flexibility, suitable for low-pressure applications |

| Cost | Generally lower cost due to manufacturing efficiencies | Higher initial cost due to material and manufacturing | Moderate cost, but may require more frequent replacements |

| Ease of Implementation | Easy to install and available in various sizes | Requires specialized tools for installation | Simple installation but can be cumbersome in tight spaces |

| Maintenance | Low maintenance; resistant to wear and tear | Requires regular inspections for corrosion | Higher maintenance; susceptible to wear and environmental damage |

| Best Use Case | Ideal for medical, food, and chemical industries | Best for high-pressure and high-temperature applications | Suitable for agricultural, automotive, and low-pressure systems |

Detailed Breakdown of Alternatives

Metal Tubing: Is It Worth the Investment?

Metal tubing, often made from materials like stainless steel or aluminum, excels in high-pressure environments. It boasts superior durability and resistance to extreme temperatures, making it ideal for industrial applications where strength is paramount. However, its higher cost and weight may deter some buyers, especially in projects where flexibility and ease of handling are crucial. Additionally, installation can be labor-intensive, requiring specialized tools and expertise.

Rubber Hoses: A Flexible Option for Specific Applications

Rubber hoses are renowned for their flexibility and ease of use, particularly in agricultural and automotive settings. They can bend easily around obstacles, making them suitable for applications requiring frequent movement or repositioning. However, rubber hoses may not be suitable for high-pressure or high-temperature environments and can degrade faster than polymer or metal options. Regular maintenance is necessary to check for cracks or leaks, which can lead to increased costs over time.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the appropriate tubing solution hinges on several factors, including performance requirements, budget constraints, and specific application contexts. Polymer tubing offers a versatile, cost-effective solution with low maintenance, making it ideal for a wide range of industries. In contrast, metal tubing provides unmatched strength for demanding applications, while rubber hoses serve well in flexible, low-pressure scenarios. B2B buyers should carefully assess their operational needs, environmental conditions, and budget to determine the best fit for their projects.

Illustrative image related to polymer tubing

Essential Technical Properties and Trade Terminology for polymer tubing

What Are the Key Technical Properties of Polymer Tubing?

When selecting polymer tubing, understanding its technical properties is crucial for ensuring the right fit for your application. Here are some essential specifications to consider:

1. Material Grade

The material grade of polymer tubing—such as PVC, nylon, or polyethylene—affects its performance characteristics. Each material offers different benefits, including chemical resistance, flexibility, and durability. For instance, nylon tubing is highly regarded for its strength and resistance to wear, making it ideal for demanding applications. Choosing the right material ensures the tubing can withstand the specific environmental conditions it will encounter.

2. Tolerance

Tolerance refers to the allowable variation in dimensions of the tubing, such as diameter and wall thickness. This specification is critical for applications requiring precise fits, such as medical devices or aerospace components. Tighter tolerances can lead to improved performance and reduced failure rates, which is essential for maintaining operational efficiency and safety in sensitive applications.

3. Wall Thickness

The wall thickness of polymer tubing influences its strength, flexibility, and pressure resistance. Thicker walls provide greater durability and can withstand higher pressures, making them suitable for fluid transport in industrial applications. Conversely, thinner walls may be more suitable for lightweight applications or where flexibility is paramount. Understanding the required wall thickness helps in selecting tubing that meets the application’s demands.

4. Chemical Resistance

Chemical resistance is the tubing’s ability to withstand various substances without degrading. This property is particularly important in industries such as pharmaceuticals and food processing, where exposure to chemicals can lead to contamination or failure. Assessing the chemical compatibility of the tubing material with the intended fluids is vital to ensure long-term performance and compliance with industry regulations.

5. Operating Temperature Range

The operating temperature range specifies the temperatures the tubing can endure without losing its structural integrity or performance. Different applications may require tubing that can withstand extreme heat or cold. For example, PTFE tubing is known for its high-temperature resistance, making it suitable for applications in harsh environments. Ensuring the tubing can operate within the expected temperature range is essential for reliability.

What Common Trade Terms Should B2B Buyers Know in the Polymer Tubing Industry?

Understanding industry jargon can facilitate smoother communication and negotiation in B2B transactions. Here are some common terms you should be familiar with:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that are marketed by another company. In the context of polymer tubing, an OEM may require custom tubing specifications tailored to their products. Knowing the OEM’s requirements is crucial for ensuring compatibility and performance in their applications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In the polymer tubing market, understanding MOQ helps buyers assess whether they can meet purchasing requirements without overcommitting resources. This term is particularly important for startups or smaller businesses that may have limited budgets.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers for specific products or services. When requesting polymer tubing, an RFQ should detail the required specifications, quantities, and delivery timelines. This process helps buyers compare options and negotiate favorable terms.

4. Incoterms

Incoterms, short for International Commercial Terms, define the responsibilities of buyers and sellers in international transactions. These terms clarify who bears the costs and risks associated with shipping, insurance, and customs duties. Familiarity with Incoterms can help buyers understand their obligations and avoid unexpected costs in global sourcing.

5. Lead Time

Lead time refers to the time it takes from placing an order until the product is delivered. In the polymer tubing industry, lead times can vary based on material availability and production schedules. Understanding lead time is vital for effective inventory management and ensuring that production schedules are met without delays.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, streamline procurement processes, and enhance their operational efficiency when sourcing polymer tubing.

Navigating Market Dynamics and Sourcing Trends in the polymer tubing Sector

What Are the Current Market Dynamics and Key Trends in the Polymer Tubing Sector?

The global polymer tubing market is witnessing significant growth, driven by the increasing demand across various industries, including medical, automotive, and consumer goods. The rise in the adoption of polymer tubing in medical devices, particularly for minimally invasive procedures, is a notable trend. As healthcare systems in regions like Africa and South America develop, the need for reliable and cost-effective medical solutions is propelling this growth. Additionally, advancements in extrusion technologies are enabling manufacturers to produce tubing with precise specifications, catering to diverse applications.

Emerging B2B technologies, such as 3D printing and automation, are reshaping sourcing strategies in the polymer tubing sector. Businesses are increasingly adopting these technologies to streamline production processes and reduce lead times. Moreover, data analytics is playing a crucial role in demand forecasting and inventory management, helping companies mitigate risks associated with supply chain disruptions. For international buyers, particularly in developing regions, understanding these technological shifts is essential for making informed sourcing decisions.

Furthermore, the market dynamics are influenced by fluctuating raw material prices and geopolitical factors, which can affect supply chains. Buyers are encouraged to engage with multiple suppliers and explore local sourcing options to enhance supply chain resilience. The focus on customization and flexibility in production is becoming increasingly important, as clients seek tailored solutions that meet specific operational needs.

How Is Sustainability and Ethical Sourcing Shaping the Polymer Tubing Market?

Sustainability has become a critical consideration in the polymer tubing sector, with increasing scrutiny on the environmental impact of production processes. Buyers are now prioritizing suppliers who demonstrate a commitment to eco-friendly practices, such as using recycled materials and reducing waste. The demand for ‘green’ certifications, such as ISO 14001, is growing, as companies aim to align their operations with global sustainability goals.

Ethical sourcing is equally important, particularly for international buyers looking to establish a responsible supply chain. This involves ensuring that materials are sourced from suppliers who adhere to fair labor practices and environmental regulations. The transparency of the supply chain has become a key factor in supplier selection, with buyers increasingly conducting audits and assessments to verify compliance.

Moreover, the availability of sustainable materials, such as bio-based polymers, is expanding. These alternatives not only reduce the carbon footprint but also cater to the growing consumer demand for environmentally friendly products. By partnering with suppliers who prioritize sustainability, B2B buyers can enhance their brand reputation while contributing to broader environmental initiatives.

How Has the Polymer Tubing Sector Evolved Over Time?

The polymer tubing sector has undergone significant evolution since its inception in the mid-20th century. Initially dominated by traditional materials such as rubber and metal, the industry has shifted towards polymers due to their superior properties, including lightweight, flexibility, and resistance to corrosion. This transition was driven by the need for more durable and versatile solutions across various applications.

In the past two decades, advancements in polymer chemistry and manufacturing processes have further enhanced the capabilities of polymer tubing. Innovations such as multilayer tubing and composite materials have enabled the development of products that meet stringent performance requirements in specialized applications, particularly in the medical field. As the market continues to grow, ongoing research and development are expected to introduce even more sophisticated materials and technologies, ensuring that polymer tubing remains at the forefront of industrial solutions.

In summary, understanding the dynamics of the polymer tubing market, including sustainability considerations and historical context, will empower international B2B buyers to make informed decisions that align with their operational needs and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of polymer tubing

-

How do I select the right polymer tubing for my application?

Selecting the appropriate polymer tubing involves understanding your specific application requirements, such as temperature resistance, chemical compatibility, and flexibility. Start by assessing the environmental conditions the tubing will face, including exposure to chemicals or extreme temperatures. Consult with suppliers to explore materials like PVC for chemical resistance, Nylon for durability, or PTFE for lubricity. Request samples to evaluate performance before making a bulk purchase. Engaging in collaborative discussions with your engineering team can ensure the chosen tubing meets all functional requirements. -

What are the most common materials used in polymer tubing?

Common materials for polymer tubing include PVC, Polyethylene (HDPE and LDPE), Nylon, Polypropylene, and PTFE. Each material offers unique properties; for example, PVC is known for its chemical resistance, while Nylon provides excellent strength and flexibility. Polypropylene is lightweight and has high chemical resistance, making it suitable for various applications. Understanding these materials’ specific characteristics can help you choose the right tubing for your project’s demands. -

What customization options are available for polymer tubing?

Most manufacturers offer extensive customization options, including variations in diameter, wall thickness, length, and color. You can also request specific material blends to enhance performance characteristics, such as increased flexibility or temperature resistance. Custom designs can be developed to fit specific applications, such as multi-lumen tubing for medical devices. Be sure to communicate your precise specifications to potential suppliers to ensure they can meet your requirements. -

What are the minimum order quantities (MOQ) for polymer tubing?

Minimum order quantities can vary significantly between suppliers and depend on the type and customization of the tubing required. Generally, standard sizes may have lower MOQs, while custom specifications could require higher quantities to justify production costs. It’s advisable to discuss MOQs upfront with suppliers, as some may be willing to accommodate lower orders, especially for initial trials or sample runs. -

How can I ensure quality assurance in polymer tubing sourcing?

To ensure quality assurance, select suppliers who adhere to international quality standards, such as ISO 9001. Request certifications and conduct factory audits if possible. Inquire about their quality control processes, including testing for dimensional accuracy, material properties, and performance under expected conditions. Consider establishing a quality agreement that outlines specific requirements, testing protocols, and penalties for non-compliance to safeguard your interests. -

What payment terms should I expect when sourcing polymer tubing internationally?

Payment terms can vary widely based on supplier policies and the nature of the transaction. Common terms include upfront payments, net 30, or net 60 days. For larger orders, consider negotiating terms that provide payment flexibility, such as partial payments upon order confirmation and the balance upon delivery. Always clarify payment methods accepted, including wire transfers, letters of credit, or online payment platforms, to avoid delays in transactions. -

What logistics considerations should I keep in mind when importing polymer tubing?

When importing polymer tubing, consider shipping costs, lead times, and customs regulations in your country. Work with suppliers who have experience in international shipping to ensure compliance with all legal requirements. Understand the implications of import duties and taxes on your overall budget. Additionally, establish clear communication about delivery timelines and tracking options to mitigate risks associated with delays. -

How do I vet potential suppliers for polymer tubing?

Vetting suppliers involves evaluating their industry reputation, experience, and product quality. Start by checking customer reviews, case studies, and references from other B2B buyers. Assess their manufacturing capabilities, certifications, and adherence to quality standards. Request samples to evaluate product quality firsthand and visit their facilities if feasible. Engaging in initial discussions can also reveal their responsiveness and willingness to collaborate, which are crucial for long-term partnerships.

Top 6 Polymer Tubing Manufacturers & Suppliers List

1. Pexco – Key Product Details

Domain: pexco.com

Registered: 1997 (28 years)

Introduction: Key Product Details: 1. Polymer Tubing and Profiles: – Types: Fluoropolymer Tubing, Pipe, Sheet, Rod, Film Products. – Brands: Altaflo® (various types including PTFE, FEP, PFA, PVDF), Enflon Filled PTFE Products, Extruded PTFE Rod, Molded PTFE Products. 2. Heat Shrink and Insulation Tubing: – Types: UV Treated, Medical-Grade, Food-Grade, Polyolefin, PVC, Non-Heat Shrink Tubing. – Assortments and K…

2. Professional Plastics – Plastic Tubing & Sheets

Domain: professionalplastics.com

Registered: 1997 (28 years)

Introduction: Plastic Tubing – Plastic Tubes – Order Online – Tubing Supplier. Leader in Plastic Sheets, Rods, Tubing, Profiles, & Parts since 1984. Materials include ABS, Acetal/Delrin®, Acrylic/Plexiglass, Acrylite®, ECTFE/Halar®, ETFE/Tefzel®, FDA Materials, Fiberglass, Flexible Tubing & Hose, HDPE, Nylon®, PEEK, PFA & FEP, Polycarbonate, Polypropylene, PTFE, PVC & CPVC, PVDF/Kynar®, UHMW, Urethane, and more…

3. Meditube – Tungsten Loaded Marker Bands

Domain: meditube.com

Registered: 2003 (22 years)

Introduction: [{‘name’: ‘Tungsten Loaded Marker Bands’, ‘type’: ‘Polymer Tubing’, ‘material’: ‘Tungsten Loaded’, ‘ID’: ‘0.09″‘, ‘OD’: ‘0.098″‘, ‘length’: ’49″‘, ‘quantity’: ‘5/bag’, ‘price’: ‘$150.00’}, {‘name’: ‘Tungsten Loaded Marker Bands’, ‘type’: ‘Polymer Tubing’, ‘material’: ‘Grilamid L25’, ‘ID’: ‘0.0875″‘, ‘OD’: ‘0.0935″‘, ‘length’: ’40″‘, ‘quantity’: ‘5/bag’, ‘price’: ‘$150.00’}, {‘name’: ‘Nylon Tubing’…

4. Confluent Medical – Polymer Tubing Solutions

Domain: confluentmedical.com

Registered: 2015 (10 years)

Introduction: Polymer Tubing capabilities include: PTFE Liners and Polyimide Tubing, utilizing filmcast technology for lubricious PTFE liners and polyimide tubing with composite options. Key features include extremely thin wall thicknesses and tight tolerances for high performance, minimally invasive applications. Core mandrel process allows for intimate fit without oversleeving. PTFE liners support sizes from …

5. Polyconn – Nylon Tubing

Domain: polyconn.com

Registered: 1995 (30 years)

Introduction: Nylon tubing, also known as polyamide tubing, withstands higher temperatures, making it suitable for various applications. Compared to other Nylon resins, it offers a lighter weight wall, greater flexibility, and a smaller bend radius. It is more corrosion resistant due to its moisture absorption resistance, and its heat and UV stabilization helps prevent stress-cracking, making it ideal for sunny…

6. APT – Advanced Polymer Tubing Solutions

Domain: aptubing.com

Registered: 2010 (15 years)

Introduction: APT Advanced Polymer Tubing offers a range of fluoropolymer products including:

– PFA (Standard-PFA, High-Purity-PFA, PFA-Flex)

– FEP (Standard-FEP, FEP-Flex)

– PVDF

– ETFE

– ECTFE

– THV

– Antistatic Tubing

– Customized Tubing Solutions

– Shrink Tubes (PTFE heat shrinks with 4:1 and 2:1 shrinking ratios, PTFE-FEP Dual Wall Heat Shrink, FEP Heat Shrink, FEP Roll Covers)

– Individual Heat …

Strategic Sourcing Conclusion and Outlook for polymer tubing

In today’s competitive landscape, strategic sourcing of polymer tubing is paramount for businesses aiming to enhance operational efficiency and product quality. By leveraging a diverse range of materials—such as nylon, polyethylene, and polycarbonate—buyers can tailor solutions that meet specific industry needs, from medical devices to automotive applications. The ability to collaborate closely with manufacturers ensures that organizations can not only optimize cost but also innovate rapidly, enabling quicker time-to-market for new products.

Illustrative image related to polymer tubing

As international markets continue to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, buyers should prioritize suppliers who demonstrate a commitment to quality, sustainability, and technological advancement. Engaging with manufacturers that offer customization options and adhere to stringent quality standards can provide a competitive edge.

Looking ahead, the demand for high-performance polymer tubing is set to grow, driven by advancements in technology and increasing applications across various sectors. Now is the time for businesses to evaluate their sourcing strategies and align with reputable partners who can support their goals. Embrace the opportunities that strategic sourcing offers and position your company for success in the dynamic global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.