Unlocking Value: A Strategic Analysis of the Plexiglass Sheets 4X8 Market

Introduction: Navigating the Global Market for plexiglass sheets 4×8

In the competitive landscape of international trade, sourcing high-quality plexiglass sheets 4×8 can present significant challenges for B2B buyers. With varying standards, pricing, and supplier reliability across regions like Africa, South America, the Middle East, and Europe, making informed purchasing decisions is crucial. This comprehensive guide addresses these challenges by delving into the diverse types of plexiglass sheets available, their myriad applications—from retail displays to custom furniture—and essential criteria for vetting suppliers.

Throughout this guide, we will explore the critical factors influencing cost, including thickness options and manufacturing processes. By equipping you with actionable insights, we aim to empower you to navigate the complexities of the global market with confidence. Whether you are a procurement manager in Germany seeking durable materials for a construction project or a business owner in Nigeria looking for innovative display solutions, this resource will provide you with the knowledge necessary to optimize your purchasing strategy. Understanding the landscape of plexiglass sheets is not just about making a purchase; it’s about enhancing your business’s operational efficiency and ensuring that you select the right products to meet your specific needs.

Understanding plexiglass sheets 4×8 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Clear Cast Acrylic | Higher molecular weight, superior clarity | Aquariums, signage, high-end displays | Pros: Excellent optical clarity, shatter-resistant. Cons: More expensive than extruded sheets. |

| Extruded Acrylic | Lightweight, less clarity than cast | Budget signage, DIY projects, protective barriers | Pros: Cost-effective, easy to handle. Cons: Lower impact resistance and clarity compared to cast. |

| Colored Acrylic | Available in various colors and finishes | Retail displays, decorative applications | Pros: Versatile aesthetic options, can enhance branding. Cons: Limited transparency; color may fade over time. |

| Frosted Acrylic | Translucent finish, diffuses light | Privacy screens, decorative panels | Pros: Provides privacy while allowing light; modern look. Cons: Less suitable for applications requiring clarity. |

| UV-Resistant Acrylic | Enhanced protection against UV rays | Outdoor signage, skylights, and displays | Pros: Long-lasting color and clarity outdoors. Cons: Typically higher cost; may require specific care. |

What Are the Characteristics of Clear Cast Acrylic Sheets?

Clear cast acrylic sheets are known for their exceptional clarity and strength, making them a preferred choice for applications where transparency is essential. With a higher molecular weight, these sheets are more durable and less prone to scratching than their extruded counterparts. B2B buyers should consider the initial cost versus long-term value, especially in high-visibility applications like aquariums or high-end displays where clarity is crucial.

How Do Extruded Acrylic Sheets Differ from Cast?

Extruded acrylic sheets are lighter and generally more affordable than cast sheets, making them a popular option for budget-conscious projects. While they are easier to handle and cut, they do not offer the same level of clarity or impact resistance. Businesses looking for cost-effective solutions for signage or protective barriers may find extruded sheets suitable, but they should weigh the trade-offs in durability and aesthetic quality.

What Advantages Do Colored Acrylic Sheets Offer for Businesses?

Colored acrylic sheets come in a variety of hues and finishes, providing businesses with ample options to enhance their branding through visual appeal. They are commonly used in retail displays and decorative applications. However, while they add aesthetic value, buyers should be aware that colored sheets may not provide the same level of transparency and could fade over time when exposed to sunlight.

Why Choose Frosted Acrylic Sheets for Privacy Solutions?

Frosted acrylic sheets offer a unique translucent finish that diffuses light while ensuring privacy. These sheets are ideal for applications such as office partitions or decorative panels in public spaces. Buyers should consider that while frosted sheets provide a modern aesthetic, they may not be suitable for applications requiring clear visibility, thus limiting their use in certain contexts.

How Does UV-Resistant Acrylic Benefit Outdoor Applications?

UV-resistant acrylic sheets are specifically designed to withstand prolonged exposure to sunlight, making them ideal for outdoor signage, skylights, and displays. They maintain their clarity and color over time, which is a significant advantage for businesses operating in sunny climates. However, the enhanced properties of UV-resistant sheets often come at a higher price point, so B2B buyers should evaluate the cost against the longevity and performance benefits for outdoor use.

Key Industrial Applications of plexiglass sheets 4×8

| Industry/Sector | Specific Application of plexiglass sheets 4×8 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail Displays | Custom retail signage and product showcases | Enhances product visibility, attracts customers | Look for UV resistance and customization options |

| Construction | Windows and safety barriers | Lightweight yet strong alternative to glass | Ensure compliance with local building regulations |

| Aquaculture | Aquariums and fish tanks | Provides a clear, durable environment for marine life | Consider thickness and impact resistance |

| Automotive | Protective shields and custom vehicle parts | Reduces weight and increases fuel efficiency | Check for specific automotive-grade certifications |

| Art and Design | Framing and display cases | Adds aesthetic value while protecting artworks | Focus on clarity and custom fabrication capabilities |

How Are Plexiglass Sheets 4×8 Used in Retail Displays?

In the retail sector, plexiglass sheets 4×8 are widely used for creating custom signage and product displays. Their exceptional clarity allows products to shine, while their lightweight nature makes installation easy. Retailers benefit from the durability and impact resistance of acrylic, ensuring that displays can withstand the rigors of a bustling shopping environment. International buyers should prioritize sourcing sheets that offer UV resistance to prevent fading and consider custom sizes to fit specific display needs.

What Role Do Plexiglass Sheets Play in Construction?

In construction, plexiglass sheets serve as an excellent alternative to traditional glass for windows and safety barriers. Their lightweight composition not only simplifies handling but also reduces the structural load on buildings. The strength of plexiglass makes it ideal for high-traffic areas, providing safety without compromising visibility. Buyers in regions with specific building codes, such as Germany or Nigeria, should ensure that their selected sheets meet local regulations regarding safety and insulation properties.

How Are Plexiglass Sheets Beneficial for Aquaculture?

Plexiglass sheets 4×8 are particularly valuable in aquaculture for constructing aquariums and fish tanks. Their clarity allows for unobstructed viewing of aquatic life, while their resistance to moisture ensures longevity in humid environments. The impact resistance is crucial for preventing breakage, thus maintaining a stable habitat for marine species. Buyers should focus on sourcing sheets with appropriate thickness and clarity, considering the specific needs of the aquatic life they intend to house.

How Is Plexiglass Used in the Automotive Industry?

In the automotive industry, plexiglass sheets are utilized for protective shields and custom vehicle parts. Their lightweight nature contributes to improved fuel efficiency, making them an attractive option for manufacturers aiming to reduce vehicle weight. Additionally, the impact resistance of acrylic ensures that protective components can withstand various driving conditions. International buyers should seek suppliers that provide automotive-grade plexiglass, ensuring compliance with safety standards and performance requirements.

What Are the Applications of Plexiglass in Art and Design?

Artists and designers frequently use plexiglass sheets 4×8 for framing artworks and creating display cases. The transparency of the material enhances the visual appeal of art pieces, while also providing essential protection against environmental factors. Custom fabrication options allow for unique designs that cater to specific artistic visions. Buyers in this sector should prioritize sourcing high-clarity sheets that can be easily cut or shaped, ensuring that their creative projects are executed flawlessly.

3 Common User Pain Points for ‘plexiglass sheets 4×8’ & Their Solutions

Scenario 1: Sourcing Quality Plexiglass Sheets Amid Supply Chain Disruptions

The Problem: B2B buyers, especially those operating in regions like Africa and South America, often face challenges in sourcing high-quality plexiglass sheets due to supply chain disruptions. These disruptions can lead to inconsistencies in product availability, affecting project timelines and budgets. Buyers may find themselves receiving inferior materials that do not meet their specifications, leading to delays in production and potential loss of business opportunities.

The Solution: To mitigate these risks, buyers should establish relationships with multiple suppliers to diversify their sourcing channels. Conduct thorough due diligence to vet suppliers, focusing on their reputation, quality assurance processes, and delivery capabilities. Consider sourcing from suppliers with a robust international shipping network to ensure timely delivery. Additionally, it’s beneficial to order in bulk when possible to secure lower prices and guarantee stock availability. Leverage technology such as supply chain management software to monitor inventory levels and anticipate shortages, allowing for proactive purchasing decisions.

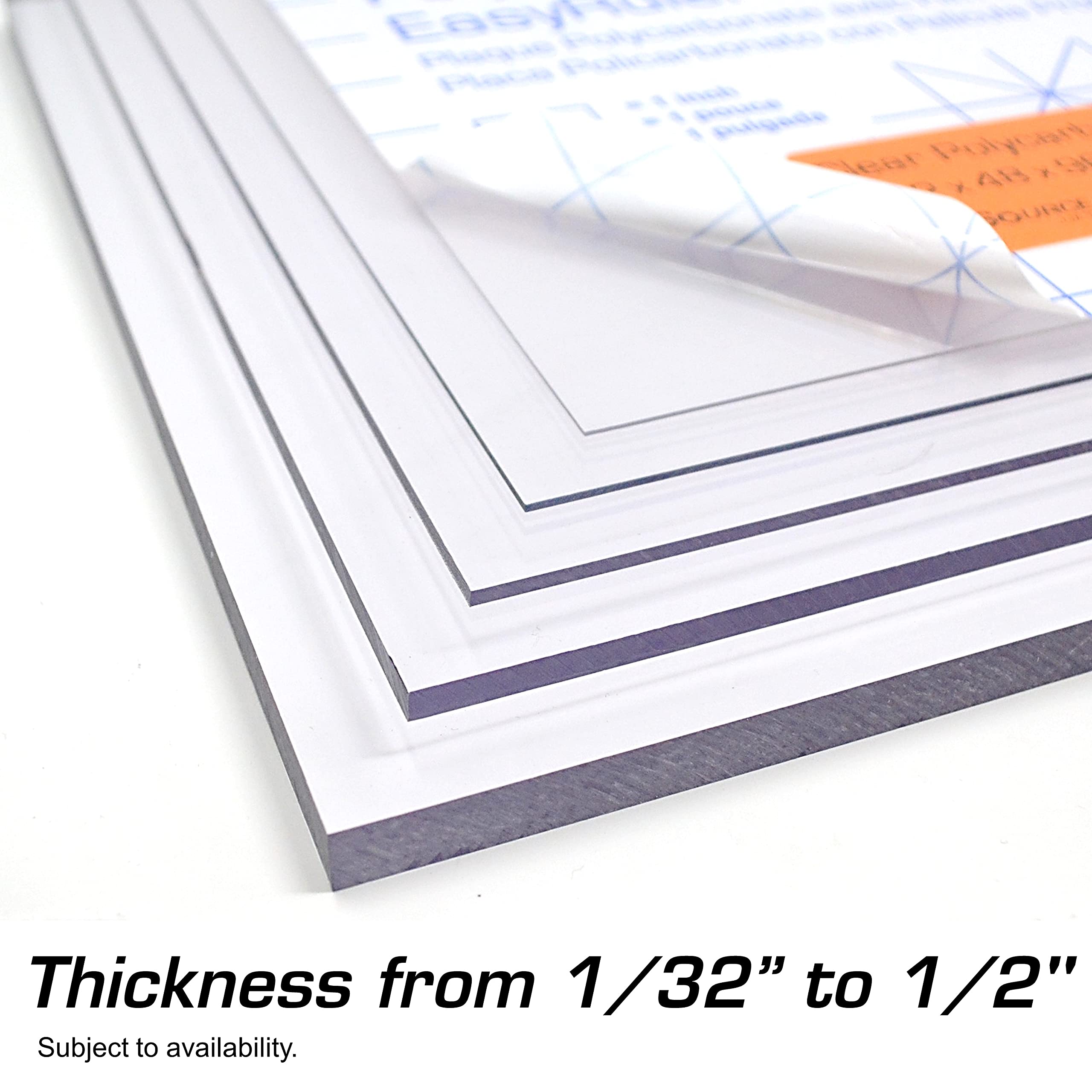

Scenario 2: Navigating the Complexity of Thickness Specifications

The Problem: Another common pain point for B2B buyers is understanding the intricacies of thickness specifications when ordering 4×8 plexiglass sheets. Misunderstanding the required thickness can lead to purchasing sheets that are either too thin, compromising durability, or too thick, resulting in unnecessary costs. This is particularly critical in industries where precise specifications are paramount, such as construction or custom display fabrication.

The Solution: To navigate this complexity, buyers should clearly define the intended use of the plexiglass sheets before placing an order. Collaborate with design engineers or technical experts to determine the optimal thickness based on factors such as stress load, environmental conditions, and aesthetic requirements. Utilize reference materials and thickness charts provided by suppliers to inform decisions. When in doubt, consult with suppliers directly for recommendations based on their product offerings and real-world applications. Establishing a clear line of communication with suppliers will help ensure that the specifications align with project requirements, minimizing the risk of costly errors.

Scenario 3: Ensuring Safe Handling and Installation of Plexiglass Sheets

The Problem: Handling and installing large 4×8 plexiglass sheets can pose safety risks and logistical challenges, particularly for businesses with limited experience in working with acrylic materials. Improper handling can lead to damage, such as scratches or breakage, which not only incurs additional costs but also delays project timelines. Furthermore, without the right installation techniques, the sheets may not perform as expected, leading to functional issues in the final product.

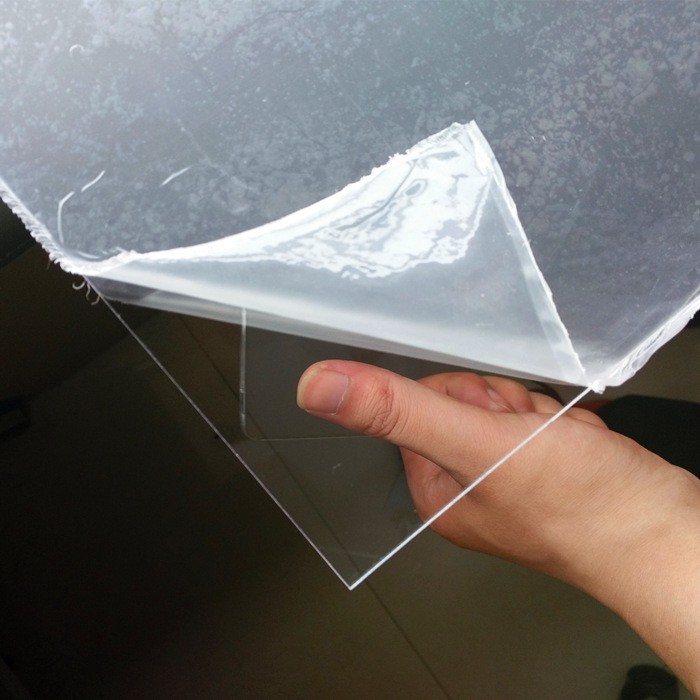

The Solution: To address these challenges, companies should implement comprehensive training programs for their staff on the safe handling and installation of plexiglass sheets. This training should cover essential practices such as using protective gear, employing proper lifting techniques, and utilizing suitable tools for cutting and installation. It’s also advisable to keep the protective film on the sheets during handling to prevent scratches until installation. Suppliers often provide installation guides or videos that can serve as valuable resources. Additionally, consider hiring professional installers for complex projects to ensure that the sheets are fitted correctly and securely, optimizing their performance and longevity. Investing in these practices not only enhances safety but also boosts overall project quality.

Strategic Material Selection Guide for plexiglass sheets 4×8

What Are the Key Properties of Common Materials for Plexiglass Sheets 4×8?

When selecting materials for plexiglass sheets, particularly in the 4×8 size, it’s essential to understand the properties of various acrylic types. The most common materials include extruded acrylic, cast acrylic, polycarbonate, and PETG. Each material offers unique advantages and disadvantages that can significantly impact their application in various industries.

How Does Extruded Acrylic Perform in Plexiglass Applications?

Extruded acrylic sheets are manufactured by forcing acrylic resin through a die, resulting in a uniform thickness and surface finish. They are lightweight and offer good optical clarity but have lower impact resistance compared to cast acrylic. Extruded sheets are suitable for applications like signage and displays, where cost-effectiveness is a priority.

Pros: Cost-effective, lightweight, easy to fabricate.

Cons: Lower impact resistance, less suitable for high-stress applications.

Impact on Application: Ideal for indoor use where durability is not critical.

Considerations for International Buyers: Compliance with local standards (e.g., ASTM) is crucial, especially in regions like Europe and the Middle East, where quality specifications are stringent.

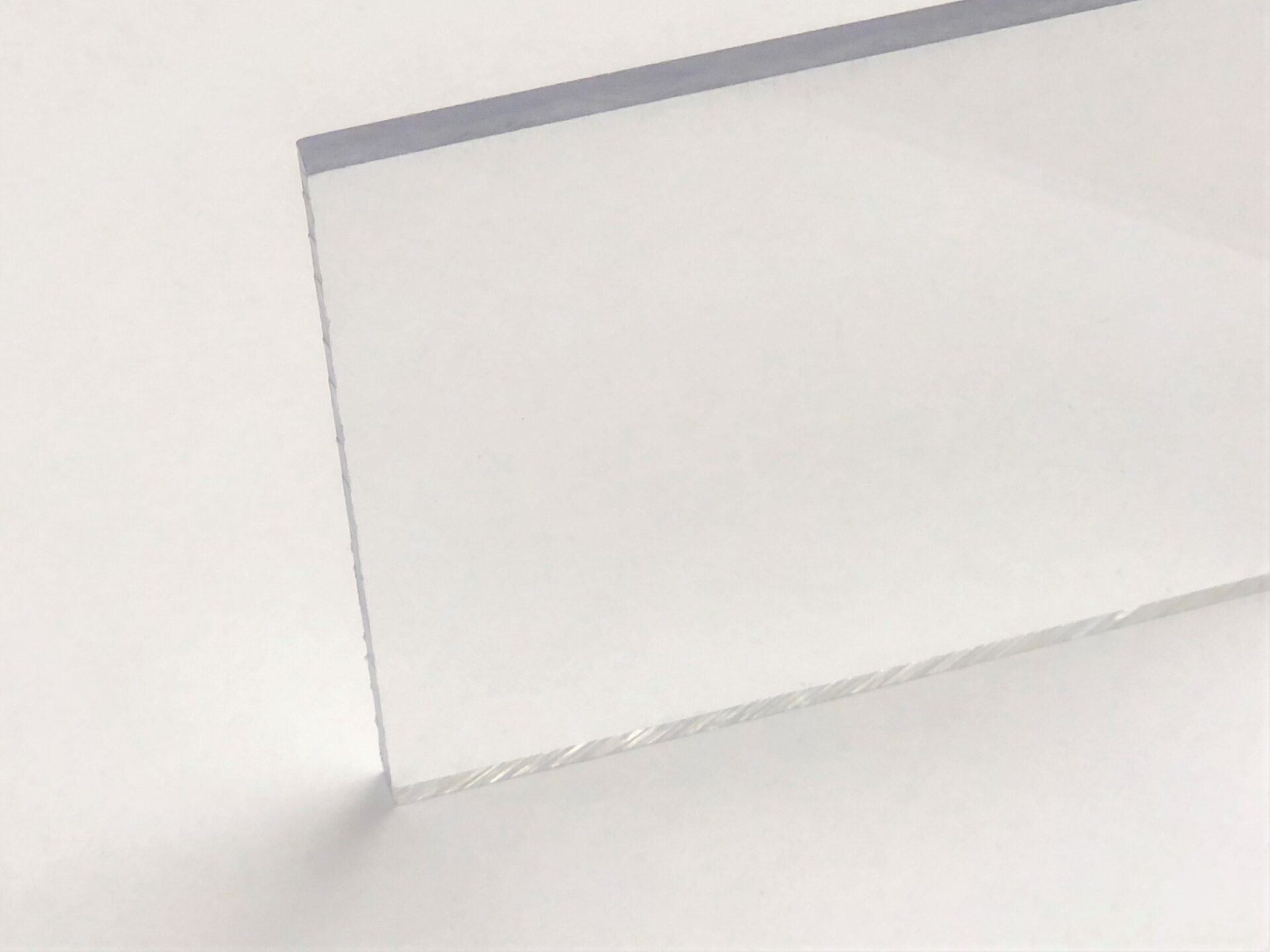

What Advantages Does Cast Acrylic Offer for Plexiglass Sheets?

Cast acrylic sheets are produced by pouring liquid acrylic into molds, resulting in a thicker, more durable product. They offer superior optical clarity and impact resistance, making them ideal for high-end applications such as aquariums and protective barriers.

Illustrative image related to plexiglass sheets 4×8

Pros: High durability, excellent optical clarity, better UV resistance.

Cons: Higher cost, more complex manufacturing process.

Impact on Application: Suitable for outdoor and high-stress environments.

Considerations for International Buyers: Buyers from Africa and South America should ensure that cast acrylic meets local safety and quality standards.

Why Choose Polycarbonate for Plexiglass Applications?

Polycarbonate sheets are known for their exceptional impact resistance, making them a preferred choice for applications requiring high durability, such as safety shields and protective covers. They are also lightweight and can withstand extreme temperatures.

Pros: Extremely impact-resistant, versatile, can be used in various environments.

Cons: More expensive than acrylic, can scratch easily.

Impact on Application: Best for environments where safety is paramount.

Considerations for International Buyers: Compliance with international safety standards is essential, especially in construction and manufacturing sectors.

When to Use PETG for Plexiglass Sheets?

PETG (Polyethylene Terephthalate Glycol) is a durable, flexible material that is easy to fabricate and offers good chemical resistance. It is often used in applications requiring transparency and toughness, such as medical devices and food packaging.

Pros: Good chemical resistance, easy to thermoform, lightweight.

Cons: Less rigid than acrylic, can be more expensive.

Impact on Application: Suitable for applications requiring flexibility and durability.

Considerations for International Buyers: Ensure compliance with food safety standards when used for packaging in regions with strict regulations.

Illustrative image related to plexiglass sheets 4×8

Summary Table of Material Selection for Plexiglass Sheets 4×8

| Material | Typical Use Case for plexiglass sheets 4×8 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Extruded Acrylic | Signage, displays | Cost-effective, lightweight | Lower impact resistance | Low |

| Cast Acrylic | Aquariums, protective barriers | High durability, excellent clarity | Higher cost, complex manufacturing | High |

| Polycarbonate | Safety shields, protective covers | Extremely impact-resistant | More expensive, scratches easily | High |

| PETG | Medical devices, food packaging | Good chemical resistance, flexible | Less rigid than acrylic | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various materials used in plexiglass sheets. Understanding these factors can help ensure that the right material is chosen for specific applications, aligning with regional compliance and market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for plexiglass sheets 4×8

What Are the Main Stages in the Manufacturing Process of Plexiglass Sheets 4×8?

The manufacturing process of plexiglass sheets, particularly those sized 4×8 feet, involves several critical stages that ensure the final product meets the desired quality and specifications. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Plexiglass Sheet Production?

The journey begins with the preparation of raw materials, primarily polymethyl methacrylate (PMMA), which is the foundational polymer for acrylic sheets. This material is often supplied in large pellets or granules that must undergo a purification process to eliminate impurities. The purification enhances clarity and durability. Once purified, the PMMA is melted and extruded into sheets of the desired thickness.

Illustrative image related to plexiglass sheets 4×8

During this stage, additives may also be incorporated to enhance properties such as UV resistance, impact strength, and color. The choice of additives can significantly affect the performance characteristics of the final product, making it essential for manufacturers to select them carefully based on the intended application of the plexiglass sheets.

What Techniques Are Used in Forming Plexiglass Sheets?

The forming process involves shaping the melted PMMA into sheets. Two primary techniques are commonly used: extrusion and casting.

-

Extrusion: In this method, melted PMMA is forced through a die to form a continuous sheet. This technique is efficient for producing large volumes of uniform thickness sheets, making it ideal for standard applications. However, extruded sheets may have slight variations in thickness and can be less optically clear compared to cast sheets.

-

Casting: This technique involves pouring liquid PMMA into molds where it hardens over time. Cast sheets generally exhibit superior optical clarity and thickness uniformity. They are also less prone to internal stresses, making them ideal for applications requiring high transparency and durability, such as aquariums and high-end display cases.

What Are the Assembly and Finishing Steps for Plexiglass Sheets?

After forming, the sheets undergo assembly, which may include cutting to specific sizes, drilling holes, or adding customized features based on client specifications. This stage is crucial for ensuring that the sheets meet the precise dimensions and functionalities required by the end-user.

Finishing processes involve polishing the edges and surfaces to enhance clarity and aesthetic appeal. Techniques such as flame polishing or chemical polishing are often employed to achieve a smooth, shiny surface. Additionally, protective films may be applied to prevent scratches during handling and shipping.

What Quality Assurance Measures Are in Place for Plexiglass Sheet Production?

Quality assurance (QA) is vital in plexiglass sheet manufacturing to ensure that products meet both international standards and customer expectations. Various quality control checkpoints are established throughout the manufacturing process.

Which International Standards Are Relevant for Plexiglass Sheets?

Manufacturers typically adhere to international quality standards such as ISO 9001, which outlines a framework for quality management systems. Compliance with ISO 9001 assures B2B buyers that the manufacturer has established effective processes for production and quality control.

In addition to ISO certifications, industry-specific standards may also apply. For instance, CE marking is essential for products sold in the European market, indicating compliance with health, safety, and environmental protection standards. For specialized applications, manufacturers might also comply with American Petroleum Institute (API) standards, particularly in industries like oil and gas.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control is conducted at various stages, including:

-

Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival to ensure they meet specified standards before entering the production process.

-

In-Process Quality Control (IPQC): During production, operators monitor key parameters such as temperature, pressure, and thickness to detect any deviations from established norms.

-

Final Quality Control (FQC): Once manufacturing is complete, the finished sheets undergo rigorous testing for optical clarity, thickness consistency, and impact resistance. This ensures that only products meeting quality benchmarks are shipped to clients.

What Common Testing Methods Are Used for Plexiglass Sheets?

To validate the quality of plexiglass sheets, several testing methods are commonly employed:

-

Optical Testing: This includes measuring light transmission and clarity, ensuring the sheets meet the required transparency standards.

-

Mechanical Testing: Tests such as impact resistance and tensile strength assessments are conducted to evaluate the durability of the sheets.

-

Thermal Testing: This involves assessing the performance of the sheets under varying temperature conditions to ensure they can withstand environmental stresses.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is crucial for ensuring product reliability.

What Steps Should Buyers Take to Ensure Supplier Compliance?

-

Supplier Audits: Conducting on-site audits can provide insights into a manufacturer’s processes, equipment, and adherence to quality standards. This first-hand observation is invaluable in assessing the supplier’s capability to deliver quality products.

-

Requesting Quality Reports: Buyers should request documentation of quality control processes, including inspection reports, certifications, and compliance records. This documentation serves as proof of the manufacturer’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturer’s quality control processes. These services can verify compliance with international standards and industry-specific requirements.

What Are the Quality Control Nuances for International Buyers?

When dealing with international suppliers, buyers should be aware of potential differences in quality standards and practices across regions. For instance, while ISO certifications are recognized globally, certain markets may have local regulations that impact product specifications and quality assurance processes.

Illustrative image related to plexiglass sheets 4×8

B2B buyers must ensure that the products they source comply with both international standards and the specific regulations of their home countries. This approach not only mitigates risks but also enhances the credibility of the buyer’s operations in their respective markets.

Conclusion

In summary, the manufacturing processes and quality assurance measures for plexiglass sheets 4×8 are intricate and designed to meet high standards of performance and reliability. Understanding these processes enables B2B buyers to make informed decisions when sourcing plexiglass products, ensuring they receive high-quality materials tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plexiglass sheets 4×8’

In the competitive landscape of B2B procurement, sourcing high-quality plexiglass sheets, particularly the 4×8 variety, requires a systematic approach. This guide offers a step-by-step checklist designed to help international buyers navigate the complexities of purchasing these materials, ensuring they make informed decisions that align with their business needs.

Step 1: Define Your Technical Specifications

Clearly outline the properties and dimensions required for your plexiglass sheets. Knowing the specific thickness, clarity, and type (cast vs. extruded) is essential, as these factors affect the sheet’s performance and suitability for various applications. For instance, if you’re creating retail displays, opt for clear cast acrylic for superior clarity and strength.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reliable suppliers. Utilize platforms such as industry directories, trade shows, and online marketplaces to compile a list of potential vendors. Look for suppliers with a proven track record in delivering quality products and excellent customer service. Additionally, consider their geographical location, especially if shipping times and costs are critical for your project timeline.

Step 3: Evaluate Supplier Certifications

Verify that your shortlisted suppliers hold relevant certifications. Certifications such as ISO 9001 indicate adherence to quality management standards, which can provide assurance of product quality and consistency. Additionally, check for compliance with regional regulations, especially if you are sourcing from different countries, as this can impact your operations.

Step 4: Request Sample Products

Before making a bulk purchase, request samples of the plexiglass sheets. This step allows you to assess the material’s quality, clarity, and durability firsthand. When evaluating samples, consider conducting specific tests relevant to your application, such as impact resistance or UV stability, to ensure they meet your operational requirements.

Step 5: Compare Pricing Structures

Analyze the pricing from different suppliers to ensure competitive rates. Look beyond the initial cost per sheet; consider additional factors such as shipping fees, bulk order discounts, and payment terms. This comprehensive view will help you determine the total cost of ownership and avoid unexpected expenses down the line.

Step 6: Assess Customer Support and Return Policies

Evaluate the level of customer service and the supplier’s return policy. A responsive support team can greatly enhance your purchasing experience, especially if issues arise post-purchase. Understand the supplier’s return and exchange policies to ensure you have recourse in case the products do not meet your expectations.

Step 7: Finalize Your Order and Monitor Delivery

Once you select a supplier, place your order and set up a system to monitor delivery. Ensure that you have a clear agreement on timelines, shipping methods, and tracking options. Communication with the supplier during this phase is crucial to mitigate potential delays and ensure that your project stays on schedule.

Illustrative image related to plexiglass sheets 4×8

By following this checklist, B2B buyers can effectively navigate the sourcing process for 4×8 plexiglass sheets, enhancing their procurement strategy and ensuring they receive high-quality materials tailored to their needs.

Comprehensive Cost and Pricing Analysis for plexiglass sheets 4×8 Sourcing

What are the Key Cost Components of Sourcing Plexiglass Sheets 4×8?

When sourcing plexiglass sheets, specifically the 4×8 size, understanding the cost structure is crucial for international B2B buyers. The cost comprises several components:

-

Materials: The primary cost driver is the raw material, polymethyl methacrylate (PMMA), used to manufacture plexiglass. Prices can fluctuate based on global supply and demand, impacting overall costs.

-

Labor: Manufacturing labor costs vary significantly by region. In countries with higher labor costs, such as Germany, the overall price of plexiglass sheets may increase compared to regions like Nigeria or South America, where labor is generally less expensive.

-

Manufacturing Overhead: This includes costs related to utilities, maintenance, and operational expenses of production facilities. Efficient manufacturing processes can help lower these costs, which can be a negotiating point for buyers.

-

Tooling: Custom molds and tools for specific applications increase initial costs but may be necessary for high-volume orders or specialized designs. This is especially relevant for buyers seeking customized specifications.

-

Quality Control (QC): Implementing rigorous QC measures ensures product quality and compliance with industry standards, but it adds to the overall cost. Certifications such as ISO can also influence pricing.

-

Logistics: Shipping costs are a significant factor, especially for international buyers. Factors such as distance, shipping method, and import duties can heavily influence the final price.

-

Margin: Suppliers will include their profit margins in pricing, which can vary based on market competition and perceived value.

How Do Price Influencers Affect Plexiglass Sheet Costs?

Several factors can influence the pricing of plexiglass sheets:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders typically receive better pricing due to economies of scale. Understanding the supplier’s MOQ can help buyers negotiate better terms.

-

Specifications and Customization: Customized sheets (in terms of thickness, color, or finish) may incur additional costs. Standard sizes and specifications are generally more cost-effective.

-

Material Quality and Certifications: Higher quality materials often come at a premium. Buyers should consider the long-term benefits of investing in certified products that may offer better durability and performance.

-

Supplier Factors: Supplier reliability and reputation can affect pricing. Established suppliers may charge more due to their track record, but they often provide better service and product quality.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international transactions. They determine the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly impact overall costs.

What Tips Can Help Buyers Negotiate Better Prices?

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, effective negotiation and cost management are essential:

-

Research and Benchmarking: Conduct thorough market research to understand prevailing prices and terms. Benchmark against competitors to leverage better deals.

-

Total Cost of Ownership (TCO): Focus on the TCO rather than just the upfront cost. Consider factors like longevity, maintenance, and potential savings from energy efficiency in your purchasing decisions.

-

Negotiate Payment Terms: Flexible payment terms can improve cash flow management. Discuss options like extended payment periods or discounts for upfront payments.

-

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing, more favorable terms, and priority service.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing strategies. For instance, suppliers in Europe might have different pricing structures compared to those in Africa or South America, influenced by local market conditions and currency fluctuations.

Conclusion

Understanding the comprehensive cost and pricing analysis for plexiglass sheets 4×8 is essential for making informed purchasing decisions. By considering key cost components, price influencers, and negotiation strategies, buyers can optimize their sourcing processes and ensure they achieve the best value for their investments. Always keep in mind that prices can vary widely, so obtaining multiple quotes and understanding the market landscape is crucial for successful procurement.

Alternatives Analysis: Comparing plexiglass sheets 4×8 With Other Solutions

When considering the procurement of materials for various applications, it is essential for B2B buyers to evaluate multiple options. In the case of 4×8 plexiglass sheets, various alternatives exist that can meet similar needs across industries, from retail displays to protective barriers. This analysis compares plexiglass sheets with polycarbonate sheets and tempered glass, focusing on their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Plexiglass Sheets 4X8 | Polycarbonate Sheets 4X8 | Tempered Glass 4X8 |

|---|---|---|---|

| Performance | Excellent clarity and impact resistance; UV resistant | Higher impact resistance, lightweight; good clarity | Superior strength and scratch resistance; excellent clarity |

| Cost | Moderate cost, typically lower than tempered glass | Generally higher than plexiglass, but lower than tempered glass | Higher upfront cost; often requires specialized installation |

| Ease of Implementation | Easy to cut and shape; can be fabricated on-site | Also easy to cut; may require specialized tools for optimal results | Requires professional installation; heavy and cumbersome |

| Maintenance | Low maintenance; requires gentle cleaning | Low maintenance; resistant to yellowing | High maintenance; requires careful handling and cleaning |

| Best Use Case | Retail displays, signage, furniture, protective barriers | Security applications, greenhouses, safety equipment | Windows, doors, high-traffic areas needing durability |

What Are the Advantages and Disadvantages of Polycarbonate Sheets Compared to Plexiglass?

Polycarbonate sheets are a robust alternative to plexiglass, offering superior impact resistance. They are approximately 250 times stronger than glass, making them ideal for security applications and environments where high durability is crucial. However, polycarbonate is generally more expensive than plexiglass and may require specialized cutting tools for installation, making the implementation slightly more complex. Additionally, while they have good clarity, they can yellow over time when exposed to UV light, which can affect aesthetics in long-term applications.

How Does Tempered Glass Stack Up Against Plexiglass Sheets?

Tempered glass is another viable alternative, especially when strength and scratch resistance are priorities. It is often used in high-traffic areas and applications that demand durability, such as storefronts and doors. However, tempered glass comes with a higher price tag and requires professional installation due to its weight and fragility during handling. While it offers excellent clarity, the maintenance can be more demanding, as any damage can result in complete replacement, unlike plexiglass, which can often be repaired.

What Should B2B Buyers Consider When Choosing Between These Options?

For B2B buyers, the choice between plexiglass, polycarbonate, and tempered glass hinges on specific project requirements. If cost efficiency and ease of use are paramount, plexiglass is often the best choice. However, for projects that prioritize impact resistance, polycarbonate may be the better option despite its higher cost. Conversely, for applications requiring the highest durability and aesthetics, tempered glass is unmatched, albeit at a higher expense and complexity in installation. Ultimately, understanding the unique demands of each application will guide buyers in selecting the most suitable material for their needs.

Essential Technical Properties and Trade Terminology for plexiglass sheets 4×8

What Are the Key Technical Properties of Plexiglass Sheets 4×8?

When considering plexiglass sheets, specifically the 4×8 size, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications:

Illustrative image related to plexiglass sheets 4×8

1. Material Grade

Plexiglass, or acrylic sheets, are commonly made from polymethyl methacrylate (PMMA). The material grade indicates its quality, clarity, and durability. Higher-grade materials provide better impact resistance and UV stability, which is vital for applications exposed to sunlight or physical stress. For B2B buyers, selecting the appropriate material grade ensures longevity and performance in demanding environments.

2. Thickness Tolerance

Thickness tolerance refers to the allowable variation in the sheet’s thickness. Typical tolerances for acrylic sheets range from +/- 10% to as low as +/- 5%. For projects requiring precision, such as CNC machining or laser cutting, understanding these tolerances helps avoid costly errors and ensures that the final product meets design specifications. B2B buyers should always verify thickness specifications with suppliers to ensure compatibility with their applications.

3. Impact Resistance

One of the standout properties of plexiglass is its impact resistance, which is approximately 17 times stronger than glass. This property is particularly important for applications like protective barriers, safety glazing, and outdoor displays. For businesses in sectors such as retail or construction, using impact-resistant materials can significantly reduce the risk of damage and enhance safety.

4. UV Resistance

Plexiglass sheets often come with UV-resistant coatings or properties, preventing yellowing and degradation over time. This is crucial for applications involving direct sunlight exposure, such as signage or aquariums. B2B buyers must ensure that the UV resistance meets the needs of their specific application, especially when considering long-term investments.

5. Moisture Resistance

Acrylic sheets are inherently moisture-resistant, making them suitable for environments subject to humidity or wet conditions. This property is critical for industries such as food and beverage, where hygiene and durability are paramount. Buyers should assess the moisture resistance of the product to ensure it aligns with their operational conditions.

Illustrative image related to plexiglass sheets 4×8

6. Thermal Stability

Plexiglass can withstand a range of temperatures, but it does have limits. Understanding the thermal stability of the material is vital for applications that may experience extreme heat or cold. B2B buyers should inquire about the temperature range for safe usage to avoid warping or melting, which can compromise the integrity of the product.

What Are Common Trade Terms Related to Plexiglass Sheets?

Familiarity with industry jargon can significantly streamline the purchasing process. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of plexiglass, knowing the OEM can help buyers assess the quality and compatibility of the sheets with existing products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it can affect purchasing decisions, especially for smaller companies or those testing new products.

3. RFQ (Request for Quotation)

An RFQ is a formal request to suppliers for pricing and availability of products. It’s a critical step in the procurement process, allowing buyers to compare offers and negotiate terms before making a purchase.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping costs, risk transfer, and delivery obligations. Understanding these terms is essential for international B2B buyers to avoid misunderstandings and ensure smooth logistics.

5. CNC Routing

CNC (Computer Numerical Control) routing refers to the automated cutting of materials using a computer-controlled router. This process is often used for precision cutting of plexiglass sheets, making it a relevant term for buyers seeking customized solutions.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing plexiglass sheets, ensuring they select the right products for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the plexiglass sheets 4×8 Sector

What Are the Key Market Trends Influencing the Plexiglass Sheets 4×8 Sector?

The global market for plexiglass sheets, particularly in the 4×8 size, is experiencing notable growth driven by several factors. Increasing demand for lightweight, durable materials across industries such as construction, automotive, and retail is propelling the use of acrylic sheets. The rise of e-commerce has also led to a surge in demand for visually appealing packaging and displays, where plexiglass serves as an ideal material due to its clarity and versatility. Furthermore, advancements in manufacturing technologies, such as CNC routing and laser cutting, are enhancing customization capabilities, allowing businesses to meet specific client needs more efficiently.

In emerging markets in Africa and South America, the adoption of plexiglass is growing rapidly as local industries recognize its benefits over traditional materials like glass. Countries like Nigeria and Brazil are seeing increased investments in infrastructure, which further drives demand for durable and cost-effective building materials. Additionally, businesses in the Middle East and Europe are increasingly focusing on aesthetic applications, such as retail displays and signage, highlighting the importance of design in their sourcing decisions.

How Is Sustainability Shaping the Sourcing of Plexiglass Sheets 4×8?

Sustainability has become a critical factor for B2B buyers in the plexiglass sheets sector. As environmental concerns grow, companies are increasingly prioritizing ethical sourcing and sustainable materials. Plexiglass, made from polymethyl methacrylate (PMMA), is often viewed as a more eco-friendly alternative to glass due to its lower energy consumption during production and lighter weight, which reduces transportation emissions.

Buyers are now looking for suppliers who can demonstrate a commitment to sustainability through certifications such as ISO 14001 or those that offer recycled materials. The demand for ‘green’ plexiglass sheets—produced with less harmful chemicals and energy-efficient processes—is on the rise. Moreover, brands are increasingly transparent about their supply chains, as customers favor suppliers who implement responsible practices. This trend not only mitigates environmental impact but also enhances brand reputation, making it a vital consideration for international buyers, especially in regions with stringent regulations and eco-conscious consumers.

What Is the Historical Context of Plexiglass Sheets in B2B Markets?

The evolution of plexiglass sheets dates back to the mid-20th century when acrylic was first commercialized as a lightweight, shatter-resistant alternative to glass. Initially popularized for its clarity and durability, plexiglass found applications in various sectors, from aviation to architecture. Over the decades, innovations in manufacturing processes have expanded its versatility, enabling the production of various thicknesses and finishes to meet diverse customer needs.

In recent years, the shift towards sustainable materials has revitalized interest in plexiglass sheets, positioning them as a preferred choice in modern applications. As B2B buyers increasingly seek materials that balance performance with environmental responsibility, plexiglass continues to adapt, ensuring its relevance in the ever-evolving marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of plexiglass sheets 4×8

-

How do I select the right thickness of plexiglass sheets for my project?

Choosing the correct thickness for your 4×8 plexiglass sheets depends on the intended application. For lightweight displays or protective barriers, thinner sheets (around 1/8″ or 3mm) may suffice. However, for structural uses like aquariums or furniture, consider thicker options (1/4″ to 1/2″) for enhanced durability and resistance to impact. It’s also important to evaluate the environmental conditions, such as exposure to UV light or temperature variations, which can affect the performance of thinner sheets. -

What customization options are available for plexiglass sheets?

Many suppliers offer customization for plexiglass sheets, including cutting to specific dimensions, drilling holes, and laser engraving. You can also find options for different colors, finishes (like frosted or mirrored), and thicknesses. When ordering, provide detailed specifications to ensure the final product meets your requirements. Customization can help you achieve unique designs for signage, displays, or protective barriers tailored to your business needs. -

What are the typical minimum order quantities (MOQs) for plexiglass sheets?

Minimum order quantities for plexiglass sheets can vary significantly by supplier and region. Generally, MOQs can range from a single sheet for smaller suppliers to several hundred sheets for larger manufacturers. When sourcing, inquire about the MOQ to ensure it aligns with your project scale. Larger orders may also qualify for bulk pricing, providing cost savings for businesses planning extensive use of plexiglass. -

How can I verify the quality of plexiglass sheets from suppliers?

To ensure quality, request samples before placing large orders, allowing you to assess clarity, thickness, and durability. Verify suppliers’ certifications and industry standards, such as ISO or ASTM compliance, to ensure they meet quality benchmarks. Reading customer reviews and testimonials can also provide insights into a supplier’s reliability. Establishing a relationship with suppliers through communication can further enhance trust in product quality. -

What payment terms should I expect when sourcing plexiglass sheets internationally?

Payment terms can vary by supplier and region but typically include options like upfront payment, net 30, or net 60 days. For international transactions, consider using secure payment methods such as letters of credit or escrow services to protect your investment. Always clarify payment terms in advance to avoid misunderstandings and ensure smooth transactions. Discussing bulk purchase discounts may also be beneficial. -

What logistics considerations should I keep in mind when importing plexiglass sheets?

When importing plexiglass sheets, consider factors such as shipping costs, delivery times, and customs regulations. Evaluate the supplier’s logistics capabilities, including their experience with international shipping and handling of customs documentation. Understand the potential impact of tariffs or import duties on your total costs. Working with a reliable freight forwarder can streamline the process and help navigate any logistical challenges. -

How can I ensure compliance with local regulations regarding plexiglass products?

Research local regulations regarding the use of plexiglass, especially in applications like construction or signage. Compliance may include safety standards, environmental regulations, and fire safety codes. Suppliers familiar with your region can provide valuable insights into necessary certifications or testing required for your products. It’s advisable to consult with local authorities or industry bodies for specific compliance guidelines. -

What are the best practices for maintaining plexiglass sheets once installed?

To maintain the clarity and integrity of plexiglass sheets, avoid using ammonia-based cleaners, which can damage the surface. Instead, opt for gentle cleaning solutions or products specifically designed for acrylic maintenance. Regularly inspect for scratches or damage and consider protective coatings for high-traffic areas. Proper handling during installation and maintenance will prolong the lifespan of your plexiglass sheets and keep them looking their best.

Top 5 Plexiglass Sheets 4X8 Manufacturers & Suppliers List

1. Acme Plastics – Acrylic Sheets

Domain: acmeplastics.com

Registered: 1997 (28 years)

Introduction: Acrylic Sheets 4’x 8′ | 48″ x 96″ | Available in various types including Acrylic Cast Clear Sheet, Acrylic Extruded Clear Sheet, Acrylic P95 Sheets, Acrylic Non-Glare Sheet, Acrylic Bullet Resistant Sheet, Acrylic Mirror Sheet, Acrylic Cast Color Sheet, Acrylic Cast White Sheet, Recycled Acrylic Clear Sheet, and Glowforge®-Compatible Acrylic Sheets. Custom sizes available for Clear Extruded Acryli…

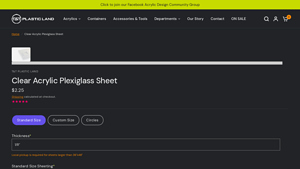

2. TT Plastic Land – Custom Clear Acrylic Sheets

Domain: ttplasticland.com

Registered: 2004 (21 years)

Introduction: Custom clear acrylic sheets are available in various sizes and thicknesses. They are lightweight, shatter-resistant, and offer excellent optical clarity. Ideal for a range of applications including displays, signage, and protective barriers. Customization options include cutting, drilling, and finishing to meet specific project needs.

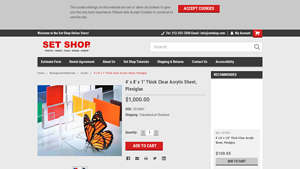

3. SetShop – 4′ x 8′ Clear Acrylic Sheet

Domain: setshop.com

Registered: 1994 (31 years)

Introduction: {“name”: “4′ x 8′ x 1″ Thick Clear Acrylic Sheet, Plexiglas”, “dimensions”: “4′ x 8′”, “thickness”: “1 inch”, “color”: “clear”, “material”: “acrylic”, “features”: [“glossy on both sides”, “impact strength”, “versatile applications”, “easy to work with”], “applications”: [“sawed”, “drilled”, “routed”, “glued”, “painted”, “decorated”, “silk-screened”, “formed”], “price”: “$1,000.00”, “sku”: “3510001…

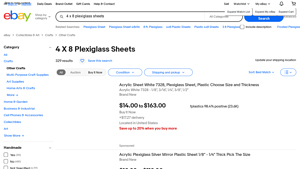

4. eBay – 4×8 Plexiglass Sheets

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: 4×8 Plexiglass Sheets available on eBay. Prices range from $7.93 to $840.00 depending on size and thickness. Options include clear, smoke gray, and mirror finishes. Condition is new with free delivery and returns available. Various thicknesses offered, including 1/8″ and 1/4″.

5. Clearly Plastic – White or Black Plexiglass Sheets

Domain: clearlyplastic.com

Registered: 2017 (8 years)

Introduction: Product Name: White or Black Plexiglass Sheets

SKU: UOMPLASTICS

Regular Price: $62.93 – $351.45

Thickness Options: 1/8″, 3/16″, 1/4″

Size Options: 24″ x 48″, 48″ x 48″, 48″ x 96″

Color Options: White, Black

Common Uses: Signage, aquariums, POP displays, furniture, windows, winterizing, screen porches, animal and reptile enclosures, retail product displays, backlit exterior signage.

Product Feature…

Strategic Sourcing Conclusion and Outlook for plexiglass sheets 4×8

In the competitive landscape of international trade, strategic sourcing of 4×8 plexiglass sheets offers significant advantages for businesses across Africa, South America, the Middle East, and Europe. By leveraging high-quality acrylic sheets, companies can enhance product offerings while benefiting from superior durability, lightweight design, and impressive versatility. The ability to customize sheets for various applications—ranging from signage to retail displays—positions businesses to meet diverse market demands effectively.

Moreover, understanding the intricacies of sourcing, including thickness options and the differences between extruded and cast acrylic, empowers buyers to make informed decisions that align with their operational needs and project requirements. This strategic approach not only mitigates risks associated with supply chain disruptions but also fosters long-term partnerships with reliable suppliers.

As we look ahead, the growing demand for sustainable and innovative materials will shape the future of the plexiglass market. International B2B buyers are encouraged to embrace strategic sourcing practices that prioritize quality and adaptability. By doing so, they will not only secure a competitive edge but also contribute to the evolution of their respective industries. Engage with trusted suppliers today to explore opportunities and unlock the full potential of plexiglass sheets in your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.