Unlocking Value: A Strategic Analysis of the Oven Conveyor Market

Introduction: Navigating the Global Market for oven conveyor

In the competitive landscape of the foodservice industry, sourcing the right oven conveyor can significantly impact operational efficiency and product quality. B2B buyers often face the challenge of identifying equipment that not only meets their culinary needs but also aligns with their budget and local regulations. This comprehensive guide on oven conveyors addresses these critical considerations, offering insights into various types, applications, and the nuances of supplier vetting.

From gas and electric models to specialized designs for pizza and baked goods, understanding the diverse offerings available in the market is essential for making informed purchasing decisions. We delve into the operational benefits of conveyor ovens, such as consistent cooking results, reduced labor costs, and increased throughput, empowering businesses in high-demand environments.

Furthermore, this guide provides actionable strategies for evaluating suppliers, ensuring that international buyers from regions like Africa, South America, the Middle East, and Europe—such as Nigeria and Germany—can navigate the complexities of sourcing effectively. By equipping you with the knowledge to assess costs, technical specifications, and compliance requirements, this resource aims to facilitate smarter investments that enhance your kitchen’s performance and profitability.

Understanding oven conveyor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gas Conveyor Ovens | Uses natural gas for heating; efficient combustion | High-volume pizza, baked goods, sandwiches | Pros: Faster cooking, lower operating costs. Cons: Requires gas line installation. |

| Electric Conveyor Ovens | Powered by electricity; often more compact | Cafés, small restaurants, bakeries | Pros: Easier installation, no gas required. Cons: Higher energy costs, slower cooking times. |

| Impingement Conveyor Ovens | Utilizes high-velocity air for even cooking | Fast-casual dining, high-output kitchens | Pros: Consistent results, versatile cooking options. Cons: Higher initial investment. |

| Ventless Conveyor Ovens | Designed to operate without external ventilation | Urban locations, space-constrained areas | Pros: Flexible placement, saves on installation costs. Cons: Limited cooking capacity compared to vented models. |

| Modular Conveyor Ovens | Configurable with stackable units; customizable | Large-scale food production, catering | Pros: Scalability, tailored to specific needs. Cons: Higher complexity in setup and maintenance. |

What Are the Key Characteristics of Gas Conveyor Ovens?

Gas conveyor ovens are favored for their rapid heating capabilities, utilizing natural gas to achieve high temperatures efficiently. This type of oven is particularly suitable for high-volume applications, such as pizzerias and bakeries, where speed is crucial. When considering a gas oven, B2B buyers should evaluate the availability of gas lines in their facilities, as installation can be more complex than electric models. The operational cost tends to be lower, making it an attractive option for businesses focused on cost efficiency.

How Do Electric Conveyor Ovens Compare in the Market?

Electric conveyor ovens are known for their ease of installation, as they do not require gas lines, making them ideal for small restaurants, cafés, and bakeries. These ovens are typically more compact, catering to establishments with limited kitchen space. However, buyers should be aware of the potentially higher energy costs associated with electric models. When purchasing, consider the specific power requirements and whether the electric supply can handle the oven’s demands without overloading circuits.

What Makes Impingement Conveyor Ovens Stand Out?

Impingement conveyor ovens are designed to circulate high-velocity hot air around the food, ensuring even cooking and browning. This feature makes them a popular choice in fast-casual dining settings and high-output kitchens where consistency and speed are paramount. B2B buyers should consider the initial investment, as these ovens may be pricier than traditional models. However, their ability to produce high-quality results can justify the cost, particularly in competitive markets.

Why Choose Ventless Conveyor Ovens for Urban Locations?

Ventless conveyor ovens offer a unique solution for businesses operating in urban environments where space and ventilation options are limited. These ovens can be placed in various locations without the need for extensive ductwork, making them suitable for food trucks, small cafés, and pop-up restaurants. Buyers should evaluate the cooking capacity, as ventless models may have limitations compared to traditional ovens. The cost savings on installation can also be a significant factor when considering these ovens.

What Are the Benefits of Modular Conveyor Ovens?

Modular conveyor ovens provide flexibility and scalability, allowing businesses to configure their cooking equipment according to specific needs. These ovens can be stacked or combined, making them suitable for large-scale food production and catering operations. When considering modular options, buyers should assess their long-term growth plans and the potential need for additional units in the future. While the complexity of setup and maintenance may be higher, the ability to customize these ovens can lead to increased efficiency and productivity.

Key Industrial Applications of oven conveyor

| Industry/Sector | Specific Application of Oven Conveyor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service | High-Volume Pizza Production | Increases output efficiency, ensuring quick service | Energy efficiency, customization options, stackability |

| Bakery | Continuous Baking of Bread and Pastries | Ensures consistent quality and reduces labor costs | Temperature control, belt speed adjustments, size options |

| Snack Food Manufacturing | Production of Frozen Snacks | Streamlines cooking process and enhances product uniformity | Versatility in cooking methods, maintenance requirements |

| Automotive Parts Manufacturing | Curing Coatings on Automotive Components | Improves production speed and quality control | Heat distribution, material compatibility, safety features |

| Pharmaceutical Industry | Sterilization of Medical Equipment | Ensures compliance with health regulations and safety | Precision temperature control, reliability, energy consumption |

How is Oven Conveyor Used in High-Volume Pizza Production?

In the food service sector, particularly for pizza production, oven conveyors are essential for managing high volumes during peak times. These ovens allow for continuous baking, ensuring that pizzas are cooked evenly and quickly, which is crucial for maintaining customer satisfaction. For international buyers, especially in regions like Africa and Europe, sourcing options that offer energy efficiency and customization for different pizza styles can significantly enhance operational efficiency.

What Role Does Oven Conveyor Play in Bakery Operations?

In bakeries, oven conveyors facilitate the continuous baking of bread and pastries, providing a consistent cooking environment that enhances product quality. By eliminating the need for manual monitoring, these ovens reduce labor costs and improve throughput. Buyers from South America and the Middle East should consider models with precise temperature controls and adjustable belt speeds to accommodate various baked goods while ensuring consistent results.

How is Oven Conveyor Beneficial in Snack Food Manufacturing?

For snack food manufacturers, oven conveyors are pivotal in the production of frozen snacks, where uniform cooking is essential for product quality. These ovens streamline the cooking process, allowing for higher production rates and consistent flavor profiles. B2B buyers in regions such as Africa should evaluate the versatility of oven conveyor systems, ensuring they can handle different types of snacks and offer easy maintenance features.

How Does Oven Conveyor Enhance Automotive Parts Manufacturing?

In the automotive sector, oven conveyors are utilized for curing coatings on components, ensuring that products meet stringent quality standards. The ability to maintain precise temperatures and consistent airflow improves production speed and quality control. Buyers from Europe and the Middle East need to focus on sourcing ovens that provide reliable heat distribution and safety features, as these are critical in high-stakes manufacturing environments.

What Importance Does Oven Conveyor Hold in the Pharmaceutical Industry?

In the pharmaceutical industry, oven conveyors are crucial for the sterilization of medical equipment, a process that demands strict compliance with health regulations. These ovens ensure that equipment is adequately sterilized, minimizing risks to patient safety. International buyers, particularly in regions like Europe, should prioritize sourcing options with precise temperature control and reliability to meet regulatory standards effectively.

3 Common User Pain Points for ‘oven conveyor’ & Their Solutions

Scenario 1: Struggling with High Volume Cooking Consistency

The Problem: In high-demand environments, such as busy pizzerias or catering services, maintaining cooking consistency can be a daunting challenge. B2B buyers often report issues where uneven cooking leads to customer complaints and wasted food. For instance, if a conveyor oven is not calibrated correctly or if the airflow is compromised, some pizzas may come out burnt while others remain undercooked. This inconsistency not only affects customer satisfaction but also impacts the establishment’s reputation and revenue.

The Solution: To address this challenge, it’s essential to invest in conveyor ovens that offer advanced features such as precision airflow control and adjustable cooking speeds. When sourcing equipment, prioritize models that provide variable temperature settings and independent control over top and bottom heating elements. For example, selecting an oven with built-in diagnostic features can help monitor performance and identify potential issues before they lead to cooking discrepancies. Regular maintenance, including cleaning the fans and checking for blockages, is also crucial. Establish a routine where staff members are trained to perform these checks daily, ensuring optimal performance and consistency in cooking outcomes.

Scenario 2: Navigating Equipment Space Constraints in Commercial Kitchens

The Problem: Many businesses face the challenge of limited kitchen space, particularly in urban settings or smaller establishments. As B2B buyers seek to enhance their cooking capabilities with conveyor ovens, they often struggle to find equipment that fits without sacrificing performance. A large oven may dominate the kitchen layout, restricting movement and workflow, which can hinder efficiency and increase the risk of accidents in a bustling environment.

The Solution: To mitigate space issues, look for compact conveyor oven models that do not compromise on capacity or functionality. Double-stack ovens can be an excellent solution, allowing you to maximize vertical space while maintaining a high output. When purchasing, consider ovens with a smaller footprint but that still have adjustable belt speeds and temperature controls. Additionally, explore options with ventless designs to eliminate the need for extensive ductwork, freeing up additional space. It’s also advisable to involve kitchen staff in the selection process, as their input on workflow can help ensure that the new equipment integrates smoothly into existing operations without creating bottlenecks.

Scenario 3: Reducing Energy Costs While Maintaining Performance

The Problem: Energy consumption is a significant concern for many commercial kitchens, especially in regions where electricity costs are high. B2B buyers are often tasked with finding ways to cut operational costs without compromising the quality and speed of food preparation. Conveyor ovens, while efficient, can lead to substantial energy bills if not utilized correctly or if they lack energy-efficient features.

The Solution: To address energy concerns, opt for conveyor ovens that include energy-saving features such as programmable timers and power-save modes. Models that allow for precise temperature control can help minimize energy waste by ensuring that the oven operates only when needed. Conduct a cost-benefit analysis comparing the energy consumption of different models before making a purchase. Additionally, consider implementing a maintenance schedule that includes regular inspections of insulation and seals to prevent heat loss, which can contribute to higher energy costs. Training staff on best practices for efficient oven use, such as loading the oven correctly and avoiding unnecessary door openings, can also significantly reduce energy consumption over time.

Strategic Material Selection Guide for oven conveyor

What Are the Key Materials Used in Oven Conveyor Construction?

When selecting materials for oven conveyors, various factors such as temperature resistance, durability, and cost-effectiveness play crucial roles. Here, we analyze four common materials used in the construction of oven conveyors, focusing on their properties, pros and cons, and specific considerations for international B2B buyers.

Stainless Steel: The Industry Standard

Key Properties: Stainless steel is known for its excellent corrosion resistance, high-temperature tolerance, and structural integrity. It can withstand temperatures up to 1,500°F (815°C) depending on the grade, making it ideal for high-heat applications.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust and staining. However, it can be more expensive than other materials, and its manufacturing complexity may require specialized equipment for shaping and welding.

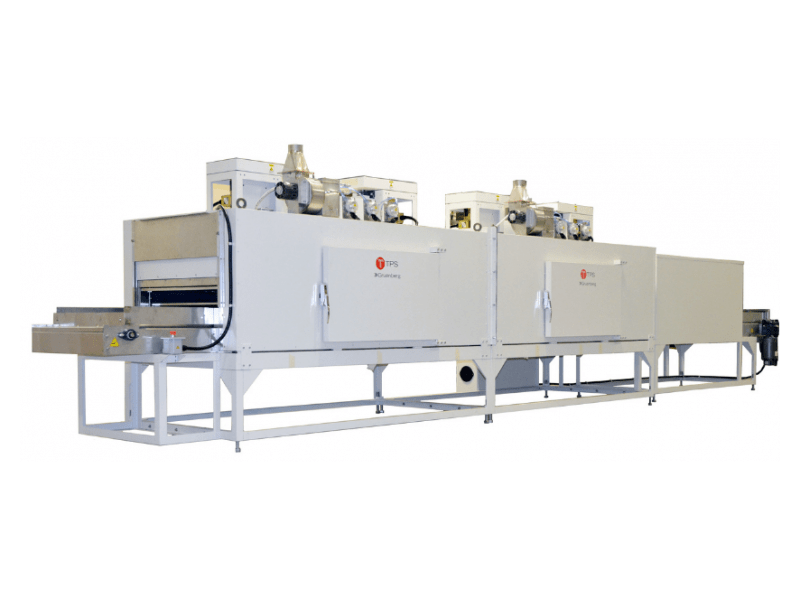

Illustrative image related to oven conveyor

Impact on Application: Stainless steel is compatible with various food media, making it suitable for applications in food processing and commercial kitchens. Its non-reactive nature ensures that food quality is maintained.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM and DIN for food-grade stainless steel. In Africa and South America, local regulations may also dictate specific grades and finishes.

Aluminum: Lightweight and Cost-Effective

Key Properties: Aluminum offers a good balance of strength and lightweight characteristics, with a melting point around 1,220°F (660°C). It is also resistant to corrosion, particularly when anodized.

Pros & Cons: The lightweight nature of aluminum makes it easier to handle and install, reducing labor costs. However, it has a lower temperature tolerance compared to stainless steel, which may limit its use in high-heat applications.

Impact on Application: Aluminum is often used in conveyor belts and frames where weight reduction is beneficial. However, its lower heat resistance may restrict its use in certain high-temperature cooking processes.

Considerations for International Buyers: Buyers should be aware of local standards for aluminum alloys and finishes. In regions like Nigeria and Germany, compliance with local and international standards can affect material selection.

Carbon Steel: Strength and Affordability

Key Properties: Carbon steel is known for its high strength and toughness, with a melting point around 2,500°F (1,370°C). However, it is more susceptible to corrosion than stainless steel and aluminum.

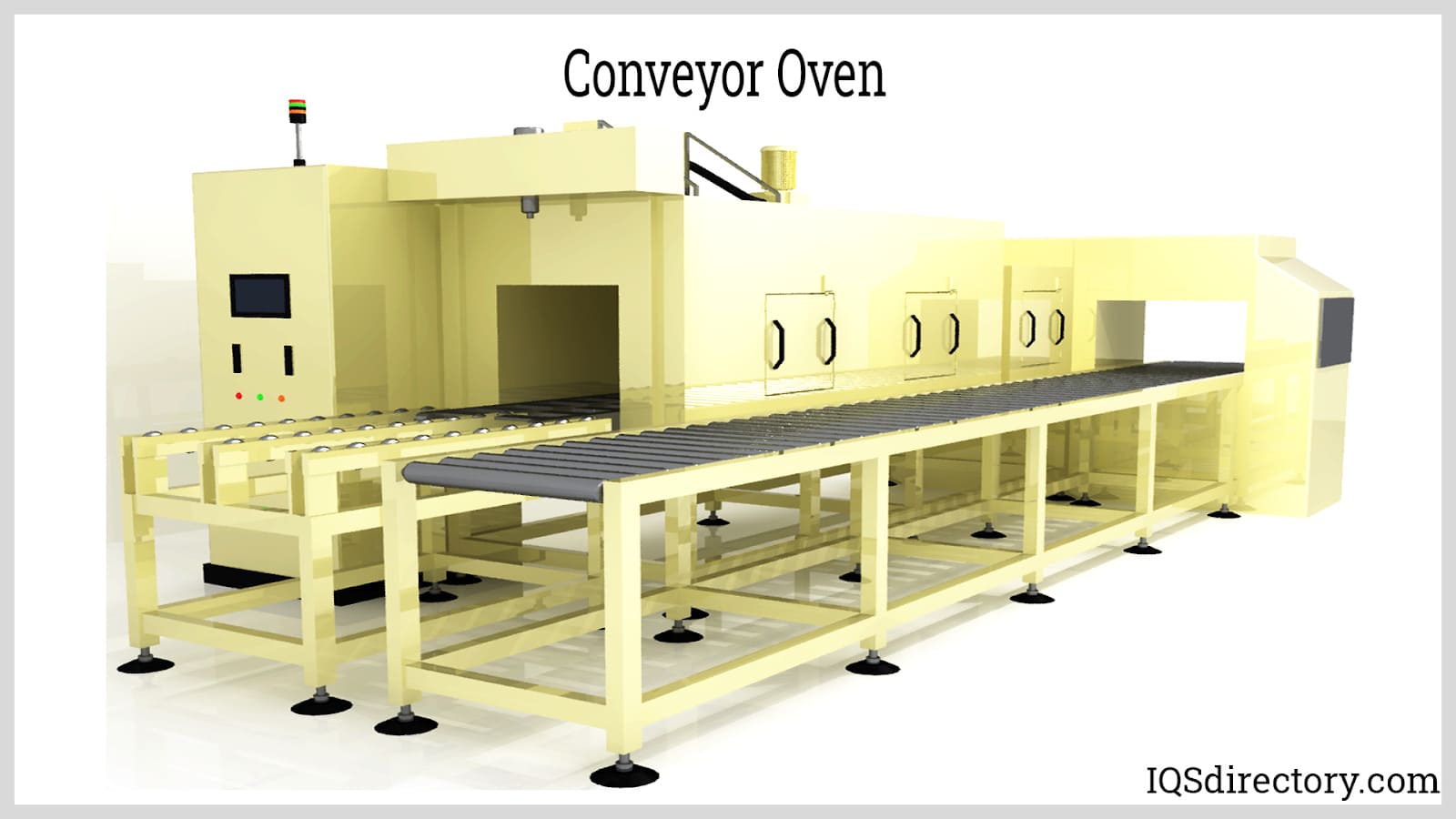

Illustrative image related to oven conveyor

Pros & Cons: The main advantage of carbon steel is its cost-effectiveness and strength. However, its susceptibility to rust means it may require additional coatings or treatments, increasing long-term maintenance costs.

Impact on Application: Carbon steel is suitable for structural components of conveyor ovens, but its corrosion issues can limit its use in direct contact with food. Proper surface treatment is essential for food safety.

Considerations for International Buyers: Buyers should consider the need for protective coatings and ensure compliance with food safety standards, particularly in regions with stringent regulations like Europe.

High-Temperature Resistant Plastics: Versatile and Innovative

Key Properties: High-temperature resistant plastics, such as PTFE and PEEK, can withstand temperatures up to 500°F (260°C) and offer excellent chemical resistance.

Pros & Cons: These materials are lightweight and can be molded into complex shapes, providing design flexibility. However, they can be more expensive than metals and may not be suitable for all applications.

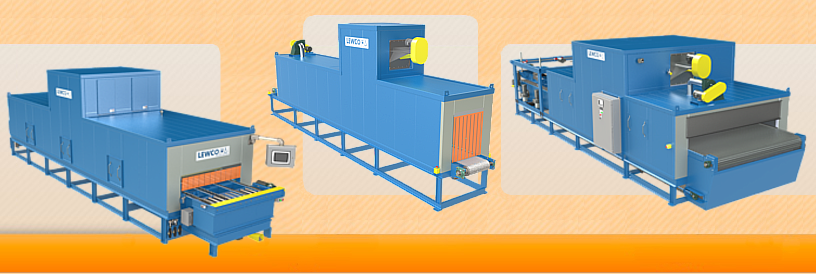

Illustrative image related to oven conveyor

Impact on Application: Ideal for conveyor belts and non-stick surfaces, these plastics can enhance cooking efficiency and reduce food sticking. However, their lower temperature threshold limits their use in high-heat environments.

Considerations for International Buyers: Buyers should verify compliance with food safety regulations and temperature ratings, especially in regions like the Middle East, where high temperatures are common.

Summary Table of Material Selection for Oven Conveyors

| Material | Typical Use Case for oven conveyor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, cooking surfaces | High durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Conveyor belts, lightweight frames | Lightweight and cost-effective | Lower temperature tolerance | Medium |

| Carbon Steel | Structural elements | Cost-effective and strong | Prone to corrosion, requires treatment | Low |

| High-Temperature Plastics | Conveyor belts, non-stick surfaces | Design flexibility and lightweight | Higher cost and limited heat resistance | Medium to High |

This material selection guide aims to provide B2B buyers with the insights needed to make informed decisions when sourcing oven conveyors, ensuring compliance with local standards and optimizing operational efficiency.

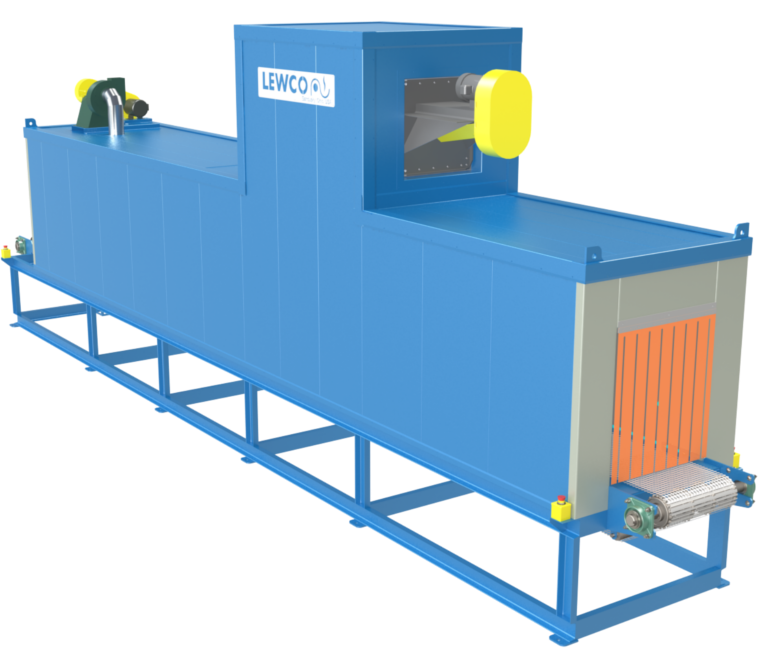

Illustrative image related to oven conveyor

In-depth Look: Manufacturing Processes and Quality Assurance for oven conveyor

What Are the Main Stages in the Manufacturing Process of Oven Conveyors?

The manufacturing process of oven conveyors typically comprises several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a pivotal role in ensuring that the final product meets the high standards required for commercial kitchen equipment.

How Does Material Preparation Affect Conveyor Oven Quality?

Material preparation begins with sourcing high-quality raw materials, which commonly include stainless steel for durability and heat resistance, insulation materials for energy efficiency, and various electronic components for control systems. Suppliers must ensure that the materials meet specific industry standards, such as ASTM (American Society for Testing and Materials) and ISO certifications, to guarantee reliability and safety.

Once materials are sourced, they undergo initial quality checks to verify their integrity and compliance with specifications. This is the first quality control (QC) checkpoint, often termed Incoming Quality Control (IQC). Here, suppliers can identify any defects or inconsistencies early in the manufacturing process, preventing wasted time and resources.

What Techniques Are Used in Forming Conveyor Ovens?

The forming stage involves various fabrication techniques, including laser cutting, bending, and welding. These methods require precision to ensure that components fit together seamlessly. Advanced techniques, such as CNC (Computer Numerical Control) machining, are often employed to enhance accuracy and repeatability.

In this stage, quality control measures continue through In-Process Quality Control (IPQC). Manufacturers will conduct inspections at various points in the forming process to ensure that dimensions and tolerances are met. This attention to detail is crucial for the final assembly and performance of the oven.

How Is Assembly Conducted in the Manufacturing of Oven Conveyors?

During the assembly phase, the various components—such as the conveyor belt, heating elements, and control systems—are brought together. This stage often involves both manual labor and automated processes, with a focus on ensuring that each unit is assembled correctly and efficiently.

QC during assembly includes checks for proper installation and functionality of components. Manufacturers may utilize functional testing to verify that electrical connections are secure and that the conveyor operates as intended. These checks help minimize the risk of malfunctions in the field.

What Finishing Processes Are Important for Conveyor Ovens?

The finishing stage involves surface treatment, such as powder coating or polishing, which enhances the oven’s appearance and provides additional protection against corrosion and wear. This stage is critical for ensuring longevity and maintaining the aesthetic appeal of the equipment in a commercial kitchen setting.

Final Quality Control (FQC) occurs after finishing, where the completed ovens undergo thorough testing to ensure they meet performance standards. This includes checking temperature consistency, cooking efficiency, and safety features. Certifications such as CE (Conformité Européenne) and UL (Underwriters Laboratories) may also be obtained during this stage to validate compliance with safety regulations.

What International Standards Are Relevant for Oven Conveyor Manufacturing?

For B2B buyers, understanding international standards is essential for ensuring product quality and compliance. The ISO 9001 standard is a globally recognized quality management system that outlines requirements for consistent quality in manufacturing processes. Adhering to ISO 9001 can provide assurance that the manufacturer has a robust quality management system in place.

In addition to ISO 9001, industry-specific standards such as CE for European markets and various safety certifications (e.g., NSF for food safety) are crucial. These certifications indicate that the ovens meet stringent safety and performance criteria, which is vital for international trade, especially in regions like Africa, South America, the Middle East, and Europe.

Illustrative image related to oven conveyor

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should employ several strategies to verify the quality control processes of their suppliers. Regular audits are an effective way to assess a manufacturer’s compliance with international standards and internal quality protocols. During these audits, buyers can evaluate the entire manufacturing process, from material sourcing to final assembly.

Additionally, requesting quality assurance reports can provide insights into the manufacturer’s QC performance over time. Third-party inspections are also beneficial, as independent organizations can provide unbiased evaluations of a manufacturer’s practices and product quality.

What Are the Common Testing Methods for Oven Conveyors?

Manufacturers typically use a variety of testing methods to ensure the quality and performance of oven conveyors. Common methods include:

Illustrative image related to oven conveyor

- Thermal Testing: To measure heat distribution and cooking efficiency.

- Mechanical Testing: To evaluate the structural integrity and durability of components.

- Electrical Testing: To ensure that all electronic components function correctly and safely.

- Safety Testing: To verify compliance with safety standards, such as fire resistance and electrical safety.

These testing methods not only ensure product quality but also help in identifying potential issues before the ovens reach the market.

What Quality Control Nuances Should International Buyers Consider?

International buyers, particularly those from regions like Africa and South America, should be aware of potential nuances in quality control practices. Local regulations and market expectations can vary significantly, impacting the required certifications and standards.

Understanding these differences is crucial for navigating international procurement successfully. Buyers should communicate clearly with suppliers regarding their specific quality requirements and ensure that all necessary documentation is provided to facilitate compliance with local regulations.

In summary, the manufacturing process and quality assurance of oven conveyors are complex but essential for ensuring high-quality products. By understanding these processes and standards, B2B buyers can make informed purchasing decisions and establish long-term relationships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘oven conveyor’

In today’s fast-paced food service industry, selecting the right conveyor oven is crucial for enhancing operational efficiency and maintaining food quality. This guide provides a step-by-step checklist to help B2B buyers navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Before beginning your search, establish the specific requirements for your conveyor oven. Consider factors such as the type of food you will be cooking (e.g., pizza, sandwiches), the volume of production, and the available kitchen space. This will help in identifying ovens that meet your operational needs and ensure compatibility with your existing kitchen infrastructure.

Step 2: Assess Power Source Options

Evaluate whether you need a gas or electric conveyor oven based on your kitchen’s infrastructure and local energy costs. Gas ovens typically offer faster heating times and can be more cost-effective in areas where natural gas is readily available. On the other hand, electric ovens are often easier to install and may require less maintenance, making them suitable for various kitchen environments.

Step 3: Evaluate Supplier Certifications

It’s essential to verify that potential suppliers hold the necessary certifications and comply with international safety standards. Look for certifications such as UL, CE, or ISO that indicate the oven has been tested for safety and efficiency. This step minimizes risks associated with equipment failure and ensures you are investing in a reliable product.

Step 4: Review Product Features and Technology

Consider the advanced features of different conveyor ovens that can enhance cooking efficiency and food quality. Look for options like variable speed controls, programmable settings for different recipes, and energy-saving modes. These features can significantly improve productivity and reduce operational costs in the long run.

Step 5: Conduct Cost Analysis

Perform a comprehensive cost analysis that includes not just the initial purchase price, but also installation, maintenance, and operational costs over time. Compare multiple suppliers to find the best value for your investment. Remember to consider the warranty and after-sales support offered, as these can impact your total cost of ownership.

Step 6: Seek Customer Reviews and Case Studies

Gather insights from other businesses that have purchased conveyor ovens from your shortlisted suppliers. Look for case studies or testimonials that reflect their experiences, especially in similar markets or applications. This information can provide valuable context regarding the oven’s performance, reliability, and customer service quality.

Step 7: Request Demonstrations and Samples

Whenever possible, request live demonstrations or samples of the equipment. Observing the oven in action allows you to assess its performance firsthand and verify that it meets your expectations. This step can also help in understanding the ease of use and cleaning, which are critical factors in a high-volume kitchen environment.

By following this checklist, you can make a well-informed decision when sourcing a conveyor oven that aligns with your operational needs and contributes to your business’s success.

Comprehensive Cost and Pricing Analysis for oven conveyor Sourcing

When sourcing oven conveyors, understanding the comprehensive cost structure and pricing dynamics is crucial for B2B buyers, especially those operating in diverse international markets such as Africa, South America, the Middle East, and Europe. This analysis will delve into the primary cost components, influential pricing factors, and actionable tips for effective procurement.

What Are the Key Cost Components in Oven Conveyor Manufacturing?

-

Materials: The choice of materials significantly impacts the cost of oven conveyors. High-quality stainless steel and specialized insulation materials may increase upfront costs but enhance durability and efficiency. Budget-conscious buyers may opt for less expensive materials, but this could compromise longevity and performance.

-

Labor: Labor costs can vary widely depending on the manufacturing location. Regions with higher labor costs, such as Western Europe, may lead to higher overall prices. Conversely, sourcing from countries with lower labor rates can reduce costs but may introduce challenges in quality control and consistency.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and administrative expenses. Efficient manufacturing processes can help minimize overhead costs, which are often reflected in the final pricing of the product.

-

Tooling: Custom tooling for specific conveyor designs or features can add to initial costs. However, investing in specialized tools may yield long-term savings through improved production efficiency and reduced waste.

-

Quality Control (QC): Rigorous QC processes ensure that the ovens meet safety and performance standards. While this may increase costs, it is essential for maintaining product reliability and customer satisfaction.

-

Logistics: Shipping costs can vary based on the origin of the product, mode of transportation, and destination. International buyers should consider these logistics costs when evaluating total expenses.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on market competition, brand reputation, and perceived value of the product.

What Influences Pricing for Oven Conveyors in B2B Transactions?

-

Volume/MOQ: Bulk purchases can lead to significant discounts. Establishing a Minimum Order Quantity (MOQ) can often unlock better pricing, making it advantageous for large-scale buyers.

-

Specifications and Customization: Custom features such as variable speed controls, energy-efficient designs, or specific dimensions can increase costs. Buyers should weigh the need for customization against budget constraints.

-

Material Quality and Certifications: Higher-quality materials and certifications (like UL or CE) can elevate costs but are crucial for compliance and performance assurance in different markets.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Well-established suppliers with a proven track record may charge more but offer better service and support.

-

Incoterms: Understanding shipping terms and responsibilities defined by Incoterms is vital. Costs associated with shipping, insurance, and duties can vary significantly based on the chosen terms.

How Can Buyers Negotiate and Optimize Costs?

-

Effective Negotiation: Engage in discussions with multiple suppliers to compare prices and terms. Highlighting potential long-term partnerships may encourage suppliers to offer better rates.

-

Total Cost of Ownership (TCO): Beyond the initial purchase price, consider factors such as energy consumption, maintenance, and potential downtime costs. A lower-priced oven may incur higher operational costs over its lifespan.

-

Pricing Nuances for International Buyers: When sourcing from different regions, be aware of currency fluctuations and tariffs that may impact final costs. Additionally, understanding local market conditions and competitive pricing can provide leverage during negotiations.

Conclusion

Understanding the cost structure and pricing influences of oven conveyors is essential for making informed purchasing decisions. By considering all cost components, engaging in strategic negotiations, and evaluating the total cost of ownership, B2B buyers can optimize their procurement processes and achieve better value. As market dynamics continue to evolve, staying informed and adaptable will be key to successful sourcing in this competitive landscape.

Alternatives Analysis: Comparing oven conveyor With Other Solutions

Exploring Alternatives to Oven Conveyors: A Comprehensive Comparison

In the fast-paced world of commercial kitchens, choosing the right cooking technology can significantly impact operational efficiency and food quality. While oven conveyors are popular for their ability to deliver consistent cooking in high-volume environments, several alternatives exist that can also meet various needs. This analysis compares oven conveyors with other viable cooking solutions to help B2B buyers make informed decisions.

| Comparison Aspect | Oven Conveyor | Impingement Oven | Batch Oven |

|---|---|---|---|

| Performance | High throughput, consistent cooking results. | Excellent for speed and even heat distribution. | Good for large batches but less consistent. |

| Cost | Mid to high range ($5,000 – $40,000). | Mid-range ($4,000 – $30,000). | Lower initial cost ($2,000 – $10,000). |

| Ease of Implementation | Requires dedicated space and ventilation. | Requires less space, often ventless options available. | Flexible installation, can fit in various kitchen layouts. |

| Maintenance | Requires regular cleaning and checks on belts. | Easier to maintain with fewer moving parts. | More labor-intensive due to manual loading/unloading. |

| Best Use Case | Ideal for continuous cooking of pizzas, sandwiches, and baked goods. | Best for items needing quick cooking and crisping, like pastries. | Suitable for baking large quantities, such as bread and cakes. |

What Are the Benefits and Drawbacks of Impingement Ovens?

Impingement ovens utilize powerful jets of hot air to cook food quickly and evenly, making them ideal for high-demand kitchens. Their ability to produce crisp, well-cooked items in a short time frame is a significant advantage. However, the initial investment can be substantial, and they may require specific installation conditions to optimize airflow. For businesses that prioritize speed and consistency, particularly in baking and reheating, impingement ovens offer a compelling alternative to oven conveyors.

How Do Batch Ovens Compare to Oven Conveyors?

Batch ovens are another alternative, particularly suitable for establishments that focus on baking larger quantities of food. These ovens are generally less expensive and can be more flexible in terms of kitchen layout. However, they often require more manual labor for loading and unloading, which can slow down service in busy environments. For businesses that produce a variety of baked goods but do not need the continuous flow of a conveyor system, batch ovens may provide a cost-effective solution.

Illustrative image related to oven conveyor

Conclusion: How to Choose the Right Cooking Technology for Your Business

Selecting the appropriate cooking technology depends on various factors, including your business model, kitchen layout, and the types of food you serve. Oven conveyors excel in high-volume, fast-paced settings where consistency is paramount. In contrast, impingement and batch ovens may offer advantages in terms of cost and flexibility but may require different operational approaches. By carefully evaluating your specific needs and the characteristics of each option, B2B buyers can make informed decisions that will enhance their kitchen’s efficiency and profitability.

Essential Technical Properties and Trade Terminology for oven conveyor

What Are the Key Technical Properties of Conveyor Ovens?

In the competitive landscape of commercial kitchens, understanding the essential technical specifications of conveyor ovens is crucial for B2B buyers. Here are some key properties to consider:

1. Material Grade

The material composition of a conveyor oven is vital for durability and performance. Most commercial ovens are constructed from stainless steel, which is resistant to corrosion and easy to clean. The grade of stainless steel (e.g., 304 or 316) can impact the oven’s resistance to heat and chemical exposure, making it important for kitchens that utilize a variety of cleaning agents. Selecting the right material grade ensures longevity and reduces maintenance costs.

Illustrative image related to oven conveyor

2. Temperature Range

The temperature range of a conveyor oven determines its versatility. Many models can operate between 200°F and 600°F (93°C to 316°C). This flexibility allows businesses to cook a wide array of dishes, from pizzas to pastries. For buyers, a broader temperature range can enhance menu diversity and operational efficiency, enabling quicker adaptations to customer demands.

3. Belt Width and Speed

The width of the conveyor belt and its adjustable speed are critical factors that influence cooking efficiency. Typical belt widths range from 10 inches to over 50 inches, accommodating different food sizes and types. Adjustable speeds allow operators to customize cooking times based on menu items, ensuring consistent quality. Understanding these specifications helps buyers select ovens that align with their production needs.

4. Energy Consumption

Energy efficiency is a growing concern for commercial kitchens, impacting both operational costs and environmental sustainability. Ovens are available in gas and electric models, with varying BTU ratings or wattages. Selecting an energy-efficient model can lead to significant savings on utility bills and align with corporate sustainability goals, making it an important consideration for B2B buyers.

5. Ventilation Requirements

Proper ventilation is essential for safety and compliance with local health regulations. Some conveyor ovens are ventless, utilizing advanced filtration systems, while others require external ventilation. Understanding the ventilation needs not only ensures compliance but also helps in planning the kitchen layout effectively, reducing unexpected installation costs.

What Are Common Trade Terms in the Conveyor Oven Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B market. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another company under its brand name. In the context of conveyor ovens, understanding OEM relationships can help buyers ensure they are sourcing quality equipment and components.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. For B2B buyers, knowing the MOQ is crucial for budget planning and inventory management, especially when sourcing equipment for large-scale operations.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting price quotes for specific products or services. This process is vital for B2B buyers to compare costs, terms, and capabilities, ensuring they make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. These terms clarify who is responsible for shipping costs, insurance, and liability during transportation. Familiarity with Incoterms helps buyers avoid misunderstandings and unexpected expenses in cross-border transactions.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. Understanding lead times is critical for B2B buyers to manage inventory levels and ensure timely service delivery, especially in fast-paced kitchen environments.

By grasping these technical specifications and trade terms, international B2B buyers can make more informed purchasing decisions regarding conveyor ovens, enhancing operational efficiency and profitability.

Navigating Market Dynamics and Sourcing Trends in the oven conveyor Sector

What Are the Current Market Dynamics and Key Trends in the Oven Conveyor Sector?

The global oven conveyor market is witnessing dynamic shifts driven by increased demand for efficiency and automation in foodservice operations. The rise of fast-casual dining and the need for quick service are pushing businesses to adopt conveyor ovens that enhance throughput while maintaining food quality. Countries in Africa, South America, the Middle East, and Europe, particularly Nigeria and Germany, are experiencing significant growth in this sector. As international buyers seek reliable equipment, they are increasingly looking for models that offer customizable settings to cater to diverse culinary styles, which is essential in multi-cultural markets.

Emerging technologies are shaping sourcing trends, with digital controls and smart connectivity becoming standard features. This trend allows operators to monitor performance and adjust settings remotely, enhancing operational efficiency. Another key trend is the integration of energy-efficient designs that not only reduce operational costs but also meet regulatory standards across various regions. These advancements are crucial for businesses seeking to optimize their kitchen workflows and reduce downtime during peak hours.

Furthermore, the market is evolving towards more versatile products that accommodate a range of cooking methods, including baking, roasting, and air frying. Buyers are increasingly interested in equipment that can handle diverse menus, aligning with consumer preferences for variety and quality. This adaptability is particularly vital for businesses in developing regions, where culinary innovation is essential for competitiveness.

How Can Sustainability and Ethical Sourcing Impact the Oven Conveyor Market?

As global awareness of environmental issues grows, sustainability has become a cornerstone of sourcing strategies in the oven conveyor sector. The environmental impact of manufacturing and operating these ovens is significant, prompting companies to adopt more sustainable practices. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint through eco-friendly materials and energy-efficient technologies.

Ethical sourcing is equally important in this sector. Buyers are seeking manufacturers that ensure fair labor practices and responsible sourcing of raw materials. This focus on ethical supply chains not only enhances brand reputation but also resonates with consumers who are increasingly scrutinizing the origins of the products they purchase. Certifications such as ENERGY STAR® and ISO 14001 are becoming essential for suppliers looking to gain a competitive edge in the international market. These certifications signal a commitment to sustainability and can influence purchasing decisions.

Additionally, as regulations around environmental standards tighten in various regions, B2B buyers must ensure compliance. This involves selecting ovens that meet local and international standards for emissions and energy use, which can also lead to long-term cost savings and improved operational efficiency.

What Is the Brief Evolution of the Oven Conveyor Sector?

The oven conveyor sector has evolved significantly since its inception, transitioning from simple designs to complex machines capable of multitasking. Initially developed for baking bread and pastries, the technology expanded to accommodate various cooking methods as the foodservice industry grew. The introduction of gas and electric models enhanced versatility, catering to different operational needs and preferences.

In the late 20th century, advancements in automation and digital controls revolutionized the sector, enabling precise temperature control and cooking times. Today, oven conveyors are integral to high-volume kitchens, providing consistent results and improving workflow efficiency. As the market continues to innovate, the emphasis on sustainability and ethical practices is shaping the next phase of evolution, aligning with the broader global shift towards responsible manufacturing and consumption. This ongoing transformation presents significant opportunities for international B2B buyers looking to invest in cutting-edge, efficient, and eco-friendly cooking solutions.

Illustrative image related to oven conveyor

Frequently Asked Questions (FAQs) for B2B Buyers of oven conveyor

-

How do I choose the right conveyor oven for my business?

Selecting the right conveyor oven involves assessing your specific cooking needs, such as the volume of food you prepare, the types of dishes, and the available kitchen space. Consider factors like the oven’s capacity, energy source (gas or electric), and cooking technology (like impingement or convection). Additionally, prioritize features such as temperature control, belt speed adjustment, and ease of cleaning. Evaluating these elements will help you align the oven’s specifications with your operational goals, ensuring efficiency and consistency in food preparation. -

What is the best conveyor oven for high-volume pizza production?

For high-volume pizza production, a gas-powered impingement conveyor oven is often the best choice. This type of oven provides rapid heating and consistent cooking, allowing for quick service during peak hours. Models with adjustable belt speeds and dual heating elements ensure even cooking, which is crucial for achieving the desired crust and topping quality. Brands like Edge and Ultra-Max offer specialized options that cater to large pizza operations, ensuring optimal performance and durability. -

What are the common payment terms for purchasing conveyor ovens internationally?

Payment terms for international purchases of conveyor ovens typically include options such as Letter of Credit (LC), advance payment, or open account terms. Letters of Credit are often preferred as they provide security for both buyer and seller. It’s essential to discuss and negotiate these terms with your supplier before finalizing the deal. Additionally, consider currency exchange rates and transaction fees, as these can impact the overall cost of your purchase. -

How can I ensure the quality of conveyor ovens from international suppliers?

To ensure quality, conduct thorough vetting of potential suppliers by checking their certifications, customer reviews, and product warranties. Request samples or specifications to assess the build quality and performance of their ovens. Additionally, inquire about their manufacturing processes and quality assurance protocols. Establishing clear communication regarding your quality expectations and receiving regular updates during production can further help mitigate risks related to quality. -

What are the typical lead times for conveyor oven delivery?

Lead times for conveyor oven delivery can vary significantly based on the supplier’s location, manufacturing capacity, and customization requirements. Generally, expect lead times of 4 to 12 weeks for standard models, while custom configurations may take longer. It’s advisable to confirm the estimated delivery time with your supplier during the ordering process and consider potential delays in shipping, especially for international orders that involve customs clearance. -

Can conveyor ovens be customized to meet specific cooking needs?

Yes, many manufacturers offer customization options for conveyor ovens to suit specific cooking requirements. Custom features may include adjustable belt widths, unique temperature controls, and specialized heating elements. When discussing your needs with suppliers, provide detailed specifications about your cooking processes and menu items to ensure the oven is tailored to your operational demands. This customization can lead to enhanced efficiency and product quality. -

What logistics considerations should I keep in mind when importing conveyor ovens?

When importing conveyor ovens, consider logistics factors such as shipping method (air or sea), freight costs, and customs duties. Ensure you have a reliable freight forwarder who understands the import regulations of your country. Additionally, confirm the packaging and handling requirements with your supplier to prevent damage during transit. It’s also wise to have insurance for high-value equipment to protect against potential loss or damage during shipping. -

What is the minimum order quantity (MOQ) for conveyor ovens?

Minimum order quantities (MOQs) for conveyor ovens can vary by supplier and model. Some manufacturers may have MOQs as low as one unit for standard models, while others may require bulk orders for custom ovens. It’s important to clarify these details with potential suppliers during your initial discussions. If you’re starting with a limited budget, consider negotiating for a lower MOQ or exploring financing options to facilitate your purchase.

Top 5 Oven Conveyor Manufacturers & Suppliers List

1. Pizza Solutions – Edge EDGE 1830-1-G2 Gas Conveyor Oven

Domain: pizzasolution.com

Registered: 2011 (14 years)

Introduction: Conveyor Ovens from Pizza Solutions include a wide selection of Edge and other leading brands, with guaranteed lowest prices. They can be customized for various pizza styles while delivering large volumes. Key models include:

– Edge EDGE 1830-1-G2 Gas Conveyor Oven – $9,784.00

– Edge EDGE 2440-1-G2 Single Stack Gas Conveyor Oven – $11,649.00

– Edge EDGE 3240-1-G2 Gas Conveyor Oven – $12,212.00 …

2. Equippers – Commercial Conveyor Ovens

Domain: equippers.com

Registered: 1999 (26 years)

Introduction: Commercial Conveyor Ovens available in Gas, Electric, and Propane options.

3. Star Manufacturing – Holman Conveyor Ovens

Domain: star-mfg.com

Registered: 1995 (30 years)

Introduction: {“products”:[{“name”:”Holman 210HX Conveyor Oven”,”features”:”Quartz Heater, Analog Controls, 120V, 1PH”},{“name”:”Holman 214HX Conveyor Oven”,”features”:”Quartz Heater, Analog Controls, 208, 1PH”},{“name”:”Holman 314HX Conveyor Oven”,”features”:”Quartz Heater, Analog Controls, 208V, 1PH”},{“name”:”Ultra-Max UM1854 Gas Impingement Conveyor Oven”,”features”:”Digital Controls, Natural Gas, 40000 Tot…

4. Vollrath – Conveyor Sandwich Ovens

Domain: vollrathfoodservice.com

Registered: 2017 (8 years)

Introduction: The Vollrath® conveyor sandwich ovens easily create beautifully toasted sandwiches with gooey melted cheese and warm tasty toppings. Key features include variable controls for quick adjustments, energy-efficient quartz heating elements that are fast and powerful, forced convection for consistent heating and improved energy efficiency, variable-speed control for desired results, and a maintenance-f…

5. TurboChef – Ventless High-Speed Conveyors

Domain: turbochef.com

Registered: 1997 (28 years)

Introduction: Ventless High-speed Conveyors include three models: High h Conveyor 1618, High h Conveyor 2020, and High h Conveyor 2620. These conveyors are designed for various applications in the foodservice industry, including fast casual, fine dining, hotels, military, and schools. They utilize ventless technology and air impingement for efficient cooking. The conveyors are stackable and can accommodate diff…

Strategic Sourcing Conclusion and Outlook for oven conveyor

As the demand for efficient cooking solutions continues to rise across the globe, the strategic sourcing of conveyor ovens emerges as a pivotal element for B2B buyers in various regions, including Africa, South America, the Middle East, and Europe. These ovens not only enhance operational efficiency but also ensure consistency and quality in food preparation, making them an indispensable asset in high-volume kitchens. By investing in reliable conveyor oven technology, businesses can significantly reduce labor costs and improve throughput, thereby maximizing profitability.

Understanding the diverse range of conveyor oven models—ranging from gas to electric options and single to multi-deck configurations—allows buyers to tailor their purchases to specific operational needs. Moreover, leveraging supplier relationships can lead to advantageous pricing and service agreements, ensuring long-term value.

Looking ahead, the evolution of conveyor oven technology promises exciting advancements in energy efficiency and cooking precision. International buyers are encouraged to stay abreast of these developments and consider integrating innovative solutions into their operations. Now is the time to take proactive steps in sourcing the right conveyor ovens that align with your business goals, enhancing your culinary capabilities for the future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.