Unlocking Value: A Strategic Analysis of the O Bolt Market

Introduction: Navigating the Global Market for o bolt

In an increasingly interconnected world, sourcing the right components like the o bolt can pose significant challenges for international B2B buyers. Whether you’re a manufacturer in Germany, a construction firm in Saudi Arabia, or a supplier in South America, navigating the complexities of product specifications, supplier reliability, and price competitiveness is critical. This guide will demystify the global market for o bolts, providing a comprehensive overview of the various types, applications, and crucial factors to consider when selecting a supplier.

From understanding the nuances of bolt types—such as sizes and head variations—to recognizing the diverse applications across industries, our guide equips you with actionable insights. We delve into essential topics, including supplier vetting processes and cost considerations, ensuring you make informed purchasing decisions that meet your operational needs.

By addressing the unique requirements of B2B buyers from Africa, South America, the Middle East, and Europe, this guide not only enhances your sourcing strategy but also empowers you to leverage the best practices in procurement. The insights provided will help you navigate the global landscape of o bolts effectively, ensuring that your projects are supported by reliable and high-quality components.

Understanding o bolt Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| O Bolt 1 | Available in 1.5, 2.0, and 3.0mm sizes; versatile head types | Model kits, hobbyist applications | Pros: Customizable; easy to mold. Cons: Limited load capacity. |

| O Bolt 2 | Enhanced design for improved stability; same size options as O Bolt 1 | Precision engineering, prototyping | Pros: Better strength; suitable for detailed work. Cons: Slightly higher cost. |

| Eye Bolt | Features a loop for secure attachment; available in various sizes | Hoisting, rigging, anchoring | Pros: Strong load-bearing capacity; versatile. Cons: Requires proper installation for safety. |

| Forged Eye Bolt | Continuous circle design for added strength; typically heavier gauge | Heavy-duty applications, construction | Pros: High strength; ideal for demanding tasks. Cons: More expensive than bent eye bolts. |

| Bent Eye Bolt | Nearly closed eye design; lighter than forged versions | Light-duty applications, hanging items | Pros: Cost-effective; suitable for vertical loads. Cons: Weaker than forged options; limited to lighter tasks. |

What Are the Characteristics of O Bolt 1 and O Bolt 2?

O Bolt 1 and O Bolt 2 are designed for versatile applications, particularly in model kits and hobbyist projects. Both types come in sizes of 1.5mm, 2.0mm, and 3.0mm, allowing users to select the most suitable size for their specific needs. The heads can be interchanged based on the intended use, making them highly customizable. However, their load capacity is limited, making them more suitable for light-duty applications rather than heavy structural uses.

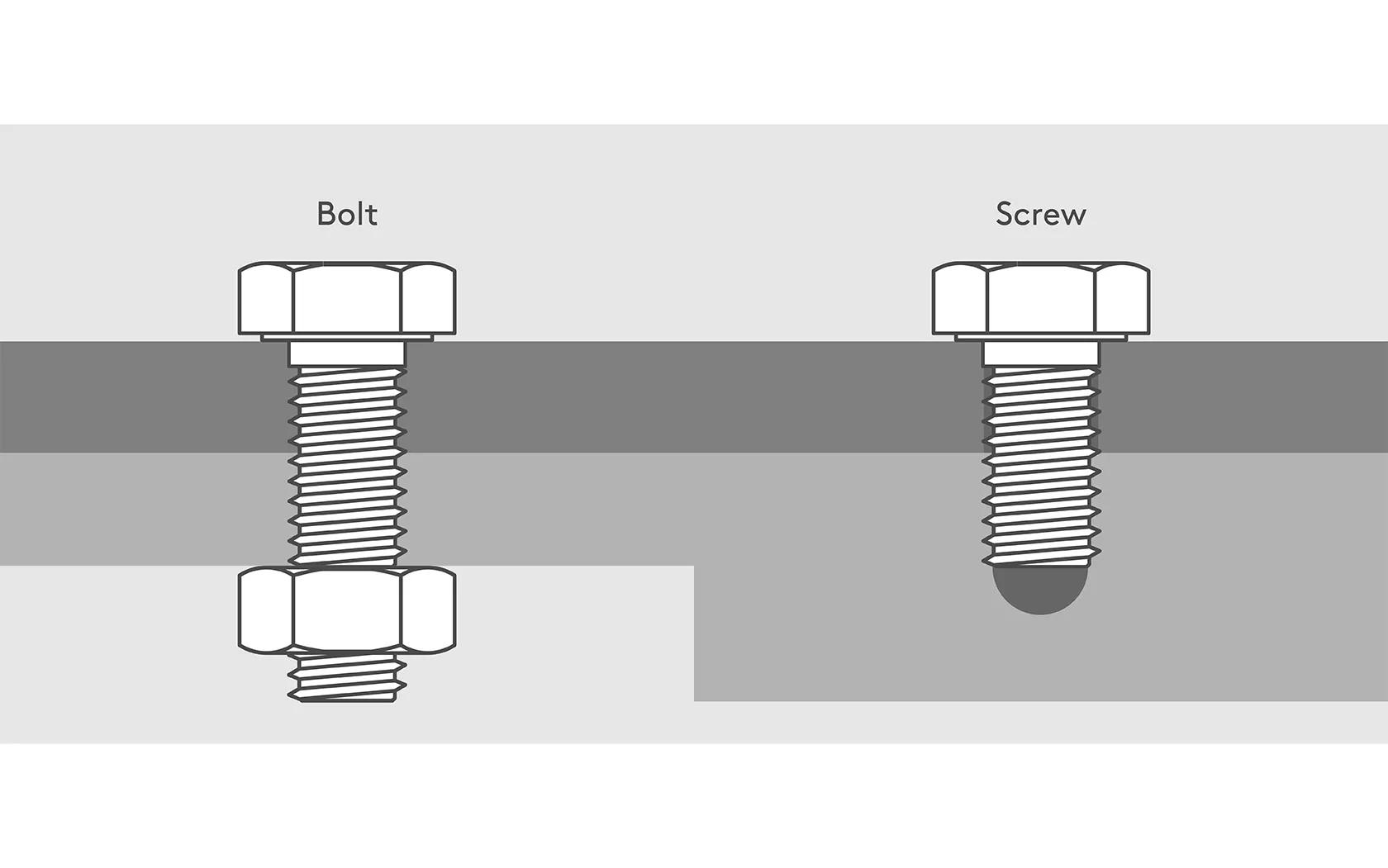

How Do Eye Bolts Differ from O Bolts?

Eye bolts are characterized by their loop at the top, designed for secure attachment points in hoisting, rigging, and anchoring applications. They are available in various sizes and materials, such as galvanized and stainless steel, to suit different environmental conditions. Eye bolts can handle significant loads, but proper installation is crucial for safety. Unlike O bolts, which are primarily used in modeling, eye bolts are essential in construction and heavy-duty operations.

What Advantages Do Forged Eye Bolts Offer?

Forged eye bolts are crafted with a continuous circle design, providing superior strength compared to bent eye bolts. They are typically made from heavier gauge materials, making them ideal for demanding applications in construction and industrial settings. While they are more expensive, their high load-bearing capacity and durability make them a reliable choice for critical tasks. Businesses should consider their specific load requirements and environmental factors when selecting forged eye bolts.

When Should You Use Bent Eye Bolts?

Bent eye bolts are designed for lighter applications and are often used for hanging items vertically. Their nearly closed eye design makes them more cost-effective than forged eye bolts. However, they are not suitable for heavy loads and should only be used in light-duty tasks. B2B buyers should evaluate the weight capacity and application requirements before choosing bent eye bolts, ensuring they align with project specifications.

Key Industrial Applications of o bolt

| Industry/Sector | Specific Application of o bolt | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Precision assembly in machinery and equipment | Enhances product reliability and performance | Ensure compatibility with existing machinery specifications |

| Automotive | Customization of automotive parts and accessories | Reduces lead times for production and increases flexibility | Evaluate material specifications for durability and corrosion resistance |

| Construction | Structural reinforcement in building projects | Increases safety and longevity of structures | Look for local suppliers to mitigate logistics costs and delays |

| Aerospace | Lightweight fastening solutions for aircraft components | Improves fuel efficiency and overall performance | Assess compliance with international aerospace standards |

| Hobby and Model Making | Custom modeling applications for scale models | Offers versatility and customization for enthusiasts | Consider availability of various head types and sizes for specific projects |

How is ‘o bolt’ Used in Manufacturing?

In the manufacturing sector, ‘o bolt’ is crucial for precision assembly in machinery and equipment. Its customizable design allows for easy integration into various applications, enhancing product reliability and overall performance. For international buyers, particularly in regions like Europe and the Middle East, sourcing ‘o bolt’ from local manufacturers can reduce lead times and facilitate easier compliance with regional regulations. Additionally, understanding the compatibility of ‘o bolt’ with existing machinery is essential to avoid operational disruptions.

What Role Does ‘o bolt’ Play in Automotive Customization?

In the automotive industry, ‘o bolt’ serves as a key component for the customization of parts and accessories. Its adaptability allows manufacturers to create bespoke solutions tailored to specific vehicle models, thus reducing lead times for production. Buyers must prioritize sourcing materials that offer durability and corrosion resistance, especially in regions with harsh climates, such as parts of Africa and South America. This ensures that the customized parts maintain their integrity over time, enhancing vehicle performance and safety.

How Does ‘o bolt’ Contribute to Construction Projects?

Within the construction industry, ‘o bolt’ is used for structural reinforcement in various building projects. Its strength and reliability contribute to the safety and longevity of structures, making it a preferred choice among contractors. For B2B buyers, especially in developing regions, sourcing ‘o bolt’ from local suppliers can help mitigate logistics costs and ensure timely delivery. Additionally, understanding local building codes and standards is crucial when integrating ‘o bolt’ into construction applications.

Why is ‘o bolt’ Essential in Aerospace Applications?

In the aerospace sector, ‘o bolt’ provides lightweight fastening solutions that are essential for aircraft components. By using ‘o bolt’, manufacturers can improve fuel efficiency and overall performance, which is vital in an industry where weight savings are critical. Buyers need to assess compliance with international aerospace standards when sourcing these components, ensuring that they meet stringent safety and performance requirements. This is particularly important for companies operating in regions like Europe, where regulations are stringent.

How is ‘o bolt’ Beneficial for Hobby and Model Making?

The hobby and model-making sector utilizes ‘o bolt’ for custom modeling applications, allowing enthusiasts to create detailed and unique scale models. Its versatility and range of head types provide endless possibilities for customization. For international buyers, understanding the availability of various sizes and types is essential for successful project execution. Sourcing from local suppliers can also enhance the speed of delivery, ensuring that hobbyists can complete their projects without unnecessary delays.

3 Common User Pain Points for ‘o bolt’ & Their Solutions

Scenario 1: Sourcing the Right O Bolt for Specific Applications

The Problem: B2B buyers often struggle with sourcing the correct type of O Bolt for their unique applications. With various sizes and head types available—1.5mm, 2.0mm, and 3.0mm—the challenge lies in understanding which specifications are best suited for their projects. This confusion can lead to over-ordering or under-ordering parts, resulting in project delays and increased costs. Additionally, international buyers may encounter compatibility issues with local suppliers who might not stock the specific variants needed.

The Solution: To effectively source the right O Bolt, it’s crucial for buyers to first assess their project requirements thoroughly. This involves determining the weight load, environmental conditions (such as exposure to moisture or corrosive elements), and the intended use of the bolt. Buyers should engage with suppliers who offer comprehensive product catalogs that outline the specifications and applications of each O Bolt variant. Establishing a relationship with a knowledgeable supplier can provide insights into the most suitable options for your specific needs. Additionally, consider reaching out to manufacturers directly for custom solutions that can accommodate unique project specifications.

Scenario 2: Difficulty in Installing O Bolts Properly

The Problem: Many B2B buyers encounter difficulties during the installation of O Bolts, particularly when it comes to creating the correct holes for the bolt heads. Inaccurate drilling can lead to misalignment, weakened structures, and ultimately project failures. This is especially problematic in regions where local labor might lack training in precision installation techniques, causing further complications and costs.

The Solution: To ensure proper installation of O Bolts, it is essential to provide adequate training and resources to the installation team. Begin by supplying detailed installation guides that include step-by-step instructions and visual aids. Conduct training sessions that focus on the use of a pin vise for precise drilling, emphasizing the importance of measuring and marking before proceeding. Furthermore, consider using pilot holes to ensure accuracy. Collaborating with local experts or engineers can also enhance the installation process by offering on-site guidance. By investing in training and resources, buyers can mitigate installation issues and ensure the structural integrity of their projects.

Scenario 3: Managing Inventory and Stock Levels of O Bolts

The Problem: B2B buyers often face challenges in managing inventory levels of O Bolts, leading to either excess stock or shortages. This issue can arise from unpredictable project demands, varying lead times for international shipments, and fluctuations in supplier availability. Such inventory mismanagement can disrupt production schedules and increase holding costs.

The Solution: Implementing a robust inventory management system is vital for managing O Bolt stock levels effectively. Buyers should utilize inventory tracking software that integrates with their procurement process, allowing for real-time visibility of stock levels and usage rates. Establishing a reorder point based on historical data can help trigger timely restocking before shortages occur. Additionally, forming strategic partnerships with suppliers can provide flexibility in order quantities and lead times, enabling buyers to adapt to changing project demands. Regular audits of inventory can also help identify slow-moving items, allowing for more informed purchasing decisions. By adopting these strategies, B2B buyers can maintain optimal inventory levels, reducing both excess stock and shortages.

Strategic Material Selection Guide for o bolt

What Are the Key Materials for O Bolt and Their Properties?

When selecting materials for o bolts, it is crucial to consider their properties, advantages, and limitations in various applications. Here, we analyze four common materials used in the manufacturing of o bolts: stainless steel, carbon steel, aluminum, and plastic.

How Does Stainless Steel Benefit O Bolt Applications?

Stainless steel is renowned for its excellent corrosion resistance and high strength, making it ideal for applications exposed to moisture and harsh environments. Its temperature rating can withstand high heat, which is beneficial in industries such as automotive and aerospace.

Pros: Stainless steel offers exceptional durability, making it suitable for heavy-duty applications. It is also aesthetically pleasing, which can be an advantage in consumer-facing products.

Cons: The primary drawback is its higher cost compared to other materials, which can impact budget-sensitive projects. Additionally, manufacturing processes for stainless steel can be more complex due to its hardness.

Impact on Application: Stainless steel is compatible with a wide range of media, including water, oil, and chemicals, making it versatile for various industrial applications.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM and DIN, particularly for applications in corrosive environments.

What Advantages Does Carbon Steel Offer for O Bolt?

Carbon steel is a popular choice due to its strength and cost-effectiveness. It has a high tensile strength and is suitable for applications requiring robust fastening solutions.

Pros: The material is relatively inexpensive and widely available, making it a go-to option for many manufacturers. Its ability to be heat-treated enhances its strength.

Cons: Carbon steel is prone to rust and corrosion, which limits its use in humid or corrosive environments unless adequately coated.

Illustrative image related to o bolt

Impact on Application: It is primarily used in construction and automotive applications where high strength is required without exposure to harsh conditions.

Considerations for International Buyers: Buyers must be aware of the need for protective coatings to ensure longevity, especially in humid regions like South America and parts of Africa.

Why Choose Aluminum for O Bolt Applications?

Aluminum is lightweight and resistant to corrosion, making it suitable for applications where weight reduction is critical, such as in aerospace and automotive industries.

Pros: The low density of aluminum allows for easy handling and installation. It also has good thermal conductivity, which can be beneficial in specific applications.

Cons: While aluminum is resistant to corrosion, it is not as strong as steel, limiting its use in high-load applications. It can also be more expensive than carbon steel.

Illustrative image related to o bolt

Impact on Application: Aluminum o bolts are ideal for applications where weight savings are paramount, but they may not be suitable for high-stress environments.

Considerations for International Buyers: Compliance with international standards is essential, especially for aerospace applications, where safety is paramount.

What Role Does Plastic Play in O Bolt Manufacturing?

Plastic o bolts are increasingly used in applications where electrical insulation and resistance to corrosion are required, such as in electrical and electronic devices.

Pros: Plastic is lightweight, non-corrosive, and can be produced at a lower cost than metals. It is also available in various colors and can be molded into complex shapes.

Cons: Plastic lacks the strength and durability of metals, making it unsuitable for high-load applications. It can also be sensitive to temperature changes, which may limit its use in high-heat environments.

Impact on Application: Plastic o bolts are ideal for lightweight applications and environments where electrical conductivity must be minimized.

Considerations for International Buyers: Buyers should ensure that the plastic materials comply with relevant standards for electrical insulation and environmental safety.

Summary of Material Selection for O Bolt

| Material | Typical Use Case for o bolt | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy-duty applications in corrosive environments | Excellent corrosion resistance and durability | Higher cost and complex manufacturing | High |

| Carbon Steel | Construction and automotive applications | Cost-effective and high tensile strength | Prone to rust without coatings | Low |

| Aluminum | Aerospace and automotive applications | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

| Plastic | Electrical and electronic devices | Lightweight and non-corrosive | Limited strength and temperature sensitivity | Low |

This guide provides a comprehensive overview of the strategic material selection for o bolts, helping international B2B buyers make informed decisions based on application requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for o bolt

What Are the Main Stages in the Manufacturing Process of O Bolts?

The manufacturing process of O bolts involves several critical stages that ensure high-quality output and adherence to industry standards. These stages are typically broken down into material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting high-quality raw materials. O bolts are often made from various metals, including stainless steel, carbon steel, or alloy steel, depending on the application. The chosen materials undergo a thorough inspection to ensure they meet specified mechanical properties and chemical compositions. This initial quality check is crucial as it sets the foundation for the entire manufacturing process.

-

Forming: The next step is forming the bolts into their desired shapes. Techniques such as cold heading or hot forging are commonly employed. Cold heading involves deforming the metal at room temperature, resulting in a strong and durable product. Hot forging, on the other hand, uses high temperatures to shape the metal, which can be advantageous for larger or more complex designs. This stage may also include the creation of various head types to cater to specific applications.

-

Assembly: After forming, the bolts may require additional components, such as nuts or washers. During the assembly phase, these components are attached to the bolts through processes like threading or welding. Precision is key at this stage to ensure that the final product can withstand the intended loads and environmental conditions.

-

Finishing: The final stage involves surface treatments to enhance corrosion resistance, aesthetic appeal, and durability. Common finishing techniques include galvanization, powder coating, or applying protective oils. Each method has its benefits; for instance, galvanization is particularly effective in environments exposed to moisture or corrosive elements.

How Is Quality Assurance Implemented Throughout the Manufacturing Process?

Quality assurance (QA) is an integral part of the manufacturing process for O bolts. It ensures that every product meets the required standards and specifications before it reaches the customer.

-

International Standards Compliance: Many manufacturers adhere to international quality standards such as ISO 9001, which focuses on effective quality management systems. Compliance with these standards demonstrates a commitment to quality and reliability. Additionally, industry-specific certifications like CE (Conformité Européenne) or API (American Petroleum Institute) may be relevant depending on the application of the bolts.

-

Quality Control Checkpoints: Quality control (QC) checkpoints are established throughout the manufacturing process. Incoming Quality Control (IQC) verifies the quality of raw materials before they are processed. In-Process Quality Control (IPQC) monitors the production stages to identify any deviations from quality standards. Finally, Final Quality Control (FQC) inspects the finished products before they are packaged and shipped.

-

Testing Methods: Various testing methods are employed to ensure product integrity. Common tests include tensile strength testing, hardness testing, and corrosion resistance testing. These tests help confirm that the bolts can withstand the intended loads and environmental conditions without failure.

What Steps Can B2B Buyers Take to Verify Supplier Quality Control?

For B2B buyers, especially those operating in international markets such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial to ensure the reliability of O bolts.

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality control systems. An on-site visit allows buyers to observe the production environment, quality control measures, and compliance with international standards.

-

Reviewing Quality Reports: Requesting quality control reports from suppliers can help buyers assess the effectiveness of their QC processes. These reports should detail the results of various tests and inspections conducted throughout the manufacturing process.

-

Third-Party Inspections: Engaging third-party inspection services can provide an objective assessment of supplier quality. These independent organizations conduct thorough inspections and testing, offering an additional layer of assurance to buyers.

What Are the Nuances of Quality Control and Certification for International B2B Buyers?

When dealing with international suppliers, B2B buyers must navigate various nuances related to quality control and certification.

-

Understanding Regional Standards: Different regions may have specific quality standards and certifications relevant to the manufacturing of O bolts. For instance, European buyers may prioritize CE marking, while buyers in the Middle East might look for compliance with local standards. Understanding these regional requirements is essential for ensuring that the products are acceptable in the target market.

-

Language and Communication Barriers: Language differences can complicate the verification process. Buyers should ensure that they have clear communication channels with suppliers, preferably with documentation provided in a language that both parties understand. This clarity is vital for discussing quality standards, certifications, and any necessary compliance documentation.

-

Cultural Considerations: Business practices vary across cultures, influencing how quality control is perceived and implemented. Buyers should be aware of these cultural differences to foster effective relationships with suppliers and ensure that quality expectations are met.

Conclusion

The manufacturing processes and quality assurance practices for O bolts are critical elements that influence the reliability and performance of these components in various applications. By understanding the stages of production, the importance of quality assurance, and the steps to verify supplier credibility, B2B buyers can make informed decisions that align with their operational needs and regional standards. Whether sourcing locally or internationally, a thorough approach to quality assurance will lead to better outcomes and reduced risks in the supply chain.

Illustrative image related to o bolt

Practical Sourcing Guide: A Step-by-Step Checklist for ‘o bolt’

To effectively source ‘o bolt’ products, particularly for international B2B transactions, it is essential to follow a structured approach. This guide provides a step-by-step checklist to ensure that you procure high-quality products that meet your business needs while navigating the complexities of international supply chains.

Step 1: Define Your Technical Specifications

Clearly articulate the technical specifications required for the ‘o bolt’ products you need. Consider factors such as size, type of heads (e.g., 1.5mm, 2.0mm, 3.0mm), and any specific material requirements. Having detailed specifications helps in comparing products from different suppliers and ensures that the items meet your project needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in ‘o bolt’ products. Look for manufacturers with a proven track record in your target regions, such as Africa, South America, the Middle East, and Europe. Focus on suppliers that have industry certifications and positive reviews from previous clients, which can be indicative of their reliability.

Illustrative image related to o bolt

- Tip: Utilize platforms like Alibaba, Global Sources, or industry-specific directories to find reputable suppliers.

Step 3: Evaluate Supplier Capabilities

Before committing to a supplier, assess their production capabilities. This includes their manufacturing processes, quality control measures, and ability to meet your required lead times. A supplier’s capability to handle bulk orders and customization can also be vital, especially if you have specific design requirements.

- Action Item: Request samples of the ‘o bolt’ products to evaluate quality firsthand.

Step 4: Verify Supplier Certifications

Ensuring that your suppliers have the necessary certifications is crucial for maintaining quality standards. Look for certifications relevant to your industry, such as ISO 9001 for quality management systems or CE marking for products sold in Europe. These certifications can provide assurance of compliance with international standards.

Step 5: Assess Pricing and Payment Terms

Request detailed quotes from shortlisted suppliers and compare pricing structures. Be aware of additional costs such as shipping, taxes, and tariffs that may apply, especially for international orders. Additionally, clarify payment terms to avoid any misunderstandings; consider options like letters of credit for larger transactions to enhance security.

- Consideration: Negotiate terms that allow for flexibility in case of unforeseen delays or quality issues.

Step 6: Check Logistics and Shipping Options

Review the logistics capabilities of your chosen supplier. Understand their shipping methods, delivery times, and how they handle customs clearance. Efficient logistics are crucial in minimizing delays and ensuring that your order arrives in good condition.

- Action Item: Discuss potential shipping partners and options available for your region.

Step 7: Establish a Communication Plan

Develop a clear communication plan with your supplier. Regular updates on order status, shipping schedules, and any potential issues can help mitigate risks associated with international procurement. Establishing a point of contact will facilitate smoother interactions and quicker resolutions to any problems that may arise.

Illustrative image related to o bolt

By following this checklist, you can effectively navigate the sourcing process for ‘o bolt’ products, ensuring you secure high-quality supplies that meet your business objectives.

Comprehensive Cost and Pricing Analysis for o bolt Sourcing

What Are the Key Cost Components in O Bolt Sourcing?

When sourcing O bolts, understanding the underlying cost structure is crucial for effective budgeting and supplier negotiations. Key cost components include:

-

Materials: The choice of materials significantly influences the cost. O bolts typically use high-grade metals or plastics, which vary in price based on availability and quality. For instance, stainless steel options may cost more due to their corrosion resistance, essential for applications in humid or saline environments.

-

Labor: Labor costs encompass the workforce involved in manufacturing O bolts. Regions with higher labor costs, like Germany, may result in elevated overall pricing compared to those in lower-cost countries.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overhead, impacting the final cost positively.

-

Tooling: Investment in specialized tooling for O bolts, particularly for customized specifications, can add to initial costs. However, these costs can be amortized over larger production runs, making them more economical in bulk orders.

-

Quality Control (QC): Rigorous QC processes are vital to ensure product reliability and safety. This can increase costs but is essential for maintaining standards, especially when exporting to markets with stringent regulations.

-

Logistics: Shipping and handling costs vary based on distance, mode of transport, and Incoterms. International shipments often incur additional fees, including customs duties and insurance.

-

Margin: Suppliers typically mark up prices to cover their costs and achieve profitability. Understanding the typical margin range in the industry can aid buyers in evaluating price fairness.

How Do Price Influencers Affect O Bolt Costs?

Several factors can influence the pricing of O bolts, making it essential for buyers to consider these elements:

-

Volume/MOQ: Suppliers often provide discounts for larger orders or minimum order quantities (MOQs). Buyers should assess their needs to leverage these pricing advantages effectively.

-

Specifications and Customization: Custom features or non-standard specifications can lead to higher costs. Standard sizes and types are typically more economical due to mass production.

-

Materials and Quality Certifications: Higher-quality materials or certifications (like ISO) may increase upfront costs but can result in lower Total Cost of Ownership (TCO) through improved durability and reduced failure rates.

-

Supplier Factors: The supplier’s reputation, location, and operational efficiency can impact pricing. It’s advisable to research potential suppliers to ensure they align with your quality and pricing expectations.

-

Incoterms: Understanding shipping terms can help clarify responsibility for costs and risks during transit. For instance, “CIF” (Cost, Insurance, and Freight) includes shipping costs, while “FOB” (Free on Board) places responsibility on the buyer once the goods are on board.

What Are Some Effective Buyer Tips for Sourcing O Bolts?

-

Negotiation Strategies: Engage in open dialogue with suppliers about pricing, and don’t hesitate to negotiate terms. Highlighting potential for repeat business can often lead to better pricing.

-

Cost-Efficiency Approaches: Evaluate the TCO rather than just the purchase price. Consider factors like potential maintenance costs, lifespan, and performance when comparing suppliers.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe must be aware of currency fluctuations and import tariffs that can affect the final cost. Building relationships with local suppliers can mitigate some of these risks.

-

Understand Market Trends: Stay informed about market dynamics, such as changes in raw material prices or shifts in demand, which can affect pricing strategies.

-

Request Samples: Before committing to a large order, request samples to evaluate quality. This can help avoid costly mistakes later in the procurement process.

Disclaimer on Indicative Prices

Prices for O bolts can vary widely based on the factors mentioned above. It is crucial for buyers to obtain quotes from multiple suppliers and compare them based on the complete cost structure to make informed decisions.

Alternatives Analysis: Comparing o bolt With Other Solutions

Exploring Alternative Solutions to ‘O Bolt’

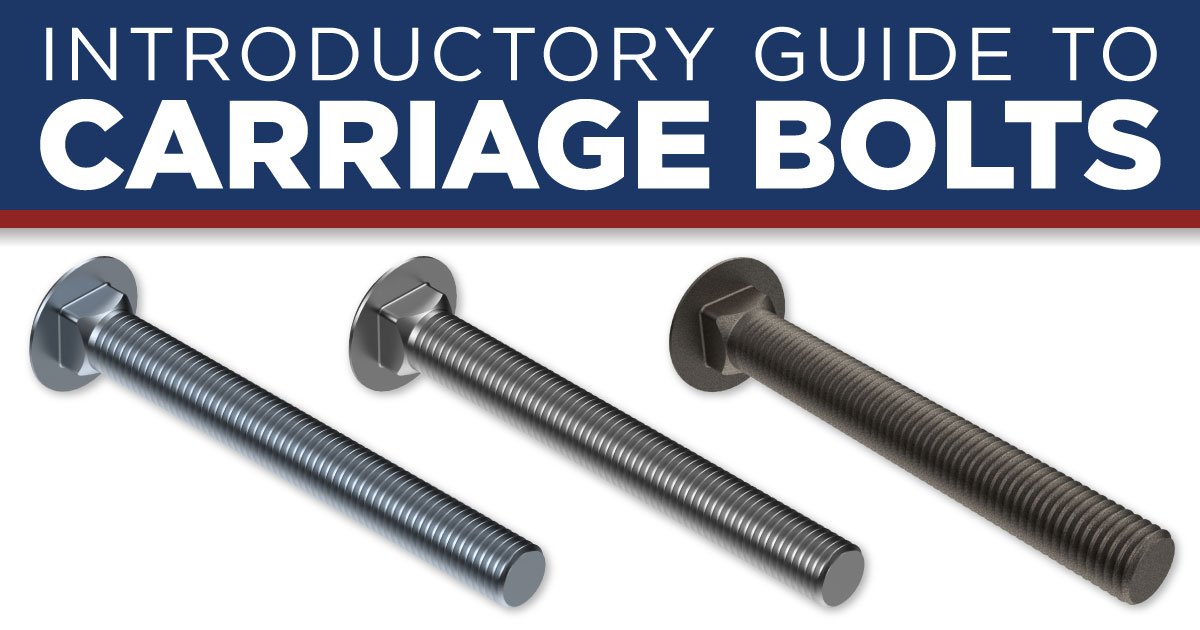

When evaluating options for fastening solutions, particularly in the context of model kits and similar applications, it’s vital to consider alternatives that can meet specific needs while providing distinct advantages or disadvantages. In this analysis, we will compare ‘O Bolt’ against two notable alternatives: traditional Eyebolts and modular screw systems. This will help international B2B buyers assess which solution aligns best with their project requirements.

| Comparison Aspect | ‘O Bolt’ | Eyebolts | Modular Screw Systems |

|---|---|---|---|

| Performance | High versatility for modeling; can be tailored for various applications | Suitable for heavy-duty tasks; reliable load-bearing capacity | Offers customizable lengths and head types for diverse applications |

| Cost | Generally low-cost ($3.99-$4.44) | Moderate cost, varies by size and material (approx. $2-$10) | Higher initial investment, with prices ranging from $10 to $50+ for sets |

| Ease of Implementation | Simple to use; requires drilling and insertion of heads | Easy installation; requires pre-drilled holes | Installation may require specialized tools, depending on the system |

| Maintenance | Minimal maintenance required; durable if used properly | Low maintenance; inspect for wear | Moderate; requires periodic checking of screws for tightness |

| Best Use Case | Ideal for model kits and crafts where customization is key | Best for heavy lifting and rigging applications | Suitable for versatile assembly in construction and DIY projects |

In-Depth Look at Alternatives

Eyebolts

Eyebolts are a classic fastening solution that excels in heavy-duty applications. They are designed to handle significant loads, making them ideal for rigging and lifting tasks. One of the main advantages of eyebolts is their straightforward installation process. However, they may require pre-drilled holes, which can limit their flexibility in certain scenarios. Their cost can vary significantly based on size and material, with stainless steel options being pricier but more resistant to corrosion.

Modular Screw Systems

Modular screw systems offer a high degree of customization and flexibility. These systems allow users to select different lengths and head types, which can be particularly advantageous in applications where adjustments and modifications are frequently necessary. However, the initial cost can be higher, and installation might require specialized tools or expertise. While they are not the best choice for lightweight or casual projects, they shine in construction and assembly tasks that demand precision and adaptability.

Conclusion: Choosing the Right Fastening Solution

For B2B buyers, selecting the appropriate fastening solution requires careful consideration of the specific application, budget constraints, and long-term maintenance expectations. ‘O Bolt’ stands out for projects that prioritize versatility and ease of use, particularly in the modeling sector. In contrast, eyebolts are better suited for heavy-duty applications, while modular screw systems cater to diverse assembly needs. Ultimately, the best choice will depend on the unique requirements of each project, making it essential to evaluate each option’s strengths and limitations thoroughly.

Essential Technical Properties and Trade Terminology for o bolt

What Are the Key Technical Properties of O Bolts?

When considering the procurement of O bolts for various applications, understanding their technical properties is crucial for ensuring performance and compatibility with your specific needs. Here are some of the essential specifications to consider:

-

Material Grade: O bolts are typically made from materials such as steel, stainless steel, or plastic, depending on the intended application. For heavy-duty tasks, stainless steel is preferred due to its superior resistance to corrosion and fatigue. Material grade affects strength, durability, and suitability for environments that may expose the bolt to moisture or chemicals.

-

Head Type: O bolts come with various head types, such as flat, round, or hex. The choice of head impacts how the bolt interacts with other components, including ease of installation and the torque applied. Understanding the head type is essential for ensuring compatibility with the tools and equipment in use.

-

Size and Thread Specifications: O bolts are available in different sizes, typically measured in millimeters (1.5mm, 2.0mm, 3.0mm). The size affects the load-bearing capacity and the type of applications for which the bolt is suitable. Additionally, thread specifications, including pitch and diameter, are critical for ensuring a secure fit with corresponding nuts or tapped holes.

-

Tolerance Levels: Tolerance refers to the allowable variation in dimensions. For O bolts, tighter tolerances are essential in applications requiring precise alignment or where high stress is expected. Understanding tolerance levels can help mitigate the risk of mechanical failure and ensure optimal performance in critical applications.

-

Load Capacity: Each O bolt is rated for a specific load capacity, indicating how much weight it can support safely. This specification is vital for selecting the right bolt for lifting, securing, or anchoring tasks. Exceeding the load capacity can lead to bolt failure and potential safety hazards.

-

Finish: The finish of an O bolt, such as zinc plating or anodizing, affects its resistance to corrosion and wear. A suitable finish can enhance the longevity of the bolt, especially in harsh environments. Buyers should consider the operational environment when selecting the appropriate finish.

What Are Common Trade Terms Related to O Bolts?

Familiarity with industry jargon is essential for efficient communication and negotiation in B2B transactions. Here are several key terms relevant to the procurement of O bolts:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is crucial for ensuring that the O bolts sourced meet the required standards for compatibility with existing equipment.

-

MOQ (Minimum Order Quantity): MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ for O bolts is important for budgeting and inventory management, particularly for businesses that may not require large quantities but need to ensure a steady supply.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing and terms for specific products. Submitting an RFQ for O bolts allows buyers to compare offers from different suppliers, helping them secure the best pricing and terms.

-

Incoterms (International Commercial Terms): These are a set of international rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with Incoterms is essential for understanding shipping costs, insurance responsibilities, and risk transfer when procuring O bolts from international suppliers.

-

Lead Time: This term refers to the time taken from placing an order to receiving the product. Understanding lead times for O bolts is critical for project planning and ensuring that production schedules are met without delays.

-

Certification Standards: Many O bolts are subject to industry certification standards, such as ISO or ASTM. These certifications ensure that the bolts meet specific performance and safety criteria. Buyers should verify certification to ensure compliance with local regulations and industry best practices.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when procuring O bolts, ensuring that their choices align with project requirements and operational standards.

Navigating Market Dynamics and Sourcing Trends in the o bolt Sector

What Are the Current Market Dynamics and Key Trends in the O Bolt Sector?

The global o bolt market is witnessing significant growth driven by an increase in industrial applications, especially in sectors such as construction, automotive, and manufacturing. B2B buyers from Africa, South America, the Middle East, and Europe are increasingly seeking innovative fastening solutions that offer both functionality and versatility. A notable trend is the customization of o bolts, allowing businesses to tailor products to specific needs, which enhances operational efficiency and reduces waste.

Technological advancements are also shaping the market, with digital platforms facilitating easier sourcing and procurement processes. B2B buyers are leveraging e-commerce solutions to access a broader range of products, compare prices, and evaluate supplier reliability in real-time. Additionally, there is a growing emphasis on product quality and performance, with buyers prioritizing suppliers who provide detailed specifications and testing certifications.

Emerging markets in Africa and South America are particularly noteworthy, as infrastructure development projects surge. For instance, in countries like Saudi Arabia and Germany, the demand for high-strength, corrosion-resistant o bolts is on the rise, driven by stringent industry standards and an increase in large-scale construction projects. As such, international buyers must remain vigilant about evolving market requirements and adapt their sourcing strategies accordingly.

How Can Sustainability and Ethical Sourcing Impact B2B Buyers in the O Bolt Sector?

Sustainability is becoming a cornerstone in the decision-making process for B2B buyers in the o bolt sector. The environmental impact of production methods and materials is increasingly under scrutiny, with businesses prioritizing suppliers who implement sustainable practices. Buyers should look for manufacturers that utilize recycled materials or eco-friendly alternatives in their o bolt production, as these options not only reduce the carbon footprint but also resonate with environmentally conscious consumers.

Ethical sourcing is equally vital, as transparency in the supply chain becomes a key factor for many organizations. B2B buyers are encouraged to engage with suppliers who can demonstrate compliance with ethical labor practices and environmental regulations. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical practices. By choosing certified suppliers, businesses can enhance their brand reputation and meet the growing consumer demand for responsible sourcing.

What Is the Historical Context of the O Bolt Market for B2B Buyers?

The o bolt has evolved significantly over the past few decades. Initially designed for basic fastening applications, the product has transformed into a sophisticated component utilized across various industries. The introduction of advanced materials and manufacturing techniques has enhanced the strength and versatility of o bolts, making them indispensable in modern engineering and construction projects.

In the early days, o bolts were primarily made from standard steel, but with the advent of new technologies, manufacturers began to explore corrosion-resistant materials like stainless steel and specialized coatings. This evolution has enabled businesses to expand their application range, catering to specific industry needs such as marine, automotive, and heavy machinery sectors. As the o bolt market continues to innovate, B2B buyers can expect further advancements that will enhance performance and sustainability.

In conclusion, understanding the market dynamics, sustainability implications, and historical context of the o bolt sector can empower international B2B buyers to make informed sourcing decisions that align with their operational goals and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of o bolt

-

How do I solve issues with inconsistent bolt quality from suppliers?

To address inconsistent bolt quality, establish a stringent supplier vetting process. Research potential suppliers by checking certifications, customer reviews, and production capabilities. Consider requesting samples to assess quality firsthand before making bulk purchases. Implementing a quality assurance (QA) protocol, including regular audits and inspections of incoming shipments, will help maintain quality standards throughout your supply chain. -

What is the best type of bolt for different applications?

Selecting the right bolt type depends on the specific application and load requirements. For heavy-duty tasks, forged eye bolts are recommended due to their strength and durability. In contrast, galvanized bolts are suitable for environments exposed to moisture, while stainless steel options offer the best corrosion resistance. Understand the load capacity and environmental conditions to choose the most appropriate bolt type for your needs. -

How can I customize my bolt orders?

Customization options for bolts typically include size, material, and head type. When sourcing from suppliers, inquire about their capability to accommodate custom orders, including specific dimensions or finishes. Providing detailed specifications and drawings will facilitate the customization process. Establishing a close working relationship with your supplier can also enhance flexibility and responsiveness to your unique requirements. -

What are the minimum order quantities (MOQ) for bolts?

Minimum order quantities can vary widely among suppliers. Some may have a low MOQ for standard products, while custom orders might require larger quantities. To ensure you meet the MOQ, clarify these terms during initial discussions with suppliers. Negotiating flexible terms based on your projected needs may also yield favorable outcomes, especially for long-term partnerships. -

What payment terms should I expect when sourcing bolts internationally?

Payment terms can differ significantly depending on the supplier and the region. Common practices include upfront deposits (usually 30% to 50%) with the balance due upon shipment or delivery. Letters of credit and PayPal are also popular methods for ensuring secure transactions. Always confirm payment terms in advance to avoid misunderstandings and safeguard your financial interests. -

How do I ensure timely logistics and delivery for my bolt orders?

To ensure timely logistics, work closely with your supplier to establish clear delivery timelines and shipping methods. Utilize reliable freight forwarders familiar with international shipping regulations. Consider potential customs delays and factor them into your timelines. Regular communication with your supplier during the shipping process can help address any issues proactively. -

What quality assurance practices should I implement when sourcing bolts?

Implementing a robust QA process involves defining quality standards upfront and conducting regular supplier audits. Request certification documents, such as ISO or ASTM compliance, to verify product quality. Establish inspection protocols for incoming shipments, including random sampling and testing for strength and durability. This proactive approach will help mitigate risks associated with low-quality products. -

How do I handle disputes with suppliers over product quality or delivery?

In the event of a dispute regarding product quality or delivery issues, maintain open communication with your supplier to resolve the matter amicably. Document all correspondence and agreements to provide a clear reference point. If necessary, refer to the terms outlined in your contract. In cases where resolution is not possible, consider mediation or arbitration as outlined in your contract to protect your interests.

Top 4 O Bolt Manufacturers & Suppliers List

1. McMaster – O-Ring Bolts

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – O-Ring Bolts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. O Bolt – Bolt 2

Domain: newtype.us

Registered: 2019 (6 years)

Introduction: {“product_name”: “O Bolt Bolt 2”, “price”: “$3.99”, “availability”: “Out of stock”, “types_of_heads”: [“1.5mm”, “2mm”, “3mm”], “description”: “Bolt molds can be easily reproduced by anyone. Other uses are infinite!”, “sku”: “OP-342”, “related_products”: [“O Bolt Bolt 1”, “R Rivets Round”, “R Rivets Corner”, “U Vernier Square M”, “U Vernier Flat 4 (Rectangle)”, “U Vernier Square S”, “Z Vernier”, “Z…

3. Wave Co., Ltd. – O-Bolt

Domain: hobby-wave.com

Registered: 2005 (20 years)

Introduction: {“name”:”O-Bolt”,”manufacturer”:”Wave Co., Ltd.”,”price”:”¥330 each (tax included)”,”types”:”O-Bolt 1 and O-Bolt 2″,”product_codes”:[“OP-341″,”OP-342″],”sizes”:[“2.0mm”,”3.0mm”,”3mm”],”description”:”There are 5 types of heads and 1.5 sizes available. Drill a hole with a pin vise where you want to mold the bolt and insert the type of head depending on the purpose of use. Anyone can easily reproduce…

4. Panda Hobby – O-Bolt #02 Enhancement Part

Domain: pandahobby.ca

Registered: 2018 (7 years)

Introduction: O-Bolt #02 – Bolt Enhancement Part (1.5mm, 2.0mm, 3.0mm) OP342

Strategic Sourcing Conclusion and Outlook for o bolt

As global industries increasingly pivot towards efficiency and innovation, the importance of strategic sourcing for products like the O Bolt cannot be overstated. This versatile component, available in multiple sizes and head types, offers unparalleled flexibility for various applications in model building and hardware solutions. By integrating O Bolt into your supply chain, you not only enhance product offerings but also cater to a diverse customer base, from hobbyists to industrial users.

Illustrative image related to o bolt

International buyers from regions such as Africa, South America, the Middle East, and Europe stand to gain significantly from sourcing O Bolts. The adaptability of these components allows for easy customization and rapid deployment in projects, fostering greater productivity and innovation. Engaging with reputable suppliers ensures quality and reliability, critical factors in maintaining competitive advantage.

Looking ahead, the demand for customizable and high-quality hardware solutions is set to grow. Now is the opportune moment for B2B buyers to invest in strategic partnerships that prioritize sustainability and innovation. Embrace the potential of O Bolts in your projects and enhance your market offerings today!

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.