Unlocking Value: A Strategic Analysis of the Moldable False Teeth Market

Introduction: Navigating the Global Market for moldable false teeth

Navigating the global market for moldable false teeth presents unique challenges for B2B buyers, particularly in sourcing reliable suppliers who can provide high-quality, customizable products. As the demand for innovative dental solutions continues to rise, understanding the various types of moldable false teeth and their applications becomes paramount. This guide offers a comprehensive overview of the market, detailing essential information on product types, applications, supplier vetting processes, and cost considerations.

International buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Vietnam—will find actionable insights tailored to their specific needs. By focusing on the intricacies of sourcing moldable false teeth, this guide empowers businesses to make informed purchasing decisions that align with their operational requirements and customer expectations.

Whether you are looking to enhance your product offerings or streamline your procurement process, our guide serves as a vital resource. It not only highlights the latest trends and innovations within the industry but also provides practical strategies to ensure you partner with reputable suppliers. Equip yourself with the knowledge to navigate this dynamic market confidently, ensuring your business remains competitive and responsive to the evolving demands of dental care.

Understanding moldable false teeth Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Thermal Beads Teeth | Moldable with heat, customizable fit | Dental labs, prosthetic suppliers | Pros: Easy to mold; cost-effective. Cons: Limited durability compared to other types. |

| Acrylic False Teeth | Rigid structure, high aesthetic appeal | Dental clinics, cosmetic dentistry | Pros: Long-lasting; natural appearance. Cons: Requires professional fitting. |

| Silicone Moldable Teeth | Flexible, soft, and comfortable | Elderly care facilities, home care | Pros: Comfortable for wearers; hypoallergenic. Cons: Can be less stable over time. |

| Thermoplastic Teeth | Durable and heat-responsive | Orthodontic practices, dental labs | Pros: Resilient; good for temporary solutions. Cons: More complex molding process. |

| Biocompatible Resin Teeth | Advanced materials for dental applications | High-end dental practices | Pros: Strong and aesthetically pleasing; customizable. Cons: Higher cost; requires specialized equipment. |

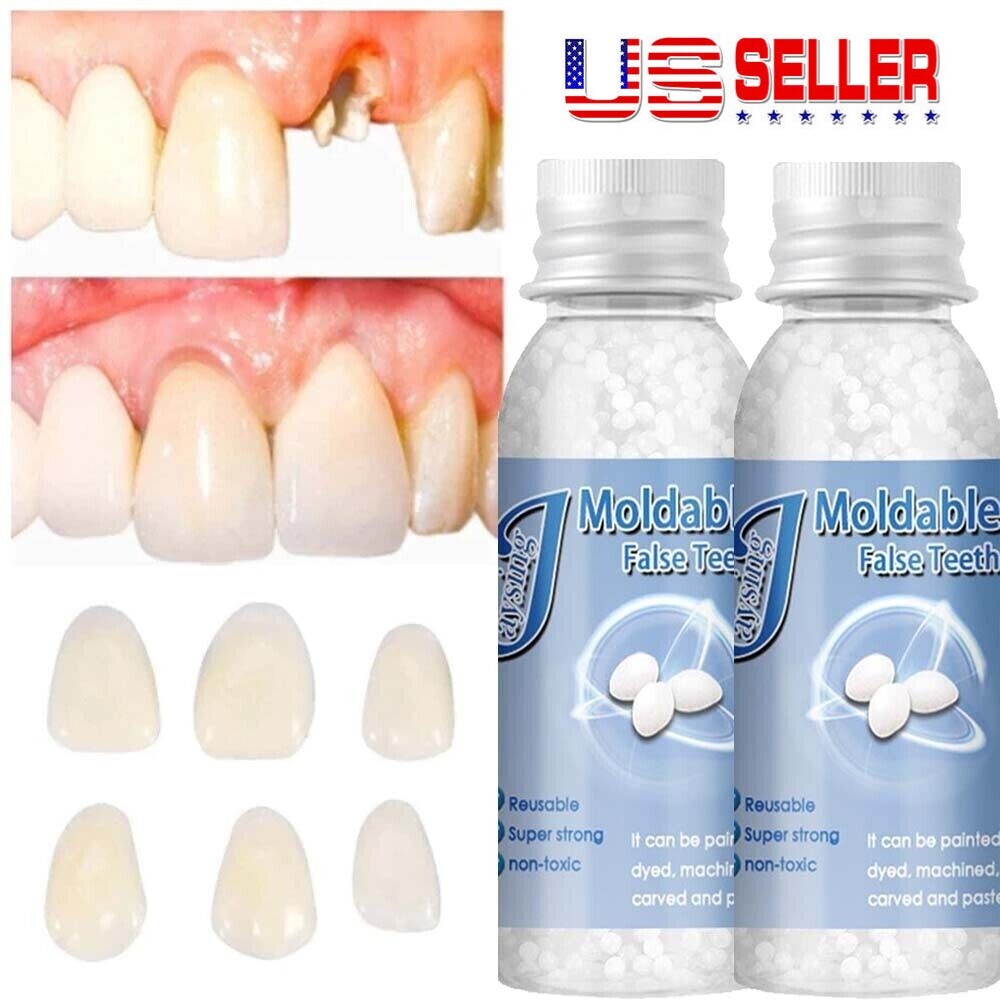

What Are the Characteristics and Suitability of Thermal Beads Teeth?

Thermal beads teeth are a versatile option that can be easily molded by heating the beads in water. This type is particularly suitable for temporary dental solutions, such as for patients awaiting permanent fixtures. B2B buyers should consider the cost-effectiveness of thermal beads, as they provide a quick solution for dental labs and prosthetic suppliers. However, the durability may be a concern for long-term use, as these teeth can wear down faster than more rigid alternatives.

How Do Acrylic False Teeth Stand Out in the Market?

Acrylic false teeth are known for their rigid structure and natural aesthetic appeal, making them a popular choice in dental clinics and cosmetic dentistry. They can be customized to match the patient’s natural teeth, offering a high level of satisfaction. For B2B buyers, the long-lasting nature of acrylic teeth is a significant advantage, although they require professional fitting, which may add to the overall cost and time of service.

Why Choose Silicone Moldable Teeth for Comfort?

Silicone moldable teeth are designed for flexibility and comfort, making them ideal for elderly care facilities and home care applications. Their soft texture allows for a more natural feel, which can improve patient compliance. B2B buyers should note that while silicone teeth are hypoallergenic and comfortable, they may not provide the same stability as other types over extended periods, potentially necessitating more frequent replacements.

What Are the Benefits of Using Thermoplastic Teeth?

Thermoplastic teeth are distinguished by their durability and heat-responsive properties, making them suitable for orthodontic practices and dental labs that require temporary solutions. They can withstand significant wear and tear, which is a crucial consideration for B2B buyers looking for resilient options. However, the molding process can be more complex, requiring additional training or equipment, which could impact operational efficiency.

How Do Biocompatible Resin Teeth Enhance Dental Solutions?

Biocompatible resin teeth represent a cutting-edge advancement in dental materials, offering both strength and aesthetic appeal. These teeth are highly customizable, making them a preferred choice for high-end dental practices. For B2B buyers, the investment in biocompatible resin is often justified by the superior results and longevity, although the higher cost and need for specialized equipment can be a barrier for some businesses.

Key Industrial Applications of moldable false teeth

| Industry/Sector | Specific Application of moldable false teeth | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dental Clinics | Custom prosthetics for patients | Enhanced patient satisfaction and comfort | Quality of materials, regulatory compliance, and customization options |

| Dental Laboratories | Prototyping for dental products | Accelerated product development and testing | Material consistency, delivery timelines, and technical support |

| Educational Institutions | Training tools for dental students | Improved hands-on learning experiences | Durability of materials, safety standards, and cost-effectiveness |

| Medical Equipment Suppliers | Supply for emergency dental kits | Readiness for disaster response and patient care | Bulk purchasing options, shelf-life of products, and compliance with health regulations |

| Cosmetic Dentistry | Aesthetic enhancements for temporary solutions | Increased service offerings and patient retention | Material aesthetics, ease of use, and patient feedback mechanisms |

How Are Moldable False Teeth Utilized in Dental Clinics?

In dental clinics, moldable false teeth are employed to create custom prosthetics tailored to individual patient needs. These products enhance patient satisfaction by providing a comfortable fit and natural appearance. For international buyers, especially in regions like Africa and South America, considerations around material quality and compliance with local health regulations are crucial. Sourcing from reputable manufacturers ensures that clinics can meet patient demands effectively while adhering to safety standards.

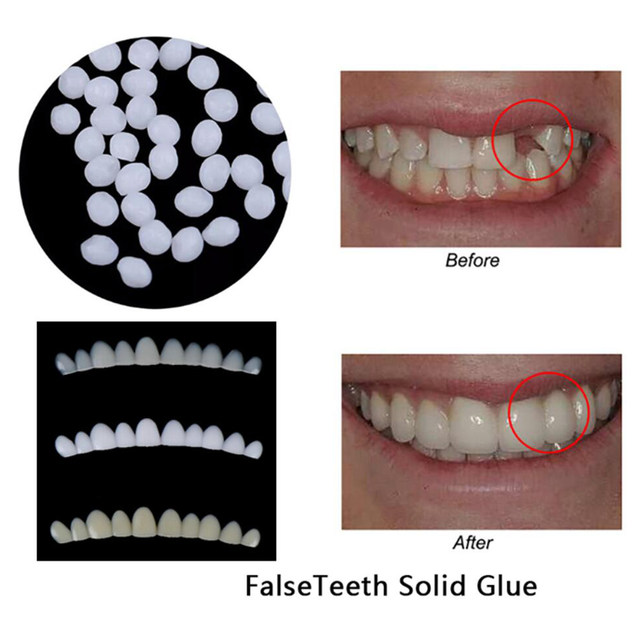

Illustrative image related to moldable false teeth

What Role Do Moldable False Teeth Play in Dental Laboratories?

Dental laboratories leverage moldable false teeth for rapid prototyping of dental products. This application allows for accelerated product development cycles, enabling labs to test and refine designs before full-scale production. For B2B buyers in Europe and the Middle East, ensuring material consistency and having reliable delivery timelines are key factors. Additionally, technical support from suppliers can facilitate smoother integration of these products into existing workflows.

How Are Moldable False Teeth Beneficial for Educational Institutions?

Educational institutions, particularly those offering dental programs, utilize moldable false teeth as training tools. These products provide dental students with realistic hands-on experiences, enhancing their learning outcomes. For buyers in this sector, durability and adherence to safety standards are vital. Sourcing cost-effective solutions without compromising quality will also ensure that institutions can provide adequate training resources while managing budgets effectively.

Why Are Moldable False Teeth Important for Medical Equipment Suppliers?

Medical equipment suppliers include moldable false teeth in emergency dental kits, which are essential for disaster response scenarios. These kits allow healthcare providers to offer immediate care to patients in urgent situations. International buyers must consider bulk purchasing options and the shelf-life of these products to ensure readiness. Compliance with health regulations is also critical to maintain the integrity and safety of the supplies.

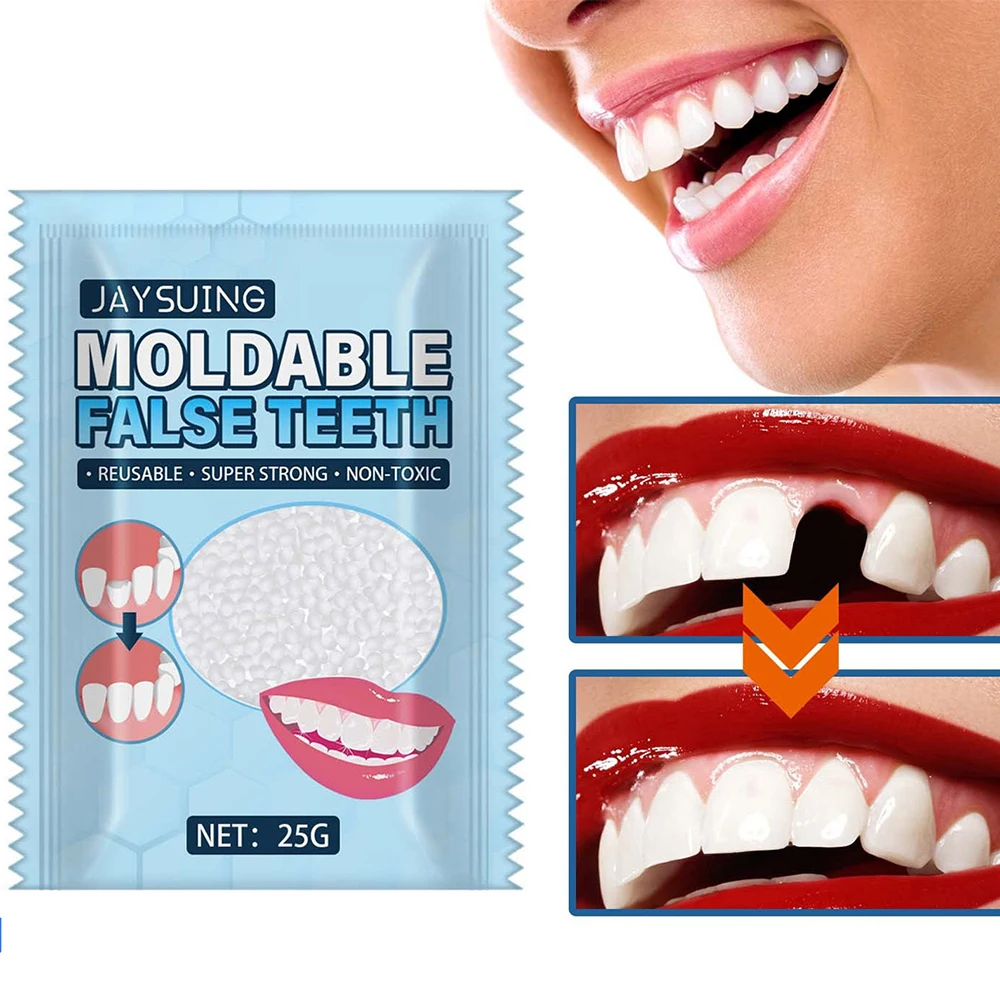

Illustrative image related to moldable false teeth

How Do Moldable False Teeth Enhance Services in Cosmetic Dentistry?

In cosmetic dentistry, moldable false teeth are used for aesthetic enhancements, providing temporary solutions that can improve patient appearance and confidence. This application allows dental practices to expand their service offerings, potentially increasing patient retention. For B2B buyers, the aesthetics of the materials used, ease of application, and mechanisms for gathering patient feedback are essential factors to consider when sourcing these products.

3 Common User Pain Points for ‘moldable false teeth’ & Their Solutions

Scenario 1: Difficulty in Achieving a Comfortable Fit

The Problem: Many B2B buyers, particularly dental clinics and prosthetic suppliers, encounter significant challenges in ensuring that moldable false teeth fit comfortably for their patients. The process of molding can lead to discrepancies in fit due to variations in temperature, timing, and application techniques. A poor fit not only causes discomfort for users but can also lead to dissatisfaction with the product, resulting in increased returns and negative reviews.

The Solution: To overcome this issue, buyers should invest in training their staff on the best practices for using moldable false teeth. This includes proper heating methods, such as using water at controlled temperatures to avoid overheating the material. Additionally, incorporating a step-by-step instructional guide or video can enhance the molding process. Providing patients with a detailed fitting session that allows for adjustments can also improve the comfort level significantly. Partnering with suppliers who offer high-quality materials that have a wider temperature tolerance can further minimize fitting issues.

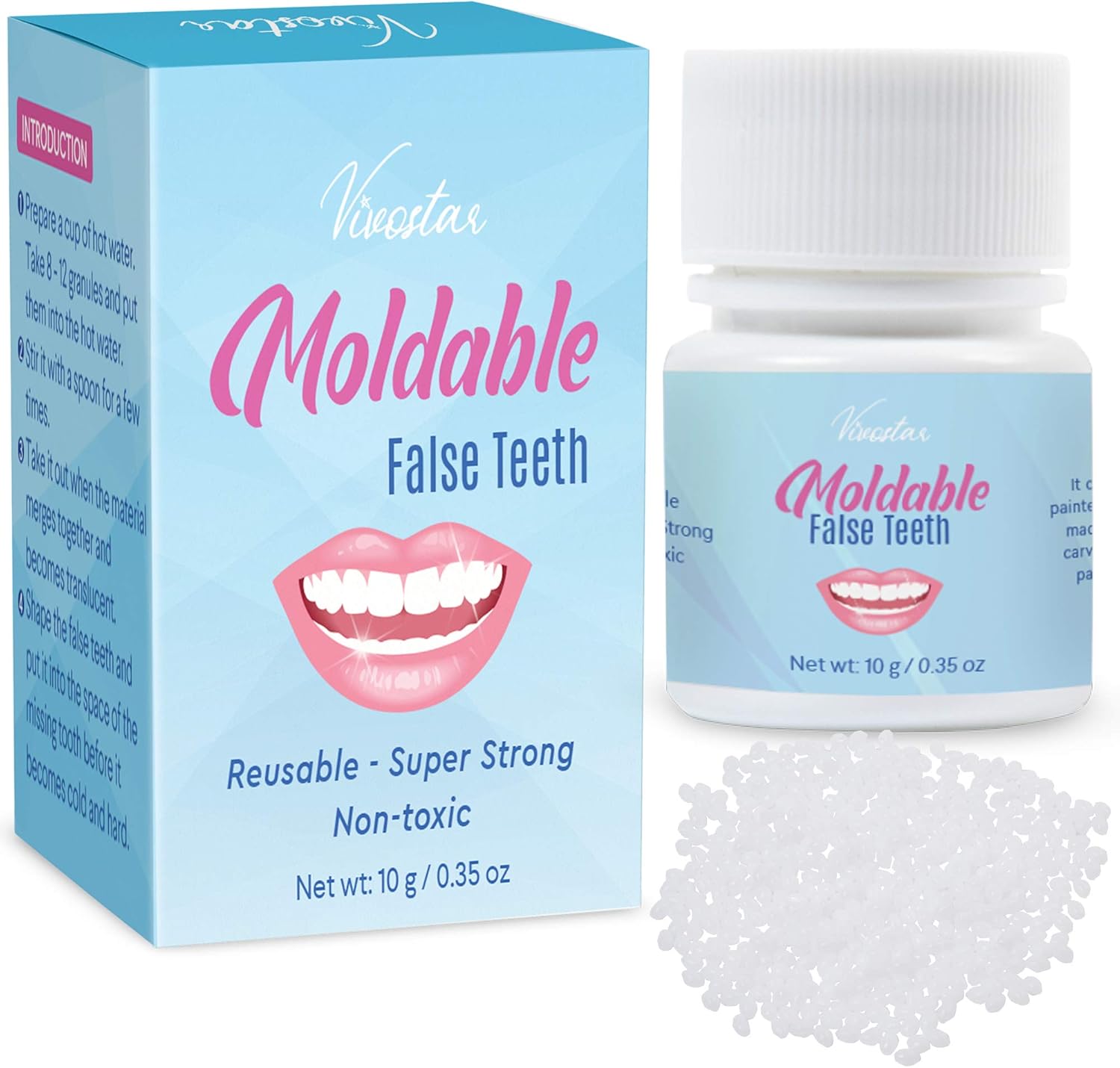

Illustrative image related to moldable false teeth

Scenario 2: Concerns About Durability and Longevity

The Problem: B2B buyers are often worried about the durability of moldable false teeth. There is a perception that these products do not last as long as traditional dentures, leading to concerns over repeat purchases and customer satisfaction. This is particularly critical in markets where cost sensitivity is high, as clients expect value for their investment.

The Solution: To address durability concerns, buyers should focus on sourcing moldable false teeth made from advanced materials that have proven longevity. Engaging with manufacturers who provide data on the material’s wear resistance and lifespan is essential. Additionally, offering warranties or guarantees can instill confidence in customers. Providing care instructions and maintenance tips can also help users prolong the life of their teeth, ensuring that they remain satisfied and return for future purchases.

Scenario 3: Limited Customization Options

The Problem: A common pain point for B2B buyers is the limited customization options available with standard moldable false teeth. Different patients have varying aesthetic preferences and dental needs, which can make it challenging for buyers to meet all their clients’ expectations. This lack of customization can lead to a feeling of dissatisfaction and might push customers toward competitors who offer more tailored solutions.

Illustrative image related to moldable false teeth

The Solution: To enhance customization, B2B buyers should collaborate with manufacturers that offer a range of colors, shapes, and sizes for moldable false teeth. This can include creating a color palette that aligns with natural teeth shades and providing adjustable features for different dental needs. Offering a consultation service that allows patients to express their preferences can also enhance the customer experience. Furthermore, developing a feedback loop with clients to gather insights on desired features can guide future product development, ensuring that offerings remain competitive and aligned with market demand.

Strategic Material Selection Guide for moldable false teeth

When selecting materials for moldable false teeth, it is essential to consider various factors that impact product performance, manufacturing processes, and compliance with international standards. Below is a detailed analysis of four common materials used in the production of moldable false teeth, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What are the Key Properties of Thermoplastic Elastomers (TPE) for Moldable False Teeth?

Thermoplastic elastomers (TPE) are widely used in the dental industry due to their excellent flexibility and comfort. They exhibit a significant temperature range, allowing them to be molded at lower temperatures while maintaining structural integrity. TPEs are also resistant to various chemicals, which is crucial for dental applications that may involve exposure to oral fluids.

Illustrative image related to moldable false teeth

Pros & Cons: TPE offers high durability and is easy to process, making it suitable for mass production. However, they can be more expensive than traditional plastics, which might not be ideal for all markets. Additionally, while TPEs are versatile, they may not always provide the same level of hardness as other materials.

Impact on Application: TPEs are compatible with a range of media, including saliva and various oral hygiene products, ensuring longevity and comfort for users.

International Considerations: Buyers from regions such as Europe and the Middle East should ensure compliance with EU regulations regarding medical devices, while those in Africa and South America may need to consider local standards.

Illustrative image related to moldable false teeth

How Do Acrylic Resins Compare for Moldable False Teeth?

Acrylic resins are another common choice for moldable false teeth due to their excellent aesthetic qualities and strength. They can be easily molded and are available in a variety of colors, making them suitable for creating lifelike appearances.

Pros & Cons: Acrylics are relatively cost-effective and offer good durability. However, they can be brittle and may not withstand high-impact scenarios. Additionally, the manufacturing process can be complex, requiring precise temperature control to avoid defects.

Impact on Application: Acrylics are compatible with various dental adhesives and can be easily repaired if damaged, which is a significant advantage in dental applications.

International Considerations: Compliance with standards such as ASTM D256 for impact resistance is crucial for international buyers, particularly in Europe and North America.

What are the Benefits of Polyvinyl Chloride (PVC) in Moldable False Teeth?

Polyvinyl chloride (PVC) is a versatile plastic known for its durability and resistance to environmental factors. It can be formulated to be flexible or rigid, making it adaptable for various dental applications.

Pros & Cons: PVC is cost-effective and readily available, making it a popular choice for manufacturers. However, it can be less comfortable than TPE or acrylics, and there may be concerns about its long-term biocompatibility.

Impact on Application: PVC is resistant to moisture and chemicals, making it suitable for dental applications that require durability under varying conditions.

International Considerations: Buyers should be aware of regulations regarding phthalate content in PVC, especially in the European market, where compliance with REACH regulations is mandatory.

Illustrative image related to moldable false teeth

Why Consider Silicone Rubber for Moldable False Teeth?

Silicone rubber is gaining popularity in dental applications due to its excellent biocompatibility and flexibility. It can withstand a wide range of temperatures and is resistant to UV light and ozone, making it suitable for long-term use.

Pros & Cons: Silicone offers superior comfort and is highly durable, but it tends to be more expensive than other materials. The manufacturing process can also be more complex, requiring specialized equipment.

Impact on Application: Silicone’s compatibility with various oral products enhances its usability in dental applications, ensuring a comfortable fit for users.

International Considerations: Buyers should ensure that silicone products meet ISO 10993 standards for biocompatibility, especially in markets with strict regulatory requirements.

Summary Table of Material Selection for Moldable False Teeth

| Material | Typical Use Case for moldable false teeth | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic Elastomers (TPE) | Flexible, comfortable false teeth | High durability and comfort | Higher cost than traditional plastics | Medium |

| Acrylic Resins | Aesthetic false teeth with color options | Cost-effective and durable | Brittle and complex manufacturing | Low |

| Polyvinyl Chloride (PVC) | Durable, cost-effective false teeth | Resistant to moisture and chemicals | Less comfort and biocompatibility concerns | Low |

| Silicone Rubber | Flexible and biocompatible false teeth | Excellent comfort and durability | Higher cost and complex manufacturing | High |

This guide provides a comprehensive overview of material options for moldable false teeth, helping international B2B buyers make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for moldable false teeth

What Are the Key Stages in the Manufacturing Process of Moldable False Teeth?

The production of moldable false teeth involves several critical stages that ensure the final product is both functional and comfortable for users. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Moldable False Teeth?

The initial step in the manufacturing process is the preparation of raw materials. Typically, thermoplastic polymers are used due to their moldability and biocompatibility. Suppliers must ensure that these materials meet specific regulatory standards, which may vary by region. This preparation stage involves sourcing high-quality materials from reputable suppliers, verifying material certifications, and conducting initial quality assessments.

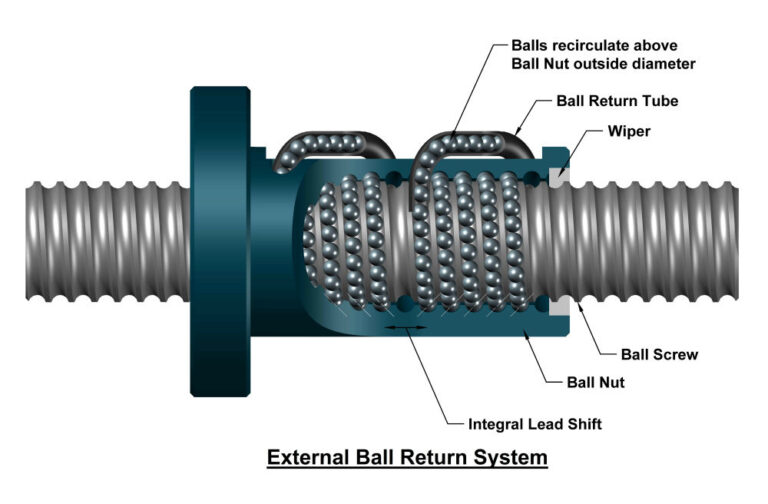

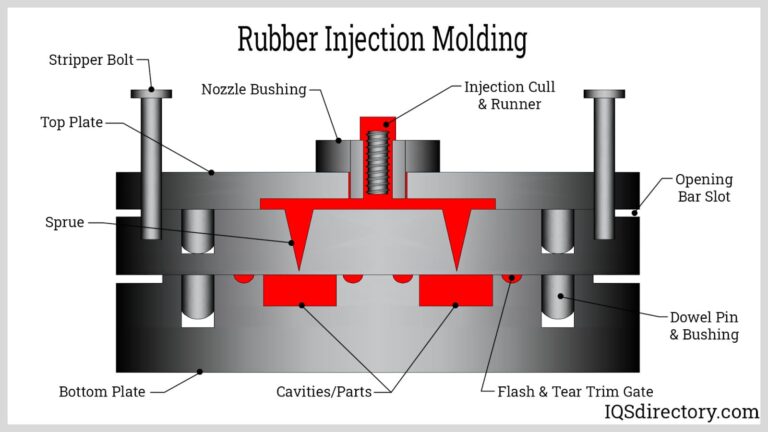

What Techniques Are Employed in the Forming Stage?

Once materials are ready, the forming process begins. This typically involves heating the thermoplastic to a malleable state, allowing it to be shaped into the desired form. Techniques such as injection molding or vacuum forming are commonly utilized. In injection molding, the heated material is injected into a mold under pressure, ensuring precision and uniformity. Vacuum forming, on the other hand, involves heating a sheet of plastic until it becomes pliable, then using a vacuum to pull it into a mold. Both methods require skilled operators to maintain the integrity of the mold and the material throughout the process.

Illustrative image related to moldable false teeth

What Are the Assembly and Finishing Processes for Moldable False Teeth?

After forming, the next phase is assembly, where the various components of the false teeth are joined together. This may include attaching clasps, adjusting fit, or integrating other features that enhance usability. Following assembly, the finishing process is crucial for ensuring the aesthetic appeal and functionality of the product. This step often involves polishing, painting, or applying surface treatments that enhance durability and comfort. Rigorous checks are performed to ensure that the teeth not only look appealing but also meet the required functional specifications.

What International Standards and Quality Assurance Measures Are Relevant?

Quality assurance (QA) is a vital aspect of manufacturing moldable false teeth, ensuring that products meet both safety and performance standards. International standards such as ISO 9001 provide a framework for quality management systems, focusing on consistent quality and customer satisfaction. Additionally, industry-specific certifications like CE marking (for European markets) and API (for specific medical applications) play a crucial role in validating product safety and efficacy.

How Is Quality Control Implemented Throughout the Manufacturing Process?

Quality control (QC) is implemented at various checkpoints throughout the manufacturing process. These checkpoints typically include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): This stage includes monitoring the manufacturing processes to catch any deviations or defects in real-time, allowing for immediate corrective actions.

- Final Quality Control (FQC): At this stage, finished products are thoroughly inspected and tested before shipment. This may involve checking dimensions, aesthetics, and functionality.

What Common Testing Methods Are Used for Moldable False Teeth?

Various testing methods are applied to ensure the quality of moldable false teeth. These may include mechanical testing to evaluate strength and durability, biocompatibility testing to confirm safety for human use, and aesthetic evaluations to ensure color and finish meet consumer expectations. Additionally, suppliers may conduct wear tests to simulate long-term usage and assess performance over time.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers must be diligent when evaluating suppliers’ quality control measures. One effective strategy is to conduct audits of potential suppliers, which can provide insight into their manufacturing processes and adherence to quality standards. Requesting quality assurance reports and certifications is also crucial; these documents should detail compliance with international standards such as ISO and CE. Furthermore, engaging third-party inspection services can add an additional layer of assurance, as these entities provide unbiased evaluations of the manufacturing processes and final products.

What Are the Nuances of Quality Control for International B2B Buyers?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Different regions may have specific regulatory requirements and standards that must be adhered to. For instance, European markets often require CE marking, which involves comprehensive testing and documentation to demonstrate compliance with EU regulations. Buyers should familiarize themselves with these regional standards and work closely with suppliers to ensure all necessary certifications are in place.

Moreover, language barriers and cultural differences can impact communication regarding quality expectations. Establishing clear lines of communication and regular updates can help mitigate misunderstandings and ensure that all parties are aligned on quality objectives.

Conclusion: Ensuring Quality in Moldable False Teeth Manufacturing

The manufacturing and quality assurance processes for moldable false teeth are intricate and demand strict adherence to international standards. By understanding the key stages of production, the importance of quality control, and how to verify supplier practices, B2B buyers can make informed decisions. Investing time in evaluating suppliers and their processes not only ensures compliance with quality standards but also enhances the overall reliability of the products offered in the market. This strategic approach will ultimately contribute to the success of businesses in the competitive landscape of dental products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘moldable false teeth’

To assist B2B buyers in procuring moldable false teeth, this guide provides a practical checklist to ensure a streamlined and efficient sourcing process. By following these steps, buyers can navigate the complexities of supplier selection, quality assurance, and compliance, ultimately leading to successful procurement.

1. Identify Your Target Market Needs

Understanding the specific requirements of your target market is crucial. Assess local preferences, demographic factors, and dental health trends in regions such as Africa, South America, the Middle East, and Europe. Tailoring your product offerings to meet these needs will enhance market acceptance and drive sales.

2. Define Your Technical Specifications

Establish clear technical specifications for the moldable false teeth you intend to source. This includes details like material composition, durability, aesthetics, and moldability features. Precise specifications will help you communicate effectively with suppliers and ensure that the products meet your quality standards.

3. Research and Shortlist Potential Suppliers

Conduct thorough research to identify suppliers specializing in dental products, particularly moldable false teeth. Look for suppliers with a proven track record and positive reviews. Utilize industry directories, trade shows, and online platforms to compile a list of potential candidates.

Illustrative image related to moldable false teeth

4. ✅ Verify Supplier Certifications

Before engaging with a supplier, it is essential to verify their certifications and compliance with industry standards. Check for relevant certifications such as ISO, CE marking, or FDA approval, depending on your target market. These certifications ensure that the products meet safety and quality regulations, which is critical for customer satisfaction and legal compliance.

5. Request Samples and Evaluate Quality

Once you have shortlisted suppliers, request product samples to evaluate quality firsthand. Pay attention to factors such as fit, comfort, and aesthetic appeal. Testing samples allows you to assess whether the products align with your defined specifications and meet your customers’ expectations.

6. Negotiate Pricing and Terms

Initiate negotiations with your chosen suppliers to discuss pricing, payment terms, and delivery schedules. Aim for a mutually beneficial agreement that considers both parties’ needs. Transparency in pricing and clear terms will help prevent misunderstandings and foster a positive working relationship.

7. Establish a Quality Assurance Process

Implement a robust quality assurance process to ensure consistent product quality. This may include regular inspections, compliance audits, and feedback loops with suppliers. Establishing quality benchmarks will help maintain high standards and reduce the risk of returns or customer dissatisfaction.

By following this checklist, B2B buyers can effectively navigate the sourcing process for moldable false teeth, ensuring that they select the right suppliers and products to meet their market’s needs.

Comprehensive Cost and Pricing Analysis for moldable false teeth Sourcing

What Are the Key Cost Components in Sourcing Moldable False Teeth?

When sourcing moldable false teeth, understanding the cost structure is critical for effective budgeting and decision-making. The primary cost components include:

-

Materials: The quality of the thermoplastic materials used directly impacts both the cost and the final product’s performance. Standard thermal beads or advanced polymers can vary significantly in price. Sourcing high-quality materials is essential for ensuring durability and user satisfaction.

-

Labor: Labor costs encompass the wages of skilled workers involved in production and assembly. In regions with lower labor costs, such as parts of Africa and South America, buyers may find competitive pricing. However, this should be balanced against the potential trade-offs in quality and expertise.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Understanding a supplier’s overhead can provide insight into their pricing strategy.

-

Tooling: Initial tooling costs for molds and production setups can be substantial. Buyers should inquire about these costs, especially if custom designs are required, as they can significantly affect overall pricing.

-

Quality Control (QC): Implementing stringent QC measures ensures that the moldable false teeth meet necessary standards. While this incurs additional costs, it can save money in the long run by reducing defects and returns.

-

Logistics: Transportation and shipping costs can vary widely based on the supplier’s location and the destination market. International buyers must account for potential tariffs and customs fees, which can add to the total cost.

-

Margin: Supplier profit margins can vary based on market demand, competition, and the uniqueness of their product offering. Understanding these margins can aid in negotiation.

How Do Price Influencers Affect Moldable False Teeth Costs?

Several factors can influence the pricing of moldable false teeth, particularly for B2B buyers:

-

Volume/MOQ: Purchasing in larger quantities often leads to better pricing. Suppliers typically offer discounts based on Minimum Order Quantities (MOQs), so negotiating the best deal is crucial.

-

Specifications and Customization: Custom molds or specific design requirements can increase costs. Buyers should clearly define their specifications to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., FDA approval) can raise the price. Buyers should weigh the benefits of these certifications against their budget constraints.

-

Supplier Factors: The reputation and reliability of a supplier can also affect pricing. Established suppliers may charge a premium for their experience and quality assurance.

-

Incoterms: Understanding Incoterms is essential for determining who bears the cost of shipping, insurance, and customs clearance. This can significantly impact the total landed cost of goods.

What Buyer Tips Can Help Optimize Costs When Sourcing Moldable False Teeth?

B2B buyers should consider the following strategies to enhance cost efficiency:

-

Negotiation: Engaging in thorough negotiations can lead to better pricing and terms. Establishing long-term relationships with suppliers may also yield favorable conditions.

-

Total Cost of Ownership (TCO): It’s crucial to consider not just the initial purchase price but the entire lifecycle cost of the product. This includes maintenance, replacement, and potential return costs.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, local taxes, and shipping times, which can affect pricing. Establishing clear communication regarding these factors with suppliers can mitigate risks.

-

Market Research: Conducting comprehensive market research on suppliers in various regions can reveal competitive pricing and innovative product offerings.

Conclusion

Navigating the complexities of sourcing moldable false teeth requires a comprehensive understanding of cost components, price influencers, and effective negotiation strategies. By prioritizing quality, leveraging volume purchases, and considering the total cost of ownership, international B2B buyers can make informed decisions that align with their business goals. Always remember that prices can vary widely based on these factors, so seeking multiple quotations and conducting thorough due diligence is advisable.

Alternatives Analysis: Comparing moldable false teeth With Other Solutions

Exploring Alternatives to Moldable False Teeth

In the dental prosthetics market, moldable false teeth present a unique solution for individuals seeking a customizable and cost-effective option. However, several alternative solutions exist that cater to different needs and preferences. Understanding these alternatives can empower international B2B buyers to make informed decisions based on performance, cost, and ease of use.

| Comparison Aspect | Moldable False Teeth | Pre-Made Dentures | 3D Printed Dentures |

|---|---|---|---|

| Performance | Custom fit, but may lack durability over time | Good fit, limited customization options | Highly precise fit and aesthetics |

| Cost | Low to moderate | Moderate to high | High initial investment but cost-effective for large orders |

| Ease of Implementation | Easy, requires minimal tools | Quick fit, but limited adjustments | Requires advanced technology and expertise |

| Maintenance | Simple, requires regular cleaning | Regular maintenance needed | Similar to traditional dentures, requires care |

| Best Use Case | Temporary solutions or for those on a budget | Long-term use for established users | Ideal for custom designs and precision needs |

What are the Pros and Cons of Pre-Made Dentures?

Pre-made dentures are a popular alternative that offers a balance of affordability and effectiveness. These dentures come ready to wear and can be fitted quickly, making them ideal for patients who need immediate solutions. However, they lack the customization that moldable false teeth provide, which may lead to discomfort or fit issues for some users. Additionally, while they are generally durable, the materials used may not last as long as those in custom-made solutions.

Illustrative image related to moldable false teeth

How Do 3D Printed Dentures Compare?

3D printed dentures represent a cutting-edge solution in dental prosthetics. Utilizing advanced printing technology, these dentures can be produced with high precision, ensuring a better fit and more natural appearance. This method allows for significant customization, accommodating individual patient needs more effectively than moldable options. However, the initial investment is higher due to the technology and expertise required for production, making it less accessible for smaller practices or those with budget constraints.

Conclusion: How Can B2B Buyers Choose the Right Dental Solution?

When selecting the right dental solution, B2B buyers must evaluate their specific needs, including patient demographics, budget constraints, and the desired level of customization. Moldable false teeth can be an excellent option for temporary or budget-conscious solutions, while pre-made dentures offer a quick fix with moderate durability. For practices seeking to provide high-quality, custom solutions, 3D printed dentures may be the best choice despite the higher costs. Ultimately, understanding the unique features and limitations of each option will guide buyers toward the most suitable product for their market.

Essential Technical Properties and Trade Terminology for moldable false teeth

What Are the Key Technical Properties of Moldable False Teeth?

When sourcing moldable false teeth, understanding the technical specifications is crucial for ensuring product quality and suitability for end-users. Here are several essential properties to consider:

1. Material Grade

The material used in moldable false teeth significantly affects their durability, comfort, and aesthetic appeal. Typically, materials like thermoplastic elastomers (TPE) or polyvinyl chloride (PVC) are used due to their flexibility and moldability. Higher-grade materials can enhance product lifespan and user satisfaction, making it essential for buyers to verify the material grade before procurement.

2. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. For moldable false teeth, tight tolerances ensure proper fit and comfort for the wearer. Inaccurate dimensions can lead to discomfort and affect the product’s functionality. Buyers must ensure that suppliers can meet specified tolerances to maintain quality standards.

3. Thermal Properties

The thermal properties of moldable false teeth indicate how they respond to heat. Products that can withstand high temperatures without losing their shape or functionality are preferable, especially for those requiring sterilization. Understanding thermal resistance is vital for ensuring that the teeth remain effective throughout their usage.

4. Moldability

Moldability is the ease with which the material can be shaped and adjusted. A high degree of moldability allows users to customize the fit of the false teeth, ensuring comfort and effectiveness. This property is particularly important for markets in regions where individual customization is a common practice.

Illustrative image related to moldable false teeth

5. Biocompatibility

Biocompatibility is a critical property for any dental product. Moldable false teeth must not cause adverse reactions when in contact with oral tissues. Ensuring that the materials used are biocompatible is essential for regulatory compliance and user safety, making it a top priority for B2B buyers.

6. Color Stability

Color stability refers to the ability of the material to retain its color over time, especially when exposed to various environmental factors. Moldable false teeth should maintain their aesthetic appearance for as long as possible, which is particularly important for consumer satisfaction. Buyers should inquire about colorfastness and any available options for customization.

What Are Common Trade Terminology and Jargon Related to Moldable False Teeth?

Familiarity with trade terminology is essential for effective communication and negotiation in the procurement of moldable false teeth. Here are some key terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand name. When sourcing moldable false teeth, buyers may engage with OEMs to create customized products that meet specific market needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is critical for B2B buyers to ensure they can meet demand without overcommitting to excessive inventory.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request price quotes for specific quantities of products. This process helps buyers compare prices and terms from multiple suppliers, making it an important step in the procurement process.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for understanding shipping costs, insurance, and delivery responsibilities, which can significantly impact the total cost of procurement.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. Understanding lead times is crucial for inventory management and planning, especially in regions with fluctuating demand.

6. Compliance Standards

Compliance standards refer to the regulations and quality standards that products must meet to be sold in specific markets. Buyers should ensure that moldable false teeth comply with local and international standards to avoid legal complications and ensure consumer safety.

Illustrative image related to moldable false teeth

By understanding these properties and terms, B2B buyers can make informed decisions when sourcing moldable false teeth, ensuring quality, compliance, and satisfaction for their customers.

Navigating Market Dynamics and Sourcing Trends in the moldable false teeth Sector

What are the Current Market Dynamics and Key Trends in the Moldable False Teeth Sector?

The moldable false teeth market is experiencing significant growth driven by rising dental health awareness and the increasing prevalence of dental issues worldwide. Key market dynamics include the expansion of the elderly population and the demand for affordable dental solutions, particularly in regions like Africa and South America where access to traditional dental care may be limited. Emerging trends in this sector focus on technological advancements in materials and manufacturing processes. For instance, the incorporation of thermal beads and thermoplastic materials enhances the user experience, allowing for easier molding and better fitting.

International B2B buyers are increasingly leveraging e-commerce platforms for sourcing moldable false teeth, recognizing the benefits of bulk purchasing and competitive pricing. Additionally, the rise of digital marketplaces facilitates connections between manufacturers and distributors, streamlining the supply chain. As buyers look for innovative solutions, the integration of smart technology, such as online fitting guides and augmented reality applications for product visualization, is also gaining traction.

Moreover, the COVID-19 pandemic has accelerated the shift toward online shopping and remote consultations, making it essential for suppliers to adapt their offerings to meet evolving customer needs. As such, businesses focusing on enhancing their digital presence and improving customer engagement are likely to gain a competitive edge in this dynamic market.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in the Moldable False Teeth Sector?

Sustainability and ethical sourcing are increasingly critical considerations for B2B buyers in the moldable false teeth sector. The environmental impact of dental products, particularly in terms of waste generation and plastic use, necessitates a commitment to sustainable practices. Buyers should prioritize suppliers that utilize eco-friendly materials, such as biodegradable polymers and recyclable packaging, to minimize their ecological footprint.

Furthermore, establishing ethical supply chains is vital to ensure that products are sourced responsibly. Buyers should seek out manufacturers that adhere to fair labor practices and have transparent sourcing policies. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

Investing in ‘green’ certifications not only demonstrates corporate social responsibility but can also enhance brand reputation and appeal to environmentally conscious consumers. As global regulatory frameworks tighten around sustainability, aligning sourcing strategies with these trends can provide a competitive advantage in the market.

How Has the Moldable False Teeth Sector Evolved Over Time?

The evolution of the moldable false teeth sector can be traced back to the early developments in dental prosthetics. Initially, false teeth were made from ivory and porcelain, which posed various challenges, including discomfort and poor fit. The introduction of moldable materials transformed the industry, allowing for personalized fittings that cater to individual patient needs.

In recent years, advancements in material science have led to the development of thermoplastic and thermal beads, which provide greater flexibility and ease of use. This shift has made moldable false teeth more accessible to a broader audience, particularly in emerging markets where affordability is paramount. As the sector continues to innovate, the focus is increasingly on creating products that not only meet functional requirements but also enhance the overall user experience.

Frequently Asked Questions (FAQs) for B2B Buyers of moldable false teeth

-

How do I choose the right supplier for moldable false teeth?

Selecting the right supplier involves several key factors. Start by assessing their manufacturing capabilities and quality certifications, such as ISO standards, to ensure consistency and safety in production. Request samples to evaluate product quality firsthand. Check for positive reviews and testimonials from other B2B clients, especially those in your region. Additionally, consider their ability to provide customized solutions to meet your specific market needs, as well as their responsiveness to inquiries and concerns. -

What are the typical minimum order quantities (MOQs) for moldable false teeth?

Minimum order quantities can vary significantly by supplier and market. Generally, MOQs for moldable false teeth range from 100 to 1,000 units, depending on the supplier’s production capabilities and your customization requirements. Always confirm MOQs before entering negotiations, as some suppliers may offer flexible terms for larger orders. Additionally, consider the potential for economies of scale, which can reduce per-unit costs as your order size increases. -

What customization options are available for moldable false teeth?

Most suppliers offer a range of customization options, including size, shape, color, and packaging. You may also have the option to incorporate branding elements, such as logos or specific design features tailored to your target market. Discuss your requirements with potential suppliers early in the negotiation process to ensure they can accommodate your needs. Be sure to request prototypes to evaluate the customization before committing to a large order. -

What payment terms should I expect when sourcing moldable false teeth?

Payment terms can vary widely among suppliers, but common practices include a 30% deposit upon order confirmation, with the remaining 70% due before shipping. Some suppliers may offer credit terms for established businesses, while others may require full payment upfront for first-time orders. Always negotiate terms that work for your cash flow and financial strategy, and ensure that you receive a clear invoice detailing all costs associated with the order. -

How can I ensure quality assurance (QA) for moldable false teeth?

Implementing a robust quality assurance process is crucial when sourcing moldable false teeth. Work with suppliers who have established QA protocols, including regular inspections and testing of materials. Request documentation of their QA processes and any relevant certifications. Additionally, consider conducting third-party inspections before shipment, especially for large orders, to verify that the products meet your quality standards and specifications. -

What logistics considerations should I keep in mind when importing moldable false teeth?

When importing moldable false teeth, consider shipping methods, customs regulations, and delivery timelines. Choose a reliable logistics partner experienced in handling medical or dental products to ensure compliance with local regulations. Factor in lead times for production and shipping, as well as potential delays at customs. Additionally, understand the total landed cost, including duties and taxes, to avoid surprises that could impact your profitability. -

How do I handle potential disputes with suppliers of moldable false teeth?

To minimize disputes, establish clear communication channels and expectations from the outset. Document all agreements, including product specifications, delivery timelines, and payment terms. In the event of a dispute, attempt to resolve issues directly with the supplier through open dialogue. If necessary, refer to your contract for dispute resolution procedures, which may include mediation or arbitration. Building a solid relationship with suppliers can also help mitigate future conflicts. -

What are the market trends influencing the demand for moldable false teeth?

The demand for moldable false teeth is influenced by several factors, including the aging population, increasing awareness of dental health, and advancements in dental technology. Growing markets in regions like Africa and South America highlight the need for affordable dental solutions. Additionally, the rise of e-commerce has made it easier for consumers to access these products. Staying informed about these trends can help you better position your offerings and meet the evolving needs of your target audience.

Top 5 Moldable False Teeth Manufacturers & Suppliers List

1. eBay – Moldable False Teeth

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Moldable False Teeth available on eBay. Various options include: Teeth Repair Temporary Fix Kit Fitting Beads Reusable Fast Moldable False Tooth priced at $13.49, DIY Denture Basic Kit for $54.99, Resin False Teeth Solid Glue Temporary Tooth Gap Filler for $8.98, and Tooth Repair Granules Temporary Kit for $10.35. Most products are brand new and offer free delivery. Locations include South San Fra…

2. Pinterest – Moldable False Teeth Kit

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Moldable False Teeth, Temporary Tooth Repair Kit, Thermal Fitting Beads for Snap On Instant Smile, includes Mouth Mirror, Mouth Tweezer, Dental Probe, suitable for men and women, perfect for temporary fillings and fixing smiles, available on Amazon and Shopee, includes resin false teeth that fit solid glue, and is reusable and easy to mold with boiling water.

3. DentalPro – Moldable False Teeth

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Moldable False Teeth, temporary fillings, cavities, shapeable dental gel, comfortable fit, easy to use, portable, on-the-go fixes.

4. Reddit – Moldable False Teeth

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Moldable false teeth that can be shaped to fit the user’s mouth, similar to instant veneers. The product is mentioned in the context of providing a temporary solution for individuals with dental issues, specifically for those who have experienced damage to their front teeth.

5. Lunaanda – Temporary Tooth Repair Kits

Domain: amazon.ie

Registered: 2000 (25 years)

Introduction: {“Product Name”: “Temporary Tooth Repair Kits”, “Brand”: “Lunaanda”, “Price”: “€6.56”, “Rating”: “3.2 out of 5 stars”, “Key Features”: [{“Tooth Repair Granules”: “Reliable solution to fill and repair missing or broken teeth spaces, suitable for immediate and temporary use.”}, {“User-friendly”: “Easy-to-follow instructions for crafting temporary teeth, made from high-quality, safe, and non-toxic ma…

Strategic Sourcing Conclusion and Outlook for moldable false teeth

Moldable false teeth represent a growing segment within the dental care market, driven by increasing consumer demand for customizable and affordable dental solutions. Strategic sourcing of these products offers significant advantages, including improved supplier relationships, enhanced product quality, and cost efficiency. By understanding the diverse needs of international markets, particularly in Africa, South America, the Middle East, and Europe, B2B buyers can effectively navigate the complexities of sourcing moldable false teeth.

Investing in high-quality materials and innovative manufacturing processes is crucial for suppliers aiming to meet the expectations of discerning consumers. Additionally, staying informed about regional regulatory standards and market trends will empower buyers to make strategic decisions that align with their business goals.

Looking ahead, the market for moldable false teeth is poised for expansion, driven by technological advancements and increasing awareness of dental health. International B2B buyers are encouraged to leverage strategic partnerships and adopt a proactive sourcing approach to capitalize on emerging opportunities. By doing so, they can ensure their offerings remain competitive and relevant in a rapidly evolving marketplace. Embrace the future of dental solutions today—invest in strategic sourcing for moldable false teeth and position your business for sustained success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to moldable false teeth

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.