Unlocking Value: A Strategic Analysis of the Material Wheel Market

Introduction: Navigating the Global Market for material wheel

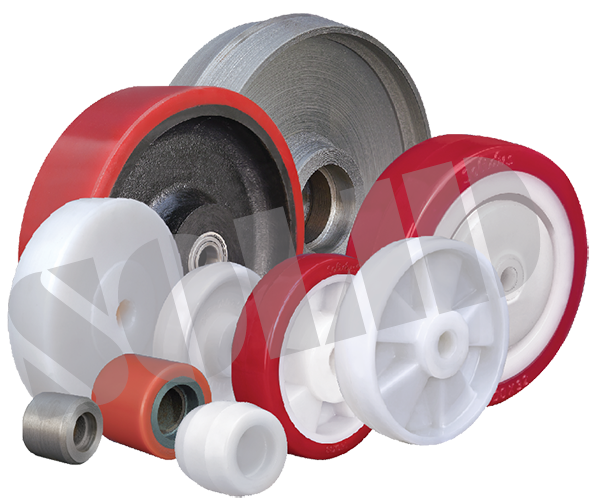

In today’s rapidly evolving global market, sourcing the right material wheel can pose significant challenges for international B2B buyers. Whether you are in the construction, manufacturing, or logistics sectors, the need for high-quality, durable wheels tailored to specific applications is critical. This guide delves into the diverse world of material wheels, exploring various types including those made from metals, plastics, and composites, and their respective applications across industries.

By providing insights into supplier vetting processes, cost considerations, and performance metrics, this comprehensive resource empowers businesses in regions such as Africa, South America, the Middle East, and Europe—particularly in emerging markets like Vietnam and Nigeria—to make informed purchasing decisions. Understanding the nuances of different materials and their suitability for various operational environments is crucial for enhancing efficiency and ensuring product longevity.

Additionally, we will address key factors that influence the selection process, from load capacity and environmental resilience to maintenance requirements. This guide aims to equip B2B buyers with the knowledge and confidence needed to navigate the complexities of sourcing material wheels, ultimately leading to improved operational outcomes and a competitive edge in the global marketplace.

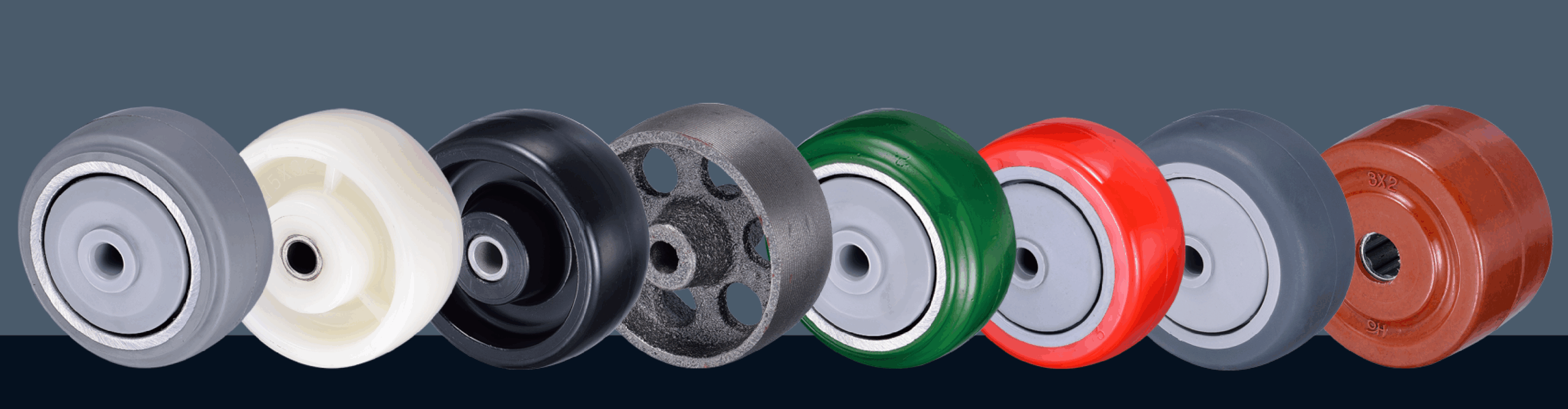

Understanding material wheel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Composite Material | Combination of two or more materials for enhanced properties | Aerospace, automotive, construction | Pros: Lightweight, high strength. Cons: Higher cost, complex manufacturing. |

| Metal Wheels | Durable and often used in heavy-duty applications | Industrial machinery, construction equipment | Pros: Long-lasting, high load capacity. Cons: Can rust without proper treatment. |

| Plastic Wheels | Lightweight and corrosion-resistant | Material handling, furniture | Pros: Cost-effective, versatile. Cons: Limited load capacity compared to metals. |

| Rubber Wheels | Excellent shock absorption and traction | Transportation, medical equipment | Pros: Quiet operation, good grip. Cons: Wear over time, less suited for heavy loads. |

| Ceramic Wheels | High hardness and wear resistance | Manufacturing, high-temperature applications | Pros: Exceptional durability, heat resistant. Cons: Brittle, can be expensive. |

What Are the Characteristics of Composite Material Wheels?

Composite material wheels are engineered from a combination of two or more different materials, providing enhanced properties such as strength, durability, and weight reduction. These wheels are particularly suitable for industries like aerospace and automotive where performance and efficiency are paramount. When considering B2B purchases, companies should evaluate the specific performance needs, as well as the potential for higher upfront costs due to advanced manufacturing processes.

How Do Metal Wheels Compare for Heavy-Duty Applications?

Metal wheels are recognized for their durability and ability to handle heavy loads, making them ideal for industrial machinery and construction equipment. Commonly made from steel or aluminum, they can withstand harsh environments. Buyers should consider their specific application needs, including load capacity and environmental factors, as well as the necessity for protective coatings to prevent rust and corrosion.

What Benefits Do Plastic Wheels Offer in Various Industries?

Plastic wheels are lightweight, corrosion-resistant, and often more cost-effective than their metal counterparts. They are widely used in material handling and furniture applications due to their versatility. However, buyers should note their limitations in load capacity compared to metal wheels. When purchasing, it’s essential to assess the intended use and weight requirements to ensure optimal performance.

Why Choose Rubber Wheels for Transportation and Medical Equipment?

Rubber wheels are favored for their excellent shock absorption and traction, making them suitable for transportation and medical equipment. They provide a quiet operation, which is beneficial in settings like hospitals. However, they may wear out faster than other materials under heavy loads. Buyers should consider the environment and expected usage frequency to determine if rubber wheels meet their longevity and performance expectations.

What Are the Advantages and Limitations of Ceramic Wheels?

Ceramic wheels are known for their high hardness and wear resistance, making them ideal for manufacturing and high-temperature applications. They offer exceptional durability but can be brittle and more expensive. B2B buyers must weigh the benefits of longevity and performance against the potential for breakage and higher costs, ensuring they choose the right type for their specific industrial needs.

Key Industrial Applications of material wheel

| Industry/Sector | Specific Application of Material Wheel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Precision machining and cutting of components using grinding wheels | Enhanced productivity and accuracy in production processes | Material durability, compatibility with machinery, and cost efficiency |

| Construction | Use of concrete and masonry cutting wheels | Improved efficiency in cutting and shaping construction materials | Availability of specific wheel types for different materials |

| Automotive | Wheel manufacturing and tire production | Streamlined production and reduced waste in manufacturing | Quality of materials, adherence to industry standards, and supplier reliability |

| Aerospace | Composite material cutting and shaping | High precision and safety in manufacturing aerospace components | Certification of materials, weight considerations, and sourcing from compliant suppliers |

| Arts and Crafts | Cutting and shaping various materials for artistic projects | Versatility and creativity in project execution | Range of material options, pricing, and supplier support for bulk purchases |

How is the Material Wheel Used in Manufacturing?

In the manufacturing sector, the material wheel is integral to precision machining, particularly with grinding wheels designed for cutting and shaping metal components. These wheels enhance productivity by enabling faster and more accurate machining processes. International buyers should prioritize sourcing grinding wheels that offer durability and compatibility with their existing machinery. Additionally, cost efficiency is crucial, especially for manufacturers in regions like Africa and South America, where budget constraints may be significant.

What Role Does the Material Wheel Play in Construction?

In construction, specific applications of the material wheel include concrete and masonry cutting wheels. These tools improve efficiency in cutting and shaping various construction materials, making them essential for contractors and builders. Buyers should consider the availability of different wheel types tailored for specific materials, as well as their performance in local conditions. For companies in the Middle East and Europe, sourcing from reliable suppliers who understand regional construction standards is vital.

How is the Material Wheel Applied in the Automotive Industry?

The automotive industry utilizes the material wheel for manufacturing wheels and tires, where precise cutting and shaping are paramount. This application streamlines production processes and reduces material waste, leading to cost savings. Buyers in this sector must focus on the quality of materials used in wheel manufacturing, ensuring adherence to industry standards. Sourcing from reliable suppliers who can guarantee consistent quality is essential for automotive manufacturers in emerging markets.

In What Ways is the Material Wheel Beneficial for Aerospace Applications?

In the aerospace sector, the material wheel is crucial for cutting and shaping composite materials used in aircraft manufacturing. The high precision required in this industry ensures safety and performance in aerospace components. Buyers should look for certified materials and suppliers who meet stringent aerospace standards. Weight considerations are also critical, as lighter materials can enhance fuel efficiency, making it essential for buyers in Europe and other advanced markets to prioritize these factors.

How Does the Material Wheel Enhance Arts and Crafts Projects?

The material wheel finds a valuable place in arts and crafts, allowing artists to cut and shape a variety of materials, from wood to textiles. This versatility fosters creativity and enables the execution of diverse projects. For international buyers, sourcing a wide range of material options at competitive prices is essential, as is ensuring reliable supplier support for bulk purchases. Understanding local artistic trends can also guide buyers in selecting the most relevant materials for their markets.

3 Common User Pain Points for ‘material wheel’ & Their Solutions

Scenario 1: Difficulty in Material Selection for Specific Applications

The Problem: B2B buyers often struggle with selecting the right material from a diverse range of options available in a material wheel, especially when the application requires specific properties such as strength, weight, or thermal resistance. For instance, a manufacturer in Nigeria may need a lightweight yet durable material for aerospace components but finds it overwhelming to sift through metals, composites, and plastics that all claim to be suitable. This indecision can lead to project delays and increased costs.

The Solution: To effectively navigate material selection, buyers should start by clearly defining the requirements of their specific application, including mechanical properties, environmental considerations, and cost constraints. Utilizing a structured approach, such as a decision matrix, can help weigh the pros and cons of different materials. For example, if lightweight and strength are priorities, the buyer might focus on carbon fiber or aluminum alloys. Additionally, leveraging digital tools and databases that provide comparative analysis on material properties can significantly streamline the decision-making process. Engaging with suppliers who offer samples or prototype materials can also provide practical insights and help buyers make informed choices.

Scenario 2: Inconsistent Quality Across Suppliers

The Problem: Another common pain point is the inconsistency in quality and specifications when sourcing materials from different suppliers. For example, a construction firm in South America may order concrete mixes or metals only to find variations in strength and composition, impacting the integrity of their projects. This inconsistency can lead to costly rework, project delays, and damaged relationships with clients.

The Solution: To mitigate quality issues, B2B buyers should establish clear and stringent quality standards that all suppliers must meet. This includes requiring certifications for materials, such as ISO standards, and conducting regular audits of suppliers to ensure compliance. Implementing a robust vendor management system can help track supplier performance over time, enabling buyers to identify reliable partners. Additionally, fostering strong communication channels with suppliers can facilitate immediate feedback and resolution of quality concerns. Utilizing third-party testing services for critical materials can provide an extra layer of assurance, ensuring that every batch meets the required specifications before it is utilized in production.

Scenario 3: Lack of Knowledge About Material Properties and Applications

The Problem: Many buyers are not fully versed in the properties and potential applications of various materials on the wheel. This gap in knowledge can lead to poor material choices that don’t meet the performance criteria necessary for the intended use. For instance, a textile manufacturer in Europe might be unaware of the benefits of synthetic fibers over traditional materials, resulting in products that do not meet market demands for durability and performance.

The Solution: To bridge this knowledge gap, companies should invest in training and development programs for their procurement teams. Workshops, webinars, and online courses can provide essential insights into material properties, applications, and innovations. Buyers can also benefit from partnerships with material experts or consultants who can offer tailored advice based on current industry trends and advancements. Creating an internal knowledge repository where team members can share insights and experiences regarding material performance can also enhance collective understanding. Moreover, attending industry trade shows or conferences can expose buyers to the latest materials and technologies, providing them with the knowledge needed to make more informed procurement decisions.

Strategic Material Selection Guide for material wheel

What Are the Key Properties of Common Materials Used in Material Wheels?

When selecting materials for wheels in various applications, it is crucial to consider properties such as temperature and pressure ratings, corrosion resistance, and overall material performance. Here, we analyze four common materials used in manufacturing wheels: metals, plastics, rubber, and composites.

How Do Metals Perform as Wheel Materials?

Metals, particularly steel and aluminum, are widely used in wheel manufacturing due to their strength and durability. Steel wheels often have high-temperature resistance and can withstand significant pressure, making them suitable for heavy-duty applications. Aluminum, while lighter, offers good corrosion resistance and is often used in environments where weight savings are essential.

Pros: Metals are highly durable and can handle heavy loads. They are also recyclable, which can be a significant advantage for environmentally conscious companies.

Cons: The main drawbacks include higher costs and susceptibility to rust and corrosion if not properly treated. Additionally, metal wheels can be noisy and may require more complex manufacturing processes.

Impact on Application: Metal wheels are ideal for industrial settings where heavy loads and durability are priorities, such as manufacturing plants and construction sites.

Considerations for International Buyers: Compliance with standards like ASTM for metals is crucial. Buyers should also consider the local availability of metals and the impact of tariffs on international purchases.

What Advantages Do Plastics Offer for Wheel Manufacturing?

Plastic wheels, made from materials like nylon or polypropylene, are lightweight and resistant to corrosion. They can operate effectively in environments with moisture and chemicals, making them suitable for various applications, including food processing and pharmaceuticals.

Pros: The lightweight nature of plastic wheels reduces overall equipment weight, which can enhance efficiency. They are also less expensive to manufacture compared to metal wheels.

Cons: However, plastic wheels may not support as heavy a load as metal wheels and can wear out faster under high-stress conditions. They can also be less heat-resistant.

Impact on Application: Plastic wheels are often used in applications where weight and corrosion resistance are critical, such as in hospitals or cleanroom environments.

Considerations for International Buyers: Compliance with food safety standards (e.g., FDA regulations) is essential for buyers in the food industry. Additionally, local manufacturing capabilities may affect availability and cost.

How Does Rubber Compare as a Wheel Material?

Rubber wheels are known for their excellent shock absorption and grip, making them ideal for applications requiring mobility on uneven surfaces. They are often used in trolleys and carts.

Pros: Rubber wheels provide smooth operation and are less damaging to floors. They also offer good resistance to wear and tear.

Cons: The main limitations include susceptibility to temperature extremes, which can cause degradation. Rubber wheels may also have a shorter lifespan compared to metal options.

Impact on Application: They are particularly effective in environments where noise reduction and floor protection are priorities, such as in hospitals and retail spaces.

Considerations for International Buyers: Buyers should ensure compliance with local environmental regulations regarding rubber materials. Additionally, understanding local market preferences for wheel types can guide purchasing decisions.

What Role Do Composites Play in Wheel Manufacturing?

Composite materials, such as fiberglass or carbon fiber, offer a unique combination of strength and lightweight properties. They are increasingly used in specialized applications, including aerospace and high-performance vehicles.

Pros: Composites are resistant to corrosion and can be engineered for specific performance characteristics, making them versatile.

Cons: The primary drawbacks include higher manufacturing costs and complexity. Additionally, not all composite materials are suitable for heavy loads.

Impact on Application: Composites are ideal for applications requiring high performance and low weight, such as in racing or specialized industrial equipment.

Considerations for International Buyers: Compliance with international standards for composites, such as those set by ISO, is critical. Buyers should also assess local suppliers’ capabilities to meet their specific needs.

Summary Table of Material Selection for Material Wheels

| Material | Typical Use Case for material wheel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Metals | Heavy-duty industrial applications | High durability and load capacity | Higher cost, potential corrosion | High |

| Plastics | Food processing, pharmaceuticals | Lightweight and corrosion-resistant | Lower load capacity, wear over time | Medium |

| Rubber | Trolleys, carts | Shock absorption and floor protection | Temperature sensitivity, shorter lifespan | Medium |

| Composites | Aerospace, high-performance vehicles | Customizable performance characteristics | High cost, complexity in manufacturing | High |

This guide provides a comprehensive overview of material options for wheels, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for material wheel

What Are the Key Stages in the Manufacturing Process of Material Wheels?

The manufacturing process of material wheels involves several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a crucial role in ensuring the final product meets the required specifications and performance standards.

How Is Material Prepared for Wheel Manufacturing?

Material preparation is the first step in the manufacturing process. Depending on the type of wheel being produced—be it composite, metal, or plastic—different raw materials are sourced. For instance, metal wheels might utilize high-grade steel or aluminum, while plastic wheels may rely on high-density polyethylene or polypropylene. Suppliers often focus on quality sourcing, ensuring materials meet specific industry standards.

Once sourced, materials undergo initial quality checks to identify defects or inconsistencies. This step is crucial, as any flaws in the raw materials can compromise the integrity of the final product.

What Techniques Are Used in Forming Material Wheels?

The forming stage involves transforming raw materials into the desired shape. Techniques vary based on the material type:

-

Casting: Commonly used for metal wheels, this technique involves pouring molten metal into molds. It allows for complex shapes and high precision.

-

Injection Molding: Predominantly used for plastic wheels, this process injects molten plastic into molds under high pressure, ensuring uniformity and strength.

-

CNC Machining: For precision parts, CNC (Computer Numerical Control) machining is employed. This technique allows for the creation of intricate designs with tight tolerances.

-

Die Cutting: In textile wheels, die cutting is utilized to shape materials into specific designs, enhancing performance and durability.

Each technique has its benefits and is chosen based on the wheel’s intended application, weight-bearing capacity, and environmental factors.

How Are Material Wheels Assembled?

The assembly stage involves combining various components to create the final wheel product. For multi-part wheels, such as those incorporating bearings or hubs, precision is critical to ensure smooth operation.

Components are typically assembled using automated machinery, which enhances efficiency and consistency. Manual assembly may also be utilized for complex designs requiring human oversight. After assembly, wheels undergo initial functional tests to verify they meet performance criteria before proceeding to the finishing stage.

What Finishing Techniques Are Applied to Material Wheels?

Finishing processes are essential for enhancing the aesthetic appeal and functional durability of material wheels. Common finishing techniques include:

-

Surface Treatment: Methods such as powder coating or anodizing are applied to metal wheels to improve corrosion resistance and surface hardness.

-

Polishing and Buffing: For aesthetic appeal, especially in consumer-facing products, wheels may undergo polishing to achieve a high-gloss finish.

-

Quality Coatings: Depending on the application, specialized coatings can be applied to enhance wear resistance and reduce friction.

These finishing touches not only improve the visual appeal of the wheels but also extend their lifespan and performance in various conditions.

What Quality Control Standards Are Relevant for Material Wheel Manufacturing?

Quality assurance is paramount in the manufacturing of material wheels, particularly for B2B buyers who require reliable products. Adherence to international standards such as ISO 9001 ensures that manufacturers maintain a consistent quality management system.

In addition to ISO standards, industry-specific certifications can provide added assurance. For example, CE marking is essential for products sold in Europe, while API (American Petroleum Institute) certifications may be necessary for wheels used in oil and gas applications.

How Are Quality Control Checkpoints Implemented During Manufacturing?

Quality control checkpoints are strategically placed throughout the manufacturing process.

-

Incoming Quality Control (IQC): This initial checkpoint assesses raw materials upon arrival. Any materials not meeting specifications are rejected.

-

In-Process Quality Control (IPQC): During manufacturing, regular checks are conducted to ensure that processes remain within established parameters. This includes monitoring temperature, pressure, and material consistency.

-

Final Quality Control (FQC): After assembly, wheels undergo rigorous testing for performance, durability, and safety. This may include load testing, rolling resistance assessments, and dimensional checks.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial for building trust and ensuring product reliability. Here are some actionable steps:

-

Supplier Audits: Conducting on-site audits allows buyers to review quality control processes and compliance with international standards firsthand.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their testing methods and outcomes.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the manufacturing process and quality standards.

What Nuances Should International Buyers Consider Regarding Quality Control?

International buyers must navigate various nuances when it comes to quality control. Different countries may have varying regulations and standards, making it essential to understand local compliance requirements.

Additionally, language barriers and cultural differences can impact communication about quality expectations. Establishing clear quality agreements and maintaining open lines of communication can help mitigate misunderstandings.

Overall, understanding the manufacturing processes and quality assurance practices for material wheels is vital for B2B buyers. By focusing on these aspects, buyers can ensure they procure high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘material wheel’

In the fast-paced world of B2B procurement, understanding the nuances of sourcing materials is crucial, especially when it comes to specialized products like material wheels. This checklist serves as a comprehensive guide to help international buyers navigate the sourcing process effectively, ensuring they make informed decisions that align with their operational needs.

Illustrative image related to material wheel

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the foundation of a successful sourcing process. Specify the type of material wheel you need based on factors such as load capacity, wheel diameter, and intended surface use. This clarity helps suppliers tailor their offerings to meet your exact needs, reducing the risk of acquiring unsuitable products.

- Consider application requirements: Identify whether the wheels will be used for heavy-duty industrial applications or lighter tasks, as this influences material choice and design.

Step 2: Research Material Options

Different applications require different materials for wheels, each with unique properties. Familiarize yourself with options like rubber, polyurethane, metal, and composite materials, understanding their strengths and weaknesses in relation to your requirements.

- Analyze durability and performance: For instance, polyurethane wheels are often preferred for their resistance to wear and tear, while metal wheels may be more suitable for extreme conditions.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request company profiles, product catalogs, and case studies to gauge their experience and reliability. Assess their reputation through reviews and testimonials from similar industries.

- Check certifications and compliance: Ensure that suppliers meet international quality standards and local regulations, which is particularly important when sourcing from diverse regions.

Step 4: Request Samples

Obtaining samples is a critical step in the procurement process. Samples allow you to assess the quality and performance of the material wheels firsthand, ensuring they meet your expectations before making a bulk purchase.

Illustrative image related to material wheel

- Test in real-world conditions: If possible, test the wheels in the environment they will be used to confirm their suitability for your specific application.

Step 5: Negotiate Pricing and Terms

Once you have selected potential suppliers, engage in negotiations regarding pricing, payment terms, and delivery schedules. Transparent discussions help establish a mutually beneficial relationship and can lead to better deals.

- Consider total cost of ownership: Evaluate not just the upfront cost but also factors like maintenance, lifespan, and potential downtime to understand the true cost of the wheels over time.

Step 6: Establish a Quality Control Process

Implementing a quality control process ensures that the material wheels received meet the agreed specifications. Define quality benchmarks and inspection methods prior to shipment.

- Utilize third-party inspections: If sourcing internationally, consider hiring third-party quality inspectors to verify product quality before shipment, reducing the risk of receiving subpar materials.

Step 7: Build Long-Term Relationships

Finally, focus on building lasting relationships with your suppliers. Consistent communication and feedback can lead to improved service, better pricing, and priority support in future dealings.

- Engage in regular reviews: Schedule periodic assessments of supplier performance to ensure ongoing alignment with your evolving needs.

By following this checklist, international B2B buyers can streamline their sourcing process for material wheels, ensuring they acquire products that meet their technical requirements and operational needs efficiently.

Comprehensive Cost and Pricing Analysis for material wheel Sourcing

Analyzing the cost structure and pricing for material wheels is crucial for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. Understanding these dynamics can lead to better sourcing decisions and optimized procurement strategies.

What are the Key Cost Components in Material Wheel Manufacturing?

The cost structure for material wheels encompasses several components:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials include metals, plastics, and composites. High-performance materials like carbon fiber or specialized alloys come at a premium but may offer superior durability and performance.

-

Labor: Labor costs vary by region and can significantly influence pricing. Skilled labor is often required for precision manufacturing processes, particularly for custom or high-specification wheels.

-

Manufacturing Overhead: This includes costs associated with factory operations such as utilities, equipment maintenance, and indirect labor. Efficient manufacturing processes can help reduce these overheads.

-

Tooling: The initial investment in molds and tools for production can be substantial, especially for custom designs. Buyers should consider these costs as part of the overall pricing strategy.

-

Quality Control (QC): Rigorous QC processes ensure that products meet required specifications and safety standards. This can increase costs but is vital for maintaining product integrity and buyer trust.

-

Logistics: Shipping and handling costs can vary significantly based on the distance from the supplier to the buyer, the mode of transport, and the Incoterms agreed upon. These costs are especially crucial for international transactions.

-

Margin: Suppliers often build in a margin to cover risks and ensure profitability. Understanding typical margins in your specific industry can aid in negotiations.

How Do Price Influencers Affect Material Wheel Sourcing?

Several factors can influence pricing in the material wheel market:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for bulk orders. Understanding the MOQ can help buyers negotiate better terms and lower per-unit costs.

-

Specifications and Customization: Custom wheels tailored to specific applications may incur additional costs. Buyers should weigh the benefits of customization against the increased expense.

-

Material Quality and Certifications: Higher-quality materials or those with specific certifications (e.g., ISO, ASTM) may be more expensive but can lead to lower failure rates and longer life spans, thereby reducing the Total Cost of Ownership (TCO).

-

Supplier Factors: The supplier’s location, reputation, and reliability can influence pricing. Established suppliers with a proven track record may charge more but offer better service and quality assurance.

-

Incoterms: The terms of shipping (e.g., FOB, CIF) can affect the final price. Buyers should understand these terms to accurately calculate total landed costs.

What Tips Can Enhance Negotiation and Cost Efficiency for Buyers?

To navigate the complexities of sourcing material wheels effectively, consider the following strategies:

-

Negotiate Wisely: Leverage bulk purchasing and long-term contracts to negotiate better terms. Establishing a strong relationship with suppliers can also yield favorable pricing.

-

Evaluate Total Cost of Ownership: Look beyond the initial purchase price. Consider factors such as maintenance, durability, and performance over time to make informed decisions.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations, tariffs, and trade agreements can affect pricing. Buyers should stay informed about these factors, particularly in volatile markets.

-

Conduct Market Research: Regularly compare supplier offerings and market prices to ensure you are getting competitive rates. Understanding market trends can empower buyers during negotiations.

Disclaimer

The pricing insights provided here are indicative and can vary based on specific supplier negotiations, market conditions, and regional factors. Buyers are encouraged to conduct thorough market research and supplier assessments to achieve the best sourcing outcomes.

Alternatives Analysis: Comparing material wheel With Other Solutions

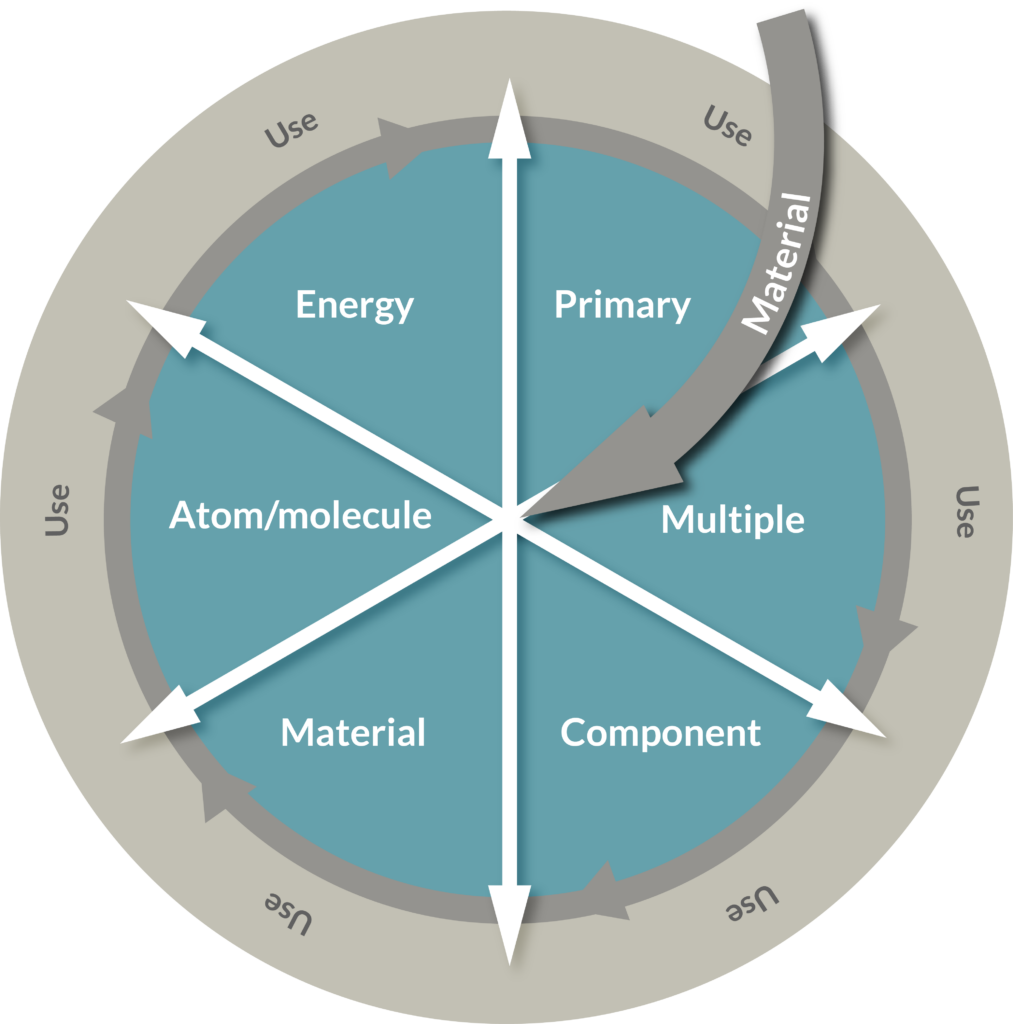

Understanding Alternative Solutions to the Material Wheel

In the quest for optimal material handling and selection, the material wheel serves as a creative and functional tool. However, various alternatives exist that can cater to the diverse needs of B2B buyers across different regions. This analysis will compare the material wheel against two viable alternatives: digital material selection software and physical material sample kits. Each alternative offers unique advantages and drawbacks that should be considered when making a purchasing decision.

Comparison Table

| Comparison Aspect | Material Wheel | Digital Material Selection Software | Physical Material Sample Kits |

|---|---|---|---|

| Performance | Visual and interactive; allows for quick material exploration | Comprehensive database; offers detailed specifications and comparisons | Tangible and tactile; enables direct assessment of material properties |

| Cost | Low to moderate | Varies (subscription or one-time fee) | Moderate to high (shipping and material costs) |

| Ease of Implementation | Simple setup and use | Requires software installation and training | Requires sourcing and inventory management |

| Maintenance | Low maintenance | Regular updates needed for databases | Periodic replenishment of samples required |

| Best Use Case | Creative brainstorming and initial material selection | In-depth analysis and technical specifications | Material testing and selection for specific projects |

Detailed Breakdown of Alternatives

Digital Material Selection Software

Digital material selection software provides a robust platform for engineers and designers to explore and compare materials based on performance metrics, costs, and environmental impact. The primary advantage of this solution is its comprehensive database, which allows users to filter materials according to specific project requirements. However, it may require training to use effectively and can involve recurring costs associated with software licenses. This solution is best suited for organizations that require detailed material analysis for engineering projects.

Physical Material Sample Kits

Physical material sample kits allow users to physically handle and assess materials, providing a tactile experience that digital solutions cannot replicate. These kits often include a variety of materials, allowing buyers to evaluate texture, weight, and durability firsthand. While they offer immediate insights into material properties, they can be costly and require careful inventory management to ensure the availability of samples. This approach is ideal for industries where material properties significantly influence project outcomes, such as construction and manufacturing.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right material handling solution depends on various factors, including budget, project requirements, and the level of detail needed in material assessment. For creative teams looking for an engaging way to brainstorm material options, the material wheel is a valuable tool. In contrast, organizations needing in-depth analysis and technical specifications may benefit more from digital material selection software. For those who prioritize hands-on evaluation, physical material sample kits can provide significant advantages. Ultimately, B2B buyers should assess their specific needs and operational contexts to choose the most effective solution for their material selection processes.

Essential Technical Properties and Trade Terminology for material wheel

Understanding the technical properties and trade terminology associated with material wheels is essential for B2B buyers, especially those involved in manufacturing, logistics, and construction across diverse regions such as Africa, South America, the Middle East, and Europe. This knowledge enables informed decision-making and enhances negotiation capabilities.

Illustrative image related to material wheel

What Are the Key Technical Properties of Material Wheels?

1. Material Grade

Material grade refers to the classification of the material used in the wheel’s construction, such as steel, aluminum, or plastic. Each grade has specific mechanical properties, including strength, durability, and corrosion resistance. For B2B buyers, understanding material grades is crucial as it directly impacts the wheel’s performance and lifespan, influencing overall operational efficiency and cost-effectiveness.

2. Load Capacity

Load capacity indicates the maximum weight that a wheel can safely support. It is essential to match the load capacity with the application requirements to prevent wheel failure, which can lead to downtime and increased operational costs. Buyers must consider load capacity when selecting wheels for different environments, such as warehouses or construction sites, ensuring safety and reliability.

3. Tolerance

Tolerance describes the permissible limits of variation in wheel dimensions, including diameter and width. Precision in manufacturing is critical, as improper tolerances can affect the wheel’s fit and functionality. For B2B buyers, understanding tolerance specifications helps in ensuring compatibility with existing equipment and machinery, ultimately reducing maintenance issues and enhancing productivity.

4. Durometer Hardness

Durometer hardness measures the hardness of the wheel material, typically for elastomers like rubber or polyurethane. This property influences the wheel’s grip, shock absorption, and wear resistance. Buyers need to assess durometer ratings to select wheels that provide the right balance between durability and performance, depending on the surface conditions and operational demands.

5. Wheel Diameter

Wheel diameter affects the speed and maneuverability of the equipment. Larger wheels generally roll more smoothly over obstacles, making them suitable for uneven surfaces, while smaller wheels may offer better control in tight spaces. B2B purchasers should consider the application environment when selecting wheel diameter to optimize equipment performance.

Illustrative image related to material wheel

Which Trade Terms Are Essential for B2B Buyers of Material Wheels?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that are used in another company’s end products. In the context of material wheels, OEMs often supply wheels that meet specific requirements for various industrial applications. Buyers should prioritize OEMs for quality assurance and compatibility with their machinery.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers as it impacts inventory management and purchasing decisions. Buyers should negotiate MOQs to align with their operational needs without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request price quotations for specific products. This process is essential for comparing costs and ensuring competitive pricing. Buyers should prepare RFQs that detail their requirements to facilitate accurate and timely responses from suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international trade. Understanding Incoterms is crucial for B2B buyers as they clarify who is responsible for shipping, insurance, and tariffs, helping to avoid disputes and ensure smooth transactions.

Illustrative image related to material wheel

5. Lead Time

Lead time refers to the time taken from placing an order to its delivery. It is a critical factor in supply chain management, impacting project timelines and operational efficiency. Buyers should assess lead times when planning purchases to ensure they align with production schedules and minimize disruptions.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can enhance their procurement strategies, ensuring they select the most suitable material wheels for their specific applications. This knowledge not only supports better purchasing decisions but also fosters stronger relationships with suppliers and manufacturers.

Navigating Market Dynamics and Sourcing Trends in the material wheel Sector

What Are the Key Trends Influencing the Material Wheel Market?

The material wheel sector is witnessing significant transformations driven by globalization, technological advancements, and evolving consumer preferences. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly looking for innovative and efficient sourcing solutions. The global demand for diverse materials such as composites, metals, and plastics is on the rise, fueled by industries ranging from construction to automotive manufacturing. Additionally, the integration of digital platforms for sourcing and procurement is gaining traction. These platforms enable buyers to streamline their purchasing processes, access a wider range of suppliers, and leverage data analytics for better decision-making.

Emerging trends include the growing interest in advanced materials like carbon fiber and graphene, which offer superior strength-to-weight ratios and enhanced performance characteristics. This shift is particularly relevant for sectors focused on sustainability and energy efficiency. Furthermore, the demand for customization is increasing, as businesses seek materials tailored to specific applications, which can enhance operational efficiency and reduce waste.

Illustrative image related to material wheel

How Is Sustainability Shaping Sourcing Decisions in the Material Wheel Sector?

Sustainability is no longer a niche consideration; it has become a central pillar in the decision-making processes of B2B buyers. The environmental impact of material sourcing has led to a heightened focus on ethical supply chains and sustainable practices. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainability through certifications and adherence to environmental regulations. This shift is particularly pertinent in regions like Europe, where regulatory frameworks are stringent, and sustainability initiatives are robust.

Green certifications, such as ISO 14001 or LEED, are becoming vital indicators of a supplier’s environmental stewardship. Additionally, the use of recycled or bio-based materials in the production of wheels is gaining popularity, allowing companies to reduce their carbon footprints while maintaining quality and performance. For international buyers, understanding the sustainability practices of potential suppliers not only aligns with corporate social responsibility goals but also appeals to a growing segment of environmentally conscious consumers.

What Is the Historical Context of Material Wheel Development?

The evolution of the material wheel sector is rooted in advancements in material science and manufacturing technologies. Initially, wheels were predominantly made from wood and metal, serving basic transportation needs. However, the industrial revolution catalyzed a shift towards more durable materials, such as rubber and plastics, enhancing performance and longevity.

Illustrative image related to material wheel

As industries evolved, so did the demands for specialized wheels tailored for specific applications, leading to innovations in composite materials and synthetic fibers. The introduction of high-performance materials, such as carbon fiber and aerogels, has further transformed the landscape, enabling manufacturers to create lighter, stronger, and more efficient wheels. This historical trajectory underscores the importance of ongoing research and development, which continues to drive the material wheel sector forward, catering to the diverse needs of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of material wheel

-

How do I ensure the quality of material wheels from international suppliers?

To ensure the quality of material wheels, start by conducting thorough research on potential suppliers. Request samples to assess the material’s durability and performance in your specific application. It’s also beneficial to ask for certifications such as ISO standards or other industry-specific quality assurances. Establish clear quality metrics in your purchase agreements and consider conducting factory audits if feasible. Engaging third-party inspection services can further mitigate risks associated with international sourcing. -

What are the common materials used in manufacturing material wheels?

Material wheels can be made from various materials, including metals (like steel and aluminum), plastics, rubber, and composites. Each material offers unique properties; for instance, steel wheels are known for their strength and durability, while plastic wheels are lighter and resistant to corrosion. When selecting a wheel, consider the application requirements such as load capacity, environmental conditions, and surface type to determine the most suitable material. -

What customization options are available for material wheels?

Many suppliers offer customization options for material wheels, including size, material composition, tread design, and color. Customization can enhance performance based on specific operational needs or brand requirements. When discussing customization, provide detailed specifications and engage in a dialogue with the supplier to ensure that your requirements are fully understood and achievable. Be aware that custom orders may have longer lead times and could require a minimum order quantity. -

What is the minimum order quantity (MOQ) for material wheels?

The minimum order quantity for material wheels varies by supplier and product type. Generally, MOQs can range from a few dozen to several hundred units, particularly for custom-designed wheels. It’s advisable to communicate your needs with potential suppliers to negotiate MOQs that align with your purchasing strategy. Some suppliers may offer flexibility or tiered pricing based on order volume, which can be beneficial for larger projects. -

What payment terms should I expect when purchasing material wheels internationally?

Payment terms can vary significantly among international suppliers. Common terms include advance payment, letter of credit, or net payment terms (e.g., net 30 or net 60 days). It’s essential to clarify payment conditions upfront and ensure they are documented in your purchase agreement. Discussing payment methods such as wire transfers, credit terms, or escrow services can enhance security and trust in the transaction, especially in cross-border deals. -

How do I assess the reliability of a supplier for material wheels?

To assess a supplier’s reliability, review their reputation within the industry by checking customer testimonials and references. Investigate their production capabilities, quality control processes, and delivery timelines. Tools such as third-party ratings or trade associations can provide additional insights. Engaging in direct communication and visiting the supplier’s facility, if possible, can also help you gauge their operational standards and commitment to customer service. -

What logistics considerations should I be aware of when importing material wheels?

When importing material wheels, consider logistics aspects such as shipping methods, lead times, customs regulations, and import duties specific to your country. Collaborating with a logistics provider experienced in international trade can streamline the process. Additionally, ensure that the supplier provides accurate documentation to facilitate customs clearance. Understanding the logistics landscape in your region, including potential delays or restrictions, is crucial to avoid disruptions. -

What are the best practices for maintaining material wheels once received?

To maintain material wheels effectively, implement a routine inspection schedule to check for wear, damage, or misalignment. Regular cleaning can prevent the buildup of debris that may affect performance. Depending on the material, lubrication may be necessary to ensure smooth operation. Documenting maintenance activities can help identify patterns and inform future purchasing decisions. Training staff on proper handling and maintenance protocols will further enhance the longevity and performance of the wheels.

Top 2 Material Wheel Manufacturers & Suppliers List

1. DH Castors – Key Wheel Materials

Domain: dhcasters.com

Registered: 2004 (21 years)

Introduction: Key Wheel Materials: Flat Free, Hard Rubber, Hi Temp Mold On Rubber, Non-Marking, Phenolic, Pneumatic, Polyurethane, Polyolefin Rubber, Semi-Pneumatic, Soft Rubber, Steel – Cast Iron, TPR – Thermoplastic Rubber, Plastic, Nylon. Wheel Sizes Available: 2 inch, 3 inch, 4 inch, 5 inch, 6 inch, 7 inch, 8 inch, 10 inch, 12 inch, 16 inch. Load Capacities: 45-99 lbs, 100-299 lbs, 300-499 lbs, 500-999 lbs,…

2. DrivingLine – Wheels Overview

Domain: drivingline.com

Registered: 2011 (14 years)

Introduction: Steel wheels: Cost-effective, durable, heavy, limited design choices; ideal for budget-conscious off-roaders. Aluminum Alloy wheels: Lighter than steel, available in various styles, strong, more expensive; entry-level cast for daily driving, flow-formed for light off-roading, forged for track use. Carbon Fiber wheels: Extremely lightweight, strong, resistant to heat, expensive; best for racing, no…

Strategic Sourcing Conclusion and Outlook for material wheel

How Can Strategic Sourcing Enhance Your Material Wheel Procurement?

In the dynamic landscape of material sourcing, understanding the diverse options available is crucial for B2B buyers. The material wheel serves as an invaluable tool, offering insights into a wide range of materials—from metals and composites to textiles and plastics—each with unique properties and applications. Strategic sourcing not only allows businesses to optimize costs but also enhances supply chain resilience by identifying reliable suppliers and fostering long-term partnerships.

For international buyers, particularly those in Africa, South America, the Middle East, and Europe, leveraging the material wheel can drive innovation and operational efficiency. By staying informed about emerging materials like graphene and aerogel, companies can gain a competitive edge in their industries. Moreover, adapting sourcing strategies to local market conditions can facilitate better negotiations and ensure compliance with regional regulations.

As you move forward, consider how a strategic approach to sourcing can transform your procurement process. Embrace the insights from the material wheel to make informed decisions that align with your business goals. The future of sourcing is not just about materials; it’s about creating value through strategic partnerships and innovation. Engage with suppliers who can help you navigate this landscape and unlock new opportunities for growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to material wheel

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.