Unlocking Value: A Strategic Analysis of the Latch For Toolbox Market

Introduction: Navigating the Global Market for latch for toolbox

In the quest for durable and efficient latches for toolboxes, international B2B buyers often grapple with the complexities of sourcing reliable components that meet their specific needs. The global market for toolbox latches is diverse, presenting challenges in identifying suitable suppliers, understanding various latch types, and navigating regional regulations. This comprehensive guide serves as a strategic resource, equipping buyers with essential insights into the different types of latches, their applications, and the nuances of supplier vetting.

Buyers can expect to explore a wide range of latch options, including paddle latches, compression latches, and T-handle latches, tailored to various toolbox designs. We will also delve into the critical factors influencing cost and quality, ensuring that decision-makers can balance budget considerations with performance requirements.

Additionally, this guide addresses the specific needs of international buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Germany and Brazil. By offering actionable insights and best practices, we empower businesses to make informed purchasing decisions, ultimately enhancing their operational efficiency and product reliability in a competitive market. Whether you are a small-scale manufacturer or a large distributor, understanding the landscape of toolbox latches will position your business for success in the global marketplace.

Understanding latch for toolbox Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Paddle Latch | Simple push-to-open mechanism, often weatherproof. | Toolboxes, storage cabinets, trailers. | Pros: Easy to use, low maintenance. Cons: Limited security compared to keyed options. |

| T-Handle Compression Latch | Offers adjustable tension, often with a rubber seal. | Heavy-duty toolboxes, truck beds. | Pros: Excellent sealing against elements. Cons: More complex installation. |

| Locking Latch | Keyed mechanism for enhanced security. | Job sites, secure storage solutions. | Pros: High security, deters theft. Cons: Requires keys, can be cumbersome. |

| Slide Latch | Simple design that allows for quick access. | Light-duty toolboxes, quick-access areas. | Pros: Cost-effective, easy to install. Cons: Less secure, may wear out faster. |

| Cam Latch | Rotating mechanism for a secure closure. | Industrial storage, utility vehicles. | Pros: Strong hold, reliable. Cons: May require more force to operate. |

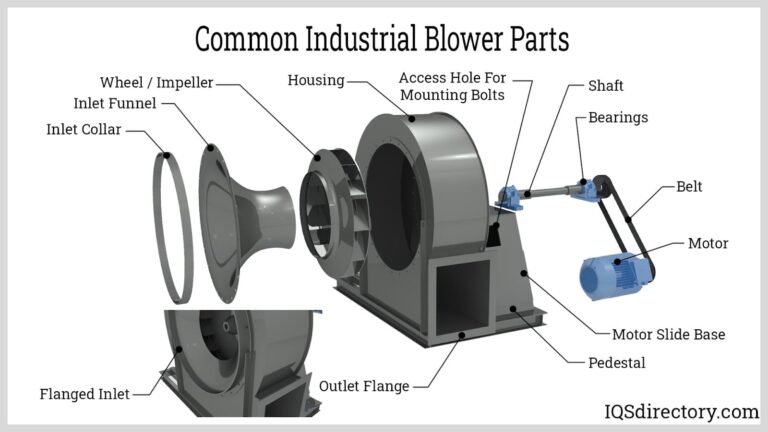

What Are the Characteristics of Paddle Latches and Their Suitability for B2B Buyers?

Paddle latches are designed for ease of use, featuring a push-to-open mechanism that allows quick access to stored items. They are often weatherproof, making them suitable for outdoor applications such as toolboxes and trailers. B2B buyers should consider paddle latches for environments where speed and convenience are crucial, although they may not provide the highest level of security.

How Do T-Handle Compression Latches Offer Advantages for Heavy-Duty Applications?

T-handle compression latches are characterized by their adjustable tension and sealing capabilities, often including rubber gaskets for enhanced protection against moisture and dust. These latches are ideal for heavy-duty toolboxes and truck beds, providing a reliable seal that keeps contents secure. Buyers should weigh the benefits of superior sealing against the more complex installation process.

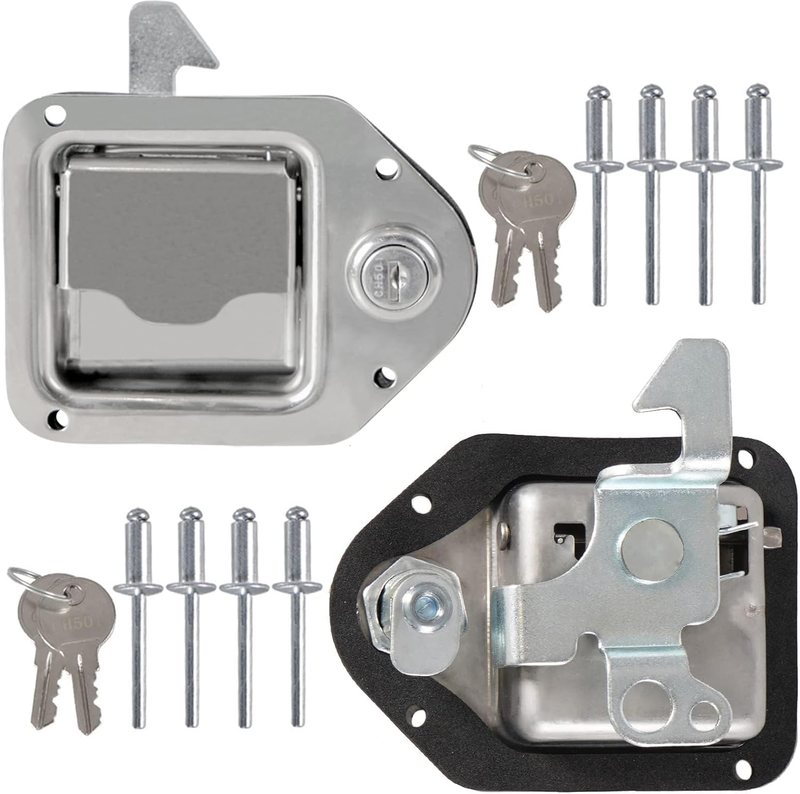

Why Choose Locking Latches for Enhanced Security in Job Sites?

Locking latches feature a keyed mechanism that significantly enhances security, making them an excellent choice for job sites or any environment where theft is a concern. They provide peace of mind for B2B buyers looking to secure valuable tools and equipment. However, the need for keys can be a drawback, as it may complicate access for multiple users.

What Are the Benefits of Using Slide Latches in Light-Duty Applications?

Slide latches are straightforward in design, allowing for quick access to stored items. They are typically used in light-duty toolboxes and areas where quick access is essential. While they are cost-effective and easy to install, buyers should be aware that slide latches may not offer the same level of security or durability as other options.

How Do Cam Latches Provide Reliable Closure in Industrial Settings?

Cam latches operate using a rotating mechanism that securely holds doors or lids closed, making them suitable for industrial storage and utility vehicles. Their strong hold and reliability make them a popular choice among B2B buyers in sectors requiring robust storage solutions. However, the operation may require more force, which could be a consideration depending on user accessibility.

Key Industrial Applications of latch for toolbox

| Industry/Sector | Specific Application of latch for toolbox | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Latches for mobile toolboxes used by mechanics | Enhances tool security and organization, reducing theft and loss. | Durability, weather resistance, and compatibility with various toolbox designs. |

| Construction | Latches for job site toolboxes | Protects tools from environmental damage and unauthorized access. | Corrosion resistance, ease of installation, and compliance with safety standards. |

| Manufacturing | Latches for storage cabinets in factories | Improves workplace safety and efficiency by securing tools and equipment. | Load capacity, material strength, and availability of spare parts. |

| Transportation & Logistics | Latches for cargo transport toolboxes | Secures tools and equipment during transit, minimizing damage and loss. | Weight considerations, locking mechanisms, and compliance with shipping regulations. |

| Agriculture | Latches for farm toolboxes | Protects equipment from weather elements and theft, ensuring operational readiness. | Resistance to agricultural chemicals, ease of use, and robust design for outdoor conditions. |

How Are Latches for Toolboxes Utilized in the Automotive Repair Industry?

In the automotive repair sector, latches are critical for securing mobile toolboxes used by mechanics. These latches enhance tool security, preventing theft and loss, which can be financially devastating for repair shops. Buyers in this sector require durable, weather-resistant latches that can withstand the rigors of a workshop environment and fit various toolbox designs seamlessly. Ensuring that the latches can endure frequent use without degradation is essential for long-term investment.

Why Are Latches Important for Construction Toolboxes?

Construction sites often face challenges such as theft and exposure to harsh weather conditions. Latches for job site toolboxes play a vital role in protecting tools from both environmental damage and unauthorized access. These latches must be corrosion-resistant and easy to install, as downtime can be costly. Buyers should prioritize latches that comply with safety standards to ensure the well-being of workers on-site while maintaining tool organization.

What Role Do Latches Play in Manufacturing Storage Solutions?

In manufacturing, latches are used on storage cabinets to secure tools and equipment, significantly improving workplace safety and operational efficiency. By keeping tools locked and organized, businesses reduce the risk of accidents and streamline workflows. Buyers should look for latches with a high load capacity and material strength to withstand factory conditions. Additionally, the availability of spare parts is crucial for minimizing downtime during maintenance.

How Do Latches Enhance Security in Transportation and Logistics?

In the transportation and logistics industry, latches are essential for securing cargo transport toolboxes. They prevent tools and equipment from shifting during transit, minimizing the risk of damage or loss. Buyers need to consider weight implications, especially for vehicle loading, as well as effective locking mechanisms that comply with shipping regulations. A reliable latch system can significantly enhance the overall security of transported goods.

Why Are Latches Critical for Agricultural Toolboxes?

Agricultural operations require robust latches for farm toolboxes to protect equipment from theft and the elements. These latches must be resistant to agricultural chemicals and designed for outdoor use, ensuring they can withstand various weather conditions. Buyers should look for latches that are easy to use and provide a secure fit to maintain operational readiness while minimizing equipment downtime due to theft or damage.

3 Common User Pain Points for ‘latch for toolbox’ & Their Solutions

Scenario 1: Difficulty in Ensuring Security for Valuable Tools

The Problem: B2B buyers, particularly those managing fleets or construction equipment, often face the challenge of securing valuable tools within their toolboxes. Theft is a pervasive issue, and traditional latches may not provide the necessary level of security. The risk of losing expensive equipment not only impacts operational efficiency but can also lead to increased insurance costs and potential project delays. This situation is particularly pressing in regions where theft rates are high, necessitating a robust solution.

The Solution: To mitigate this issue, buyers should consider investing in high-security latches designed specifically for toolboxes. Look for latches that feature heavy-duty materials, reinforced locking mechanisms, and tamper-resistant designs. For instance, a latch with a built-in lock cylinder can provide an extra layer of security. Additionally, when selecting latches, prioritize those that are weather-resistant to prevent rusting and deterioration, which can compromise the lock over time. It’s also beneficial to conduct a thorough evaluation of the toolbox’s mounting options; latches should be installed in a way that minimizes vulnerabilities, such as using multiple latches for larger boxes or integrating them with an alarm system for enhanced security.

Scenario 2: Issues with Latch Durability and Performance

The Problem: Frequent users of toolboxes, such as mechanics or construction workers, often encounter issues with latch durability. Over time, latches can become worn or break, leading to toolbox malfunction or, worse, tools spilling out during transport. This not only poses a safety risk but can also result in costly tool replacements. The challenge is exacerbated in harsh working environments where exposure to elements like dust, moisture, and extreme temperatures can quickly degrade latch performance.

The Solution: To address durability concerns, B2B buyers should opt for latches made from corrosion-resistant materials, such as stainless steel or reinforced polyamide. It’s crucial to assess the latch’s specifications based on the working environment; for example, a compression latch may be more suitable for mobile applications where vibration is a factor. Regular maintenance is key; implement a routine to inspect latches for wear and tear, and lubricate moving parts to ensure smooth operation. Additionally, consider investing in latches with adjustable features, allowing for fine-tuning to maintain a secure fit over time.

Scenario 3: Complexity in Sourcing the Right Latch for Specific Applications

The Problem: Many B2B buyers face challenges when it comes to sourcing the right latch for specific toolbox applications. With numerous options available in the market, selecting the appropriate latch that meets both functional and aesthetic requirements can be overwhelming. Buyers often struggle with compatibility issues, leading to frustration and potential delays in project timelines, especially in industries where time is of the essence.

The Solution: To streamline the sourcing process, buyers should begin by clearly defining their requirements, including the type of toolbox, the tools being stored, and the desired latch functionality. Conducting thorough research on various latch types—such as paddle latches, T-handle latches, and slide latches—can help narrow down choices. It’s also advisable to consult with manufacturers or suppliers who specialize in toolbox accessories to gain insights into compatibility and performance. Additionally, leveraging online platforms that offer comparison tools can aid in evaluating features and pricing. Finally, consider requesting samples or prototypes to test the latches in real-world conditions before making a bulk purchase, ensuring they meet the operational demands effectively.

Strategic Material Selection Guide for latch for toolbox

What Are the Common Materials Used for Latches in Toolboxes?

When selecting latches for toolboxes, the choice of material significantly influences performance, durability, and cost. Understanding the properties, advantages, and limitations of various materials can help international B2B buyers make informed decisions tailored to their specific needs and regional standards.

How Does Steel Perform as a Material for Tool Box Latches?

Steel is a popular choice for toolbox latches due to its exceptional strength and durability. It typically exhibits high resistance to deformation under load and can withstand considerable pressure and temperature variations. However, standard steel is prone to corrosion, which can be a significant drawback in humid or coastal environments.

Pros: Steel latches are robust and can handle heavy-duty applications, making them suitable for industrial toolboxes. They are relatively easy to manufacture and can be treated with coatings to enhance corrosion resistance.

Cons: The primary limitation is their susceptibility to rust if not properly coated or maintained. Additionally, the cost of high-quality stainless steel latches can be higher than other materials, impacting budget considerations.

Impact on Application: Steel latches are ideal for environments where strength is paramount, but they require careful consideration of the surrounding conditions to prevent corrosion.

What Are the Benefits of Using Plastic for Toolbox Latches?

Plastic latches, often made from high-density polyethylene (HDPE) or polyamide, offer a lightweight alternative to metal. They are resistant to corrosion and can withstand a range of temperatures, making them suitable for various environments.

Illustrative image related to latch for toolbox

Pros: The primary advantage of plastic latches is their resistance to rust and corrosion, which is ideal for outdoor use. They are also lightweight, reducing the overall weight of the toolbox, and are generally less expensive than metal options.

Cons: However, plastic latches may not provide the same level of strength and durability as metal counterparts. They can be more susceptible to cracking under extreme stress or impact.

Impact on Application: Plastic latches are well-suited for light to medium-duty applications, particularly in environments where moisture is a concern.

How Do Zinc-Alloy Latches Compare in Terms of Performance?

Zinc-alloy latches combine the strength of metal with enhanced corrosion resistance. These latches are often used in environments where exposure to moisture and chemicals is a concern.

Pros: Zinc-alloy latches offer good strength while being more resistant to corrosion than standard steel. They can be easily manufactured into various shapes and sizes, making them versatile for different toolbox designs.

Illustrative image related to latch for toolbox

Cons: While they are generally more resistant to corrosion, zinc-alloy latches can still corrode under harsh conditions if the protective coating wears off. They may also be more expensive than standard steel options.

Impact on Application: These latches are particularly suitable for toolboxes used in industries like automotive or marine, where exposure to water and chemicals is common.

What Role Does Aluminum Play in Toolbox Latch Selection?

Aluminum is another viable option for toolbox latches, known for its lightweight and corrosion-resistant properties. It is often used in applications where weight savings are critical.

Pros: Aluminum latches are lightweight and resistant to rust, making them an excellent choice for portable toolboxes. They are also relatively easy to manufacture and can be anodized for additional corrosion protection.

Cons: The main drawback is that aluminum latches may not be as strong as steel or zinc-alloy options, which could be a concern for heavy-duty applications. Additionally, they can be more expensive than plastic options.

Impact on Application: Aluminum latches are ideal for portable toolboxes and applications where weight is a critical factor, such as in aviation or outdoor equipment.

Summary Table of Material Selection for Toolbox Latches

| Material | Typical Use Case for latch for toolbox | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial toolboxes | Exceptional strength and durability | Prone to corrosion without coating | Medium |

| Plastic | Lightweight portable toolboxes | Corrosion-resistant and lightweight | Less durable under stress | Low |

| Zinc-Alloy | Toolboxes in humid or chemical-rich environments | Good strength with corrosion resistance | Can corrode if coating wears off | Medium |

| Aluminum | Portable and lightweight toolboxes | Lightweight and rust-resistant | Not as strong as steel or zinc-alloy | High |

This comprehensive analysis of materials will assist international B2B buyers in selecting the most appropriate latches for their toolbox applications, ensuring optimal performance and durability while considering regional standards and conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for latch for toolbox

What Are the Main Stages in the Manufacturing Process for Tool Box Latches?

The manufacturing of tool box latches involves several critical stages, each requiring precision and adherence to quality standards. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in manufacturing tool box latches is the selection and preparation of raw materials. Common materials include stainless steel, zinc-plated steel, and reinforced polymers. These materials are chosen for their strength, corrosion resistance, and durability, which are essential for the latch’s performance in various environments. The preparation process often involves cutting raw materials into specific dimensions, which is essential for ensuring that each component fits together accurately during assembly.

Illustrative image related to latch for toolbox

How Are Tool Box Latches Formed?

Once the materials are prepared, the next stage is forming. This can involve various techniques such as stamping, forging, or machining. For instance, stamping is widely used for producing metal components due to its efficiency and ability to create complex shapes with high precision. Forging may be used for components that require additional strength, while machining is applicable for more intricate designs. This stage is crucial as it defines the latch’s functionality, ensuring it operates smoothly under different conditions.

What Does the Assembly Process Entail?

After forming, the components are assembled. This stage can be manual or automated, depending on the production volume and complexity of the latch design. During assembly, components such as the latch body, handle, and locking mechanism are combined. It’s vital to ensure that all parts fit together seamlessly to maintain the integrity of the latch. Quality control checks are often integrated into this stage to catch any misalignments or defects early in the process.

What Finishing Techniques Are Commonly Used for Tool Box Latches?

The final stage is finishing, which enhances the latch’s appearance and protects it from environmental damage. Common finishing processes include plating, powder coating, and anodizing. Plating, such as chrome or nickel plating, provides a shiny surface and corrosion resistance. Powder coating offers a durable, aesthetically pleasing finish that can withstand harsh conditions. Each finishing technique not only improves the latch’s durability but also its market appeal, which is crucial for B2B buyers looking for reliable products.

What Quality Assurance Measures Are Essential for Tool Box Latch Manufacturing?

Quality assurance (QA) is critical in ensuring that tool box latches meet the required specifications and industry standards. This involves adhering to international standards such as ISO 9001, which outlines criteria for a quality management system.

Illustrative image related to latch for toolbox

Which International Standards Should B2B Buyers Be Aware Of?

ISO 9001 is a globally recognized standard that emphasizes continuous improvement and customer satisfaction. In addition, specific industry standards, such as CE marking for products sold in the European Union and API standards for oil and gas applications, may also apply. These certifications ensure that the latches are safe, reliable, and compliant with regional regulations.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control typically involves several checkpoints throughout the manufacturing process, including:

-

Incoming Quality Control (IQC): This initial inspection evaluates the raw materials before they enter production, ensuring they meet specified quality standards.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing stages, this ensures that the processes are being followed correctly and that the components are being produced to specifications.

-

Final Quality Control (FQC): This final inspection assesses the finished product against established standards, checking for defects and ensuring functionality.

These checkpoints are essential for maintaining quality throughout the manufacturing process, helping to reduce waste and improve overall efficiency.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers adhere to stringent quality control measures, B2B buyers can take several proactive steps:

What Methods Can Buyers Use to Audit Suppliers?

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes and quality assurance practices directly. This includes reviewing documentation, inspecting facilities, and assessing the handling of materials.

-

Quality Reports: Requesting regular quality reports from suppliers can provide insights into their performance metrics, including defect rates and compliance with international standards.

-

Third-Party Inspections: Engaging independent third-party inspectors can offer an unbiased evaluation of the supplier’s quality control processes. These inspections can be particularly valuable for international buyers who may not have the resources to conduct on-site audits.

What Are the Unique Quality Control Considerations for International B2B Buyers?

International buyers, especially those in regions such as Africa, South America, the Middle East, and Europe, face unique challenges regarding quality control. Understanding local regulations and standards is crucial, as these can vary significantly from one region to another.

Illustrative image related to latch for toolbox

How Can Buyers Navigate Different Regulatory Environments?

-

Research Local Standards: Buyers should familiarize themselves with local quality standards and regulations relevant to tool box latches. This includes understanding CE marking for European markets or specific compliance requirements in emerging markets.

-

Establish Clear Communication: Maintaining open lines of communication with suppliers can help clarify quality expectations and ensure that both parties understand compliance requirements.

-

Leverage Technology: Utilizing technology for tracking and managing supply chain quality can help international buyers monitor supplier compliance and performance in real-time, allowing for quicker responses to any issues that may arise.

Conclusion

For B2B buyers seeking tool box latches, understanding the manufacturing processes and quality assurance measures is essential for making informed purchasing decisions. By focusing on the stages of manufacturing, adhering to international standards, and implementing robust quality control practices, buyers can ensure they source reliable and durable products that meet their specific needs. This knowledge not only aids in supplier selection but also contributes to building long-term, successful partnerships in the global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘latch for toolbox’

Introduction

This sourcing guide aims to equip B2B buyers with a practical checklist for procuring latches for toolboxes. Understanding the nuances of sourcing this component is critical, as it directly impacts the security and functionality of your toolbox solutions. Whether you are based in Africa, South America, the Middle East, or Europe, following these steps will help you make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical specifications required for the latches. Consider factors such as size, material, and locking mechanism. Knowing these details upfront will streamline the sourcing process and ensure compatibility with your toolbox design.

- Material Selection: Choose between materials like stainless steel, aluminum, or plastic, based on durability and environmental factors.

- Size and Compatibility: Measure existing latches to avoid discrepancies and ensure a perfect fit.

Step 2: Research Market Trends and Standards

Stay informed about the latest trends and standards in latch manufacturing. Understanding industry benchmarks can guide you in selecting high-quality products that meet safety and performance requirements.

- Global Standards Compliance: Ensure that the latches comply with international safety standards, especially if exporting or importing across borders.

- Innovation and Features: Look for advanced features such as corrosion resistance or enhanced locking mechanisms that may offer competitive advantages.

Step 3: Identify Potential Suppliers

Create a shortlist of suppliers specializing in toolbox latches. A diverse range of suppliers can provide insights into pricing, availability, and product variations.

- Supplier Reputation: Check online reviews and testimonials to gauge the reliability and quality of the suppliers.

- Product Range: Ensure the supplier offers a variety of latches to meet different needs, such as T-latches, compression latches, and paddle latches.

Step 4: Evaluate Supplier Certifications

Before making a commitment, verify that potential suppliers hold necessary certifications. This step is crucial for ensuring product quality and compliance with safety regulations.

- ISO Certifications: Look for suppliers with ISO 9001 certification, which indicates a commitment to quality management.

- Environmental Certifications: Consider suppliers with certifications like ISO 14001, which demonstrates environmental responsibility.

Step 5: Request Samples for Testing

Request samples from shortlisted suppliers to assess the quality and functionality of the latches. Testing samples in real-world conditions can reveal potential issues before bulk purchasing.

- Durability Tests: Conduct stress and corrosion tests to ensure the latch can withstand the intended use.

- Compatibility Checks: Verify that the samples fit seamlessly with your toolbox design.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, negotiate terms that work for both parties. This includes pricing, payment terms, lead times, and after-sales support.

- Volume Discounts: Inquire about discounts for bulk orders or long-term contracts.

- Warranty and Support: Ensure the supplier provides a warranty and reliable customer support for any post-purchase issues.

Step 7: Finalize the Purchase Order

After all terms have been agreed upon, finalize your purchase order. Ensure that all specifications, quantities, and delivery timelines are clearly stated to avoid misunderstandings.

- Documentation: Keep a record of all communications and agreements for future reference.

- Follow-Up: Confirm delivery dates and maintain communication with the supplier throughout the shipping process.

By following this comprehensive checklist, B2B buyers can ensure a successful procurement process for latches for toolboxes, enhancing both product quality and customer satisfaction.

Comprehensive Cost and Pricing Analysis for latch for toolbox Sourcing

What Are the Key Cost Components in Sourcing Toolbox Latches?

When sourcing latches for toolboxes, several cost components come into play. The primary factors include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials significantly impacts the cost. Common materials include stainless steel, aluminum, and reinforced plastics. Higher quality materials may increase initial costs but can lead to lower maintenance and replacement costs over time.

-

Labor: Labor costs vary by region and can be influenced by the complexity of the latch design. In regions with higher labor costs, such as parts of Europe, this can substantially affect the overall price.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and administrative expenses. Manufacturers often allocate these costs based on production volume, meaning smaller orders may carry a higher overhead per unit.

-

Tooling: Custom tooling for specific latch designs can be a significant upfront investment. Buyers should consider whether the tooling cost can be amortized over a large production run to mitigate the impact on individual unit pricing.

-

Quality Control (QC): Ensuring the latches meet industry standards and certifications can add to costs. QC processes help maintain product reliability, which is especially important for international buyers who may face stricter compliance requirements.

-

Logistics: Shipping costs can fluctuate based on distance, shipping method, and weight. For international buyers, understanding Incoterms can help clarify who bears responsibility for shipping costs, customs duties, and risks during transit.

-

Margin: Suppliers typically include a margin to cover their risks and profit. This can vary based on competition and market demand.

How Do Price Influencers Affect the Cost of Toolbox Latches?

Several factors influence the pricing of toolbox latches beyond just the basic cost structure.

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounts due to economies of scale. Buyers should negotiate the MOQ with suppliers to find a balance between cost savings and inventory management.

-

Specifications and Customization: Unique specifications or custom designs can lead to increased costs due to additional engineering and production time. Buyers should evaluate if customization adds sufficient value to justify the higher price.

-

Materials and Quality Certifications: The choice of material and associated certifications (like ISO or CE) can affect pricing. Buyers should weigh the importance of certification against potential cost increases.

-

Supplier Factors: The supplier’s location, reputation, and reliability can also influence price. Established suppliers with a proven track record may charge more but can offer benefits such as better quality assurance and customer service.

-

Incoterms: Understanding Incoterms can help buyers manage costs associated with shipping and customs. For instance, opting for DDP (Delivered Duty Paid) can simplify the import process but may increase the overall cost.

What Are Some Buyer Tips for Negotiating Toolbox Latch Prices?

To navigate the complexities of sourcing toolbox latches, buyers should consider the following strategies:

-

Negotiate Effectively: Engage in discussions about pricing, particularly for larger orders. Be prepared to discuss your specific needs and how they can align with the supplier’s capabilities.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, consider the TCO, which includes maintenance, durability, and potential replacement costs. Investing in higher-quality latches may yield long-term savings.

-

Understand Pricing Nuances for International Markets: Buyers from regions such as Africa, South America, and the Middle East may face different pricing dynamics due to import tariffs, currency fluctuations, and local market conditions. Researching these factors can lead to better-informed purchasing decisions.

-

Seek Multiple Quotes: Obtaining quotes from various suppliers allows for better price comparisons and can provide leverage in negotiations. This practice is especially beneficial in competitive markets.

Disclaimer for Indicative Prices

Prices for toolbox latches can vary widely based on the factors discussed above. It is advisable for buyers to conduct thorough market research and obtain tailored quotes to ensure accurate budgeting and cost forecasting.

Alternatives Analysis: Comparing latch for toolbox With Other Solutions

Understanding Alternatives in Toolbox Latch Solutions

In the competitive landscape of B2B supply, selecting the appropriate latch for toolboxes is critical for ensuring security, accessibility, and durability. While traditional latches offer reliable performance, several alternative solutions exist that may cater to different operational needs and budgets. This section evaluates the efficacy of latch systems against two viable alternatives: electronic locking mechanisms and padlocks.

Comparison Table

| Comparison Aspect | Latch For Toolbox | Electronic Locking Mechanism | Padlock |

|---|---|---|---|

| Performance | Reliable, mechanical action | High security, programmable | Basic security, easy to use |

| Cost | Moderate upfront cost | Higher initial investment | Low-cost, widely available |

| Ease of Implementation | Simple installation | Requires electrical setup | Very easy to implement |

| Maintenance | Low, minimal upkeep | Moderate, may require software updates | Low, replaceable easily |

| Best Use Case | General toolbox security | High-security environments | Temporary or low-security needs |

Detailed Breakdown of Alternatives

Electronic Locking Mechanism

Electronic locking mechanisms represent a modern approach to toolbox security. These systems allow for keyless entry, which can enhance convenience and access control. Users can program multiple codes, making them suitable for environments where tools are shared among different personnel. However, the initial cost is typically higher due to the technology involved, and installation may require specialized skills. Additionally, these locks can be susceptible to electronic failures or battery depletion, necessitating more maintenance than traditional latches.

Padlock

Padlocks serve as a straightforward and cost-effective alternative for securing toolboxes. They are simple to use and can provide a basic level of security against unauthorized access. The affordability of padlocks makes them an attractive choice for businesses that may not have significant security needs. However, they offer limited protection compared to electronic locks and can be vulnerable to picking or cutting. Padlocks are best used in low-security scenarios or as a temporary measure when the toolbox needs to be secured quickly.

Conclusion: How to Choose the Right Toolbox Latch Solution

When selecting the right toolbox latch solution, B2B buyers should consider their specific operational requirements, budget constraints, and security needs. For businesses focused on high security and ease of access, investing in electronic locking mechanisms may be justified despite the higher initial costs. In contrast, companies with lower security demands or those seeking economical options might find that traditional latches or padlocks meet their needs effectively. Ultimately, the choice should align with the organizational priorities, ensuring that the selected solution enhances both security and operational efficiency.

Illustrative image related to latch for toolbox

Essential Technical Properties and Trade Terminology for latch for toolbox

What Are the Key Technical Properties of a Toolbox Latch?

When sourcing latches for toolboxes, understanding the technical properties is crucial to ensure reliability and compatibility with your specific applications. Here are several critical specifications to consider:

-

Material Grade

Latches are commonly made from materials such as stainless steel, zinc-plated steel, or reinforced polyamide. Stainless steel offers superior corrosion resistance, making it ideal for outdoor or harsh environments. Zinc-plated steel, while less resistant to rust, is often more cost-effective. Selecting the right material affects the latch’s durability, longevity, and overall performance, which is vital for minimizing replacement costs. -

Load Capacity

The load capacity of a latch indicates the maximum weight it can securely hold. This specification is essential for ensuring that the latch can withstand the weight of the tools and equipment stored in the toolbox. Overloading a latch beyond its specified load capacity can lead to failure, posing safety risks and potential damage to valuable tools. -

Tolerance Levels

Tolerance refers to the allowable variation in dimensions during the manufacturing process. High tolerance levels ensure that latches fit precisely with the toolbox, preventing misalignment and ensuring smooth operation. For B2B buyers, tight tolerances can mean reduced installation time and better overall functionality, which is especially important in high-volume production. -

Finish Type

The finish of a latch, such as powder coating or plating, can impact its resistance to wear and corrosion. A powder-coated finish not only enhances aesthetics but also provides additional protection against environmental factors. Understanding the finish type helps buyers choose latches that align with their specific usage conditions and branding requirements. -

Locking Mechanism

Different latches may feature various locking mechanisms, such as paddle locks or compression locks. The choice of locking mechanism affects security levels and ease of access. For businesses that prioritize security, understanding the locking mechanism is essential in safeguarding tools and equipment from theft or unauthorized access.

What Are Common Trade Terms Used in the Toolbox Latch Industry?

Familiarizing yourself with industry terminology can streamline communication and enhance negotiation processes with suppliers. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that are used in another company’s end product. When sourcing latches, knowing whether a supplier is an OEM can impact the quality and compatibility of the components with your existing tools or equipment. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers, as it affects inventory management and cash flow. Suppliers may have different MOQs based on production costs and inventory levels, which can influence purchasing decisions. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For B2B buyers, crafting a clear RFQ can facilitate better pricing negotiations and ensure that all specifications are met, helping to streamline the procurement process. -

Incoterms

International Commercial Terms (Incoterms) define the responsibilities of buyers and sellers in international trade. Understanding Incoterms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), is essential for managing shipping costs and liability, particularly for buyers importing latches from overseas. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the goods are delivered. For businesses, managing lead times is critical to maintaining production schedules and ensuring that tools are available when needed.

By mastering these technical properties and industry terms, B2B buyers can make informed decisions when selecting latches for toolboxes, ultimately leading to better product performance and value.

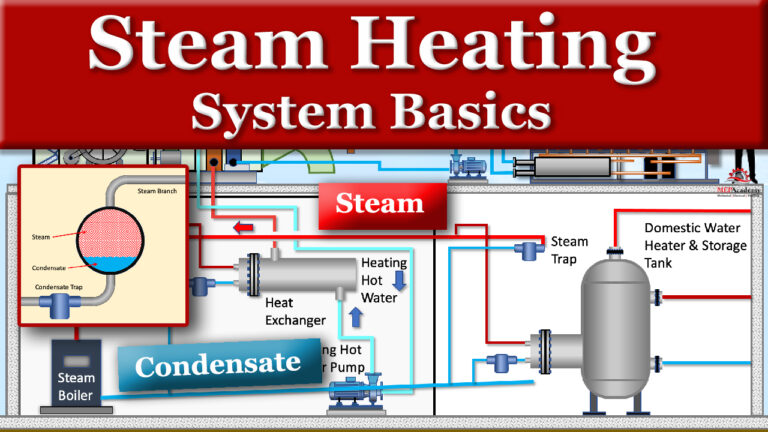

Navigating Market Dynamics and Sourcing Trends in the latch for toolbox Sector

What Are the Current Market Dynamics and Key Trends Influencing the Latch for Toolbox Sector?

The latch for toolbox sector is experiencing significant growth driven by several global factors. The increasing demand for secure storage solutions across various industries, such as construction, automotive, and manufacturing, has propelled the market forward. Additionally, the rise in DIY projects and home improvement activities, particularly in emerging markets in Africa and South America, has led to an uptick in toolbox sales, subsequently boosting the demand for high-quality latches.

Emerging technologies are transforming sourcing trends within this sector. The integration of smart technology into latches—such as electronic locking systems—offers enhanced security features that appeal to a tech-savvy customer base. Moreover, the adoption of e-commerce platforms is reshaping how international buyers source products, allowing for easier comparison, access to diverse suppliers, and streamlined logistics. B2B buyers are increasingly seeking suppliers that can provide detailed product specifications online, ensuring they make informed purchasing decisions.

Sourcing dynamics are also shifting as buyers prioritize suppliers with robust supply chain capabilities. Companies that can demonstrate agility, transparency, and the ability to quickly respond to market demands are favored. This is particularly pertinent for international buyers from regions like the Middle East and Europe, where market fluctuations can significantly impact supply availability.

How Are Sustainability and Ethical Sourcing Impacting the Latch for Toolbox Market?

Sustainability is becoming a cornerstone of the latch for toolbox sector, with both buyers and suppliers recognizing the importance of minimizing environmental impact. The production of latches often involves materials such as metals and plastics, which can have substantial ecological footprints. As such, many manufacturers are now investing in sustainable practices, including the use of recycled materials and eco-friendly coatings.

Ethical sourcing is equally critical, as B2B buyers are increasingly scrutinizing their supply chains for ethical practices. This includes ensuring that labor conditions are fair and that suppliers adhere to environmental regulations. Certifications such as ISO 14001 for environmental management and other “green” certifications are becoming vital in supplier selection processes. Buyers from Europe, particularly in Germany, are highly influenced by these criteria, as they seek to align their procurement strategies with corporate social responsibility goals.

Moreover, the shift towards sustainability is fostering innovation in product design, leading to the development of latches that not only meet functional requirements but also contribute to a circular economy. For instance, manufacturers are exploring modular designs that allow for easy repair and recycling, which aligns with global sustainability goals.

What Is the Evolution of the Latch for Toolbox Market?

The evolution of the latch for toolbox market reflects broader trends in manufacturing and consumer preferences. Initially, latches were simple mechanical devices designed for basic security. Over the decades, advancements in materials science and engineering led to the development of more durable and reliable latches, incorporating materials like stainless steel and advanced polymers.

Illustrative image related to latch for toolbox

The late 20th century saw a significant shift towards user-friendly designs, with features such as ergonomic handles and easy installation mechanisms becoming standard. In recent years, the integration of smart technology has further revolutionized the sector, offering enhanced security options that cater to a digitally connected world. This evolution not only reflects advancements in technology but also the changing expectations of consumers who prioritize both functionality and security in their toolbox solutions.

As the market continues to grow, it is crucial for B2B buyers to stay informed about these trends and adapt their sourcing strategies accordingly, ensuring they are aligned with both current market demands and future innovations.

Frequently Asked Questions (FAQs) for B2B Buyers of latch for toolbox

-

1. How do I solve issues with toolbox latches not functioning properly?

To address malfunctioning toolbox latches, start by inspecting the latch for any visible damage or wear. Ensure that all moving parts are clean and lubricated, as debris can impede functionality. If the latch is still unresponsive, consider replacing it with a high-quality model that meets your specific requirements. When sourcing replacements, look for suppliers who offer robust warranties and customer support to assist with installation and troubleshooting. -

2. What is the best latch for securing toolboxes in harsh environments?

The best latch for securing toolboxes in harsh environments is typically a heavy-duty, corrosion-resistant model, such as stainless steel or reinforced polyamide options. These materials withstand extreme temperatures, moisture, and chemical exposure. Additionally, consider features like weather seals and tamper-proof designs to enhance security. For international buyers, ensure that the latch complies with local regulations and standards, particularly in regions with stringent safety requirements. -

3. How can I customize toolbox latches for my specific needs?

Customization options for toolbox latches often include size, shape, material, and locking mechanisms. When contacting suppliers, provide detailed specifications and any design requirements you have. Many manufacturers offer bespoke solutions that can be tailored to fit your toolbox dimensions or specific security needs. Be prepared to discuss minimum order quantities (MOQs) and lead times for custom products, as these can vary significantly among suppliers. -

4. What are the common minimum order quantities (MOQs) for toolbox latches?

MOQs for toolbox latches can range from as few as 100 units to several thousand, depending on the manufacturer and the complexity of the product. When sourcing latches, inquire about the MOQ upfront to ensure it aligns with your purchasing capabilities. Some suppliers may offer flexibility for bulk orders or new clients, so it’s worthwhile to negotiate or explore options for smaller trial orders. -

5. How do I vet suppliers for toolbox latches in international markets?

To vet suppliers for toolbox latches in international markets, start by researching their reputation through reviews, testimonials, and case studies. Request references from previous clients, especially those within your industry. Ensure the supplier complies with international quality standards, such as ISO certifications, and ask for product samples to evaluate quality firsthand. Additionally, consider visiting the supplier’s facility if feasible, or utilize third-party verification services for added assurance. -

6. What payment terms are typically offered by suppliers for toolbox latches?

Payment terms for toolbox latches can vary widely, but common options include net 30, net 60, or payment upon receipt of goods. Some suppliers may require a deposit upfront, especially for custom orders. It’s crucial to clarify payment terms during negotiations to avoid misunderstandings. Additionally, inquire about options for secure payment methods, including letters of credit or escrow services, to protect your transaction. -

7. How can I ensure quality assurance for latches sourced internationally?

To ensure quality assurance for internationally sourced latches, establish clear specifications and standards with your supplier from the outset. Request certifications and quality control processes that the manufacturer adheres to. Conduct routine inspections during production and before shipment, and consider hiring third-party inspection services to verify compliance with your quality requirements. Implementing these measures will help mitigate risks associated with product defects. -

8. What logistics considerations should I be aware of when importing toolbox latches?

When importing toolbox latches, consider logistics factors such as shipping methods, customs duties, and lead times. Choose a reliable freight forwarder familiar with your destination country’s regulations to streamline the process. Be aware of any import restrictions or tariffs that may apply to your products. Additionally, ensure that your supplier provides accurate documentation to facilitate smooth customs clearance, minimizing delays and additional costs.

Top 5 Latch For Toolbox Manufacturers & Suppliers List

1. Buyers Products – Heavy-Duty Hinged Security Hasps

Domain: buyersproducts.com

Registered: 1997 (28 years)

Introduction: This company, Buyers Products – Heavy-Duty Hinged Security Hasps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Bolt Lock – Toolbox Latch Retro-fit Kit Toyota

Domain: boltlock.com

Registered: 2000 (25 years)

Introduction: {“product_name”: “Toolbox Latch Retro-fit Kit Toyota”, “material”: “Stainless Steel”, “msrp”: “$39.99”, “part_number”: “7023549”, “compatibility”: “Fits DeeZee, UWS and other leading makers of toolboxes”, “note”: “Not Compatible with Toyota Center Cut Keys”}

3. McMaster-Carr – Tool Box Latches

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster-Carr – Tool Box Latches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Zips – Toolbox Latches & Gaskets

Domain: zips.com

Registered: 1995 (30 years)

Introduction: Toolbox Latches & Gaskets | Paddle & T-Latch | Various Styles | Free Shipping on orders over $199 for ground shipments within the contiguous 48 states for products weighing less than 150 lbs. Special handling fees may apply for some products.

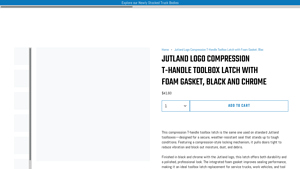

5. Jutland – Logo Compression T-Handle Toolbox Latch

Domain: jutlandtruckbodies.com

Registered: 2019 (6 years)

Introduction: {“Product Name”: “Jutland Logo Compression T-Handle Toolbox Latch with Foam Gasket, Black and Chrome”, “Price”: “$41.60”, “Features”: [“OEM-style latch used on Jutland aluminum toolboxes”, “Compression-locking design for tight, rattle-free closure”, “Integrated foam gasket for superior weather sealing”, “Durable black and chrome finish resists corrosion”], “Specifications”: {“Style”: “Compression …

Strategic Sourcing Conclusion and Outlook for latch for toolbox

How Can Strategic Sourcing Enhance Your Procurement of Tool Box Latches?

In today’s competitive landscape, strategic sourcing is essential for B2B buyers seeking high-quality tool box latches. By understanding market trends, evaluating supplier capabilities, and leveraging cross-border partnerships, businesses can secure durable and reliable latches that meet specific operational needs. Emphasizing quality and compliance, especially in regions with stringent safety standards, will not only enhance product integrity but also build customer trust.

International buyers from Africa, South America, the Middle East, and Europe must navigate diverse supply chains and regulatory frameworks. Engaging with suppliers who demonstrate a commitment to sustainability and ethical practices can further enhance brand reputation and operational efficiency.

As you look to the future, consider the potential of innovative latch designs and materials that offer improved functionality and security. The ongoing evolution in manufacturing technologies presents an opportunity to source cutting-edge products that can provide a competitive edge.

Take action now: assess your current suppliers, explore new partnerships, and invest in strategic sourcing initiatives that align with your business goals. By prioritizing a well-informed sourcing strategy, you can ensure that your toolbox latches not only meet today’s demands but also anticipate future industry challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.