Unlocking Value: A Strategic Analysis of the How To Wire A Pressure Switch Market

Introduction: Navigating the Global Market for how to wire a pressure switch

In today’s global market, navigating the complexities of wiring a pressure switch is a critical challenge for many B2B buyers, especially those operating in diverse industries such as manufacturing, construction, and agricultural irrigation. As international buyers from regions like Africa, South America, the Middle East, and Europe (including Nigeria and Germany) seek reliable solutions, understanding the intricacies of pressure switch wiring becomes essential. This comprehensive guide addresses not only the technical specifications and various types of pressure switches but also their applications across different sectors, ensuring that buyers can make informed decisions.

The guide meticulously outlines the wiring process, common pitfalls to avoid, and best practices for installation, which are crucial for ensuring safety and operational efficiency. Additionally, it delves into the importance of supplier vetting, helping businesses identify trusted manufacturers and distributors who meet quality standards and compliance regulations. By providing insights into cost considerations and maintenance practices, this guide empowers B2B buyers to optimize their investment in pressure switch technology, ultimately enhancing their operational capabilities.

With a focus on actionable insights and practical knowledge, this resource serves as a valuable tool for companies looking to streamline their purchasing processes while navigating the global market’s complexities. Whether you are a seasoned professional or new to the field, this guide equips you with the necessary information to confidently wire a pressure switch and maximize its potential in your operations.

Understanding how to wire a pressure switch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Pressure Switch Wiring | Basic wiring configuration with separate terminals for line and load | Water pumps, HVAC systems | Pros: Simple and cost-effective. Cons: Limited adjustability. |

| Dual Pressure Switch Configuration | Allows for different pressure settings and control over multiple motors | Industrial compressors, irrigation systems | Pros: Enhanced control and efficiency. Cons: More complex installation. |

| Adjustable Pressure Switch Wiring | Features adjustable settings for cut-in and cut-out pressures | Manufacturing, pneumatic tools | Pros: Customizable operation. Cons: Requires technical knowledge for setup. |

| Single Pole Pressure Switch Wiring | Uses a single pole for simpler applications | Small pumps, basic HVAC systems | Pros: Easy to wire. Cons: Limited functionality and control. |

| Multi-Stage Pressure Switch Wiring | Capable of managing multiple stages of pressure | Advanced HVAC systems, large compressors | Pros: High efficiency and control. Cons: Higher cost and complexity. |

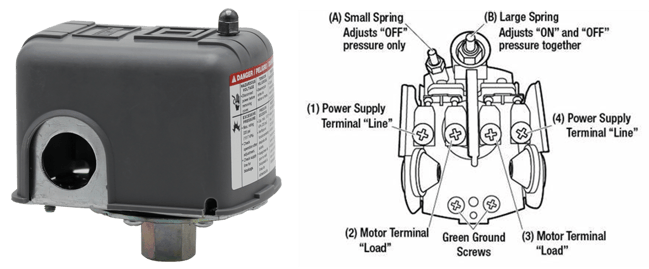

What Are the Key Characteristics of Standard Pressure Switch Wiring?

Standard pressure switch wiring is the most commonly used configuration, characterized by its straightforward setup. It typically includes separate terminals for line (power supply) and load (motor). This wiring method is particularly suitable for applications such as water pumps and HVAC systems, where simplicity and reliability are paramount. Buyers should consider that while this option is cost-effective, it may lack the flexibility required for more complex systems.

How Does Dual Pressure Switch Configuration Enhance Operational Control?

The dual pressure switch configuration allows users to set different pressure thresholds for multiple motors, making it ideal for industrial compressors and irrigation systems. This setup is advantageous for applications requiring precise control over pressure levels, thereby improving operational efficiency. However, the complexity of installation and configuration might necessitate skilled technicians, which could increase initial costs.

Why Choose Adjustable Pressure Switch Wiring for Customization?

Adjustable pressure switch wiring is designed for applications needing specific pressure settings, allowing users to modify cut-in and cut-out pressures easily. This feature is beneficial in manufacturing and pneumatic tool applications where precise pressure control is essential for optimal performance. Buyers should be prepared for a steeper learning curve, as proper setup and adjustments require technical expertise.

What Are the Benefits of Single Pole Pressure Switch Wiring?

Single pole pressure switch wiring is an excellent choice for simpler applications, utilizing only one pole for operation. It is commonly used in small pumps and basic HVAC systems where ease of wiring is a priority. While this option is straightforward and user-friendly, it may not provide the advanced control features found in more sophisticated configurations, limiting its applicability in larger or more complex systems.

How Does Multi-Stage Pressure Switch Wiring Improve Efficiency?

Multi-stage pressure switch wiring is designed to manage several pressure stages, making it suitable for advanced HVAC systems and large compressors. This configuration enhances system efficiency by enabling precise control of pressure levels across different operational stages. However, the complexity and higher costs associated with installation and maintenance may deter some buyers, particularly in markets where budget constraints are significant.

Key Industrial Applications of how to wire a pressure switch

| Industry/Sector | Specific Application of how to wire a pressure switch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water Management | Wiring pressure switches in irrigation systems | Efficient water distribution and reduced waste | Local regulations, compatibility with existing systems |

| Manufacturing | Integration of pressure switches in pneumatic systems | Enhanced operational efficiency and safety | Reliability of components, supplier certifications |

| Oil & Gas | Pressure control in drilling and extraction equipment | Increased safety and operational reliability | Compliance with industry standards, durability |

| HVAC | Wiring pressure switches for air conditioning systems | Improved energy efficiency and system longevity | Voltage compatibility, climate considerations |

| Food & Beverage | Control of pressure in processing equipment | Quality assurance and compliance with safety standards | Hygiene standards, material certifications |

How is wiring a pressure switch used in water management systems?

In the water management sector, wiring pressure switches in irrigation systems is crucial for regulating water flow and pressure. Properly wired pressure switches ensure that pumps operate only when needed, preventing over-irrigation and conserving water resources. Buyers in this sector must consider local regulations regarding water usage and ensure compatibility with existing systems to maximize efficiency and sustainability.

What role do pressure switches play in manufacturing?

In manufacturing, pressure switches are integral to pneumatic systems, controlling the activation and deactivation of machinery based on pressure levels. Correct wiring of these switches enhances operational efficiency, minimizes downtime, and ensures safety by preventing equipment overload. Buyers should prioritize sourcing reliable components and suppliers with industry certifications to ensure seamless integration into their production processes.

How does wiring a pressure switch enhance safety in the oil and gas industry?

In the oil and gas industry, pressure switches are vital for maintaining safe operating conditions in drilling and extraction equipment. Proper wiring allows for real-time monitoring of pressure levels, helping to prevent hazardous situations such as blowouts or equipment failures. Buyers must focus on sourcing pressure switches that comply with stringent industry standards and are designed for durability in harsh environments to ensure safety and reliability.

Why is wiring a pressure switch important in HVAC systems?

Wiring pressure switches in HVAC systems is essential for regulating air pressure and ensuring efficient system operation. Properly configured pressure switches help maintain optimal pressure levels, improving energy efficiency and extending the lifespan of HVAC equipment. Buyers should consider voltage compatibility and the specific climate conditions of their installation sites when sourcing pressure switches to ensure optimal performance.

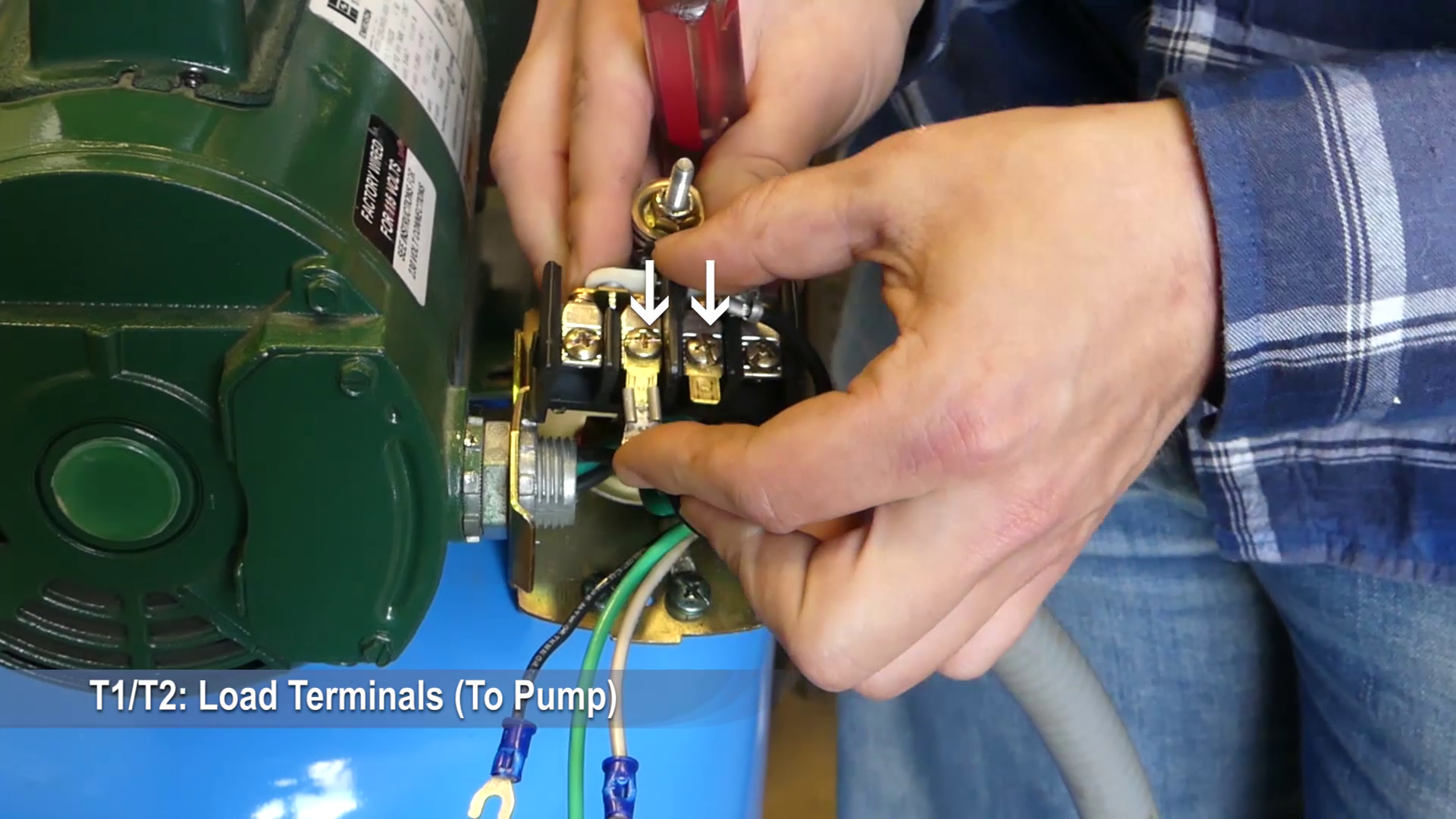

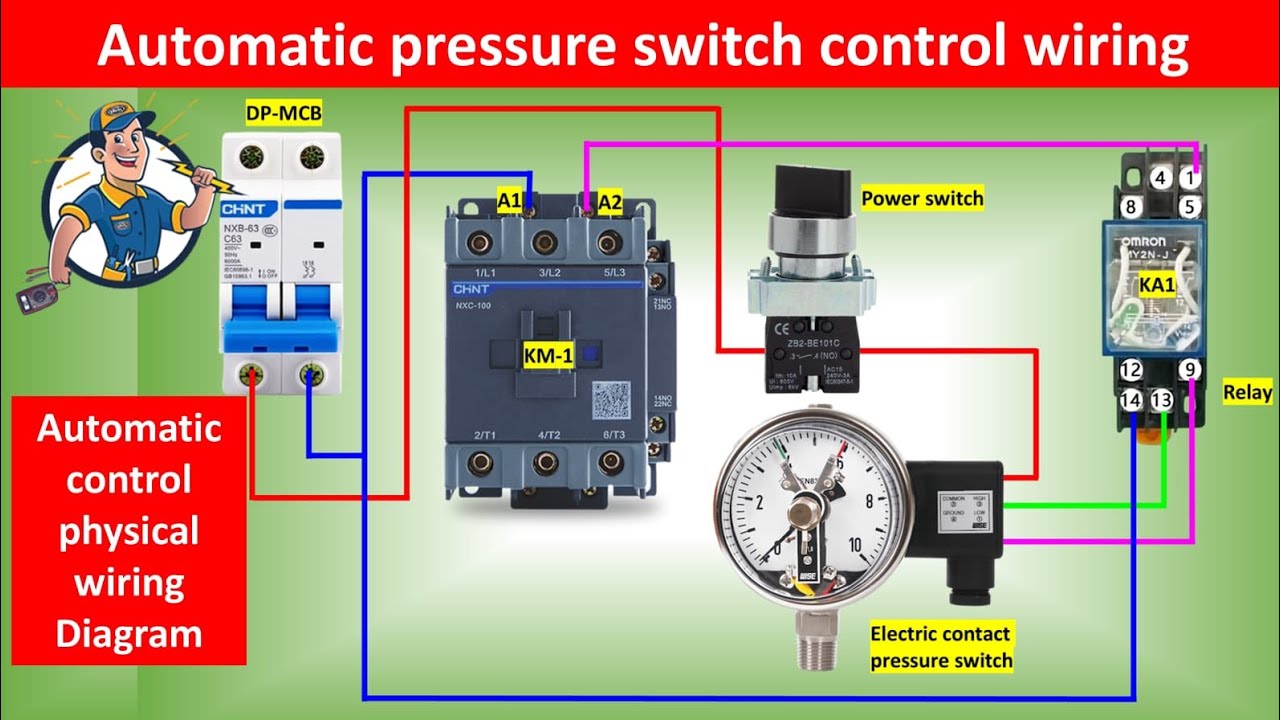

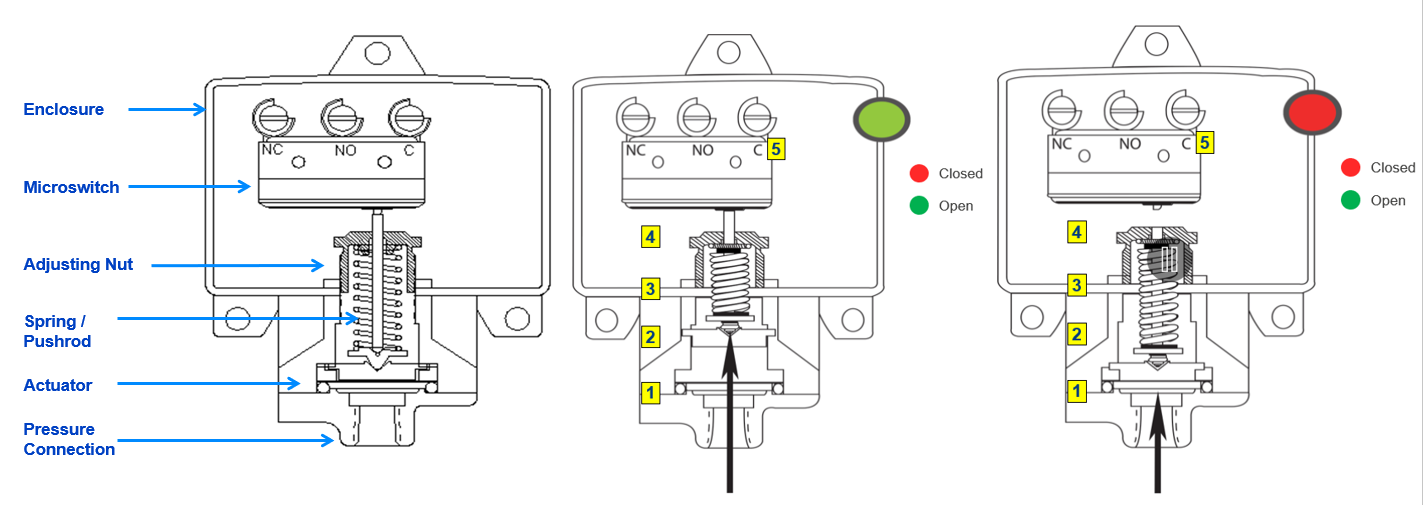

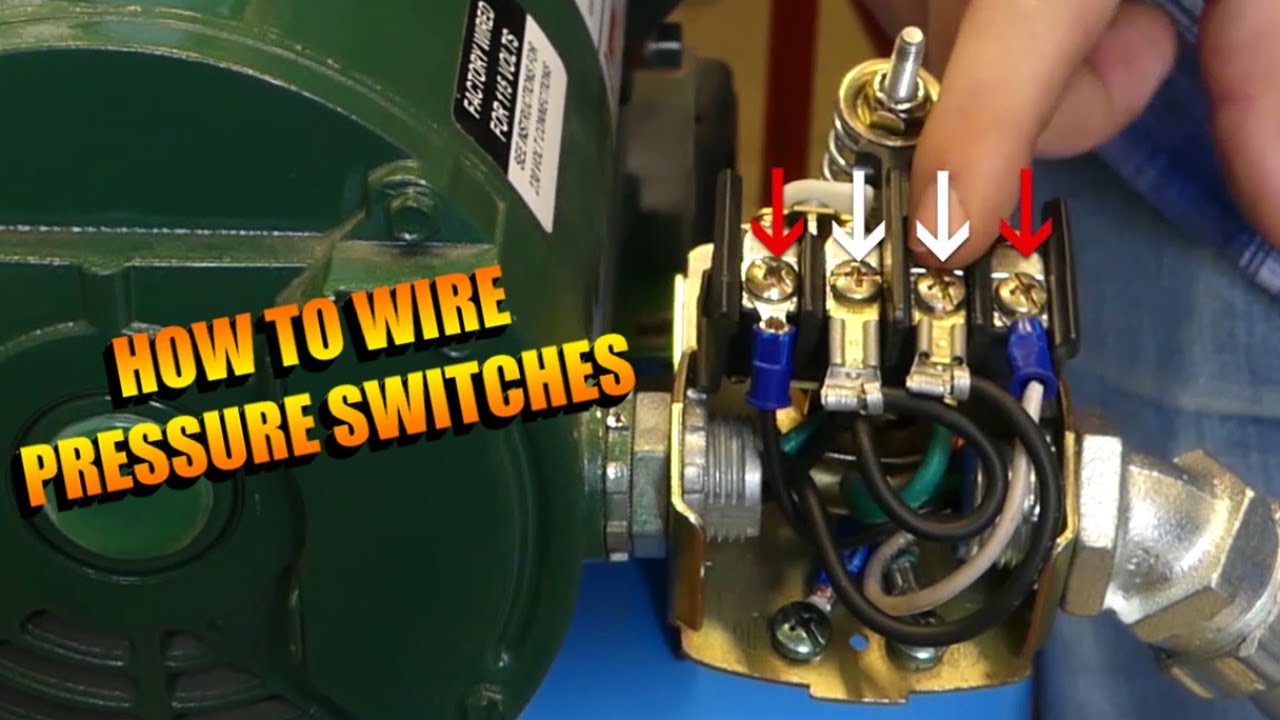

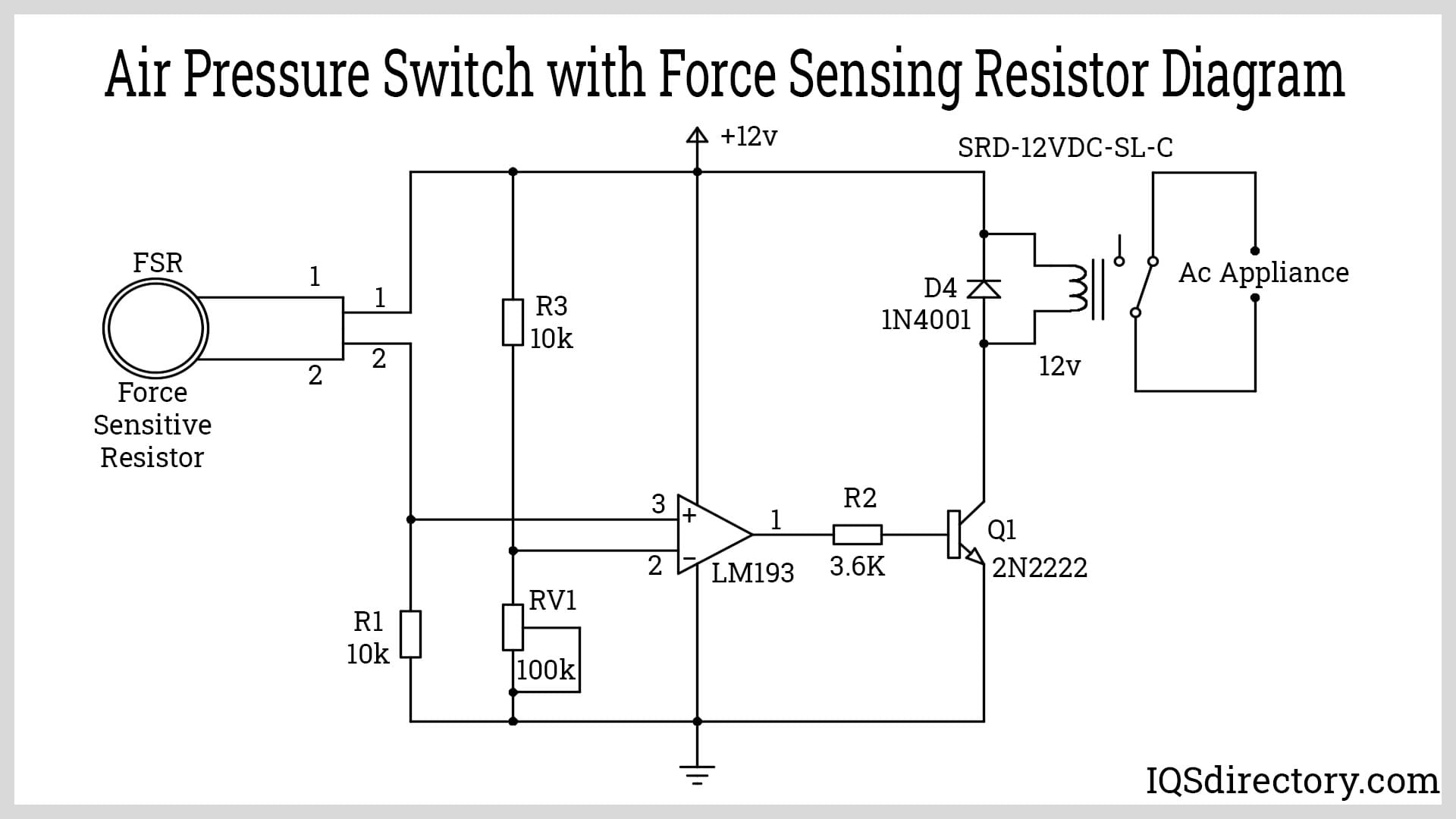

Illustrative image related to how to wire a pressure switch

How do pressure switches contribute to quality assurance in the food and beverage industry?

In the food and beverage sector, pressure switches control pressure levels in processing equipment, which is critical for maintaining product quality and safety. Correct wiring prevents over-pressurization, which can compromise food safety standards. Buyers in this industry should prioritize hygiene standards and seek pressure switches with appropriate material certifications to ensure compliance with safety regulations and maintain product integrity.

3 Common User Pain Points for ‘how to wire a pressure switch’ & Their Solutions

Scenario 1: Confusion Over Wiring Configurations

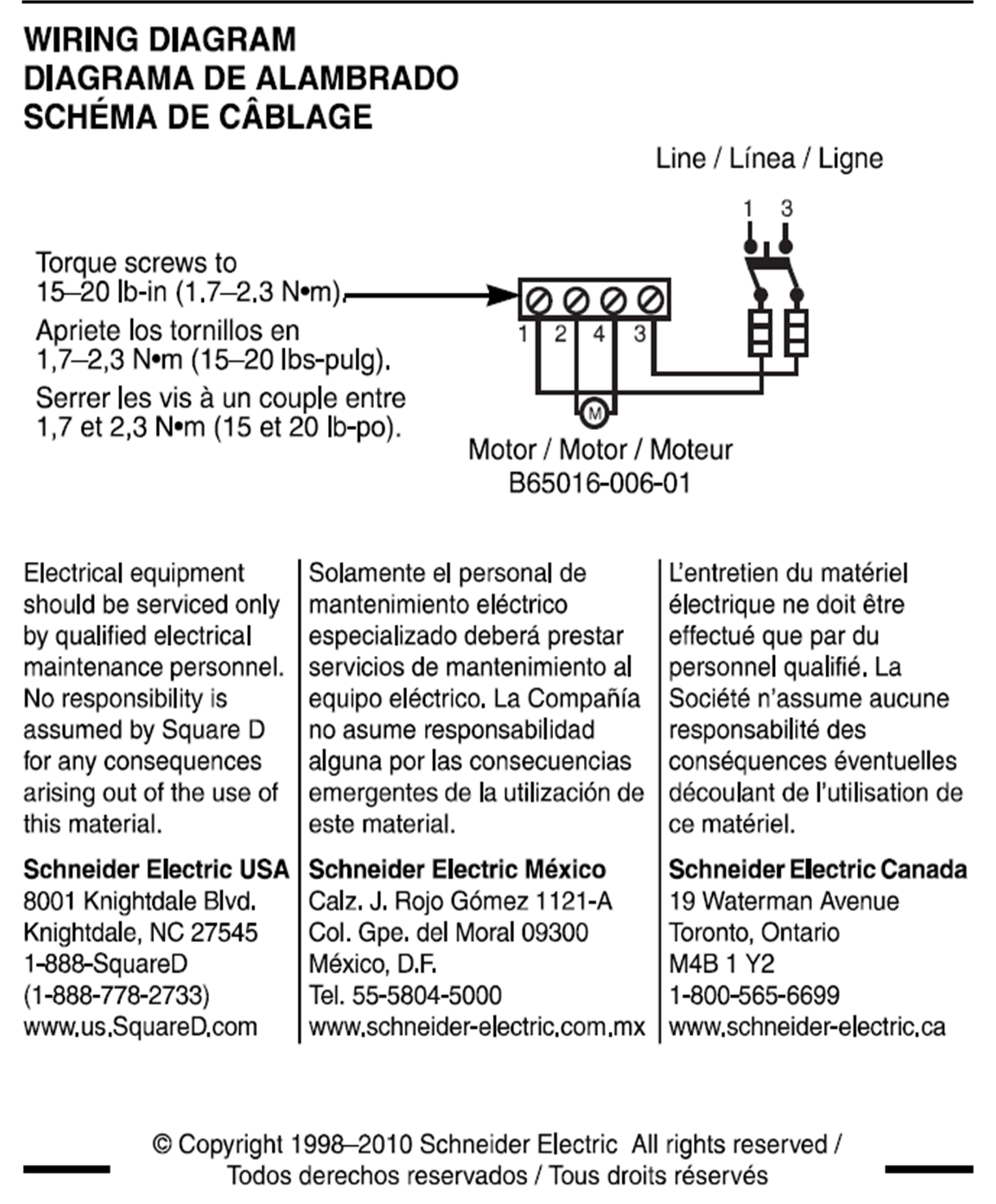

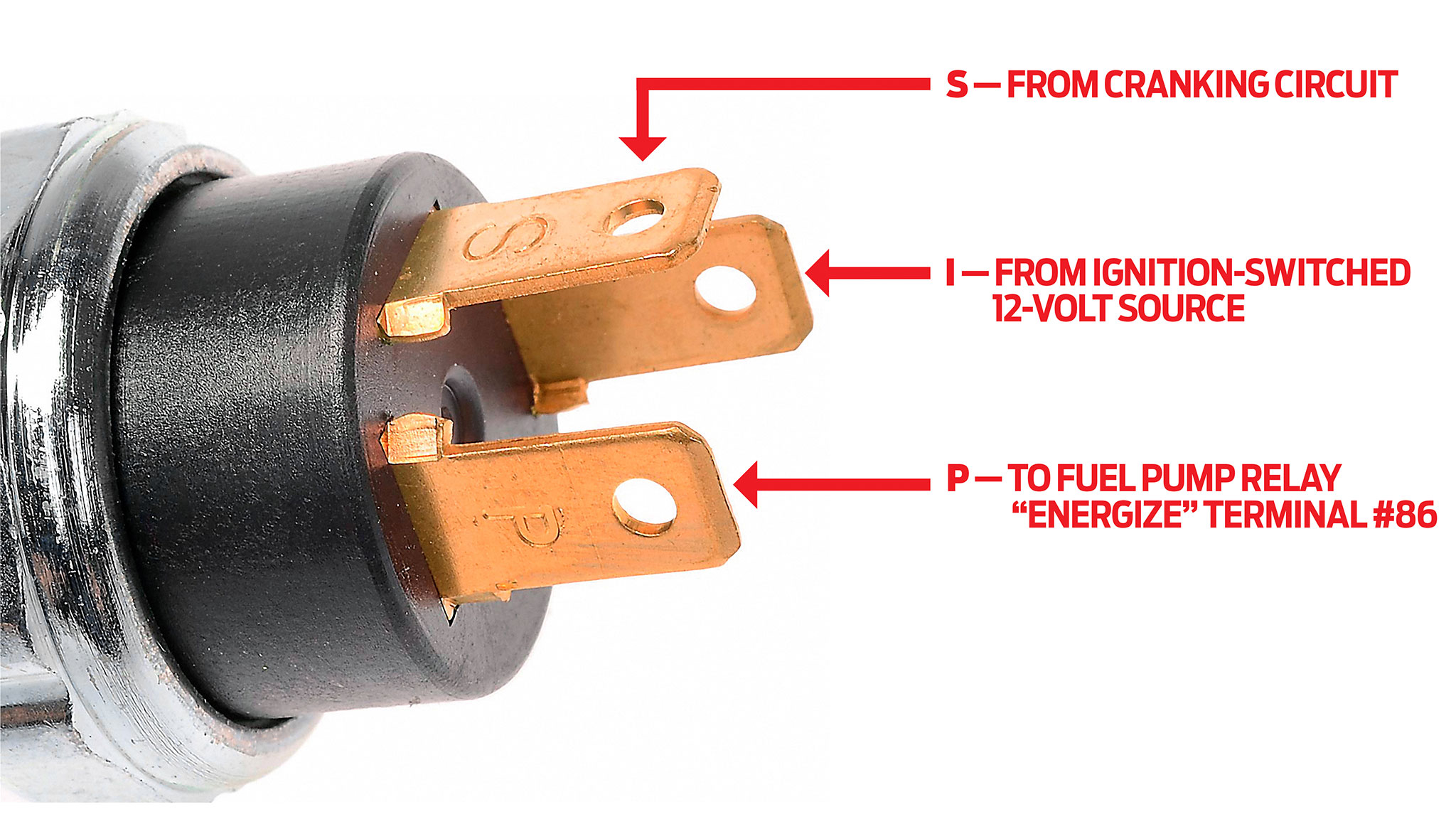

The Problem: B2B buyers often face confusion when wiring pressure switches, especially when dealing with multiple terminals and varying models. This is particularly prevalent among technicians or engineers who may not have extensive experience with specific switch brands or types. Misunderstanding terminal configurations can lead to incorrect wiring, causing equipment malfunctions, safety hazards, or costly downtime. For instance, a technician attempting to wire a Square D pressure switch to a Sta-Rite pump motor might struggle to determine which wires correspond to the correct terminals, leading to frustration and potential errors.

The Solution: To overcome this challenge, it is crucial to consult the manufacturer’s wiring diagram specific to the pressure switch model being used. Most manufacturers provide detailed documentation, including terminal designations and wiring configurations, which can be essential for proper installation. If the documentation is not readily available, consider using a multimeter to test the terminals while the switch is powered to understand their function in different states (tripped vs. untripped). Additionally, engaging with online forums or professional communities can provide insights and shared experiences that clarify wiring configurations. Training sessions or workshops on pressure switch installations can also equip teams with the necessary skills and confidence to tackle these tasks effectively.

Scenario 2: Risk of Overpressurization Due to Improper Wiring

The Problem: One of the most significant risks associated with improperly wired pressure switches is overpressurization, which can lead to equipment failure or safety incidents. This is particularly common in industries utilizing air compressors or hydraulic systems. For example, a company may wire a pressure switch directly to the motor without proper connections, causing the compressor to run continuously regardless of pressure levels. This oversight can lead to the activation of safety valves or even catastrophic equipment failure, resulting in costly repairs and operational delays.

The Solution: To mitigate the risk of overpressurization, it is essential to ensure that the wiring is done correctly and that the pressure switch is properly integrated into the system. Always wire the switch according to the manufacturer’s instructions, ensuring that the line and load terminals are used correctly. It is also advisable to implement pressure regulation checks as part of routine maintenance. Installing pressure gauges can provide real-time monitoring of system pressure, allowing technicians to detect issues early. Furthermore, conducting regular training for staff on the importance of proper wiring and system integration can significantly reduce the likelihood of overpressurization incidents.

Scenario 3: Misunderstanding Contact Functions in Pressure Switches

The Problem: Many B2B buyers encounter difficulties in understanding the distinct functions of various contacts within pressure switches. Misinterpreting the purpose of motor and line contacts can lead to incorrect wiring, preventing the switch from effectively controlling the connected equipment. For example, a technician might mistakenly connect the power supply to the motor contacts instead of the line contacts, resulting in the compressor running continuously without pressure regulation. This misunderstanding can lead to operational inefficiencies and increased energy costs.

The Solution: To prevent these misunderstandings, it is vital to provide comprehensive training focused on the functionality of pressure switch contacts. Detailed documentation from manufacturers should be utilized to clarify the roles of each terminal. Conducting hands-on training sessions can reinforce this knowledge, allowing technicians to practice wiring under supervision. Additionally, developing a checklist for wiring procedures can serve as a valuable reference, ensuring all steps are followed correctly. Encouraging a culture of asking questions and seeking clarification on wiring issues can also help to solidify understanding and reduce the occurrence of these mistakes in the future.

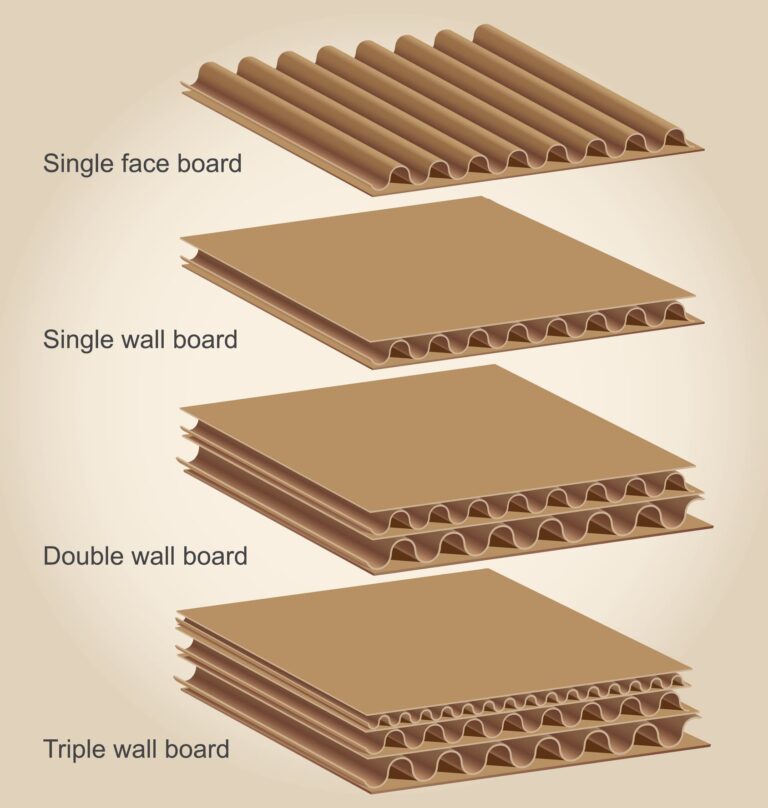

Strategic Material Selection Guide for how to wire a pressure switch

When selecting materials for wiring a pressure switch, it’s essential to consider their properties, advantages, disadvantages, and suitability for various applications. This analysis will focus on four common materials: copper, aluminum, PVC, and rubber. Each material offers distinct characteristics that can influence the performance and reliability of the pressure switch in different environments.

What Are the Key Properties of Copper for Wiring a Pressure Switch?

Copper is widely recognized for its excellent electrical conductivity, which is crucial for efficient power transfer. It has a high melting point (approximately 1,984°F or 1,085°C) and good corrosion resistance, making it suitable for various environments. Copper wires are also flexible, allowing for easier installation in tight spaces.

Pros & Cons: The primary advantage of copper is its superior conductivity, which reduces energy loss. However, its higher cost compared to other materials can be a drawback, especially for large-scale projects. Additionally, copper may corrode in certain environments, necessitating protective coatings or alloys.

Illustrative image related to how to wire a pressure switch

Impact on Application: Copper is compatible with a wide range of media, including water and air, making it versatile for different pressure switch applications. However, international buyers should be aware of standards such as ASTM B3 for copper wire.

How Does Aluminum Compare as a Wiring Material for Pressure Switches?

Aluminum is another common choice for wiring due to its lightweight nature and relatively good conductivity (approximately 61% that of copper). It is also less expensive, making it an attractive option for budget-conscious projects.

Pros & Cons: The main advantage of aluminum is its cost-effectiveness and reduced weight, which can simplify installation. However, aluminum is more prone to oxidation, which can impair conductivity over time. This necessitates careful consideration of protective coatings or alloys to enhance durability.

Impact on Application: Aluminum is suitable for applications involving air and non-corrosive fluids. However, international buyers should ensure compliance with standards like ASTM B800 for aluminum wire to avoid potential issues.

What Role Does PVC Play in Wiring Pressure Switches?

Polyvinyl Chloride (PVC) is often used for insulation in wiring applications. Its excellent chemical resistance and electrical insulation properties make it a popular choice for protecting wires from environmental factors.

Pros & Cons: PVC is lightweight, cost-effective, and provides good insulation, which enhances safety. However, it has a lower temperature tolerance (typically around 176°F or 80°C), which may limit its use in high-temperature environments.

Impact on Application: PVC-insulated wires are suitable for low to moderate pressure applications. International buyers should check for compliance with relevant standards such as IEC 60227 for PVC cables to ensure safety and reliability.

Why Is Rubber Important for Wiring Pressure Switches?

Rubber is primarily used as a protective material for wiring in pressure switches, especially in environments where moisture and mechanical stress are concerns. Its flexibility and resilience make it ideal for various applications.

Pros & Cons: The key advantage of rubber is its excellent flexibility and ability to withstand environmental stressors. However, rubber can degrade over time when exposed to certain chemicals or high temperatures, which may limit its longevity.

Impact on Application: Rubber is particularly effective in applications where wires are subject to movement or vibration. International buyers should consider standards like ASTM D2000 for rubber materials to ensure compatibility with their specific applications.

Illustrative image related to how to wire a pressure switch

Summary Table of Material Selection for Wiring a Pressure Switch

| Material | Typical Use Case for how to wire a pressure switch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Wiring connections for high-performance applications | Superior electrical conductivity | Higher cost and potential for corrosion | High |

| Aluminum | Cost-effective wiring for light-duty applications | Lightweight and budget-friendly | Prone to oxidation, requiring protective measures | Medium |

| PVC | Insulation for wiring in low to moderate pressure applications | Excellent chemical resistance and insulation | Limited temperature tolerance | Low |

| Rubber | Protective covering for wiring in dynamic environments | Flexibility and resilience under stress | Degradation risk from chemicals or heat | Medium |

This material selection guide provides international B2B buyers with critical insights into choosing the right materials for wiring pressure switches, ensuring optimal performance and compliance with industry standards.

In-depth Look: Manufacturing Processes and Quality Assurance for how to wire a pressure switch

What Are the Key Stages in the Manufacturing Process for Wiring a Pressure Switch?

The manufacturing process for wiring a pressure switch involves several critical stages that ensure the product meets quality standards and functions correctly. These stages include material preparation, forming, assembly, and finishing.

1. Material Preparation

The first step involves sourcing high-quality materials that meet industry standards. Common materials include durable plastics for the housing, copper or aluminum for terminals, and high-grade electrical wires. During this stage, suppliers often conduct incoming quality control (IQC) to ensure materials conform to specifications.

2. Forming

Once materials are prepared, they undergo forming processes. This includes molding plastic parts for the switch housing and machining metal components for terminals. Techniques such as injection molding and CNC machining are commonly used to achieve precise dimensions and tolerances. Quality checks during this phase are crucial to prevent defects that could compromise the switch’s functionality.

Illustrative image related to how to wire a pressure switch

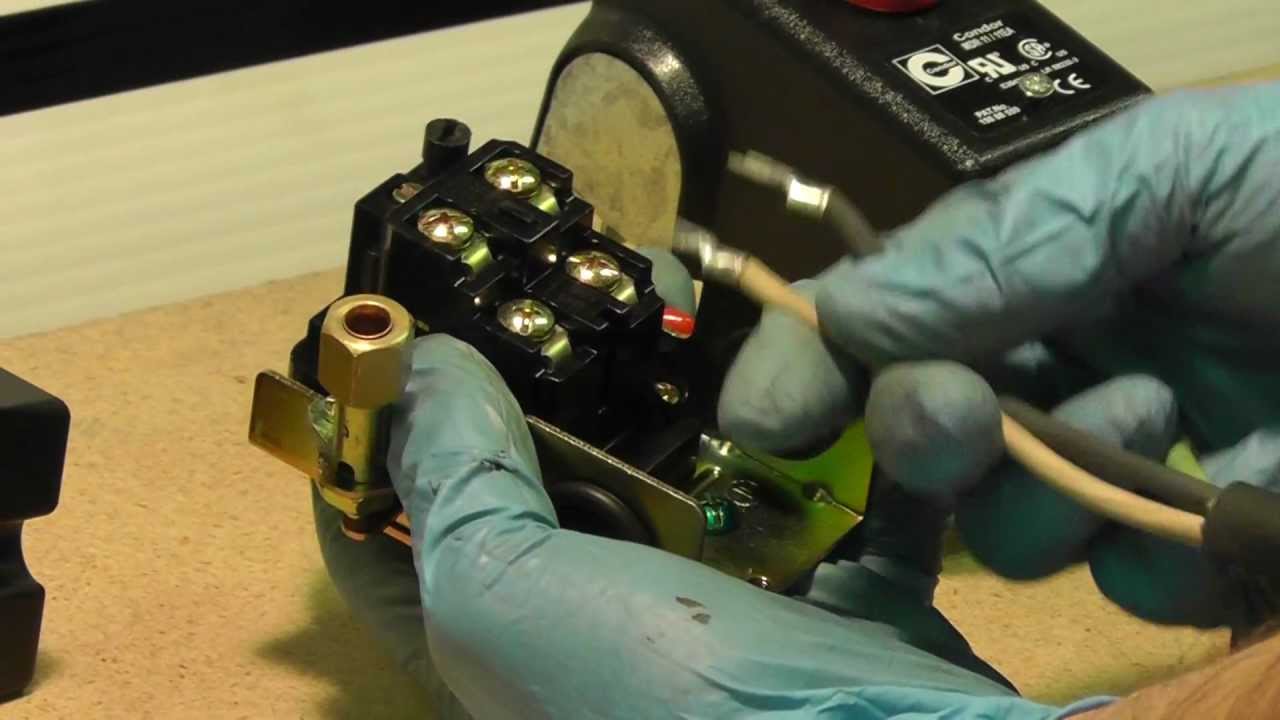

3. Assembly

The assembly stage involves the careful integration of all components. Technicians wire the pressure switch according to specific diagrams, ensuring that each terminal is correctly connected to prevent issues like short-circuiting. Automated assembly lines may be employed to enhance efficiency, but manual checks are essential to ensure the correct configuration. This is often where in-process quality control (IPQC) is applied, with checks at various assembly points.

4. Finishing

After assembly, the pressure switches undergo finishing processes, which may include cleaning, painting, and the application of protective coatings. This stage not only improves aesthetics but also enhances durability against environmental factors. Final quality assurance checks are performed to ensure that the switches meet all operational and safety standards before packaging.

How is Quality Assurance Implemented in the Manufacturing of Pressure Switches?

Quality assurance (QA) in the manufacturing of pressure switches is vital to ensure reliability and safety. Manufacturers typically adhere to international standards such as ISO 9001, which focuses on quality management systems.

1. Compliance with International Standards

Manufacturers often seek certifications like ISO 9001 to demonstrate their commitment to quality. Compliance with these standards ensures that the manufacturing processes are consistently monitored and improved. Additionally, industry-specific standards such as CE marking for European markets or API standards for oil and gas applications play a crucial role in ensuring the switches meet safety and performance criteria.

2. Quality Control Checkpoints

Quality control checkpoints are established at various stages of production:

Illustrative image related to how to wire a pressure switch

- Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before production begins.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify defects early, ensuring that corrective actions can be taken promptly.

- Final Quality Control (FQC): This final inspection assesses the finished product for compliance with specifications and functionality. Common tests may include pressure tests, electrical continuity checks, and durability assessments.

3. Common Testing Methods

Testing methods are crucial in verifying the performance of pressure switches. Some common methods include:

- Electrical Testing: This checks for continuity, insulation resistance, and operational response under various pressure conditions.

- Environmental Testing: Switches may be subjected to temperature and humidity tests to ensure they operate under expected environmental conditions.

- Durability Testing: This assesses the switch’s lifespan through repeated cycling to simulate long-term use.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to ensure product reliability.

1. Audits and Reports

Buyers should request detailed quality control reports from suppliers, including audit results and compliance certifications. Regular audits by external parties can provide an unbiased assessment of the supplier’s quality management practices.

2. Third-Party Inspections

Engaging third-party inspection services can add an extra layer of assurance. These services can verify that the manufacturing processes and final products meet specified standards before shipment, reducing the risk of receiving defective goods.

3. Understanding QC Nuances

International buyers should be aware of specific quality control nuances that may differ by region. For instance, some countries may have unique regulatory requirements or standards that could affect product compliance. It is advisable to engage local experts or consultants who understand these regional variations.

What Are the Common Challenges in Quality Assurance for Pressure Switches?

Quality assurance for pressure switches can present several challenges, especially for international buyers. Understanding these challenges can help in making informed purchasing decisions.

1. Variability in Standards

Different regions may have varying quality standards, which can complicate sourcing efforts. For example, a pressure switch that meets CE standards may not necessarily comply with API standards. Buyers should clarify the applicable standards for their specific market and ensure suppliers can demonstrate compliance.

2. Communication Barriers

Language and cultural differences can lead to misunderstandings regarding quality expectations. Establishing clear communication channels and using standardized documentation can mitigate these risks.

3. Supply Chain Disruptions

Global supply chains can be affected by unforeseen events, such as political instability or natural disasters, impacting the availability of quality materials. B2B buyers should consider suppliers with robust supply chain management practices to minimize disruptions.

Conclusion

The manufacturing processes and quality assurance practices for wiring a pressure switch are critical components that directly influence the product’s performance and reliability. By understanding these processes and how to verify supplier quality control, B2B buyers can make more informed decisions, ensuring they procure high-quality pressure switches that meet their operational needs.

Illustrative image related to how to wire a pressure switch

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to wire a pressure switch’

In the context of wiring a pressure switch, ensuring that you have a clear and practical approach is crucial for safety and efficiency. This guide will provide B2B buyers with a step-by-step checklist to navigate the procurement and installation process effectively.

Step 1: Identify Your Requirements

Before procuring a pressure switch, define the specific requirements for your application. Consider factors such as voltage ratings, pressure range, and the type of system (e.g., air compressor or water pump) in which the switch will be used. Understanding these parameters will help you select the right product and avoid compatibility issues.

Step 2: Research Suitable Pressure Switch Models

Conduct thorough research to identify pressure switch models that meet your specifications. Look for reputable manufacturers known for quality and reliability. It’s beneficial to compare features, such as adjustable pressure settings and build quality, to ensure you choose a switch that aligns with your operational needs.

Step 3: Evaluate Supplier Certifications

Before making a purchase, verify that potential suppliers hold relevant certifications and comply with international standards. This includes certifications like ISO 9001 for quality management and CE marking for products sold in Europe. Suppliers with these certifications are more likely to provide reliable products and services.

Step 4: Request Technical Documentation

Always request technical documentation, including wiring diagrams and installation manuals, from suppliers. These documents are essential for understanding how to properly wire the pressure switch to your system. Ensure that the documentation is clear and comprehensive to facilitate a smooth installation process.

Step 5: Inquire About Warranty and Support

Before finalizing your purchase, inquire about the warranty period and the level of customer support offered by the supplier. A robust warranty reflects the manufacturer’s confidence in their product, while responsive customer support can be invaluable if you encounter issues during installation or operation.

Step 6: Assess Installation Requirements

Evaluate the installation requirements for the pressure switch in your specific application. Determine whether additional components, such as connectors or protection devices, are necessary. This assessment will help you prepare adequately and avoid delays during installation.

Step 7: Plan for After-Sales Support and Maintenance

Consider the after-sales support and maintenance services offered by the supplier. Reliable suppliers often provide ongoing support, including troubleshooting and maintenance tips, which can prolong the lifespan of the pressure switch and ensure optimal performance.

By following this checklist, B2B buyers can navigate the complexities of procuring and wiring a pressure switch with confidence, ensuring that their systems operate safely and efficiently.

Comprehensive Cost and Pricing Analysis for how to wire a pressure switch Sourcing

What Are the Key Cost Components in Wiring a Pressure Switch?

When sourcing materials and services for wiring a pressure switch, understanding the cost structure is crucial for effective budgeting and financial planning. The primary cost components include:

-

Materials: This encompasses the cost of the pressure switch itself, electrical wires, connectors, and any additional components like circuit breakers or relays. The quality and type of materials can significantly influence the overall cost. For instance, copper wiring is generally more expensive than aluminum but offers better conductivity and longevity.

-

Labor: Installation costs are often a significant portion of the total expenditure. Labor rates can vary widely depending on the region, the complexity of the job, and the experience level of the technicians involved. In markets like Nigeria or South America, local labor costs may be lower than in Europe, but the skill level can also vary.

-

Manufacturing Overhead: This includes costs related to production facilities, utilities, and administrative expenses. For manufacturers, these overheads can constitute a notable percentage of the final product price.

-

Tooling: If specialized tools or equipment are needed for installation, these costs must be factored in. Some suppliers may include basic tooling in their service costs, while others might charge separately.

-

Quality Control (QC): Ensuring that all components meet safety and performance standards incurs additional costs. This is particularly critical for pressure switches used in industrial applications where failure could result in significant damage or safety hazards.

-

Logistics: Shipping and handling fees are essential to consider, especially for international transactions. Costs will vary depending on the distance, mode of transport, and any tariffs or duties applicable in the destination country.

-

Margin: Suppliers typically add a margin to cover their risks and ensure profitability. This margin can vary based on the supplier’s market position and the competitive landscape.

How Do Price Influencers Affect the Cost of Pressure Switch Wiring?

Several factors can influence pricing for pressure switch wiring, including:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often result in discounted rates. Buyers should negotiate terms that allow for greater flexibility in order sizes, especially if they anticipate fluctuating demand.

-

Specifications and Customization: Custom specifications may increase costs due to specialized manufacturing processes. Buyers should evaluate whether standard components meet their needs to avoid unnecessary expenses.

-

Materials Quality and Certifications: Higher quality materials with relevant certifications may come at a premium but can reduce maintenance costs and improve reliability. This is particularly important in regions where environmental conditions might affect the longevity of electrical components.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their proven track record, while less established suppliers might offer lower prices but come with higher risk.

-

Incoterms: Understanding the terms of shipping (such as FOB, CIF, etc.) is essential for calculating total costs. These terms can affect who bears the costs and risks associated with transport.

What Buyer Tips Can Help Optimize Costs for International Purchases?

For international buyers, especially those in Africa, South America, the Middle East, and Europe, optimizing costs involves strategic planning and negotiation:

-

Negotiate Terms: Always negotiate pricing and payment terms with suppliers. Leverage bulk purchasing power or long-term contracts to secure better deals.

-

Assess Total Cost of Ownership (TCO): Consider not just the initial purchase price but also installation, maintenance, and potential downtime costs. A slightly more expensive, high-quality switch may prove more economical in the long run.

-

Understand Pricing Nuances: Be aware that currency fluctuations, local taxes, and import duties can significantly impact final costs. Consider working with suppliers who have experience in your region to navigate these complexities.

-

Research Suppliers: Conduct thorough research on potential suppliers to assess their reliability and quality. Look for testimonials, case studies, and performance metrics to make informed decisions.

-

Stay Informed on Local Regulations: Different regions may have varying standards and regulations regarding electrical components. Ensure compliance to avoid costly fines or rework.

Conclusion

Understanding the cost structure and pricing influences when wiring a pressure switch is vital for making informed purchasing decisions. By focusing on the key cost components, negotiating effectively, and considering the total cost of ownership, international B2B buyers can optimize their sourcing strategies and enhance their operational efficiencies.

Illustrative image related to how to wire a pressure switch

Alternatives Analysis: Comparing how to wire a pressure switch With Other Solutions

Exploring Alternative Solutions for Wiring Pressure Switches

In the world of industrial automation and fluid control systems, pressure switches play a crucial role in regulating operations based on pressure levels. However, there are alternative methods and technologies available that can achieve similar objectives. This analysis will compare the conventional method of wiring a pressure switch with two viable alternatives: using a programmable logic controller (PLC) and employing smart pressure sensors. Understanding these alternatives can aid B2B buyers in making informed decisions tailored to their specific operational requirements.

Comparison Table

| Comparison Aspect | How to Wire A Pressure Switch | PLC Control System | Smart Pressure Sensor |

|---|---|---|---|

| Performance | Reliable for basic applications; limited in complex systems | High performance with complex logic capabilities | Excellent real-time monitoring and data logging |

| Cost | Low initial cost; minimal components needed | Higher upfront investment; requires training | Moderate cost; may require additional infrastructure |

| Ease of Implementation | Straightforward; requires basic wiring knowledge | Requires programming skills and understanding of logic | Relatively easy; often plug-and-play |

| Maintenance | Minimal maintenance; occasional checks required | Regular updates and troubleshooting needed | Low maintenance; self-diagnostic features |

| Best Use Case | Simple control systems; irrigation and basic pump applications | Complex industrial systems; automation and integration | Advanced monitoring; data-driven decision-making |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Using a PLC Control System?

A programmable logic controller (PLC) offers a sophisticated alternative to traditional pressure switch wiring. PLCs are capable of handling complex control logic, allowing for more precise regulation of machinery based on multiple inputs and conditions. However, they come with a higher initial cost and require personnel with programming expertise. While they provide great flexibility and scalability for complex industrial applications, the need for training and ongoing support can be a barrier for some organizations.

How Do Smart Pressure Sensors Compare in Functionality and Cost?

Smart pressure sensors represent a modern approach to pressure monitoring and control. These devices provide real-time data and can communicate with other systems for enhanced automation. Their plug-and-play nature makes them relatively easy to install and integrate into existing systems. However, they may have a moderate cost and require additional infrastructure for data management. Smart sensors excel in applications requiring continuous monitoring and data analysis, making them ideal for industries focusing on efficiency and optimization.

Conclusion: How Should B2B Buyers Choose the Right Solution for Their Needs?

When selecting the appropriate method for controlling pressure, B2B buyers must consider the specific requirements of their applications. For straightforward systems with minimal complexity, wiring a pressure switch remains a cost-effective and reliable choice. However, for organizations looking to enhance automation and efficiency, investing in a PLC or smart pressure sensors may provide long-term benefits despite the higher initial costs. Ultimately, the decision should align with the operational goals, available expertise, and budget constraints of the business.

Essential Technical Properties and Trade Terminology for how to wire a pressure switch

What Are the Key Technical Properties When Wiring a Pressure Switch?

When wiring a pressure switch, several technical properties are critical to ensure safe and efficient operation. Understanding these specifications is vital for B2B buyers in making informed purchasing decisions.

-

Voltage Rating

The voltage rating indicates the maximum voltage the pressure switch can handle. Common ratings include 115V and 230V, depending on the application. Selecting a switch with an appropriate voltage rating is essential to prevent electrical failures and ensure compliance with local regulations. -

Current Rating

This specification refers to the maximum current that the switch can carry without overheating. It is typically expressed in amperes (A). Choosing a switch with a suitable current rating is crucial for avoiding circuit overloads, which can lead to equipment damage and safety hazards. -

Contact Configuration

Contact configuration defines how the switch operates under different pressure conditions. Common configurations include normally open (NO) and normally closed (NC). Understanding the configuration helps in selecting the right switch for specific applications, ensuring proper system functionality. -

Pressure Range

The pressure range specifies the operational limits of the pressure switch, usually measured in psi (pounds per square inch). It is critical to choose a switch that accommodates the pressure requirements of the system, as using an inappropriate range may lead to inaccurate readings or premature switch failure. -

Material Grade

The material used in the construction of the pressure switch impacts its durability and resistance to environmental factors. Common materials include brass, stainless steel, and plastic. Selecting the right material is important for applications exposed to corrosive conditions or extreme temperatures. -

Temperature Rating

This indicates the maximum and minimum temperatures the pressure switch can withstand. For applications in harsh environments, choosing a switch with an appropriate temperature rating ensures reliable operation and longevity.

What Are the Common Trade Terms Related to Wiring a Pressure Switch?

Familiarity with industry jargon can enhance communication and negotiation during the procurement process. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for ensuring compatibility between components in a pressure switch assembly. -

MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product that a supplier is willing to sell. Knowing the MOQ can help businesses manage inventory effectively and avoid over-purchasing, which can tie up capital. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for price estimates for specific products. It is a critical step in the procurement process, allowing buyers to compare costs and select suppliers based on budget and quality. -

Incoterms (International Commercial Terms)

Incoterms are standardized terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for avoiding disputes over shipping costs, insurance, and delivery responsibilities. -

Lead Time

This term refers to the amount of time it takes from placing an order to receiving the product. Knowing the lead time helps businesses plan for project timelines and manage customer expectations effectively. -

Certification Standards

These standards, such as UL (Underwriters Laboratories) or CE (Conformité Européenne), indicate that a product meets specific safety and quality requirements. Ensuring compliance with these standards is vital for operational safety and market acceptance, especially in regulated industries.

Understanding these technical properties and trade terms empowers B2B buyers to make informed decisions when sourcing pressure switches, ensuring compatibility, safety, and efficiency in their applications.

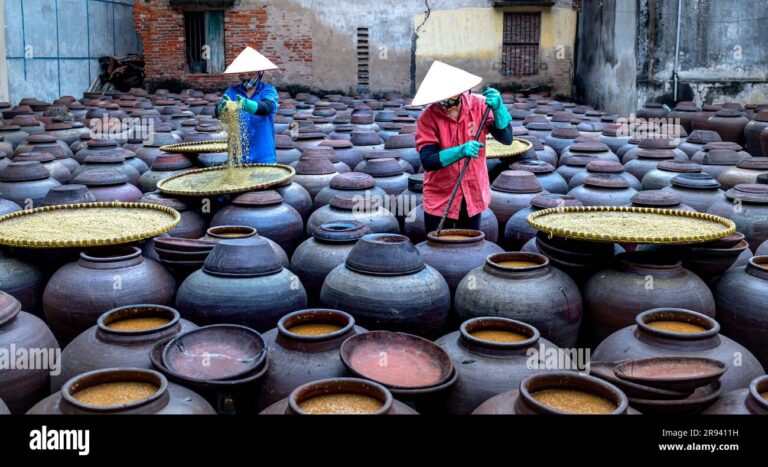

Navigating Market Dynamics and Sourcing Trends in the how to wire a pressure switch Sector

What Are the Global Drivers Shaping the Market for Wiring Pressure Switches?

The market for wiring pressure switches is influenced by several global drivers, particularly the increasing demand for efficient automation in industries such as manufacturing, oil and gas, and water management. As automation technologies evolve, pressure switches have become integral to systems requiring precise pressure control, leading to a surge in their adoption. Additionally, the growth of renewable energy sectors, particularly in regions like Africa and South America, is driving demand for reliable pressure management solutions in solar and wind energy systems.

Emerging technologies such as IoT-enabled pressure switches are also gaining traction, allowing for real-time monitoring and control. This advancement not only improves operational efficiency but also enhances predictive maintenance capabilities, reducing downtime and maintenance costs. For international B2B buyers, particularly in Nigeria and Germany, understanding these dynamics is crucial for making informed sourcing decisions.

What Are the Current and Emerging B2B Tech Trends in Wiring Pressure Switches?

One of the key trends in the wiring pressure switch sector is the integration of smart technologies. Manufacturers are increasingly offering pressure switches that can connect to centralized control systems, enabling automated adjustments based on real-time data. This trend is particularly relevant for buyers in industrial sectors, where operational efficiency is paramount.

Illustrative image related to how to wire a pressure switch

Additionally, the shift towards modular and customizable wiring solutions is on the rise. Buyers are looking for products that can be easily integrated into existing systems without extensive modifications. This flexibility is particularly advantageous for companies in regions with varying regulatory standards and operational requirements, such as the Middle East and Europe.

How Is Sustainability Impacting the Sourcing of Pressure Switch Wiring Components?

Sustainability is becoming a significant consideration in the sourcing of wiring components for pressure switches. Environmental concerns are prompting buyers to prioritize suppliers who adhere to sustainable practices and can provide eco-friendly materials. The impact of manufacturing processes on the environment is under scrutiny, and businesses are increasingly seeking certifications that demonstrate compliance with environmental standards.

Ethical sourcing is also gaining importance, as buyers look to build supply chains that are not only efficient but also socially responsible. This means selecting suppliers who ensure fair labor practices and minimize their carbon footprint. For B2B buyers, particularly those operating in environmentally conscious markets like Germany, understanding the sustainability credentials of suppliers can be a key differentiator in the purchasing process.

What Are the Implications of ‘Green’ Certifications and Materials for Wiring Pressure Switches?

The use of ‘green’ certifications and materials is increasingly influencing purchasing decisions in the wiring pressure switch sector. Buyers are now more inclined to choose products that are certified by recognized environmental standards, such as ISO 14001 or RoHS compliance. These certifications not only indicate that a product meets specific environmental criteria but also enhance brand reputation and consumer trust.

Moreover, integrating sustainable materials into pressure switch wiring—such as recyclable plastics and low-impact metals—can reduce the overall environmental footprint of industrial operations. For international buyers, particularly in emerging markets, adopting sustainable practices can also open up new business opportunities, as more companies seek partnerships with suppliers committed to sustainability.

How Has the Wiring of Pressure Switches Evolved Over Time?

The evolution of pressure switch wiring reflects broader technological advancements and industry needs. Initially, pressure switches were simple mechanical devices, primarily used in basic applications. Over the decades, the introduction of electronic components transformed these switches into sophisticated devices capable of precise control and integration with automated systems.

As industries evolved, so did the complexity of wiring configurations, leading to the development of more intuitive designs and user-friendly installation processes. Today’s pressure switches often feature advanced functionalities, such as adjustable pressure settings and diagnostic capabilities, making them essential components in modern industrial applications. For B2B buyers, understanding this evolution is critical, as it highlights the importance of investing in advanced, reliable technology that can adapt to future needs.

Frequently Asked Questions (FAQs) for B2B Buyers of how to wire a pressure switch

-

How do I solve wiring issues with a pressure switch?

To resolve wiring issues, first, ensure that you have the correct wiring diagram specific to your pressure switch model. Identify the terminals labeled for line and load connections; typically, these are marked as “LINE” and “LOAD.” Use a multimeter to check for continuity and proper voltage. Common mistakes include miswiring the motor contacts instead of the line contacts, which can cause the system to operate incorrectly. If problems persist, consult the manufacturer’s specifications or engage a qualified technician for assistance. -

What is the best way to wire a pressure switch for a water pump?

The best method for wiring a pressure switch to a water pump involves connecting the supply line to the “LINE” terminals and the pump motor to the “LOAD” terminals. For a typical configuration, connect the hot wire from the power supply to terminal 1, the hot wire to the pump motor to terminal 2, and the neutral wires to the appropriate terminals. Always refer to the specific model’s wiring diagram, as configurations may vary. Proper wiring ensures efficient operation and prevents potential damage to the pump. -

How can I ensure quality when sourcing pressure switches internationally?

To ensure quality when sourcing pressure switches internationally, conduct thorough supplier vetting. Check for certifications that meet international standards, such as ISO or CE marks. Request product samples to evaluate build quality and functionality. Additionally, review customer testimonials and case studies to gauge supplier reliability. Establish clear communication regarding quality expectations and compliance with local regulations to avoid potential issues upon delivery. -

What are the minimum order quantities (MOQ) for pressure switches?

Minimum order quantities for pressure switches can vary significantly based on the manufacturer and the specifics of the order. Some suppliers may have a MOQ of 100 units, while others may accommodate smaller orders, especially for custom designs. When negotiating with suppliers, inquire about flexibility in MOQs, particularly if you are testing new products or entering a new market. Discuss potential discounts for larger orders to maximize cost-effectiveness. -

What payment terms should I consider when sourcing pressure switches?

When sourcing pressure switches, payment terms can vary widely among suppliers. Common terms include full payment in advance, a 30% deposit with the balance due before shipment, or net 30/60 days after delivery. It’s essential to negotiate terms that align with your cash flow and risk tolerance. Consider using escrow services for larger orders to ensure that funds are only released upon satisfactory receipt of goods. Always confirm payment methods accepted by the supplier to avoid delays. -

How do I handle logistics and shipping for pressure switches?

Handling logistics for shipping pressure switches requires careful planning. Choose a reliable freight forwarder who understands international shipping regulations and can navigate customs clearance efficiently. Ensure that the supplier packages the products securely to prevent damage during transit. Discuss shipping options, such as air freight for faster delivery or sea freight for cost savings. Track shipments closely and prepare for any potential delays, particularly in regions with complex import/export regulations. -

What customization options are available for pressure switches?

Many manufacturers offer customization options for pressure switches, including adjustments to pressure settings, materials, and terminal configurations. To explore these options, communicate your specific requirements early in the sourcing process. Custom designs may involve additional costs and longer lead times, so ensure that you factor these into your project timeline. Requesting prototypes can also be beneficial to assess the custom features before committing to a larger order. -

How can I ensure compliance with local regulations when importing pressure switches?

To ensure compliance with local regulations when importing pressure switches, research the specific standards applicable in your region, such as electrical safety and environmental regulations. Verify that the supplier’s products meet these standards and can provide necessary documentation, such as test reports or certification labels. Engage with local customs authorities to understand import duties and taxes. Consider consulting with a compliance expert to navigate complex regulations and avoid potential penalties.

Top 5 How To Wire A Pressure Switch Manufacturers & Suppliers List

1. Lennox – Pressure Switch for G50UH-36B-090-12

Domain: justanswer.com

Registered: 2004 (21 years)

Introduction: Pressure switch for HVAC units, specifically for Lennox G50UH-36B-090-12 model. Both wires are purple, indicating that polarity does not matter for connection.

2. HornBlasters – Pressure Switch Wiring Guide

Domain: hornblasters.com

Registered: 2003 (22 years)

Introduction: Wiring Your Pressure Switch with Separate 40A Relay

3. Do It Yourself – Well Pressure Switch

Domain: doityourself.com

Registered: 1995 (30 years)

Introduction: well pressure switch, contactor, terminals, wiring, well control box, well pump

4. Boshart – Class 9013FSG2 Pressure Switch Installation

Domain: support.boshart.com

Registered: 1997 (28 years)

Introduction: Wiring a Class 9013FSG2 pressure switch; intended for installation by technically qualified personnel; compliance with national and local electrical codes is required; potential hazards include electrical shock, fire hazard, unsatisfactory performance, and equipment failure; instructional video available at www.youtube.com/watch?v=PzFZDzEesmw.

5. RPS – 220V Well Pump Pressure Switch

Domain: rpswaterpumps.com

Registered: 2022 (3 years)

Introduction: 220V regular action well pump pressure switch; designed for use with pressure tanks or pressurized irrigation systems; requires wiring for connecting pump starter box to pressure switch and from pressure switch to breaker or outlet; includes terminals L1, L2 for power supply and T1, T2 for pump connections; features grounding screws; safety instructions include turning off power and testing voltag…

Strategic Sourcing Conclusion and Outlook for how to wire a pressure switch

In conclusion, effectively wiring a pressure switch is essential for ensuring the reliable operation of your equipment, whether in industrial applications or smaller scale operations. Key takeaways include the importance of understanding terminal functions and ensuring correct connections to prevent issues such as continuous motor operation or system overloading. Strategic sourcing of quality components can lead to enhanced performance and durability, significantly impacting operational efficiency and maintenance costs.

For international B2B buyers in Africa, South America, the Middle East, and Europe, investing in high-quality pressure switches and related components is crucial for maximizing equipment performance. As you explore suppliers, consider their expertise, product reliability, and support services to ensure you make informed decisions.

Looking ahead, the demand for efficient and reliable pressure control systems is set to rise as industries evolve. Now is the time to solidify partnerships with trusted manufacturers and distributors, enabling you to stay ahead in a competitive marketplace. Reach out to potential suppliers today to discuss your needs and explore solutions that will enhance your operational capabilities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.