Unlocking Value: A Strategic Analysis of the Hidden Door Hardware Hinge Market

Introduction: Navigating the Global Market for hidden door hardware hinge

In today’s competitive landscape, sourcing high-quality hidden door hardware hinges presents a unique challenge for international B2B buyers. As the demand for innovative design solutions rises, businesses are increasingly turning to hidden door hinges to maximize space and enhance aesthetics. However, navigating this specialized market requires an understanding of the various types of hinges available, their applications, and the nuances of supplier vetting.

This comprehensive guide delves into the diverse range of hidden door hardware hinges, including concealed, flush mount, and pivot hinges, while outlining their specific applications in residential, commercial, and industrial settings. Additionally, it offers valuable insights into the procurement process, including cost considerations and best practices for evaluating potential suppliers, ensuring that buyers can make informed decisions tailored to their specific needs.

By equipping B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Brazil and Nigeria—with essential knowledge, this guide aims to empower them to navigate the complexities of the hidden door hardware hinge market confidently. Ultimately, informed purchasing decisions will not only enhance the functionality and design of projects but also contribute to the long-term success of businesses in an increasingly globalized economy.

Understanding hidden door hardware hinge Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pin Hinges | Patented pin system, flush mount design, supports heavy doors (up to 300 lbs) | Residential secret doors, bookcases | Pros: Strong, easy to install; Cons: Requires skilled carpentry for installation. |

| Concealed Hinges | Invisible when door is closed, adjustable, various finishes available | Cabinets, office partitions | Pros: Aesthetic appeal, hides imperfections; Cons: Limited weight capacity compared to heavy-duty options. |

| 3D Adjustable Hinges | Allows for three-dimensional adjustments post-installation | High-end residential, commercial doors | Pros: Easy alignment and adjustment; Cons: Higher cost than standard hinges. |

| Pivot Hinges | Allows doors to pivot rather than swing, suitable for heavy doors | High-traffic areas, commercial spaces | Pros: Space-saving design, supports heavy loads; Cons: More complex installation. |

| Spring-Loaded Hinges | Automatically closes doors, adjustable closure rates | Fire-rated doors, security applications | Pros: Enhances safety and convenience; Cons: May require more maintenance over time. |

What are the Key Characteristics of Pin Hinges?

Pin hinges are a popular choice for hidden door applications, featuring a patented pin system that allows for a seamless, flush mount design. These hinges can support heavy doors, making them ideal for secret doors or bookcases that require durability and stability. When considering a purchase, B2B buyers should note the necessity for skilled carpentry, as installation can be challenging without prior experience. The strength and ease of installation make pin hinges a preferred option for those looking to create hidden spaces.

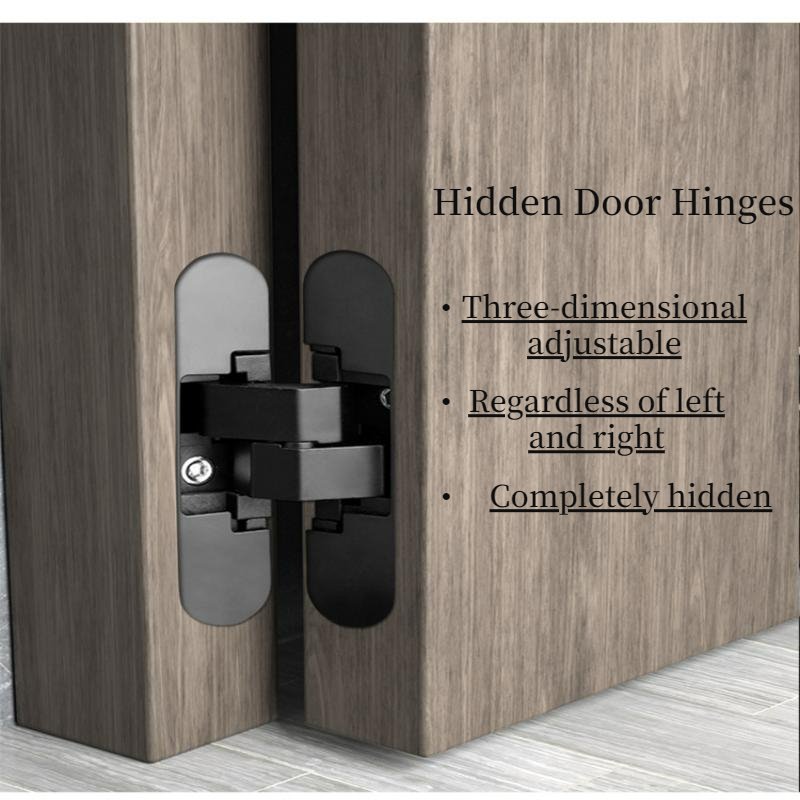

Illustrative image related to hidden door hardware hinge

How Do Concealed Hinges Enhance Aesthetic Appeal?

Concealed hinges, also known as invisible hinges, are designed to be hidden when the door is closed, providing a clean and modern look. They are adjustable and available in various finishes, making them suitable for high-end cabinetry and office partitions. B2B buyers should consider the aesthetic benefits and the ability to hide minor construction imperfections. However, it’s important to be mindful of their weight capacity limitations, which may not be suitable for all applications.

Why Choose 3D Adjustable Hinges for Your Projects?

3D adjustable hinges allow for precise three-dimensional adjustments even after installation, making them a versatile option for high-end residential and commercial doors. This feature is particularly valuable in applications where alignment is critical. While they offer ease of adjustment, buyers should be prepared for a higher price point compared to standard hinges. The investment can lead to long-term benefits in terms of functionality and finish.

What Are the Benefits of Using Pivot Hinges?

Pivot hinges differ from traditional swing hinges by allowing doors to pivot from a fixed point at the top and bottom. This design is especially advantageous in high-traffic areas and commercial spaces where space-saving solutions are necessary. They support heavy doors and provide a unique aesthetic appeal. However, the installation process can be more complex, requiring skilled labor, which is an important consideration for B2B buyers.

How Do Spring-Loaded Hinges Contribute to Safety?

Spring-loaded hinges automatically close doors after use, making them ideal for fire-rated doors and security applications. They enhance safety by ensuring doors remain closed, thus preventing unauthorized access or fire hazards. While they offer significant convenience, B2B buyers should consider the potential for increased maintenance over time, as the spring mechanism may require servicing. The balance between safety and maintenance is crucial when selecting this type of hinge.

Illustrative image related to hidden door hardware hinge

Key Industrial Applications of hidden door hardware hinge

| Industry/Sector | Specific Application of hidden door hardware hinge | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Residential Construction | Hidden doors for home libraries or secret rooms | Enhances aesthetic appeal and maximizes space utility | Quality of materials, weight capacity, and ease of installation |

| Commercial Design | Concealed access doors in office environments | Improves office aesthetics and provides secure access points | Compliance with local building codes and security requirements |

| Hospitality | Hidden doors in luxury hotel suites | Increases guest privacy and enhances luxury experience | Durability for high-traffic areas and design compatibility |

| Retail | Secret storage areas in retail spaces | Provides discreet storage for valuable merchandise | Customization options and ease of access for staff |

| Security | Concealed doors for secure facilities like data centers | Enhances security by providing hidden access points | Robustness and resistance to tampering or forced entry |

How Are Hidden Door Hardware Hinges Used in Residential Construction?

In residential construction, hidden door hardware hinges are often utilized in creating hidden doors for home libraries, secret rooms, or storage spaces. These hinges allow doors to blend seamlessly into walls or furniture, enhancing the aesthetic appeal while maximizing space utility. Buyers in this sector should prioritize the quality of materials to ensure durability and the weight capacity of the hinges, as some hidden doors can support significant loads. Additionally, ease of installation is crucial for homeowners and contractors looking to integrate such features without extensive remodeling.

What Are the Benefits of Hidden Door Hinges in Commercial Design?

In commercial design, concealed access doors play a vital role in maintaining a sleek and professional appearance in office environments. These hidden hinges are often used for doors that lead to storage areas, mechanical rooms, or even restrooms, allowing for a clean and unobtrusive design. The primary benefit here is the improvement of overall aesthetics, coupled with the functionality of secure access points. Buyers must consider compliance with local building codes, ensuring that the hidden door solutions meet safety and accessibility standards.

How Do Hospitality Businesses Utilize Hidden Door Hinges?

Hidden door hinges are particularly valuable in the hospitality sector, where they can be used to create concealed doors in luxury hotel suites. This application enhances guest privacy and contributes to a luxurious experience by allowing for discreet access to amenities like mini-bars or storage closets. When sourcing these hinges, businesses should focus on the durability of the product to withstand high-traffic usage and ensure design compatibility with the overall decor of the hotel.

What Are the Applications of Hidden Hinges in Retail?

In retail settings, hidden door hardware hinges are ideal for creating secret storage areas where valuable merchandise can be discreetly stored. This application helps retailers maintain a clean and organized appearance while ensuring security for high-value items. When sourcing hinges for retail applications, it is essential to consider customization options that fit specific store designs and the ease of access for staff, enabling quick retrieval of items without disrupting the customer experience.

How Do Security Facilities Benefit from Hidden Door Hinges?

Security facilities, such as data centers, leverage hidden door hardware hinges to create concealed access points that enhance security measures. These hidden doors can provide discreet entry to sensitive areas, minimizing the risk of unauthorized access. Buyers in this sector should prioritize robustness and resistance to tampering or forced entry when selecting hinges, ensuring that the hidden doors not only serve their functional purpose but also meet stringent security requirements.

3 Common User Pain Points for ‘hidden door hardware hinge’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Hidden Door Hinge for Heavy Doors

The Problem: A B2B buyer responsible for sourcing hardware for a commercial construction project faces a significant challenge when needing to select hidden door hinges that can support heavy doors. The buyer is concerned about the weight capacity and durability of the hinges, especially as the doors will be frequently used in high-traffic areas. Without adequate knowledge of the specifications, they risk selecting hinges that may fail, leading to costly repairs and project delays.

The Solution: To ensure the right selection of hidden door hinges, it is crucial to look for products that are specifically rated for the door weight and usage frequency. Buyers should prioritize products from reputable manufacturers that provide detailed specifications, including load capacity and material durability. For instance, hinges like the Murphy Door’s patented pin hinge system can support doors weighing up to 300 pounds. It is also advisable to consult with manufacturers directly to discuss project requirements and obtain samples for testing before bulk purchasing. This proactive approach ensures that the selected hinges not only meet but exceed the performance expectations for heavy-duty applications.

Scenario 2: Challenges in Installing Hidden Door Hardware with Limited Experience

The Problem: A buyer representing a mid-sized construction firm lacks the experience required to install hidden door hardware effectively. The complexity of the installation process can lead to improper fitting and alignment issues, resulting in doors that do not operate smoothly. This not only affects the project timeline but also compromises the aesthetic appeal of the hidden doors, which is often a key selling point for clients.

The Solution: To mitigate installation challenges, buyers should invest in comprehensive training and resources. Many manufacturers provide detailed installation manuals and online tutorials that can guide users through the process. Additionally, sourcing hidden door hardware kits that come with all necessary components—including a pin remover tool and screws—can simplify the installation process. Engaging a skilled carpenter or a professional installer with experience in hidden door systems can also be a wise investment. This collaboration ensures that the installation is completed efficiently and correctly, maintaining the integrity of the design and functionality.

Scenario 3: The Need for Customization in Hidden Door Design

The Problem: B2B buyers often encounter situations where clients require customized hidden door solutions to fit unique architectural designs or specific aesthetic preferences. This need for customization can lead to frustration when off-the-shelf products do not meet the specifications, resulting in wasted time and resources as buyers seek out alternatives.

The Solution: To address customization needs effectively, buyers should seek out manufacturers that offer bespoke solutions or modular systems that can be tailored to specific project requirements. Engaging in early discussions with suppliers about customization options can yield valuable insights into design capabilities and limitations. Additionally, utilizing advanced design software that allows for 3D modeling of hidden doors can help visualize the final product and make necessary adjustments before production. Establishing a strong relationship with suppliers who are open to collaborative design can ensure that the final product aligns perfectly with client expectations, enhancing satisfaction and driving repeat business.

Illustrative image related to hidden door hardware hinge

By understanding these common pain points and implementing targeted solutions, B2B buyers can navigate the complexities of sourcing and installing hidden door hardware hinges more effectively, ultimately leading to successful project outcomes.

Strategic Material Selection Guide for hidden door hardware hinge

What are the Key Materials Used in Hidden Door Hardware Hinges?

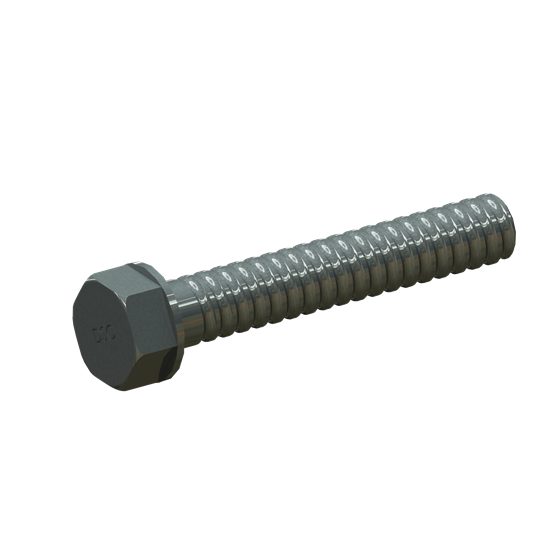

When selecting hidden door hardware hinges, the choice of material plays a crucial role in determining the performance, durability, and overall suitability for specific applications. Here, we analyze four common materials used in the manufacturing of hidden door hardware hinges: stainless steel, brass, aluminum, and plastic composites. Each material has distinct properties, advantages, and considerations for international B2B buyers.

How Does Stainless Steel Perform in Hidden Door Hardware Hinges?

Stainless steel is renowned for its excellent corrosion resistance, strength, and durability, making it a popular choice for hidden door hardware hinges. It can withstand high temperatures and pressures, which is essential for applications in various climates. The key properties include a temperature rating up to 870°C and a pressure rating that varies based on the specific alloy used.

Illustrative image related to hidden door hardware hinge

Pros: Stainless steel hinges are highly durable, resistant to rust, and require minimal maintenance. They are suitable for both indoor and outdoor applications, making them versatile for different environments.

Cons: The primary drawback is the higher cost compared to other materials. Additionally, manufacturing stainless steel hinges can be more complex due to the need for specialized tools and processes.

Impact on Application: Stainless steel is compatible with a wide range of environments, including humid and coastal areas. It is particularly beneficial in regions like Brazil and Nigeria, where humidity can lead to corrosion in lesser materials.

What Advantages Does Brass Offer for Hidden Door Hardware Hinges?

Brass is another commonly used material in hidden door hardware hinges, known for its aesthetic appeal and natural resistance to corrosion. It typically has a temperature rating of around 200°C and can handle moderate pressure levels.

Illustrative image related to hidden door hardware hinge

Pros: Brass hinges provide a classic look and are naturally antimicrobial, making them suitable for applications in healthcare and food service environments. They are also easier to machine compared to stainless steel.

Cons: Brass can tarnish over time, requiring regular maintenance to maintain its appearance. It is also less robust than stainless steel, making it less suitable for heavy-duty applications.

Impact on Application: Brass hinges are ideal for decorative applications in upscale residential or commercial settings, particularly in Europe, where aesthetics are often prioritized.

How Does Aluminum Compare for Hidden Door Hardware Hinges?

Aluminum is a lightweight and cost-effective material used in hidden door hardware hinges, with a temperature rating of up to 600°C and moderate pressure resistance.

Pros: The lightweight nature of aluminum makes it easy to install and handle. It is also resistant to corrosion, particularly when anodized, and is cost-effective for mass production.

Illustrative image related to hidden door hardware hinge

Cons: While aluminum is durable, it is not as strong as stainless steel, which may limit its use in heavy applications. It can also be more susceptible to scratches and dents.

Impact on Application: Aluminum hinges are suitable for lightweight doors and applications where cost is a primary concern, such as in budget-conscious projects in South America and parts of Africa.

What Role Do Plastic Composites Play in Hidden Door Hardware Hinges?

Plastic composites are increasingly being used in hidden door hardware hinges, particularly in applications that require lightweight and non-corrosive materials. They typically have a temperature rating of around 80°C and are not suitable for high-pressure applications.

Illustrative image related to hidden door hardware hinge

Pros: These hinges are cost-effective, lightweight, and resistant to corrosion and chemicals. They can be molded into complex shapes, allowing for innovative designs.

Cons: Plastic composites may not offer the same strength and durability as metal options, making them less suitable for heavy-duty applications. They can also degrade under UV exposure unless specifically treated.

Impact on Application: Plastic composite hinges are ideal for interior applications where aesthetics and weight are more critical than strength, making them a viable option in various markets, including residential sectors in the Middle East.

Summary Table of Material Selection for Hidden Door Hardware Hinges

| Material | Typical Use Case for hidden door hardware hinge | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy-duty applications, outdoor settings | High durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Brass | Decorative applications, healthcare environments | Aesthetic appeal and antimicrobial properties | Tarnishes over time, less robust | Medium |

| Aluminum | Lightweight doors, budget projects | Cost-effective and lightweight | Less strength, prone to scratches | Low |

| Plastic Composites | Interior applications, innovative designs | Lightweight and resistant to corrosion | Lower strength, UV degradation risk | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them choose the right hidden door hardware hinge material based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for hidden door hardware hinge

What Are the Key Stages in the Manufacturing Process of Hidden Door Hardware Hinges?

The manufacturing of hidden door hardware hinges involves several critical stages, each designed to ensure the final product meets both functional and aesthetic standards. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Hidden Door Hinges?

The process begins with the selection of high-quality materials, typically stainless steel or brass, which are chosen for their durability and resistance to corrosion. Raw materials are often cut into specific shapes and sizes using precision cutting techniques, such as laser cutting or water jet cutting. This ensures that each component is manufactured to exact specifications, minimizing waste and enhancing efficiency.

Illustrative image related to hidden door hardware hinge

What Forming Techniques Are Used in the Production of Hidden Door Hinges?

Once the materials are prepared, they undergo forming processes. Techniques such as stamping, forging, or machining are employed to shape the hinge components. Stamping is particularly common for producing flat parts, while forging is utilized for components requiring greater strength. Machining processes, including CNC milling and turning, are used to achieve precise dimensions and intricate designs, which are essential for the functionality of hidden hinges.

How Are Hidden Door Hinges Assembled?

After forming, the components are assembled. This can involve manual or automated processes, depending on the scale of production. Key elements, such as pivot pins and ball bearings, are carefully integrated into the assembly to ensure smooth operation. The assembly stage is critical, as proper alignment and fitting of components directly impact the hinge’s performance and longevity.

What Finishing Techniques Are Applied to Hidden Door Hinges?

The final manufacturing stage is finishing, which not only enhances the aesthetic appeal of the hinges but also provides protective coatings. Techniques such as electroplating, powder coating, or anodizing are commonly employed. These processes improve corrosion resistance and durability while allowing for various color and texture options. The finishing touches often include quality checks to ensure consistency in appearance and performance.

Illustrative image related to hidden door hardware hinge

What Quality Assurance Standards Are Relevant for Hidden Door Hardware Hinges?

Quality assurance in the manufacturing of hidden door hinges is vital for ensuring the reliability and safety of the product. International standards such as ISO 9001 are often implemented to maintain quality management systems. Additionally, industry-specific certifications like CE marking or API standards may apply, depending on the intended use and market.

How Are Quality Control Checkpoints Structured in the Manufacturing Process?

Quality control (QC) is integrated at various stages of the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components for compliance with specified standards before they enter the production process.

- In-Process Quality Control (IPQC): During manufacturing, operators conduct regular inspections to ensure that processes are performed correctly and that components meet the desired specifications.

- Final Quality Control (FQC): After assembly and finishing, a comprehensive inspection is conducted to verify that the final product meets all quality and safety standards.

What Common Testing Methods Are Utilized for Hidden Door Hinges?

Testing methods for hidden door hinges include mechanical testing, such as load and torque tests, to assess the performance and durability of the hinges under stress. Corrosion resistance tests, including salt spray tests, are also essential to ensure that the hinges can withstand environmental factors, especially in humid or coastal areas. Additionally, functionality tests, which evaluate the ease of operation and alignment of the hinges, are crucial for confirming that the product meets usability standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is paramount. Here are several strategies:

Illustrative image related to hidden door hardware hinge

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, QC systems, and compliance with international standards firsthand.

- Quality Reports: Requesting detailed quality reports that outline testing results, compliance certifications, and production processes can provide insight into a supplier’s commitment to quality.

- Third-Party Inspections: Engaging independent inspection agencies to evaluate the manufacturing facility and product quality can add an extra layer of assurance. These inspections can be particularly important for buyers unfamiliar with local manufacturers.

What Are the QC and Certification Nuances for International B2B Buyers?

B2B buyers must navigate various QC and certification nuances when sourcing hidden door hardware hinges internationally. Understanding local regulations and standards is crucial, as these can vary significantly across regions. For example, European buyers may prioritize CE marking, while North American clients might focus on compliance with ANSI standards.

Additionally, language barriers and cultural differences can impact communication regarding quality expectations. Buyers should establish clear guidelines and expectations from the outset to mitigate misunderstandings. It is also advisable to build relationships with local representatives or consultants who can facilitate smoother transactions and provide insights into regional market practices.

Conclusion

The manufacturing processes and quality assurance practices for hidden door hardware hinges are multifaceted and critical for ensuring high-quality products that meet international standards. By understanding these processes, B2B buyers can make informed decisions when sourcing hinges for their projects, ensuring reliability and satisfaction in their purchases. Engaging with suppliers who demonstrate rigorous quality control and compliance with relevant standards can significantly enhance the success of international transactions in this niche market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hidden door hardware hinge’

In the evolving landscape of construction and design, hidden door hardware hinges have gained popularity for their aesthetic appeal and functionality. This practical sourcing guide provides a step-by-step checklist to assist international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, in procuring high-quality hidden door hardware hinges that meet their specific needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to establish clear technical specifications for the hidden door hardware hinges you require. Consider factors such as door weight capacity, material durability, and dimensions. This clarity ensures that you procure products that fit seamlessly into your design and functional requirements.

Illustrative image related to hidden door hardware hinge

Step 2: Research and Identify Reputable Suppliers

Conduct thorough research to identify potential suppliers who specialize in hidden door hardware hinges. Look for suppliers with a strong track record in the industry, positive customer reviews, and a comprehensive product range. Supplier reliability is paramount, as it impacts not only the quality of your hinges but also delivery timelines and service levels.

Step 3: Evaluate Product Quality and Compliance

Quality assurance is critical when sourcing hidden door hardware hinges. Verify that the products meet relevant industry standards and certifications. Look for features such as corrosion resistance, load-bearing capabilities, and ease of installation. These aspects are crucial for ensuring the longevity and reliability of the hinges in your applications.

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples of the hidden door hardware hinges from shortlisted suppliers. This allows you to assess the product’s quality, functionality, and compatibility with your specific projects. Testing samples will help you avoid costly mistakes and ensure that the hinges meet your expectations.

Step 5: Compare Pricing and Terms

Once you have selected a few suitable suppliers, compare their pricing structures and payment terms. While it’s tempting to choose the lowest price, consider the total cost of ownership, including shipping, handling, and potential customs duties. A slightly higher-priced product may offer better quality and longer-term savings.

Step 6: Verify Supplier Certifications

Ensure that your chosen suppliers have the necessary certifications and quality management systems in place. Look for ISO certifications or other relevant industry standards that indicate a commitment to quality and safety. This step helps mitigate risks associated with sourcing from unverified suppliers.

Step 7: Establish Clear Communication Channels

Effective communication is vital throughout the sourcing process. Establish clear channels for discussing specifications, delivery schedules, and any potential issues. Regular communication helps foster a positive relationship with suppliers, ensuring timely updates and quick resolutions to any challenges that may arise.

By following this checklist, B2B buyers can navigate the complexities of sourcing hidden door hardware hinges with confidence, ensuring they select the right products for their projects while minimizing risks and maximizing value.

Comprehensive Cost and Pricing Analysis for hidden door hardware hinge Sourcing

What Are the Key Cost Components in Hidden Door Hardware Hinge Sourcing?

When sourcing hidden door hardware hinges, understanding the cost structure is crucial for effective budgeting and decision-making. The cost components typically include:

-

Materials: The choice of materials significantly affects the price. High-quality metals (e.g., stainless steel, brass) provide durability and corrosion resistance but come at a premium. Additionally, specialized finishes (like matte black or brushed nickel) can increase costs.

-

Labor: Labor costs encompass both manufacturing and installation. Skilled labor is essential for precision assembly, especially for custom designs. In regions like Africa and South America, labor costs may vary, impacting overall pricing.

-

Manufacturing Overhead: This includes expenses associated with the production process, such as utilities, equipment depreciation, and factory maintenance. Efficient manufacturing processes can help keep these costs lower.

-

Tooling: Custom tooling for specialized hinges can be a significant upfront investment. However, it allows for tailored designs, which can be beneficial for unique projects or high-volume orders.

-

Quality Control (QC): Implementing stringent QC measures ensures that products meet industry standards, which is essential for B2B buyers looking for reliability. This may add to the overall cost but reduces the risk of returns and dissatisfaction.

-

Logistics: Shipping and handling costs can vary based on the supplier’s location and the buyer’s destination. International shipping may require additional documentation and customs fees, impacting overall expenses.

-

Margin: Suppliers add a margin to cover operational costs and profit. Understanding the margin expectations can help buyers negotiate better prices.

How Do Price Influencers Affect Hidden Door Hardware Hinge Costs?

Several factors influence the pricing of hidden door hardware hinges:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often attract volume discounts. Buyers should assess their needs and negotiate MOQs to optimize costs.

-

Specifications and Customization: Customized hinges will typically incur higher costs due to the additional design and manufacturing efforts. Buyers should clearly define their specifications to ensure accurate pricing.

-

Material Quality and Certifications: High-quality materials and certifications (like ISO or CE) can drive up costs. Buyers should weigh the benefits of premium materials against their project requirements.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but offer better quality assurance and customer service.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international transactions. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, affecting the total cost.

What Buyer Tips Can Enhance Cost-Efficiency for Hidden Door Hardware Hinges?

B2B buyers, especially those from diverse regions, can leverage several strategies to ensure cost-effectiveness:

-

Negotiation: Always engage in negotiations. Suppliers may have flexibility in pricing, especially for larger orders or long-term partnerships. Don’t hesitate to ask for discounts or favorable payment terms.

-

Total Cost of Ownership (TCO): Consider the long-term costs associated with the hinges, including maintenance, durability, and potential replacement needs. Investing in higher-quality hinges can reduce overall TCO.

-

Research and Compare: Explore various suppliers and their offerings. This enables buyers to identify competitive pricing and quality options that meet their needs.

-

Local Suppliers: For buyers in regions like Africa or South America, sourcing from local suppliers can reduce shipping costs and lead times, enhancing overall project efficiency.

-

Awareness of Pricing Nuances: Understand that international pricing can be influenced by exchange rates, tariffs, and local market conditions. Stay informed about these factors to make better purchasing decisions.

Disclaimer on Indicative Prices

Prices for hidden door hardware hinges can vary widely based on the factors discussed. The figures mentioned in product references (e.g., $149 for a basic kit or $899 for high-capacity systems) serve as a guideline. Actual costs may differ based on specific requirements, supplier negotiations, and market conditions. Always obtain quotes tailored to your project needs for accurate budgeting.

Alternatives Analysis: Comparing hidden door hardware hinge With Other Solutions

Exploring Alternative Solutions for Hidden Door Hardware Hinges

In the realm of door solutions, hidden door hardware hinges have gained popularity for their aesthetic appeal and functional efficiency. However, there are several alternative options available in the market that may suit different project requirements or budget constraints. This section evaluates hidden door hardware hinges against other viable solutions, providing insights for international B2B buyers looking to make informed decisions.

| Comparison Aspect | Hidden Door Hardware Hinge | Concealed Pivot Hinges | Traditional Hinges |

|---|---|---|---|

| Performance | High load capacity (up to 300 lbs), seamless operation | Very good for heavy doors, limited visibility | Reliable but more visible, varied load capacities |

| Cost | Moderate ($149.00 per kit) | Varies ($119.00 to $900.00) | Low to moderate ($20.00 to $100.00) |

| Ease of Implementation | Requires advanced woodworking skills for installation | Moderate complexity, may require professional installation | Simple installation, suitable for DIY |

| Maintenance | Low maintenance; durable with a 3-year warranty | Low maintenance; robust design | Moderate; may require regular tightening and replacement |

| Best Use Case | Ideal for secret doors, hidden rooms, or aesthetic applications | Best for heavy-duty applications, such as commercial spaces | Suitable for standard residential doors |

What Are the Benefits and Drawbacks of Concealed Pivot Hinges?

Concealed pivot hinges are a strong alternative to hidden door hardware hinges, particularly for heavy-duty applications. These hinges are designed to support the weight of large doors and provide a clean aesthetic by keeping the hardware hidden. While they offer excellent performance and a low maintenance requirement, their installation can be complex, often necessitating professional assistance. The cost can vary significantly based on the brand and specifications, with some models reaching up to $900. Therefore, while they are suitable for high-traffic or commercial environments, the investment may not be justified for standard residential applications.

How Do Traditional Hinges Compare to Hidden Door Hardware Hinges?

Traditional hinges are a classic choice, widely used for various door applications. They are cost-effective, with prices starting as low as $20.00, making them accessible for budget-conscious projects. However, they are more visible and can detract from the aesthetic appeal of a hidden door. Installation is straightforward, often suitable for DIY enthusiasts. Maintenance is moderate, as traditional hinges may require periodic tightening and eventual replacement. For buyers looking for an economical solution without the need for concealment, traditional hinges are a viable option.

Conclusion: How to Choose the Right Solution for Your Project

When selecting the appropriate door hinge solution, B2B buyers should consider specific project needs, including weight capacity, aesthetic preferences, and budget constraints. Hidden door hardware hinges are ideal for applications requiring a seamless look and the ability to support significant weight. Concealed pivot hinges provide robust options for commercial environments, while traditional hinges offer an economical choice for standard installations. By evaluating these aspects, buyers can make informed decisions that align with their project goals and operational requirements.

Essential Technical Properties and Trade Terminology for hidden door hardware hinge

What Are the Key Technical Properties of Hidden Door Hardware Hinges?

Understanding the essential technical properties of hidden door hardware hinges is crucial for B2B buyers, particularly those involved in construction, architecture, or interior design. These properties not only influence the product’s performance but also determine its suitability for various applications.

-

Material Grade

The material grade of hidden door hinges typically indicates their strength and durability. Common materials include stainless steel, brass, and zinc alloy. For example, stainless steel is often preferred for its corrosion resistance, making it ideal for humid environments. Selecting the right material grade ensures that the hinges can withstand the intended load and environmental conditions, which is vital for long-term performance. -

Weight Capacity

Each hidden door hinge has a specified weight capacity, which indicates the maximum load it can support. Many hinges can accommodate doors weighing up to 300 pounds or more. Understanding weight capacity is essential for buyers to ensure that the selected hinges will safely support the intended door design, especially in commercial applications where heavier doors may be used. -

Torque Rating

The torque rating is a measure of the hinge’s ability to handle dynamic loads without failure. For instance, a hinge with a torque rating of 1160 lbs can sustain significant stress without compromising its functionality. This specification is particularly important for high-traffic areas where doors are frequently opened and closed, as it impacts the hinge’s longevity. -

Adjustment Features

Many modern hidden door hinges come with adjustable features, allowing for fine-tuning during installation. For example, 3D adjustable hinges enable vertical, horizontal, and depth adjustments. This flexibility is crucial for ensuring a perfect fit, especially in environments where wall structures may not be perfectly level. -

Finish Options

The finish of hidden door hinges not only affects aesthetics but also impacts corrosion resistance and ease of maintenance. Common finishes include satin nickel, polished chrome, and matte black. Choosing the right finish is important for maintaining the overall design integrity of the door and its surroundings, while also ensuring long-lasting performance against wear and tear. -

Warranty Period

A robust warranty period (often ranging from 3 to 10 years) signifies the manufacturer’s confidence in their product’s durability. A longer warranty can provide peace of mind for B2B buyers, indicating that the hinges are built to withstand daily use and potential environmental challenges.

What Are Common Trade Terms in the Hidden Door Hardware Industry?

Navigating the world of hidden door hardware hinges requires familiarity with specific trade terminology that can influence purchasing decisions.

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products that are sold under another brand’s name. Understanding OEM relationships is crucial for buyers looking to source high-quality components that meet specific design requirements while maintaining brand integrity. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is important for B2B buyers, as it affects inventory management and cash flow. Knowing the MOQ helps in planning purchases and ensuring sufficient stock for projects without overcommitting financially. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing information for specific products. B2B buyers use RFQs to compare costs and terms from different manufacturers, enabling informed decision-making based on budget constraints and project specifications. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping costs, risks, and obligations, ensuring smooth transactions across borders. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times is essential for project planning, as delays in delivery can impact construction schedules and overall project timelines. -

Certification Standards

Certification standards, such as ANSI/BHMA (American National Standards Institute/Builders Hardware Manufacturers Association), indicate that the hinges meet specific performance and safety criteria. Being aware of these certifications ensures that the purchased hardware complies with local regulations and industry best practices.

By grasping these technical properties and trade terms, B2B buyers can make well-informed decisions when sourcing hidden door hardware hinges, ensuring quality, safety, and compliance with project specifications.

Illustrative image related to hidden door hardware hinge

Navigating Market Dynamics and Sourcing Trends in the hidden door hardware hinge Sector

What Are the Current Market Dynamics and Key Trends Affecting the Hidden Door Hardware Hinge Sector?

The global market for hidden door hardware hinges is experiencing a notable shift, driven by a growing demand for innovative design solutions and multifunctional living spaces. Key trends include the rise of customization, where consumers and businesses seek tailored products that fit unique architectural styles. The preference for seamless integration in interior designs is pushing manufacturers to innovate, resulting in a diverse range of products that cater to various aesthetics and functionalities. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding these trends is crucial for making informed sourcing decisions.

Technological advancements are also reshaping the industry. The integration of smart technology into door hardware is on the rise, enhancing security and user convenience. Products that allow for remote access and monitoring are becoming increasingly popular, particularly in commercial sectors. Additionally, the push towards sustainable building practices is influencing sourcing strategies, as buyers prioritize suppliers who demonstrate environmental responsibility.

Market dynamics are characterized by a competitive landscape with established manufacturers and new entrants. Buyers should be aware of the regional variations in demand; for instance, markets in Europe may prioritize aesthetic appeal, while those in Africa and South America might focus on durability and cost-effectiveness. Building strong relationships with suppliers who understand these regional nuances can provide a competitive advantage.

Illustrative image related to hidden door hardware hinge

How Can Sustainability and Ethical Sourcing Impact the Hidden Door Hardware Hinge Industry?

Sustainability has become a pivotal concern for B2B buyers in the hidden door hardware hinge sector. Environmental impact assessments are now standard practice, as businesses seek to minimize their carbon footprint and align with global sustainability goals. This shift is prompting manufacturers to adopt greener production methods and materials, such as recycled metals and eco-friendly coatings.

Ethical sourcing is equally important, as buyers are increasingly scrutinizing their supply chains. Ensuring that suppliers adhere to fair labor practices and environmental regulations not only enhances brand reputation but also mitigates risks associated with supply chain disruptions. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as benchmarks for suppliers, providing buyers with confidence in their sourcing decisions.

Furthermore, buyers are encouraged to seek partnerships with manufacturers who prioritize sustainability and ethical practices. This trend not only satisfies regulatory requirements but also appeals to environmentally conscious consumers, creating a win-win situation for businesses and the planet.

How Has the Hidden Door Hardware Hinge Industry Evolved Over Time?

The evolution of hidden door hardware hinges can be traced back to the early 20th century when innovative designs began to emerge in response to changing architectural styles. Initially used primarily in high-end residential applications, these hinges have gained popularity across various sectors, including commercial and industrial settings.

Illustrative image related to hidden door hardware hinge

As consumer preferences shifted towards minimalistic and modern aesthetics, the design of hidden door hinges evolved to accommodate these trends. The introduction of concealed hinges and flush mount systems allowed for doors to blend seamlessly into walls, providing both functionality and visual appeal. Today, the market offers a wide range of products that cater to diverse needs, from heavy-duty commercial hinges to lightweight solutions for residential projects.

Overall, the hidden door hardware hinge sector has transformed into a dynamic market characterized by innovation and adaptability, making it essential for B2B buyers to stay informed about ongoing developments and trends.

Frequently Asked Questions (FAQs) for B2B Buyers of hidden door hardware hinge

-

How do I choose the right hidden door hardware hinge for my project?

Choosing the right hidden door hardware hinge involves several factors. First, consider the weight and thickness of the door, as this will determine the type of hinge needed. Look for hinges with a suitable load capacity, typically ranging from 300 to 1,100 lbs. Additionally, assess the installation requirements—some hinges may require advanced carpentry skills. Finally, evaluate the finish and design to ensure it complements the overall aesthetic of your project. Consulting with suppliers about your specific needs can also provide valuable insights. -

What is the best type of hidden door hinge for heavy doors?

For heavy doors, such as those exceeding 300 lbs, it is advisable to choose heavy-duty concealed hinges with a robust load rating. Options like the FritsJurgens System One Pivot Set are designed to support up to 1,100 lbs. These hinges not only offer superior strength but also allow for smooth operation and easy adjustments. Always confirm the specifications with your supplier to ensure compatibility with your door design and weight requirements. -

What are the common applications for hidden door hinges?

Hidden door hinges are versatile and can be utilized in various applications. They are popular for creating hidden bookcase doors, secret passageways, and concealed storage solutions. Additionally, they are effective for cabinet doors, providing a clean and streamlined look. Depending on your design goals, you may also find them useful in commercial spaces for maintaining aesthetic integrity while providing functionality. -

What should I consider when sourcing hidden door hinges internationally?

When sourcing hidden door hinges internationally, consider factors such as quality certifications, compliance with local regulations, and the supplier’s reputation. Verify the manufacturer’s experience and production capabilities, especially if you require custom solutions. Understand the shipping logistics and potential tariffs that may apply. Engaging in direct communication with suppliers can clarify lead times, payment terms, and after-sales support, ensuring a smooth procurement process. -

How can I ensure quality assurance for hidden door hardware hinges?

To ensure quality assurance, request certifications such as ISO or CE from your suppliers, which indicate adherence to international quality standards. Ask for samples before placing bulk orders to evaluate the product’s durability and performance. Establish clear quality control criteria and consider conducting third-party inspections during production. Maintaining open communication with your supplier throughout the manufacturing process can help address any potential issues promptly. -

What are typical minimum order quantities (MOQ) for hidden door hardware hinges?

Minimum order quantities (MOQ) for hidden door hardware hinges can vary significantly based on the supplier and the type of hinge. Generally, MOQs range from 50 to several hundred units. If you are a smaller business or a first-time buyer, discuss your needs with suppliers, as some may offer flexibility or tiered pricing based on order size. Establishing a good relationship with your supplier can also lead to better negotiation opportunities. -

What payment terms are commonly offered for international purchases of hidden door hinges?

Payment terms for international purchases can differ by supplier but typically include options like advance payment, letters of credit, or net payment terms (e.g., Net 30, Net 60). Ensure you clarify these terms before finalizing your order. Some suppliers may also accept partial payments upfront, which can reduce risk. Always review the payment methods and associated fees to ensure they align with your budget and cash flow management. -

How do I handle logistics and shipping for hidden door hinges?

Handling logistics and shipping for hidden door hinges involves selecting the right shipping method and ensuring compliance with import/export regulations. Work with reliable freight forwarders who understand the complexities of international shipping, including customs clearance. Discuss shipping options with your supplier, such as air freight for faster delivery or sea freight for cost savings. Additionally, consider insurance coverage for your shipment to protect against potential losses during transit.

Top 7 Hidden Door Hardware Hinge Manufacturers & Suppliers List

1. Murphy Door – Single Flush Mount Hardware

Domain: murphydoor.com

Registered: 2012 (13 years)

Introduction: Single Flush Mount Hardware for Hidden Doors – Price: $149.00 USD – Includes: Top and bottom hinge set with pins, pin remover tool, screws, door catch, and catch plate. – Weight Capacity: Holds up to 300 pounds. – Patented Ball Bearing Lower Pivot Point rated at 1160 torque lbs. dynamic load, and 540 lbs. static. – Warranty: 3 Year Warranty. – Delivery Timeline: Hardware Kits ship within 1-3 busin…

2. Tectus – Invisible Door Hinges

Domain: hardwaresource.com

Registered: 1996 (29 years)

Introduction: Invisible Door Hinges available:

1. Tectus TE 340 3D for 1-3/4″ Thick Doors – From $137.00, Available Finishes: Satin Nickel Look, Satin Chrome Look, Satin Brass, Matte Deep Black.

2. Tectus TE 240 3D for 1-3/8″ Thick Doors – From $119.00, Available Finishes: Satin Chrome Look, Satin Nickel Look, Satin Brass, Rustic Umber.

3. Tectus TE 540 3D for 1-3/4″ Thick Doors – From $227.00, Available Finish…

3. HingeOutlet – Concealed Door Hinges

Domain: hingeoutlet.com

Registered: 2004 (21 years)

Introduction: Concealed Door Hinges available at HingeOutlet. Free shipping on orders over $160. Wide variety of door hinges and hardware for both commercial and residential applications. Expert support available at 888-250-8133.

4. Swinging Cafe Doors – Hidden Door Hinges

Domain: swingingcafedoors.com

Registered: 2008 (17 years)

Introduction: Hidden door hinges, also known as concealed hinges or invisible hinges, are designed to be hidden from view when the door is closed. They are mounted inside the door frame for a sleek appearance. The hinges are heavy-duty, supporting various door weights and sizes. Key features include:

– Hold Open Feature available

– Multiple hardware finishes: Black, Brass, Chrome, Nickel, Oil Rubbed Bronze, S…

5. Pinterest – Hidden Door Hinges

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Hidden door hinges, concealed door hinges, Soss invisible barrel hinges, 3.5 inch door hinge dimensions, pivot bookcase hinge kit, hidden door hardware, secret room ideas, DIY hidden door bookcase, rustic barn door hinges, installation guides for hidden hinges.

6. CS Hardware – InvisiDoor Bookcase Kits

Domain: cshardware.com

Registered: 1996 (29 years)

Introduction: Hidden Doors | InvisiDoor bookcase kits | Conceals: safe rooms, closets, panic rooms, food pantries, laundry rooms, storage rooms, gun storage areas | Assembled and ready to install with unique pivot hinge | Hinge kits sold separately for custom installations.

7. Hardware Hut – Concealed Door Hinges

Domain: hardwarehut.com

Registered: 1998 (27 years)

Introduction: This company, Hardware Hut – Concealed Door Hinges, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for hidden door hardware hinge

In the evolving landscape of hidden door hardware hinges, strategic sourcing remains a pivotal element for B2B buyers aiming to secure quality products and optimize costs. The variety of options available—from heavy-duty concealed hinges to elegant flush mount systems—offers significant versatility for diverse applications, whether for residential projects or commercial installations. Understanding the unique features and specifications of different hinge types, such as load capacity and ease of installation, empowers buyers to make informed decisions that align with their project requirements.

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, the potential for growth in the hidden door hardware market is substantial. As architectural trends lean towards minimalism and functionality, investing in high-quality, aesthetically pleasing hardware can enhance both the value and appeal of any project.

Looking ahead, the emphasis on quality sourcing and supplier relationships will be crucial. Engage with trusted manufacturers and suppliers to explore innovative solutions that cater to your specific needs. By prioritizing strategic sourcing, you can ensure that your projects not only meet industry standards but also exceed client expectations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to hidden door hardware hinge