Unlocking Value: A Strategic Analysis of the Harness Caterpillar Market

Introduction: Navigating the Global Market for harness caterpillar

In today’s competitive landscape, sourcing high-quality harness caterpillars presents a significant challenge for B2B buyers. Companies across various industries, from agriculture to construction, rely on these crucial components for the optimal performance of machinery and equipment. However, navigating the global market requires a deep understanding of the types, applications, and sourcing strategies available. This guide aims to demystify the complexities of harness caterpillars, providing insights into the different variations and specifications that cater to diverse operational needs.

Throughout this comprehensive resource, we will explore the wide array of harness caterpillars, detailing their specific applications across regions such as Africa, South America, the Middle East, and Europe, including key markets like Saudi Arabia and Nigeria. You’ll gain valuable insights into supplier vetting processes, enabling you to identify reliable partners that meet your quality and service standards. Additionally, we’ll discuss cost considerations, ensuring you can make informed decisions that align with your budgetary constraints without compromising on quality.

By equipping international B2B buyers with actionable information and strategic guidance, this guide empowers you to streamline your sourcing process. Whether you’re looking to enhance operational efficiency or ensure compliance with local regulations, understanding the intricacies of the harness caterpillar market is essential for driving your business forward.

Understanding harness caterpillar Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Harness Caterpillar | Basic design, versatile sizing options | General industrial applications | Pros: Cost-effective, widely available. Cons: May lack advanced features. |

| Heavy-Duty Harness Caterpillar | Reinforced structure, higher load capacity | Construction, mining, heavy machinery | Pros: Exceptional durability, reliable for heavy loads. Cons: Higher initial investment. |

| Lightweight Harness Caterpillar | Compact design, optimized for portability | Aerospace, automotive sectors | Pros: Easy to transport, reduces overall weight. Cons: Limited load capacity. |

| Custom-Made Harness Caterpillar | Tailored specifications, unique design features | Specialized industrial applications | Pros: Meets specific needs, enhances efficiency. Cons: Longer lead times, potentially higher costs. |

| Eco-Friendly Harness Caterpillar | Made from sustainable materials, biodegradable options | Green construction, eco-conscious projects | Pros: Appeals to environmentally focused buyers. Cons: May not be as durable as conventional options. |

What Are the Characteristics of Standard Harness Caterpillars?

Standard harness caterpillars are the most common type utilized across various industries. Their design allows for versatile sizing options, making them suitable for a range of applications, from manufacturing to logistics. Buyers should consider their cost-effectiveness and availability, but be aware that they may lack some advanced features found in specialized models. This type is ideal for businesses looking for a reliable, general-purpose solution without the need for heavy-duty specifications.

How Do Heavy-Duty Harness Caterpillars Stand Out?

Heavy-duty harness caterpillars are designed for extreme conditions and high-load applications, particularly in sectors like construction and mining. Their reinforced structure allows them to support heavier weights, making them a preferred choice for machinery and equipment that demand durability. While they offer exceptional reliability, the higher initial investment can be a consideration for budget-conscious buyers. Companies needing robust solutions for demanding environments will find this type particularly beneficial.

In What Situations Are Lightweight Harness Caterpillars Most Suitable?

Lightweight harness caterpillars are optimized for portability, making them ideal for industries like aerospace and automotive, where weight reduction is crucial. Their compact design facilitates easy transport and installation, which can lead to increased operational efficiency. However, buyers should note that while they are easier to handle, they typically offer a limited load capacity compared to heavier models. Businesses focused on minimizing weight without compromising functionality will find this type advantageous.

What Are the Benefits of Custom-Made Harness Caterpillars?

Custom-made harness caterpillars provide tailored solutions that meet specific operational requirements. They are designed with unique specifications, allowing businesses to enhance efficiency and optimize their processes. While these products can address niche applications effectively, buyers must consider the longer lead times and potentially higher costs associated with custom manufacturing. Companies with specialized needs will benefit from the flexibility and precision offered by this type.

How Do Eco-Friendly Harness Caterpillars Compare to Traditional Options?

Eco-friendly harness caterpillars are made from sustainable materials and often feature biodegradable options. They are increasingly sought after in green construction and eco-conscious projects, appealing to buyers looking to align with sustainability goals. However, it is essential to note that these products may not match the durability of traditional models. Companies committed to environmental responsibility will find this type aligns well with their values, despite the potential trade-offs in longevity.

Key Industrial Applications of harness caterpillar

| Industry/Sector | Specific Application of harness caterpillar | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Precision Farming Systems | Enhances crop yield through optimized machinery control | Supplier reliability, compatibility with existing systems |

| Construction | Heavy Machinery Power Distribution | Ensures efficient energy transfer in heavy equipment | Durability, resistance to environmental factors, local support |

| Mining | Equipment Connectivity and Control | Improves operational efficiency and reduces downtime | Availability of spare parts, compliance with safety standards |

| Renewable Energy | Wind Turbine Control Systems | Increases energy efficiency and reliability | Technical support, certification for international standards |

| Automotive Manufacturing | Automated Production Line Integration | Streamlines processes and reduces labor costs | Customization options, lead times, and logistics capabilities |

How is harness caterpillar used in Agriculture to Improve Crop Yields?

In agriculture, harness caterpillars are integral to precision farming systems, where they facilitate the seamless operation of various agricultural machinery. By optimizing the control of tractors and harvesters, these harnesses enable farmers to achieve precise planting, fertilization, and harvesting. This leads to increased crop yields and reduced resource waste. For international buyers, particularly in regions like Africa and South America, it is crucial to source harnesses that are compatible with local machinery and can withstand diverse environmental conditions.

What Role Does Harness Caterpillar Play in Construction for Heavy Machinery?

In the construction sector, harness caterpillars are vital for the power distribution of heavy machinery. They ensure that electrical systems within excavators, cranes, and bulldozers operate efficiently, which is essential for maintaining productivity on job sites. For businesses in the Middle East and Europe, sourcing durable and weather-resistant harnesses is critical, as these regions often face extreme conditions that can impact machinery performance. Buyers should also consider suppliers that offer robust after-sales support.

How Does Harness Caterpillar Enhance Mining Operations?

Within the mining industry, harness caterpillars are used to connect and control various pieces of equipment, ensuring efficient operation and communication between machines. This connectivity is crucial for minimizing downtime and maximizing output in often harsh environments. For international buyers in countries like Nigeria and South America, it is important to prioritize suppliers that offer compliance with local mining regulations and provide readily available spare parts to mitigate operational disruptions.

In What Ways Does Harness Caterpillar Support Renewable Energy Initiatives?

Harness caterpillars find significant applications in renewable energy, particularly in the operation of wind turbine control systems. They facilitate the reliable transfer of signals and power, which is essential for optimizing energy production and ensuring the longevity of turbine systems. For businesses in Europe focusing on green energy projects, sourcing harnesses that meet international standards and offer technical support is vital for project success and sustainability.

How Can Automotive Manufacturers Benefit from Harness Caterpillar in Production?

In the automotive manufacturing sector, harness caterpillars are essential for the integration of automated production lines. They streamline the connection between various automated systems, enhancing overall efficiency and reducing labor costs. International buyers, especially in developing markets, should seek suppliers that offer customization options to meet specific production needs, as well as reliable logistics to ensure timely delivery of components.

3 Common User Pain Points for ‘harness caterpillar’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Harness Caterpillars

The Problem: B2B buyers often face significant challenges when it comes to sourcing high-quality harness caterpillars. In regions like Africa and South America, local suppliers may not always meet international standards, leading to concerns about durability and reliability. This problem can result in project delays, increased costs, and potential safety risks if the products fail to perform as expected. Buyers may feel overwhelmed by the lack of transparency in supplier capabilities and product specifications.

The Solution: To overcome these sourcing challenges, buyers should prioritize establishing relationships with reputable suppliers who have a proven track record in the industry. Conducting thorough background checks, such as verifying certifications and reviewing customer testimonials, can provide insights into the supplier’s reliability. Additionally, engaging in industry trade shows or exhibitions can offer opportunities to connect directly with manufacturers and understand their production processes. Buyers should also consider utilizing platforms that specialize in B2B transactions to compare different suppliers based on quality, pricing, and delivery timelines. By creating a robust supplier evaluation framework, buyers can ensure they source harness caterpillars that meet their specific needs.

Scenario 2: Incompatibility with Existing Equipment

The Problem: Another common issue arises when harness caterpillars are incompatible with existing machinery or systems. This can occur if the specifications of the caterpillars do not align with the operational requirements of the equipment they are intended to work with. Such incompatibility can lead to increased operational costs, as adjustments or additional modifications may be required to integrate the new components effectively.

The Solution: To mitigate this risk, it is crucial for buyers to conduct comprehensive compatibility assessments before finalizing their purchases. This involves reviewing the technical specifications of the harness caterpillars and comparing them with the operational requirements of the existing equipment. Engaging with technical experts or consultants who can provide insights into the compatibility of different systems can also be beneficial. Furthermore, buyers should prioritize purchasing from suppliers who offer customization options, allowing them to tailor the harness caterpillars to meet specific operational needs. By investing time in the compatibility assessment, businesses can avoid costly modifications and ensure seamless integration.

Scenario 3: Lack of Technical Support and Training

The Problem: Many B2B buyers find themselves struggling with insufficient technical support and training related to harness caterpillar usage. This issue is particularly prevalent in regions where technical expertise is limited, leading to improper installation or maintenance of the products. Such shortcomings can result in decreased efficiency and increased downtime, ultimately affecting productivity and profitability.

The Solution: To address this pain point, buyers should seek suppliers that offer comprehensive technical support and training programs as part of their service package. This could include on-site training sessions, detailed user manuals, and 24/7 customer service assistance. It is also beneficial to establish a clear communication channel with the supplier for ongoing support, especially during the initial implementation phase. Additionally, companies can invest in developing an internal team of technical experts who can facilitate training and troubleshooting, ensuring that staff are well-equipped to handle the harness caterpillars effectively. By prioritizing technical support and education, businesses can enhance operational efficiency and reduce the likelihood of costly errors.

Strategic Material Selection Guide for harness caterpillar

When selecting materials for harness caterpillars, it’s crucial to consider their properties, performance in specific applications, and the unique requirements of international markets. Below is an analysis of four common materials used in harness caterpillar production, focusing on their key properties, advantages, disadvantages, and the implications for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe.

What are the Key Properties of Steel for Harness Caterpillars?

Steel, particularly carbon steel and stainless steel, is a widely used material in harness caterpillar manufacturing due to its strength and durability. Key properties include high tensile strength, excellent temperature resistance, and good corrosion resistance, especially in stainless variants. However, carbon steel may require additional coatings to enhance its corrosion resistance.

Pros and Cons: Steel’s durability makes it suitable for heavy-duty applications, but it can be heavier than other materials, impacting the overall weight of the harness. The manufacturing complexity can vary, with stainless steel often requiring more sophisticated processing techniques. In terms of cost, steel is generally medium-priced, making it accessible for various applications.

Impact on Application: Steel is compatible with a wide range of media, including oils and fuels, but its performance can degrade in highly corrosive environments without proper treatment.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM A240 for stainless steel and consider local regulations regarding material sourcing and environmental impact, especially in markets like Saudi Arabia and Nigeria.

How Does Nylon Perform in Harness Caterpillar Applications?

Nylon is a synthetic polymer known for its lightweight and flexible characteristics, making it an excellent choice for harness caterpillars that require mobility and ease of handling. Key properties include good abrasion resistance, moderate temperature tolerance, and low moisture absorption.

Pros and Cons: The primary advantage of nylon is its lightweight nature, which contributes to overall efficiency. However, nylon can be less durable than metals and may degrade under UV exposure or extreme temperatures. Manufacturing complexity is relatively low, and nylon is generally available at a lower cost compared to metals.

Impact on Application: Nylon is suitable for applications where flexibility and low weight are critical, but it may not be ideal for environments with high temperatures or aggressive chemicals.

Considerations for International Buyers: Buyers should consider the availability of nylon grades that meet specific performance requirements and ensure compliance with standards like ISO 1874, particularly in regions where temperature variations are significant.

What Advantages Do Composite Materials Offer for Harness Caterpillars?

Composite materials, such as fiberglass-reinforced plastics, are increasingly popular in harness caterpillar applications due to their unique properties. They offer high strength-to-weight ratios, excellent corrosion resistance, and the ability to be molded into complex shapes.

Pros and Cons: Composites are lightweight and resistant to many chemicals, making them suitable for harsh environments. However, they can be more expensive than traditional materials and may require specialized manufacturing techniques. The durability of composites can vary based on the specific formulation used.

Impact on Application: Composites are particularly effective in applications where weight savings and corrosion resistance are paramount, such as in marine or chemical processing environments.

Considerations for International Buyers: Buyers should be aware of the varying standards for composites in different regions and ensure that the materials used comply with local regulations, especially in Europe, where environmental standards are stringent.

How Does Aluminum Compare as a Material for Harness Caterpillars?

Aluminum is another popular choice for harness caterpillars due to its lightweight and good strength properties. Key characteristics include excellent corrosion resistance, good thermal conductivity, and a favorable strength-to-weight ratio.

Pros and Cons: Aluminum’s lightweight nature enhances efficiency, and its corrosion resistance makes it suitable for outdoor applications. However, it can be more expensive than steel and may require additional treatments for certain applications. Manufacturing processes for aluminum can also be more complex.

Impact on Application: Aluminum is compatible with various media and is particularly effective in environments where weight savings and corrosion resistance are critical.

Considerations for International Buyers: Compliance with standards such as ASTM B221 is essential, and buyers should consider the availability of aluminum grades that meet their specific needs, particularly in regions with demanding environmental conditions.

Summary Table of Material Selection for Harness Caterpillars

| Material | Typical Use Case for harness caterpillar | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty applications | High durability | Heavier weight | Medium |

| Nylon | Lightweight and flexible applications | Low weight | Less durable under extreme conditions | Low |

| Composite | Harsh environments | High strength-to-weight ratio | Higher cost and manufacturing complexity | High |

| Aluminum | Outdoor and corrosion-prone applications | Excellent corrosion resistance | Higher cost and complex processing | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties and implications of various materials for harness caterpillars, ensuring informed decision-making tailored to their specific regional needs.

In-depth Look: Manufacturing Processes and Quality Assurance for harness caterpillar

What Are the Main Stages in the Manufacturing Process of Harness Caterpillars?

The manufacturing process of harness caterpillars involves several critical stages that ensure the final product meets the required specifications and industry standards. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation

The first stage begins with material preparation. High-quality raw materials, such as synthetic polymers, metals, and composites, are selected based on the desired performance characteristics of the harness caterpillar. This stage often includes testing the materials for durability, flexibility, and resistance to environmental factors. Suppliers should provide documentation that verifies the quality of materials used, including certificates of compliance with international standards.

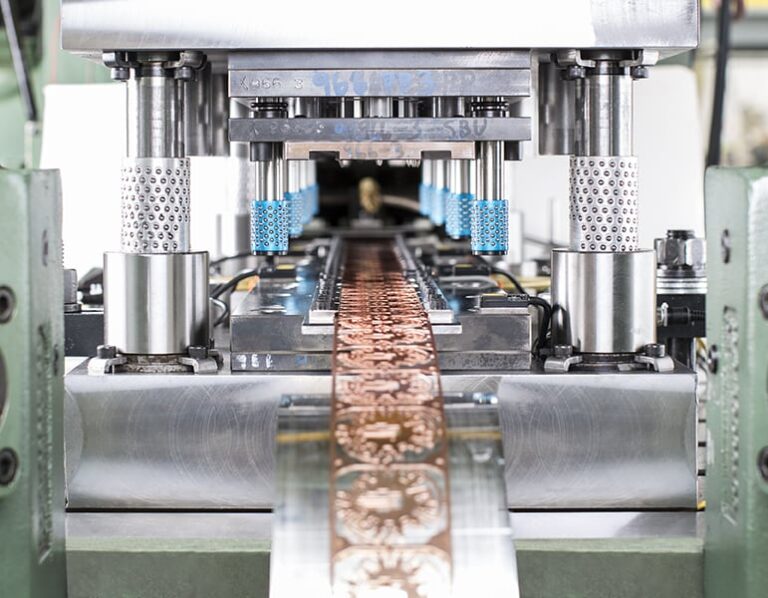

Forming Techniques: How Are Harness Caterpillars Shaped?

Once the materials are prepared, the forming process takes place. This can involve various techniques such as injection molding, extrusion, or die casting, depending on the design requirements. Each method offers distinct advantages; for example, injection molding is often used for producing complex shapes with high precision, while extrusion is suitable for continuous lengths of material.

During this phase, manufacturers should ensure that the forming processes are optimized for efficiency and quality. B2B buyers can request process documentation and samples to evaluate the manufacturer’s capability in delivering consistent products.

Assembly: What Does the Assembly Process Involve?

The assembly of harness caterpillars typically includes integrating various components, such as connectors, wires, and protective covers. This step may involve manual labor, automated systems, or a combination of both. The choice of assembly technique can significantly affect the quality and reliability of the final product.

Quality checks during assembly are crucial. B2B buyers should inquire about the assembly techniques employed and the skill level of the workforce involved. Documentation of assembly processes and operator training can provide insights into the manufacturer’s commitment to quality.

Finishing: What Are the Final Touches Applied to Harness Caterpillars?

The finishing stage includes processes such as surface treatment, coating, and quality inspections. Surface treatments may enhance the durability and corrosion resistance of harness caterpillars. Manufacturers often apply coatings to improve aesthetic appeal or functionality, such as anti-friction properties.

B2B buyers should look for manufacturers that adhere to best practices in finishing processes. Requesting samples and certifications for finishing treatments can help verify the quality of the final product.

What Quality Assurance Standards Are Relevant for Harness Caterpillar Manufacturing?

Quality assurance is a critical aspect of the manufacturing process, ensuring that products meet both international and industry-specific standards. Understanding these standards can help B2B buyers assess supplier reliability.

International Standards: How Does ISO 9001 Impact Quality Assurance?

ISO 9001 is a widely recognized international standard that focuses on quality management systems (QMS). Manufacturers that comply with ISO 9001 demonstrate a commitment to continuous improvement and customer satisfaction. B2B buyers should verify a supplier’s ISO certification as part of their due diligence process.

Compliance with ISO standards often involves regular audits and assessments. Buyers can request documentation of these audits to ensure the manufacturer maintains high-quality practices throughout the production process.

Industry-Specific Certifications: What Are CE and API Standards?

In addition to ISO 9001, harness caterpillar manufacturers may also need to adhere to industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute). CE marking indicates compliance with European health, safety, and environmental protection standards, while API certifications are crucial for products used in the oil and gas industry.

B2B buyers should confirm that their suppliers hold relevant certifications for their target markets. This not only ensures product quality but also compliance with local regulations.

What Are the Key Quality Control Checkpoints in Harness Caterpillar Manufacturing?

Quality control (QC) is integral to the manufacturing process, involving systematic inspections at various checkpoints to ensure product consistency and reliability.

Incoming Quality Control (IQC): How Are Raw Materials Assessed?

IQC focuses on inspecting the quality of raw materials before production begins. This stage involves checking the specifications and certifications of materials to ensure they meet predetermined standards. B2B buyers should inquire about the supplier’s IQC processes and the criteria used for accepting or rejecting materials.

In-Process Quality Control (IPQC): What Checks Occur During Production?

IPQC is conducted during the manufacturing process to identify any defects or deviations from quality standards. This can include visual inspections, measurements, and functional testing. Implementing IPQC helps mitigate risks early in the production cycle, reducing waste and ensuring product reliability.

Buyers can benefit from understanding the IPQC methods employed by suppliers, including the frequency of inspections and the criteria used for quality assessments.

Final Quality Control (FQC): What Is Involved in the Final Inspection?

FQC is the last checkpoint before products are shipped to customers. This stage includes comprehensive testing of finished harness caterpillars to ensure they meet all specifications and quality standards. Common testing methods may include electrical testing, mechanical stress testing, and environmental simulations.

B2B buyers should request FQC reports and documentation to verify that the products have passed all necessary quality checks before delivery.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is essential for B2B buyers looking to ensure product reliability and compliance with industry standards. Here are several actionable steps buyers can take:

Conducting Supplier Audits: What Should Be Included?

Regular audits of potential suppliers can provide valuable insights into their manufacturing processes and quality assurance practices. Buyers should develop a comprehensive audit checklist that includes evaluating the manufacturer’s facilities, equipment, and quality management systems.

Reviewing Quality Reports and Certifications: What to Look For?

Buyers should request copies of quality reports, certifications, and testing results from suppliers. This documentation should clearly outline the quality control measures in place and any relevant certifications. Pay close attention to the date of the certifications and the scope of the testing performed.

Engaging Third-Party Inspectors: How Can They Enhance Confidence?

Third-party inspection services can offer an unbiased evaluation of a supplier’s quality control processes. Engaging these services can provide additional assurance that the products meet industry standards and specifications.

B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, should consider the nuances of international quality standards. Understanding the specific requirements and certifications relevant to their markets can enhance their negotiation power and ensure they are sourcing high-quality products.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for harness caterpillars is essential for B2B buyers. By focusing on key stages, relevant standards, and effective verification methods, buyers can make informed decisions that align with their quality expectations and market requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘harness caterpillar’

The procurement of harness caterpillars is a critical process for businesses looking to enhance their operational efficiency and product offerings. This guide provides a practical checklist to help B2B buyers navigate the sourcing journey, ensuring they make informed decisions that align with their operational needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to establish clear technical specifications for the harness caterpillar. This includes understanding the load capacity, size, material, and any specific features required for your application. Having precise specifications helps streamline the selection process and ensures that the products meet your operational requirements.

Step 2: Research Market Trends and Pricing

Conduct thorough market research to gain insights into current trends and pricing benchmarks for harness caterpillars. Understanding market dynamics allows you to set realistic budgets and identify competitive suppliers. Pay attention to factors such as regional pricing variations and emerging technologies that may influence costs.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, it’s crucial to vet them thoroughly. Request comprehensive company profiles, product catalogs, and case studies to assess their capabilities. Look for references or testimonials from other businesses in your industry or region to gauge their reliability and performance.

- Consider their experience: Suppliers with a long-standing presence in the market often have better insights and reliability.

- Check for industry certifications: Certifications can indicate adherence to quality standards and regulations.

Step 4: Request Samples and Conduct Quality Tests

Once you have shortlisted potential suppliers, request samples of their harness caterpillars. This step is vital for assessing the quality and suitability of the products for your specific needs. Conduct thorough quality tests to evaluate factors such as durability, performance under load, and compliance with your specifications.

Step 5: Verify Supplier Certifications

Ensure that your selected suppliers possess the necessary certifications relevant to your industry and region. Certifications such as ISO, CE, or specific safety standards demonstrate compliance with international quality benchmarks. This verification process minimizes the risk of sourcing subpar products and enhances your supply chain reliability.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, engage in negotiations to finalize the terms and conditions of the procurement. Discuss pricing, payment terms, delivery schedules, and warranties to ensure mutual agreement. Clear communication during this phase helps prevent misunderstandings and establishes a solid foundation for a long-term partnership.

Step 7: Establish a Communication Plan

After finalizing your supplier, set up a communication plan to facilitate ongoing collaboration. Regular updates on production, shipping schedules, and any potential issues are crucial for maintaining a smooth supply chain. A proactive communication strategy helps address concerns promptly and fosters a positive working relationship.

By following this practical checklist, B2B buyers can effectively navigate the sourcing process for harness caterpillars, ensuring they select the right products and partners to support their business objectives.

Comprehensive Cost and Pricing Analysis for harness caterpillar Sourcing

What Are the Key Cost Components in Sourcing Harness Caterpillars?

When sourcing harness caterpillars, understanding the cost structure is crucial for effective budgeting and financial planning. The primary cost components include:

- Materials: The choice of materials significantly impacts the overall cost. High-quality polymers and metals are often used, which can drive up prices but provide better durability and performance.

- Labor: Labor costs vary widely based on the region and the complexity of the manufacturing process. Skilled labor is often more expensive but can enhance product quality.

- Manufacturing Overhead: This encompasses indirect costs associated with production, including utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce these overhead costs.

- Tooling: Initial tooling costs for custom designs can be substantial. Investing in high-quality tooling upfront can lead to better precision and lower defect rates.

- Quality Control (QC): Robust QC measures ensure that products meet specifications and standards. While this incurs additional costs, it can prevent expensive returns and rework down the line.

- Logistics: Transportation and shipping fees are critical, especially for international buyers. Costs can vary based on distance, mode of transport, and whether duties and tariffs are applicable.

- Margin: Suppliers typically build a margin into their pricing to cover risks and ensure profitability. This can vary based on market conditions and competition.

How Do Volume and Customization Affect Pricing for Harness Caterpillars?

Volume and minimum order quantities (MOQs) play a significant role in pricing strategies. Generally, larger orders lead to lower per-unit costs due to economies of scale. Conversely, smaller orders may incur higher prices due to setup costs that must be spread over fewer units.

Customization also impacts price. Tailored designs or specific material requirements can lead to increased costs, both in terms of materials and labor. Buyers should weigh the benefits of customization against the potential for higher expenses.

What External Factors Influence Pricing for Harness Caterpillars?

Several external factors can influence the pricing of harness caterpillars:

- Material Prices: Fluctuations in the cost of raw materials, driven by market demand and supply chain issues, can affect final pricing.

- Quality Certifications: Products that meet international quality standards or certifications may command higher prices, but they also offer buyers assurance of reliability.

- Supplier Factors: The reputation and reliability of the supplier can also impact pricing. Established suppliers with a track record of quality may charge more, but they reduce risks associated with poor-quality products.

- Incoterms: The terms of trade (Incoterms) chosen can affect costs, including shipping responsibilities and risk. Understanding these terms is essential for budgeting.

What Are the Best Negotiation Strategies for International Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant cost savings:

- Research and Benchmarking: Conduct thorough market research to understand standard pricing and identify competitive suppliers. This information can strengthen your negotiation position.

- Total Cost of Ownership (TCO): Consider the long-term costs associated with a purchase, including maintenance, logistics, and potential downtime. Presenting TCO to suppliers can justify a request for better pricing.

- Flexible Terms: Be open to negotiating payment terms and delivery schedules. This flexibility can lead to better pricing arrangements.

- Build Relationships: Establishing a rapport with suppliers can lead to better deals and improved terms over time.

What Pricing Nuances Should International Buyers Be Aware Of?

International buyers should be mindful of several pricing nuances:

- Currency Fluctuations: Exchange rates can impact the final cost. Locking in prices or negotiating in a stable currency can mitigate this risk.

- Tariffs and Duties: Understand the applicable tariffs and duties that may arise when importing products, as these can significantly affect total costs.

- Shipping Delays: Anticipate potential delays in logistics, especially in regions with less reliable infrastructure, which can affect delivery timelines and costs.

Disclaimer

Prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific project requirements. Buyers are encouraged to conduct thorough research and engage in direct discussions with suppliers for the most accurate and current pricing information.

Alternatives Analysis: Comparing harness caterpillar With Other Solutions

Understanding the Alternatives to Harness Caterpillar Solutions

In today’s competitive B2B landscape, organizations are often faced with the challenge of selecting the most effective tools and methods for their operational needs. While the harness caterpillar offers unique advantages, it’s crucial to evaluate alternative solutions that might align better with specific business requirements. This analysis will compare harness caterpillar against other viable options, providing insights that can inform decision-making processes for international buyers.

Comparison Table

| Comparison Aspect | Harness Caterpillar | Alternative 1: Chain Drive System | Alternative 2: Pneumatic Conveyors |

|---|---|---|---|

| Performance | High torque and stability for heavy loads | Good for moderate loads with high speed | Versatile for various materials, but lower capacity |

| Cost | Moderate initial investment; durable over time | Lower initial cost, but higher long-term maintenance | Variable costs based on material and system complexity |

| Ease of Implementation | Requires specialized knowledge for setup | Easier to install with standard tools | Complex setup; requires specialized installation |

| Maintenance | Low maintenance, long lifespan | Moderate maintenance needs, frequent inspections | High maintenance; components may wear out quickly |

| Best Use Case | Heavy-duty applications in rugged environments | Suitable for manufacturing lines needing speed | Ideal for bulk material handling in various industries |

Detailed Breakdown of Alternatives

Chain Drive System

The chain drive system is a mechanical solution that utilizes a series of interlinked chains to transmit power. This system is particularly beneficial in environments where speed is essential, and moderate load capacities are sufficient. The primary advantage of a chain drive is its lower initial cost compared to harness caterpillar. However, it necessitates regular maintenance and inspections to ensure optimal performance, which can add to the long-term costs. Companies looking for a cost-effective solution for moderate load applications may find this alternative appealing, but they must be prepared for ongoing maintenance requirements.

Pneumatic Conveyors

Pneumatic conveyors utilize air pressure to transport materials through a system of tubes. This method is highly versatile and can handle a variety of materials, making it an attractive option for industries such as food processing and pharmaceuticals. One of the significant advantages of pneumatic systems is their ability to operate in confined spaces and transport materials over long distances. However, the initial setup can be complex and may require specialized knowledge. Additionally, pneumatic systems often have higher maintenance needs, as components can wear out more quickly due to the high-speed movement of materials. Businesses should assess their material handling needs and the potential for downtime when considering this alternative.

How Can B2B Buyers Choose the Right Solution?

When selecting the appropriate solution, B2B buyers should consider their specific operational needs, including the types of materials they handle, the required load capacities, and their budget constraints. It’s essential to evaluate both the initial investment and the long-term maintenance costs associated with each alternative. Additionally, companies should assess the expertise available within their workforce for installation and maintenance. By aligning these factors with the operational goals, buyers can make informed decisions that enhance productivity and reduce costs in the long run. Ultimately, the right choice will depend on a comprehensive understanding of both the harness caterpillar and its alternatives, enabling businesses to achieve their desired outcomes effectively.

Essential Technical Properties and Trade Terminology for harness caterpillar

What are the Key Technical Properties of Harness Caterpillars?

When considering harness caterpillars for industrial applications, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some of the essential properties to evaluate:

-

Material Grade: The material grade of a harness caterpillar significantly impacts its durability and performance. Common materials include high-grade steel and reinforced polymers, which offer varying degrees of strength, corrosion resistance, and weight. Selecting the appropriate material is vital for ensuring longevity and reliability, particularly in harsh environments often found in sectors such as mining and agriculture.

-

Load Capacity: This specification indicates the maximum weight the harness caterpillar can safely handle without compromising structural integrity. Load capacity is critical for buyers to assess, as it directly influences the type of machinery or application it can be used for. Understanding this property helps in selecting a caterpillar that meets specific operational demands without risking failure.

-

Tolerance Levels: Tolerance refers to the allowable deviation in dimensions from a specified standard. Precise tolerance levels are essential in ensuring that the harness caterpillar fits correctly within its application. In industries where precision is critical, such as automotive or aerospace, tight tolerances can enhance performance and safety, reducing the likelihood of equipment malfunction.

-

Temperature Resistance: Many applications expose harness caterpillars to extreme temperatures. Understanding the temperature resistance rating helps buyers determine if a caterpillar can maintain its performance under specific environmental conditions. This property is particularly important in regions with significant temperature fluctuations or in applications involving high heat.

-

Flexibility and Bend Radius: The flexibility of a harness caterpillar affects its ability to maneuver through various applications. The bend radius is the minimum radius the caterpillar can bend without damaging it. Knowledge of these factors is crucial for ensuring the caterpillar can operate efficiently within the intended environment and application.

What are Common Trade Terms Related to Harness Caterpillars?

Navigating the trade landscape for harness caterpillars requires familiarity with specific terminology that facilitates clearer communication among buyers and suppliers. Here are some essential terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of harness caterpillars, understanding OEM relationships can help buyers identify reputable suppliers and ensure compatibility with existing machinery.

-

MOQ (Minimum Order Quantity): MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for buyers to manage inventory costs and plan procurement strategies effectively. This term is especially relevant for businesses looking to maintain efficient supply chain operations.

-

RFQ (Request for Quotation): An RFQ is a document that potential buyers send to suppliers to request pricing and terms for specific products. For those sourcing harness caterpillars, issuing an RFQ can streamline the procurement process, ensuring that all necessary specifications are communicated clearly to receive accurate and competitive quotes.

-

Incoterms: Short for International Commercial Terms, Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms is essential for international transactions, as they clarify who is responsible for costs and risks at different stages of the shipping process.

-

Lead Time: This term refers to the amount of time it takes from placing an order to receiving the product. For businesses in need of harness caterpillars, understanding lead time is crucial for effective project planning and inventory management, ensuring that operations are not delayed due to supply chain issues.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing harness caterpillars, ultimately enhancing their operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the harness caterpillar Sector

What Are the Key Market Dynamics and Trends Influencing the Harness Caterpillar Sector?

The harness caterpillar sector is experiencing dynamic shifts driven by several global factors, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. An increasing demand for sustainable and efficient agricultural practices is propelling the market forward. The rise of precision agriculture technology is allowing farmers to maximize yield while minimizing resource use, making harness caterpillars essential in modern farming equipment. Furthermore, the global push towards mechanization, especially in developing regions, is fostering a greater need for robust and reliable harness caterpillar systems.

Digital transformation is also reshaping the sourcing landscape, with B2B buyers leveraging advanced analytics and e-commerce platforms to streamline procurement processes. Buyers are increasingly utilizing online marketplaces that facilitate direct connections with manufacturers, enabling them to negotiate better terms and access a wider variety of products. Additionally, partnerships between manufacturers and technology providers are emerging, enabling the development of smart harness caterpillar solutions that integrate IoT capabilities for real-time monitoring and maintenance alerts.

How Is Sustainability Reshaping Sourcing Practices in the Harness Caterpillar Sector?

Sustainability is becoming a cornerstone of sourcing practices in the harness caterpillar sector. As environmental concerns gain prominence, B2B buyers are increasingly prioritizing suppliers who demonstrate commitment to ethical sourcing and sustainability. This includes the use of eco-friendly materials and processes that reduce carbon footprints. Suppliers are now seeking certifications such as ISO 14001, which reflects an organization’s commitment to effective environmental management.

Moreover, the demand for sustainable harness caterpillars is pushing manufacturers to innovate. This includes integrating biodegradable materials or recyclable components into their products, thus aligning with global sustainability goals. For international buyers, particularly in regions like Africa and South America, this shift not only enhances brand reputation but can also lead to cost savings in the long run due to reduced waste and energy consumption. Ethical supply chains are becoming a competitive advantage, enabling companies to attract environmentally conscious consumers and partners.

What Is the Historical Context of the Harness Caterpillar Sector’s Development?

The harness caterpillar sector has evolved significantly over the past few decades, transitioning from traditional manual farming methods to modern mechanized solutions. Initially, harness caterpillars were primarily used in agriculture for tilling and soil preparation. However, as agricultural practices advanced, the technology surrounding harness caterpillars also developed, leading to more sophisticated systems designed to meet the demands of larger and more diverse farming operations.

The introduction of hydraulic systems and enhanced materials has improved the durability and efficiency of harness caterpillars, making them indispensable in contemporary agricultural machinery. Today, the sector is characterized by innovation, with a focus on integrating technology to improve performance and sustainability. This evolution not only reflects changes in agricultural practices but also highlights the importance of adaptability in a rapidly changing market landscape, providing valuable insights for B2B buyers looking to invest in reliable and advanced harness caterpillar solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of harness caterpillar

-

How do I choose the right harness caterpillar for my project?

Selecting the appropriate harness caterpillar involves evaluating your specific application needs, including load capacity, environmental conditions, and any compatibility requirements with existing equipment. Start by consulting with suppliers who can provide technical specifications and performance data. Consider conducting pilot tests with sample products to assess their effectiveness in real-world scenarios. Additionally, gather feedback from your engineering team to ensure alignment with operational standards and safety protocols. -

What are the common materials used in harness caterpillars?

Harness caterpillars are typically constructed from durable materials such as nylon, polyester, or specialized polymers. These materials are chosen for their strength, flexibility, and resistance to environmental factors like UV exposure and moisture. When sourcing, inquire about the specific material grades and their certifications, as this can impact the longevity and performance of the caterpillars in different applications. It’s also advisable to discuss any customization options that may enhance durability for your specific environment. -

What is the minimum order quantity (MOQ) for harness caterpillars?

Minimum order quantities for harness caterpillars can vary significantly between suppliers and depend on factors like material type and customization. Generally, MOQs can range from a few dozen to several hundred units. When engaging with suppliers, clarify their MOQ policies early in the negotiation process, as this can affect your budgeting and inventory management. Some suppliers may offer flexibility for first-time buyers or for bulk orders, so it’s worth discussing your needs openly. -

How can I ensure quality assurance (QA) in harness caterpillar sourcing?

To ensure quality assurance when sourcing harness caterpillars, implement a multi-step vetting process for suppliers. Request product samples and certifications that demonstrate compliance with industry standards. Conduct factory audits to assess manufacturing processes and quality control measures. Additionally, establish clear QA expectations in your contracts, including inspection protocols and return policies for defective items. This proactive approach will help mitigate risks associated with product quality. -

What payment terms should I expect when purchasing harness caterpillars internationally?

Payment terms for international purchases can vary widely based on the supplier’s location, your creditworthiness, and the nature of the transaction. Common terms include letters of credit, advance payments, or net payment terms (e.g., 30/60/90 days). Be sure to negotiate terms that balance security with cash flow needs. It’s also prudent to review any potential currency exchange risks and include provisions for handling these in your contract to avoid unexpected costs. -

What logistics considerations should I keep in mind when importing harness caterpillars?

When importing harness caterpillars, consider the logistics involved in shipping, customs clearance, and delivery timelines. Work with suppliers who can provide detailed shipping options and estimated transit times. Ensure that all necessary documentation, such as commercial invoices and packing lists, is accurate and complete to facilitate smooth customs processing. Additionally, factor in any local regulations regarding import duties and taxes, as these can impact overall costs. -

How do I vet potential suppliers of harness caterpillars effectively?

Effective supplier vetting involves a combination of research, direct communication, and due diligence. Start by reviewing online ratings and testimonials from other B2B buyers. Request references and conduct background checks to verify their business credentials. Engage in discussions about their manufacturing capabilities, lead times, and customer service approach. Additionally, consider visiting their facilities if feasible, as this can provide deeper insights into their operations and commitment to quality. -

Can harness caterpillars be customized for specific applications?

Yes, many suppliers offer customization options for harness caterpillars to meet specific application requirements. Customizations can include variations in size, material, color, and additional features such as reinforced stitching or integrated components. When discussing customization, provide detailed specifications and intended use cases to help suppliers understand your needs. Be aware that custom orders may have longer lead times and potentially higher costs, so plan accordingly in your procurement process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

A Look at Harness Caterpillar Manufacturers & Suppliers

We are currently compiling a detailed list of top harness caterpillar suppliers. Please check back later.

Strategic Sourcing Conclusion and Outlook for harness caterpillar

In the competitive landscape of harness caterpillar procurement, strategic sourcing emerges as a pivotal factor in ensuring quality, cost efficiency, and supply chain resilience. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must prioritize establishing robust relationships with reputable suppliers. This not only mitigates risks associated with fluctuating market dynamics but also enhances the overall value proposition of their sourcing strategies.

Investing in comprehensive market research and leveraging advanced analytics can empower businesses to identify the most competitive suppliers and negotiate favorable terms. Additionally, embracing sustainable sourcing practices can align with global trends towards environmental responsibility, appealing to a broader customer base.

As we look to the future, the importance of agility and adaptability in sourcing strategies cannot be overstated. Buyers should remain vigilant of emerging technologies and market shifts that can impact supply chains. Engaging with local suppliers and exploring diverse sourcing options will be crucial for fostering resilience and ensuring long-term success. By taking proactive steps now, B2B buyers can position themselves favorably in the harness caterpillar market, unlocking new opportunities for growth and innovation.