Unlocking Value: A Strategic Analysis of the Foam Wall Panels Market

Introduction: Navigating the Global Market for foam wall panels

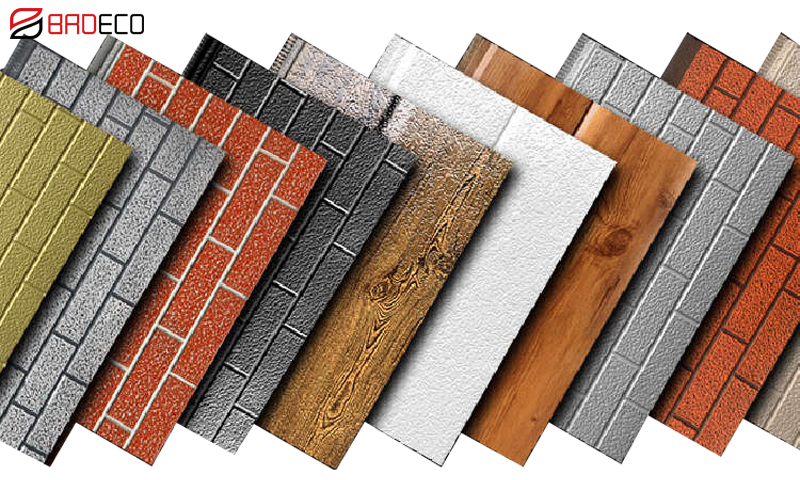

Navigating the global market for foam wall panels can present a unique set of challenges for international B2B buyers. From sourcing high-quality materials to ensuring compliance with diverse regional standards, the complexities can be overwhelming. This guide aims to simplify the process of procuring foam wall panels, offering insights into various types, applications, and the benefits they bring to different sectors. Whether you are looking for panels that provide thermal and acoustic insulation or those that emulate the appearance of traditional materials like brick or wood, understanding the landscape is crucial for informed purchasing decisions.

Our comprehensive resource covers essential topics, including supplier vetting processes, cost considerations, and innovative applications across industries. Special attention is given to the specific needs and preferences of buyers from Africa, South America, the Middle East, and Europe—regions characterized by their distinct market dynamics and purchasing habits. By equipping you with actionable insights and expert advice, this guide empowers you to make strategic decisions that align with your business goals. Whether you are enhancing a commercial space or seeking sustainable building solutions, understanding the foam wall panel market will enable you to navigate effectively and competitively in today’s global economy.

Understanding foam wall panels Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Faux Brick Panels | Lightweight, realistic brick appearance, easy installation | Retail spaces, restaurants, offices | Pros: Aesthetic appeal, quick installation. Cons: Limited insulation properties. |

| Acoustic Foam Panels | Specialized design for sound absorption, often fabric-covered | Recording studios, conference rooms | Pros: Excellent soundproofing, customizable. Cons: Can be more expensive, requires careful installation. |

| 3D Decorative Panels | Textured designs for visual impact, available in various finishes | Commercial interiors, exhibitions | Pros: Unique aesthetic, adds depth. Cons: May require specialized installation techniques. |

| Thermal Insulation Panels | Enhanced thermal resistance, often thicker and denser | Warehouses, industrial facilities | Pros: Energy efficiency, cost savings on heating/cooling. Cons: Heavier, may require professional installation. |

| Peel & Stick Panels | Easy to apply, no additional adhesive required | Residential renovations, temporary displays | Pros: User-friendly, quick application. Cons: May not adhere well in humid conditions. |

Faux brick panels are a popular choice among B2B buyers looking for an attractive yet lightweight solution for interior spaces. These panels mimic the appearance of traditional brick, making them suitable for retail environments, restaurants, and corporate offices. Their easy installation process allows for rapid transformation of spaces, although they may not offer significant insulation benefits.

Acoustic foam panels are specifically designed to absorb sound, making them ideal for environments where noise control is crucial, such as recording studios and conference rooms. These panels often come with fabric coverings that enhance their aesthetic appeal while serving their functional purpose. Buyers should consider the higher costs associated with these panels, as well as the need for precise installation to maximize their soundproofing capabilities.

3D decorative panels provide a striking visual impact, making them ideal for commercial interiors and exhibitions. Available in a range of textures and finishes, these panels can significantly enhance the aesthetic of any space. However, their installation may require specialized techniques, which could lead to additional labor costs.

Thermal insulation panels are designed to provide superior thermal resistance, making them a valuable investment for warehouses and industrial facilities. These panels help reduce energy costs associated with heating and cooling, contributing to long-term savings. However, their increased weight may necessitate professional installation, which is an important consideration for B2B buyers.

Peel and stick panels are gaining traction due to their ease of use, making them suitable for residential renovations and temporary displays. With no need for additional adhesives, these panels can be applied quickly, allowing for rapid updates to a space. However, buyers should be cautious about their performance in humid environments, as adhesion may diminish under such conditions.

Key Industrial Applications of foam wall panels

| Industry/Sector | Specific Application of foam wall panels | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Renovation | Interior wall insulation and aesthetic enhancement | Provides thermal and acoustic insulation while enhancing aesthetics, reducing energy costs and improving comfort. | Ensure compliance with local building codes and fire safety standards. Evaluate the environmental impact and sourcing of materials. |

| Hospitality | Decorative wall treatments in hotels and restaurants | Enhances guest experience through appealing design while being lightweight and easy to install. | Look for customizable options to match brand aesthetics and durability against wear and tear. |

| Retail | Store displays and branding elements | Offers cost-effective and visually appealing solutions for merchandising and branding, attracting customers. | Consider the ease of installation and potential for reusability or relocation of displays. |

| Manufacturing | Soundproofing and insulation in factories | Reduces noise pollution and improves working conditions, leading to higher productivity and employee satisfaction. | Assess the panels’ acoustic performance and compatibility with existing structures. |

| Transportation | Interior finishes for vehicles and public transport | Lightweight panels improve fuel efficiency while providing aesthetic appeal and insulation. | Evaluate weight specifications, durability against wear, and compliance with safety regulations. |

How Are Foam Wall Panels Used in Construction & Renovation?

In the construction and renovation sector, foam wall panels are employed for both insulation and aesthetic purposes. They provide superior thermal and acoustic insulation, which is crucial for energy efficiency and comfort in residential and commercial buildings. These panels can be quickly installed, reducing labor costs and time on the project. For international buyers, especially in regions like Africa and the Middle East, sourcing panels that comply with local building codes and standards is essential to ensure safety and performance.

What Role Do Foam Wall Panels Play in Hospitality?

In the hospitality industry, foam wall panels are used extensively for decorative wall treatments in hotels, restaurants, and lounges. Their lightweight nature allows for easy installation, making it possible to transform spaces rapidly and cost-effectively. Additionally, these panels contribute to sound absorption, enhancing the guest experience. Buyers in Europe, such as those in Germany, should consider customization options that reflect their brand identity while ensuring durability against high foot traffic.

How Are Foam Wall Panels Beneficial for Retail Spaces?

Retail environments utilize foam wall panels to create engaging store displays and branding elements. The panels can be designed to match corporate branding while being cost-effective and visually appealing. Their ease of installation allows retailers to frequently update displays, keeping the shopping experience fresh. When sourcing for retail applications, businesses should focus on the adaptability of the panels for various layouts and their potential for reuse in different locations.

How Do Foam Wall Panels Improve Conditions in Manufacturing?

In manufacturing facilities, foam wall panels serve as effective soundproofing and insulation solutions. By minimizing noise pollution, these panels create a more conducive work environment, leading to improved productivity and employee satisfaction. Additionally, they can help regulate temperatures, which is vital in maintaining equipment efficiency. For international buyers, particularly in South America, it is crucial to assess the panels’ acoustic properties and their compatibility with existing structures to maximize benefits.

What Are the Applications of Foam Wall Panels in Transportation?

Foam wall panels find their application in the transportation sector, particularly in vehicles and public transport systems. Their lightweight properties not only enhance fuel efficiency but also contribute to the overall aesthetic and comfort of the interiors. Buyers should evaluate the panels for durability, weight specifications, and adherence to safety regulations, ensuring they meet the necessary standards for transportation applications.

3 Common User Pain Points for ‘foam wall panels’ & Their Solutions

Scenario 1: Difficulty in Achieving Desired Aesthetic Appeal

The Problem: B2B buyers often struggle to find foam wall panels that meet their design aspirations while also being functional. Many businesses, such as hotels or restaurants, seek to create a specific ambiance that reflects their brand identity. However, they may find that available foam wall panels either lack the desired aesthetic or do not integrate well with existing decor. This mismatch can lead to dissatisfaction with the product, increased costs from rework, and ultimately, a negative impact on customer experience.

The Solution: To overcome this challenge, buyers should prioritize sourcing foam wall panels that offer customizable designs or a wide range of finishes. Working with manufacturers that provide high-quality, HD printed foam panels can ensure that the aesthetic appeal aligns with brand standards. Additionally, consider panels that mimic materials like brick or wood, which can add a sophisticated touch without compromising on practicality. It’s also beneficial to request samples before making large orders, allowing for evaluation of texture, color, and overall fit with the intended environment. Engaging with design consultants who specialize in commercial spaces can also provide valuable insights into the best options available, ensuring the chosen panels enhance the overall aesthetic.

Scenario 2: Installation Challenges and Associated Costs

The Problem: Many businesses face installation challenges when using foam wall panels, especially if the panels require specialized tools or skills. Inadequate installation can lead to misalignment, which not only detracts from visual appeal but can also result in additional costs for repairs and replacements. This issue is particularly pressing for international buyers in regions where skilled labor may be limited or more expensive, leading to project delays and frustration.

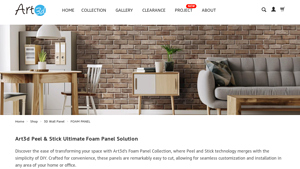

Illustrative image related to foam wall panels

The Solution: To mitigate installation issues, buyers should look for foam wall panels designed for easy application. Options that feature peel-and-stick or adhesive backing can simplify the installation process and reduce the need for professional labor. It’s essential to ensure that the surface is properly prepared before installation, which may involve cleaning and priming the wall to enhance adhesion. Providing training or detailed installation guides from the supplier can also empower in-house teams to complete the installation efficiently. Additionally, consider suppliers who offer installation support or partnerships with local contractors for international buyers who may need assistance navigating regional labor markets.

Scenario 3: Concerns Over Durability and Performance

The Problem: Durability and performance are critical concerns for B2B buyers investing in foam wall panels, especially in high-traffic commercial environments. Buyers often worry that foam panels may not withstand wear and tear, leading to frequent replacements and increased lifecycle costs. This is a significant concern in sectors such as hospitality or retail, where aesthetic integrity and functionality are paramount.

The Solution: To address durability concerns, buyers should prioritize sourcing foam wall panels made from high-density materials that are specifically designed for commercial use. Look for panels that are moisture-resistant, mold-resistant, and treated to withstand impacts. Requesting performance certifications or test results from manufacturers can also provide assurance regarding durability. Additionally, consider panels with a warranty that covers wear and tear; this not only protects the investment but also ensures peace of mind. Regular maintenance, such as cleaning with appropriate solutions, can further enhance the lifespan of the panels, making them a more sustainable choice for long-term use. Engaging with suppliers who understand the specific needs of commercial applications can lead to better-informed purchasing decisions and ultimately, higher satisfaction.

Strategic Material Selection Guide for foam wall panels

What Are the Key Properties of Common Materials Used in Foam Wall Panels?

When selecting foam wall panels for various applications, understanding the materials involved is crucial for ensuring optimal performance and compliance with industry standards. Here, we analyze four common materials used in foam wall panels: Expanded Polystyrene (EPS), Polyurethane (PU), Polyethylene (PE), and Styrofoam. Each material has distinct properties, advantages, and limitations that can significantly impact the buyer’s decision-making process.

Expanded Polystyrene (EPS)

Key Properties: EPS is lightweight, offers excellent thermal insulation, and has good compressive strength. It is resistant to moisture, making it suitable for various environments, including humid conditions.

Pros & Cons: The durability of EPS is moderate; while it can withstand pressure, it is susceptible to UV degradation and should be protected from direct sunlight. Cost-effective and easy to manufacture, EPS panels are often used in residential and commercial applications. However, their environmental impact is a concern, as they are not biodegradable.

Impact on Application: EPS is compatible with a wide range of finishes, including paint and decorative coatings. It is commonly used in both interior and exterior wall applications.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with local building codes, such as DIN standards in Germany. EPS panels must also adhere to fire safety regulations, which can vary significantly between countries.

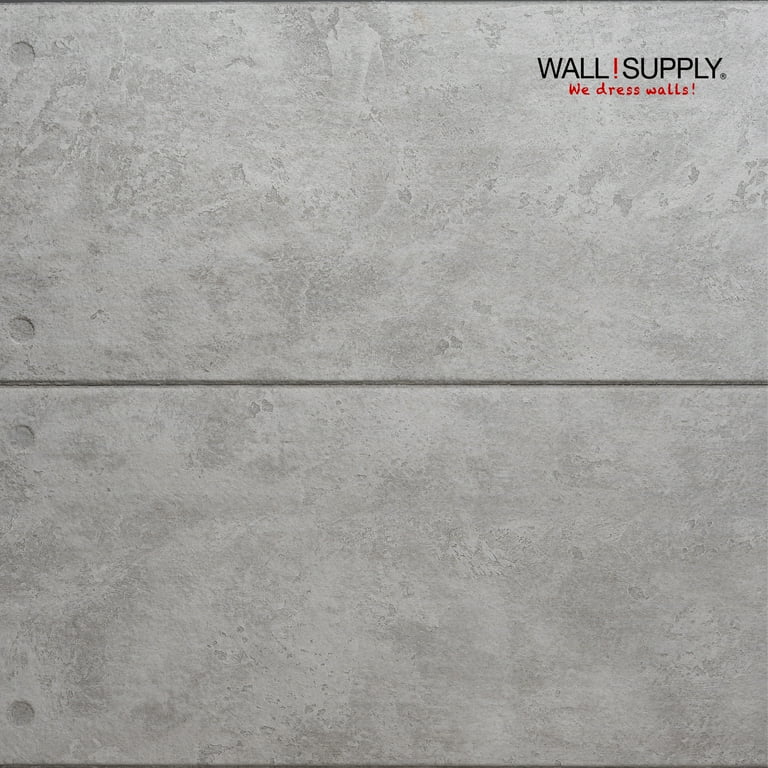

Illustrative image related to foam wall panels

Polyurethane (PU)

Key Properties: PU foam panels offer superior insulation properties, with higher R-values than EPS. They are also more resistant to moisture and mold, making them ideal for environments prone to dampness.

Pros & Cons: The durability of PU is high, and it can withstand significant wear and tear. However, the manufacturing process is more complex and costly compared to EPS. While PU panels provide excellent thermal performance, they can be more expensive, which may deter budget-conscious buyers.

Impact on Application: PU is particularly well-suited for applications requiring high thermal resistance, such as cold storage facilities and refrigerated spaces.

Considerations for International Buyers: In regions like South America, where humidity levels can be high, PU panels are preferred due to their moisture resistance. Buyers should also consider compliance with ASTM standards for insulation materials.

Polyethylene (PE)

Key Properties: PE foam panels are known for their flexibility, lightweight nature, and resistance to chemicals. They provide decent thermal insulation and are often used in soundproofing applications.

Pros & Cons: The main advantage of PE is its versatility; it can be used in various applications, including packaging and wall insulation. However, its insulation properties are lower than those of EPS and PU, making it less suitable for extreme temperature environments.

Impact on Application: PE is often used in commercial settings where flexibility and ease of installation are paramount. It can be easily cut and shaped to fit specific design requirements.

Considerations for International Buyers: Buyers from Africa and the Middle East should be aware of the varying chemical resistance standards in their regions. PE panels should meet local regulations to ensure safety and compliance.

Styrofoam

Key Properties: Styrofoam, a brand of expanded polystyrene, shares many properties with EPS but is often marketed for its aesthetic appeal and ease of installation. It provides good insulation and is lightweight.

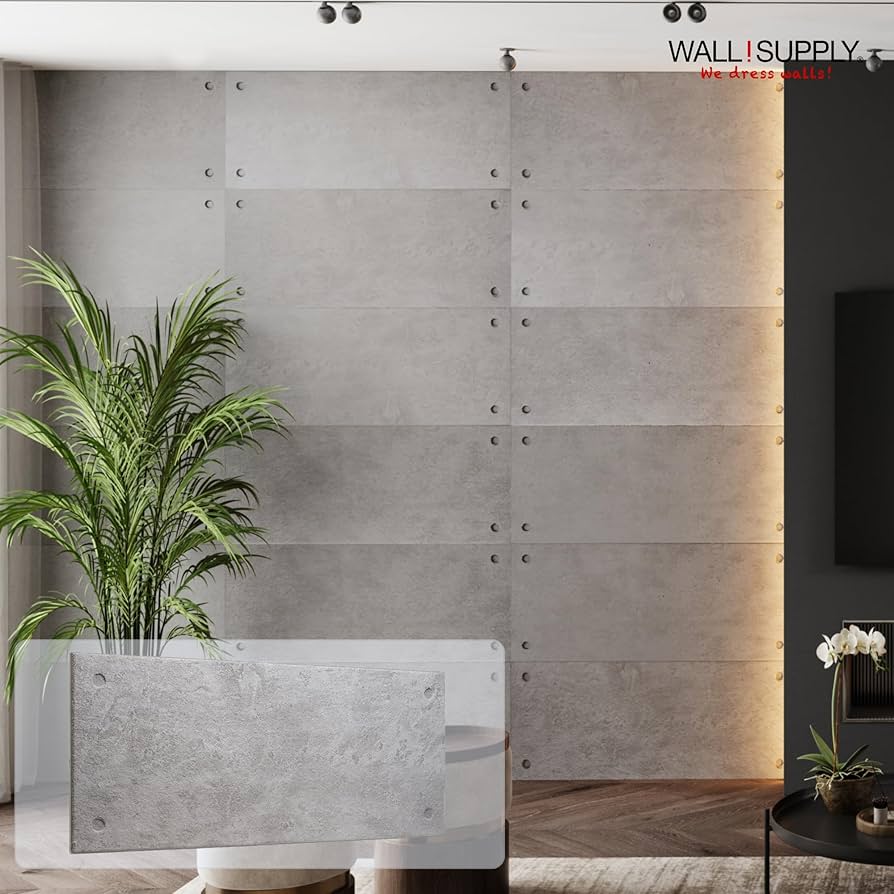

Illustrative image related to foam wall panels

Pros & Cons: Styrofoam panels are cost-effective and easy to install, making them popular in DIY projects. However, they are not as durable as PU and can be easily damaged. Their environmental impact is also a concern, as they are not recyclable in many regions.

Impact on Application: Styrofoam is widely used for decorative wall applications and is often favored in residential settings due to its aesthetic versatility.

Considerations for International Buyers: Buyers in Europe may need to consider environmental regulations regarding Styrofoam disposal and recycling. Compliance with local standards is essential for long-term sustainability.

Summary Table of Material Selection for Foam Wall Panels

| Material | Typical Use Case for Foam Wall Panels | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Expanded Polystyrene (EPS) | Residential and commercial wall insulation | Lightweight and cost-effective | Susceptible to UV degradation | Low |

| Polyurethane (PU) | Cold storage facilities | Superior thermal insulation | Higher cost and complex manufacturing | High |

| Polyethylene (PE) | Soundproofing and flexible applications | Versatile and easy to install | Lower insulation properties | Medium |

| Styrofoam | Decorative wall applications | Aesthetic appeal and easy installation | Not very durable and environmental concerns | Low |

This guide provides a comprehensive overview of the key materials used in foam wall panels, aiding international B2B buyers in making informed decisions that align with their specific needs and regional regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for foam wall panels

What Are the Key Stages in the Manufacturing Process of Foam Wall Panels?

The manufacturing process of foam wall panels involves several critical stages that ensure the final product meets aesthetic and functional requirements.

Illustrative image related to foam wall panels

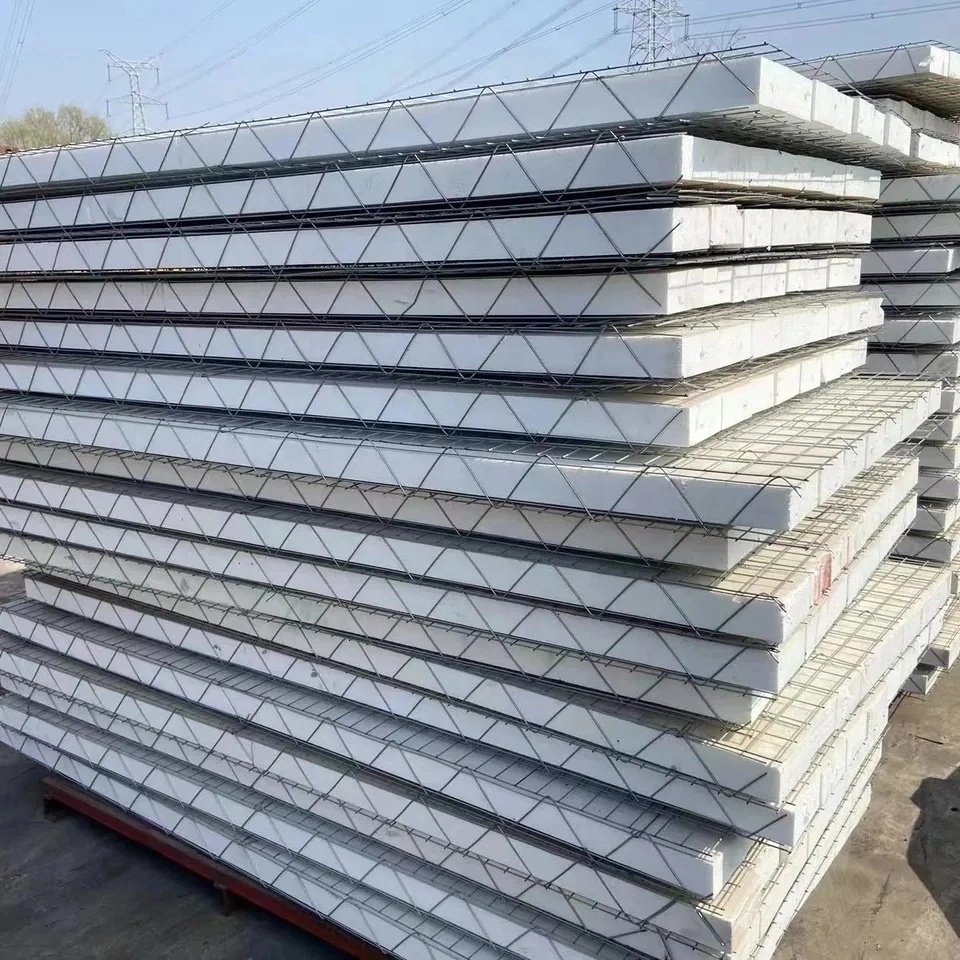

Material Preparation: What Materials Are Used?

The first step in manufacturing foam wall panels is the preparation of raw materials, primarily expanded polystyrene (EPS) or polyurethane foam. These materials are selected for their lightweight properties, insulation capabilities, and ease of handling. Manufacturers often source materials from reputable suppliers to ensure quality and consistency. The foam is typically produced in large blocks or sheets, which are then cut into specific sizes based on design requirements.

Forming: How Are Panels Shaped?

In the forming stage, the prepared foam is shaped into panels using various techniques. Common methods include:

- Molding: This involves pouring liquid foam into molds to create panels with specific textures and designs, such as faux brick or wood finishes.

- Cutting and Shaping: For panels that require a more customized shape or size, cutting machines utilize CNC technology for precision cutting. This ensures that each panel fits perfectly into the intended application.

- Printing: Advanced printing technologies, such as high-definition digital printing, are employed to apply realistic textures and colors to the surface of the foam panels, enhancing their aesthetic appeal.

Assembly: What Techniques Are Used for Panel Assembly?

After shaping, the panels may go through an assembly process if they require additional components, such as backing or framing. This can involve:

- Adhesive Bonding: Panels are often bonded together or to other materials using industrial-grade adhesives that provide strong, durable connections.

- Mechanical Fastening: In some cases, mechanical fasteners may be used, particularly for larger installations where structural integrity is paramount.

Finishing: How Are Panels Prepared for Market?

The finishing stage includes surface treatments and quality checks to ensure that the panels are ready for market. This may involve:

- Coating: Applying protective coatings can enhance the panels’ resistance to moisture, UV light, and abrasion, extending their lifespan and performance.

- Quality Inspection: Before packaging, panels undergo visual inspections and testing to ensure they meet specific quality standards.

How Does Quality Assurance Ensure Product Integrity?

Quality assurance (QA) is crucial in the manufacturing process, as it helps maintain product integrity and customer satisfaction. The following outlines key QA practices relevant to foam wall panels.

Illustrative image related to foam wall panels

What International Standards Should Buyers Be Aware Of?

B2B buyers should familiarize themselves with international quality standards that manufacturers may adhere to, including:

- ISO 9001: This standard focuses on quality management systems and ensuring consistent quality in manufacturing processes.

- CE Marking: In Europe, CE marking indicates that products comply with health, safety, and environmental protection standards.

- API Standards: For applications that require specific performance characteristics, such as in industrial settings, adherence to API standards can be critical.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated into the manufacturing process to monitor and verify product quality at various stages:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): During manufacturing, samples are taken at different stages to check for consistency in dimensions, weight, and finish.

- Final Quality Control (FQC): Before products are shipped, a final inspection is conducted to ensure that the foam wall panels meet all specifications and quality standards.

What Testing Methods Are Commonly Used for Foam Wall Panels?

To ensure product performance, several testing methods can be applied:

- Thermal Conductivity Testing: Measures the insulation properties of foam panels, ensuring they meet energy efficiency standards.

- Acoustic Testing: Evaluates sound absorption capabilities, which is essential for applications requiring noise reduction.

- Moisture Resistance Testing: Assesses the panels’ resistance to moisture, critical for installations in humid environments.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers looking to ensure the quality of foam wall panels can take several steps to verify supplier QC:

What Are the Best Practices for Auditing Suppliers?

- Supplier Audits: Conducting on-site audits can provide insights into the manufacturing processes, quality control measures, and overall operational standards of the supplier.

- Requesting Quality Reports: Buyers should request detailed QC reports and certifications that demonstrate adherence to international standards.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturer’s quality assurance practices.

What Are the Nuances of Quality Control for International Buyers?

International B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

- Regulatory Compliance: Different regions may have varying regulatory requirements regarding product safety and quality. It’s essential to understand local regulations to ensure compliance.

- Cultural Expectations: Understanding cultural expectations regarding product quality and customer service can aid in building strong relationships with suppliers.

- Logistical Considerations: Quality control processes may vary based on shipping and handling practices, so buyers should consider how products will be transported and stored upon arrival.

By understanding the manufacturing processes and quality assurance practices for foam wall panels, B2B buyers can make informed decisions when selecting suppliers and products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘foam wall panels’

To successfully source foam wall panels for your business, follow this practical checklist that outlines essential steps to ensure you make informed decisions. This guide will help you navigate through the procurement process efficiently, catering specifically to the needs of international B2B buyers.

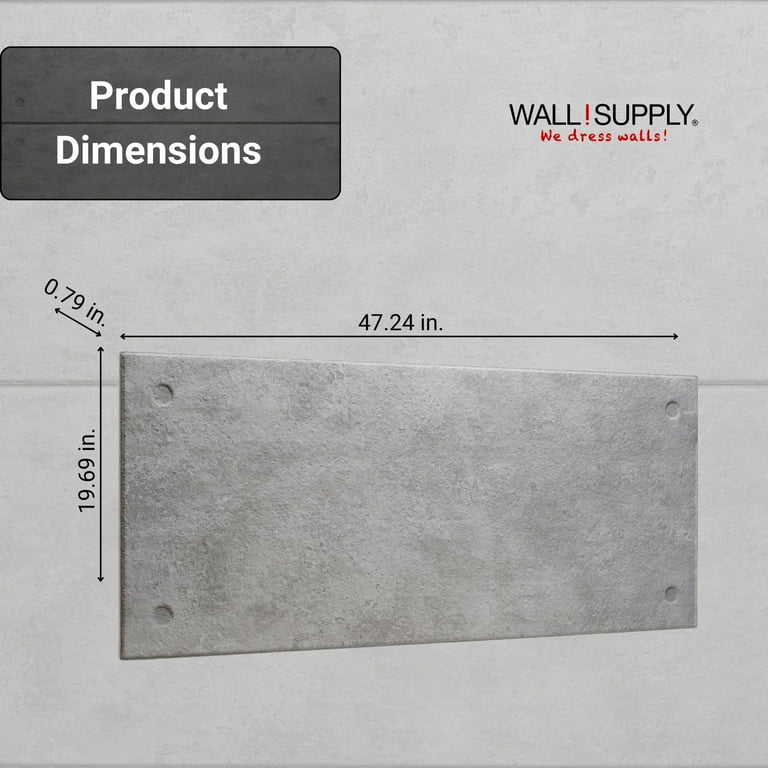

Step 1: Define Your Technical Specifications

Before you begin sourcing, clearly outline your requirements for foam wall panels. This includes dimensions, thickness, insulation properties, and aesthetic preferences (e.g., color, texture). Knowing these details will streamline your search and help you communicate effectively with suppliers.

- Key Considerations:

- Thermal and acoustic insulation values.

- Surface finish (e.g., faux brick, wood, or stone).

- Compliance with local building codes and standards.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in foam wall panels. Look for companies that have a strong presence in your target regions, such as Africa, South America, the Middle East, and Europe.

Illustrative image related to foam wall panels

- Action Items:

- Review online directories and trade platforms.

- Check for customer reviews and feedback on social media.

Step 3: Evaluate Supplier Certifications

It’s critical to verify the certifications and compliance of potential suppliers. Certifications related to quality management (like ISO 9001) or environmental standards (like ISO 14001) can indicate a commitment to quality and sustainability.

- Specifics to Check:

- Safety certifications (e.g., fire resistance, toxicity).

- Product warranties and guarantees.

Step 4: Request Samples

Once you have a shortlist of suppliers, request samples of the foam wall panels. This allows you to evaluate the quality, texture, and appearance of the panels firsthand before making a bulk purchase.

- Why It Matters:

- Assess compatibility with your project requirements.

- Ensure the aesthetic meets your expectations.

Step 5: Compare Pricing and Terms

Gather quotes from multiple suppliers and compare not only the prices but also the terms of delivery, payment options, and minimum order quantities. This will help you identify the best value for your investment.

- Considerations:

- Look for hidden costs, such as shipping or customs fees.

- Analyze bulk order discounts and return policies.

Step 6: Assess Delivery and Lead Times

Understanding the supplier’s delivery capabilities is essential. Confirm lead times for production and shipping to ensure they align with your project schedules.

- Questions to Ask:

- What is the typical lead time for your products?

- Do you have the capacity to meet urgent orders?

Step 7: Establish Communication and Support

Finally, establish a clear line of communication with your chosen supplier. Good communication can facilitate smoother transactions and provide support for any questions or issues that arise post-purchase.

- Key Points:

- Ensure you have a dedicated contact person.

- Discuss channels for ongoing support and product updates.

By following this checklist, you can effectively navigate the procurement process for foam wall panels, ensuring that you choose the right products from reputable suppliers that meet your business needs.

Comprehensive Cost and Pricing Analysis for foam wall panels Sourcing

What Are the Key Cost Components in Foam Wall Panel Manufacturing?

When analyzing the costs associated with sourcing foam wall panels, several critical components come into play. Materials typically represent the largest share of the total cost, with options ranging from basic Styrofoam to high-density foam, which can influence both price and performance characteristics. Labor costs also factor in, particularly if the production involves specialized skills for custom designs or installations.

Manufacturing overhead encompasses expenses related to factory operations, including utilities and equipment maintenance. Tooling costs may arise if custom molds or production setups are required for specific panel designs, adding to initial expenditures. Additionally, quality control (QC) processes ensure that products meet industry standards, which can further impact pricing.

Finally, logistics costs play a significant role in the overall cost structure. This includes transportation, warehousing, and customs fees, especially important for international buyers. Lastly, the margin that suppliers add to cover their risks and profits can vary significantly based on their market positioning and the competitiveness of their offerings.

How Do Price Influencers Affect Foam Wall Panel Sourcing?

Several factors can influence the pricing of foam wall panels in a B2B context. Volume or Minimum Order Quantity (MOQ) is a critical aspect; larger orders often lead to discounts, allowing buyers to achieve better pricing per unit. The specifications and customization of panels can also lead to price variations. Custom designs or high-quality finishes will typically incur additional costs.

The choice of materials significantly affects pricing as well. For instance, panels with enhanced thermal insulation or soundproofing properties may command higher prices due to their advanced manufacturing processes. Quality certifications can also impact costs, as certified products often undergo rigorous testing, which can add to their price but also enhance their marketability.

Supplier factors, including their reputation and production capabilities, can further influence pricing. International buyers must also consider Incoterms, which define the responsibilities of buyers and sellers in shipping. Understanding these terms can help in calculating total landed costs, which is crucial for accurate budgeting.

What Tips Should Buyers Consider for Cost-Efficiency in Foam Wall Panels?

To optimize sourcing foam wall panels, buyers should adopt a strategic approach. Negotiation is key; understanding market prices and being prepared to discuss terms can yield better deals. Establishing long-term relationships with suppliers may provide further leverage for discounts and favorable payment terms.

Evaluating the Total Cost of Ownership (TCO) is essential for making informed decisions. This includes not only the purchase price but also logistics, installation, and maintenance costs over the product’s lifecycle. Buyers should also be mindful of pricing nuances in international contexts. Variability in local regulations, tariffs, and currency fluctuations can affect final costs and should be factored into budgeting.

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding local market dynamics is crucial. Engaging with local suppliers or distributors can sometimes mitigate high logistics costs associated with international shipping. Lastly, always request indicative prices from multiple suppliers to establish a competitive benchmark, ensuring that you are making cost-effective purchasing decisions.

Alternatives Analysis: Comparing foam wall panels With Other Solutions

When considering wall coverings, foam wall panels stand out for their aesthetic appeal and functional benefits. However, it’s important for B2B buyers to evaluate alternative solutions that may suit their specific requirements better. This section explores three alternatives to foam wall panels: traditional drywall, wood paneling, and PVC wall panels. Each option has its own set of advantages and drawbacks that can impact decision-making for various applications.

| Comparison Aspect | Foam Wall Panels | Traditional Drywall | Wood Paneling | PVC Wall Panels |

|---|---|---|---|---|

| Performance | Excellent thermal and acoustic insulation; lightweight | Good insulation; durable but heavy | High durability; natural aesthetic | Water-resistant; good durability |

| Cost | Moderate (approx. $5-$10/sq. ft.) | Lower initial cost (approx. $1-$3/sq. ft.) but higher labor costs | Higher (approx. $8-$15/sq. ft.) | Moderate (approx. $3-$8/sq. ft.) |

| Ease of Implementation | Easy installation (peel & stick or adhesive) | Requires skilled labor for installation | Moderate; requires tools and skills | Very easy (often peel & stick) |

| Maintenance | Low maintenance; easy to clean | Moderate; may require patching and painting | Higher; may need refinishing over time | Low; resistant to moisture and stains |

| Best Use Case | Interior decorative applications | General construction and offices | High-end residential and commercial | Wet areas (kitchens, bathrooms) |

What Are the Advantages and Disadvantages of Traditional Drywall?

Traditional drywall is a popular choice due to its cost-effectiveness and availability. It provides a solid surface for painting and can be easily repaired if damaged. However, the installation process can be labor-intensive and requires skilled workers. Additionally, drywall offers less aesthetic flexibility compared to foam wall panels, which can replicate various textures and finishes.

Illustrative image related to foam wall panels

How Does Wood Paneling Compare?

Wood paneling offers a natural, classic look that appeals to upscale markets. It has a warm aesthetic and can add significant value to a property. However, it is often more expensive and requires regular maintenance, such as refinishing and sealing, to preserve its appearance. Wood is also heavier, making installation more challenging, especially in larger projects.

What Are the Benefits of Using PVC Wall Panels?

PVC wall panels are becoming increasingly popular, particularly in areas where moisture is a concern. They are water-resistant, easy to clean, and can be installed quickly. Their affordability makes them an attractive option for budget-conscious projects. However, they may not offer the same aesthetic appeal as foam wall panels or wood, and their longevity can vary based on quality.

How Can B2B Buyers Choose the Right Solution?

For B2B buyers, selecting the right wall covering solution involves assessing specific project requirements, including budget, installation capabilities, and aesthetic goals. Foam wall panels excel in environments where quick installation and decorative appeal are paramount, while traditional drywall might be more suitable for budget-sensitive projects. Wood paneling provides a premium look but requires more upkeep, whereas PVC panels serve well in moisture-prone areas. By carefully considering these factors, buyers can make informed decisions that align with their operational and aesthetic needs.

Essential Technical Properties and Trade Terminology for foam wall panels

What Are the Key Technical Properties of Foam Wall Panels for B2B Buyers?

Understanding the technical properties of foam wall panels is essential for B2B buyers looking to make informed purchasing decisions. Here are some critical specifications that you should consider:

-

Material Composition

Foam wall panels are typically made from materials such as Expanded Polystyrene (EPS), Extruded Polystyrene (XPS), or Polyurethane. Each type offers varying degrees of thermal insulation, durability, and moisture resistance. For instance, EPS is lightweight and cost-effective, while XPS provides superior moisture resistance, making it ideal for humid environments. -

Thermal Resistance (R-Value)

The R-value measures the panel’s thermal resistance. Higher R-values indicate better insulation properties, which can lead to significant energy savings in temperature-controlled environments. B2B buyers should consider panels with appropriate R-values based on regional climate conditions and energy efficiency goals. -

Fire Rating

The fire rating of foam wall panels is critical, especially in commercial applications. Panels may be classified as Class A, B, or C based on their ability to resist ignition and flame spread. Understanding the fire safety standards applicable in your region can help mitigate risks and ensure compliance with local building codes. -

Thickness and Density

The thickness and density of foam panels affect their structural integrity and insulation performance. Thicker panels provide better sound insulation and thermal resistance, while denser panels are often more durable and resistant to damage. Buyers should evaluate the specific requirements of their projects to select the appropriate thickness and density. -

Moisture Resistance

Some foam wall panels come with moisture-resistant coatings that help prevent mold and mildew growth. This is particularly important for applications in areas prone to high humidity, such as bathrooms or kitchens. Evaluating moisture resistance can enhance the longevity of the installation. -

Surface Finish Options

Foam wall panels are available in various surface finishes, including textured, smooth, or printed designs that mimic natural materials like wood, brick, or stone. These aesthetic options allow for creative freedom in design while maintaining the functional benefits of foam.

What Are Common Trade Terminology and Jargon in the Foam Wall Panel Industry?

Familiarity with industry terminology is crucial for effective communication and negotiation in the B2B marketplace. Here are some common terms to know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand name. In the context of foam wall panels, OEM relationships can lead to customized solutions tailored to specific client needs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to avoid overcommitting to inventory that may not sell, especially in regions with fluctuating demand. -

RFQ (Request for Quotation)

An RFQ is a formal document requesting price quotes from suppliers for specific quantities of products. This is an essential tool for buyers to compare pricing, terms, and conditions from multiple vendors before making a purchase decision. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Familiarity with these terms can help B2B buyers navigate the complexities of international shipping and logistics. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is essential for project planning and ensuring that materials arrive on schedule. -

Certification Standards

Certification standards, such as ISO or ASTM, indicate that the products meet specific quality and safety benchmarks. Buyers should look for certifications relevant to their market to ensure that the foam wall panels comply with industry regulations.

By grasping these technical properties and trade terms, B2B buyers can enhance their procurement strategies and ensure that they select the most suitable foam wall panels for their projects.

Navigating Market Dynamics and Sourcing Trends in the foam wall panels Sector

Global drivers influencing the foam wall panels market include urbanization, increased demand for energy-efficient building materials, and a growing preference for lightweight, easy-to-install solutions. As countries in Africa, South America, the Middle East, and Europe continue to experience rapid construction and renovation projects, foam wall panels are becoming increasingly popular due to their aesthetic appeal and functional benefits, such as thermal and acoustic insulation. Moreover, the rise of modular construction techniques is shifting the focus towards materials that enhance speed and efficiency in building projects.

Emerging technologies in the sourcing of foam wall panels, such as advanced manufacturing processes and smart inventory management systems, are making it easier for international buyers to access a diverse range of products. Innovations in 3D printing and digital design tools are also allowing manufacturers to create customized solutions tailored to specific client needs, further enhancing market competitiveness. Buyers should keep an eye on the integration of AI and machine learning in supply chain logistics, which can streamline procurement processes and reduce lead times.

In terms of market dynamics, the foam wall panels sector is characterized by a blend of established manufacturers and emerging startups, creating a diverse competitive landscape. Buyers from regions like Germany and Saudi Arabia are increasingly seeking suppliers that can offer high-quality products with reliable delivery timelines. Additionally, as the market matures, there is a noticeable shift towards collaborative partnerships between manufacturers and distributors, emphasizing long-term relationships over transactional engagements.

Illustrative image related to foam wall panels

How is Sustainability Impacting the Sourcing of Foam Wall Panels?

The environmental impact of foam wall panels is a critical consideration for today’s B2B buyers. As awareness of climate change and resource depletion grows, companies are prioritizing sustainability in their sourcing decisions. Foam wall panels, particularly those made from recycled materials or with low VOC emissions, are increasingly in demand. Buyers are encouraged to seek suppliers that provide transparent information about their production processes and material sourcing.

Ethical supply chains are becoming a non-negotiable aspect of B2B procurement. Buyers should look for manufacturers who prioritize fair labor practices and sustainable sourcing methods. Certifications such as LEED (Leadership in Energy and Environmental Design) and ISO 14001 (Environmental Management Systems) can serve as indicators of a supplier’s commitment to sustainability. By choosing suppliers with these credentials, businesses not only align with environmental goals but also enhance their brand reputation in an increasingly eco-conscious marketplace.

What is the Historical Context of Foam Wall Panels in the B2B Market?

The evolution of foam wall panels can be traced back to the mid-20th century when the demand for lightweight and versatile construction materials began to rise. Initially used primarily in commercial applications, advancements in manufacturing technology expanded their use into residential and industrial sectors. Over the decades, foam wall panels have transitioned from basic insulation solutions to sophisticated products that offer aesthetic versatility, mimicking materials such as wood, stone, and brick. This evolution reflects broader trends in the construction industry towards energy efficiency, design flexibility, and ease of installation, making foam wall panels a staple for modern building projects across the globe.

In summary, the foam wall panels market is not only shaped by current trends and technologies but also by a strong emphasis on sustainability and ethical practices, making it essential for international B2B buyers to remain informed and proactive in their sourcing strategies.

Illustrative image related to foam wall panels

Frequently Asked Questions (FAQs) for B2B Buyers of foam wall panels

-

How do I choose the right foam wall panels for my project?

Selecting the appropriate foam wall panels depends on several factors, including the intended use, aesthetic preferences, and insulation requirements. Consider the thickness, texture, and color that align with your design vision. Evaluate the panel’s thermal and acoustic insulation properties to ensure they meet your project’s needs. It’s also essential to assess the installation method, as some panels come with peel-and-stick options while others require adhesive. Request samples from suppliers to see how the panels look in your environment before making a bulk purchase. -

What are the advantages of using foam wall panels in commercial spaces?

Foam wall panels offer several benefits for commercial spaces, including lightweight construction, ease of installation, and excellent insulation properties. They can enhance the aesthetic appeal of a space with various designs mimicking brick, wood, or stone without the associated weight or cost. Their soundproofing capabilities are ideal for offices, restaurants, and hotels, helping to create a more comfortable environment. Additionally, foam panels are often moisture-resistant and easy to clean, making them suitable for high-traffic areas. -

What is the typical lead time for foam wall panel orders?

Lead times for foam wall panels can vary based on several factors, including the supplier’s inventory, customization options, and shipping logistics. Generally, standard orders may take anywhere from 2 to 4 weeks, while customized panels can take longer. It’s advisable to confirm the lead time with your supplier before placing an order, especially if your project has specific deadlines. Also, factor in additional time for shipping, particularly for international orders, which may be subject to customs delays. -

What are the minimum order quantities (MOQ) for foam wall panels?

Minimum order quantities for foam wall panels can differ significantly among suppliers and depend on the type of panels being ordered. Some manufacturers may have an MOQ as low as 50 square feet, while others may require orders of 100 square feet or more for certain designs. Always inquire about MOQs when sourcing from potential suppliers, as this can impact your budget and project timeline. Negotiating lower MOQs may be possible, especially for larger or repeat orders. -

How can I ensure quality when sourcing foam wall panels internationally?

To ensure quality when sourcing foam wall panels from international suppliers, conduct thorough research and vet potential partners. Request product samples to assess material quality and craftsmanship. Look for certifications that indicate compliance with industry standards, such as fire safety and environmental regulations. It’s also beneficial to read reviews and ask for references from previous clients. Establish clear quality assurance protocols in your purchase agreement, including inspection rights upon delivery. -

What payment terms should I expect when purchasing foam wall panels?

Payment terms for foam wall panels can vary widely based on the supplier’s policies and the nature of the order. Common practices include a deposit upfront (typically 30-50%) with the balance due before shipment. Some suppliers may offer net terms (e.g., net 30 or net 60) for established buyers. Always clarify payment terms before finalizing your order to avoid misunderstandings. Consider using secure payment methods that offer buyer protection, especially for large transactions. -

Can foam wall panels be customized to meet specific design requirements?

Yes, many manufacturers offer customization options for foam wall panels, allowing you to choose specific colors, textures, and sizes. Custom designs can help align the panels with your branding or aesthetic goals. However, custom orders may come with longer lead times and higher costs compared to standard products. It is advisable to discuss your design requirements with potential suppliers and request a prototype or mock-up before proceeding with a full order. -

What are the shipping considerations for importing foam wall panels?

When importing foam wall panels, consider factors such as shipping method, costs, and customs regulations. Sea freight is often the most cost-effective option for large shipments, but it may take longer than air freight. Understand the import duties and taxes applicable in your destination country, which can affect the total cost. It is also wise to work with a freight forwarder who can assist with logistics and ensure compliance with all shipping regulations. Make sure to track your shipment to anticipate any potential delays.

Top 5 Foam Wall Panels Manufacturers & Suppliers List

1. Pro Foam Panels – Premium Soundproofing Solution

Domain: onestopsimshop.com

Registered: 2020 (5 years)

Introduction: Pro Foam Panels

– Regular price: $49.99

– Sale price: $49.99

– Dimensions: 16″x24″x2″

– Thickness: 2 inches

– Material: Pro Foam covered in soft luxurious fabric (similar to loop velcro)

– Installation: Easy to install with adhesive-backed velcro (included)

– Sold individually

– Ideal companion to Better Baffles

– Current lead time for panels: 3 weeks

– Note: Item has a lead time of 4 weeks, which…

2. Dundee Deco – Foam Wall Panels

Domain: dundeedeco.com

Registered: 2020 (5 years)

Introduction: Foam Wall Panels | Dundee Deco | Easy Install | FREE SHIPPING FOR RETAIL ORDERS OVER 500$ | Shop by Room: Shower, Bathroom, Basement, Garage, Exterior, Bedroom, Kitchen | Shop by Material: PVC, Styrofoam, MDF, Waterproof, Foam, Fiber, Wood, UV PVC, Marble, Thin stone veneer | Shop by Style: 3D, Decorative, Soundproof, Fluted, Textured, Accent, Acoustic | Shop By Finish: Faux brick, Faux stone, Fau…

3. Pinterest – Foam Wall Panels 10-Pack

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Foam Wall Panels: 10-Pack White Foam 3D Wall Tile Panels, Material: Foam, Color: White, Coverage: 58 sq.ft., Panel Length: 2.5ft (30 inches), Panel Width: 2.3ft (27.5 inches), Thickness: 2mm, Features: Waterproof, Anti Collision, Peel and stick application, Easy peeling with hair dryer. Custom made acoustic panels available, designed in California, produced in Turkey, with certifications including…

4. Residence Supply – Aaget Wall Panel

Domain: residencesupply.com

Registered: 2023 (2 years)

Introduction: {“product_name”: “Aaget Wall Panel”, “price”: “$35.00”, “dimensions”: “20” x 20″ / 50 x 50cm”, “colors”: [“Bright White”, “Matte White”, “Matte Black”, “Bright Black”, “Bright Gold”, “Matte Apple Gold”, “Bright Gray”, “Bright Silver”, “Matte Gray”, “Matte Silver”, “Double Sided Tape”], “material”: “PE Foam”, “design”: “Geometric diamond-cut”, “suitable_for”: [“dining rooms”, “bedrooms”, “TV walls”…

5. Art3d – Foam Panel Collection

Domain: art3d.com

Registered: 1998 (27 years)

Introduction: Art3d Foam Panel Collection features Peel and Stick technology for easy DIY installation. The panels are designed for convenience, allowing for seamless customization and easy cutting. They incorporate anti-collision technology for enhanced safety, while the 3D foam material adds aesthetic value and comfort to spaces. Maintenance is simplified with easy cleaning. Popular products include: 20-Pack …

Strategic Sourcing Conclusion and Outlook for foam wall panels

In today’s competitive market, strategic sourcing of foam wall panels presents a unique opportunity for international B2B buyers. By leveraging innovative materials such as lightweight, high-density foam, companies can enhance their product offerings with stylish, cost-effective solutions that meet diverse aesthetic and functional needs. Buyers should prioritize suppliers that offer a range of designs—from faux brick to wood textures—enabling them to cater to varied customer preferences while ensuring ease of installation and durability.

Investing in quality foam wall panels not only improves thermal and acoustic insulation but also contributes to sustainability, as many products are designed with eco-friendly materials. This is particularly relevant for markets in Africa, South America, the Middle East, and Europe, where environmental considerations are increasingly influencing purchasing decisions.

Looking ahead, B2B buyers are encouraged to establish strong relationships with reliable manufacturers and distributors to optimize their supply chains. By embracing a strategic sourcing approach, businesses can secure competitive pricing, ensure product quality, and ultimately drive customer satisfaction. Seize this opportunity to enhance your portfolio and stay ahead in the evolving landscape of interior design and construction.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.