Unlocking Value: A Strategic Analysis of the Floor Glides Round Rectangular Market

Introduction: Navigating the Global Market for floor glides round rectangular

In the competitive landscape of international trade, sourcing high-quality floor glides round rectangular can pose significant challenges for B2B buyers. With varied applications across furniture industries, from office chairs to dining sets, understanding the nuances of these essential components is crucial for ensuring both functionality and aesthetic appeal. This guide delves into the diverse types of floor glides available, their applications, and the critical factors to consider when selecting suppliers.

From identifying the right materials—such as durable plastics or rubber—to understanding the impact of glide design on floor protection, each aspect plays a vital role in making informed purchasing decisions. We will also explore cost considerations, supplier vetting processes, and best practices for integrating these glides into your product offerings.

Designed specifically for international B2B buyers in regions such as Africa, South America, the Middle East, and Europe—including markets like Vietnam and Brazil—this comprehensive resource empowers you to navigate the complexities of sourcing floor glides. By equipping you with actionable insights and practical knowledge, we aim to facilitate smarter investments that enhance your product line while safeguarding your customers’ floors from damage. Join us as we explore the global market for floor glides and unlock the potential for your business growth.

Understanding floor glides round rectangular Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Plastic Round Glides | Made from durable LDPE; designed for hollow legs | Office furniture, chairs, tables | Pros: Easy installation, cost-effective; Cons: May wear out over time. |

| Rectangular Insert Glides | Ribbed design for secure fit; available in various sizes | Commercial furniture, equipment | Pros: Reduces noise, protects floors; Cons: Limited aesthetic options. |

| Swivel Glides | Rotating base for mobility; available in multiple materials | Hospitality, healthcare furniture | Pros: Enhances maneuverability; Cons: Higher cost compared to fixed glides. |

| Nail-On Glides | Fastened with nails for secure attachment; various sizes | Residential furniture, DIY projects | Pros: Strong hold, versatile; Cons: Installation can be more labor-intensive. |

| Felt Pad Glides | Soft felt bottom to prevent scratches; adhesive backing | Retail displays, home furniture | Pros: Excellent floor protection; Cons: Adhesive may degrade over time. |

What Are the Key Characteristics of Plastic Round Glides?

Plastic round glides are a popular choice for many businesses due to their durability and ease of installation. Typically made from low-density polyethylene (LDPE), these glides fit snugly inside the hollow legs of furniture, providing a protective barrier against scratches and damage to floors. They are versatile and can be used on various furniture types, including chairs and tables. When purchasing, consider the outer and inner diameter specifications to ensure a proper fit.

How Do Rectangular Insert Glides Benefit Commercial Applications?

Rectangular insert glides feature a ribbed design that ensures a secure fit within furniture legs. They come in various sizes, making them suitable for a wide range of commercial applications, from office furniture to equipment. These glides are particularly effective in reducing noise when furniture is moved, which is a significant advantage in environments such as restaurants and hospitals. Buyers should assess the dimensions and material durability to match their specific needs.

What Advantages Do Swivel Glides Offer for Mobility?

Swivel glides are designed to enhance mobility, making them ideal for environments where furniture needs to be frequently rearranged, such as in hospitality settings. The rotating base allows for smooth movement across different surfaces, which can be particularly beneficial in busy dining areas or conference rooms. While they provide superior functionality, buyers should be aware that swivel glides often come at a higher price point compared to standard fixed options.

Why Choose Nail-On Glides for Secure Attachment?

Nail-on glides are known for their strong attachment due to the nails used in installation. They are available in various sizes and materials, making them suitable for both residential and commercial applications. While they offer excellent durability and stability, the installation process can be more labor-intensive compared to other glide types. Businesses should consider their workforce’s capabilities and the volume of furniture needing glides when opting for this solution.

How Do Felt Pad Glides Protect Floors?

Felt pad glides are specifically designed to provide a soft barrier between furniture and flooring, preventing scratches and marring. These glides often come with an adhesive backing for easy application, making them popular for retail displays and home furniture. However, buyers should note that the adhesive may degrade over time, necessitating periodic replacements. Selecting high-quality felt pads can enhance longevity and effectiveness in protecting flooring surfaces.

Key Industrial Applications of floor glides round rectangular

| Industry/Sector | Specific Application of floor glides round rectangular | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Used as protective caps for chair and table legs | Prevents floor damage, enhances product durability, and reduces warranty claims | Material quality, compatibility with leg dimensions, and cost-effectiveness |

| Hospitality | Installed on furniture in hotels and restaurants | Minimizes noise and floor scratches, improving guest experience | Aesthetic appeal, ease of installation, and bulk purchasing options |

| Education | Utilized in school desks and chairs | Reduces maintenance costs from floor repairs and enhances safety | Compliance with safety standards, durability, and availability in various sizes |

| Healthcare | Applied to medical equipment and furniture | Ensures safety and cleanliness in patient areas, reducing the risk of injury | Chemical resistance, ease of cleaning, and compatibility with different equipment types |

| Retail and Commercial Spaces | Used on display fixtures and retail furniture | Enhances mobility and flexibility of displays while protecting floors | Customization options, load-bearing capacity, and aesthetic design |

In the furniture manufacturing industry, floor glides round rectangular are commonly used as protective caps for the legs of chairs and tables. These glides safeguard floors from scratches and dents, thus prolonging the lifespan of both the furniture and the flooring. For B2B buyers, it is crucial to ensure that the glides are made from high-quality materials to withstand everyday use, and that they fit the specific dimensions of the furniture being produced.

In the hospitality sector, these glides are essential for furniture in hotels and restaurants. They help minimize noise when furniture is moved and prevent damage to flooring, thereby enhancing the overall guest experience. Buyers in this sector should consider sourcing options that not only provide durability but also align with the aesthetic of their establishments, as well as options for bulk purchasing to reduce costs.

Within education, floor glides are utilized in school desks and chairs to protect floors from wear and tear. This application reduces maintenance costs associated with floor repairs and contributes to a safer environment for students. Buyers must ensure that the glides comply with safety standards and are durable enough to endure frequent use in busy school settings.

In the healthcare industry, floor glides are applied to medical equipment and furniture to ensure safety and cleanliness in patient areas. They help in preventing slips and falls, which is critical in maintaining a safe environment. Buyers in this sector should prioritize glides that offer chemical resistance for easy cleaning and compatibility with various types of medical equipment.

Lastly, in retail and commercial spaces, these glides are used on display fixtures and retail furniture to enhance mobility while protecting floors. This flexibility allows retailers to easily rearrange displays, which can be crucial for seasonal promotions. When sourcing, businesses should consider customization options to fit specific display needs, as well as the load-bearing capacity of the glides to ensure they can support heavy retail items.

3 Common User Pain Points for ‘floor glides round rectangular’ & Their Solutions

Scenario 1: Difficulty in Finding the Right Size and Fit for Floor Glides

The Problem: B2B buyers often encounter significant challenges when sourcing floor glides that fit specific furniture leg dimensions. For instance, a buyer may need glides for a range of furniture products with different outer and inner diameter specifications. Mismatched sizes can lead to the glides not fitting securely, resulting in potential damage to floors and furniture. This not only affects the aesthetic of the furniture but can also lead to increased maintenance costs and customer dissatisfaction.

The Solution: To address this issue, it is crucial for buyers to conduct thorough measurements of the furniture legs before making a purchase. A detailed measurement guide should be utilized to ensure accuracy in determining both the outer diameter (OD) and inner diameter (ID) of the furniture legs. When sourcing floor glides, consider suppliers that offer a comprehensive size range and customizable options. Additionally, leveraging technology, such as digital measuring tools, can provide precise measurements. Establishing a relationship with a reliable supplier who can provide samples or support in the selection process will ensure that the chosen glides fit perfectly, thereby enhancing customer satisfaction and reducing the risk of damage.

Scenario 2: Floor Damage and Noise Issues Caused by Inadequate Glides

The Problem: Many businesses face the issue of floor damage and noise due to the use of subpar or inappropriate floor glides. For instance, in a bustling office environment, chairs without proper glides can scratch hardwood floors and create disruptive noises as they are moved. This not only detracts from the workplace ambiance but also leads to costly repairs and a negative impact on the overall workplace environment.

The Solution: To mitigate these issues, it is essential to select high-quality floor glides specifically designed for the type of flooring present in the workspace. Buyers should look for glides made from durable materials, such as high-density polyethylene or nylon, which provide superior protection and noise reduction. Opting for glides with a felt base can further minimize friction and protect flooring surfaces. When purchasing, request product specifications and performance reviews to ensure that the glides can withstand the daily wear and tear typical in office settings. Implementing a regular maintenance schedule to inspect and replace worn-out glides will help preserve floor integrity and enhance workplace comfort.

Scenario 3: Installation Challenges Leading to Inefficiencies

The Problem: B2B buyers often struggle with the installation of floor glides, especially when dealing with a large volume of furniture pieces. Complicated installation processes can lead to inefficiencies, as employees spend more time than necessary fitting glides, which can disrupt business operations. Additionally, improper installation can lead to further issues, such as glides falling out or not providing adequate protection.

The Solution: To streamline the installation process, buyers should prioritize selecting glides that offer straightforward installation methods, such as press-fit or snap-on designs. Providing training or instructional materials to staff can significantly enhance the efficiency of the installation process. Additionally, purchasing glides that come with installation tools or guides can further simplify the task. For larger operations, consider investing in professional installation services or outsourcing this task to ensure that all glides are fitted correctly and efficiently. This not only saves time but also guarantees that the glides perform as intended, ultimately protecting both furniture and flooring.

Strategic Material Selection Guide for floor glides round rectangular

What Are the Key Properties of Common Materials Used for Floor Glides Round Rectangular?

When selecting materials for floor glides, it is essential to consider how their properties align with the intended application. Here, we analyze four common materials: Low-Density Polyethylene (LDPE), High-Density Polyethylene (HDPE), Nylon, and Rubber. Each material has unique attributes that cater to different performance requirements.

Illustrative image related to floor glides round rectangular

How Does Low-Density Polyethylene (LDPE) Perform in Floor Glides?

Low-Density Polyethylene (LDPE) is a widely used material for floor glides due to its flexibility and low cost. LDPE has a temperature rating of up to 80°C (176°F) and offers moderate impact resistance.

Pros:

– LDPE is lightweight and easy to install, making it suitable for various furniture types.

– It provides good floor protection, reducing scratches and scuff marks.

Cons:

– It may not withstand heavy loads as effectively as other materials.

– Over time, LDPE can become brittle, especially in extreme temperatures.

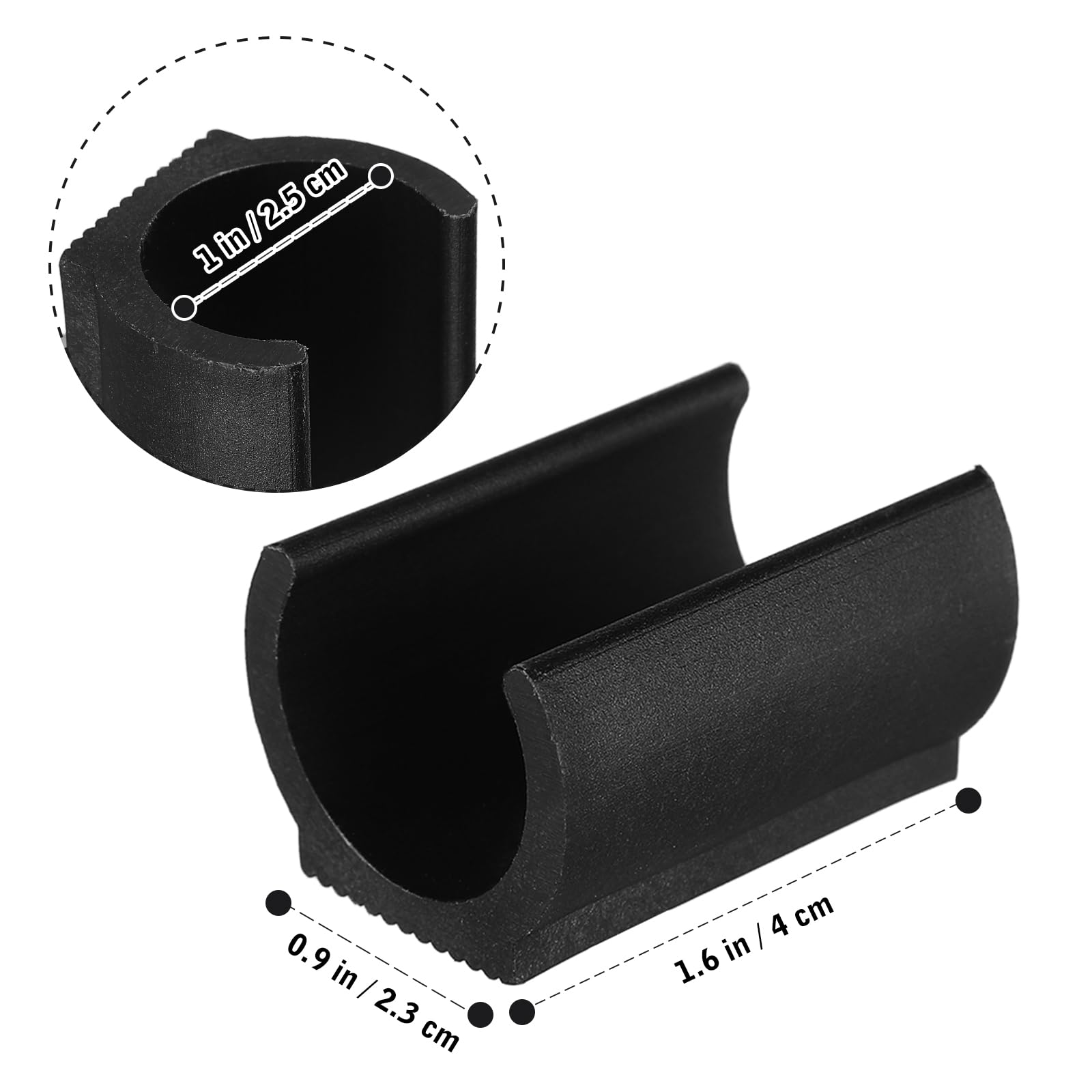

Illustrative image related to floor glides round rectangular

For international buyers, LDPE glides are compliant with common standards, but it is crucial to ensure they meet local regulations regarding environmental impact, especially in regions focused on sustainability.

What Advantages Does High-Density Polyethylene (HDPE) Offer?

High-Density Polyethylene (HDPE) is known for its strength and durability. It can handle temperatures up to 120°C (248°F) and is resistant to many chemicals, making it suitable for diverse environments.

Pros:

– HDPE glides are extremely durable and can support heavier furniture without deforming.

– They have excellent wear resistance, leading to a longer lifespan.

Illustrative image related to floor glides round rectangular

Cons:

– HDPE can be more expensive than LDPE, which may affect budget considerations.

– The manufacturing process can be more complex, leading to longer lead times.

For B2B buyers in regions like Africa and South America, the robust nature of HDPE makes it suitable for various applications, but it is essential to verify compliance with local standards such as ASTM or DIN.

How Does Nylon Compare as a Material for Floor Glides?

Nylon is a synthetic polymer known for its high strength and resistance to abrasion. It performs well under varying temperatures, with a rating up to 120°C (248°F).

Pros:

– Nylon glides are highly durable and can withstand significant wear and tear.

– They provide excellent noise reduction when sliding furniture.

Cons:

– Nylon can be more expensive than plastic alternatives.

– It may absorb moisture, which can lead to degradation in humid environments.

International buyers should consider the specific climate conditions of their region when selecting nylon glides. Compliance with JIS or similar standards may also be necessary in certain markets.

What Role Does Rubber Play in Floor Glide Applications?

Rubber is often used for its excellent grip and shock-absorbing properties. It can withstand temperatures ranging from -30°C to 70°C (-22°F to 158°F).

Pros:

– Rubber glides provide superior floor protection and noise reduction.

– They are ideal for non-slip applications, enhancing safety.

Cons:

– Rubber can wear down more quickly than other materials in high-traffic areas.

– It may be less aesthetically pleasing compared to plastic options.

For buyers in the Middle East and Europe, rubber glides must meet specific safety and environmental regulations, which can vary by country.

Summary Table of Material Selection for Floor Glides

| Material | Typical Use Case for floor glides round rectangular | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Low-Density Polyethylene (LDPE) | Lightweight furniture | Cost-effective and easy to install | Brittle over time, limited load capacity | Low |

| High-Density Polyethylene (HDPE) | Heavy-duty furniture | Durable and chemical-resistant | Higher cost, complex manufacturing | Medium |

| Nylon | Office chairs and furniture | High abrasion resistance | Moisture absorption risk | High |

| Rubber | High-traffic areas | Excellent grip and noise reduction | Faster wear in heavy use | Medium |

This strategic material selection guide serves as a valuable resource for B2B buyers looking to make informed decisions regarding floor glides, ensuring they choose the right material for their specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for floor glides round rectangular

What are the Main Stages in the Manufacturing Process of Round Rectangular Floor Glides?

The manufacturing process for floor glides, particularly round rectangular types, involves several key stages that ensure both functionality and durability.

-

Material Preparation: The process begins with selecting the right materials. Commonly used materials for floor glides include low-density polyethylene (LDPE), high-density polyethylene (HDPE), and other durable plastics. These materials are chosen for their resilience and ability to withstand wear and tear. Suppliers typically source these materials from certified vendors to ensure quality.

-

Forming: Once the materials are prepared, the next step is forming the glides. This can be achieved through various techniques such as injection molding or extrusion. Injection molding is particularly popular for producing intricate shapes and is favored for its efficiency in mass production. During this stage, precise molds are used to create the desired glide shapes, ensuring that they fit securely within the furniture legs.

-

Assembly: After forming, glides may undergo an assembly process, especially if they have multiple components. For example, some glides might include additional features like felt pads for enhanced floor protection. This stage involves ensuring that all parts are correctly aligned and securely attached to prevent any future issues.

-

Finishing: The final stage is finishing, which may include surface treatment to enhance aesthetics and functionality. This can involve polishing, painting, or applying protective coatings. The finishing process not only improves the visual appeal of the glides but also increases their resistance to environmental factors like moisture and UV rays.

How is Quality Assurance Integrated into the Manufacturing of Floor Glides?

Quality assurance (QA) is a critical component in the manufacturing process of floor glides, ensuring that each product meets international standards and customer expectations.

-

Adherence to International Standards: Many manufacturers comply with international standards such as ISO 9001, which focuses on quality management systems. This certification is crucial for B2B buyers as it demonstrates that the manufacturer has consistent processes in place to ensure product quality. Additionally, industry-specific certifications like CE marking (for European markets) and API standards (for certain applications) may also be relevant.

-

Quality Control Checkpoints: The quality control process typically includes several checkpoints:

– Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards. Materials that do not meet quality criteria are rejected.

– In-Process Quality Control (IPQC): During the manufacturing process, samples are tested at various stages. This helps identify any defects early, allowing for corrective actions before proceeding to the next stage.

– Final Quality Control (FQC): After assembly and finishing, a thorough inspection is conducted to ensure that the finished products meet quality standards. This may include dimensional checks, visual inspections, and functional tests. -

Common Testing Methods for Floor Glides: Various testing methods are employed to assess the quality of floor glides. These include:

– Durability Testing: Simulating wear and tear to determine the lifespan of the glides.

– Load Testing: Evaluating how much weight the glides can support without deformation.

– Slip Resistance Testing: Ensuring that the glides provide adequate traction to prevent slipping on various surfaces.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential.

-

Supplier Audits: Conducting on-site audits of potential suppliers is one of the most effective ways to verify their quality control measures. During these audits, buyers can assess the manufacturing processes, quality control checkpoints, and overall compliance with international standards.

-

Quality Reports and Certifications: Requesting detailed quality reports from suppliers is another strategy. These reports should include information on testing results, quality control procedures, and any certifications obtained. Suppliers should be transparent about their QA processes and willing to share documentation.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control. These inspections can be conducted at various stages of the manufacturing process, ensuring that products meet the agreed-upon specifications.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers must navigate several nuances when it comes to quality control in international markets. Understanding these nuances can significantly impact the procurement process.

-

Cultural Differences in Quality Expectations: Different regions may have varying standards and expectations regarding product quality. For instance, European buyers might prioritize eco-friendly materials and certifications, while buyers in other regions may focus more on cost-effectiveness. It’s crucial to communicate clearly and align expectations with suppliers.

-

Regulatory Compliance: Each market has its own regulations regarding product safety and quality. B2B buyers should familiarize themselves with these regulations to ensure compliance. For example, products sold in the EU must adhere to CE marking requirements, which signify conformity with health, safety, and environmental protection standards.

-

Supply Chain Transparency: Transparency in the supply chain is increasingly important for buyers. They should inquire about the source of materials, manufacturing practices, and labor conditions. Suppliers that maintain high standards throughout their supply chain are more likely to produce quality products.

-

Building Long-Term Relationships: Establishing strong relationships with suppliers can facilitate better quality assurance. Long-term partnerships often lead to improved communication, trust, and a mutual understanding of quality expectations.

In conclusion, understanding the manufacturing processes and quality assurance measures for round rectangular floor glides is essential for B2B buyers. By focusing on these aspects, buyers can ensure they source high-quality products that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘floor glides round rectangular’

Introduction

This sourcing guide is designed to assist B2B buyers in procuring round rectangular floor glides. These essential components protect flooring and enhance furniture longevity, making them crucial for a variety of applications across industries. Following this checklist will ensure that you select the right products and suppliers that meet your business needs.

Step 1: Define Your Technical Specifications

Begin by determining the specific dimensions and material requirements for the floor glides you need. Consider factors such as the outer diameter (OD) and inner diameter (ID) to ensure a proper fit.

– Material Considerations: Common materials include low-density polyethylene (LDPE) and high-density polyethylene (HDPE), each offering different durability and aesthetic properties.

– Load Capacity: Assess the weight capacity needed based on the furniture type to avoid premature wear.

Step 2: Research Market Options

Conduct thorough market research to identify available types of round rectangular floor glides. Look for variations that suit different applications, such as those designed for chairs, tables, or industrial equipment.

– Supplier Catalogs: Review supplier catalogs for a comprehensive range of sizes and styles.

– Compare Features: Focus on features like noise reduction, floor protection capabilities, and ease of installation.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to vet them thoroughly. Request detailed company profiles, case studies, and references from other businesses in your sector.

– Supplier Reputation: Look for reviews or testimonials that highlight their reliability and product quality.

– Certifications: Verify any relevant certifications that demonstrate their compliance with international quality standards.

Step 4: Request Samples

Always request samples before placing a bulk order. This allows you to assess the quality and suitability of the floor glides for your specific needs.

– Testing for Fit and Function: Ensure that the samples fit your furniture legs and provide the desired floor protection.

– Material Inspection: Check the durability and finish of the materials used to ensure they meet your quality expectations.

Step 5: Negotiate Pricing and Terms

Once you have identified a suitable supplier, engage in pricing negotiations to secure the best deal possible. Consider not just the price but also payment terms, delivery schedules, and minimum order quantities.

– Bulk Order Discounts: Inquire about discounts for larger orders or long-term contracts.

– Shipping Costs: Factor in international shipping costs, especially if sourcing from suppliers in different regions.

Step 6: Finalize Your Order

After negotiating terms and confirming specifications, proceed to finalize your order. Ensure all details are documented in a formal purchase agreement to avoid misunderstandings later.

– Order Confirmation: Request an order confirmation that outlines product specifications, pricing, and delivery timelines.

– Communication Channels: Establish clear lines of communication for any questions or updates regarding your order.

Step 7: Plan for Quality Control

Implement a quality control process upon receipt of the floor glides. Inspect the products to ensure they meet your specifications and quality standards.

– Defect Management: Have a plan in place for handling defective items, including returns or exchanges.

– Feedback Loop: Consider setting up a feedback loop with your supplier to address any issues that may arise in future orders.

By following these steps, B2B buyers can effectively source round rectangular floor glides that meet their operational requirements, ensuring both product quality and supplier reliability.

Comprehensive Cost and Pricing Analysis for floor glides round rectangular Sourcing

When sourcing floor glides, particularly round and rectangular options, understanding the cost structure and pricing dynamics is crucial for B2B buyers. This analysis will break down the various components that contribute to the total cost, the factors influencing pricing, and offer practical tips for buyers operating in diverse international markets.

What Are the Key Cost Components for Floor Glides?

-

Materials: The choice of materials significantly impacts costs. Common options include plastic (such as LDPE or HDPE), rubber, and metal. Plastic glides typically offer a balance between cost and performance, making them popular for various applications. High-quality materials may incur higher upfront costs but can lead to lower maintenance and replacement expenses over time.

-

Labor: Labor costs vary by region and manufacturing practices. Countries with lower labor costs may offer competitive pricing, but it’s essential to consider the potential trade-offs in quality. Automated processes may reduce labor costs but could increase initial investment in machinery.

-

Manufacturing Overhead: This includes all indirect costs related to production, such as utilities, depreciation, and facility costs. Efficient manufacturing processes can help minimize overhead, allowing suppliers to offer more competitive pricing.

-

Tooling: Custom tooling for specific glide designs or sizes can be a significant cost factor. While initial tooling costs can be high, they can be amortized over large production runs, making it essential to consider minimum order quantities (MOQs) when evaluating costs.

-

Quality Control (QC): Implementing stringent QC measures ensures that products meet specified standards. While this adds to costs, the investment is critical for maintaining product reliability, especially in competitive markets.

-

Logistics: Shipping costs can vary widely based on distance, shipping method, and Incoterms. Understanding the logistics involved is vital for accurately calculating total costs, especially for international transactions.

-

Margin: Suppliers typically add a markup to cover their costs and profit margin. This can vary significantly based on supplier reputation, market demand, and competition.

How Do Price Influencers Affect Floor Glide Sourcing?

-

Volume/MOQ: Purchasing in larger quantities often leads to lower per-unit costs. Suppliers may offer better pricing for bulk orders, making it advantageous for businesses anticipating high demand.

-

Specifications/Customization: Custom designs or specific materials can lead to higher prices. Buyers should weigh the benefits of customization against the added costs and ensure that specifications align with their needs.

-

Materials and Quality: Higher-quality materials generally command higher prices. Buyers should assess the long-term value of investing in quality glides versus opting for lower-cost alternatives that may require more frequent replacements.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with a track record of quality may charge more but offer better assurance of product performance.

-

Incoterms: Understanding the terms of shipping and delivery is essential for managing costs. Different Incoterms can shift responsibilities and costs between buyers and suppliers, affecting the overall pricing structure.

What Are the Best Negotiation Tips for International B2B Buyers?

-

Focus on Total Cost of Ownership (TCO): When evaluating suppliers, consider not just the purchase price but the TCO, including maintenance, replacement, and disposal costs. A lower initial price may result in higher long-term costs if the product is of inferior quality.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Regular communication and collaboration can enhance trust and facilitate negotiations.

-

Market Research: Conduct thorough market research to understand pricing trends in your region. This knowledge can empower buyers during negotiations and help identify competitive offers.

-

Be Aware of Pricing Nuances: Different regions may have unique pricing structures influenced by local market conditions, tariffs, and currency fluctuations. International buyers should remain vigilant about these factors to make informed decisions.

Conclusion

In summary, a comprehensive understanding of the cost components and pricing dynamics for floor glides can significantly enhance sourcing decisions for B2B buyers. By focusing on the total cost of ownership, leveraging supplier relationships, and conducting thorough market research, buyers can navigate the complexities of international procurement effectively. Always be mindful of the indicative nature of prices, as they can fluctuate based on market conditions and supplier negotiations.

Alternatives Analysis: Comparing floor glides round rectangular With Other Solutions

Understanding Alternatives to Floor Glides Round Rectangular

When considering solutions for protecting flooring and enhancing furniture mobility, it is essential to evaluate various options available in the market. Floor glides round rectangular serve a specific purpose, but other alternatives may provide different advantages based on specific needs and applications. This analysis compares floor glides round rectangular with two viable alternatives: furniture pads and swivel glides.

Comparison Table

| Comparison Aspect | Floor Glides Round Rectangular | Furniture Pads | Swivel Glides |

|---|---|---|---|

| Performance | Excellent floor protection; prevents scratches and scuffing | Good for static furniture; limited mobility | Enhances mobility; reduces friction |

| Cost | Moderate ($0.75 – $3.25 each) | Low ($0.20 – $1.00 each) | Moderate to High ($2.00 – $5.00 each) |

| Ease of Implementation | Simple installation; fits into hollow legs | Easy to apply; self-adhesive options available | Requires more effort to install; may need adjustments |

| Maintenance | Low; durable and long-lasting | Moderate; may require replacement over time | Low; durable but can wear out |

| Best Use Case | Ideal for movable furniture like chairs and tables | Best for stationary furniture like sofas | Suitable for office chairs and furniture requiring frequent movement |

Detailed Breakdown of Alternatives

Furniture Pads

Furniture pads are a popular choice for protecting floors and preventing scratches, particularly in static applications. They come in various materials, including felt and rubber, and can be self-adhesive for easy installation. The primary advantage of furniture pads is their affordability and simplicity; however, they are not as effective for movable items, as they may slide or wear down over time, requiring regular replacements. For B2B buyers dealing with less mobile furniture, furniture pads can be a cost-effective solution.

Swivel Glides

Swivel glides are designed to enhance the mobility of furniture while providing floor protection. They allow for easier movement across various surfaces, making them ideal for office environments or settings where furniture is frequently rearranged. The installation of swivel glides can be more complex, as they often require precise fitting and adjustments. While they can be more expensive than floor glides round rectangular, they offer significant benefits in terms of mobility and ease of use, particularly for businesses that prioritize flexibility in their furniture arrangements.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate flooring protection solution involves assessing your specific requirements and constraints. If your focus is on protecting floors while maintaining the ability to move furniture easily, floor glides round rectangular may be the ideal choice due to their durability and ease of installation. Conversely, if your furniture is primarily stationary, furniture pads could provide a more economical option. For environments where frequent movement is essential, such as offices or event spaces, swivel glides may offer the best combination of mobility and protection. By carefully evaluating these factors, B2B buyers can make informed decisions that best suit their operational needs.

Essential Technical Properties and Trade Terminology for floor glides round rectangular

What Are the Key Technical Properties of Floor Glides Round Rectangular?

Understanding the technical specifications of floor glides, particularly round and rectangular types, is crucial for B2B buyers. Here are some essential properties to consider:

-

Material Composition

Floor glides are commonly made from materials like Low-Density Polyethylene (LDPE) or High-Density Polyethylene (HDPE). LDPE is known for its flexibility and impact resistance, making it ideal for indoor furniture. In contrast, HDPE offers superior durability and resistance to wear, suitable for outdoor applications. Knowing the material helps buyers select glides that will withstand their specific environmental conditions. -

Outer and Inner Diameter (OD/ID)

The outer diameter (OD) and inner diameter (ID) are critical measurements for ensuring a proper fit within the furniture legs. For example, a glide with a 7/8″ OD and a 3/4″ ID is designed for hollow rectangular legs of compatible sizes. Accurate measurements are vital to avoid installation issues, which can lead to additional costs and downtime. -

Load Capacity

The load capacity indicates how much weight a glide can support without deforming or failing. This is particularly important for commercial applications where furniture may be subject to frequent movement and heavy usage. Buyers should assess the load requirements of their furniture to choose glides that can handle the expected weight. -

Surface Finish

The finish of the glide affects both aesthetics and functionality. A polished or textured surface can enhance floor protection by reducing friction and noise. Buyers should consider the glide’s surface finish, especially in environments where noise reduction is a priority, such as offices or hospitals. -

Installation Type

Glides can be installed in various ways—press-fit, nail-on, or threaded. Understanding the installation method is essential for selecting the right product for the furniture type. For example, press-fit glides are easy to install and remove, making them ideal for temporary setups, while threaded options provide a more permanent solution. -

Non-Skid Features

Non-skid properties are important for preventing movement and ensuring stability. This is particularly relevant in high-traffic areas or where safety is a concern. Buyers should look for glides that offer anti-slip features to enhance safety and performance.

What Are Common Trade Terms Associated with Floor Glides Round Rectangular?

Familiarity with industry terminology can facilitate smoother transactions and clearer communication between buyers and suppliers. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships helps buyers identify the source of the products they are purchasing, ensuring quality and compatibility. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their purchases effectively and avoid overstocking or understocking issues. -

RFQ (Request for Quotation)

An RFQ is a document that potential buyers send to suppliers to request pricing and terms for specific products. Submitting an RFQ is essential for obtaining accurate pricing and understanding the terms of purchase, particularly when dealing with bulk orders. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and rights regarding shipping and delivery, which is crucial for international transactions. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is essential for inventory management and ensuring that production schedules are met. -

Quality Assurance (QA)

QA refers to the processes that ensure a product meets specified quality standards before delivery. Buyers should inquire about QA practices to ensure that the glides they purchase will perform reliably and meet their expectations.

Incorporating this knowledge into purchasing decisions can greatly enhance the efficiency and effectiveness of sourcing floor glides, ultimately leading to better product performance and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the floor glides round rectangular Sector

What Are the Key Market Drivers Influencing the Floor Glides Round Rectangular Sector?

The global market for floor glides, particularly round rectangular variants, is experiencing significant growth driven by various factors. One of the primary drivers is the increasing demand for furniture that protects flooring surfaces, especially in regions like Africa, South America, the Middle East, and Europe. The rise in urbanization and the subsequent growth in residential and commercial construction projects are propelling the demand for protective furniture accessories.

In addition, the market is witnessing the emergence of innovative technologies that facilitate easier sourcing and procurement processes. B2B platforms are increasingly incorporating AI-driven tools for inventory management and demand forecasting, helping buyers make informed decisions. Furthermore, the trend towards modular and multifunctional furniture is increasing the need for versatile glides that can fit a variety of leg shapes and sizes, thus enhancing product offerings for manufacturers and suppliers.

As international B2B buyers seek competitive pricing and reliable suppliers, the dynamics of global trade are shifting. Buyers are now focusing on suppliers that can provide consistent quality and timely delivery. This shift is particularly evident in emerging markets such as Vietnam and Brazil, where local production capabilities are being developed alongside international sourcing relationships.

How Are Sustainability and Ethical Sourcing Shaping the Floor Glides Market?

Sustainability and ethical sourcing are becoming paramount in the floor glides round rectangular sector. The environmental impact of manufacturing practices, including the use of non-biodegradable materials, is under scrutiny. Buyers are increasingly looking for suppliers who prioritize eco-friendly materials, such as recycled plastics or sustainably sourced wood, to minimize their carbon footprint.

Additionally, the importance of ethical supply chains is gaining traction. International buyers are holding suppliers accountable for their labor practices and sourcing transparency. Certifications such as ISO 14001 for environmental management and FSC for sustainable forestry are becoming critical criteria for evaluating potential suppliers. This shift not only enhances the brand reputation of B2B companies but also aligns them with the growing consumer preference for sustainable products.

Furthermore, innovations in materials science are leading to the development of ‘green’ glides that meet both functional and environmental standards. For example, glides made from low-density polyethylene (LDPE) offer durability while being recyclable, thus appealing to eco-conscious buyers.

What Is the Historical Context Behind Floor Glides?

The evolution of floor glides can be traced back to the early 20th century when furniture design began to prioritize both aesthetics and functionality. Initially, glides were made from metal or hard rubber, providing basic protection for floors. However, as interior design trends evolved, so did the materials and designs of glides.

By the late 20th century, advancements in plastic manufacturing allowed for a wider range of designs, including the popular round and rectangular shapes that are now common in the market. These materials not only offered improved durability and floor protection but also enabled manufacturers to produce glides in various colors and styles to match different furniture designs.

Today, the market continues to innovate, focusing on enhancing user experience through better design and sustainability, making floor glides an essential component in both residential and commercial furniture markets.

Frequently Asked Questions (FAQs) for B2B Buyers of floor glides round rectangular

-

How do I ensure the right size of floor glides for my furniture?

To ensure the correct size of floor glides for your furniture, measure both the outer and inner diameters of the leg or tube where the glide will be inserted. Use a caliper or a measuring tape for precise measurements. It’s crucial to choose glides that fit snugly to prevent them from falling out during use. Most suppliers offer detailed specifications, including size charts, so consult those resources or contact the supplier for assistance if you’re uncertain. -

What materials are best for round rectangular floor glides?

The best materials for round rectangular floor glides typically include durable plastics like polyethylene or nylon, as they offer excellent floor protection and longevity. For applications requiring additional strength or noise reduction, consider glides with felt or rubber bases. The choice of material can also depend on the surface type—hard surfaces may benefit from softer materials to minimize scratches, while rougher surfaces may require sturdier options. -

What are the advantages of using floor glides in a commercial setting?

Using floor glides in a commercial setting provides multiple advantages, including enhanced floor protection from scratches and dents, improved mobility of furniture, and reduced noise during movement. They also help maintain the aesthetic appeal of the furniture, as they can be designed to blend seamlessly with the furniture’s style. Additionally, glides can extend the life of your furniture by minimizing wear and tear on the legs. -

How can I vet suppliers for floor glides in international trade?

To vet suppliers for floor glides in international trade, start by checking their certifications and compliance with international quality standards. Request samples to assess product quality firsthand. Investigate their reputation through reviews and testimonials from other B2B buyers, and inquire about their production capabilities and lead times. Additionally, consider visiting their facilities if possible, or using third-party verification services to ensure reliability. -

What is the minimum order quantity (MOQ) for floor glides from suppliers?

Minimum order quantities (MOQs) for floor glides can vary significantly between suppliers. Typically, MOQs may range from a few hundred to several thousand pieces, depending on the material, size, and customization options. It’s advisable to communicate directly with suppliers to understand their specific requirements. Some manufacturers may offer flexibility in MOQs for first-time buyers or larger orders, so discussing your needs could yield better terms. -

What payment terms should I expect when sourcing floor glides internationally?

When sourcing floor glides internationally, payment terms can vary but often include options such as upfront payment, partial payment before shipment, or letters of credit. Common practices involve a 30% deposit upon order confirmation and the remaining balance before shipping. Always clarify payment terms in the contract to avoid misunderstandings and ensure that you are comfortable with the terms offered by the supplier. -

How do I handle logistics and shipping for international orders of floor glides?

Handling logistics for international orders of floor glides involves selecting a reliable shipping partner experienced in handling bulk orders. Consider factors such as shipping costs, transit times, and customs clearance processes. Ensure that the supplier provides necessary documentation, including invoices and packing lists, to facilitate smooth customs processing. Additionally, it’s wise to include insurance for high-value shipments to mitigate risks during transit. -

What quality assurance measures should I look for when purchasing floor glides?

When purchasing floor glides, look for suppliers that implement rigorous quality assurance measures, such as ISO certifications or regular quality control inspections. Request information on their testing procedures for durability and material integrity. Some suppliers may provide third-party testing results or offer warranties on their products. Establishing clear quality expectations in your purchase agreement can also help ensure that the glides meet your standards upon delivery.

Top 6 Floor Glides Round Rectangular Manufacturers & Suppliers List

1. MyChairParts – Essential Glides

Domain: mychairparts.com

Registered: 2014 (11 years)

Introduction: {“Glides”: {“Round”: {“Material”: “Plastic”, “Sizes Available”: “9”, “SKU”: “1600 series”, “Price”: “$1.30”}, “Square”: {“Material”: “Plastic”, “Sizes Available”: “6”, “SKU”: “1200 series”, “Price”: “$1.10”}, “Rectangular”: {“Material”: “Plastic”, “Sizes Available”: “3”, “SKU”: “1000 series”, “Price”: “$0.75”}, “Round Cup Glide”: {“Color”: “White”, “Sizes Available”: “3”, “SKU”: “1700 series”, “Pr…

2. All Glides – PR87A Low-Density Polyethylene Glides

Domain: allglides.com

Registered: 2004 (21 years)

Introduction: {“Part Number”: “PR87A”, “Outer Diameter”: “7/8 inch”, “Inner Diameter”: “3/4 inch”, “Material”: “Black LDPE (Low-Density Polyethylene)”, “Price”: {“1+”: “$0.55”, “200+”: “$0.495”}, “Features”: [“Secure fit for hollow rectangular legs”, “Enhanced floor protection from scratches and damage”, “Effortless installation”, “Functional and stylish design”], “Uses”: [“Chair feet”, “Table feet”, “Tube caps…

3. Shiffler – Chair Glides & Floor Protection

Domain: shifflerequip.com

Registered: 1997 (28 years)

Introduction: Shiffler offers a variety of chair glides and slides designed for floor protection, suitable for different furniture and flooring styles. Key product categories include: Swivel Chair Glides, Adjustable Leveling Glides, Felt Caps, Chair Leg Caps, Insert Glides and Plugs, Miscellaneous Glides, Nail Glides, and Sled Base and Wraps. Products are available in various colors such as Beige, Black, Blue, …

4. IFSCO – Rectangular Insert Glides

Domain: ifscoind.com

Registered: 2006 (19 years)

Introduction: Rectangular Insert Glides:

– Product Codes: 41155, 41160, 41161, 41162, 41165, 41163, 41166, 41164, 41169, 41167, 41168

– Sizes and Prices:

– 2″ x 2-7/8″ – $1.68 (Min 16)

– 1-1/2″ x 2″ x 18 Gauge – $1.59 (Min 16)

– 1-1/4″ x 2″ x 18 Gauge – $1.23 (Min 16)

– 1″ x 2″ x 18 Gauge – $0.76 (Min 16)

– 5/8″ x 2″ 16 gauge – $0.76 (Min 16)

– 1/2″ x 1-1/2″ x 18 Gauge – $0.60 (Min 16)

– …

5. Uxcell – 24Pcs Nail-on Felt Furniture Pads

Domain: theraleighbeergarden.com

Registered: 2013 (12 years)

Introduction: Uxcell 24Pcs Nail-on Felt Furniture Pads, Rounded Rectangle Felt

6. GorillaOutdoor™ – Stretchable Rectangular Chair Leg Protectors

Domain: floorprotectors.com.au

Introduction: {“product_name”: “GorillaOutdoor™ Stretchable Rectangular Chair Leg Protectors Clear Sleeve Berber Glides CB5002”, “price”: “$19.95”, “quantity”: “Set of 8”, “dimensions”: “4 × 17 × 20 cm”, “weight”: “112 g”, “features”: [“Designed to fit outdoor chair and furniture rectangular legs from 16mm x 52mm to 21mm x 58mm”, “Premium Outdoor Protection: Engineered to withstand harsh outdoor elements”, “Str…

Strategic Sourcing Conclusion and Outlook for floor glides round rectangular

The competitive landscape for floor glides, particularly round and rectangular variants, emphasizes the importance of strategic sourcing for international B2B buyers. By understanding the diverse range of options available—from plastic glides for various furniture types to specialized designs for unique applications—businesses can ensure they select products that not only protect their floors but also enhance the aesthetic appeal of their furnishings.

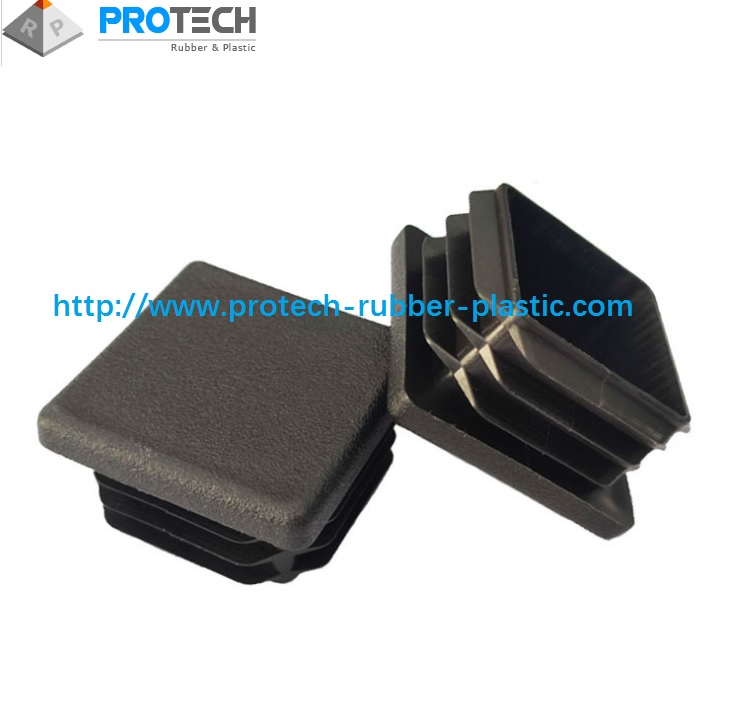

Illustrative image related to floor glides round rectangular

Investing in quality floor glides translates to long-term cost savings by reducing floor maintenance and replacement costs. Additionally, leveraging suppliers that provide a variety of sizes, materials, and styles can help meet specific project needs while ensuring timely delivery and compliance with local regulations.

As markets in Africa, South America, the Middle East, and Europe continue to evolve, now is the time for buyers to explore innovative sourcing strategies that encompass sustainability and durability. By fostering strong relationships with reliable manufacturers and suppliers, businesses can secure a competitive edge in their respective markets.

Looking ahead, we encourage international buyers to proactively assess their sourcing strategies for floor glides. Prioritize quality, versatility, and supplier reliability to position your business for success in an increasingly dynamic global landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.