Unlocking Value: A Strategic Analysis of the Flexible Plastic Sheet Market

Introduction: Navigating the Global Market for flexible plastic sheet

In today’s dynamic global marketplace, sourcing flexible plastic sheets poses a significant challenge for B2B buyers. The variety of materials, thicknesses, and applications can be overwhelming, especially when balancing cost, quality, and supplier reliability. This guide is designed to demystify the complexities surrounding flexible plastic sheets, providing a comprehensive overview of the different types available—including polycarbonate, acrylic, and PVC—as well as their diverse applications in industries ranging from construction to packaging.

International buyers, particularly those from Africa, South America, the Middle East, and Europe, will find valuable insights into the supplier vetting process, ensuring they partner with reputable manufacturers who meet specific quality standards. Additionally, this guide will delve into pricing strategies, helping businesses navigate the cost implications associated with different materials and sourcing options.

By equipping buyers with actionable insights and expert recommendations, this guide empowers informed purchasing decisions, ultimately enhancing operational efficiency and product quality. Whether you are seeking durable materials for construction projects or lightweight options for packaging solutions, understanding the flexible plastic sheet market is crucial for achieving competitive advantage in your respective industry.

Understanding flexible plastic sheet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Acrylic Sheets | Lightweight, shatter-resistant, available in various colors | Signage, displays, furniture | Pros: High clarity, easy to fabricate. Cons: Can scratch easily. |

| Polycarbonate Sheets | High impact resistance, UV stabilization | Safety shields, greenhouses, automotive | Pros: Extremely durable, good thermal insulation. Cons: More expensive than acrylic. |

| PVC Sheets | Cost-effective, versatile, available in rigid and flexible forms | Construction, packaging, signage | Pros: Lightweight, easy to install. Cons: Less durable than polycarbonate. |

| HDPE Sheets | Chemical resistance, moisture-resistant, high-density | Food packaging, medical applications | Pros: Durable, easy to clean. Cons: Limited color options. |

| Corrugated Plastic Sheets | Lightweight, corrugated structure for added strength | Temporary signage, packaging, insulation | Pros: Cost-effective, recyclable. Cons: Less durable than solid sheets. |

What Are the Key Characteristics of Acrylic Sheets for B2B Buyers?

Acrylic sheets, also known as polymethyl methacrylate (PMMA), are known for their exceptional clarity and lightweight properties. They are available in various colors and thicknesses, making them suitable for a wide range of applications, including signage, displays, and furniture. B2B buyers should consider the ease of fabrication and potential for customization, but also be aware that while acrylic is shatter-resistant, it can scratch easily, which may impact long-term aesthetics.

How Do Polycarbonate Sheets Stand Out in the Market?

Polycarbonate sheets are recognized for their high impact resistance and UV stabilization, making them ideal for applications that require durability, such as safety shields, greenhouses, and automotive components. These sheets offer excellent thermal insulation and can withstand extreme weather conditions. However, B2B buyers should note that polycarbonate sheets are generally more expensive than acrylic, which could influence budget considerations.

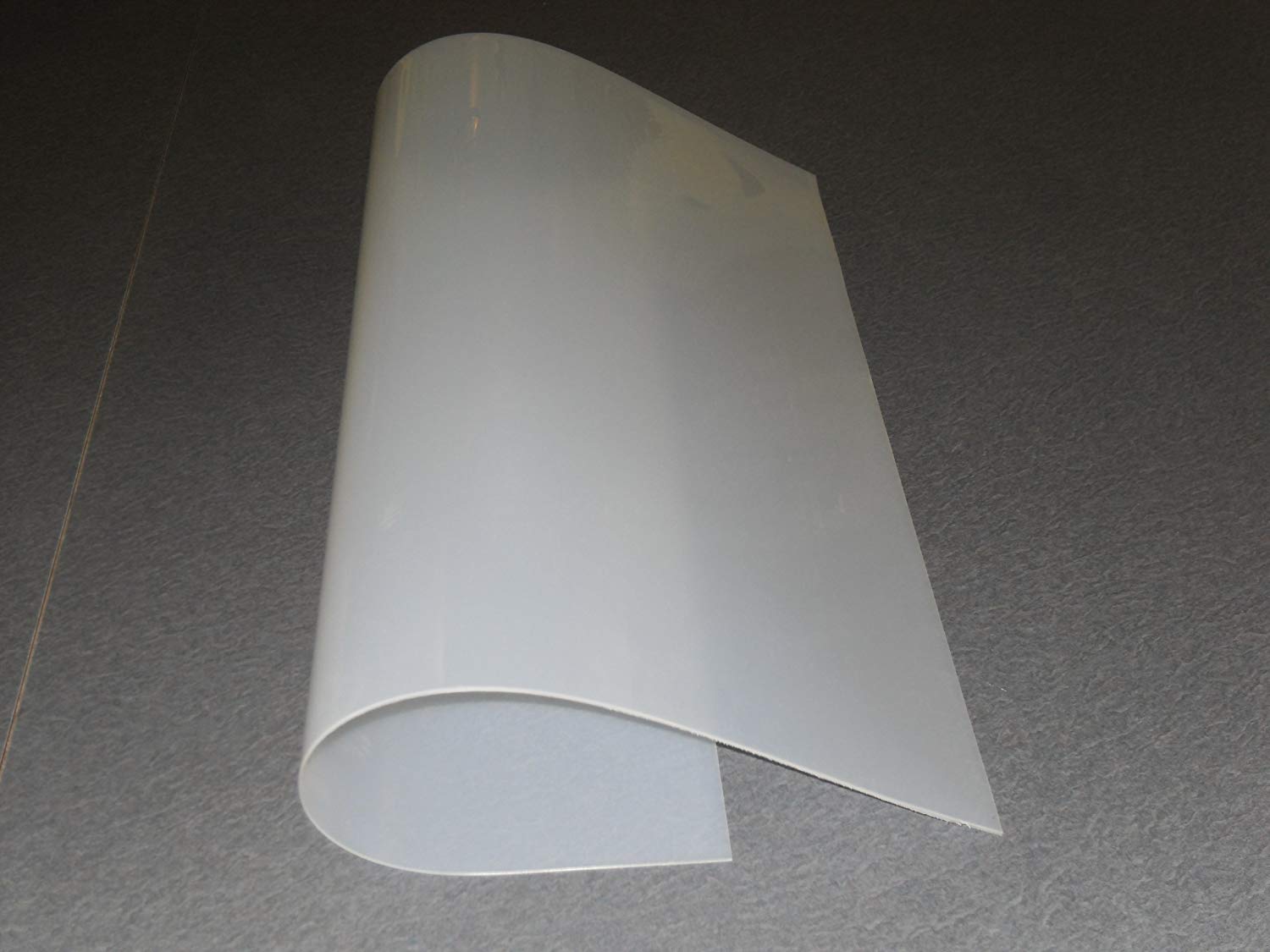

Illustrative image related to flexible plastic sheet

Why Choose PVC Sheets for Versatility?

PVC sheets are a cost-effective option that offers versatility in both rigid and flexible forms. They are commonly used in construction, packaging, and signage due to their lightweight nature and ease of installation. When purchasing PVC sheets, B2B buyers should weigh the benefits of affordability and adaptability against their relatively lower durability compared to other materials like polycarbonate.

What Makes HDPE Sheets Suitable for Medical and Food Applications?

High-Density Polyethylene (HDPE) sheets are known for their chemical and moisture resistance, making them an excellent choice for food packaging and medical applications. They are durable and easy to clean, which is critical in environments where hygiene is paramount. However, buyers should consider the limited color options available, which may affect aesthetic preferences in certain applications.

How Do Corrugated Plastic Sheets Provide Cost-Effective Solutions?

Corrugated plastic sheets, often referred to by brand names like Coroplast, feature a lightweight and corrugated structure that enhances strength while remaining cost-effective. They are commonly used for temporary signage, packaging, and insulation. While they offer recyclability and are budget-friendly, B2B buyers should keep in mind that corrugated sheets may not provide the same level of durability as solid sheets, impacting their longevity in certain applications.

Key Industrial Applications of flexible plastic sheet

| Industry/Sector | Specific Application of flexible plastic sheet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Greenhouse Covers | Enhanced plant growth through controlled climate | UV resistance, thickness options, and durability under extreme weather conditions. |

| Construction & Architecture | Temporary Barriers and Enclosures | Cost-effective solutions for site safety and protection | Compliance with local building regulations and fire safety standards. |

| Packaging | Flexible Packaging for Food Products | Extended shelf life and reduced spoilage | Food-grade materials, barrier properties, and compliance with health regulations. |

| Automotive | Interior Paneling and Trim | Lightweight, customizable, and durable components | Compatibility with existing designs and adherence to automotive standards. |

| Healthcare | Medical Equipment Covers | Protection against contamination and easy cleaning | Biocompatibility, antimicrobial properties, and compliance with healthcare regulations. |

How is Flexible Plastic Sheet Used in Agriculture and What Problems Does It Solve?

In the agricultural sector, flexible plastic sheets are primarily used as greenhouse covers, providing a controlled environment that promotes optimal plant growth. These sheets help in regulating temperature, humidity, and light penetration, which are critical for crop yields. For international buyers, especially in regions like Africa and South America, sourcing UV-resistant materials is crucial to withstand intense sunlight, while durability against harsh weather conditions is also a key consideration.

Illustrative image related to flexible plastic sheet

What Role Does Flexible Plastic Sheet Play in Construction and Architecture?

Flexible plastic sheets serve as temporary barriers and enclosures on construction sites, offering safety and protection from dust and debris. This application is particularly beneficial in urban areas where regulations demand strict adherence to safety protocols. Buyers from the Middle East and Europe should prioritize materials that comply with local building codes and fire safety standards to ensure project compliance and safety.

How Does Flexible Plastic Sheet Enhance Packaging Solutions?

In the packaging industry, flexible plastic sheets are utilized to create packaging for food products, extending shelf life and reducing spoilage. This is particularly vital for international buyers looking to optimize supply chains in regions with varying climates. Sourcing food-grade materials that meet health regulations is essential, along with ensuring that the sheets possess adequate barrier properties against moisture and oxygen.

What Benefits Does Flexible Plastic Sheet Provide in the Automotive Sector?

Flexible plastic sheets are increasingly used in the automotive industry for interior paneling and trim. Their lightweight nature contributes to overall vehicle efficiency, while customization options allow for aesthetic flexibility. Buyers, especially from Europe and Asia, should consider sourcing materials that meet stringent automotive standards for safety and durability, ensuring compatibility with existing vehicle designs.

How is Flexible Plastic Sheet Utilized in Healthcare Applications?

In healthcare, flexible plastic sheets are vital for covering medical equipment, offering protection against contamination while allowing for easy cleaning. The demand for biocompatible and antimicrobial materials is high, particularly for international buyers in the Middle East and Europe, where stringent health regulations are in place. Suppliers must ensure that their products meet these standards to facilitate safe and effective healthcare solutions.

3 Common User Pain Points for ‘flexible plastic sheet’ & Their Solutions

Scenario 1: Sourcing Quality Flexible Plastic Sheets for Diverse Applications

The Problem: B2B buyers often struggle to find high-quality flexible plastic sheets that meet specific industry requirements, particularly when sourcing from international suppliers. Issues such as inconsistent material quality, lack of certifications, and varying thicknesses can lead to significant project delays and increased costs. Buyers may also face language barriers and misunderstandings during negotiations, complicating the sourcing process even further.

Illustrative image related to flexible plastic sheet

The Solution: To effectively source flexible plastic sheets, buyers should prioritize suppliers who have a proven track record and positive reviews from previous clients. Establishing clear communication channels is essential; consider using professional translation services or hiring local representatives if language barriers exist. Buyers should request samples before committing to large orders, ensuring that the materials meet their specific quality standards. Additionally, it’s vital to inquire about certifications that validate the material’s compliance with industry standards, which can help mitigate risks associated with subpar products.

Scenario 2: Managing Inventory and Storage Challenges with Flexible Plastic Sheets

The Problem: Many businesses face difficulties in managing inventory and storage for flexible plastic sheets, particularly when dealing with varying sizes and thicknesses. Limited storage space can lead to damage of sheets, while improper inventory management can result in overstocking or stockouts. This not only affects operational efficiency but can also escalate costs due to wasted materials or emergency orders.

The Solution: Implementing an efficient inventory management system tailored for flexible plastic sheets can significantly alleviate these challenges. Use software solutions that track inventory levels, usage rates, and reorder points, allowing for proactive management. Consider investing in adjustable shelving or vertical storage solutions to maximize space and protect sheets from damage. Additionally, categorizing sheets by size, thickness, and application can streamline access and minimize handling time, ensuring that your team can quickly find the right materials when needed.

Scenario 3: Overcoming Challenges with Customization and Processing of Flexible Plastic Sheets

The Problem: Customization and processing of flexible plastic sheets can be a daunting task for many B2B buyers. Challenges include finding the right machinery for cutting, shaping, or printing on these materials and ensuring that the processes do not compromise the integrity of the sheets. Buyers may also struggle with understanding the limitations of different types of plastics, leading to costly mistakes.

The Solution: To navigate these challenges, businesses should invest in proper training for staff on the specific processing techniques suitable for the types of flexible plastic sheets they are using. Collaborating with suppliers who offer technical support and processing guidelines can also be beneficial. Additionally, conducting thorough research on the properties of different plastics can help buyers make informed decisions on which materials are best suited for customization. For example, certain plastics may be more amenable to heat bending or laser cutting than others. Establishing a partnership with a local processing facility that specializes in flexible plastics can provide additional support and resources, ensuring that customization efforts are efficient and cost-effective.

Illustrative image related to flexible plastic sheet

Strategic Material Selection Guide for flexible plastic sheet

When selecting flexible plastic sheets for various applications, understanding the properties, advantages, and limitations of different materials is essential for B2B buyers. Here, we analyze four common materials used in flexible plastic sheets: Polycarbonate, PVC, Acrylic, and HDPE. Each material has unique characteristics that can significantly influence its suitability for specific applications.

What Are the Key Properties of Polycarbonate Sheets?

Polycarbonate sheets are known for their exceptional impact resistance and durability. They can withstand high temperatures, typically ranging from -40°F to 240°F (-40°C to 115°C), making them suitable for a variety of environments. Additionally, polycarbonate is UV stabilized, which prevents yellowing and degradation from sunlight exposure. This material is also lightweight, which facilitates easier handling and installation.

Pros and Cons:

The primary advantage of polycarbonate is its shatter resistance, making it ideal for applications requiring safety and durability, such as in automotive and construction sectors. However, it tends to be more expensive than other plastic options, which can be a consideration for budget-conscious buyers. Additionally, it may require special tools for cutting and shaping, adding to manufacturing complexity.

Impact on Application:

Polycarbonate is compatible with various media, including chemicals and moisture, making it suitable for outdoor applications like greenhouses and patio covers.

Considerations for International Buyers:

Buyers from regions like Europe and the Middle East should ensure compliance with local regulations and standards, such as DIN and ASTM. The availability of polycarbonate sheets in different thicknesses may also vary by region.

How Does PVC Perform as a Flexible Plastic Sheet Material?

Polyvinyl Chloride (PVC) is a versatile and cost-effective material widely used in flexible plastic sheets. It offers good chemical resistance and can operate effectively at temperatures up to 140°F (60°C). PVC sheets can be manufactured in various thicknesses and colors, providing flexibility in design.

Pros and Cons:

PVC is relatively inexpensive and easy to fabricate, making it a popular choice for signage, packaging, and construction applications. However, it has lower impact resistance compared to polycarbonate and may become brittle over time when exposed to UV light unless treated.

Impact on Application:

PVC sheets are suitable for indoor applications and can handle moisture, but they may not be ideal for prolonged outdoor exposure without protective coatings.

Illustrative image related to flexible plastic sheet

Considerations for International Buyers:

B2B buyers should be aware of compliance with environmental regulations, especially regarding the use of phthalates in PVC production. Standards like ASTM and ISO may apply depending on the application.

What Advantages Do Acrylic Sheets Offer in Flexible Applications?

Acrylic sheets, often known by brand names like Plexiglass, are prized for their clarity and aesthetic appeal. They are lightweight and can withstand temperatures from -20°F to 180°F (-29°C to 82°C). Acrylic offers good UV resistance, making it suitable for outdoor use.

Pros and Cons:

The major advantage of acrylic is its optical clarity, making it ideal for applications like display cases and signage. However, it is more susceptible to scratching and can be more expensive than PVC. Additionally, acrylic can be more challenging to work with due to its brittleness.

Impact on Application:

Acrylic sheets are compatible with a variety of media, including paints and adhesives, making them versatile for artistic and commercial applications.

Considerations for International Buyers:

Buyers should check for compliance with local safety and environmental standards, such as JIS in Japan or EN in Europe, particularly for applications involving food contact.

What Makes HDPE a Strong Contender for Flexible Plastic Sheets?

High-Density Polyethylene (HDPE) is known for its excellent chemical resistance and durability. It can withstand temperatures ranging from -40°F to 120°F (-40°C to 49°C) and is resistant to moisture, making it suitable for outdoor applications.

Pros and Cons:

HDPE is highly durable and resistant to impact, making it ideal for applications like outdoor furniture and storage solutions. Its cost-effectiveness is another significant advantage. However, HDPE can be more challenging to print on and may not provide the same aesthetic appeal as acrylic or polycarbonate.

Impact on Application:

HDPE is compatible with a wide range of chemicals and is often used in food-grade applications, making it a preferred choice in the packaging and food service industries.

Considerations for International Buyers:

B2B buyers should ensure that HDPE products meet local food safety standards and regulations, which can vary significantly between regions.

Summary Table of Material Selection for Flexible Plastic Sheets

| Material | Typical Use Case for flexible plastic sheet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | Safety glazing, greenhouse covers | High impact resistance | Higher cost, manufacturing complexity | High |

| PVC | Signage, packaging | Cost-effective, easy to fabricate | Lower impact resistance, UV sensitivity | Low |

| Acrylic | Display cases, decorative applications | Optical clarity | Susceptible to scratching, more expensive | Med |

| HDPE | Outdoor furniture, food packaging | Excellent chemical resistance | Difficult to print on, less aesthetic | Low |

This strategic material selection guide provides a comprehensive overview of flexible plastic sheet materials, helping international B2B buyers make informed decisions based on their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for flexible plastic sheet

What Are the Key Stages in the Manufacturing Process of Flexible Plastic Sheets?

The manufacturing of flexible plastic sheets involves several critical stages, each designed to ensure that the final product meets the specific needs of various industries. Understanding these stages is essential for B2B buyers looking to source high-quality materials.

Material Preparation: What Materials Are Used and How Are They Processed?

The first stage in manufacturing flexible plastic sheets is material preparation. Typically, raw materials such as polyethylene, polypropylene, or polyvinyl chloride (PVC) are selected based on the desired properties of the final product. These materials are often delivered in pellet form and must undergo a series of processes including drying and blending, where additives such as UV stabilizers or colorants may be mixed in. The precise formulation is critical, as it impacts the flexibility, durability, and overall performance of the sheets.

How Are Flexible Plastic Sheets Formed?

Once the materials are prepared, the next stage is forming. This can be accomplished through several techniques, including extrusion, calendering, and blow molding.

-

Extrusion involves melting the raw materials and forcing them through a die to create continuous sheets. This method is highly efficient and allows for uniform thickness.

-

Calendering is another method where heated rollers flatten the melted plastic into sheets. This technique is ideal for producing thicker sheets with specific surface textures.

-

Blow Molding can be used for producing hollow shapes or tubes but is less common for flat sheets.

The choice of forming technique will depend on the specific requirements of the application, including thickness, flexibility, and surface finish.

What Finishing Processes Are Commonly Used?

After forming, the sheets may undergo various finishing processes. This can include cutting to size, surface treatment (such as polishing or coating), and printing or laminating. Finishing is crucial for enhancing the aesthetic appeal and functional properties of the sheets. For instance, anti-static coatings can be applied for electronic applications, while UV coatings can provide additional protection for outdoor use.

What Quality Assurance Measures Are Essential in the Manufacturing of Flexible Plastic Sheets?

Quality assurance (QA) is a critical component of the manufacturing process, ensuring that products meet both international standards and customer expectations. B2B buyers should be familiar with the various QA measures that suppliers implement.

Which International Standards Should Buyers Be Aware Of?

International standards such as ISO 9001 play a significant role in ensuring quality management systems are in place. Compliance with ISO 9001 indicates that a manufacturer has established processes for consistent quality control and improvement. Additionally, other certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for specific industries may also be relevant, depending on the intended application of the plastic sheets.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control involves several checkpoints throughout the manufacturing process, including:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials before they enter production to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor processes and detect defects early. This includes checking parameters such as temperature, pressure, and thickness during forming.

-

Final Quality Control (FQC): After production, finished sheets are subjected to rigorous testing for physical properties, such as tensile strength, flexibility, and surface finish.

These checkpoints help maintain high quality and consistency, reducing the risk of defects in the final product.

Illustrative image related to flexible plastic sheet

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, must adopt a proactive approach to verify supplier quality control practices.

What Methods Can Buyers Use to Audit Supplier Quality?

Conducting audits is a primary method for verifying a supplier’s quality control measures. Buyers should request access to quality assurance documentation, including:

-

Quality Manuals: Detailing the quality management system in place.

-

Inspection Reports: Providing evidence of compliance with specified standards.

-

Certification Documents: Indicating adherence to international standards like ISO 9001.

Additionally, engaging third-party inspection services can provide unbiased assessments of a supplier’s processes and products. These inspections typically include both on-site evaluations and laboratory testing, offering a comprehensive overview of quality compliance.

What Nuances Should International Buyers Consider Regarding Quality Control?

International buyers must also consider the nuances of quality control that may vary by region. For example, different countries may have specific regulatory requirements that affect material certifications or testing methods. Understanding these regional differences is crucial for ensuring compliance and avoiding potential legal issues.

Moreover, language barriers and cultural differences can impact communication regarding quality expectations. Establishing clear, documented agreements on quality standards and expectations can help mitigate these challenges.

Conclusion: Why Is Understanding Manufacturing and Quality Assurance Vital for B2B Buyers?

In summary, a thorough understanding of the manufacturing processes and quality assurance measures for flexible plastic sheets is essential for B2B buyers. This knowledge not only aids in selecting reliable suppliers but also ensures that the materials sourced meet the required standards for performance and safety. By being informed about manufacturing techniques, quality checkpoints, and verification methods, buyers can make more strategic purchasing decisions that align with their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘flexible plastic sheet’

When sourcing flexible plastic sheets, B2B buyers must navigate various considerations to ensure they acquire the right materials for their specific applications. This checklist serves as a practical guide to streamline the procurement process, helping buyers make informed decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential before beginning your search. Consider the intended application of the flexible plastic sheets—whether for packaging, construction, or manufacturing—and identify key factors such as thickness, flexibility, and material type (e.g., polyethylene, PVC, or polycarbonate). This step ensures that the sheets meet performance requirements and compliance standards specific to your industry.

Step 2: Research Market Trends and Applications

Understanding current market trends and applications of flexible plastic sheets can significantly impact your sourcing decisions. Investigate how similar industries utilize these materials and any emerging technologies or innovations that could enhance performance or reduce costs. This knowledge allows you to align your procurement strategy with market demands and gain a competitive edge.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your requirements. Request detailed company profiles, product catalogs, and certifications to assess their credibility and capabilities. Look for suppliers with experience in your industry, as they will be more familiar with specific needs and compliance issues. Don’t hesitate to ask for references or case studies from previous clients.

Step 4: Request Samples for Testing

Before finalizing any orders, it’s prudent to request samples of the flexible plastic sheets you’re considering. Testing samples allows you to evaluate their physical properties, such as flexibility, durability, and resistance to environmental factors. This step is critical to ensure that the materials perform as expected in your specific applications.

Step 5: Check Compliance and Certifications

Verify that the flexible plastic sheets comply with relevant industry standards and regulations. Depending on your market, look for certifications such as ISO, ASTM, or FDA approvals, which demonstrate that the materials meet safety and quality benchmarks. Compliance is crucial to avoid legal issues and ensure product reliability in your end-use applications.

Step 6: Negotiate Pricing and Terms

Once you have identified suitable suppliers and tested the materials, engage in negotiations to secure the best pricing and terms. Consider factors such as bulk purchasing discounts, payment terms, and delivery timelines. Clear communication about your expectations can lead to mutually beneficial agreements and long-term partnerships.

Step 7: Establish a Quality Control Process

Implement a quality control process to monitor the performance of the flexible plastic sheets upon delivery. This may involve visual inspections, measuring dimensions, and testing for specific properties. Establishing a quality assurance protocol ensures that the materials received align with your original specifications and helps mitigate any potential issues down the line.

Illustrative image related to flexible plastic sheet

By following this structured checklist, B2B buyers can effectively source flexible plastic sheets that meet their needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for flexible plastic sheet Sourcing

Understanding the cost structure and pricing dynamics of flexible plastic sheets is crucial for international B2B buyers looking to make informed sourcing decisions. This analysis will delve into the various cost components, price influencers, and provide actionable buyer tips to optimize purchasing strategies.

What are the Key Cost Components in Flexible Plastic Sheet Manufacturing?

The cost structure for flexible plastic sheets typically includes several critical components:

-

Materials: The choice of material significantly affects costs. Common materials include polyethylene, polypropylene, and polycarbonate, each with varying price points based on quality and market demand. Specialty materials can further increase costs.

-

Labor: Labor costs encompass both direct and indirect labor involved in the manufacturing process. In regions with higher wage standards, labor costs can represent a significant portion of the total cost.

-

Manufacturing Overhead: This includes utilities, facility costs, and indirect labor expenses. Efficient manufacturing processes can help minimize overhead, impacting the overall cost.

-

Tooling: The initial setup for production, including molds and dies, can be a significant upfront investment. Custom tooling for unique specifications can further elevate this cost.

-

Quality Control (QC): Implementing stringent quality control measures ensures product consistency and compliance with international standards, adding to the overall production costs.

-

Logistics: Transportation and handling fees contribute to the final pricing. These costs can vary based on the distance from the manufacturing site to the buyer’s location and the chosen shipping method.

-

Margin: Suppliers will apply a margin based on their cost structure and market positioning, which can vary significantly among manufacturers.

How Do Volume and Customization Affect Pricing?

Volume and customization are pivotal factors influencing pricing. Generally, larger order quantities (MOQ) lead to lower per-unit costs due to economies of scale. Conversely, customized products often incur additional charges due to specialized manufacturing processes. Buyers should assess their needs carefully to balance between standard and custom solutions while maximizing cost efficiency.

Illustrative image related to flexible plastic sheet

What Role Do Quality and Certifications Play in Pricing?

Quality certifications can impact pricing significantly. Products that meet international standards (e.g., ISO, ASTM) often command higher prices due to the assurance of quality and performance. Buyers from regions such as Africa and South America may find that investing in certified products can lead to lower long-term costs by reducing the risk of product failure and associated liabilities.

How Can Buyers Optimize Negotiation Strategies?

-

Understand Total Cost of Ownership (TCO): Beyond the initial purchase price, consider logistics, maintenance, and disposal costs. A lower upfront price may not always translate into savings if long-term costs are higher.

-

Leverage Market Research: Conduct thorough market research to understand prevailing prices and supplier options. This data can provide leverage during negotiations.

-

Establish Strong Relationships: Building long-term relationships with suppliers can lead to better pricing, favorable terms, and priority service during peak demand periods.

-

Be Aware of Pricing Nuances: International buyers should understand the implications of Incoterms on pricing. Terms such as CIF (Cost, Insurance, and Freight) or FOB (Free on Board) can significantly affect landed costs.

What Should Buyers Keep in Mind About Indicative Prices?

It’s essential to recognize that prices for flexible plastic sheets can fluctuate based on market conditions, raw material availability, and geopolitical factors. Therefore, buyers should request quotes from multiple suppliers and consider these variations when budgeting for procurement. Always ask for detailed breakdowns of costs to ensure transparency and facilitate informed decision-making.

By understanding the intricacies of cost components, price influencers, and effective negotiation strategies, international B2B buyers can optimize their sourcing processes for flexible plastic sheets, ultimately leading to better procurement outcomes.

Alternatives Analysis: Comparing flexible plastic sheet With Other Solutions

Exploring Alternatives to Flexible Plastic Sheets: A Comprehensive Comparison

In the quest for optimal material solutions, businesses often evaluate various options to meet their specific needs. Flexible plastic sheets are versatile and widely used across industries, but several alternatives may also serve similar purposes. This analysis compares flexible plastic sheets against two viable alternatives: polycarbonate sheets and corrugated plastic sheets. By examining performance, cost, ease of implementation, maintenance, and best use cases, B2B buyers can make informed decisions tailored to their requirements.

| Comparison Aspect | Flexible Plastic Sheet | Polycarbonate Sheets | Corrugated Plastic Sheets |

|---|---|---|---|

| Performance | Good flexibility and durability; resistant to impact and weather | High impact resistance; excellent insulation properties | Lightweight; suitable for short-term applications |

| Cost | Moderate cost; affordable for bulk purchases | Higher initial investment; long-term cost-effective due to durability | Low cost; ideal for budget-conscious projects |

| Ease of Implementation | Easy to cut and shape; requires minimal tools | Requires specialized tools for cutting; installation can be complex | Simple to handle and install; often used in DIY projects |

| Maintenance | Low maintenance; easy to clean | Durable but may require occasional inspection | Generally low maintenance; prone to wear over time |

| Best Use Case | Signage, protective covers, furniture | Greenhouses, skylights, safety barriers | Temporary signage, packaging, lightweight structures |

What Are the Advantages and Disadvantages of Polycarbonate Sheets?

Polycarbonate sheets are renowned for their exceptional durability and high impact resistance, making them suitable for applications where safety is paramount. They offer superior insulation properties, which can lead to energy savings in environments like greenhouses or commercial buildings. However, the initial cost of polycarbonate sheets is higher than that of flexible plastic sheets, which may deter budget-sensitive buyers. Additionally, while they provide excellent longevity, the complexity of installation might require specialized labor, impacting overall project timelines.

How Do Corrugated Plastic Sheets Compare in Versatility?

Corrugated plastic sheets are an economical alternative that excels in lightweight applications, making them ideal for temporary signage and packaging. They are easy to handle and install, often favored in DIY projects. Their affordability is a significant advantage for businesses operating on tight budgets. However, corrugated sheets may not offer the same level of durability and long-term performance as flexible plastic or polycarbonate sheets. This makes them less suitable for permanent installations or environments subject to harsh conditions.

How Should B2B Buyers Decide on the Right Material Solution?

When selecting between flexible plastic sheets and their alternatives, B2B buyers should consider specific application requirements and budget constraints. Businesses focused on durability and long-term use may lean towards polycarbonate sheets despite the higher upfront cost. Conversely, those seeking a cost-effective, temporary solution might find corrugated plastic sheets to be the better choice. Ultimately, the decision should align with the intended use, desired lifespan, and available resources, ensuring that the chosen material effectively meets operational needs while maximizing value.

Essential Technical Properties and Trade Terminology for flexible plastic sheet

Understanding the technical properties and terminology associated with flexible plastic sheets is crucial for international B2B buyers. This knowledge helps ensure that the products meet specific requirements and facilitate smoother transactions. Below are key properties and industry terms that buyers should be familiar with.

What Are the Essential Technical Properties of Flexible Plastic Sheets?

1. Material Composition

Flexible plastic sheets can be made from various materials, including polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and polycarbonate. Each material has distinct characteristics affecting durability, flexibility, and resistance to chemicals and UV light. Understanding the material composition is vital for selecting the right sheet for specific applications, such as packaging, construction, or signage.

2. Thickness Tolerance

Thickness is a critical specification that affects the sheet’s strength and application suitability. Flexible plastic sheets typically range from 0.01 inches to over 1 inch thick. Tolerance refers to the allowable deviation from the specified thickness, which can impact the performance and integrity of the product. Buyers should ensure that the supplier can meet the required tolerances to avoid issues during manufacturing or installation.

3. Durability Features

Durability features include resistance to impact, UV exposure, moisture, and chemicals. For example, UV-stabilized sheets are essential for outdoor applications to prevent degradation. Assessing these durability features helps buyers select sheets that will perform reliably in their specific environments, reducing the risk of premature failure and associated costs.

4. Flexibility and Bend Radius

Flexibility refers to how easily a plastic sheet can bend without breaking. The bend radius is the minimum radius the sheet can be bent around without damage. These properties are particularly important for applications requiring shaping or forming, such as in automotive or architectural designs. Understanding these aspects can help buyers identify sheets that will meet their design requirements effectively.

5. Surface Finish Options

Flexible plastic sheets come with various surface finishes, such as matte, glossy, or textured. The surface finish can affect not only aesthetics but also functionality, including glare reduction or ease of cleaning. Buyers should choose finishes based on their application needs, whether for visibility, branding, or hygiene.

What Common Trade Terms Should Buyers Know?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of flexible plastic sheets, understanding OEM relationships can help buyers identify reliable suppliers who provide quality materials tailored for specific applications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For flexible plastic sheets, knowing the MOQ is essential for budgeting and inventory management. Buyers should negotiate MOQs that align with their production schedules and demand to optimize costs.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It typically includes product specifications, quantities, and delivery requirements. Issuing an RFQ is a critical step in the procurement process, allowing buyers to compare offers and select the best supplier based on price and terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for buyers to clarify shipping responsibilities, risk management, and cost allocation, ensuring smoother cross-border transactions.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. This metric is essential for supply chain planning. Buyers should be aware of lead times for flexible plastic sheets to ensure timely delivery and avoid production delays.

By grasping these essential properties and trade terms, B2B buyers can make informed decisions, optimize their procurement processes, and enhance their overall operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the flexible plastic sheet Sector

What Are the Key Trends Shaping the Flexible Plastic Sheet Market?

The flexible plastic sheet market is experiencing significant transformation driven by global demand for versatile, lightweight, and cost-effective materials. Key trends include the rise of advanced manufacturing technologies such as 3D printing and CNC machining, which allow for customized and rapid production. This shift is particularly relevant for B2B buyers looking for tailored solutions in sectors like automotive, construction, and packaging. Additionally, the increasing adoption of digital platforms for sourcing and procurement is streamlining supply chains, enabling international buyers from regions like Africa, South America, the Middle East, and Europe to access a wider array of suppliers and products efficiently.

Furthermore, sustainability is becoming a crucial factor in purchasing decisions. Buyers are increasingly seeking materials that offer not only functional benefits but also environmental advantages. This trend is especially pronounced in Europe and parts of Africa, where regulatory frameworks are tightening around plastic use and disposal. As such, companies are investing in R&D to develop bio-based and recycled materials that meet these sustainability criteria while still delivering on performance.

How Is Sustainability Impacting Sourcing Decisions in the Flexible Plastic Sheet Sector?

Sustainability and ethical sourcing are at the forefront of the flexible plastic sheet market. The environmental impact of plastic production and waste is prompting B2B buyers to reevaluate their supply chains. Ethical sourcing practices, such as ensuring fair labor conditions and responsible material sourcing, are becoming essential for companies aiming to enhance their brand reputation and meet regulatory compliance.

Buyers are increasingly prioritizing suppliers who can demonstrate their commitment to sustainability through certifications such as ISO 14001 (Environmental Management) and the use of recycled or bio-based materials. These certifications not only validate the environmental claims of suppliers but also facilitate market access, particularly in Europe where consumer and regulatory pressure is mounting. Additionally, B2B buyers are looking for innovative solutions such as biodegradable plastics and reusable packaging options that align with a circular economy model. This shift is not just a trend; it represents a fundamental change in how businesses operate and interact with their suppliers and customers.

What Is the Historical Context of the Flexible Plastic Sheet Industry?

The flexible plastic sheet industry has evolved significantly since the mid-20th century when plastic materials began to gain traction in various applications. Initially, products like polyethylene and PVC were primarily used for packaging and construction, valued for their durability and cost-effectiveness. Over the decades, technological advancements in polymer science and manufacturing processes led to the development of a wider range of flexible plastic materials, such as polycarbonate and acrylic sheets, which offer enhanced performance characteristics like UV resistance and impact strength.

The late 20th century saw a marked increase in environmental awareness, prompting the industry to explore more sustainable practices. This included the introduction of recycled materials and the development of biodegradable options. Today, the flexible plastic sheet sector is characterized by a focus on innovation, sustainability, and the ability to meet diverse customer needs across global markets. As businesses increasingly prioritize environmental responsibility, the evolution of this industry reflects a broader commitment to sustainable development and ethical sourcing practices.

Frequently Asked Questions (FAQs) for B2B Buyers of flexible plastic sheet

-

How can I determine the right type of flexible plastic sheet for my project?

To select the appropriate flexible plastic sheet, consider the specific application requirements such as durability, chemical resistance, and environmental conditions. For example, polycarbonate sheets are ideal for high-impact applications, while PVC sheets are suitable for signage due to their lightweight nature. Evaluate factors like thickness, UV resistance, and whether the sheet needs to be transparent or opaque. Consulting with suppliers about your project’s specific needs can also provide valuable insights and recommendations. -

What are the common applications for flexible plastic sheets in various industries?

Flexible plastic sheets are widely used across multiple sectors including construction, automotive, packaging, and signage. They serve as protective barriers, insulation, and decorative elements. In construction, polycarbonate sheets are utilized for roofing and glazing, while PVC sheets are common in signage and displays. Understanding the applications will help you choose the right material that aligns with your industry needs. -

What should I consider when vetting suppliers for flexible plastic sheets?

When evaluating suppliers, prioritize their reputation, industry experience, and customer reviews. Check for certifications related to quality management, such as ISO standards, which indicate adherence to quality practices. Request samples to assess product quality firsthand, and inquire about their production capabilities, lead times, and flexibility in meeting custom specifications. Building a relationship with reliable suppliers can enhance your procurement process and ensure consistent quality. -

What are the typical minimum order quantities (MOQs) for flexible plastic sheets?

Minimum order quantities can vary significantly by supplier and product type. Many manufacturers may set MOQs ranging from 100 to 500 sheets, depending on the material and thickness. For customized sheets, MOQs may be higher due to additional processing requirements. It’s advisable to discuss your needs directly with suppliers to negotiate MOQs that align with your purchasing strategy while maintaining cost-effectiveness. -

How can I ensure the quality of flexible plastic sheets before finalizing my order?

Quality assurance can be achieved by requesting product specifications and certifications from suppliers. Consider conducting pre-shipment inspections to verify that the sheets meet your requirements regarding thickness, clarity, and strength. Additionally, review return policies and warranty options, which can provide added assurance in case the products do not meet expected standards. Establishing clear quality criteria upfront will also facilitate better communication with suppliers. -

What payment terms should I expect when sourcing flexible plastic sheets internationally?

Payment terms can vary by supplier, but common practices include 30% upfront payment and 70% upon delivery. Some suppliers may offer net 30 or net 60 terms for established buyers. Ensure you discuss payment methods (e.g., bank transfer, letter of credit) and any additional fees related to currency exchange or international transactions. Understanding these terms can help you manage cash flow effectively and avoid unexpected costs. -

What logistics considerations should I keep in mind for shipping flexible plastic sheets?

When planning logistics, consider shipping methods, lead times, and customs regulations. Flexible plastic sheets are often shipped via sea freight for cost efficiency, but air freight may be necessary for urgent orders. Ensure that the sheets are properly packaged to prevent damage during transit. Familiarize yourself with import duties and compliance requirements in your country to avoid delays at customs. -

How can I customize flexible plastic sheets to meet my specific requirements?

Customization options for flexible plastic sheets typically include size, thickness, color, and surface finishes. Many suppliers offer cutting, printing, and additional processing services to tailor products to your specifications. Communicate your exact needs clearly and request samples of customized sheets to ensure they meet your expectations. Collaborating closely with suppliers during the design phase can lead to better outcomes and satisfaction with the final product.

Top 5 Flexible Plastic Sheet Manufacturers & Suppliers List

1. Interstate Plastics – Bendable Plastic Sheets

Domain: interstateplastics.com

Registered: 1997 (28 years)

Introduction: Bendable Plastic Sheet options include Worbla Hand-Formable Thermoplastic Sheets in Black and Beige, Delrin® Plastic Sheet in Black, Acetal Plastic Sheet in Natural Color, various Craft Plastic Sheets in multiple colors (including Clear, Green, Blue, Brown, Red, White, Yellow), Plastic Lumber Sheets in various woodgrain finishes (Hickory, Ironwood, Coastal Grey, Elm, Kona, Aspen White, Maple), Med…

2. Tap Plastics – HDPE M M Opaque Sheet

Domain: tapplastics.com

Registered: 1999 (26 years)

Introduction: HDPE M M Opaque is a high-density polyethylene sheet that offers excellent impact resistance and durability. It is available in various thicknesses and sizes, making it suitable for a wide range of applications. The sheet is lightweight, easy to fabricate, and resistant to chemicals and moisture. It is ideal for use in environments where strength and reliability are essential.

3. Reddit – Flexible Plastic Sheets

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Flexible plastic sheets such as PETG or acetate are recommended for moldmaking. PETG is durable, comes in assorted thicknesses (around 1mm is commonly used), and is inexpensive. It is often used for making flat backs on cast items or covering vents. Other alternatives mentioned include polycarbonate and acrylic sheets, with a suggestion to look for sheets in the 0.5mm range. Users recommend checki…

4. Longview Supply – Flexible Black Plastic Sheet

Domain: longviewsupply.com

Registered: 2019 (6 years)

Introduction: Flexible Black Plastic Sheet

– Material: High Density Polyethylene (HDPE)

– Texture: Smooth

– Thickness Options: 30 Mil, 40 Mil, 60 Mil, 80 Mil, 100 Mil

– Size Options: 12″ x 100′, 18″ x 100′, 24″ x 100′, 30″ x 100′, 36″ x 100′, 48″ x 100′, 96″ x 40′, 10″ x 100′, 3″ x 3″ samples

– Price Range: $20.00 (samples) to $1,116.59 (80 Mil, 96″ x 40′)

– Features: Waterproof, Commercial Grade, UV Resistant,…

5. Pro Fabric Supply – Strong Plastic Sheets

Domain: profabricsupply.com

Registered: 2018 (7 years)

Introduction: Strong Plastic Sheets

– Price: $303.39 (30 Mil Thickness – 18″ x 100′ Roll – Black)

– Free Shipping

– Available Thicknesses: 30 Mil, 40 Mil, 60 Mil, 80 Mil, 100 Mil

– Available Sizes:

– 18″ x 100′

– 24″ x 100′

– 30″ x 100′

– 36″ x 100′

– 48″ x 100′

– 60″ x 80′

– Material: High Density Polyethylene (HDPE)

– Features: Waterproof, UV Resistant, Puncture and Tear Resistant, Non-Biodegradab…

Strategic Sourcing Conclusion and Outlook for flexible plastic sheet

As global demand for flexible plastic sheets continues to surge, strategic sourcing remains paramount for international B2B buyers. Understanding the diverse range of products—from polycarbonate to acrylic and HDPE sheets—enables businesses to select materials that best meet their specific needs. The ability to assess product features such as durability, UV resistance, and thermal stability is crucial for making informed purchasing decisions.

Moreover, sourcing from reputable suppliers can lead to cost efficiencies and enhanced product quality, which are vital in competitive markets across Africa, South America, the Middle East, and Europe. By leveraging strategic partnerships, buyers can ensure a steady supply chain that can adapt to fluctuating market demands.

Looking ahead, the flexible plastic sheet market is poised for innovation, driven by sustainability trends and technological advancements. As buyers, it is essential to stay informed and agile, ready to embrace new materials and solutions that will shape the future of your industries. Engage with trusted suppliers today to explore options that not only fulfill immediate requirements but also align with your long-term business goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.