Unlocking Value: A Strategic Analysis of the Expanded Steel Grill Market

Introduction: Navigating the Global Market for expanded steel grill

Navigating the complex landscape of sourcing expanded steel grills can be a daunting challenge for international B2B buyers, especially when considering the diverse applications and regional specifications involved. From industrial uses in construction and infrastructure to innovative designs in outdoor cooking and grilling, understanding the full spectrum of expanded steel grill options is crucial for making informed purchasing decisions. This comprehensive guide delves into the various types of expanded steel grills, their applications across different sectors, and essential supplier vetting processes.

In addition, we explore the critical factors influencing cost, including material specifications and manufacturing techniques, which are vital for buyers operating in regions such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Germany. By equipping B2B buyers with actionable insights and detailed information, this guide empowers them to navigate the global market effectively, ensuring that they choose the right products that meet their operational needs while optimizing their procurement strategies. Whether you are looking to enhance your manufacturing capabilities or provide high-quality grilling solutions, understanding the nuances of expanded steel grills will enable you to make strategic, informed choices that drive business success.

Understanding expanded steel grill Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Expanded Metal | Diamond-shaped openings; various thicknesses available | Industrial flooring, security enclosures | Pros: Cost-effective, versatile; Cons: Limited load capacity in thinner variants |

| Flattened Expanded Metal | Smooth surface; easier to clean; offers stability | Cooking grates, decorative applications | Pros: Enhanced durability, aesthetic appeal; Cons: Higher cost than standard types |

| Heavy-Duty Expanded Metal | Thicker strands for increased strength | Heavy machinery guards, elevated walkways | Pros: High load capacity, long-lasting; Cons: Heavier and more expensive |

| Architectural Expanded Metal | Custom patterns and designs; aesthetic focus | Facades, decorative screens | Pros: Unique designs, high visual appeal; Cons: Potentially higher fabrication costs |

| Anti-Slip Expanded Metal | Textured surface for enhanced grip | Stair treads, ramps, outdoor applications | Pros: Safety features, versatile use; Cons: May require more maintenance due to texture |

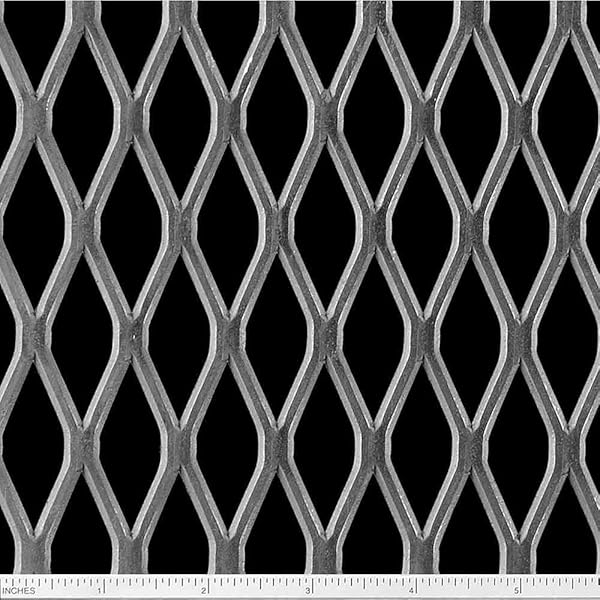

What are the Characteristics of Standard Expanded Metal?

Standard expanded metal is characterized by its diamond-shaped openings, which are created by slitting and stretching metal sheets. This type is commonly used in industrial applications, such as flooring and security enclosures, due to its cost-effectiveness and versatility. Buyers should consider the thickness of the metal, as thinner variants may not support heavy loads effectively, potentially limiting their applications in high-stress environments.

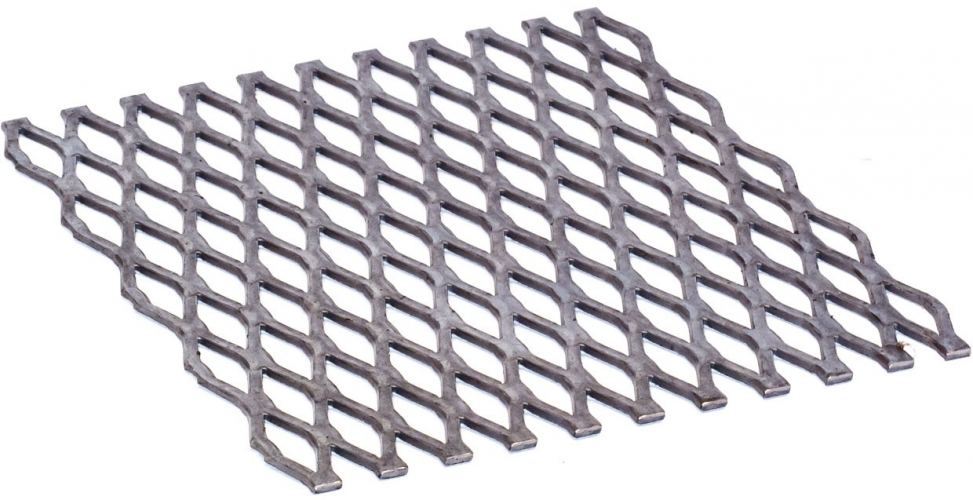

Why Choose Flattened Expanded Metal for Cooking Grates?

Flattened expanded metal features a smooth surface, making it ideal for cooking grates in BBQ grills and smokers. This type provides stability and ease of cleaning, which is essential for food safety. B2B buyers should evaluate the thickness and material (such as stainless steel) to ensure longevity and performance, especially in high-temperature cooking environments. While it may be pricier than standard expanded metal, the benefits often outweigh the costs in culinary applications.

What are the Benefits of Heavy-Duty Expanded Metal?

Heavy-duty expanded metal is designed with thicker strands, providing enhanced strength and durability. This type is suitable for applications requiring high load-bearing capabilities, such as machine guards and elevated walkways. B2B buyers should consider the specific weight requirements of their applications, as this type can handle significant stress. However, the increased weight and cost may be a consideration for projects with budget constraints.

How Does Architectural Expanded Metal Enhance Aesthetics?

Architectural expanded metal is notable for its custom patterns and designs, making it a popular choice for decorative applications, such as building facades and screens. This type allows architects and designers to incorporate unique visual elements into their projects. While the aesthetic appeal is a major advantage, buyers should be aware that the fabrication costs may be higher than standard options, depending on the complexity of the design.

What Makes Anti-Slip Expanded Metal Ideal for Safety Applications?

Anti-slip expanded metal features a textured surface that enhances grip, making it perfect for safety applications such as stair treads and ramps. This type not only provides a secure footing but also complies with safety regulations in various industries. When purchasing, B2B buyers should consider the maintenance needs associated with the textured surface, as it may accumulate debris more easily than smoother options. Despite this, the safety benefits make it a worthwhile investment in environments where slip hazards are prevalent.

Illustrative image related to expanded steel grill

Key Industrial Applications of expanded steel grill

| Industry/Sector | Specific Application of expanded steel grill | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Safety barriers and walkways | Provides strong, lightweight, and durable surfaces | Ensure compliance with local safety regulations |

| Manufacturing | Machine guards and platforms | Enhances safety by preventing accidents | Consider thickness and size for specific machinery |

| Agriculture | Livestock enclosures and fencing | Durable and weather-resistant solutions | Assess corrosion resistance for outdoor use |

| Transportation | Trailer ramps and loading docks | Improves traction and safety during loading/unloading | Evaluate load capacity and durability |

| Food Industry | Cooking grates for commercial grills and smokers | Ensures even heat distribution and durability | Check for food-grade materials and cleaning ease |

How is Expanded Steel Grill Used in Construction?

In the construction sector, expanded steel grill is commonly utilized for safety barriers and walkways. Its unique design allows for air and light to pass through while providing a robust surface that can support significant weight. This application solves the problem of slip hazards in industrial settings, particularly in regions with heavy rainfall. Buyers should consider local safety regulations and the specific load requirements of their projects, especially in countries like Nigeria and Germany, where construction standards may vary.

What Role Does Expanded Steel Grill Play in Manufacturing?

In manufacturing, expanded steel grill serves as machine guards and platforms, enhancing workplace safety by preventing accidental contact with moving parts. This application is critical in factories where heavy machinery is operated. The material’s strength and lightweight properties allow for easy installation and maintenance. International buyers should focus on the thickness and size specifications to match their machinery needs, ensuring compliance with occupational safety standards.

How is Expanded Steel Grill Beneficial in Agriculture?

Agriculture utilizes expanded steel grill for constructing livestock enclosures and fencing. Its durability and resistance to harsh weather conditions make it ideal for outdoor use, providing a secure environment for animals. This application addresses the issue of traditional fencing materials degrading over time. Buyers in regions like South America and the Middle East should assess the corrosion resistance of the material to ensure longevity in diverse climates.

Illustrative image related to expanded steel grill

Why is Expanded Steel Grill Important in Transportation?

In the transportation industry, expanded steel grill is often used for trailer ramps and loading docks. Its design enhances traction, reducing the risk of slips during loading and unloading operations. This application is particularly beneficial in heavy-duty transport scenarios where safety is paramount. When sourcing, businesses must evaluate the load capacity and durability of the grill to ensure it meets the demands of their specific operations.

How Does Expanded Steel Grill Enhance the Food Industry?

In the food industry, expanded steel grill is utilized for cooking grates in commercial grills and smokers. Its ability to withstand high temperatures while ensuring even heat distribution is crucial for food preparation. This application helps solve issues related to uneven cooking and durability of grilling surfaces. Buyers should verify that materials are food-grade and easy to clean, ensuring compliance with health regulations in their respective markets.

3 Common User Pain Points for ‘expanded steel grill’ & Their Solutions

Scenario 1: Difficulty in Sourcing the Right Expanded Steel Grill for Specific Applications

The Problem: B2B buyers often struggle to find expanded steel grills that meet specific application requirements, such as load-bearing capacities, environmental resistance, or custom dimensions. For example, a manufacturer in Nigeria may need grills that withstand high humidity without rusting, while a construction firm in Germany might require heavy-duty grills for industrial flooring. This difficulty can lead to delays in production schedules and increased costs due to sourcing incorrect materials.

The Solution: To address these challenges, buyers should conduct thorough research on suppliers who specialize in expanded steel grills tailored for various applications. Engaging with manufacturers that offer customization options is essential. When specifying materials, buyers should detail their environmental conditions, load requirements, and dimensions. Additionally, asking suppliers for test results or certifications, such as ASTM or ISO standards, can help ensure the selected grills will perform as needed. Establishing a dialogue with potential suppliers can also lead to valuable insights about the best options available based on specific industry needs.

Scenario 2: Concerns Over the Durability and Maintenance of Expanded Steel Grills

The Problem: Many B2B buyers worry about the long-term durability and maintenance of expanded steel grills, especially in harsh working environments. For instance, companies in the Middle East may face extreme temperatures and sand exposure, which can deteriorate low-quality steel grills over time. This concern can result in increased operational costs and unscheduled downtimes due to frequent replacements or repairs.

Illustrative image related to expanded steel grill

The Solution: To mitigate these concerns, buyers should prioritize sourcing grills made from high-quality, corrosion-resistant materials such as galvanized or stainless steel. It’s important to inquire about the manufacturing process and any protective coatings that can enhance durability. Buyers should also consider the application environment and choose grills designed specifically for such conditions. Implementing a regular maintenance schedule that includes inspections for wear and tear can help prolong the lifespan of the grills. Collaborating with suppliers who offer maintenance tips or training can further ensure that the grills remain in optimal condition.

Scenario 3: Complexity in Installation and Customization Requirements

The Problem: B2B buyers often encounter challenges related to the installation and customization of expanded steel grills. A company in South America, for instance, may need specific grill dimensions to fit existing structures but lacks the in-house expertise to fabricate these grills efficiently. This can lead to costly mistakes, project delays, and resource wastage.

The Solution: To streamline the installation and customization process, buyers should engage with suppliers that provide comprehensive support, including design consultation and fabrication services. Before placing an order, it’s advisable to communicate specific project requirements clearly, including dimensions, load specifications, and installation methods. Some suppliers may offer pre-fabricated options or assembly instructions that simplify the installation process. Additionally, buyers could consider collaborating with local fabricators who are familiar with the expanded steel grill specifications and can provide on-site assistance. Leveraging these resources can significantly reduce the complexity and risks associated with installing expanded steel grills.

Strategic Material Selection Guide for expanded steel grill

What are the Key Materials for Expanded Steel Grills?

When selecting materials for expanded steel grills, several options are commonly considered. Each material has unique properties that impact performance, durability, and cost. Below, we analyze four prevalent materials used in the production of expanded steel grills, highlighting their key properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Carbon Steel

Key Properties:

Carbon steel is known for its high tensile strength and durability. It can withstand high temperatures, making it suitable for grilling applications. However, it has limited corrosion resistance, which can be a significant drawback in humid or wet environments.

Pros & Cons:

The primary advantage of carbon steel is its cost-effectiveness and strength. It is relatively easy to manufacture and can be produced in various thicknesses. However, its susceptibility to rust and corrosion necessitates regular maintenance, which can increase long-term costs.

Impact on Application:

Carbon steel is ideal for applications where high strength is required, but it may not perform well in environments exposed to moisture or corrosive substances.

Considerations for International Buyers:

Buyers in regions like Africa and South America should consider the local climate when selecting carbon steel. Compliance with local standards, such as ASTM for the U.S. or DIN for Europe, is crucial to ensure product reliability.

Illustrative image related to expanded steel grill

2. Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance due to its chromium content. It can withstand high temperatures and is less prone to warping compared to carbon steel.

Pros & Cons:

The key advantage of stainless steel is its longevity and low maintenance requirements, making it ideal for outdoor applications. However, it is more expensive than carbon steel, which may deter some buyers.

Impact on Application:

Stainless steel is suitable for grilling applications exposed to moisture, such as coastal areas. Its resistance to rust enhances the grill’s lifespan and performance.

Considerations for International Buyers:

For buyers in the Middle East and Europe, it’s essential to ensure that the stainless steel used meets specific standards (e.g., AISI, ASTM). Understanding the various grades of stainless steel (like 304 vs. 316) is also critical for selecting the right material for specific applications.

3. Aluminum

Key Properties:

Aluminum is lightweight and has excellent corrosion resistance. It can handle moderate temperatures but is not as strong as steel, which may limit its applications.

Illustrative image related to expanded steel grill

Pros & Cons:

The primary advantage of aluminum is its lightweight nature, making it easy to handle and transport. However, its lower strength compared to steel can be a disadvantage in high-stress applications, and it is generally more expensive than carbon steel.

Impact on Application:

Aluminum is suitable for portable grills and applications where weight is a concern. However, it may not be ideal for heavy-duty grilling due to its lower structural integrity.

Considerations for International Buyers:

Buyers in regions with high humidity or corrosive environments, such as coastal areas, may prefer aluminum for its corrosion resistance. Compliance with local manufacturing standards is also essential.

4. Galvanized Steel

Key Properties:

Galvanized steel is carbon steel that has been coated with zinc to enhance its corrosion resistance. It retains the strength of carbon steel while providing better protection against rust.

Illustrative image related to expanded steel grill

Pros & Cons:

The main advantage of galvanized steel is its cost-effectiveness combined with improved corrosion resistance. However, the zinc coating can wear off over time, especially in harsh environments, which may lead to corrosion.

Impact on Application:

Galvanized steel is suitable for outdoor applications where exposure to moisture is a concern. It provides a balance between cost and durability.

Considerations for International Buyers:

For buyers in Europe and Africa, understanding the local standards for galvanized products is essential. Ensuring that the galvanization process meets industry standards can help maintain product integrity.

Summary Table

| Material | Typical Use Case for Expanded Steel Grill | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Heavy-duty grills | Cost-effective and strong | Susceptible to rust | Low |

| Stainless Steel | Outdoor and coastal grills | Excellent corrosion resistance | Higher cost | High |

| Aluminum | Portable grills | Lightweight and corrosion-resistant | Lower strength | Medium |

| Galvanized Steel | Outdoor grills exposed to moisture | Cost-effective with corrosion resistance | Zinc coating can wear off | Medium |

This guide provides a comprehensive overview of the materials available for expanded steel grills, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

Illustrative image related to expanded steel grill

In-depth Look: Manufacturing Processes and Quality Assurance for expanded steel grill

What are the Key Stages in the Manufacturing Process of Expanded Steel Grills?

The manufacturing process of expanded steel grills involves several critical stages, each designed to ensure the product meets the necessary specifications for strength, durability, and functionality. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

In this initial stage, high-quality steel sheets are selected based on the desired thickness and type. Commonly used materials include carbon steel and stainless steel due to their favorable properties such as corrosion resistance and structural integrity. The sheets are then cleaned to remove any contaminants that could affect the final product’s performance. -

Forming

The core process of creating expanded steel involves slitting and stretching the prepared sheets. This is typically done using hydraulic or mechanical presses, which cut the metal into predetermined patterns before expanding it to create diamond-shaped openings. The size of these openings can vary significantly depending on the application, allowing for customized solutions that meet specific client requirements. -

Assembly

In cases where expanded grills require additional components, such as frames or support structures, assembly occurs at this stage. This may involve welding or bolting parts together to create a sturdy and reliable end product. Attention to detail is crucial to ensure structural integrity and longevity. -

Finishing

The final stage includes surface treatments such as galvanization, powder coating, or painting to enhance corrosion resistance and aesthetic appeal. These treatments not only improve the longevity of the grill but also ensure compliance with relevant industry standards.

How is Quality Assurance Implemented in the Manufacturing of Expanded Steel Grills?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that the final product meets international standards and customer expectations. The QA process encompasses several checkpoints and compliance measures.

-

International Standards and Certifications

Compliance with international standards like ISO 9001 is crucial for manufacturers targeting global markets. This standard focuses on quality management systems, ensuring that products consistently meet customer and regulatory requirements. Additionally, certifications such as CE marking (for European markets) and API (American Petroleum Institute) certifications may be relevant depending on the application of the expanded steel grill. -

Quality Control Checkpoints

Quality control (QC) is typically divided into three key checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified criteria.

– In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor the processes and identify any deviations from standards.

– Final Quality Control (FQC): Once the product is completed, a thorough inspection is performed to verify that it meets all quality specifications and standards before shipping. -

Common Testing Methods for Expanded Steel Grills

Various testing methods are employed to ensure the durability and reliability of expanded steel grills. These may include:

– Tensile Testing: Measures the strength of the material and its ability to withstand pulling forces.

– Bend Testing: Assesses the material’s flexibility and resistance to deformation.

– Corrosion Testing: Evaluates how well the material holds up against environmental factors that may cause rust or degradation.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers is essential to ensure product reliability. Here are several strategies to consider:

-

Supplier Audits

Conducting audits of potential suppliers can provide valuable insights into their manufacturing processes, quality control measures, and overall operational effectiveness. This can be done through on-site visits or by requesting detailed reports that outline their QA processes. -

Requesting Quality Assurance Documentation

Buyers should ask suppliers for documentation that demonstrates compliance with international standards and certifications. This may include ISO certificates, test reports, and quality control manuals. A transparent supplier will readily provide this information. -

Third-Party Inspections

Engaging third-party inspection services can add an extra layer of assurance. These independent entities can conduct comprehensive evaluations of the manufacturing processes, materials used, and final products to verify compliance with specified standards.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

When engaging with suppliers across different regions, B2B buyers must navigate various nuances related to quality control:

-

Regional Standards and Regulations

Understanding the specific regulations and standards that apply in different regions is crucial. For example, European buyers may have different compliance requirements compared to those in Africa or South America. Familiarizing oneself with these differences can prevent costly misalignments. -

Cultural Differences in Quality Perception

Quality perception can vary significantly across cultures. What is considered acceptable in one market may not be in another. B2B buyers should engage in open discussions with suppliers to ensure mutual understanding of quality expectations. -

Logistical Challenges

International shipping can pose challenges regarding the integrity of the product during transit. Buyers should consider suppliers that have robust packaging and handling practices to minimize damage and ensure quality is maintained from manufacturing to delivery.

Conclusion

The manufacturing processes and quality assurance practices for expanded steel grills are critical components that B2B buyers must consider. By understanding the stages of production, the implementation of quality control measures, and the nuances of international trade, buyers can make informed decisions that lead to successful partnerships and high-quality products. Engaging actively with suppliers and verifying their compliance with international standards will ultimately safeguard investments and enhance operational efficiency.

Illustrative image related to expanded steel grill

Practical Sourcing Guide: A Step-by-Step Checklist for ‘expanded steel grill’

When sourcing expanded steel grills, it’s essential to follow a structured approach to ensure quality and compatibility with your intended applications. This guide provides a practical checklist for B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, to streamline their procurement process.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. This includes determining the dimensions, thickness, and type of expanded metal (e.g., flattened or raised) that suits your application. Specific dimensions and material specifications are critical as they directly impact the grill’s performance and durability.

- Considerations:

- Thickness options typically range from #6 to #16.

- Choose between diamond shapes that fit your airflow and strength needs.

Step 2: Identify Reliable Suppliers

Research potential suppliers who specialize in expanded steel grills. Look for manufacturers or distributors with a proven track record in your industry. Reliable suppliers will not only provide quality products but also offer insights into industry trends and regulations.

- Action Items:

- Check online reviews and testimonials.

- Verify their experience with international shipping, especially if you are importing.

Step 3: Request Samples for Evaluation

Once you have a shortlist of suppliers, request samples of the expanded steel grills you are considering. Evaluating physical samples allows you to assess the quality, sturdiness, and finish of the product firsthand, which is crucial for making an informed decision.

- Tips:

- Inspect for any defects or inconsistencies.

- Consider the weight and feel of the material to judge its robustness.

Step 4: Verify Supplier Certifications

Ensure that the suppliers you are considering have the necessary certifications and compliance with international standards. Certifications indicate that the products meet specific quality and safety regulations, which is vital for maintaining operational integrity.

- Key Certifications to Look For:

- ISO 9001 for quality management.

- CE marking for products sold in Europe.

Step 5: Analyze Pricing and Payment Terms

Compare pricing structures across different suppliers but remember that the cheapest option isn’t always the best. Evaluate the pricing relative to the quality and service offered. Additionally, understand the payment terms, including any upfront deposits or payment schedules.

- Important Considerations:

- Look for bulk order discounts.

- Be clear on shipping costs and delivery timelines.

Step 6: Assess After-Sales Support and Warranty

After confirming your order, inquire about after-sales support and warranty options. A reputable supplier should provide assistance in case of defects or issues with the product. A solid warranty policy can also safeguard your investment.

- What to Confirm:

- Duration of the warranty.

- Availability of customer support for troubleshooting.

Step 7: Finalize the Contract and Place Your Order

After completing the above steps, finalize the contract with your chosen supplier. Ensure that all specifications, pricing, delivery timelines, and payment terms are clearly documented to avoid any misunderstandings.

- Final Checks:

- Review the contract for clarity and completeness.

- Confirm the delivery schedule and logistics arrangements.

By following this checklist, B2B buyers can confidently source expanded steel grills that meet their specific needs, ensuring both quality and value in their procurement process.

Comprehensive Cost and Pricing Analysis for expanded steel grill Sourcing

What Are the Key Cost Components in Expanded Steel Grill Sourcing?

Understanding the cost structure for sourcing expanded steel grills is crucial for B2B buyers looking to optimize their procurement strategies. The primary cost components include:

-

Materials: The choice of raw materials significantly affects pricing. Steel quality, thickness, and type (e.g., galvanized, stainless) can vary costs. Higher-grade materials typically command a premium but offer enhanced durability and corrosion resistance.

-

Labor: Labor costs encompass both manufacturing and assembly. In regions with higher wage standards, labor costs can escalate, affecting overall pricing. Conversely, sourcing from countries with lower labor costs may yield savings, albeit with potential trade-offs in quality.

-

Manufacturing Overhead: This includes expenses related to the production process, such as utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can lower overhead and thus the final price.

-

Tooling: Custom tooling for specialized designs or unique specifications can add significant costs. Buyers should consider whether the investment in tooling will be offset by the expected volume of orders.

-

Quality Control (QC): Rigorous QC processes ensure that products meet specified standards. While this may increase upfront costs, it can reduce returns and enhance customer satisfaction in the long run.

-

Logistics: Transportation and warehousing costs are critical, especially for international shipments. These costs can fluctuate based on distance, mode of transport, and any tariffs or duties applicable in the destination country.

-

Margin: Suppliers will include a profit margin in their pricing, influenced by market competition, demand, and their operational costs.

How Do Price Influencers Affect Expanded Steel Grill Pricing?

Several factors influence pricing beyond the basic cost structure, including:

-

Volume/MOQ: Suppliers often provide tiered pricing based on order volume. Larger orders can lead to significant discounts, making it advantageous for buyers to consolidate purchases.

-

Specifications and Customization: Custom specifications (e.g., unique dimensions, finishes) can lead to increased costs. Buyers should assess the necessity of such customizations against potential cost increases.

-

Materials and Quality Certifications: Products meeting international quality standards or certifications (like ISO or ASTM) may be priced higher. These certifications can provide assurance of quality and compliance, particularly important for industrial applications.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their proven track record, while newer suppliers might offer lower prices to gain market share.

-

Incoterms: Understanding shipping terms (like FOB, CIF) is essential as they define responsibility for shipping costs, insurance, and risk. This knowledge can aid in negotiating better terms.

What Buyer Tips Can Optimize Cost Efficiency in Expanded Steel Grill Sourcing?

B2B buyers can adopt several strategies to enhance cost efficiency:

-

Negotiate Effectively: Engage suppliers in discussions about pricing, especially if you can offer bulk orders or long-term contracts. Leverage competitive quotes from multiple suppliers to strengthen your negotiating position.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also operational costs, including maintenance, lifespan, and potential replacement costs. Investing in higher-quality materials may yield lower TCO over time.

-

Understand Pricing Nuances for International Buyers: International buyers, particularly from Africa, South America, the Middle East, and Europe, must be aware of currency fluctuations, import duties, and shipping logistics. These factors can significantly influence overall costs.

-

Stay Informed on Market Trends: Keeping abreast of market conditions can help buyers anticipate price changes and make informed purchasing decisions. Engaging with industry reports or market analysis can provide valuable insights.

Disclaimer on Indicative Prices

Pricing for expanded steel grills can vary widely based on the factors mentioned above. It is essential for buyers to conduct thorough market research and obtain multiple quotes to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing expanded steel grill With Other Solutions

Introduction to Alternatives for Expanded Steel Grill Solutions

In the realm of industrial applications, choosing the right material or method is critical for achieving desired performance outcomes. Expanded steel grills, known for their strength and versatility, face competition from various alternative solutions. This analysis will compare expanded steel grills with two prominent alternatives: perforated metal sheets and welded wire mesh. Understanding these alternatives allows B2B buyers to make informed decisions tailored to their specific operational needs.

Comparison Table

| Comparison Aspect | Expanded Steel Grill | Perforated Metal Sheets | Welded Wire Mesh |

|---|---|---|---|

| Performance | High strength, durable; allows airflow and visibility | Moderate strength; customizable hole patterns | Good tensile strength; offers varying openness |

| Cost | Generally low to moderate | Moderate to high, depending on customization | Low to moderate, depending on gauge and size |

| Ease of Implementation | Easy to cut and shape; requires minimal tools | Requires specific tooling for custom patterns | Simple to install; lightweight for easy handling |

| Maintenance | Low maintenance; resistant to corrosion | Moderate; may require cleaning depending on application | Low; prone to rust without coating |

| Best Use Case | Heavy-duty applications like flooring, catwalks | Aesthetic applications in architecture, sound barriers | Fencing, gardening, and light-duty applications |

Detailed Breakdown of Alternatives

1. Perforated Metal Sheets

Perforated metal sheets are sheets of metal with holes punched in a specific pattern. These sheets provide a unique combination of strength and aesthetic appeal, making them ideal for architectural applications, sound barriers, and filtration systems. The primary advantage of perforated sheets is their customizability; buyers can specify hole sizes and patterns to meet specific design requirements. However, this customization often leads to higher costs and longer lead times. Maintenance can also be a concern, as dirt and debris can accumulate in the holes, necessitating periodic cleaning.

Illustrative image related to expanded steel grill

2. Welded Wire Mesh

Welded wire mesh consists of intersecting wire strands that are welded at their junctions, creating a grid-like structure. This alternative is celebrated for its lightweight nature and ease of installation, making it suitable for various applications, including fencing, gardening, and light-duty flooring. Welded wire mesh is generally more affordable compared to expanded steel grills, but it may not offer the same level of durability and strength, especially in heavy-duty scenarios. Additionally, without proper coatings, welded wire mesh is susceptible to rust and corrosion, which can increase long-term maintenance costs.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate solution for industrial applications, B2B buyers must consider their specific requirements, including performance, cost, and maintenance needs. Expanded steel grills excel in heavy-duty environments where durability is paramount, while perforated metal sheets offer design flexibility for aesthetic applications. In contrast, welded wire mesh serves as a cost-effective option for lighter applications. By weighing these factors, buyers can make strategic decisions that align with their operational goals and budget constraints, ensuring optimal performance and longevity for their investments.

Essential Technical Properties and Trade Terminology for expanded steel grill

What Are the Key Technical Properties of Expanded Steel Grills for B2B Buyers?

When considering expanded steel grills for industrial applications, several critical technical properties must be evaluated. Understanding these specifications not only aids in selecting the right product but also ensures compliance with project requirements and performance expectations.

-

Material Grade

The most common materials for expanded steel grills include carbon steel and stainless steel. Each material grade has unique properties, such as tensile strength and corrosion resistance. For example, stainless steel is often preferred for outdoor applications due to its resistance to rust and environmental factors, making it a long-lasting choice for grills used in harsh conditions. Identifying the right material grade is essential for ensuring durability and suitability for specific applications. -

Thickness

The thickness of expanded steel grills varies typically from 1/16” to 1/4”, affecting both strength and weight. Thicker materials can withstand greater loads and provide increased stability, which is vital for applications like flooring or platforms. For B2B buyers, understanding thickness helps in determining the grill’s suitability for specific uses, such as heavy machinery support or pedestrian traffic areas. -

Diamond Opening Size

The size of the diamond openings in expanded metal sheets can range from 1/4” to 1 ½”. This specification affects airflow, visibility, and load-bearing capabilities. Smaller openings may be required for applications needing more surface support, while larger openings are beneficial for ventilation. Knowing the appropriate diamond size is crucial for aligning with operational requirements and safety standards. -

Weight per Square Foot

The weight of expanded steel grills typically ranges from 1.5 to 3.5 pounds per square foot. This specification is critical for transport logistics, load calculations, and installation processes. Buyers must consider the weight to ensure compatibility with existing structures or equipment and to facilitate safe handling during installation. -

Finish Options

Expanded steel grills can come in various finishes, including galvanized, powder-coated, or untreated. The finish impacts not only the aesthetic appeal but also the product’s resistance to corrosion and wear. B2B buyers should select a finish that aligns with the intended environment and usage to maximize the lifespan of the product.

What Are Common Trade Terminology and Jargon in the Expanded Steel Grill Industry?

Familiarity with industry terminology can streamline communication and negotiations between buyers and suppliers. Here are key terms frequently encountered in the expanded steel grill market:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For expanded steel grills, OEMs often provide custom solutions tailored to specific client needs, which can enhance product compatibility and performance. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory costs and production planning. It helps in negotiating bulk purchases, which can lead to cost savings. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing information from suppliers for specified products. This document outlines the requirements, quantities, and specifications needed for expanded steel grills, enabling suppliers to provide accurate quotes. -

Incoterms

These are international commercial terms that define the responsibilities of buyers and sellers in global trade, including shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for B2B buyers to mitigate risks and ensure compliance with international shipping regulations. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. Understanding lead times helps buyers plan their projects effectively, ensuring that expanded steel grills arrive when needed for installation or production schedules. -

Fabrication

This term describes the process of transforming raw materials into finished products. In the context of expanded steel grills, fabrication might involve cutting, bending, or welding the grills to meet specific design requirements. Knowing the fabrication capabilities of suppliers can help buyers source tailored solutions.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring they select the most appropriate expanded steel grills for their applications while fostering efficient communication with suppliers.

Illustrative image related to expanded steel grill

Navigating Market Dynamics and Sourcing Trends in the expanded steel grill Sector

What Are the Key Market Dynamics and Trends in the Expanded Steel Grill Sector?

The expanded steel grill sector is witnessing dynamic growth driven by several global factors. One major driver is the increasing demand for durable, lightweight materials in various industries, from construction to food service. As urbanization accelerates in regions like Africa and South America, the need for robust infrastructure and outdoor grilling solutions is surging. Additionally, the rise of outdoor cooking culture, particularly in the Middle East and Europe, is propelling the market forward.

Emerging technologies are reshaping sourcing strategies. Digital platforms for procurement are becoming prevalent, allowing international B2B buyers to access a wider range of suppliers and products. This trend is notable in regions such as Germany, where technological integration in purchasing processes is being emphasized. Furthermore, the availability of customized solutions—such as various thicknesses and diamond patterns in expanded metal—enables buyers to meet specific application requirements, enhancing their competitive edge.

In terms of market dynamics, fluctuating raw material prices and supply chain disruptions are challenges that international buyers must navigate. The ongoing geopolitical tensions and the impact of the COVID-19 pandemic have highlighted the need for diversified sourcing strategies. Buyers are increasingly looking for suppliers with robust logistics capabilities and transparent supply chains to mitigate risks and ensure consistent quality.

How Can Sustainability and Ethical Sourcing Shape the Expanded Steel Grill Market?

Sustainability is becoming a cornerstone in the expanded steel grill sector. As environmental concerns escalate, B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices. The environmental impact of steel production, including energy consumption and carbon emissions, is prompting buyers to seek alternatives that minimize ecological footprints.

Ethical sourcing is equally important, with companies looking to ensure their supply chains are free from unethical labor practices. Certifications such as ISO 14001 for environmental management and sourcing from recycled materials are becoming critical factors in supplier selection. Buyers should actively seek out manufacturers who can provide evidence of their sustainability initiatives and certifications, thereby enhancing their own brand reputation and compliance with regulatory standards.

Additionally, the shift towards using ‘green’ materials—such as those made from recycled steel—can lead to cost savings and a reduction in waste. B2B buyers should consider integrating sustainability criteria into their procurement policies to foster long-term partnerships with environmentally responsible suppliers.

What Is the Historical Context of the Expanded Steel Grill Sector for B2B Buyers?

The expanded steel grill has a rich history rooted in the industrial revolution, where the need for sturdy yet lightweight materials became apparent. Initially used in construction and mining applications, expanded metal evolved into a versatile product suitable for a myriad of uses, including outdoor grilling and cooking.

Over the decades, the introduction of advanced manufacturing techniques has allowed for greater customization and improved performance of expanded metal products. Today, B2B buyers benefit from a wide array of options tailored to their specific needs, from various thicknesses to distinct diamond shapes. Understanding this evolution can help buyers appreciate the advancements in quality and application that define the current market, enabling them to make informed purchasing decisions.

As the industry continues to evolve, the historical context provides valuable insights into the capabilities and potential future directions of expanded steel grill products.

Frequently Asked Questions (FAQs) for B2B Buyers of expanded steel grill

-

How do I choose the right thickness of expanded steel grill for my application?

Choosing the correct thickness of expanded steel grill depends on the intended use and weight capacity required. For cooking applications, a thickness of at least 1/8″ (3.175 mm) is recommended to ensure durability and support for heavier items. For structural purposes, consider the load it will bear; thicker materials (up to 1/4″ or more) may be necessary for applications like walkways or safety barriers. Always consult with suppliers regarding the specific requirements of your project. -

What is the best type of expanded steel grill for outdoor cooking?

For outdoor cooking, flattened expanded steel grill is preferred due to its smooth surface, which allows for better heat distribution and easier cleaning. Stainless steel options provide additional corrosion resistance, making them ideal for various weather conditions. Be sure to consider the size of the grill and the type of cooking you plan to do, as different diamond openings will affect airflow and cooking efficiency. -

What customization options are available for expanded steel grills?

Most manufacturers offer customization options, including specific dimensions, thicknesses, and diamond opening sizes. You can also request special coatings for corrosion resistance or fireproofing. When negotiating with suppliers, discuss your exact needs to ensure the final product meets your specifications. This is especially important for unique applications, such as industrial settings or specialized cooking equipment. -

What are the minimum order quantities (MOQ) for expanded steel grills?

Minimum order quantities can vary widely among suppliers, ranging from a few sheets to several hundred, depending on the manufacturer’s capabilities and your location. For international buyers, it’s essential to clarify MOQ during initial discussions to avoid unexpected costs. Additionally, consider whether bulk purchasing could lead to cost savings, especially if you plan to use the grills in multiple projects. -

How can I vet suppliers of expanded steel grills?

To effectively vet suppliers, start by checking their industry reputation through online reviews and client testimonials. Request references from previous clients to assess their reliability and quality. Additionally, ensure that they comply with international standards and certifications relevant to your region. Conducting a factory visit or requesting product samples can also provide insights into their manufacturing processes. -

What payment terms should I expect when sourcing expanded steel grills internationally?

Payment terms can vary but are typically negotiated based on the relationship with the supplier. Common arrangements include partial payments upfront, with the balance due upon shipment or delivery. For larger orders, consider using letters of credit or escrow services to protect your investment. Always ensure that payment terms are clearly outlined in the contract to avoid disputes. -

How can I ensure quality assurance (QA) for my expanded steel grill orders?

Quality assurance can be maintained by establishing clear specifications and standards that the supplier must meet. Request certifications for materials used, and consider implementing a third-party inspection service to verify quality before shipment. Regular communication with the supplier throughout the production process can also help address any potential issues early on. -

What logistics considerations should I keep in mind when importing expanded steel grills?

When importing, consider shipping costs, customs duties, and local regulations that may affect delivery. Work with a logistics partner experienced in international trade to streamline the shipping process and ensure compliance with all regulations. It’s also wise to discuss lead times with your supplier to account for any potential delays in production or shipping, especially if you have specific project timelines.

Top 6 Expanded Steel Grill Manufacturers & Suppliers List

1. BBQ Smoker Mods – VORTEX Grill Grate

Domain: bbqsmokermods.com

Registered: 2014 (11 years)

Introduction: Expanded Metal Grates / Fire Baskets – Smoker Parts. Special prices on various products including: VORTEX (IN)DIRECT HEAT Grill Grate for Weber Kettle, Big Green Egg, Kamado, BGE and Charcoal Grills – $21.00 (Regular Price $39.99); Middle Griddle™ Flat top Grill for Weber Kettle, UDS, WSM – $17.99 (Regular Price $22.00); Vortex (in)direct heat® Grill Grate for 22 Kettle, UDS or Kamado style Charco…

2. Competitive Metals – Expanded Metal Sheets and Grating

Domain: competitivemetals.com

Registered: 2006 (19 years)

Introduction: Expanded Metal Sheets and Grating with Diamond Openings. Features include: available in flat or raised options, wire thickness options ranging from #16 to #6, diamond sizes from ¼” to 1 ½” wide, larger grating strands compared to regular expanded metal, stock full sheet size of 48” x 96” with 60” x 120” sheets available in select sizes, sold as full sheets only, and most sizes can be sheared to si…

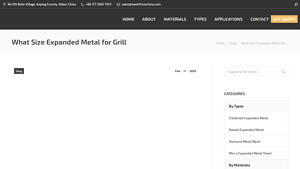

3. Expanded Metal Grates – Key Considerations

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Expanded metal grates for cooking in a pit-style smoker. Key considerations include: 1. Material: Avoid galvanized metal; prefer ungalvanized carbon steel. 2. Thickness: Thicker metal is recommended to prevent warping. 3. Surface Profile: Flat expanded metal is preferred over rippled or uneven surfaces for easier cleaning. 4. Opening Size: Ensure openings are not too large to prevent food from fal…

4. Expanded Metal – Grate Options and Recommendations

Domain: smokingmeatforums.com

Introduction: Expanded Metal for Grates: Thickness options discussed include at least 1/8″ thick (0.125″ or 3.175 mm) and #9, 3/4″ expanded metal grate. Recommendations emphasize using flattened expanded metal for better stability and ease of use. Common suppliers mentioned include McNichols, which offers 3/4″ No. 9 flattened expanded metal with a 64% open area. Pricing example: $76 for a 2×4′ piece on Amazon, …

5. Expanded Metal Sheet Mesh – BBQ Grill Mesh

Domain: expandedmetalsheetmesh.com

Registered: 2020 (5 years)

Introduction: Ideal mesh size for BBQ grill: 1/2 to 3/4 inch holes. Types: Raised expanded metal (strong but rough edges) and Flattened expanded metal (smoother surface, easier to clean). Importance: Mesh size affects cooking evenness and grill marks.

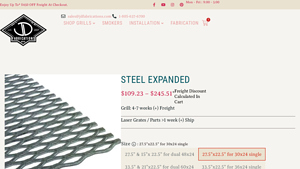

6. JD Fabrications – Steel Expanded Metal Grates

Domain: jdfabrications.com

Registered: 2011 (14 years)

Introduction: Product: Steel Expanded Metal Grates

Price Range: $109.23 – $245.51

Freight Discount: Up to $450 OFF at checkout

Shipping Time: 4-7 weeks for grill; >1 week for laser grates/parts

Sizes Available:

– 27.5″ & 15″ x 22.5″ for dual 48×24

– 27.5″ x 22.5″ for 30×24 single

– 33.5″ & 21″ x 22.5″ for dual 60×24

– 33.5″ x 22.5″ for 36×24 single

– 45.5″ & 21″ x 22.5″ for dual 72×24

– 45.5″ x 22.5″ for 48×24…

Strategic Sourcing Conclusion and Outlook for expanded steel grill

In today’s competitive landscape, strategic sourcing of expanded steel grills is paramount for international B2B buyers seeking quality and cost-effectiveness. The versatility of expanded metal, used in applications from outdoor furniture to industrial grating, offers robust solutions that cater to diverse market needs. By identifying reliable suppliers who provide customizable options—ranging from thickness to diamond sizes—businesses can enhance their product offerings while maintaining operational efficiency.

Illustrative image related to expanded steel grill

Moreover, leveraging strategic sourcing not only optimizes procurement processes but also fosters strong supplier relationships. This is particularly crucial for buyers in Africa, South America, the Middle East, and Europe, where regional demand varies significantly. Understanding local requirements and market dynamics can lead to better negotiation outcomes and enhanced supply chain resilience.

Looking ahead, businesses should prioritize innovation and sustainability in their sourcing strategies. As the market evolves, integrating eco-friendly practices will not only meet regulatory demands but also appeal to environmentally-conscious consumers. Now is the time to explore partnerships that align with these values, ensuring that your procurement strategy is both forward-thinking and impactful. Engage with trusted suppliers today to secure a competitive edge in the expanded steel grill market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.