Unlocking Value: A Strategic Analysis of the Exhaust Pipe Gasket Material Market

Introduction: Navigating the Global Market for exhaust pipe gasket material

In today’s competitive landscape, sourcing the right exhaust pipe gasket material is critical for ensuring optimal performance and longevity in exhaust systems. With the increasing demand for durable and heat-resistant gaskets, international B2B buyers face the challenge of navigating a diverse market filled with various materials and suppliers. This guide aims to illuminate the complexities of exhaust pipe gasket materials, providing a thorough understanding of the types available, their applications across different industries, and the essential criteria for vetting suppliers.

As we explore the intricacies of composite graphite, multi-layer steel, and other specialized materials, buyers will gain insights into how each type performs under extreme conditions, such as high temperatures and thermal cycling. Additionally, we will delve into cost considerations and the importance of selecting the right gasket to minimize maintenance and ensure reliability.

This comprehensive resource is designed specifically for B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including key markets like Saudi Arabia and Brazil. By empowering decision-makers with actionable knowledge, this guide will facilitate informed purchasing choices that align with their operational needs and budgetary constraints. Equip yourself with the tools to navigate the global market effectively, ensuring your procurement process is both strategic and efficient.

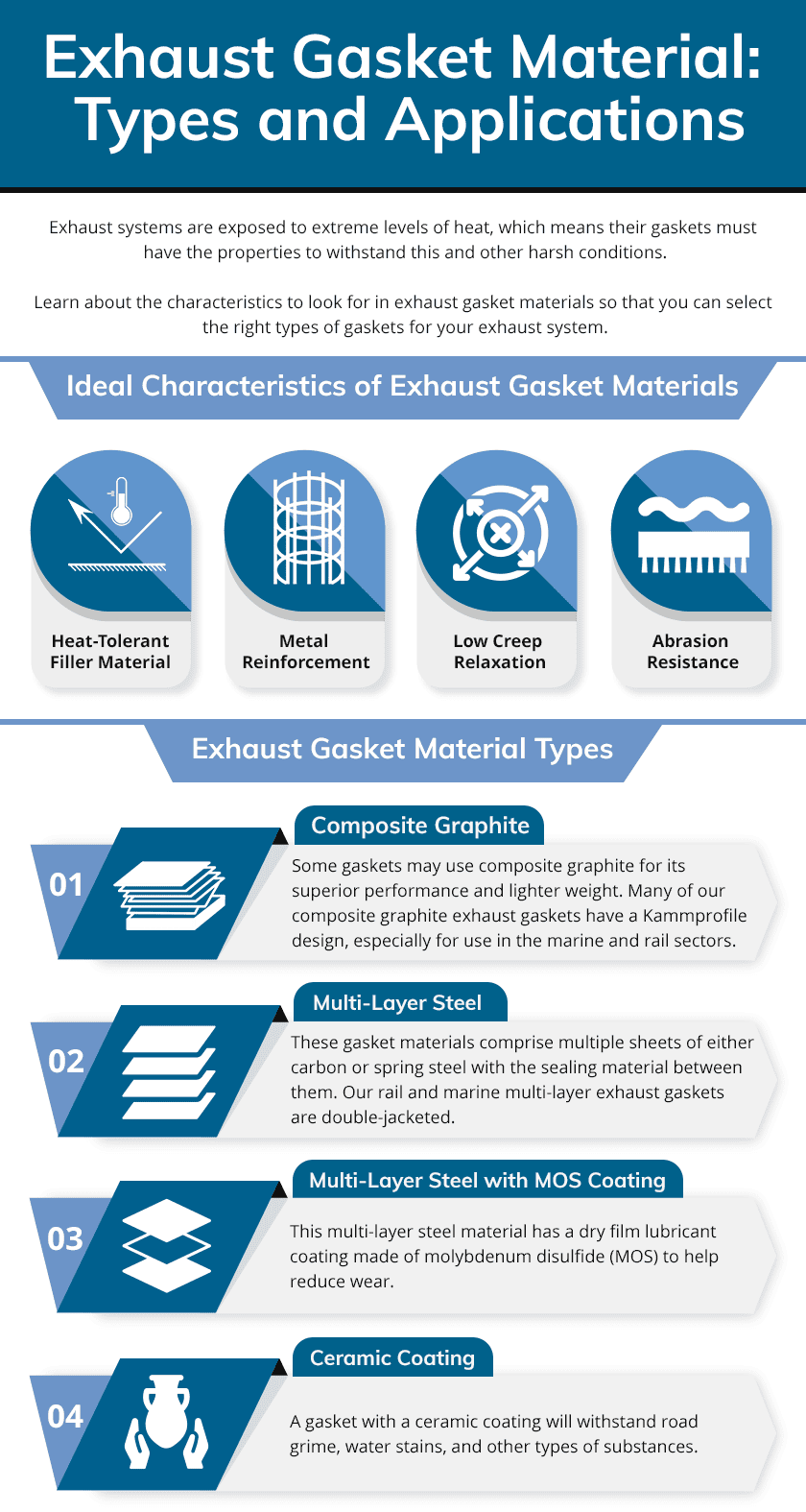

Understanding exhaust pipe gasket material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Composite Graphite | Lightweight, high heat tolerance, good sealing capability. | Automotive, marine, rail industries. | Pros: Excellent sealing, resistant to high temperatures. Cons: May require regular re-torquing. |

| Multi-layer Steel | Composed of multiple steel layers with sealing material in between. | Heavy-duty vehicles, industrial applications. | Pros: High durability, strong sealing performance. Cons: Can be heavier than other options. |

| Flexible Graphite | 100% graphite construction, designed to withstand extreme temperatures without burning out. | Performance vehicles, racing applications. | Pros: No re-torquing needed, can seal warped flanges. Cons: Higher initial cost compared to composites. |

| Sandwich Type | Features two metal layers with a graphite core, providing flexibility and strength. | Diesel engines, high-performance applications. | Pros: Good for thermal cycling, effective against leaks. Cons: May not be suitable for all exhaust systems. |

| Ceramic Coated | Metal gasket with a ceramic layer for added durability and resistance to environmental factors. | Marine, off-road vehicles, and industrial engines. | Pros: Excellent protection against corrosion and wear. Cons: Generally more expensive due to specialized coatings. |

What Are the Key Characteristics of Composite Graphite Gaskets?

Composite graphite gaskets are favored for their lightweight design and high thermal tolerance, making them suitable for various applications in the automotive and marine sectors. They provide an effective seal and are particularly useful in environments where high temperatures are prevalent. However, buyers should consider that these gaskets may require periodic re-torquing to maintain their sealing effectiveness, which could lead to additional maintenance costs.

How Do Multi-layer Steel Gaskets Stand Out?

Multi-layer steel gaskets consist of several layers of steel, enhancing their strength and durability. They are particularly effective in heavy-duty vehicles and industrial applications where robust sealing is critical. Their multi-layer design allows for excellent compressibility and adaptability to surface irregularities. However, their weight may be a drawback for applications where reducing overall vehicle weight is a priority.

Why Choose Flexible Graphite Gaskets?

Flexible graphite gaskets are engineered to withstand extreme temperatures without succumbing to burnout or shrinkage, making them ideal for performance and racing vehicles. Their unique properties allow them to seal warped flanges effectively, eliminating the need for re-torquing. While they offer superior performance, buyers should be aware that their initial cost may be higher compared to traditional gasket materials, which could impact budget considerations.

What Advantages Do Sandwich Type Gaskets Provide?

Sandwich type gaskets combine two thin metal layers with a graphite core, offering a balance of strength and flexibility. This design is particularly effective in diesel engines and high-performance applications where thermal cycling is common. They provide a reliable seal against leaks, but their suitability may vary based on specific exhaust system requirements, necessitating careful evaluation before purchase.

How Do Ceramic Coated Gaskets Enhance Performance?

Ceramic coated gaskets are designed to provide additional durability and resistance to environmental factors, such as corrosion and wear. They are particularly beneficial in marine and off-road vehicles, where exposure to harsh conditions is frequent. While they offer excellent protection and longevity, the specialized coatings can make them more expensive, which is an important consideration for B2B buyers focused on cost-effectiveness.

Key Industrial Applications of exhaust pipe gasket material

| Industry/Sector | Specific Application of exhaust pipe gasket material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Engine Exhaust Systems | Ensures optimal sealing, reducing emissions and improving engine performance. | Look for heat-resistant materials that can withstand extreme temperatures and pressures. |

| Marine Engineering | Marine Engine Exhaust Systems | Prevents leaks, enhancing safety and performance in high-stress environments. | Consider gaskets that resist corrosion and are compatible with marine fuels. |

| Heavy Machinery | Diesel Engine Exhaust Systems | Reduces noise and emissions, ensuring compliance with environmental regulations. | Source durable materials that maintain integrity under heavy thermal cycling. |

| Power Generation | Gas Turbine Exhaust Systems | Enhances efficiency and reduces operational costs by ensuring a tight seal. | Ensure the material can handle high temperatures and is resistant to creep. |

| Aerospace | Aircraft Engine Exhaust Systems | Critical for safety and efficiency, preventing exhaust leaks at high altitudes. | Look for lightweight, high-temperature resistant materials with certification for aerospace applications. |

How is Exhaust Pipe Gasket Material Used in Automotive Manufacturing?

In the automotive sector, exhaust pipe gasket material is vital for sealing engine exhaust systems. It ensures that exhaust gases do not escape, which is crucial for maintaining engine efficiency and complying with emissions regulations. Buyers in this sector should prioritize materials that can withstand high temperatures and pressures, such as composite graphite or multi-layer steel gaskets, which provide durability and performance in demanding environments.

What Role Does Exhaust Pipe Gasket Material Play in Marine Engineering?

Marine applications rely heavily on exhaust pipe gasket materials to seal exhaust systems in vessels. These gaskets prevent leaks, which can be hazardous in marine environments, affecting both safety and performance. Buyers should consider materials that resist corrosion and can endure exposure to seawater and marine fuels. Gaskets made from flexible graphite are particularly valuable in these scenarios due to their resilience under extreme conditions.

How Does Exhaust Pipe Gasket Material Benefit Heavy Machinery?

In heavy machinery, exhaust pipe gasket materials are essential for diesel engine exhaust systems. They help mitigate noise and emissions, which is increasingly important for compliance with environmental regulations. Buyers should focus on sourcing gaskets that can handle the thermal cycling typical in heavy machinery operations, as materials with low creep relaxation properties will maintain their sealing effectiveness over time, reducing maintenance costs.

Why is Exhaust Pipe Gasket Material Critical in Power Generation?

In the power generation industry, exhaust pipe gasket materials are crucial for gas turbine exhaust systems. They contribute to operational efficiency by ensuring a tight seal, which minimizes energy loss and reduces operational costs. Buyers should look for high-temperature resistant materials that can withstand the extreme conditions typical in power generation applications, ensuring long-lasting performance and reliability.

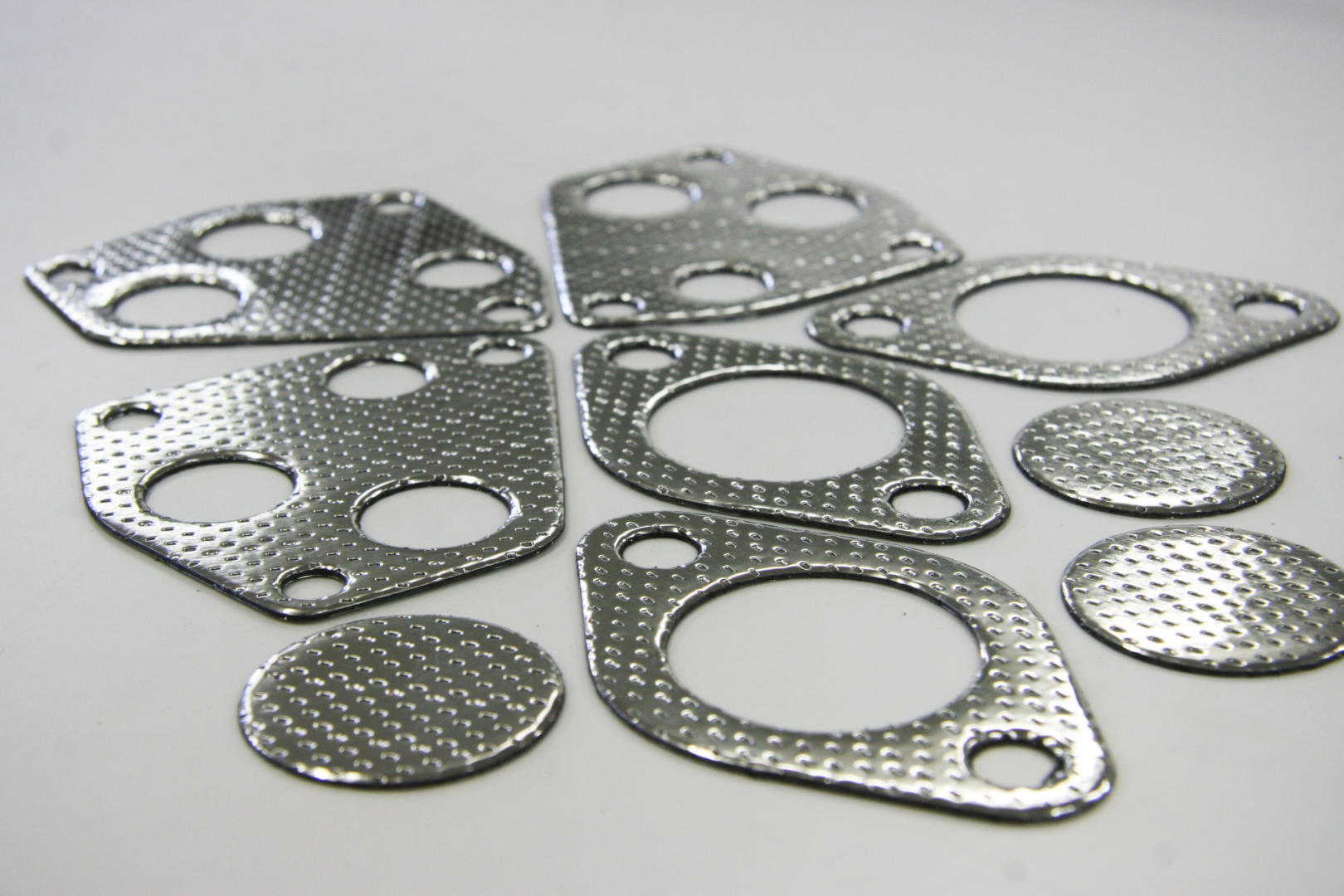

Illustrative image related to exhaust pipe gasket material

How is Exhaust Pipe Gasket Material Used in Aerospace Applications?

In aerospace, exhaust pipe gasket materials are critical for aircraft engine exhaust systems, where safety and efficiency are paramount. These gaskets prevent exhaust leaks that could compromise engine performance and safety at high altitudes. Buyers in the aerospace sector must source lightweight materials that are not only high-temperature resistant but also certified for aerospace applications, ensuring compliance with stringent safety standards.

3 Common User Pain Points for ‘exhaust pipe gasket material’ & Their Solutions

Scenario 1: Difficulty with Gasket Durability in Extreme Conditions

The Problem: Many B2B buyers operating in high-performance or heavy-duty environments face significant challenges with gasket durability. Exhaust pipe gaskets often fail under extreme temperatures and pressures, leading to costly repairs and downtime. For instance, industries reliant on heavy machinery, such as mining or construction, may experience gasket failure due to thermal cycling and exposure to corrosive substances, which can warp or degrade traditional gasket materials. This not only affects operational efficiency but also increases maintenance costs and can result in potential safety hazards.

The Solution: To combat these issues, buyers should consider sourcing exhaust pipe gaskets made from advanced materials such as flexible graphite or multi-layer steel. These materials are engineered to withstand high temperatures (up to 3,000°F for graphite) and provide better sealing capabilities under thermal stress. When specifying gaskets, ensure they are designed with features like low creep relaxation and metal reinforcement to enhance durability. Additionally, conducting regular inspections and preventive maintenance can help identify early signs of wear, allowing for timely replacements before failures occur. Collaborating with reputable suppliers who specialize in high-performance gasket materials will also ensure that you receive products that meet the stringent demands of your application.

Scenario 2: Misalignment and Flange Warping Leading to Leaks

The Problem: A common pain point in the installation of exhaust pipe gaskets is misalignment and flange warping. When exhaust systems are subjected to thermal expansion and contraction, the flanges can warp, causing gaps that standard gaskets cannot seal effectively. This results in exhaust leaks, which not only diminish engine performance but can also lead to increased emissions and potential regulatory compliance issues. B2B buyers often struggle to find a gasket that can accommodate these imperfections without requiring constant re-torquing.

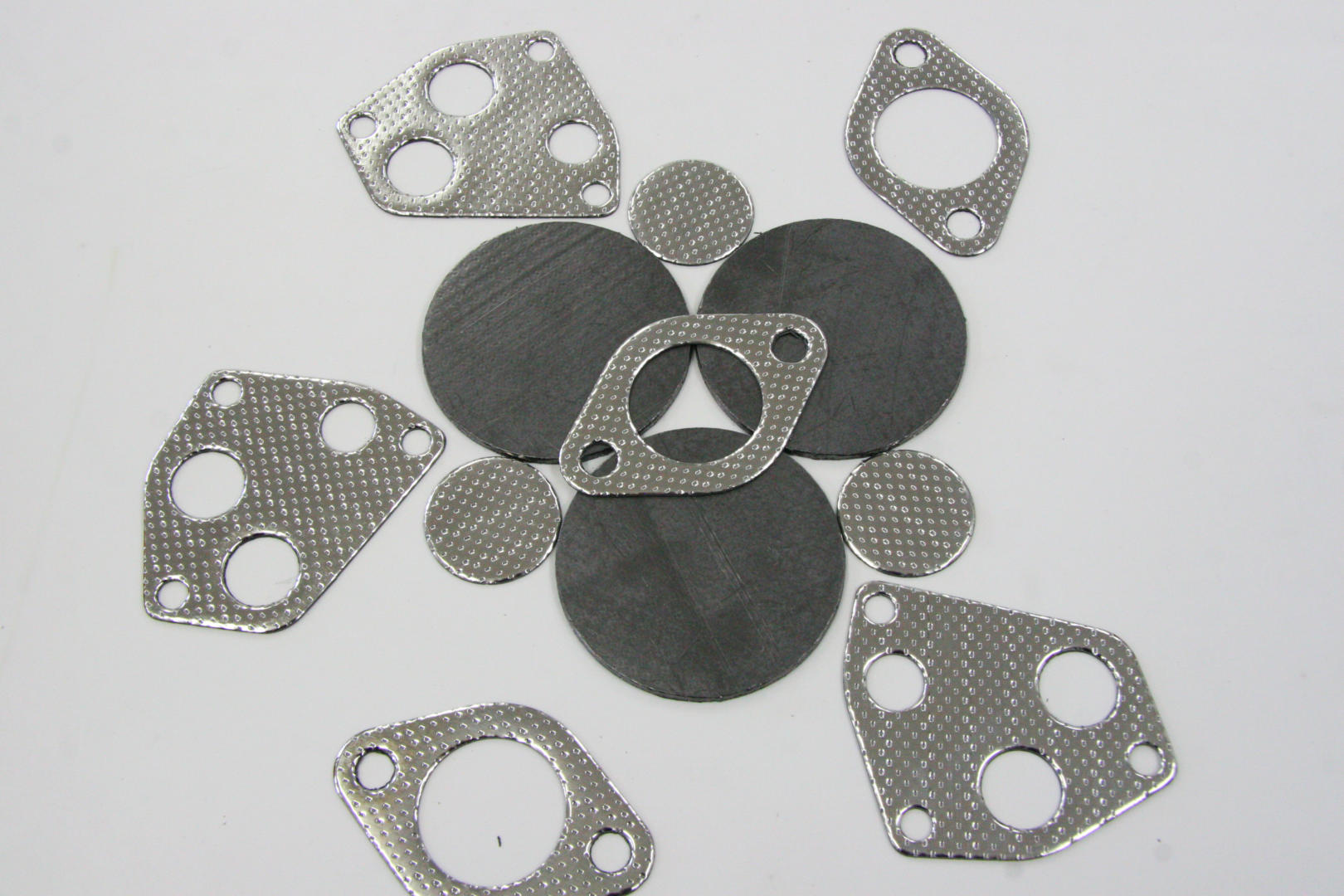

Illustrative image related to exhaust pipe gasket material

The Solution: Buyers should opt for gaskets designed with a built-in capacity to compress and fill gaps, such as those made from Remflex material, which can crush up to 50% to accommodate warped flanges. When selecting these gaskets, look for specifications that highlight their ability to handle uneven surfaces and maintain a reliable seal under thermal cycling conditions. Additionally, it is beneficial to invest in high-quality flange alignment tools and installation training for technicians to minimize misalignment during installation. Ensuring proper alignment can significantly extend the lifespan of the gasket and improve overall system reliability.

Scenario 3: Inconsistent Sourcing of Quality Gasket Materials

The Problem: B2B buyers often face challenges with inconsistent sourcing of high-quality exhaust pipe gasket materials. This inconsistency can lead to variations in performance and reliability, affecting the entire exhaust system’s efficiency. Particularly in international markets, where supply chains can be less predictable, buyers may find themselves switching between suppliers, resulting in gaskets of varying quality and performance characteristics.

The Solution: To mitigate sourcing issues, it is crucial for buyers to establish long-term relationships with trusted manufacturers and suppliers known for their quality standards. Conducting thorough supplier audits and requesting certifications that validate the quality of materials used can help ensure consistency. Additionally, consider consolidating purchases through a single supplier who can provide a range of gasket options tailored to specific applications. This not only simplifies procurement processes but also enhances the reliability of the exhaust systems, as the buyer can be confident that all gaskets meet uniform quality standards. Regularly reviewing supplier performance and maintaining open lines of communication can further ensure that any issues are addressed promptly, fostering a reliable supply chain.

Illustrative image related to exhaust pipe gasket material

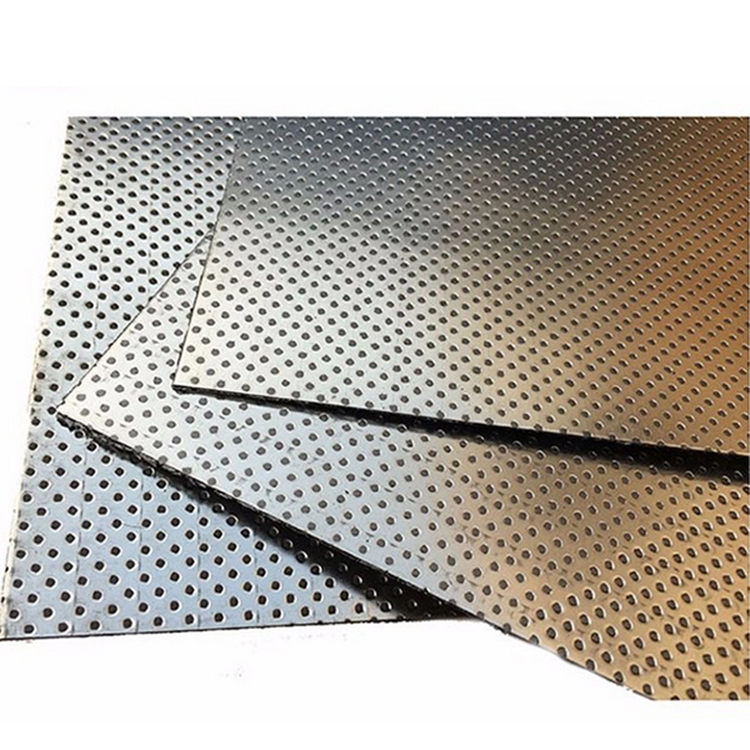

Strategic Material Selection Guide for exhaust pipe gasket material

What Are the Key Properties of Common Exhaust Pipe Gasket Materials?

When selecting exhaust pipe gasket materials for various applications, it is essential to consider properties such as temperature and pressure ratings, corrosion resistance, and mechanical strength. Below, we analyze four common materials used in exhaust pipe gaskets, highlighting their unique characteristics, advantages, disadvantages, and considerations for international B2B buyers.

How Does Composite Graphite Perform in Exhaust Applications?

Composite graphite gaskets are known for their excellent thermal stability and ability to withstand high temperatures, often exceeding 3,000°F. This material is lightweight and features low creep relaxation, which helps maintain a consistent seal over time. Its flexibility allows it to fill gaps caused by warped flanges, making it suitable for high-performance applications.

Pros: High-temperature tolerance, lightweight, and effective sealing capabilities.

Cons: While generally durable, they may not perform well in environments with high mechanical stress or abrasive conditions.

Impact on Application: Composite graphite is compatible with a variety of exhaust gases and can be used in automotive, marine, and industrial applications.

Considerations for International Buyers: Buyers in regions like Africa and the Middle East should ensure compliance with local standards, such as ASTM or DIN, and consider the availability of this material in their markets.

Illustrative image related to exhaust pipe gasket material

What Benefits Do Multi-Layer Steel Gaskets Offer?

Multi-layer steel gaskets consist of several layers of steel, often with a sealing material sandwiched in between. They provide excellent mechanical strength and durability, making them suitable for high-pressure applications. The metal reinforcement enhances the gasket’s ability to withstand extreme conditions, including thermal cycling.

Pros: High strength, excellent sealing under pressure, and low risk of deformation.

Cons: They can be heavier and more expensive than other materials, and manufacturing complexity may increase costs.

Impact on Application: Ideal for heavy-duty engines and industrial machinery, these gaskets can handle a wide range of exhaust gases.

Considerations for International Buyers: B2B buyers should verify that multi-layer steel gaskets meet local compliance standards and consider sourcing from manufacturers with a strong reputation in their region.

Illustrative image related to exhaust pipe gasket material

Why Choose Ceramic Coated Gaskets?

Ceramic-coated gaskets offer a unique combination of heat resistance and durability. The ceramic layer provides additional protection against corrosion and wear, making them suitable for harsh environments. They can withstand high temperatures while maintaining structural integrity.

Pros: Exceptional resistance to corrosion and wear, high-temperature performance.

Cons: The initial cost can be higher due to the specialized manufacturing process, and they may not be as flexible as other materials.

Impact on Application: These gaskets are particularly useful in applications where exposure to aggressive media is a concern, such as in industrial exhaust systems.

Considerations for International Buyers: Buyers should consider the specific environmental conditions in their region and ensure that ceramic-coated gaskets meet any relevant international standards.

What Are the Advantages of Using Sandwich-Type Gaskets?

Sandwich-type gaskets consist of two thin metal layers with a graphite core, providing a balance between flexibility and strength. They are designed to accommodate thermal expansion and contraction, making them suitable for high-performance applications.

Pros: Good flexibility, effective sealing, and resistance to thermal cycling.

Cons: They may not perform as well in extremely high-pressure environments compared to multi-layer steel gaskets.

Impact on Application: These gaskets are versatile and can be used in a variety of exhaust systems, including automotive and industrial applications.

Considerations for International Buyers: It is crucial to ensure that sandwich-type gaskets comply with local regulations and standards, particularly in regions with stringent quality controls.

Summary Table of Exhaust Pipe Gasket Materials

| Material | Typical Use Case for exhaust pipe gasket material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Composite Graphite | Automotive and marine exhaust systems | High-temperature tolerance | Limited performance under mechanical stress | Medium |

| Multi-Layer Steel | Heavy-duty engines and industrial machinery | Excellent mechanical strength | Higher cost and manufacturing complexity | High |

| Ceramic Coated | Industrial exhaust systems with aggressive media | Corrosion and wear resistance | Higher initial cost | High |

| Sandwich-Type | Versatile applications in automotive and industrial | Good flexibility and sealing | Less effective in extremely high-pressure environments | Medium |

This strategic material selection guide serves as a crucial resource for B2B buyers navigating the complexities of exhaust pipe gasket materials, ensuring informed decisions that align with their specific application needs and regional compliance requirements.

Illustrative image related to exhaust pipe gasket material

In-depth Look: Manufacturing Processes and Quality Assurance for exhaust pipe gasket material

What Are the Main Stages of Manufacturing Exhaust Pipe Gasket Material?

The manufacturing of exhaust pipe gasket material involves several key stages that ensure the final product meets the necessary performance and quality standards.

Material Preparation: How Is Raw Material Selected and Treated?

The first stage of the manufacturing process begins with the selection and preparation of raw materials. Common materials include composite graphite, metal reinforcements, and specialized fillers designed to withstand high temperatures and corrosive environments. Manufacturers typically assess the thermal and mechanical properties of these materials through initial testing to ensure they meet performance specifications.

Once selected, raw materials undergo treatment processes such as cutting, shredding, or grinding to achieve the desired particle size and consistency. This preparation phase is crucial, as the quality of the raw materials directly influences the performance characteristics of the final gasket.

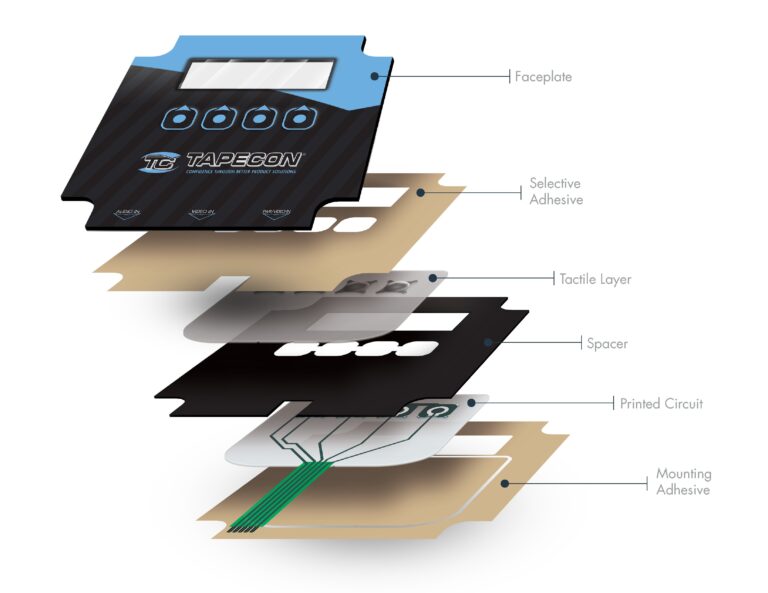

Forming: What Techniques Are Used to Shape Gasket Materials?

The forming stage involves shaping the prepared materials into gaskets. This can be achieved through several techniques, including compression molding, die-cutting, and lamination.

Compression molding is particularly effective for producing gaskets with complex shapes and thicknesses. It involves placing the material into a mold and applying heat and pressure, causing the material to flow and take the shape of the mold. Die-cutting, on the other hand, is often used for simpler, flat gaskets where precision and consistency are essential.

During this stage, manufacturers may also incorporate features like holes or grooves to enhance sealing capabilities, especially in applications involving high thermal cycling.

Assembly: How Are Gaskets Prepared for Final Inspection?

In some cases, gaskets may require additional assembly steps, particularly when they involve multiple layers or reinforcements. Multi-layer gaskets, for example, are constructed by stacking layers of different materials and bonding them through adhesives or heat.

This stage often includes quality checks to ensure that the assembly process has not compromised the gasket’s integrity. Manufacturers may use automated systems for consistency, but manual inspections are also common to catch any defects early in the process.

Finishing: What Final Steps Ensure Quality and Performance?

The finishing stage includes any additional processes that enhance the gasket’s performance or prepare it for shipment. This may involve surface treatment, such as coating with a protective layer to improve resistance against environmental factors like moisture and oil.

Final inspections are critical during this phase, as they verify that each gasket meets the specified dimensions and performance criteria. Common finishing techniques include trimming, polishing, and packaging, ensuring that the gaskets are ready for distribution without risking damage.

Illustrative image related to exhaust pipe gasket material

How Is Quality Assurance Ensured Throughout the Manufacturing Process?

Quality assurance (QA) is an integral aspect of the manufacturing process for exhaust pipe gasket materials, as it ensures product reliability and performance.

What Are the Relevant International Standards for Gasket Manufacturing?

Manufacturers often adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. This standard emphasizes continuous improvement and customer satisfaction, making it essential for B2B buyers to verify that their suppliers comply with these standards.

In addition to ISO certifications, industry-specific standards such as CE marking for products sold in the European market and API specifications for oil and gas applications are also critical. Compliance with these standards demonstrates that the manufacturer follows strict safety and quality protocols.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are vital at various stages of the manufacturing process to catch defects early. These checkpoints typically include:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet quality specifications before they enter the production process.

-

In-Process Quality Control (IPQC): Throughout manufacturing, samples are taken to monitor the production process, ensuring that any variations in material properties or production techniques are addressed immediately.

-

Final Quality Control (FQC): After manufacturing, finished gaskets undergo rigorous testing to verify they meet dimensional and performance standards. This may include thermal cycling tests, tensile strength tests, and leak tests to confirm that the gaskets will perform effectively in their intended applications.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for ensuring reliable products.

What Methods Can Buyers Use to Assess Supplier QC Practices?

Buyers can employ several strategies to verify the quality control practices of potential suppliers:

-

Audits: Conducting on-site audits allows buyers to evaluate the manufacturing environment, QC processes, and adherence to international standards firsthand.

-

Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s testing methods, results, and any corrective actions taken for past issues.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control processes, ensuring compliance with industry standards.

What Are the Quality Control Nuances for International B2B Buyers?

Buyers must also consider regional regulations and compliance requirements when sourcing gasket materials. Different countries may have specific certifications or testing standards that products must meet to be sold within their borders.

For instance, products imported into the EU may require CE marking, while those entering Middle Eastern markets may need to comply with local standards. Understanding these nuances can help buyers avoid potential compliance issues and ensure that they select suppliers who can meet their specific needs.

Illustrative image related to exhaust pipe gasket material

Conclusion: Why Is Understanding Manufacturing and Quality Assurance Crucial for B2B Buyers?

Understanding the manufacturing processes and quality assurance measures for exhaust pipe gasket materials is essential for B2B buyers. It allows them to make informed decisions, ensuring they choose suppliers who not only deliver high-quality products but also adhere to international standards and practices. By focusing on these aspects, buyers can mitigate risks and enhance the performance and reliability of their exhaust systems.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘exhaust pipe gasket material’

Introduction

This sourcing guide aims to assist B2B buyers in procuring high-quality exhaust pipe gasket materials tailored to their specific needs. By following this checklist, buyers can ensure they select the right materials that meet performance requirements while navigating supplier options effectively.

Step 1: Define Your Technical Specifications

Understanding the specific requirements of your exhaust system is crucial. Consider factors such as operating temperature, pressure, and compatibility with various exhaust gases. Clearly defining these specifications helps narrow down material types, ensuring that the gaskets will perform optimally under expected conditions.

- Temperature Tolerance: Look for materials that can withstand extreme temperatures, typically above 2,000 degrees Fahrenheit.

- Material Type: Determine whether you need composite graphite, multi-layer steel, or other specialized materials based on your application.

Step 2: Research Material Properties

Investigate the key characteristics of potential gasket materials. Essential properties include heat resistance, durability, and sealing capability. Materials like flexible graphite and multi-layer steel often provide superior performance and longevity, reducing the risk of gasket failure.

- Abrasion Resistance: Ensure the material can handle the thermal motion of dissimilar metals, which is common in exhaust systems.

- Low Creep Relaxation: This property helps maintain gasket integrity over time, ensuring reliable sealing.

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers to ensure they can meet your quality and service expectations. This includes assessing their manufacturing capabilities, experience in the industry, and product range.

- Request Documentation: Ask for certifications, quality control processes, and technical data sheets to verify their compliance with industry standards.

- Seek References: Contact other businesses in your sector to gain insights into the supplier’s reliability and product performance.

Step 4: Request Samples

Before making a bulk order, request material samples from shortlisted suppliers. Testing samples can help assess compatibility with your exhaust system and confirm the material’s performance under real-world conditions.

- Conduct Performance Tests: Evaluate the samples for heat resistance, sealing capability, and any specific application requirements.

- Assess Physical Properties: Look for signs of durability, such as tensile strength and flexibility.

Step 5: Review Pricing and Terms

Compare pricing structures and payment terms across different suppliers. While cost is an important factor, it should not compromise quality. Ensure you understand the total cost of ownership, including shipping, potential duties, and after-sale support.

- Negotiate Terms: Discuss volume discounts, lead times, and warranty provisions to secure the best deal.

- Consider Long-term Relationships: Establishing a partnership can lead to better pricing and support in the future.

Step 6: Finalize the Purchase Agreement

Once a supplier is selected, finalize the purchase agreement with clear terms. This agreement should outline product specifications, delivery schedules, payment terms, and warranty conditions.

- Document Everything: Ensure all agreed-upon terms are written down to prevent misunderstandings.

- Plan for Contingencies: Include clauses for quality assurance and returns to mitigate risks associated with product defects.

Step 7: Monitor Supplier Performance

After procurement, continuously monitor the supplier’s performance. Regular evaluation ensures that the supplier maintains quality standards and meets delivery timelines, contributing to your operational efficiency.

- Collect Feedback: Engage with your team to gather insights on the gasket performance and supplier service.

- Conduct Periodic Reviews: Schedule reviews to assess the supplier’s adherence to contract terms and explore opportunities for improvement.

Comprehensive Cost and Pricing Analysis for exhaust pipe gasket material Sourcing

What Are the Key Cost Components for Exhaust Pipe Gasket Material?

When sourcing exhaust pipe gasket materials, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The quality and type of materials significantly impact costs. For instance, flexible graphite gaskets tend to be more expensive due to their superior heat resistance and durability compared to standard composite materials. This quality directly correlates with the gasket’s performance and longevity.

-

Labor: Labor costs can vary based on the region and the complexity of the manufacturing process. Regions with lower labor costs may provide a competitive edge, but this should be balanced with quality assurance.

-

Manufacturing Overhead: This includes expenses related to equipment maintenance, factory utilities, and other operational costs. Efficient manufacturing processes can help minimize overhead, ultimately affecting the final price.

-

Tooling: Custom tooling for specific gasket designs or sizes can incur significant upfront costs. Buyers should factor in these costs, especially when considering unique applications or low-volume orders.

-

Quality Control (QC): Implementing rigorous QC measures ensures that the gaskets meet industry standards and specifications. While this adds to the cost, it is essential for maintaining product integrity and reducing warranty claims.

-

Logistics: Shipping costs, especially for international buyers, can vary widely based on distance, shipping methods, and customs duties. Understanding logistics is vital for calculating total costs.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on competition, brand reputation, and the uniqueness of the product.

How Do Price Influencers Affect Exhaust Pipe Gasket Sourcing?

Several factors can influence pricing in the B2B market for exhaust pipe gaskets:

-

Volume/MOQ: Bulk purchasing can lead to significant discounts. Suppliers often have Minimum Order Quantities (MOQs), and meeting these can lower per-unit costs.

-

Specifications and Customization: Customized gaskets tailored to specific applications will incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials: The choice of materials not only affects the initial cost but also influences the gasket’s performance and lifespan. Higher-quality materials may come at a premium but can offer cost savings in maintenance and replacements over time.

-

Quality and Certifications: Gaskets that meet international standards or hold specific certifications may demand higher prices. These certifications can provide assurance of quality, which is particularly important for buyers in regulated industries.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers with a track record of quality may charge more, but they can also minimize risks associated with poor-quality products.

-

Incoterms: Understanding Incoterms is essential for international transactions. They dictate who is responsible for shipping costs, insurance, and customs duties, impacting the overall cost structure.

What Buyer Tips Can Help Achieve Cost-Efficiency in Gasket Sourcing?

-

Negotiate Strategically: Always engage in negotiations with suppliers. Understanding their cost structure and presenting clear data on your requirements can lead to better pricing.

-

Evaluate Total Cost of Ownership (TCO): Rather than focusing solely on the purchase price, consider the TCO, which includes installation, maintenance, and operational costs. Choosing higher-quality gaskets may result in lower TCO due to reduced replacements and repairs.

-

Research Market Trends: Keep abreast of market trends and pricing fluctuations. Understanding seasonal demands and supply chain issues can provide leverage during negotiations.

-

Consider Local Suppliers: For buyers in Africa, South America, and the Middle East, sourcing from local manufacturers can reduce logistics costs and lead times. This can also facilitate easier communication and collaboration.

-

Be Aware of Pricing Nuances: International buyers should be mindful of currency fluctuations, tariffs, and local market conditions, as these can significantly affect pricing and overall procurement strategy.

Disclaimer

Prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific requirements. Buyers should conduct thorough research and engage with multiple suppliers to ensure competitive pricing and quality assurance.

Alternatives Analysis: Comparing exhaust pipe gasket material With Other Solutions

In the search for effective sealing solutions within exhaust systems, various options are available to B2B buyers. Understanding the performance and applicability of these alternatives is crucial for making informed purchasing decisions. This analysis compares exhaust pipe gasket materials against two viable alternatives: metal gaskets and liquid gasket sealants. Each option has its unique advantages and limitations, making it essential to evaluate them based on specific operational needs and conditions.

| Comparison Aspect | Exhaust Pipe Gasket Material | Metal Gasket | Liquid Gasket Sealant |

|---|---|---|---|

| Performance | Excellent heat resistance and sealing capability. Maintains integrity under extreme temperatures. | Strong and durable; suitable for high-pressure applications. Provides a rigid seal. | Flexible and can fill gaps, but performance can degrade over time under extreme conditions. |

| Cost | Moderate cost; varies by material type and brand. | Generally higher upfront cost due to metal fabrication. | Low initial cost; can vary based on brand and formulation. |

| Ease of Implementation | Requires precise cutting and fitting, which can be labor-intensive. | Simple installation but requires proper alignment and torque specifications. | Easy to apply; no special tools needed, but requires curing time. |

| Maintenance | May need re-torquing in high thermal cycling environments. | Very low maintenance; long lifespan. | Potentially higher maintenance due to degradation over time and exposure to heat. |

| Best Use Case | Ideal for standard exhaust systems with varying flange conditions. | Best suited for high-performance or high-pressure exhaust systems. | Suitable for custom applications and repairs where traditional gaskets may not fit. |

What Are the Advantages and Disadvantages of Metal Gaskets?

Metal gaskets are engineered for durability and are particularly effective in high-pressure environments, making them suitable for applications where traditional gaskets may fail. Their rigidity provides a reliable seal, especially in high-performance vehicles or heavy machinery. However, they can be more costly and may require precise installation to ensure effectiveness. Additionally, they lack the flexibility to accommodate slight misalignments or thermal expansion, which can lead to failure if not installed correctly.

How Do Liquid Gasket Sealants Compare?

Liquid gasket sealants offer a unique solution for sealing exhaust systems, particularly in custom applications where conventional gaskets may not fit. They can easily fill gaps and provide a flexible seal, which is beneficial in dynamic environments. Their application is straightforward, requiring no specialized tools, and they are generally more affordable. However, the longevity of liquid sealants can be a concern, as they may degrade over time, especially in high-temperature scenarios, leading to potential leaks that necessitate frequent inspections and reapplications.

Illustrative image related to exhaust pipe gasket material

Conclusion: Which Exhaust Sealing Solution Should a B2B Buyer Choose?

When selecting the right exhaust sealing solution, B2B buyers should consider their specific operational conditions, budget constraints, and maintenance capabilities. Exhaust pipe gasket materials provide excellent performance in typical exhaust systems, while metal gaskets are ideal for high-performance applications requiring durability. Liquid gasket sealants serve well in custom or less conventional setups, offering ease of use at a lower cost. Ultimately, understanding these differences will empower buyers to make choices that enhance the reliability and efficiency of their exhaust systems, tailored to their unique operational needs.

Essential Technical Properties and Trade Terminology for exhaust pipe gasket material

What Are the Key Technical Properties of Exhaust Pipe Gasket Material?

Understanding the essential technical properties of exhaust pipe gasket materials is crucial for B2B buyers, particularly those involved in manufacturing and automotive applications. Here are some critical specifications to consider:

1. Material Grade

Material grade indicates the quality and composition of the gasket material. Common materials include composite graphite, multi-layer steel, and flexible graphite. The choice of material affects durability, heat resistance, and sealing capability. For instance, flexible graphite can withstand extreme temperatures up to 3,000°F, making it suitable for high-performance applications. Buyers must assess the specific demands of their exhaust systems to select the appropriate material grade.

2. Thickness

The thickness of the gasket can impact its sealing effectiveness and ability to compensate for flange warping. Typical thickness ranges from 1/16 inch to 1/8 inch. A thicker gasket may offer better compression and sealing, particularly in applications where flanges are not perfectly aligned. Understanding the required thickness helps buyers ensure the gasket can maintain a robust seal under varying operating conditions.

3. Compression Set

Compression set refers to the gasket’s ability to maintain its shape after being compressed. A low compression set indicates that the gasket will not deform significantly over time, ensuring long-term sealing performance. This property is particularly important in high-temperature environments where traditional gaskets may degrade. Buyers should seek materials with low compression set ratings to minimize the risk of leaks.

Illustrative image related to exhaust pipe gasket material

4. Temperature Resistance

Temperature resistance defines the maximum operating temperature the gasket material can withstand without failing. Gaskets must endure extreme heat from exhaust gases while maintaining sealing integrity. Materials like flexible graphite excel in high-temperature applications, providing reliability where conventional gaskets may fail. Buyers should evaluate the operating conditions of their systems to choose gaskets with suitable temperature resistance.

5. Abrasion Resistance

Abrasion resistance refers to the material’s ability to withstand wear from friction and thermal motion. Gaskets that experience high thermal cycling or are in contact with dissimilar metals may require enhanced abrasion resistance to prevent premature failure. Selecting a gasket with superior abrasion resistance can prolong its service life and reduce maintenance costs.

What Are Common Trade Terms Used in Exhaust Pipe Gasket Material Procurement?

Familiarity with industry terminology is vital for effective communication and negotiation in the B2B landscape. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are used in the manufacturing of a vehicle or machinery. When sourcing gaskets, buyers often seek OEM parts to ensure compatibility and quality. Understanding OEM specifications helps buyers make informed decisions about the products they purchase.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and cost efficiency. Knowing the MOQ can help buyers plan their purchases and avoid overstocking or understocking.

3. RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers to obtain pricing information for specific products or services. This process allows buyers to compare quotes from multiple suppliers, facilitating better purchasing decisions. A well-structured RFQ can lead to favorable pricing and terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in the shipping process. Understanding these terms is essential for international transactions, as they clarify who is responsible for shipping, insurance, and tariffs. Buyers should familiarize themselves with Incoterms to navigate global supply chains effectively.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. This term is critical for production planning and inventory management. Buyers must consider lead times when sourcing gaskets to ensure timely delivery and avoid production delays.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing exhaust pipe gasket materials, ensuring they select products that meet their specific operational needs.

Navigating Market Dynamics and Sourcing Trends in the exhaust pipe gasket material Sector

What Are the Current Market Dynamics and Key Trends in Exhaust Pipe Gasket Materials?

The global market for exhaust pipe gasket materials is experiencing significant evolution driven by technological advancements and shifting consumer preferences. One of the primary drivers is the increasing demand for high-performance automotive components, especially in regions such as Africa, South America, the Middle East, and Europe. As automotive manufacturers focus on enhancing engine efficiency and reducing emissions, the need for reliable and durable gasket materials has surged. This trend is particularly evident in high-performance and aftermarket sectors, where products like composite graphite and multi-layer steel gaskets are gaining traction due to their superior heat resistance and longevity.

Emerging technologies are also reshaping sourcing trends in this sector. The integration of artificial intelligence and data analytics into supply chain management is enabling B2B buyers to make more informed purchasing decisions. Real-time data allows buyers to assess supplier performance, optimize inventory levels, and reduce lead times. Additionally, digital marketplaces are expanding access to diverse suppliers, making it easier for international buyers to source materials tailored to their specific requirements. For instance, platforms that facilitate direct connections between manufacturers and distributors can enhance competitive pricing and expedite the procurement process.

How Is Sustainability and Ethical Sourcing Impacting the Exhaust Pipe Gasket Material Sector?

Sustainability is becoming a pivotal concern in the exhaust pipe gasket material sector, influencing both production processes and sourcing decisions. As environmental regulations tighten globally, manufacturers are increasingly focused on reducing their carbon footprints. This has led to a rise in the use of environmentally friendly materials, such as biodegradable composites and recycled metals, which align with the growing demand for sustainable automotive components.

Ethical sourcing is also gaining prominence as B2B buyers prioritize transparency and social responsibility in their supply chains. Companies are seeking suppliers that uphold fair labor practices and comply with environmental standards. Certifications like ISO 14001 and other green certifications are becoming essential in supplier evaluations, ensuring that materials sourced for exhaust gaskets meet stringent environmental criteria. By partnering with suppliers committed to ethical practices, buyers not only enhance their brand reputation but also contribute to a more sustainable industry.

What Is the Evolution of Exhaust Pipe Gasket Materials and Its Relevance to B2B Buyers?

The evolution of exhaust pipe gasket materials reflects the broader advancements in automotive technology and materials science. Traditionally, gaskets were made from simple fiber and rubber composites, which often struggled to withstand the extreme conditions of modern engines. However, with the advent of advanced materials like flexible graphite and multi-layer steel, the performance and durability of exhaust gaskets have significantly improved.

In the B2B context, understanding this evolution is crucial for buyers looking to procure high-quality gasket materials. The shift towards more robust materials not only enhances the reliability of exhaust systems but also reduces maintenance costs over time. Furthermore, as automotive technologies continue to advance, B2B buyers must stay informed about emerging materials and innovations to ensure they are sourcing the best solutions for their specific applications. This knowledge can lead to strategic partnerships and long-term cost savings, making it a vital consideration in the procurement process.

Frequently Asked Questions (FAQs) for B2B Buyers of exhaust pipe gasket material

-

How do I solve exhaust leaks in my system?

To effectively address exhaust leaks, it’s essential to choose high-quality gasket materials that can withstand extreme temperatures and pressure fluctuations. Gaskets made from flexible graphite or multi-layer steel provide superior sealing capabilities and durability. Additionally, ensure that the flange surfaces are clean and free from warping. Regular inspection and maintenance can also help identify potential issues before they escalate. -

What is the best gasket material for high-performance exhaust systems?

For high-performance exhaust systems, flexible graphite gaskets are often the best choice due to their ability to withstand temperatures up to 3,000°F without burning out. These gaskets compress effectively, filling gaps in warped flanges and eliminating the need for re-torquing. Multi-layer steel gaskets are also recommended for their strength and reliability, especially in demanding applications. -

How can I vet international suppliers for exhaust gasket materials?

When vetting international suppliers, consider their industry reputation, years of experience, and client reviews. It’s crucial to request samples to assess product quality and performance. Verify their compliance with international standards and certifications relevant to exhaust systems. Additionally, establish clear communication channels to discuss technical specifications and any customization needs. -

What are typical minimum order quantities (MOQs) for exhaust gasket materials?

Minimum order quantities for exhaust gasket materials can vary significantly based on the supplier and the material type. Generally, MOQs can range from 100 to 1,000 units. It’s advisable to discuss your requirements with the supplier, as many are willing to accommodate lower MOQs for first-time orders or special projects, especially if they see potential for ongoing business. -

What payment terms should I expect when ordering internationally?

Payment terms can vary by supplier, but common practices include advance payments, letters of credit, or payment upon delivery. For first-time orders, a partial upfront payment may be required. It’s essential to clarify payment methods accepted (e.g., bank transfer, PayPal) and any additional fees related to currency conversion or international transactions. -

How do I ensure quality assurance (QA) for exhaust gasket materials?

To ensure quality assurance, request documentation of the supplier’s QA processes, including material testing and compliance with industry standards. Ask for third-party certifications or test results, particularly for high-temperature applications. Establishing a clear return policy and warranty can also protect your interests in case the products do not meet the specified standards. -

What logistics considerations should I keep in mind for international shipping?

Logistics considerations include shipping methods (air vs. sea), estimated delivery times, and customs clearance processes. Ensure that the supplier is experienced in handling international shipments and can provide necessary shipping documents. Additionally, consider the costs associated with duties and taxes in your country, as these can impact the overall cost of procurement. -

Can I customize exhaust gasket materials to fit specific applications?

Yes, many suppliers offer customization options for exhaust gasket materials, allowing you to specify dimensions, thickness, and material properties tailored to your application. Discuss your requirements with the supplier, including any unique environmental conditions or performance criteria. Customization can enhance the effectiveness of the gaskets in your specific exhaust system, ensuring optimal performance and longevity.

Top 5 Exhaust Pipe Gasket Material Manufacturers & Suppliers List

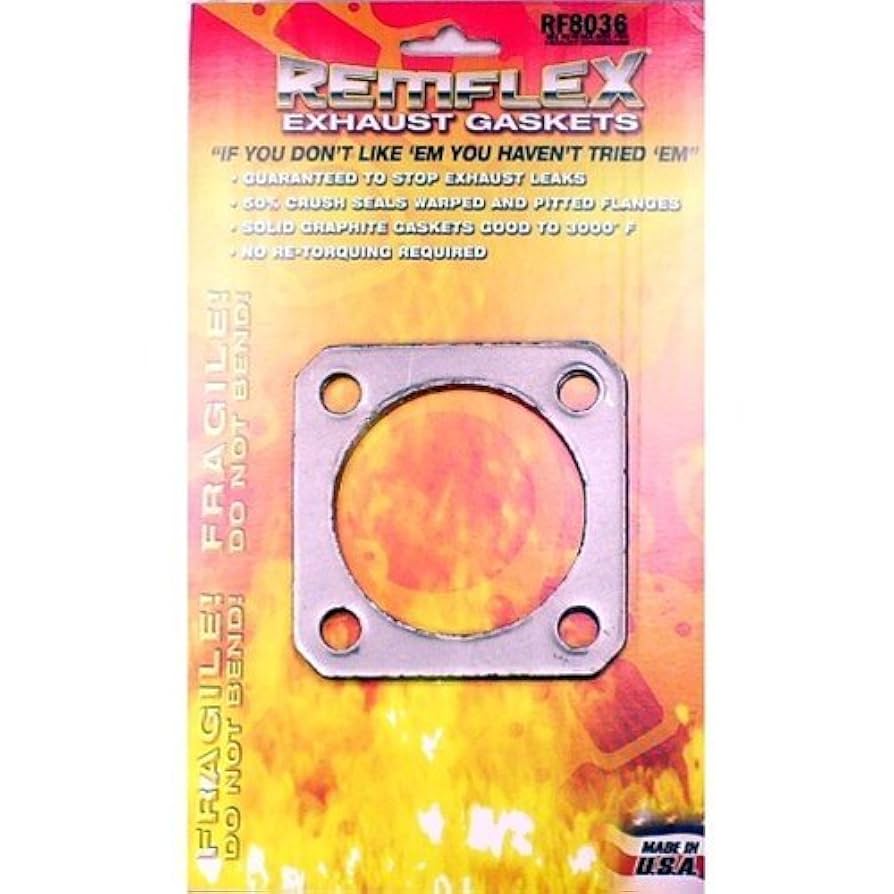

1. Remflex – Exhaust Header/Manifold Gasket

Domain: catalog.remflex.com

Registered: 2004 (21 years)

Introduction: Product Name: Remflex Exhaust Header / Manifold Gasket

Material: 100% flexible graphite

Thickness: Standard 1/8-inch, designed to crush 50%

Temperature Resistance: Up to 3,000 degrees F

Key Features:

– Seals warped flanges, filling gaps up to 1/16-inch

– No re-torquing necessary due to 30% rebound

– Proven technology for over 30 years in industrial applications

Applications: Suitable for various …

2. Reddit – BGA Metal Gasket & High Temp Sealant

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: BGA metal gasket material, high temp silicone sealant, paper gasket material (possibly carbon-based), custom downpipe, laser cut flanges from 10mm mild steel.

3. Steiner Tractor – Exhaust Manifold Gasket Material

Domain: steinertractor.com

Registered: 1997 (28 years)

Introduction: Exhaust Manifold Gasket Material

4. Fel-Pro – Exhaust System Gaskets

Domain: felpro.com

Registered: 1998 (27 years)

Introduction: Fel-Pro exhaust system gaskets are designed to carry away harmful gases from the combustion process, preventing dangerous gases from entering the cabin and cleaning up emissions before they are released into the environment. They provide a reliable seal for exhaust system joints and surfaces, compensating for imperfections such as corrosion and warping. The product range includes: 1. Exhaust Pipe …

5. Ram Gaskets – Graphite Exhaust Gaskets

Domain: ramgaskets.com

Registered: 2010 (15 years)

Introduction: Exhaust Gaskets manufactured from graphite materials. No minimum order quantity; one-off specials available. Custom manufacturing from technical drawings, sketches, samples, .dxf, .pdf, or descriptions. Complete material certification and traceability provided. Quality certifications include BSI ISO 9001:2015 and BSI ISO 14001:2015. Holds ADS SC21 Bronze Award for defense and aerospace supply.

Strategic Sourcing Conclusion and Outlook for exhaust pipe gasket material

In conclusion, strategic sourcing of exhaust pipe gasket materials is pivotal for B2B buyers seeking to optimize performance and reliability in their exhaust systems. Understanding the diverse materials—such as composite graphite, multi-layer steel, and advanced flexible graphite—enables buyers to make informed decisions tailored to their specific applications. The ability to withstand extreme temperatures, resist abrasion, and maintain integrity under thermal cycling are essential characteristics that should guide procurement strategies.

As international markets continue to evolve, especially in regions like Africa, South America, the Middle East, and Europe, sourcing high-quality exhaust gasket materials can significantly enhance operational efficiency and reduce maintenance costs. Emphasizing partnerships with reliable suppliers who understand local needs and global standards will not only ensure product quality but also foster innovation in exhaust system design.

Looking ahead, B2B buyers are encouraged to leverage this knowledge to enhance their sourcing strategies. By prioritizing high-performance materials and establishing strong supplier relationships, businesses can position themselves for success in an increasingly competitive landscape. Engage with industry leaders and explore the latest advancements to stay ahead of market demands and elevate your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.