Unlocking Value: A Strategic Analysis of the Electro Valvulas Market

Introduction: Navigating the Global Market for electro valvulas

In today’s rapidly evolving industrial landscape, sourcing reliable electro válvulas can pose significant challenges for international B2B buyers. With the critical role these devices play in controlling fluid flow across various applications—from manufacturing to energy management—the stakes are high. This comprehensive guide addresses the complexities of navigating the global market for electro válvulas, providing valuable insights into different types, applications, and key considerations for supplier vetting and cost analysis.

Throughout this guide, you will discover the various classifications of electro válvulas, including direct-acting and servo-assisted models, tailored for specific operational needs. We delve into their applications across diverse sectors, such as water treatment, HVAC systems, and pharmaceuticals, ensuring that you understand where these components can deliver the best performance. Moreover, we will outline essential criteria for evaluating suppliers, helping you make informed purchasing decisions that align with your organizational goals.

By empowering international buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Nigeria and Saudi Arabia—this guide serves as a strategic resource. It not only enhances your understanding of electro válvulas but also equips you with the tools necessary to optimize procurement processes, ensuring reliability and efficiency in your operations.

Understanding electro valvulas Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Direct-Acting Solenoid Valves | Operate directly with electrical current; compact design. | Water treatment, HVAC, automotive, and food processing industries. | Pros: Simple design, quick response. Cons: Limited flow capacity. |

| Pilot-Operated Valves | Utilize system pressure to operate; suitable for high flow rates. | Oil and gas, chemical processing, and power generation sectors. | Pros: High flow capability, energy-efficient. Cons: More complex design. |

| NAMUR Valves | Standardized interface for automation; easy to integrate. | Automation in manufacturing, process control, and robotics. | Pros: Interoperable, reduces installation costs. Cons: Limited to specific applications. |

| Two-Way Valves | Control flow in one direction; simple on/off functionality. | General industrial applications, fluid control in pipelines. | Pros: Cost-effective, reliable. Cons: Limited functionality. |

| Three-Way Valves | Allow for flow diversion; can mix or separate fluids. | HVAC systems, chemical mixing, and irrigation systems. | Pros: Versatile, can control multiple flow paths. Cons: More expensive than two-way valves. |

What Are the Characteristics and Suitability of Direct-Acting Solenoid Valves?

Direct-acting solenoid valves are known for their straightforward design, which allows them to operate directly with electrical input. This type is particularly suitable for applications requiring quick and precise control of fluids in systems with lower flow rates. They are commonly used in sectors such as water treatment, HVAC, and food processing. When purchasing, buyers should consider the valve’s response time and compatibility with their existing systems, as these factors can significantly impact operational efficiency.

How Do Pilot-Operated Valves Function and Where Are They Used?

Pilot-operated valves leverage the system’s pressure to control the main flow, making them ideal for high-flow applications. They are typically utilized in industries like oil and gas, chemical processing, and power generation, where large volumes of fluid need to be managed efficiently. Buyers should evaluate the pressure requirements and flow rates of their systems, as pilot-operated valves can provide energy savings and enhanced performance when correctly matched to application demands.

What Advantages Do NAMUR Valves Offer for B2B Automation?

NAMUR valves are designed with a standardized interface that simplifies automation integration in industrial environments. They are particularly advantageous in manufacturing and process control sectors, where interoperability is crucial. Buyers should focus on the ease of installation and maintenance, as NAMUR valves can significantly reduce overall setup costs and improve system reliability. However, their application may be limited to specific automated setups.

Why Choose Two-Way Valves for Basic Fluid Control?

Two-way valves are designed to control the flow of fluids in a single direction, providing a simple on/off functionality. They are widely used in general industrial applications and fluid control systems due to their cost-effectiveness and reliability. When considering a purchase, buyers should assess the specific flow requirements and the environment in which the valve will operate, as these factors influence the valve’s longevity and performance.

What Makes Three-Way Valves Versatile for Complex Applications?

Three-way valves are designed to manage multiple flow paths, allowing for the mixing or separation of fluids. This versatility makes them ideal for HVAC systems, chemical mixing, and irrigation applications. Buyers should consider the complexity of their systems and the specific flow requirements when selecting three-way valves, as they tend to be more expensive but offer greater functionality compared to simpler two-way options.

Key Industrial Applications of electro valvulas

| Industry/Sector | Specific Application of electro valvulas | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water Treatment | Flow control in filtration and distribution systems | Ensures efficient water management, reducing waste and operational costs. | Compatibility with local water quality standards and pressure requirements. |

| HVAC Systems | Regulation of air and gas flow in climate control | Enhances energy efficiency and comfort in buildings, lowering energy bills. | Reliability in varying temperature and humidity conditions. |

| Pharmaceutical Industry | Precise dosing of chemicals and medical gases | Guarantees product quality and safety, complying with strict regulations. | Compliance with pharmaceutical standards and materials compatibility. |

| Energy Production | Management of fuel and steam flow in power plants | Increases operational efficiency and safety in energy generation. | Ability to handle high pressures and temperatures, along with regulatory compliance. |

| Food and Beverage | Automation in processing and packaging lines | Improves product consistency and reduces labor costs through automation. | Hygiene standards and material compatibility with food products. |

How Are Electro Valvulas Used in Water Treatment Systems?

In water treatment facilities, electro valvulas play a crucial role in regulating the flow of water during filtration and distribution processes. They ensure optimal flow rates, which not only enhances the efficiency of treatment systems but also minimizes water wastage. For international buyers, especially from regions like Africa and South America, it is essential to source valves that comply with local water quality standards and can handle specific pressure requirements. This ensures that the systems function effectively within the unique environmental conditions of these regions.

What Role Do Electro Valvulas Play in HVAC Systems?

In HVAC (Heating, Ventilation, and Air Conditioning) systems, electro valvulas are employed to control the flow of air and gases, contributing to the overall climate control of buildings. By regulating airflow, these valves enhance energy efficiency and occupant comfort, ultimately leading to lower energy costs. Buyers from the Middle East and Europe should consider sourcing valves that are reliable under varying temperature and humidity conditions, ensuring consistent performance throughout the year.

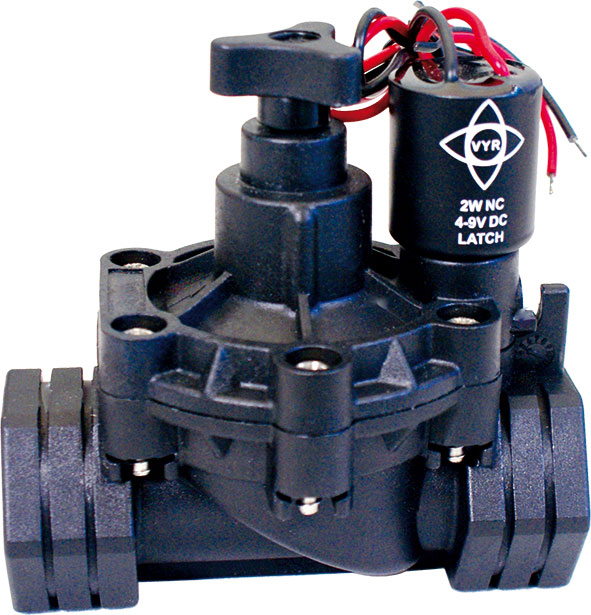

Illustrative image related to electro valvulas

How Are Electro Valvulas Essential in the Pharmaceutical Industry?

In the pharmaceutical sector, electro valvulas are critical for the precise dosing of chemicals and medical gases during manufacturing processes. Their ability to provide accurate flow control is vital for maintaining product quality and safety, especially given the stringent regulations governing the industry. International buyers must focus on sourcing valves that comply with pharmaceutical standards, ensuring that materials used are compatible with the chemicals handled, thereby avoiding contamination.

What Benefits Do Electro Valvulas Provide in Energy Production?

Electro valvulas are integral in energy production, particularly in managing the flow of fuel and steam within power plants. By optimizing these flow rates, they enhance operational efficiency and safety, which is crucial in high-stakes environments like energy generation. For buyers in regions with high energy demands, such as Saudi Arabia, sourcing valves that can withstand high pressures and temperatures while adhering to regulatory standards is essential for maintaining operational integrity.

How Do Electro Valvulas Improve Operations in the Food and Beverage Sector?

In the food and beverage industry, electro valvulas are utilized for automation in processing and packaging lines. They streamline operations by ensuring consistent flow control, which improves product quality and reduces labor costs. Buyers in this sector should prioritize valves that meet hygiene standards and are made from materials compatible with food products, ensuring compliance with health regulations while maintaining efficiency in production processes.

3 Common User Pain Points for ‘electro valvulas’ & Their Solutions

Scenario 1: Inconsistent Performance in Critical Applications

The Problem: B2B buyers often face challenges with electro valvulas that exhibit inconsistent performance, especially in critical applications such as water treatment plants or pharmaceutical manufacturing. These valves are responsible for controlling the flow of fluids, and when they fail to operate reliably, it can lead to significant process interruptions, increased operational costs, and potential regulatory compliance issues. Buyers may find it difficult to identify the root cause of these inconsistencies, whether it be due to poor quality control, inappropriate specifications, or inadequate installation.

The Solution: To mitigate performance issues, buyers should adopt a systematic approach to sourcing and specifying electro valvulas. First, engage with reputable suppliers who have a proven track record in your industry, and ensure that they provide products with robust quality assurance processes. When specifying valves, pay close attention to critical parameters such as the valve’s material compatibility with the fluids being handled, the appropriate pressure and temperature ratings, and the type of actuation required. Additionally, consider investing in valves that feature diagnostic capabilities, allowing for real-time performance monitoring. Proper installation and regular maintenance are equally crucial; ensure that your installation team is well-trained and follows best practices to minimize the risk of future inconsistencies.

Scenario 2: High Energy Costs Due to Inefficient Valve Operation

The Problem: Many B2B buyers are increasingly concerned about energy efficiency, particularly in industries where electro valvulas are integral to large-scale operations. Inefficient valves can lead to excessive energy consumption, driving up costs and contributing to an organization’s carbon footprint. Buyers may struggle to identify which valves are responsible for the inefficiencies, especially in complex systems with multiple fluid control points.

The Solution: To combat high energy costs, buyers should perform a comprehensive audit of their existing valve systems. This involves analyzing flow rates, pressure drops, and energy consumption associated with each electro valvula. When replacing or upgrading valves, opt for energy-efficient models that utilize advanced technologies such as proportional control or variable frequency drives. These technologies allow for better regulation of fluid flow, which can significantly reduce energy usage. Additionally, consider implementing automated control systems that optimize valve operation based on real-time demand, further enhancing energy savings and reducing operational costs.

Scenario 3: Difficulty in Sourcing Compatible Replacement Parts

The Problem: B2B buyers frequently encounter challenges when sourcing compatible replacement parts for their electro valvulas, particularly in regions with limited availability of specific models or brands. This can lead to extended downtime, as buyers struggle to find the correct parts to maintain or repair their systems. The situation is exacerbated in regions like Africa and South America, where logistical issues may delay shipments and increase costs.

The Solution: To streamline the sourcing of replacement parts, buyers should establish strong relationships with multiple suppliers who can provide a diverse range of electro valvulas and associated components. Creating a comprehensive inventory management system that tracks the specific models and part numbers used in your operations can facilitate quicker identification of necessary replacements. Additionally, consider engaging suppliers that offer comprehensive support services, such as technical assistance and expedited shipping options. Investing in modular valve systems can also provide flexibility, allowing for easier upgrades and compatibility with various components, thereby reducing dependency on specific models and enhancing overall system resilience.

Strategic Material Selection Guide for electro valvulas

What Are the Key Materials Used in Electro Valvulas and Their Properties?

Electro valvulas, or solenoid valves, are critical components in various industrial applications, and their performance heavily relies on the materials used in their construction. Understanding the properties, advantages, and limitations of these materials is essential for international B2B buyers, especially those operating in diverse environments such as Africa, South America, the Middle East, and Europe.

How Does Brass Perform as a Material for Electro Valvulas?

Brass is a popular choice for electro valvulas due to its excellent machinability and moderate corrosion resistance. It typically operates effectively at temperatures up to 200°C and pressures around 16 bar.

Pros: Brass is durable and relatively cost-effective, making it suitable for a wide range of applications, including water and air systems. Its good thermal conductivity aids in efficient operation.

Cons: However, brass can corrode in certain environments, particularly in the presence of chlorides, which may limit its use in specific applications, such as seawater or aggressive chemical environments.

Impact on Application: Brass is compatible with water, air, and some gases, but its limitations in corrosive environments should be carefully considered by buyers in regions with high salinity or chemical exposure.

What Are the Benefits of Stainless Steel for Electro Valvulas?

Stainless steel is renowned for its superior corrosion resistance and high strength, making it ideal for demanding applications. It can withstand temperatures up to 300°C and pressures exceeding 20 bar, depending on the grade.

Pros: Its durability and resistance to rust make stainless steel suitable for harsh environments, such as those found in the chemical and pharmaceutical industries. It also complies with various international standards, enhancing its appeal to global buyers.

Cons: The main drawback is its higher cost compared to brass and plastic options, which may deter some buyers, especially in budget-sensitive markets.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive liquids and gases, making it a versatile choice for applications in diverse industries.

Illustrative image related to electro valvulas

Why Choose Plastic for Electro Valvulas?

Plastic materials, such as PVC and PTFE, are increasingly used in electro valvulas due to their lightweight nature and excellent chemical resistance. They can typically handle temperatures up to 80°C and pressures around 10 bar.

Pros: Plastic valves are cost-effective and resistant to a wide range of chemicals, making them suitable for applications in water treatment and chemical processing.

Cons: However, their lower temperature and pressure ratings compared to metals can limit their use in high-demand applications. Additionally, plastics may not provide the same durability as metals in mechanical stress situations.

Impact on Application: Plastic electro valvulas are ideal for handling aggressive chemicals and corrosive environments, particularly in industries where metal corrosion is a concern.

What Role Does Aluminum Play in Electro Valvulas?

Aluminum is another material option for electro valvulas, known for its lightweight and good strength-to-weight ratio. It can typically operate at temperatures up to 150°C and pressures around 10-15 bar.

Pros: The advantages of aluminum include its resistance to corrosion (when anodized) and its relatively low cost compared to stainless steel. It is also highly machinable, allowing for complex designs.

Cons: However, aluminum can be less durable than stainless steel under high-stress conditions and may not be suitable for high-temperature applications without special coatings.

Impact on Application: Aluminum is suitable for applications where weight is a critical factor, such as in mobile equipment or aerospace applications, but its limitations in extreme environments should be considered.

Summary Table of Material Selection for Electro Valvulas

| Material | Typical Use Case for electro valvulas | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Water and air systems | Good machinability and cost-effective | Corrosion in aggressive environments | Medium |

| Stainless Steel | Chemical and pharmaceutical industries | Superior corrosion resistance | Higher cost compared to other materials | High |

| Plastic | Water treatment and chemical processing | Lightweight and chemically resistant | Lower temperature and pressure ratings | Low |

| Aluminum | Mobile equipment and aerospace | Lightweight and good machinability | Less durable under high stress | Medium |

This guide provides a comprehensive overview of the materials commonly used in electro valvulas, allowing B2B buyers to make informed decisions based on their specific application requirements and environmental conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for electro valvulas

What Are the Main Stages of Manufacturing Electro Valvulas?

The manufacturing process of electro valvulas (solenoid valves) is a multi-stage operation that emphasizes precision and quality. Understanding this process is essential for B2B buyers who seek reliable products for their industrial applications.

Material Preparation: What Materials Are Used and How Are They Prepared?

The manufacturing journey begins with material selection, which is crucial for ensuring the durability and functionality of the electro valvulas. Common materials include brass, stainless steel, and various polymers. Each material is chosen based on its suitability for specific applications, such as resistance to corrosion or high temperatures.

Once the materials are selected, they undergo various preparation processes, including cutting, machining, and treating. This may involve processes like heat treatment to enhance strength or surface treatment to improve corrosion resistance. Ensuring the right specifications at this stage is vital for the performance of the final product.

How Are Electro Valvulas Formed and Assembled?

The forming stage involves transforming raw materials into components through techniques such as stamping, casting, and injection molding. For instance, metal parts may be stamped into shape, while plastic components are often produced via injection molding.

After forming, the assembly process begins. This typically involves the integration of various components, such as coils, armatures, and seals, into a cohesive unit. Automated assembly lines are commonly used to enhance efficiency, but manual assembly may also be employed for complex units requiring skilled craftsmanship.

Quality control checkpoints are essential during assembly to ensure that components fit together correctly and that no defects are present.

Illustrative image related to electro valvulas

What Finishing Techniques Are Used for Electro Valvulas?

Finishing processes finalize the electro valvulas, enhancing their appearance and performance. Techniques such as polishing, painting, and anodizing are employed. These not only improve aesthetics but also provide additional protective layers against environmental factors.

Additionally, functional tests are conducted during this stage to ensure that the electro valvulas operate as intended. This includes checking for proper sealing, flow rates, and response times, which are critical for their application in various industries.

What Quality Assurance Standards Are Relevant for Electro Valvulas?

Quality assurance is paramount in the manufacturing of electro valvulas. Buyers should be aware of the relevant international standards that govern the quality and safety of these products.

Illustrative image related to electro valvulas

Which International Standards Should B2B Buyers Consider?

ISO 9001 is a key standard for quality management systems that applies to manufacturers of electro valvulas. It ensures that organizations consistently meet customer and regulatory requirements, enhancing customer satisfaction.

Additionally, industry-specific standards such as CE marking for compliance with European regulations and API standards for valves used in the petroleum industry are crucial. These certifications demonstrate that the products meet strict safety and performance criteria.

How Are Quality Control Checkpoints Implemented in Manufacturing?

Quality control (QC) is integrated throughout the manufacturing process, with several checkpoints established:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing process, periodic checks are conducted to ensure that each stage adheres to quality standards. This includes monitoring the assembly process and conducting tests on random samples.

-

Final Quality Control (FQC): At the end of the manufacturing cycle, finished products undergo rigorous testing to confirm that they meet performance and safety standards. This may involve functionality tests, pressure tests, and durability assessments.

What Testing Methods Are Commonly Used for Electro Valvulas?

B2B buyers should familiarize themselves with the common testing methods employed to ensure the reliability of electro valvulas:

-

Leak Testing: This is essential for verifying that the valves maintain their integrity under pressure and do not allow fluids to escape.

-

Flow Testing: Ensures that the valve performs correctly under specified flow rates, which is critical for applications requiring precise fluid control.

-

Electrical Testing: Involves checking the electrical components of the valve, such as coil resistance and response times, to ensure they function correctly when actuated.

-

Environmental Testing: This assesses the valve’s performance under various environmental conditions, including temperature fluctuations and exposure to corrosive substances.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial to ensure product reliability and compliance.

What Steps Can Buyers Take to Audit Supplier Quality Control?

-

Supplier Audits: Conducting on-site audits allows buyers to assess the supplier’s manufacturing processes, quality control measures, and adherence to international standards. This firsthand experience provides insights into the operational integrity of the supplier.

-

Requesting Quality Reports: Suppliers should be able to provide documentation that outlines their quality control processes, including details of certifications, testing methods, and historical performance data.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control practices. These organizations can conduct testing and inspections on behalf of buyers to ensure compliance with specified standards.

What Are the Nuances of QC and Certification for International B2B Buyers?

Navigating the landscape of quality assurance and certification can be complex for international buyers. Each region may have specific requirements and standards that must be met.

Understanding these nuances is essential for ensuring that the electro valvulas meet the necessary regulations in the buyer’s market. For instance, while CE marking may be critical for European buyers, API certifications may be more relevant for those in the oil and gas sector.

B2B buyers should also consider the potential implications of local regulations in their regions, such as import/export restrictions and safety standards, which can affect their procurement strategies.

By being informed about the manufacturing processes and quality assurance practices for electro valvulas, international B2B buyers can make more educated decisions when sourcing these critical components for their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electro valvulas’

In today’s competitive industrial landscape, sourcing electro valves (electroválvulas) effectively is crucial for optimizing operations and ensuring reliability in fluid control systems. This guide provides a comprehensive checklist for B2B buyers, helping you navigate the procurement process with confidence and precision.

Illustrative image related to electro valvulas

Step 1: Define Your Technical Specifications

Clearly defining your technical specifications is the first step in sourcing electro valves. This includes understanding the required flow rates, pressure ratings, and compatibility with various fluids and gases. By establishing these parameters early, you can streamline the selection process and ensure that the valves meet your operational needs.

- Key Considerations:

- Flow coefficient (Kv) for calculating flow rates.

- Pressure ratings and temperature limits suitable for your application.

Step 2: Research Different Types of Electro Valves

Familiarize yourself with the various types of electro valves available, including direct-acting and pilot-operated models. Each type has unique advantages depending on the application, such as pressure requirements and response times. Understanding these differences can help you select the right valve for your specific needs.

- Types to Consider:

- Direct-acting valves: Suitable for low flow applications.

- Pilot-operated valves: Better for high flow and pressure applications.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Look for established manufacturers with a proven track record in the industry. Request documentation such as company profiles, product certifications, and case studies to assess their reliability.

- What to Check:

- Customer testimonials and reviews from similar industries.

- Certifications such as ISO and industry-specific standards.

Step 4: Request Samples for Testing

Once you have shortlisted suppliers, request samples of the electro valves. Testing these samples in your specific operational environment will help verify their performance and compatibility. This step is critical to avoid costly mistakes later in the procurement process.

- Testing Focus Areas:

- Performance under expected pressure and temperature conditions.

- Response time and operational reliability.

Step 5: Verify Supplier Certifications and Compliance

Ensure that your selected suppliers comply with relevant industry standards and regulations. Certifications can indicate a commitment to quality and safety, which is essential in industries where fluid control is critical.

- Important Certifications:

- CE marking for compliance in Europe.

- Other local certifications relevant to your region or industry.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, focus on negotiating favorable terms and conditions. This includes pricing, delivery schedules, warranty terms, and post-sale support. Clear agreements can prevent misunderstandings and ensure a smoother procurement process.

- Negotiation Tips:

- Discuss bulk purchase discounts if applicable.

- Ensure clarity on lead times and support services.

Step 7: Plan for Long-term Maintenance and Support

Consider the long-term maintenance needs of the electro valves you are purchasing. Establishing a relationship with your supplier for ongoing support and parts availability can greatly enhance the longevity and efficiency of your systems.

- Maintenance Aspects:

- Availability of spare parts and service support.

- Recommendations for routine checks and maintenance schedules.

By following this step-by-step checklist, B2B buyers can ensure a thorough and effective procurement process for electro valves, ultimately leading to enhanced operational efficiency and reliability.

Comprehensive Cost and Pricing Analysis for electro valvulas Sourcing

What Are the Key Cost Components in Electro Valvulas Sourcing?

When sourcing electro valvulas, understanding the cost structure is vital for making informed purchasing decisions. The primary cost components include:

-

Materials: The selection of materials directly influences the cost of electro valvulas. Common materials include brass, stainless steel, and plastics, each offering different levels of durability and resistance to corrosion. High-quality materials often lead to higher upfront costs but can result in lower maintenance and replacement expenses over time.

-

Labor: Labor costs vary significantly based on the manufacturing location. Regions with lower labor costs, such as parts of Asia, may offer competitive pricing. However, the skill level and expertise required for precision manufacturing can influence labor costs, particularly for complex valve designs.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help minimize overhead costs, contributing to more competitive pricing.

-

Tooling: Custom tooling for specific electro valvulas can be a significant cost factor, especially for bespoke designs. Initial tooling costs can be high, but they are typically amortized over larger production runs.

-

Quality Control (QC): Ensuring the reliability and performance of electro valvulas necessitates rigorous quality control processes. These costs include testing, inspection, and certifications, which can vary based on industry standards and regulatory requirements.

-

Logistics: Shipping and handling costs can add a significant percentage to the total cost, especially for international transactions. Factors such as distance, mode of transport, and freight terms influence logistics expenses.

-

Margin: Supplier margins vary depending on market conditions, competition, and the supplier’s positioning in the market. A healthy margin is essential for suppliers to sustain operations and invest in product development.

How Do Price Influencers Affect Electro Valvulas Costs?

Several factors can influence the pricing of electro valvulas, making it essential for buyers to understand their implications:

-

Volume/MOQ: Larger orders generally result in lower per-unit costs due to economies of scale. Establishing a minimum order quantity (MOQ) can also affect pricing; suppliers may offer discounts for bulk purchases.

-

Specifications and Customization: Custom specifications can lead to increased costs. Buyers should balance their specific requirements with available standard options that may provide cost savings.

-

Materials and Quality Certifications: The choice of materials and the certifications required (e.g., ISO, CE) will affect pricing. Higher quality standards often lead to increased costs but can enhance performance and longevity.

-

Supplier Factors: The supplier’s reputation, reliability, and service offerings play a crucial role in pricing. Established suppliers may charge a premium for their products due to their proven track record.

-

Incoterms: Understanding Incoterms is crucial for international buyers as they define the responsibilities of buyers and sellers in shipping, which can significantly impact total costs.

What Are the Best Buyer Tips for Cost-Efficiency in Electro Valvulas Sourcing?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, here are actionable tips to enhance cost-efficiency:

-

Negotiate Effectively: Build strong relationships with suppliers and engage in open discussions about pricing. Leverage your purchasing power, especially if you represent a larger organization or are placing bulk orders.

-

Consider Total Cost of Ownership (TCO): Evaluate not only the purchase price but also the costs associated with installation, maintenance, and potential downtime. Choosing higher-quality products may incur a higher initial cost but can lead to lower TCO over time.

-

Stay Informed About Pricing Nuances: Monitor market trends and pricing fluctuations, particularly in regions of interest. Awareness of economic conditions, supply chain disruptions, or changes in material costs can provide leverage in negotiations.

-

Evaluate Local Suppliers: Investigate local suppliers who may offer competitive pricing without the added logistics costs associated with international shipping. This can enhance lead times and responsiveness.

-

Assess Warranty and Support: A robust warranty and post-sale support can mitigate risks associated with equipment failure. Understanding the terms of warranty can save costs in the long run.

Disclaimer

Prices for electro valvulas are indicative and can vary significantly based on the factors discussed above. It is advisable to obtain multiple quotes and perform a thorough analysis tailored to specific requirements and local market conditions.

Illustrative image related to electro valvulas

Alternatives Analysis: Comparing electro valvulas With Other Solutions

In the industrial landscape, selecting the right technology for fluid control is crucial for optimizing operational efficiency. Among various options available, electro valvulas (solenoid valves) stand out due to their precision and reliability. However, it’s essential to consider alternative solutions that may also meet specific operational needs. This analysis compares electro valvulas with two viable alternatives: pneumatic valves and manual valves, providing insights into their respective advantages and drawbacks.

| Comparison Aspect | Electro Valvulas | Pneumatic Valves | Manual Valves |

|---|---|---|---|

| Performance | High precision and speed in control | Reliable for high-flow applications | Variable, depends on manual operation |

| Cost | Moderate initial investment; low operating cost | Higher initial cost; lower maintenance costs | Low initial cost; higher labor costs |

| Ease of Implementation | Simple installation; requires electrical supply | More complex installation; requires air supply | Straightforward but labor-intensive |

| Maintenance | Low maintenance; occasional cleaning needed | Moderate; requires regular checks | High; frequent manual checks and repairs |

| Best Use Case | Automated processes needing precise control | High-volume systems and heavy-duty applications | Simple applications with low flow requirements |

What Are the Advantages and Disadvantages of Pneumatic Valves Compared to Electro Valvulas?

Pneumatic valves utilize compressed air to operate, making them suitable for high-flow applications. They are highly reliable and can handle larger volumes of fluid, which is beneficial in industries such as manufacturing and energy. However, the complexity of their installation and dependency on a continuous air supply can be seen as drawbacks. Additionally, while their maintenance needs are moderate, they may require more frequent checks than electro valvulas, which can lead to increased operational costs over time.

How Do Manual Valves Compare to Electro Valvulas in Terms of Usability?

Manual valves are often the most cost-effective solution for fluid control. They do not require electricity or compressed air, making them easy to install and maintain. However, their performance is highly dependent on the operator’s skill, leading to potential inefficiencies and errors in flow regulation. While they are best suited for simple applications with low flow requirements, they may not provide the precision needed for more complex automated systems, making them less favorable compared to electro valvulas in high-demand environments.

Conclusion: How Should B2B Buyers Choose the Right Fluid Control Solution?

Choosing the right fluid control solution requires a thorough understanding of operational needs, cost considerations, and the specific characteristics of each technology. Electro valvulas offer high precision and low maintenance, making them ideal for automated processes requiring reliable control. In contrast, pneumatic valves may be preferred in scenarios where high flow and robustness are crucial, while manual valves can serve well in low-cost, less complex applications. B2B buyers should assess their unique requirements, including budget constraints, installation capabilities, and maintenance resources, to make an informed decision that aligns with their operational goals.

Essential Technical Properties and Trade Terminology for electro valvulas

What Are the Key Technical Properties of Electro Valvulas?

When selecting electro valvulas for industrial applications, understanding critical technical properties is essential for ensuring optimal performance and reliability. Here are some key specifications to consider:

Illustrative image related to electro valvulas

-

Material Grade

The material grade of an electro valvula directly influences its durability and compatibility with various fluids. Common materials include brass, stainless steel, and plastic. Each material has specific resistance to corrosion, temperature, and pressure, making it crucial to choose one that aligns with the operational environment. For instance, stainless steel is ideal for harsh chemical applications, while brass may suffice for lower pressure systems. -

Pressure Rating

This specification indicates the maximum pressure that the valve can handle without failure. It is typically measured in bar or psi. Understanding the pressure rating is critical for ensuring safety and functionality, especially in high-pressure environments such as oil and gas or water treatment systems. Selecting a valve with an appropriate pressure rating can prevent leaks and catastrophic failures. -

Flow Coefficient (Kv Value)

The Kv value measures the flow capacity of the valve and is essential for understanding how much fluid can pass through the valve at a specified pressure drop. A higher Kv value indicates a larger flow capacity, which is vital for applications requiring rapid fluid movement. For B2B buyers, knowing the required Kv value helps in selecting the right valve size for efficient operation. -

Actuation Type

Electro valvulas can be operated through various mechanisms, including direct acting and servo-assisted types. Direct acting valves are suited for low flow rates and pressures, while servo-assisted valves are better for larger systems. Understanding the actuation type helps buyers determine the appropriate valve for their specific applications, ensuring efficient control of fluids. -

Temperature Range

The temperature range specifies the operational limits within which the electro valvula can function effectively. It is crucial for applications involving extreme temperatures, such as steam systems or refrigeration. Selecting a valve with the correct temperature rating ensures reliability and prevents premature failure in demanding conditions.

What Are Common Trade Terms Used in the Electro Valvula Industry?

Familiarizing oneself with industry jargon can facilitate smoother transactions and negotiations. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

An OEM produces parts or equipment that may be marketed by another manufacturer. In the electro valvula industry, understanding whether a product is OEM can help buyers evaluate the quality and compatibility of the components with their existing systems. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ can significantly impact budgeting and inventory management, especially for smaller businesses that may not need large quantities. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. It allows buyers to compare pricing and terms from different vendors, ensuring they receive the best value for their investment. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, insurance, and delivery responsibilities, reducing the risk of misunderstandings during the purchasing process. -

Lead Time

Lead time refers to the amount of time from the placement of an order to its delivery. Understanding lead times is critical for project planning and inventory management, especially in industries where downtime can lead to significant losses.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the right electro valvulas for their specific applications and streamline their procurement processes.

Navigating Market Dynamics and Sourcing Trends in the electro valvulas Sector

What Are the Current Market Dynamics and Key Trends Affecting the Electro Valvulas Sector?

The electro valvulas market is witnessing significant growth driven by increased automation across various industries, including manufacturing, water treatment, and energy. The demand for precision control in fluid management is pushing innovations in technology, particularly in the design and functionality of solenoid valves. Key trends include the rise of smart electro valvulas, which integrate IoT capabilities, enabling remote monitoring and control, thereby enhancing operational efficiency and reducing downtime.

Furthermore, international B2B buyers are increasingly prioritizing suppliers that offer not only high-quality products but also robust after-sales support and fast delivery times. In regions like Africa and South America, the growth of infrastructure projects is propelling the demand for reliable electro valvulas, while in the Middle East and Europe, stringent environmental regulations are influencing the adoption of more energy-efficient and environmentally friendly solutions. As a result, manufacturers that can demonstrate compliance with international standards and provide detailed product specifications are gaining a competitive edge.

How Are Sustainability and Ethical Sourcing Changing the Electro Valvulas Landscape?

The conversation around sustainability is reshaping sourcing decisions in the electro valvulas sector. Environmental impact considerations are becoming paramount, with companies increasingly seeking suppliers who prioritize eco-friendly manufacturing processes and materials. Ethical sourcing is not just about compliance; it’s about building a brand that resonates with environmentally conscious consumers and businesses.

Illustrative image related to electro valvulas

Buyers are looking for suppliers that offer ‘green’ certifications, such as ISO 14001 for environmental management systems or certifications for the use of recyclable materials in their products. The trend towards sustainability is also influencing product design, leading to innovations in materials that reduce waste and enhance energy efficiency. For instance, electro valvulas made from recyclable materials or those that minimize energy consumption during operation are becoming highly sought after. This shift not only meets regulatory requirements but also aligns with global sustainability goals, making it a critical factor in purchasing decisions.

What Is the Evolution of Electro Valvulas and Its Impact on B2B Purchasing?

The electro valvulas sector has evolved significantly since its inception, transitioning from basic mechanical valves to sophisticated electro-mechanical devices that offer enhanced control and automation. The introduction of solenoid technology revolutionized fluid control, allowing for more precise and reliable operations. Over the years, advancements in materials and engineering have led to the development of compact and efficient designs suitable for a wide range of applications, including harsh industrial environments.

This evolution has made electro valvulas indispensable in various sectors, including pharmaceuticals, food and beverage, and energy. For B2B buyers, understanding the historical context of these products enhances the ability to assess their current applications and potential future developments. As the industry continues to innovate, staying informed about technological advancements and emerging trends will be crucial for making informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of electro valvulas

-

How do I choose the right electro valvula for my application?

Choosing the right electro valvula involves understanding your specific application requirements, including the type of fluid, pressure range, and flow rate. Identify whether you need a direct-acting or servo-assisted valve based on the pressure differentials in your system. Additionally, consider the materials used in the valve construction to ensure compatibility with the fluids being controlled. It’s also beneficial to consult with suppliers who can provide technical support and recommendations tailored to your needs. -

What are the key factors to consider when sourcing electro valvulas internationally?

When sourcing electro valvulas internationally, key factors include compliance with local regulations, supplier reputation, and product quality. Evaluate the manufacturer’s certifications, such as ISO or CE, which indicate adherence to quality standards. Additionally, consider logistics, including shipping costs and delivery times, as well as payment terms that suit your financial capabilities. Establishing clear communication with suppliers about lead times and after-sales support is also crucial for a successful procurement process. -

What customization options are available for electro valvulas?

Many manufacturers offer customization options for electro valvulas, including size, material, and functionality adjustments. Custom features may include specific voltage requirements, control types (such as manual or automatic), and unique sealing materials for enhanced durability. Discuss your specific application needs with potential suppliers to explore available customization options, ensuring that the final product meets your operational requirements effectively. -

What is the typical minimum order quantity (MOQ) for electro valvulas?

Minimum order quantities (MOQs) for electro valvulas can vary significantly based on the manufacturer and the type of valve. Generally, MOQs range from 10 to 100 units, but some suppliers may offer flexibility for smaller orders. It’s advisable to communicate your needs directly with suppliers to negotiate MOQs that align with your project requirements. Consider potential savings on unit costs when ordering larger quantities, as well as the implications for inventory management. -

What payment terms should I expect when buying electro valvulas internationally?

Payment terms for international purchases of electro valvulas can differ widely among suppliers. Common arrangements include advance payment, letters of credit, or payment upon delivery. Some suppliers may offer net payment terms, allowing a period (e.g., 30 or 60 days) for payment after receipt of goods. Ensure you clearly understand the payment terms and conditions before finalizing your order, and consider using secure payment methods to protect your transaction. -

How can I ensure quality assurance (QA) in my electro valvula purchases?

To ensure quality assurance in your electro valvula purchases, request product certifications and test reports from suppliers. Many reputable manufacturers provide detailed documentation on quality control processes and testing methodologies. Consider performing on-site inspections or third-party audits if possible, especially for large orders. Establishing a good relationship with your supplier can also facilitate better communication regarding quality issues and product performance. -

What are the logistics considerations for importing electro valvulas?

Logistics play a crucial role in importing electro valvulas, including shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder experienced in handling industrial equipment to streamline the shipping process. Be aware of import duties and taxes that may apply in your country, as these can affect overall costs. Additionally, establish clear timelines with your supplier to ensure timely delivery and avoid production delays. -

How do I evaluate potential suppliers for electro valvulas?

Evaluating potential suppliers for electro valvulas involves assessing their experience, product range, and customer feedback. Look for suppliers with a proven track record in your industry and check for certifications that demonstrate compliance with international standards. Request references or case studies from previous clients to gauge reliability and service quality. Conducting thorough due diligence, including financial stability checks, can also provide insights into the supplier’s capability to meet your long-term needs.

Top 3 Electro Valvulas Manufacturers & Suppliers List

1. Burkert – Electroválvulas

Domain: burkert.es

Introduction: Una electroválvula es una válvula electromecánica utilizada para controlar el caudal de líquidos o gases. Existen dos tipos principales: electroválvulas servoasistidas, que utilizan la presión de línea para abrir y cerrar el orificio principal, y electroválvulas de acción directa, que abren o cierran el orificio directamente. Funcionan mediante un émbolo que se mueve al energizar una bobina con co…

2. Valvulas Arco – Electroválvulas para Control de Fluidos

Domain: valvulasarco.com

Registered: 2003 (22 years)

Introduction: Una electroválvula es un dispositivo electromecánico que controla el flujo de fluidos, especialmente agua, en circuitos. Funciona con posiciones de abierto y cerrado, moviéndose mediante una bobina solenoide. Existen dos tipos principales:

1. Directas: Usadas en lavadoras, lavaplatos y sistemas de riego, requieren un solenoide y un muelle para su funcionamiento.

2. Asistidas: Controladas por un …

3. Distritec – Electroválvulas Automatizadas

Domain: distritec.com.ar

Registered: 2013 (12 years)

Introduction: Las electroválvulas son dispositivos que responden a pulsos eléctricos, permitiendo abrir o cerrar válvulas para controlar el flujo de fluidos. Funcionan mediante un solenoide que genera un campo magnético, atrayendo un núcleo móvil. Son ideales para la automatización industrial y se utilizan en sistemas que manejan agua, aire, vapor, aceites livianos, gases neutros, entre otros. Se aplican en sur…

Strategic Sourcing Conclusion and Outlook for electro valvulas

In the evolving landscape of industrial automation, strategic sourcing of electro válvulas emerges as a crucial factor for businesses aiming to enhance efficiency and reliability. By prioritizing quality and supplier partnerships, organizations can ensure optimal performance in critical applications such as water treatment, HVAC systems, and energy management. The diverse range of electro válvulas available today allows for tailored solutions that meet specific operational needs, helping companies reduce downtime and improve productivity.

As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe navigate their sourcing strategies, understanding the nuances of electro válvula technology becomes essential. Investing in high-quality, reliable products not only supports operational excellence but also fosters long-term relationships with reputable suppliers who provide ongoing support and innovation.

Looking ahead, the demand for electro válvulas is set to grow, driven by advancements in automation and an increasing emphasis on sustainability. Now is the time to engage with trusted suppliers and explore cutting-edge solutions that can propel your business forward. Take action today to secure a competitive edge in your industry by making informed sourcing decisions that align with your operational goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.