Unlocking Value: A Strategic Analysis of the Electric Motor Parts Market

Introduction: Navigating the Global Market for electric motor parts

Navigating the complex landscape of the global market for electric motor parts can be a daunting task for B2B buyers, especially when faced with the challenge of sourcing high-quality components that meet specific operational needs. As industries across Africa, South America, the Middle East, and Europe increasingly rely on electric motors for efficiency and performance, understanding the nuances of electric motor parts becomes essential. This guide aims to demystify the sourcing process by covering a broad spectrum of topics, including the various types of electric motor parts, their applications in diverse sectors, and crucial factors for vetting suppliers effectively.

By diving into the specifics of electric motor components—ranging from OEM parts to thermal protectors, and sensors to cooling fans—this guide equips international buyers with the knowledge needed to make informed purchasing decisions. With insights into cost considerations, quality standards, and supplier reliability, B2B buyers will be empowered to enhance their procurement strategies and optimize their supply chains. Whether you are operating in demanding industries such as oil and gas, manufacturing, or transportation, this comprehensive resource will help you navigate the global marketplace with confidence and precision, ensuring that your operations remain efficient and competitive.

Understanding electric motor parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stators | Stationary part, houses windings and core | Industrial machinery, HVAC systems | Pros: High durability; Cons: Complex to replace. |

| Rotors | Rotating component, can be squirrel cage or wound | Electric vehicles, pumps, compressors | Pros: Efficient power transfer; Cons: Requires precise alignment. |

| Bearings | Support and reduce friction between rotating parts | Manufacturing, automotive, aerospace | Pros: Enhances longevity; Cons: Varies in cost and maintenance needs. |

| Cooling Fans | Used to dissipate heat, often integrated with motors | Power generation, mining, HVAC | Pros: Improves motor performance; Cons: Can add to overall system complexity. |

| Thermal Protectors | Prevents overheating by interrupting power flow | Manufacturing, automotive, HVAC | Pros: Increases safety; Cons: May require recalibration after activation. |

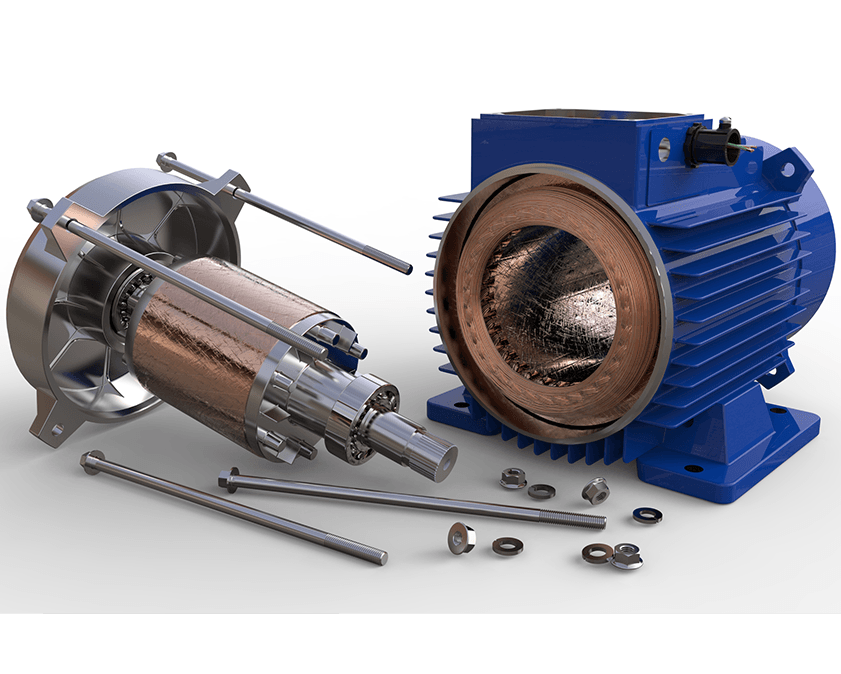

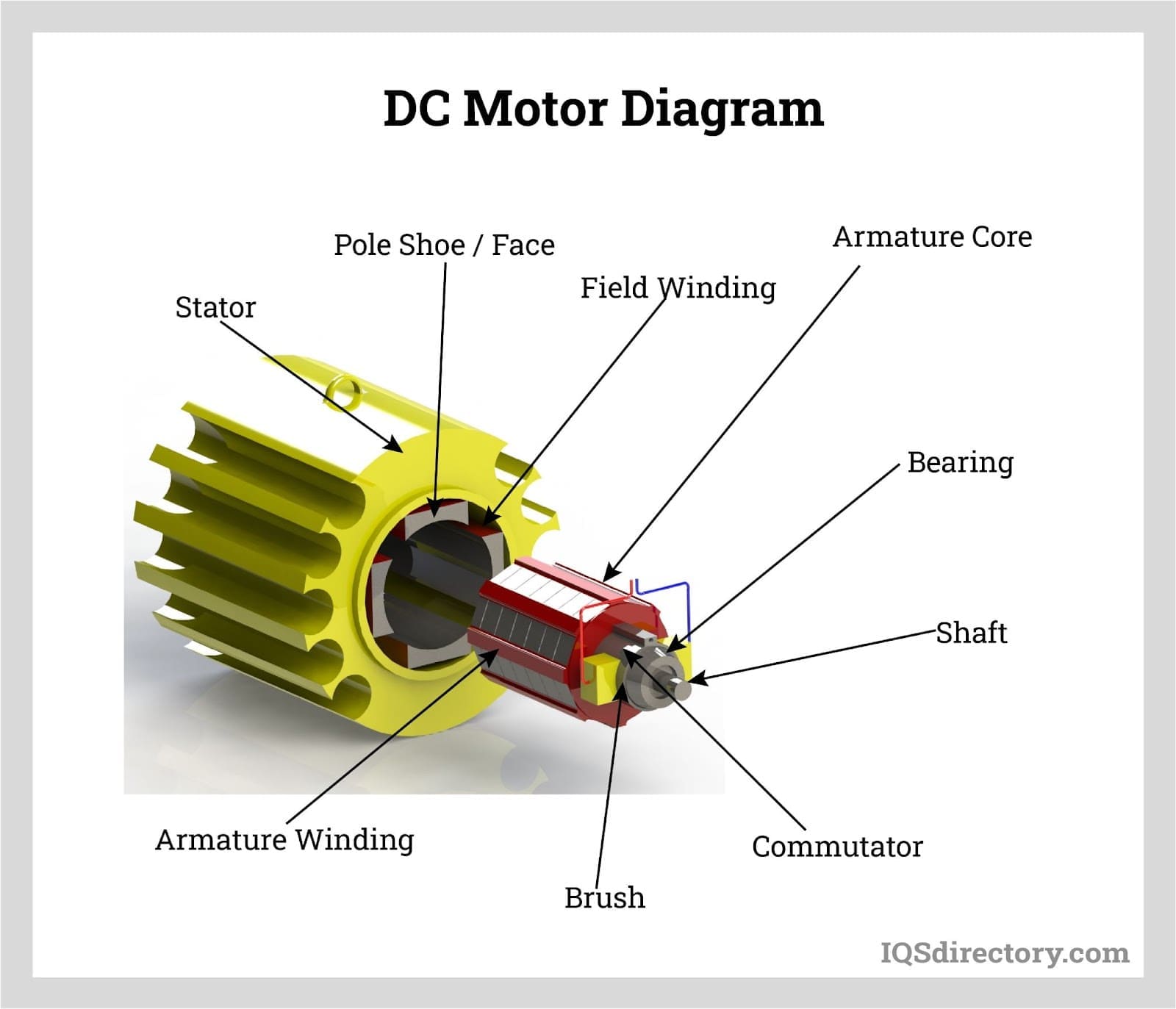

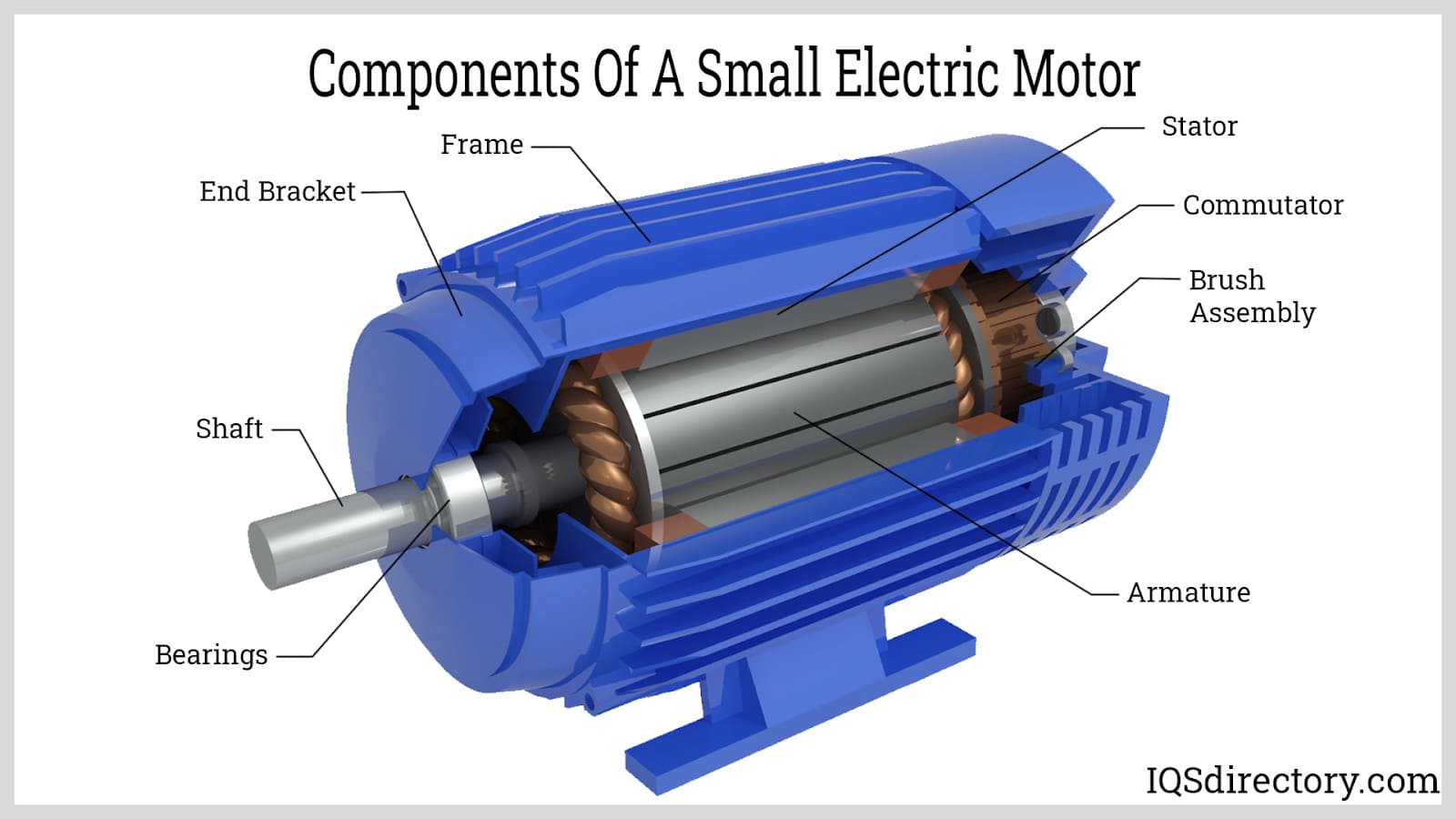

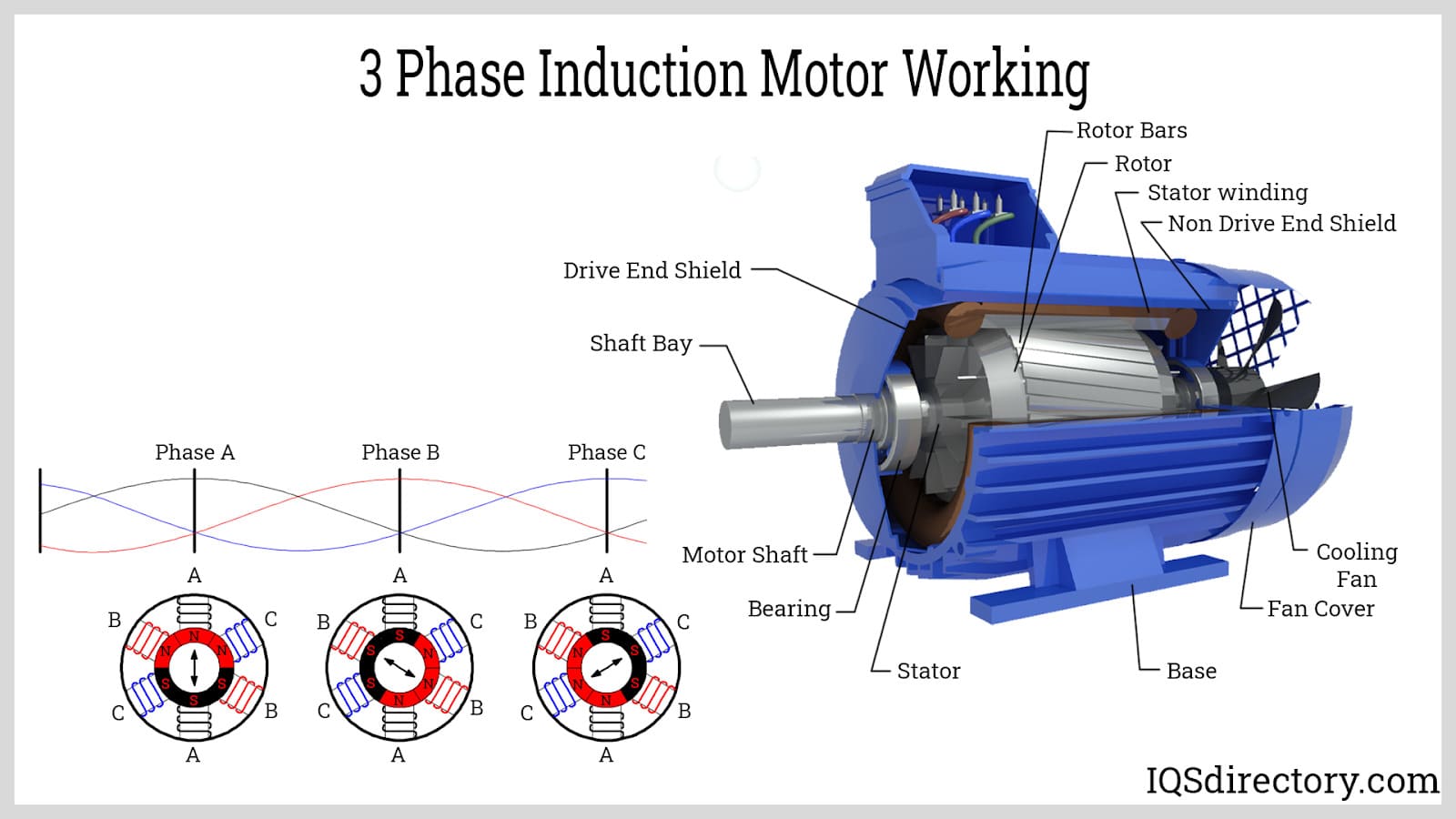

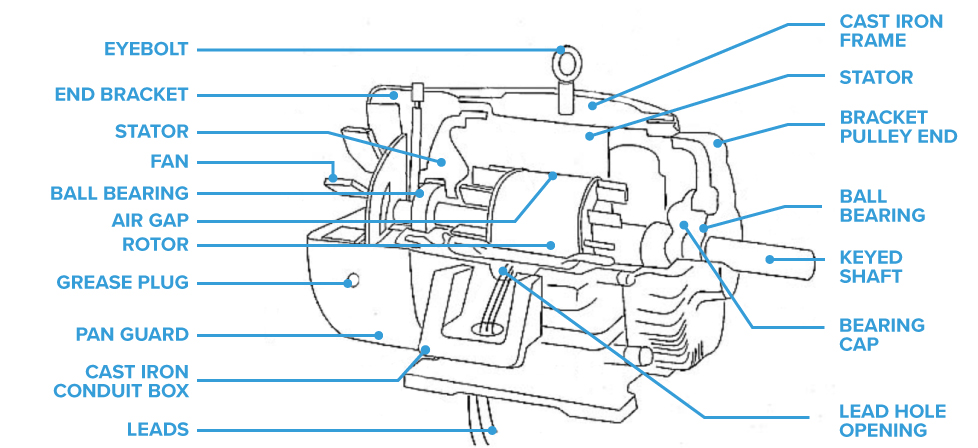

What Are the Characteristics and Suitability of Stators in Electric Motors?

Stators are the stationary parts of electric motors, consisting of windings and a core. They play a critical role in generating the magnetic field necessary for motor operation. Stators are commonly used in industrial machinery and HVAC systems, where reliability is paramount. When purchasing stators, B2B buyers should consider the motor’s voltage rating, winding type, and insulation class to ensure compatibility with their applications.

How Do Rotors Function and What Are Their Key Applications?

Rotors are the rotating components of electric motors, which can be either squirrel cage or wound types. Their design significantly influences the motor’s efficiency and torque output. Commonly found in electric vehicles, pumps, and compressors, rotors must be selected based on the required speed and load capacity. Buyers should focus on rotor material and design to optimize performance for their specific industrial needs.

Why Are Bearings Essential for Electric Motors?

Bearings are critical components that support the rotating parts of electric motors while minimizing friction. Their performance directly affects the motor’s efficiency and lifespan, making them essential in manufacturing, automotive, and aerospace applications. When sourcing bearings, B2B buyers should evaluate load ratings, lubrication types, and maintenance requirements to ensure they meet operational demands.

How Do Cooling Fans Contribute to Motor Performance?

Cooling fans are essential for dissipating heat generated during motor operation. They are often integrated into electric motors to enhance performance in environments like power generation and mining. Buyers must consider fan size, airflow capacity, and noise levels when selecting cooling fans, as these factors can impact overall system efficiency and reliability.

What Role Do Thermal Protectors Play in Motor Safety?

Thermal protectors are safety devices that prevent electric motors from overheating by interrupting the power supply when temperatures exceed safe limits. They are widely used in manufacturing, automotive, and HVAC applications. B2B buyers should assess the thermal protector’s response time and reset features, as these factors influence the device’s effectiveness and ease of use in preventing motor damage.

Key Industrial Applications of electric motor parts

| Industry/Sector | Specific Application of Electric Motor Parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Conveyor Systems | Increases efficiency and reduces downtime in production lines. | Ensure compatibility with existing systems and local regulations. |

| Oil & Gas | Pumping Systems | Enhances reliability and performance in harsh environments. | Look for durable materials and parts that meet industry standards. |

| Mining | Electric Drive Systems | Improves operational efficiency and safety in extraction processes. | Consider sourcing from suppliers with robust quality assurance. |

| Agriculture | Irrigation Systems | Optimizes water usage and enhances crop yield. | Evaluate energy efficiency ratings and availability of replacements. |

| Transportation | Electric Locomotives | Reduces operational costs and environmental impact. | Assess the availability of parts for maintenance and upgrades. |

How Are Electric Motor Parts Used in Manufacturing Conveyor Systems?

In manufacturing, electric motor parts play a crucial role in conveyor systems, which are essential for transporting materials efficiently across production lines. These motors drive the conveyor belts, ensuring a continuous flow of products, thereby increasing overall productivity. For international B2B buyers, sourcing motors that are compatible with existing systems and adhere to local safety and quality regulations is vital. Additionally, the availability of replacement parts is a critical consideration to minimize downtime.

What Role Do Electric Motor Parts Play in Oil & Gas Pumping Systems?

In the oil and gas industry, electric motor parts are integral to pumping systems that transport crude oil and natural gas. These motors must withstand extreme conditions, providing reliable performance and minimizing the risk of failures that can lead to costly downtime. Buyers in this sector should prioritize sourcing durable materials and components that meet industry standards, ensuring long-term operational efficiency and safety in challenging environments.

与electric motor parts相关的说明性图片

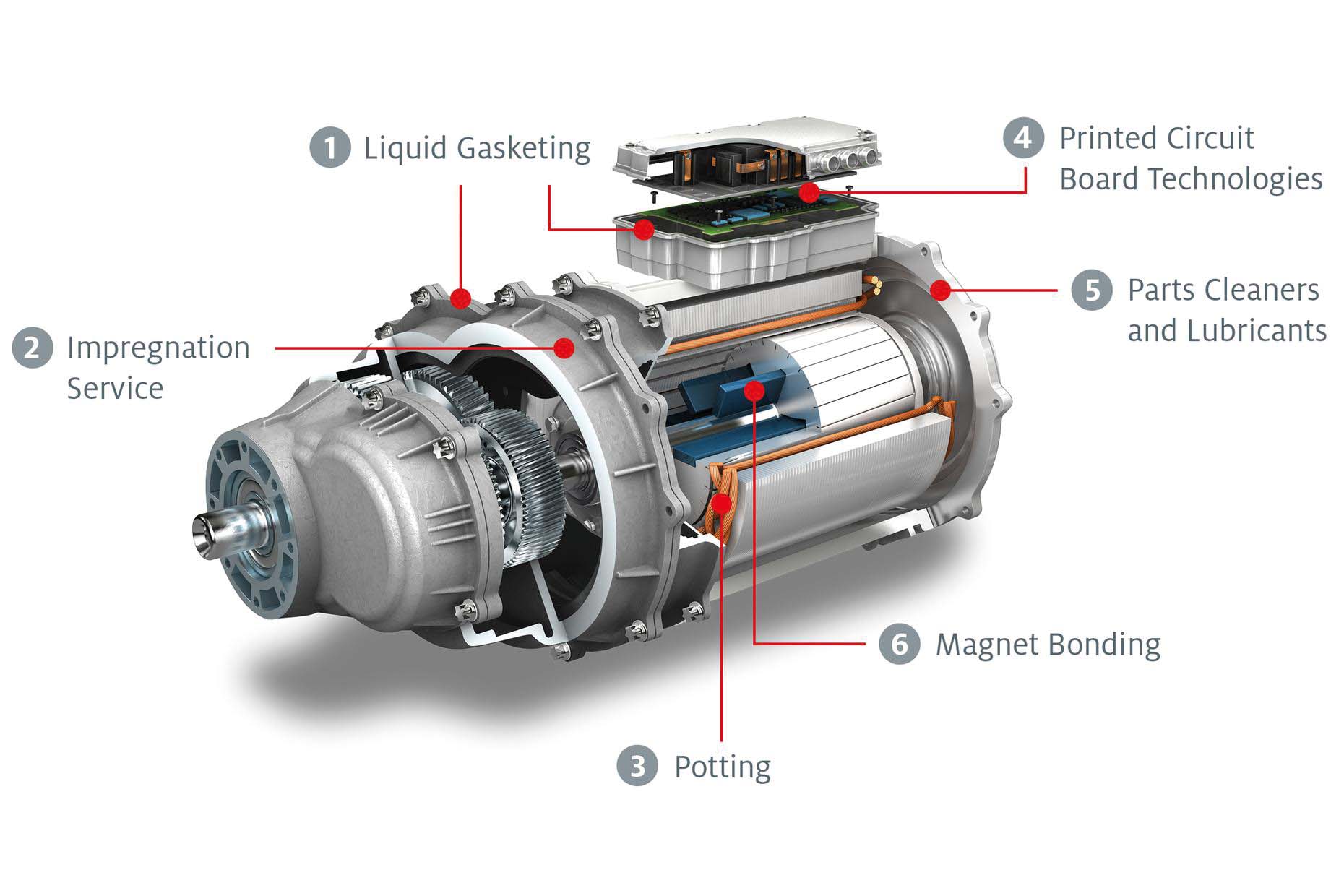

How Are Electric Motor Parts Essential in Mining Electric Drive Systems?

Electric drive systems in mining operations utilize electric motor parts to power machinery for ore extraction and processing. The reliability and efficiency of these motors directly impact productivity and safety on-site. For B2B buyers, sourcing from suppliers who offer robust quality assurance and have experience in the mining sector is essential to ensure that the motors can handle heavy loads and harsh conditions.

Why Are Electric Motor Parts Important for Agricultural Irrigation Systems?

Electric motor parts are vital in agricultural irrigation systems, driving pumps that optimize water distribution for crop cultivation. These motors contribute to efficient water usage, promoting sustainability and enhancing crop yields. Buyers should consider energy efficiency ratings when sourcing these parts, as well as the availability of replacement components to ensure uninterrupted operations throughout the growing season.

How Do Electric Motor Parts Contribute to Transportation in Electric Locomotives?

In the transportation sector, electric locomotives rely on electric motor parts to provide the necessary power for movement. These motors help reduce operational costs and lower environmental impact compared to traditional fuel-based systems. B2B buyers should assess the availability of parts for ongoing maintenance and potential upgrades, ensuring that their locomotives remain efficient and compliant with evolving environmental regulations.

3 Common User Pain Points for ‘electric motor parts’ & Their Solutions

Scenario 1: Sourcing Quality Electric Motor Parts in Remote Locations

The Problem: B2B buyers in regions such as Africa or South America often face significant challenges when sourcing high-quality electric motor parts. Limited access to suppliers, coupled with long lead times and inflated shipping costs, can hinder operational efficiency. Businesses relying on electric motors for critical processes may experience downtime, which translates into lost revenue and productivity. Furthermore, the risk of receiving substandard or counterfeit parts increases when options are limited, jeopardizing the longevity of their equipment.

The Solution: To effectively source quality electric motor parts, buyers should establish relationships with reputable suppliers who have a proven track record in international shipping and customer service. Utilizing online platforms that specialize in electric motor components can help streamline this process. It’s crucial to vet suppliers by reviewing their certifications and customer testimonials. Buyers should also inquire about the availability of OEM (Original Equipment Manufacturer) parts, as these ensure compatibility and reliability. Implementing a just-in-time inventory strategy can mitigate the impact of long lead times, allowing businesses to maintain a steady supply without overstocking. Additionally, consider collaborating with local distributors who can provide insights into reliable international suppliers and assist in logistics.

Scenario 2: Navigating Technical Specifications for Electric Motor Parts

The Problem: Many B2B buyers struggle with understanding the technical specifications of electric motor parts. This issue often arises when companies attempt to replace components without adequate knowledge of the motor’s requirements. Misunderstanding specifications such as voltage ratings, horsepower, or thermal protection can lead to incorrect part selections, resulting in further complications, including equipment malfunction and increased maintenance costs.

The Solution: To overcome this challenge, buyers should invest time in training or workshops that focus on the technical aspects of electric motors and their components. This education can be provided through partnerships with suppliers who offer technical support and documentation. Additionally, utilizing detailed datasheets and manuals available from manufacturers can clarify specifications. When sourcing parts, engage in discussions with technical representatives from suppliers to ensure that selected components meet operational needs. Creating a checklist of essential specifications for each motor type can serve as a reference guide during the procurement process. Furthermore, implementing a systematic approach to document and track the specifications of existing motors can streamline future replacement part purchases.

Scenario 3: Reducing Downtime Due to Electric Motor Failures

The Problem: Downtime caused by electric motor failures can significantly impact a company’s bottom line, especially in industries such as manufacturing or energy. B2B buyers often find themselves in a reactive position, scrambling to replace parts without a contingency plan. This lack of preparedness can lead to delays in production schedules and increased operational costs, straining relationships with clients and stakeholders.

The Solution: To mitigate downtime, businesses should adopt a proactive maintenance strategy that includes regular inspections and predictive maintenance techniques. This approach involves monitoring key performance indicators and utilizing diagnostic tools to detect potential failures before they occur. Additionally, maintaining a stock of critical electric motor parts—such as bearings, brushes, and thermal protectors—can expedite repairs. Establishing a partnership with a reliable supplier that offers fast shipping and emergency support can also enhance response times. Implementing a comprehensive inventory management system will help track parts usage and alert buyers when to reorder, ensuring that essential components are always on hand. Regular training for maintenance staff on troubleshooting and repair techniques can further reduce response times during emergencies.

Strategic Material Selection Guide for electric motor parts

What Are the Key Materials Used in Electric Motor Parts?

When selecting materials for electric motor parts, several factors must be considered, including performance characteristics, cost, and manufacturing complexity. This analysis focuses on four common materials: aluminum, steel, copper, and thermoplastics. Each material has unique properties that affect its suitability for various components in electric motors.

How Does Aluminum Benefit Electric Motor Parts?

Aluminum is a popular choice for electric motor components, particularly in housing and fan applications. It is lightweight and has excellent thermal conductivity, which is crucial for heat dissipation in motors. Aluminum also exhibits good corrosion resistance, making it suitable for various environments.

Pros: The lightweight nature of aluminum contributes to improved energy efficiency and reduced operational costs. Its excellent machinability allows for complex designs, which can enhance performance.

Cons: While aluminum is durable, it may not withstand high-stress applications as well as other materials like steel. Additionally, the initial cost can be higher than some alternatives, although this is often offset by long-term savings in energy efficiency.

Application Impact: Aluminum’s thermal properties make it ideal for applications requiring effective heat management, such as cooling fans in electric motors.

Considerations for International Buyers: Buyers should ensure compliance with international standards like ASTM and DIN, particularly in regions like Europe and the Middle East, where regulations may be more stringent.

与electric motor parts相关的说明性图片

What Role Does Steel Play in Electric Motor Parts?

Steel is a traditional choice for electric motor parts, particularly in structural components such as shafts and frames. It is known for its high strength and durability, making it suitable for heavy-duty applications.

Pros: Steel offers superior strength and resistance to wear, making it ideal for components subjected to high stress. Its cost-effectiveness is also a significant advantage, particularly for large-scale manufacturing.

Cons: The primary drawback of steel is its weight, which can lead to increased energy consumption in motor applications. Additionally, steel is susceptible to corrosion unless properly treated.

Application Impact: Steel’s robustness makes it suitable for high-torque applications, ensuring reliable performance in demanding environments.

Considerations for International Buyers: Buyers should be aware of the need for corrosion-resistant coatings in humid or corrosive environments, particularly in regions like Africa and South America, where environmental conditions can vary significantly.

How Does Copper Enhance Electric Motor Efficiency?

Copper is widely used in electric motor windings due to its excellent electrical conductivity. This property is vital for efficient energy transfer within the motor.

Pros: Copper’s high conductivity results in lower energy losses, enhancing the overall efficiency of the motor. It also has good thermal conductivity, which aids in heat dissipation.

Cons: Copper is relatively expensive compared to aluminum and can be prone to corrosion if not properly insulated. Additionally, its density can add weight to motor components.

与electric motor parts相关的说明性图片

Application Impact: The efficiency provided by copper makes it particularly suitable for applications where energy savings are critical, such as in electric vehicles or renewable energy systems.

Considerations for International Buyers: Compliance with electrical standards and regulations, such as those set by the International Electrotechnical Commission (IEC), is crucial for ensuring the performance and safety of copper components in electric motors.

What Advantages Do Thermoplastics Offer for Electric Motor Parts?

Thermoplastics are increasingly being used in electric motor applications, especially for insulation and non-structural components. They offer versatility and can be molded into complex shapes.

Pros: Thermoplastics are lightweight and resistant to corrosion and chemicals, making them suitable for various environments. They are also cost-effective and can be produced quickly.

与electric motor parts相关的说明性图片

Cons: While thermoplastics are durable, they may not withstand high temperatures as effectively as metals, limiting their use in certain high-heat applications.

Application Impact: Their insulating properties make thermoplastics ideal for components that require electrical insulation, enhancing safety and efficiency.

Considerations for International Buyers: Buyers should ensure that thermoplastics meet relevant international standards for electrical insulation and thermal resistance, particularly in regions with stringent regulations.

Summary of Material Selection for Electric Motor Parts

| Material | Typical Use Case for electric motor parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housing, cooling fans | Lightweight, excellent thermal conductivity | Less durable under high stress | Medium |

| Steel | Shafts, frames | High strength, cost-effective | Heavy, prone to corrosion | Low |

| Copper | Windings | Excellent electrical conductivity | Expensive, heavy | High |

| Thermoplastics | Insulation, non-structural components | Lightweight, corrosion-resistant | Limited high-temperature performance | Medium |

This strategic material selection guide provides insights for international B2B buyers, helping them make informed decisions based on the specific needs of their electric motor applications.

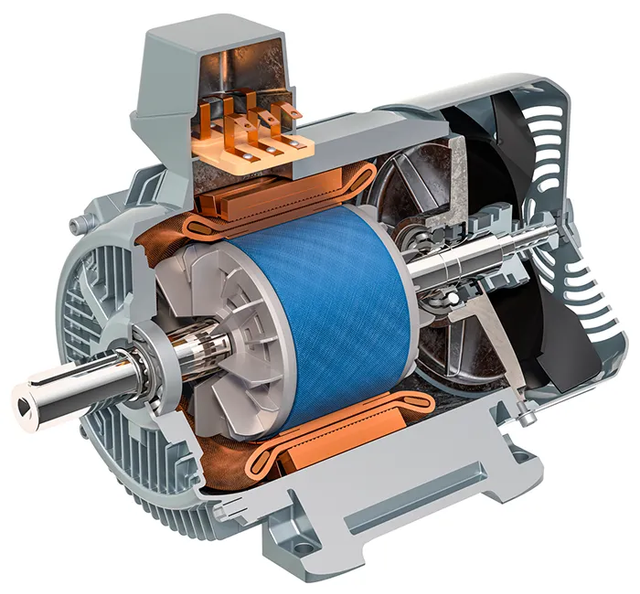

In-depth Look: Manufacturing Processes and Quality Assurance for electric motor parts

What Are the Main Stages of Manufacturing Electric Motor Parts?

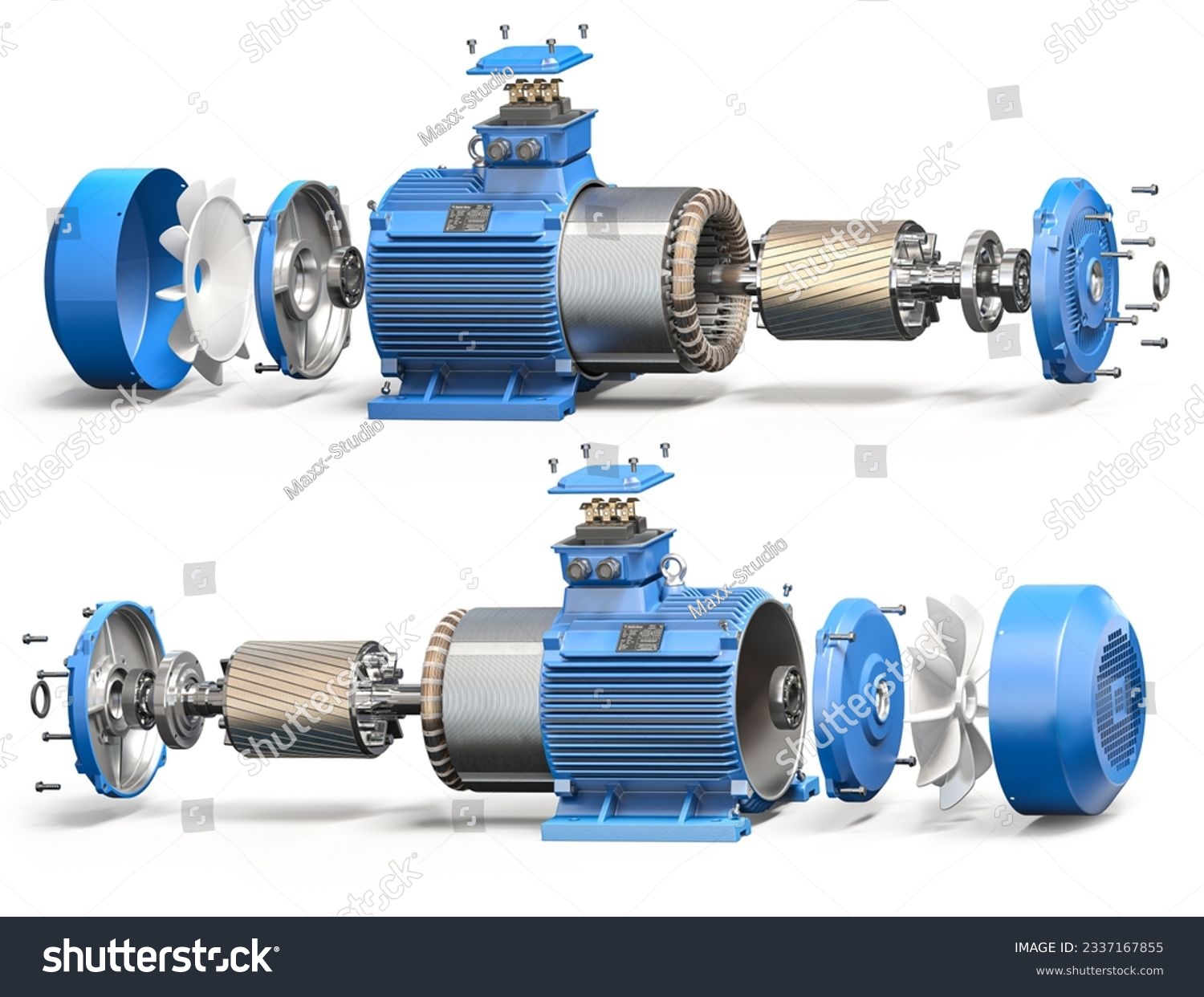

The manufacturing of electric motor parts involves several critical stages that ensure the final product meets the required performance and quality standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step in the manufacturing process is selecting high-quality raw materials such as copper, aluminum, and steel. These materials are often sourced from certified suppliers to ensure compliance with international standards. Once selected, the materials undergo various treatments, including cutting, bending, and surface preparation, to enhance their properties and suitability for use in electric motors.

-

Forming: In this stage, the prepared materials are shaped into specific components. Techniques such as stamping, forging, and machining are commonly employed. For instance, rotor laminations are typically stamped from sheets of electrical steel, while the motor shafts may be machined to precise specifications. The use of CNC (Computer Numerical Control) machines allows for high precision and repeatability in producing complex geometries.

-

Assembly: Once the individual components are formed, they are assembled into the final motor unit. This process often involves the use of automated assembly lines that can increase efficiency and reduce human error. Key components, such as the stator, rotor, and bearings, are carefully aligned and secured using fasteners or adhesives. This stage is critical as it influences the overall performance and reliability of the electric motor.

-

Finishing: The final stage involves surface treatment processes such as painting, coating, or plating to enhance corrosion resistance and aesthetic appeal. Finishing processes also include inspection and testing to ensure that all components meet the specified tolerances and performance criteria.

Which Key Techniques Are Utilized in Electric Motor Parts Manufacturing?

The manufacturing of electric motor parts incorporates various advanced techniques to enhance efficiency, quality, and performance. Some of the key techniques include:

-

Precision Machining: This technique is crucial for producing components with tight tolerances. Machining processes such as turning, milling, and grinding are employed to achieve the required dimensions for parts like shafts and housings.

-

Winding Techniques: For electric motors, winding the coils is a vital process that directly affects efficiency. Techniques such as automatic winding machines and hand winding are used, depending on the complexity and type of motor.

-

Heat Treatment: Heat treatment processes like annealing and hardening are used to improve the mechanical properties of the materials used in motor components, ensuring longevity and performance under operational stress.

-

3D Printing: Although still emerging in the electric motor sector, additive manufacturing techniques are being explored for rapid prototyping and producing complex geometries that traditional methods may struggle to achieve.

How Is Quality Assurance Implemented in Electric Motor Parts Manufacturing?

Quality assurance (QA) is essential in the manufacturing of electric motor parts to ensure that products meet both customer expectations and regulatory requirements. The implementation of QA involves adhering to international and industry-specific standards, as well as establishing robust quality control (QC) checkpoints throughout the manufacturing process.

-

International Standards: Compliance with international standards such as ISO 9001 is crucial for manufacturers aiming to export electric motor parts. ISO 9001 focuses on quality management systems and emphasizes customer satisfaction, process improvement, and regulatory compliance.

-

Industry-Specific Standards: Depending on the application, additional certifications may be required. For example, motors used in hazardous environments may need to comply with ATEX or IECEx standards. Similarly, products intended for use in the oil and gas sector might need to meet API specifications.

-

Quality Control Checkpoints: The QC process typically includes several checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Continuous monitoring during manufacturing to identify defects early and minimize waste.

– Final Quality Control (FQC): Comprehensive testing of the finished product against performance specifications before shipment. -

Common Testing Methods: Various testing methods are employed to assess the quality of electric motor parts. These may include electrical testing (insulation resistance, continuity), mechanical testing (tensile strength, fatigue), and thermal testing (temperature rise under load).

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial to ensure product reliability and compliance with local regulations.

-

Supplier Audits: Conducting on-site audits of potential suppliers allows buyers to assess their manufacturing capabilities, quality management systems, and adherence to industry standards. This firsthand evaluation can provide invaluable insights into the supplier’s commitment to quality.

-

Requesting Documentation: Buyers should request documentation such as quality manuals, inspection reports, and certificates of compliance with international standards. This paperwork serves as evidence of the supplier’s quality assurance processes.

-

Third-Party Inspections: Engaging third-party inspection services can offer an objective assessment of the supplier’s manufacturing processes and product quality. This is especially important for buyers dealing with suppliers in regions where regulatory compliance may vary.

-

Understanding Certification Nuances: Different regions may have specific certification requirements. For instance, a product certified in Europe may not automatically meet the standards required in Saudi Arabia or Nigeria. Buyers should ensure that suppliers possess the necessary certifications for their specific markets.

What Are the Challenges and Considerations for International B2B Buyers?

International B2B buyers must navigate various challenges when sourcing electric motor parts, including:

-

Cultural Differences: Understanding cultural nuances can improve communication and negotiation processes with suppliers in different regions.

-

Logistical Considerations: Factors such as shipping times, customs regulations, and tariffs can impact supply chain efficiency. Buyers should work closely with logistics partners to ensure smooth operations.

-

Regulatory Compliance: Staying informed about the regulatory landscape in both the supplier’s and buyer’s countries is essential to avoid compliance issues that could lead to product recalls or penalties.

By focusing on these aspects, B2B buyers can effectively engage with suppliers, ensuring they receive high-quality electric motor parts that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric motor parts’

Introduction

This guide serves as a comprehensive checklist for B2B buyers looking to source electric motor parts effectively. Given the critical role that these components play in various industrial applications, it is essential to approach procurement with a strategic mindset. By following these steps, you can ensure that you select the right parts from reputable suppliers, ultimately supporting your operational efficiency and reliability.

1. Define Your Technical Specifications

Begin by outlining the exact specifications required for your electric motor parts. This includes dimensions, material types, voltage ratings, and any compliance with industry standards. Clear specifications help in narrowing down potential suppliers who can meet your exact needs.

与electric motor parts相关的说明性图片

- Consider the application: Different applications may require specific features, such as corrosion resistance for marine applications or high efficiency for energy-sensitive environments.

2. Identify Your Budget

Establish a budget for your procurement process. Understanding your financial constraints will guide your sourcing decisions and help you negotiate effectively with suppliers.

- Account for additional costs: Be mindful of shipping, customs duties, and potential tariffs, especially if sourcing from international suppliers.

3. Research and Shortlist Potential Suppliers

Conduct thorough research to identify suppliers with a strong reputation in the electric motor parts market. Look for companies that specialize in the specific parts you need and have a history of reliability.

- Check for certifications: Ensure that suppliers have relevant certifications, such as ISO 9001, which indicate adherence to quality management standards.

4. Evaluate Supplier Capabilities

Before making a commitment, assess the capabilities of your shortlisted suppliers. This includes their production capacity, lead times, and the variety of parts they offer.

- Request samples: If possible, obtain samples of the parts to evaluate quality and compatibility with your existing systems.

5. Verify Supplier Certifications

Ensure that your chosen suppliers are certified to meet international quality standards. Certifications such as CE, UL, or RoHS compliance indicate that the parts have been tested for safety and environmental impact.

- Ask for documentation: Request copies of certifications and compliance reports to ensure transparency and accountability.

6. Negotiate Terms and Conditions

Engage in negotiations to establish favorable terms, including pricing, payment options, and delivery schedules. Clear communication at this stage helps prevent misunderstandings later.

- Discuss warranties and support: Understand the warranty terms for the parts, as well as the availability of technical support or after-sales service.

7. Finalize the Order and Monitor Delivery

Once you are satisfied with the negotiated terms, finalize your order. Keep in constant communication with your supplier to monitor the delivery process and address any issues that may arise.

- Implement tracking systems: Use tracking systems to monitor shipment status and ensure timely delivery, which is crucial for maintaining your operational timelines.

By following this practical checklist, B2B buyers can enhance their sourcing strategy for electric motor parts, ensuring quality, compliance, and cost-effectiveness in their procurement process.

Comprehensive Cost and Pricing Analysis for electric motor parts Sourcing

What Are the Key Cost Components in Sourcing Electric Motor Parts?

When sourcing electric motor parts, understanding the cost structure is essential for effective budgeting and decision-making. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. High-quality metals, insulating materials, and specialized components like thermistors or RTD sensors can be more expensive but are crucial for durability and performance.

-

Labor: Labor costs vary by region and complexity of manufacturing. Skilled labor for assembly and quality control often comes at a premium, especially in countries with higher wage standards.

-

Manufacturing Overhead: This includes utilities, maintenance, and factory costs. Efficient manufacturers may have lower overhead costs, which can translate to competitive pricing for buyers.

-

Tooling: Initial setup costs for custom parts can be substantial. Tooling expenses must be factored into the overall cost, particularly for specialized components that require unique manufacturing processes.

-

Quality Control (QC): Investing in quality assurance processes ensures that parts meet specifications and certifications. This may increase costs but can save buyers from future expenses related to failures or recalls.

-

Logistics: Shipping and handling can add significant costs, especially for international orders. Understanding the logistics involved, including tariffs and freight charges, is vital for accurate budgeting.

-

Margin: Suppliers will build a margin into their pricing. The level of competition in the market can influence these margins, with more competitive sectors typically offering lower prices.

How Do Price Influencers Affect Electric Motor Parts Sourcing?

Several factors can influence the pricing of electric motor parts:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in bulk often leads to discounts. Suppliers may offer better pricing for larger orders, which can be beneficial for businesses with significant operational needs.

-

Specifications and Customization: Customized parts typically incur higher costs due to the additional design and manufacturing processes involved. Buyers should assess whether customization is necessary or if standard parts can suffice.

-

Materials and Quality Certifications: The materials used and the certifications held by manufacturers can impact pricing. High-grade materials and compliance with international standards (like ISO) may increase costs but ensure reliability.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Well-established suppliers might charge more due to their proven track record, while new entrants may offer lower prices to gain market share.

-

Incoterms: Understanding the terms of trade is crucial. Incoterms define responsibilities regarding shipping, insurance, and tariffs, which can affect overall costs. Buyers should clarify these terms to avoid unexpected expenses.

What Are Effective Negotiation Strategies for B2B Buyers?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant savings. Here are some tips:

-

Understand Total Cost of Ownership (TCO): TCO goes beyond the initial price, encompassing maintenance, logistics, and potential downtime costs. Evaluating TCO can provide a clearer picture of the true expense of sourcing parts.

-

Leverage Volume Discounts: If your business can commit to larger orders, use this leverage in negotiations. Suppliers may offer better pricing tiers for higher volume commitments.

-

Build Relationships with Suppliers: Developing a strong relationship with suppliers can lead to better pricing and terms. A reliable partnership often results in enhanced service and preferential treatment during negotiations.

-

Be Aware of Pricing Nuances: International buyers should consider currency fluctuations, import duties, and local market conditions. These factors can influence the final price and should be accounted for during negotiations.

-

Request Multiple Quotes: Engaging several suppliers can provide a competitive landscape for pricing. This not only helps in negotiating better rates but also gives insights into market pricing trends.

Conclusion

In summary, understanding the cost components, price influencers, and effective negotiation strategies is crucial for international B2B buyers of electric motor parts. By evaluating these aspects, buyers can make informed decisions that enhance their procurement processes while optimizing costs. Always remember to verify indicative prices, as they can fluctuate based on market conditions and supplier capabilities.

Alternatives Analysis: Comparing electric motor parts With Other Solutions

Introduction to Electric Motor Parts Alternatives

In the realm of industrial machinery, electric motor parts are essential for ensuring operational efficiency and reliability. However, various alternative solutions exist that can fulfill similar roles, offering different benefits depending on the specific application and operational needs. This analysis will compare electric motor parts with two viable alternatives: hydraulic systems and pneumatic systems. Each alternative presents unique performance characteristics, cost implications, and maintenance requirements that are critical for B2B buyers to consider.

Comparison Table

| Comparison Aspect | Electric Motor Parts | Hydraulic Systems | Pneumatic Systems |

|---|---|---|---|

| Performance | High efficiency, continuous power | Excellent torque and lifting capacity | Quick response, lower torque |

| Cost | Moderate initial investment; varied | Higher installation and maintenance costs | Generally lower initial costs; maintenance can add up |

| Ease of Implementation | Relatively straightforward | Complex installation and setup | Simple to install, but system design can be intricate |

| Maintenance | Moderate; parts replacement needed | High; fluid leaks and system checks | Low; less frequent maintenance, but regular checks required |

| Best Use Case | Electric drives, fans, pumps | Heavy machinery, construction, lifting | Assembly lines, tools, packaging |

Detailed Breakdown of Alternatives

Hydraulic Systems

Hydraulic systems utilize fluid power to perform work and are known for their exceptional torque and lifting capabilities. They excel in applications that require heavy lifting or precise control, such as construction equipment and manufacturing machines. However, the complexity of installation and potential for fluid leaks can lead to high maintenance costs. B2B buyers in industries requiring robust lifting solutions may find hydraulic systems beneficial despite the upfront investment.

Pneumatic Systems

Pneumatic systems use compressed air to drive machinery and are favored for their quick response times and lightweight components. They are commonly used in assembly lines and tools, where speed is essential. While the initial costs are typically lower than hydraulic systems, pneumatic systems can incur ongoing maintenance costs due to the need for regular checks and the potential for air leaks. Companies focused on rapid operations may find pneumatic systems advantageous, especially in environments where air supply is readily available.

Conclusion: Choosing the Right Solution for Your Needs

When selecting between electric motor parts and alternative solutions like hydraulic or pneumatic systems, B2B buyers should carefully assess their operational requirements, budget constraints, and maintenance capabilities. Electric motor parts provide a reliable and efficient solution for continuous power needs, while hydraulic systems are ideal for heavy lifting applications. Pneumatic systems offer speed and ease of use, making them suitable for high-volume operations. By aligning the specific needs of their business with the strengths and weaknesses of each option, buyers can make informed decisions that enhance productivity and operational efficiency.

Essential Technical Properties and Trade Terminology for electric motor parts

What Are the Critical Technical Properties for Electric Motor Parts?

When selecting electric motor parts, understanding the technical specifications is crucial for ensuring compatibility, performance, and reliability. Here are some key properties to consider:

与electric motor parts相关的说明性图片

-

Material Grade

The material grade of motor components, such as stators, rotors, and windings, determines their durability and performance under various operational conditions. Common materials include aluminum for lightweight applications and copper for efficient electrical conductivity. B2B buyers should assess material specifications to ensure that the parts can withstand environmental stresses and operational demands specific to their industry. -

Tolerance Levels

Tolerance levels indicate the permissible variation in dimensions of motor parts. Tight tolerances are essential for components that require precise fitment, such as bearings and shafts, to reduce wear and enhance efficiency. Understanding tolerance specifications can help buyers avoid costly mistakes in assembly and operation, particularly in industries where precision is paramount, such as aerospace and automotive. -

Voltage and Current Ratings

Each motor part must be compatible with specific voltage and current ratings to function effectively. Buyers should verify that components, such as thermal protectors and sensors, can handle the electrical requirements of the motor system. Incorrect ratings can lead to overheating, failures, or safety hazards, making this an essential consideration for procurement. -

Power Factor

The power factor measures the efficiency of electrical power usage in motors. A high power factor indicates that the motor uses electricity more effectively, resulting in lower energy costs and reduced operational expenses. B2B buyers should prioritize parts that support high power factor operations, especially in large-scale industrial applications where energy efficiency is critical. -

Thermal Resistance

Thermal resistance is a measure of how well a component can withstand heat. This property is vital for parts such as thermal protectors and cooling fans, which help prevent overheating. Understanding the thermal specifications ensures that buyers select components that can operate safely within the temperature ranges required by their applications.

What Are Common Trade Terms in the Electric Motor Parts Industry?

Familiarity with industry jargon is essential for effective communication and negotiation. Here are some common terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the equipment. These parts are designed to meet the exact specifications and performance standards of the original product. Choosing OEM parts can ensure compatibility and reliability, which is particularly important for maintaining warranty coverage and operational efficiency. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, especially when planning inventory levels. Ordering below the MOQ may result in higher per-unit costs or inability to procure the desired parts, impacting project timelines and budgets. -

RFQ (Request for Quotation)

An RFQ is a formal process in which buyers request pricing and terms from suppliers for specific parts. This document typically includes detailed specifications and quantities. Utilizing RFQs helps buyers compare options and negotiate better deals, ensuring they secure the best value for their procurement needs. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, delivery, and risk transfer. Familiarity with Incoterms helps B2B buyers understand shipping costs, responsibilities, and liability, which is especially important when dealing with international suppliers. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is essential for effective inventory management and project planning. Buyers should consider lead times when sourcing parts to ensure timely delivery and avoid production delays.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that enhance operational efficiency and project success in the electric motor parts industry.

Navigating Market Dynamics and Sourcing Trends in the electric motor parts Sector

What Are the Current Market Dynamics and Key Trends in the Electric Motor Parts Sector?

The electric motor parts sector is witnessing significant transformations driven by several global trends. The increasing demand for energy-efficient and sustainable solutions has prompted manufacturers and suppliers to innovate continuously. One of the most notable trends is the adoption of advanced technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) in motor diagnostics and performance monitoring. These technologies allow for predictive maintenance, reducing downtime and operational costs for B2B buyers.

与electric motor parts相关的说明性图片

Furthermore, the shift towards electrification across various industries, including automotive, renewable energy, and manufacturing, is a critical driver for the electric motor parts market. As countries in Africa, South America, the Middle East, and Europe ramp up their industrial capabilities, the need for reliable and high-quality electric motor components grows. Buyers in these regions must navigate a complex landscape of suppliers, ensuring they partner with reputable manufacturers that can provide OEM (Original Equipment Manufacturer) parts and high-quality replacements.

Emerging markets are also seeing an uptick in local production capabilities, which can potentially reduce lead times and logistics costs. However, international buyers must remain vigilant about quality control and sourcing practices, particularly when dealing with newer suppliers. The landscape is competitive, and leveraging technology and local partnerships can provide a distinct advantage.

How Is Sustainability Influencing Sourcing Decisions in the Electric Motor Parts Sector?

Sustainability has emerged as a pivotal concern for businesses globally, and the electric motor parts sector is no exception. Buyers are increasingly focused on the environmental impact of their sourcing decisions. The use of sustainable materials and practices not only helps mitigate the environmental footprint but also aligns with global regulatory standards and consumer preferences.

Ethical sourcing is becoming vital, with companies seeking suppliers who adhere to socially responsible practices. This includes ensuring fair labor practices and minimizing waste throughout the supply chain. Certifications such as ISO 14001 for environmental management and LEED (Leadership in Energy and Environmental Design) can serve as benchmarks for evaluating supplier sustainability.

Additionally, the demand for “green” electric motor parts—those made from recyclable or biodegradable materials—continues to grow. Buyers are encouraged to engage with suppliers who prioritize these materials, as this can enhance their brand reputation and appeal to environmentally conscious consumers. By integrating sustainability into sourcing strategies, businesses can achieve compliance, reduce costs, and foster a positive brand image.

What Is the Evolution of the Electric Motor Parts Sector and Its Importance for B2B Buyers?

The electric motor parts sector has evolved significantly over the last century, transitioning from mechanical systems to sophisticated electronic and digital technologies. Initially, electric motors were primarily used in industrial applications; however, advancements in technology have broadened their applications to various sectors, including transportation and renewable energy.

The evolution has also seen an increase in the complexity and specialization of motor components. B2B buyers now have access to a wider range of parts, including advanced sensors, thermal protectors, and smart control systems that enhance motor performance and efficiency. This progression underscores the importance of staying updated with the latest innovations and sourcing options available in the market.

As the sector continues to grow, understanding its history provides valuable context for B2B buyers. It highlights the importance of selecting high-quality parts from reputable suppliers, as these components are critical in ensuring the reliability and efficiency of electric motors in diverse applications.

Frequently Asked Questions (FAQs) for B2B Buyers of electric motor parts

-

1. How do I solve common electric motor failure issues?

To troubleshoot electric motor failures, start by inspecting the bearings and shaft for wear or damage, as these are common failure points. Additionally, check the power source to ensure it’s supplying the correct voltage and current. If the motor has windings, inspect them for short circuits or breaks. Cooling fans should also be examined to prevent overheating. If the issue persists after these checks, consider engaging a professional for comprehensive testing and diagnostics to identify underlying problems. -

2. What is the best type of electric motor for industrial applications?

The best type of electric motor for industrial applications often depends on specific operational requirements. For heavy-duty tasks, high-efficiency induction motors are preferred due to their durability and low maintenance needs. For variable speed applications, variable frequency drives (VFD) coupled with AC motors offer flexibility and energy savings. It’s crucial to assess the load requirements, operating environment, and energy efficiency standards before making a selection. -

3. How can I ensure the quality of electric motor parts from suppliers?

To ensure quality, conduct thorough research on potential suppliers. Look for certifications such as ISO 9001, which indicates a commitment to quality management. Request samples or test reports to evaluate the performance and reliability of the parts. Additionally, consider suppliers that provide warranties or guarantees on their products, as this can be a sign of confidence in their offerings. Building a relationship with suppliers who prioritize quality assurance can also lead to better long-term partnerships. -

4. What are the typical minimum order quantities (MOQs) for electric motor parts?

Minimum order quantities for electric motor parts can vary widely based on the supplier and the type of part. Many suppliers set MOQs ranging from 10 to 100 units to ensure cost-effectiveness in production and shipping. However, some suppliers may be willing to accommodate smaller orders, especially for custom parts or urgent requirements. Always inquire about MOQs before finalizing your order to avoid unexpected costs and delays. -

5. What payment terms should I expect when sourcing electric motor parts internationally?

Payment terms can vary significantly among international suppliers. Common practices include upfront payments, letters of credit, or payment upon delivery. It’s advisable to negotiate terms that align with your cash flow needs while ensuring security. Established suppliers may offer more flexible terms based on your purchasing history. Always review the contract terms carefully, considering factors such as currency fluctuations and potential tariffs when trading across borders. -

6. How do I navigate customs regulations when importing electric motor parts?

Navigating customs regulations requires understanding both the exporting and importing countries’ requirements. Ensure that all documentation, including invoices, packing lists, and certificates of origin, is accurate and complete. Familiarize yourself with tariff classifications and import duties applicable to electric motor parts. Engaging a customs broker can facilitate the process by ensuring compliance with regulations, thereby minimizing delays and additional costs. -

7. Can I customize electric motor parts to fit my specific needs?

Yes, many suppliers offer customization options for electric motor parts to meet specific operational requirements. Customization can include modifications in size, voltage, and additional features such as thermal protection or specialized coatings. When requesting customization, provide detailed specifications and discuss timelines and costs with the supplier. Custom parts may have longer lead times, so planning ahead is essential to avoid disruptions in your operations. -

8. What logistics considerations should I keep in mind when sourcing electric motor parts?

When sourcing electric motor parts, consider logistics factors such as shipping methods, lead times, and costs. Choose suppliers that offer efficient shipping options and track record of timely delivery. Understand the implications of shipping delays on your operations and factor in potential customs clearance times. It’s also wise to evaluate the reliability of the transportation provider and ensure that there is adequate insurance coverage for high-value shipments to protect against loss or damage.

Top 4 Electric Motor Parts Manufacturers & Suppliers List

1. Baldor – Factory Replacement Motors

Domain: electricmotorwholesale.com

Registered: 2005 (20 years)

Introduction: This company, Baldor – Factory Replacement Motors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Electric Motor Parts – Replacement Parts

Domain: electricmotorparts.net

Registered: 2013 (12 years)

Introduction: Electric Motor Parts offers a variety of replacement parts for electric motors, including Brush Holders, Carbon Brushes, Insulators & Yokes, Mill Motor Parts, and Rubber Grommets. They provide OEM Parts and OEM Quality Replacement Parts from manufacturers such as ABB Electric, AEG Electric, Baldor Electric, Bull Electric, Delco/GM Electric, Dover Elevator, Electric Machinery, Electro Motive, Gener…

3. eBay – Electric Motor Parts & Accessories

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Electric Motor Parts & Accessories for sale on eBay include a variety of products such as: 1. Dayton 2MDU2 Motor Start Capacitor (460-552 MFD Round) – $8.59 2. 213t Frame Electric Motor Base Mount Adjustable Slide Plate Universal Mounting – $78.95 3. HYDAC Pilot Poppet Valve (24vdc Solenoid) – $232.21 4. Goodman Furnace Blower Motor (0131M01003S) – $350.00 5. Warner Armature Plate (5230-111-001) -…

4. DB Electrical – DC Motors Replacement Parts

Domain: dbelectrical.com

Registered: 2000 (25 years)

Introduction: DC Motors Replacement Parts | DB Electrical

– Free Same Day Shipping over $50* USA/48 only.

– Various DC Motors available:

1. Item #: 430-22044 – Pump Motor, Replaces Hino X2772302, Bosch 0-204-788-062, Prestolite HYL5006, Was: $157.13

2. Item #: 430-20094 – P56SX401 12V, 1/2HP Scott DC Reel Motor for Hannay Reels, Various CCW Rotation, Was: $369.07

3. Item #: LIA0010 – 24 Volt Insulated Gro…

Strategic Sourcing Conclusion and Outlook for electric motor parts

Why is Strategic Sourcing Essential for Electric Motor Parts?

In the dynamic landscape of electric motor parts, strategic sourcing is more than a procurement strategy; it is a vital approach to ensuring operational efficiency and cost-effectiveness. By focusing on quality OEM parts and reliable suppliers, businesses can significantly reduce downtime and enhance the longevity of their equipment. This is particularly critical for industries such as manufacturing, energy, and transportation, which depend heavily on the performance of electric motors.

How Can International Buyers Optimize Their Sourcing?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should prioritize building relationships with trusted suppliers who understand local market conditions and can provide timely support. Leveraging technology for inventory management and adopting just-in-time sourcing can further optimize procurement processes, ensuring parts are available when needed without overstocking.

What Does the Future Hold for Electric Motor Parts Sourcing?

Looking ahead, the demand for electric motor parts is set to rise as industries increasingly adopt automation and sustainable practices. Buyers should stay informed about emerging trends and innovations within the electric motor sector, such as advancements in energy efficiency and smart motor technologies. By embracing these changes and fostering strategic partnerships, businesses can position themselves to thrive in a competitive marketplace.

Now is the time to take proactive steps in your sourcing strategy—evaluate your suppliers, invest in quality, and ensure your operations are equipped for future challenges. Your commitment to strategic sourcing today will pave the way for success tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.