Unlocking Value: A Strategic Analysis of the Dust Collection System Layout Market

Introduction: Navigating the Global Market for dust collection system layout

In an increasingly competitive global marketplace, sourcing an effective dust collection system layout poses a significant challenge for B2B buyers. Effective dust collection is not just a matter of maintaining a clean workspace; it is crucial for compliance with health and safety regulations and ensuring operational efficiency. This guide delves into the complexities of dust collection system layouts, exploring various types of systems, their applications across different industries, and critical factors such as supplier vetting and cost considerations.

Understanding the nuances of dust collection is essential for buyers from diverse regions, including Africa, South America, the Middle East, and Europe, where regulatory standards and operational demands may differ. This comprehensive resource equips international B2B buyers with the knowledge needed to make informed purchasing decisions. By covering everything from layout planning to the selection of appropriate equipment and suppliers, this guide helps businesses navigate the intricacies of sourcing dust collection solutions that meet their specific needs.

With actionable insights and expert recommendations, this guide empowers companies to enhance their operational efficiency, improve workplace safety, and ensure compliance with local regulations. Whether you are setting up a new facility or upgrading an existing system, understanding the optimal dust collection system layout is pivotal to your success in today’s global market.

Understanding dust collection system layout Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Centralized Dust Collection | Features a central collector with ductwork branching out to multiple tools | Large manufacturing facilities, woodworking shops | Pros: Efficient for multiple machines, reduces dust exposure. Cons: Higher initial setup cost, complex installation. |

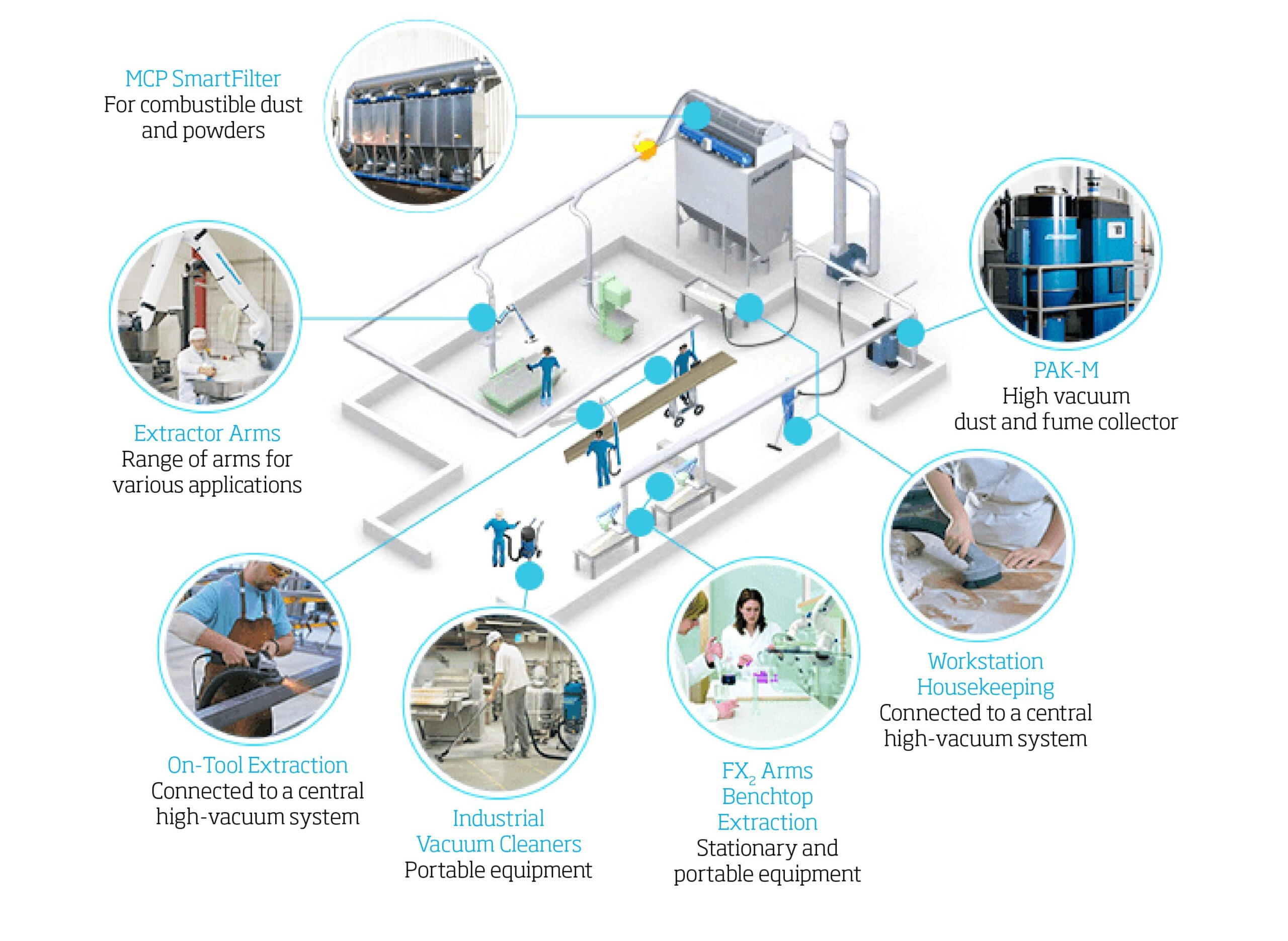

| Portable Dust Collection | Compact, mobile units typically used for individual tools | Small workshops, construction sites | Pros: Flexibility and ease of use, lower cost. Cons: Limited capacity, may require frequent emptying. |

| Cyclone Dust Collection | Utilizes centrifugal force to separate larger particles from air | Industrial applications, metalworking | Pros: Maintains airflow, longer filter life. Cons: Higher upfront investment, requires more space. |

| Modular Dust Collection | Customizable systems that can be expanded or modified easily | Growing businesses, diverse manufacturing | Pros: Scalability, tailored to specific needs. Cons: Potentially higher costs with upgrades, planning required. |

| Localized Dust Collection | Focuses on specific tools with dedicated hoods or attachments | Woodworking, metal fabrication | Pros: Targeted dust capture, often lower cost. Cons: Less effective for overall shop cleanliness, may require multiple setups. |

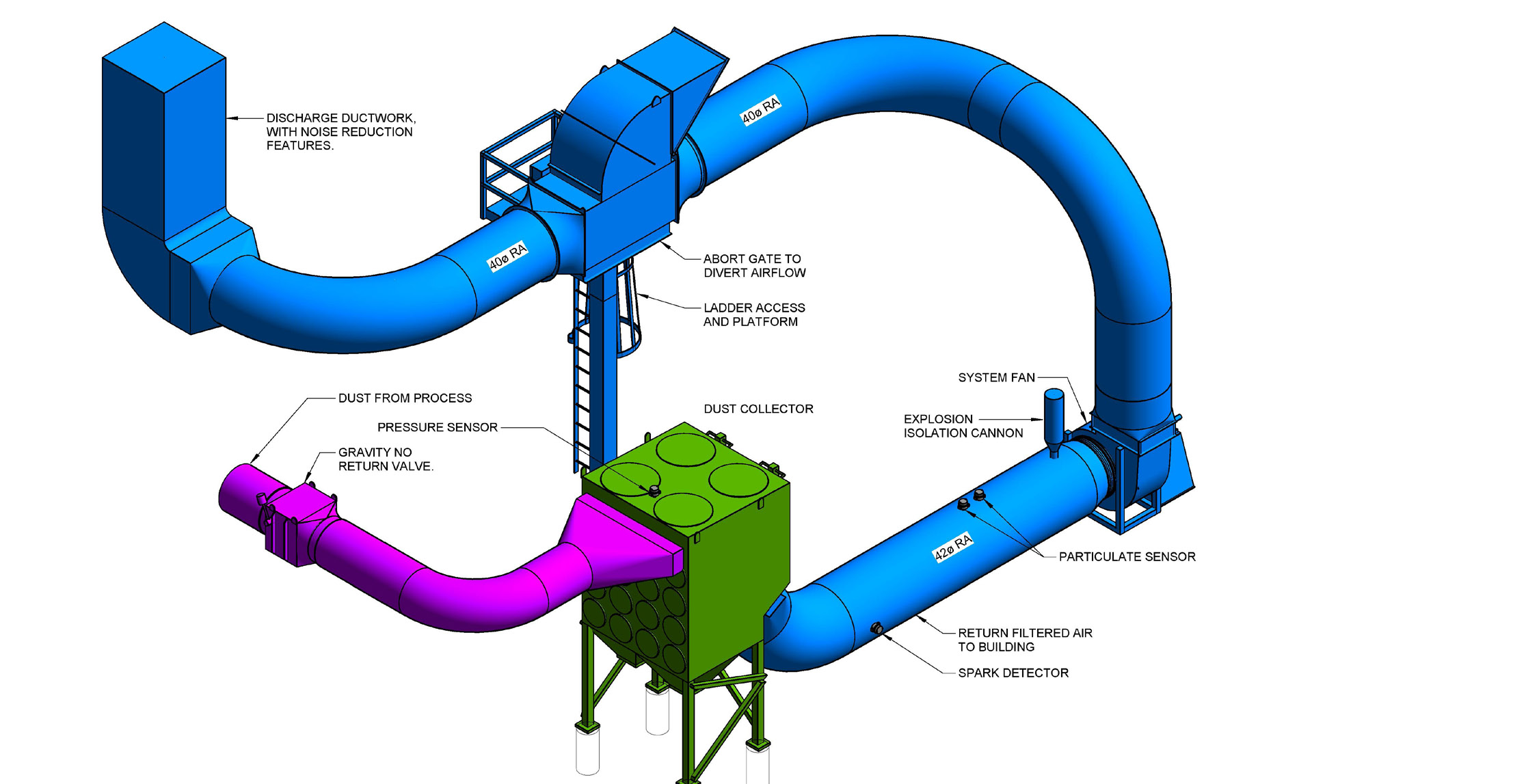

What Are the Characteristics of Centralized Dust Collection Systems?

Centralized dust collection systems are designed to serve multiple machines from a single, central collector. This layout typically involves extensive ductwork that branches out to various tools, maximizing efficiency in large workshops or manufacturing facilities. When considering a centralized system, businesses should evaluate their layout, airflow requirements, and the potential for future expansion. While the initial investment may be higher, the long-term benefits of reduced dust exposure and improved air quality often justify the cost.

How Do Portable Dust Collection Systems Benefit Smaller Operations?

Portable dust collection systems are compact, mobile units that can be easily transported to different work areas. They are ideal for small workshops or job sites where flexibility is crucial. Buyers should consider the capacity and airflow of these units, as they often have limitations compared to larger systems. While they are generally less expensive and easier to set up, frequent emptying may be necessary, particularly in high-dust environments.

What Makes Cyclone Dust Collection Systems Unique?

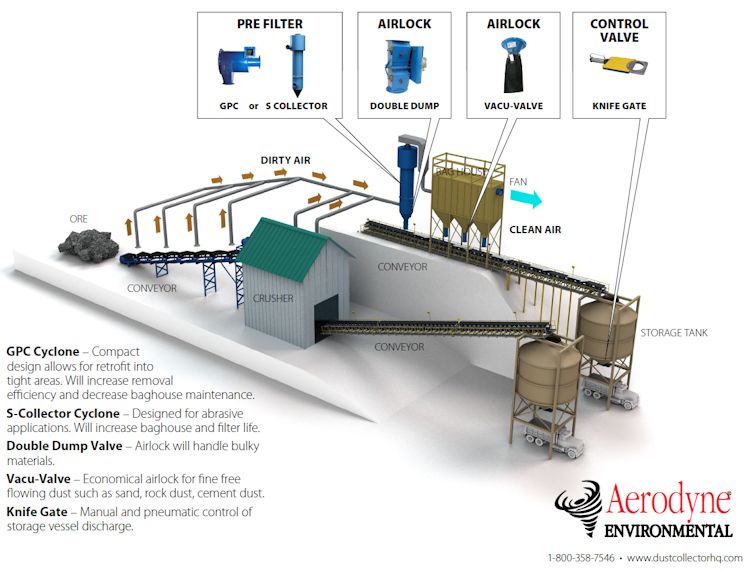

Cyclone dust collection systems leverage centrifugal force to efficiently separate larger particles from the air before they reach the filter. This design allows for sustained airflow and minimizes filter clogging, making them particularly suitable for industrial applications and metalworking environments. B2B buyers should consider the space requirements and initial costs, as cyclone systems can be more expensive. However, their efficiency and reduced maintenance make them a worthwhile investment for businesses generating significant dust.

Why Are Modular Dust Collection Systems Gaining Popularity?

Modular dust collection systems offer a customizable solution that can be easily expanded or modified as business needs evolve. This flexibility makes them ideal for growing companies or those with diverse manufacturing processes. When evaluating modular systems, businesses should assess their current and future dust management needs, as well as the costs associated with potential upgrades. The ability to tailor the system to specific requirements provides significant value, although it may come with higher initial costs.

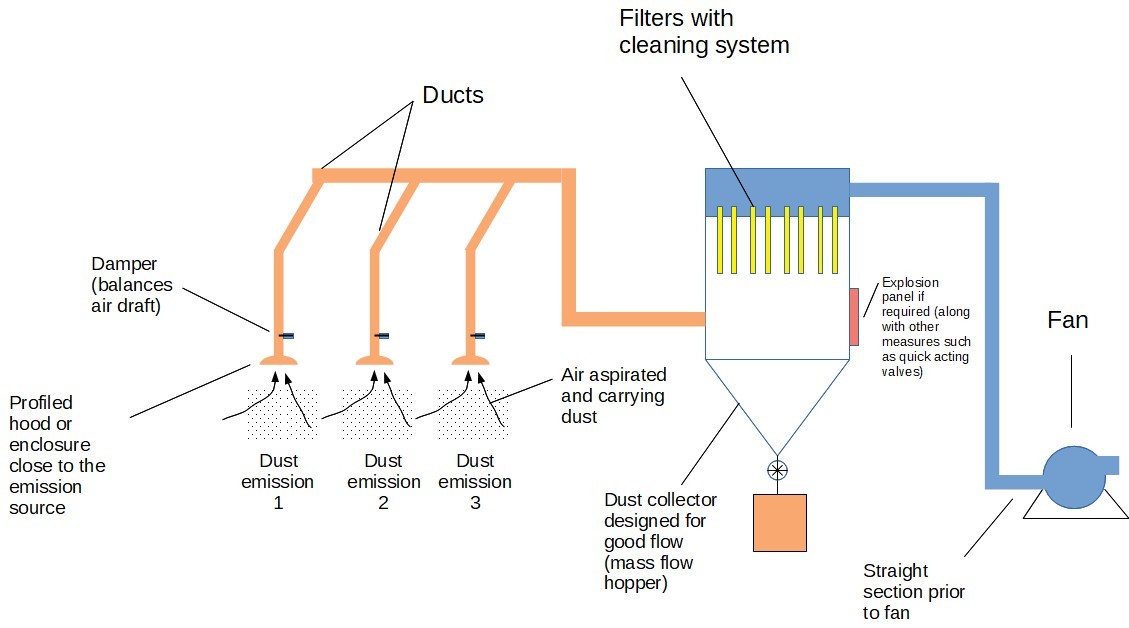

How Do Localized Dust Collection Systems Work?

Localized dust collection systems focus on capturing dust at the source, using hoods or attachments directly connected to specific tools. This approach is particularly effective in woodworking and metal fabrication environments where certain machines produce significant dust. Buyers should weigh the cost-effectiveness of these systems against their overall effectiveness in maintaining shop cleanliness. While localized systems can be less comprehensive, they are often more affordable and easier to implement for targeted dust control.

Key Industrial Applications of dust collection system layout

| Industry/Sector | Specific Application of dust collection system layout | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Woodworking | Whole-shop dust collection systems for sawdust and debris removal | Improved air quality and worker safety | System capacity, ductwork material, and filter efficiency |

| Metal Fabrication | Dust collection from grinding and welding operations | Enhanced workplace safety and compliance with regulations | Compatibility with existing equipment, durability, and maintenance needs |

| Pharmaceuticals | Containment of fine powders during production | Protection against contamination and health risks | HEPA filtration standards, system scalability, and ease of cleaning |

| Food Processing | Dust control during ingredient handling and processing | Compliance with hygiene standards and improved product quality | Material safety, system hygiene, and adaptability to varying processes |

| Cement and Construction | Collection of concrete dust during cutting and grinding | Reduced health hazards and improved workplace conditions | Robustness of the system, efficiency in high-dust environments, and installation requirements |

How is Dust Collection System Layout Used in Woodworking?

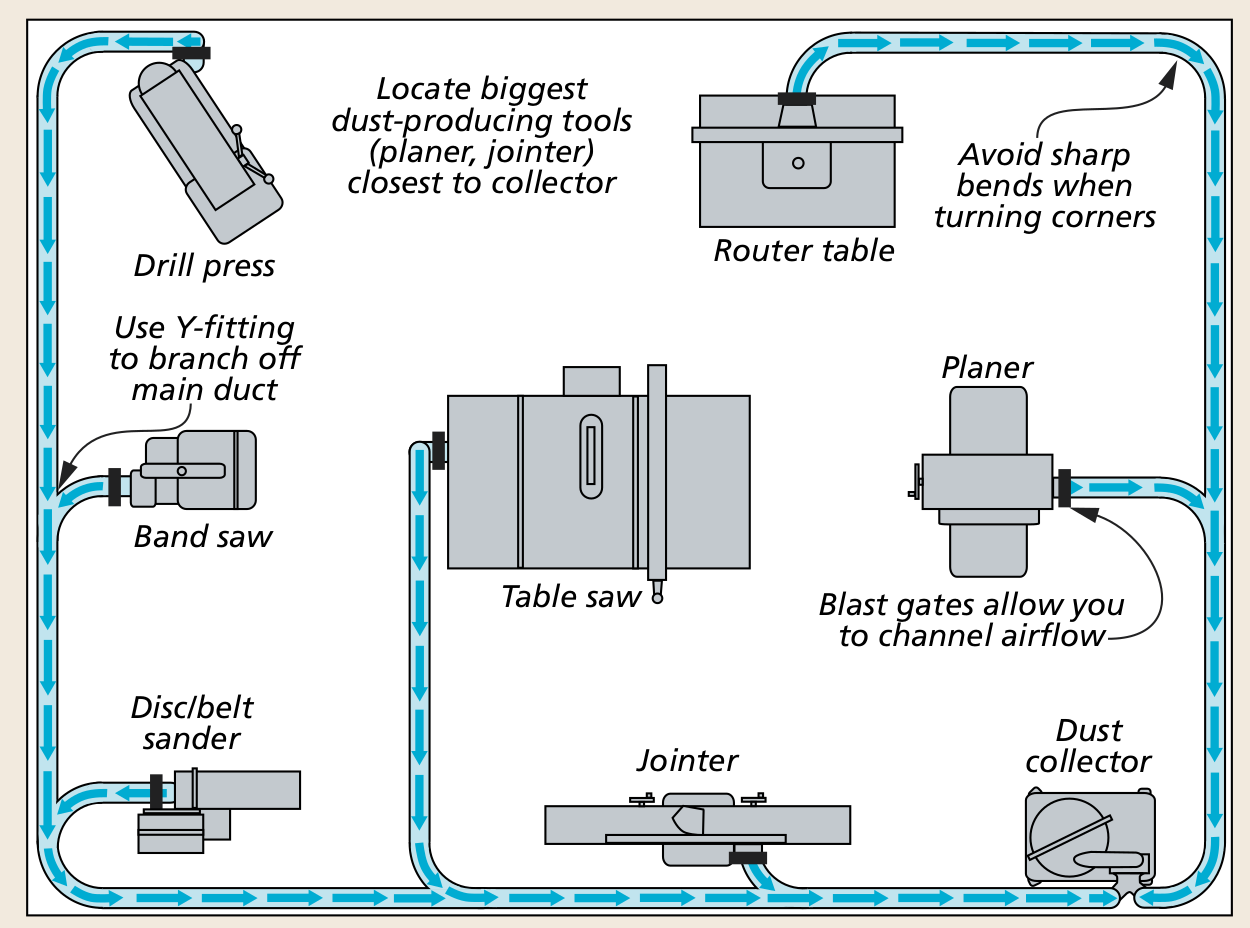

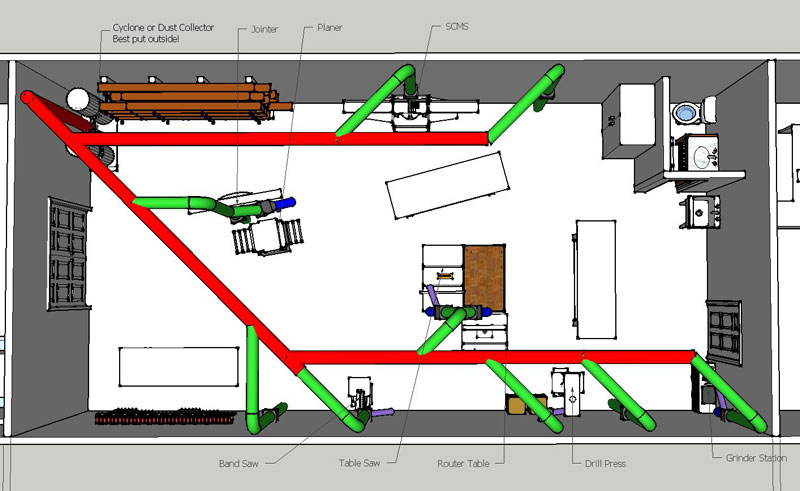

In the woodworking industry, a well-planned dust collection system layout is essential for maintaining air quality and ensuring worker safety. This involves strategically placing the dust collector near high-output machines like saws and planers to minimize duct length and resistance. By capturing sawdust and fine particles at the source, businesses can prevent respiratory issues and maintain a cleaner workspace. International buyers should consider the system’s capacity, the material used for ductwork, and the efficiency of filters to ensure compliance with local health regulations.

What Role Does Dust Collection Play in Metal Fabrication?

Metal fabrication processes, including grinding and welding, generate hazardous dust that poses safety risks. An effective dust collection system layout captures these particles before they can contaminate the air or settle on equipment. This not only enhances workplace safety but also helps companies comply with stringent industry regulations. Buyers in this sector should focus on the compatibility of the dust collection system with existing machinery, the durability of materials used, and the ease of maintenance to ensure long-term operational efficiency.

Why is Dust Collection Critical in Pharmaceuticals?

In pharmaceutical manufacturing, dust collection systems are vital for containing fine powders that can pose contamination risks. A precise layout ensures that dust is captured at various stages of production, safeguarding both product integrity and employee health. Compliance with stringent hygiene standards is crucial in this industry, making HEPA filtration systems a top priority for international buyers. When sourcing, companies must evaluate scalability to accommodate production changes and the ease of cleaning to maintain strict hygiene protocols.

How Does Dust Collection Improve Food Processing?

In the food processing sector, dust collection systems help manage dust generated during the handling and processing of ingredients. A well-designed system layout not only enhances compliance with hygiene standards but also improves the overall quality of the final product. Buyers should prioritize materials that are safe for food contact, as well as systems that can adapt to various processes to ensure efficiency. Additionally, the ability to maintain cleanliness and ease of operation is crucial in this industry.

What Are the Benefits of Dust Collection in Cement and Construction?

Cement and construction activities often produce significant amounts of dust, particularly during cutting and grinding operations. A robust dust collection system layout is essential to mitigate health hazards associated with inhalation of concrete dust. Businesses benefit from improved workplace conditions and compliance with safety regulations. When sourcing systems for this sector, buyers should consider the robustness of the equipment, its efficiency in high-dust environments, and the specific installation requirements to ensure optimal performance.

3 Common User Pain Points for ‘dust collection system layout’ & Their Solutions

Scenario 1: Inefficient Dust Collection Due to Poor Duct Layout

The Problem: Many B2B buyers face significant challenges with dust collection efficiency stemming from poorly designed duct layouts. This often occurs when duct runs are excessively long or have too many bends, causing airflow resistance and reducing the system’s overall effectiveness. In industries like woodworking and metalworking, where fine dust particles are harmful to health and safety, this inefficiency not only leads to a messy work environment but also jeopardizes employee well-being.

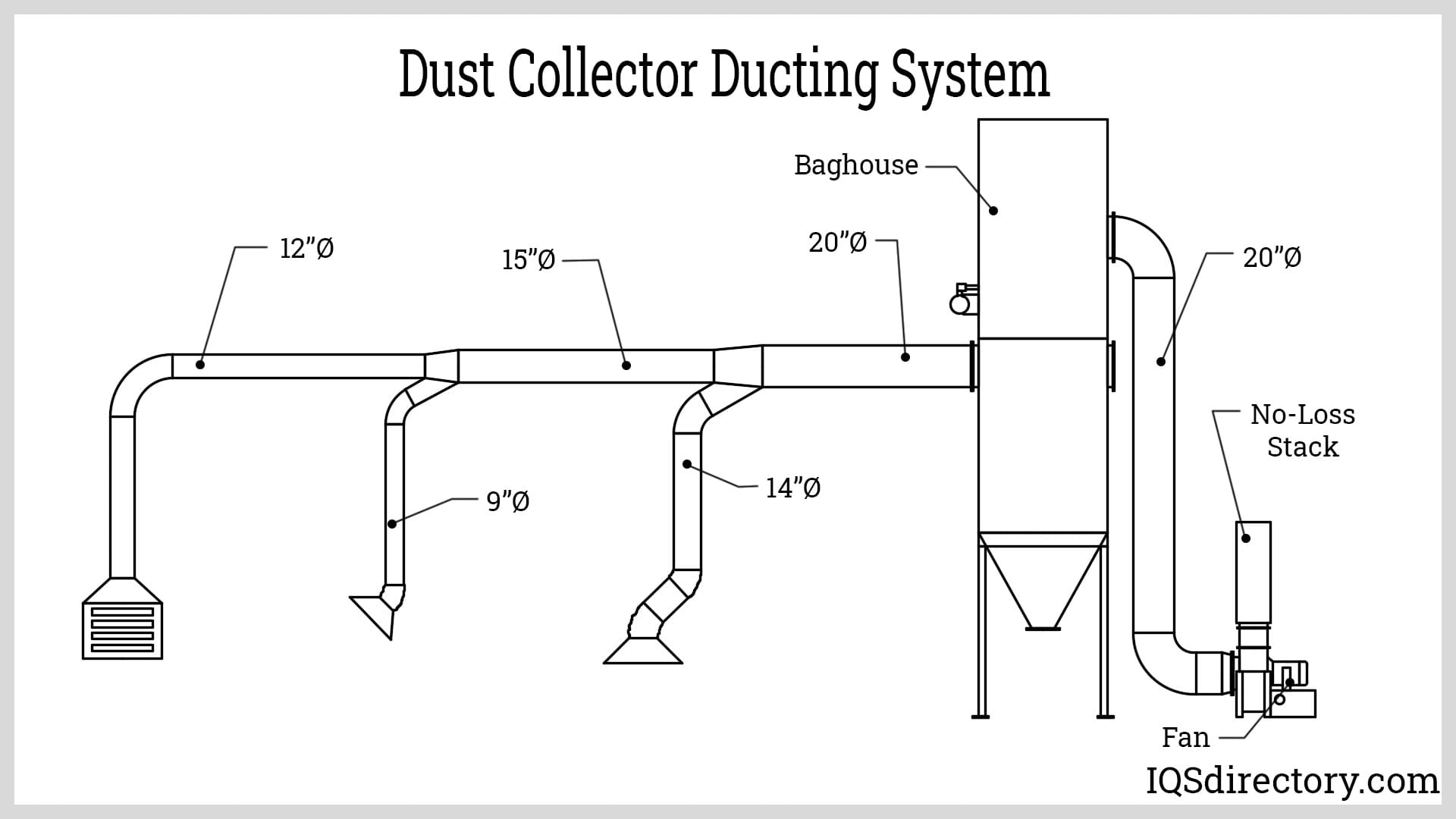

The Solution: To combat this issue, it’s crucial to start with a well-thought-out duct layout. Buyers should prioritize short duct runs with minimal bends. When designing the layout, place the dust collector centrally to minimize duct length and use larger diameter ducts to ensure optimal airflow. For instance, instead of using a 90-degree elbow that can create turbulence, opt for a 45-degree elbow that allows smoother transitions. Additionally, employing blast gates can direct airflow to specific tools, enhancing efficiency. Consulting with a dust collection expert or utilizing design software can also provide insights into optimal layouts tailored to specific workshop needs.

Scenario 2: Underestimating Dust Collector Capacity Needs

The Problem: A common pain point for B2B buyers is the miscalculation of dust collector capacity, leading to inadequate dust removal. Many buyers purchase dust collectors based on initial needs without considering future expansions or simultaneous tool usage. This can result in systems that are unable to handle the dust load, leading to reduced performance and potential health hazards from airborne particles.

The Solution: To avoid this pitfall, buyers should conduct a thorough assessment of their dust generation needs. This includes calculating the required cubic feet per minute (CFM) based on the number and type of tools in use. As a rule of thumb, consider investing in a dust collector with at least a 2-horsepower motor and a rating of 1,300 CFM for basic operations. If multiple tools will be used concurrently, it’s advisable to increase this rating to accommodate higher airflow demands. Buyers should also consider the static pressure of their ductwork and adjust their collector choice accordingly. Consulting with manufacturers for fan curves and testing different configurations can provide valuable insights, ensuring the selected dust collector meets both current and future needs.

Scenario 3: Poor Filtration Leading to Health Risks

The Problem: Inadequate filtration is a significant concern for B2B buyers, especially in environments where fine dust particles can pose serious health risks. Many dust collectors are equipped with filters that do not effectively capture the smallest particles, leading to a dusty environment that can affect employee health and create compliance issues with occupational safety regulations.

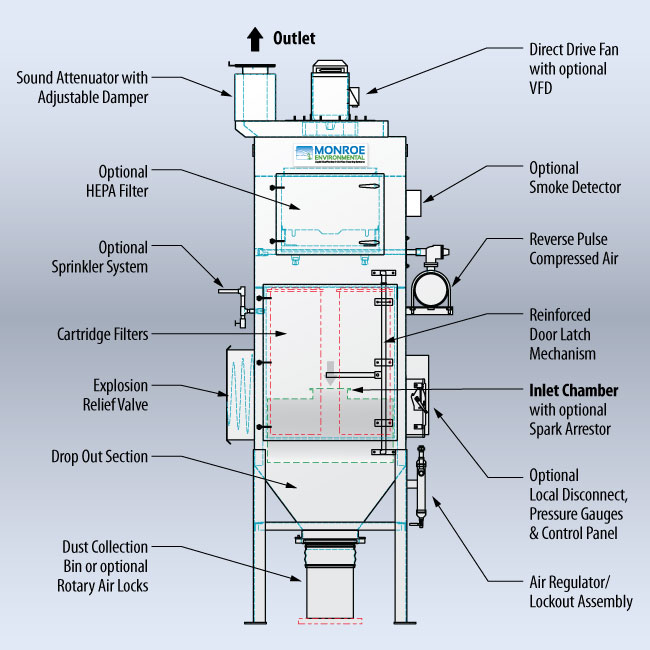

The Solution: To enhance filtration, buyers should prioritize dust collectors equipped with HEPA filters, which are certified to trap at least 99.97% of particles as small as 0.3 microns. When selecting a dust collection system, ensure that the filter is easily accessible for regular maintenance and replacement. Additionally, consider upgrading existing systems with aftermarket HEPA filters if the original equipment does not meet health standards. Regularly testing air quality in the workspace with real-time monitoring devices can help identify filtration issues early. Establishing a maintenance schedule for inspecting and cleaning filters will also ensure that the system operates at peak efficiency, protecting both the workforce and the facility from dust-related hazards.

Strategic Material Selection Guide for dust collection system layout

What Are the Key Materials for Dust Collection System Layout?

When selecting materials for dust collection systems, several options are commonly used, each with its unique properties and implications for performance. Understanding these materials helps international B2B buyers make informed decisions that align with their operational needs and regional standards.

How Does PVC Perform in Dust Collection Systems?

Key Properties: PVC (Polyvinyl Chloride) is lightweight, resistant to corrosion, and has a temperature rating of up to 140°F (60°C). It is generally not suitable for high-pressure applications.

Illustrative image related to dust collection system layout

Pros & Cons: PVC is cost-effective and easy to install, making it a popular choice for small to medium dust collection systems. However, its lower durability compared to metal options can be a concern in environments with high mechanical stress or extreme temperatures.

Impact on Application: PVC is compatible with a variety of dust types, including wood and plastic particles. However, it may not be suitable for collecting metal shavings or other abrasive materials, which can wear down the pipes over time.

Considerations for International Buyers: In regions like Africa and South America, PVC is widely available and often meets local standards. Buyers should ensure compliance with ASTM standards for safety and performance, especially in industrial applications.

What Are the Advantages of Using Metal Ductwork?

Key Properties: Metal ductwork, typically made from galvanized steel or aluminum, offers high durability and can withstand higher temperatures and pressures compared to plastic.

Illustrative image related to dust collection system layout

Pros & Cons: The primary advantage of metal ductwork is its longevity and resistance to wear and tear. However, it is generally more expensive than PVC and can be more complex to install due to its weight and the need for specialized fittings.

Impact on Application: Metal ductwork is ideal for heavy-duty applications, including those involving metal dust or high-temperature environments. Its smooth interior surfaces also enhance airflow efficiency.

Considerations for International Buyers: Buyers in the Middle East, where high temperatures are common, may prefer metal for its thermal resilience. Compliance with local and international standards, such as DIN or JIS, is crucial for ensuring safety and performance.

How Do Flexible Hoses Fit into Dust Collection Systems?

Key Properties: Flexible hoses are typically made from rubber or reinforced vinyl. They are designed to handle moderate temperatures and pressures, making them versatile for various applications.

Pros & Cons: The main advantage of flexible hoses is their adaptability; they can easily connect to tools with different port sizes and shapes. However, they may not provide the same level of airflow efficiency as rigid ducting and can be prone to wear and tear over time.

Impact on Application: Flexible hoses are particularly useful for connecting portable tools or in situations where rigid ducting is impractical. However, they may not be suitable for heavy-duty applications involving abrasive materials.

Considerations for International Buyers: In regions like Europe, where regulations on material safety are stringent, buyers should ensure that flexible hoses meet relevant standards. The availability of high-quality hoses can vary by region, so sourcing from reputable manufacturers is essential.

What Role Do Blast Gates Play in Dust Collection Systems?

Key Properties: Blast gates are typically made from metal or durable plastic and are designed to control airflow in duct systems.

Pros & Cons: They are essential for optimizing the efficiency of dust collection systems by directing airflow only to the tool in use. However, they can be more expensive than simple duct fittings and may require periodic maintenance.

Impact on Application: Proper installation of blast gates can significantly enhance the performance of a dust collection system, particularly in larger setups with multiple tools.

Illustrative image related to dust collection system layout

Considerations for International Buyers: Buyers should consider local standards for materials used in blast gates to ensure they are suitable for their specific applications. Compatibility with existing ductwork is also vital for seamless integration.

Summary Table of Material Selection for Dust Collection Systems

| Material | Typical Use Case for dust collection system layout | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Small to medium dust collection systems | Cost-effective and easy to install | Lower durability in high-stress areas | Low |

| Metal | Heavy-duty applications, high temperatures | High durability and pressure resistance | More expensive and complex to install | High |

| Flexible Hose | Connecting portable tools | Adaptable to various tool connections | Lower airflow efficiency | Medium |

| Blast Gates | Optimizing airflow in larger systems | Enhances system efficiency | More expensive and requires maintenance | Medium |

This guide serves as a strategic resource for international B2B buyers, enabling them to select the most appropriate materials for their dust collection system layouts based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for dust collection system layout

What Are the Main Manufacturing Processes for Dust Collection System Layout?

The manufacturing processes involved in creating effective dust collection systems are critical for ensuring high performance and reliability. The main stages include material preparation, forming, assembly, and finishing, each employing specific techniques tailored to the needs of the industry.

How Is Material Prepared for Dust Collection Systems?

Material preparation is the foundational step in manufacturing dust collection systems. Common materials include metals such as steel and aluminum, plastics like PVC, and composite materials. The preparation phase involves sourcing raw materials that meet industry standards for durability and resistance to corrosion.

Illustrative image related to dust collection system layout

Quality assurance begins here; suppliers must provide certification of material properties, such as tensile strength and chemical resistance. B2B buyers should verify that their suppliers adhere to international material standards, ensuring that the materials used will withstand the operational stresses they will encounter in various environments, from humid conditions in South America to arid climates in the Middle East.

What Techniques Are Used in the Forming Stage of Dust Collection Systems?

The forming stage transforms raw materials into usable components through techniques such as cutting, bending, and welding.

-

Cutting: Automated laser or plasma cutting machines are commonly used to achieve precision in creating ductwork and fittings. This technique allows for the efficient production of complex shapes that enhance airflow dynamics within the system.

-

Bending: Techniques such as roll forming or press braking are utilized to create curved ducts and branches, minimizing airflow resistance. This is crucial for maintaining optimal suction and efficiency.

-

Welding: For metal components, methods like MIG or TIG welding ensure strong, leak-proof connections. Each weld should undergo visual inspection and non-destructive testing to confirm integrity.

B2B buyers should inquire about the specific forming techniques employed by manufacturers, as these directly impact the efficiency and performance of the dust collection systems.

How Are Dust Collection Systems Assembled?

Once individual components are formed, the assembly stage begins. This involves the integration of ductwork, collectors, filters, and any electronic components such as motors or control systems.

-

Component Matching: Ensuring that all parts fit together seamlessly is vital. Manufacturers may use computer-aided design (CAD) software to simulate assembly processes and identify potential issues before production.

-

Installation of Accessories: Accessories such as blast gates, hoods, and connectors are installed at this stage. Each accessory must be tested for compatibility and effectiveness in directing airflow.

-

Final Assembly Checks: A thorough review of assembly procedures is conducted, often using checklists to ensure all components are installed correctly and securely.

B2B buyers should consider requesting assembly process documentation to understand how a manufacturer ensures quality and reliability in their systems.

What Finishing Techniques Are Applied to Dust Collection Systems?

Finishing processes enhance both the aesthetic appeal and functional durability of dust collection systems. Common techniques include:

-

Surface Treatment: Coatings such as powder coating or galvanization protect metal components from corrosion, especially in environments with high humidity or exposure to dust and debris.

-

Quality Control Inspections: After finishing, products undergo inspections to ensure that coatings meet thickness and adhesion standards. This is crucial for long-term performance.

-

Packaging: Proper packaging is essential to prevent damage during transportation. Manufacturers should provide details on their packaging processes, particularly for international shipping.

B2B buyers should evaluate the finishing techniques used by potential suppliers, as these can significantly influence the longevity and performance of the dust collection systems.

How Is Quality Assurance Managed for Dust Collection Systems?

Quality assurance (QA) is paramount in manufacturing dust collection systems. It ensures that products meet both international standards and specific industry requirements.

What International Standards Are Relevant to Dust Collection Systems?

Key international standards include:

- ISO 9001: This standard focuses on quality management systems and is essential for manufacturers seeking to demonstrate their commitment to consistent quality.

- CE Marking: For products sold in the European market, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: Relevant for systems used in specific industries such as oil and gas, ensuring that equipment meets operational and safety requirements.

B2B buyers should confirm that their suppliers are certified to these standards, providing an assurance of quality.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are integral to maintaining high standards throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival to verify compliance with specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process ensure that any deviations are caught early.

- Final Quality Control (FQC): The finished product undergoes comprehensive testing, including performance evaluations and visual inspections.

B2B buyers should request information about the specific QC checkpoints implemented by their suppliers to ensure robust quality assurance.

What Common Testing Methods Are Used in Quality Assurance?

Testing methods vary depending on the component and intended use of the dust collection system. Common methods include:

- Airflow Testing: Ensures that the system meets specified airflow requirements, which is critical for effective dust collection.

- Leak Testing: Confirms that there are no leaks in the ductwork, which can undermine system performance.

- Filtration Efficiency Testing: Validates that filters effectively capture particulate matter, ensuring compliance with health standards.

Buyers can request test reports or certifications to verify that the systems meet necessary performance criteria.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, particularly those in international markets, should take proactive steps to verify the quality control measures of their suppliers:

-

Supplier Audits: Conducting audits of suppliers’ facilities provides insight into their manufacturing processes and quality assurance practices.

-

Requesting Reports: Buyers should ask for documentation that outlines quality control procedures and results from testing.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control processes.

-

Understanding Regional Nuances: Buyers from different regions, such as Africa, South America, the Middle East, and Europe, should be aware of regional standards and practices that may influence quality assurance.

By implementing these strategies, B2B buyers can ensure they are partnering with manufacturers who prioritize quality, thereby enhancing the reliability and performance of their dust collection systems.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dust collection system layout’

Introduction

This sourcing guide serves as a practical checklist for B2B buyers looking to procure an effective dust collection system layout. An efficient dust collection system is essential for maintaining a clean and safe working environment, particularly in industries such as woodworking, manufacturing, and construction. This checklist will help you navigate the complexities of selecting the right components and suppliers for your dust collection needs.

Step 1: Assess Your Workspace Requirements

Understanding the specific needs of your workspace is crucial. Evaluate the size of your shop, the types of tools in use, and the volume of dust generated. This assessment will inform the design of your dust collection layout, ensuring you select a system that is both efficient and effective.

Illustrative image related to dust collection system layout

- Consider airflow requirements based on the tools you operate.

- Map out the layout to identify optimal duct runs and collector placement.

Step 2: Define Your Technical Specifications

Before sourcing, clearly outline the technical specifications for your dust collection system. This includes the required cubic feet per minute (CFM) airflow, static pressure, and filtration efficiency.

- Look for systems with a minimum of 1,300 CFM for effective dust removal.

- Prioritize HEPA filters for superior air quality, capturing at least 99.97% of .3-micron particles.

Step 3: Evaluate Potential Suppliers

Vetting suppliers is essential to ensure quality and reliability. Research their backgrounds, focusing on their experience in dust collection systems and their customer service reputation.

- Request case studies and references from similar industries or regions to gauge performance.

- Investigate supplier certifications to ensure compliance with industry standards.

Step 4: Examine Ductwork Options

Selecting the right ductwork is critical for system efficiency. Consider the materials, diameters, and configurations that best suit your layout.

- Choose materials like PVC or metal for durability, keeping in mind that smooth interiors enhance airflow.

- Opt for larger duct diameters close to the tools to minimize resistance and improve performance.

Step 5: Plan for Installation and Maintenance

Effective installation and maintenance are key to long-term system performance. Plan for secure mounting of ductwork and accessibility for regular inspections.

- Utilize hangers and supports to secure ductwork and keep it out of walkways.

- Incorporate blast gates to control airflow to individual tools, optimizing dust collection efficiency.

Step 6: Test Air Quality Post-Installation

Once installed, assessing air quality is vital to ensure your system is performing as intended. Use air quality monitors to detect potential issues early.

Illustrative image related to dust collection system layout

- Monitor for high dust levels to identify leaks or inefficiencies in your system.

- Adjust or upgrade components as necessary to maintain optimal performance and air quality.

Step 7: Review Your Budget and ROI

Finally, evaluate your budget and the return on investment (ROI) for the dust collection system. Consider both initial costs and long-term savings through improved air quality and reduced health risks.

- Invest in quality components to avoid frequent replacements and maintenance.

- Calculate potential savings from reduced health-related costs and improved productivity due to a cleaner workspace.

By following this checklist, B2B buyers can effectively navigate the sourcing process for dust collection systems, ensuring they choose the right layout and components for their specific needs.

Comprehensive Cost and Pricing Analysis for dust collection system layout Sourcing

In establishing a dust collection system layout, understanding the cost structure and pricing dynamics is essential for B2B buyers, especially those operating in diverse international markets. This analysis outlines the critical components affecting costs and pricing, along with valuable tips for negotiating and ensuring cost-efficiency.

Illustrative image related to dust collection system layout

What Are the Key Cost Components in Dust Collection System Layout?

-

Materials: The cost of materials significantly influences the overall pricing. High-quality ductwork, collectors, and filters—especially HEPA filters—can be more expensive but provide better performance and longevity. The choice between metal and PVC piping also affects material costs, with metal typically being more durable yet pricier.

-

Labor: Installation labor costs vary based on the complexity of the layout and the local labor market. Skilled technicians may command higher wages, particularly in regions with a shortage of qualified professionals. Consideration of labor costs should also include potential downtime during installation.

-

Manufacturing Overhead: Overhead costs encompass utilities, rent, and administrative expenses incurred by manufacturers. These costs can vary by region, impacting the final price of the dust collection systems.

-

Tooling: Specialized tooling may be necessary for custom installations, which adds to the upfront costs. Investing in quality tooling can enhance efficiency and reduce long-term costs.

-

Quality Control (QC): Ensuring that components meet quality standards is essential, particularly for systems that handle hazardous materials. QC processes can add to manufacturing costs but are critical for maintaining performance and safety standards.

-

Logistics: Shipping and handling costs can vary significantly based on geographical location and shipping method. International buyers should account for tariffs, duties, and potential delays that can impact the total cost.

-

Margin: Supplier margins can vary widely, influenced by brand reputation, quality, and service offerings. Understanding the margin structure can provide insights into potential negotiation points.

What Influences Pricing for Dust Collection Systems?

-

Volume/MOQ: The volume of purchase often dictates pricing. Larger orders typically benefit from bulk pricing, reducing the per-unit cost. Minimum Order Quantities (MOQ) can also impact small or emerging businesses.

-

Specifications and Customization: Custom solutions tailored to specific operational needs can drive up costs. Buyers should assess the necessity of customization against the potential benefits to avoid unnecessary expenditures.

-

Material Quality and Certifications: Systems that meet international certifications (e.g., ISO, CE) may command higher prices but offer assurance of quality and reliability. Buyers should weigh the importance of certifications against budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers play a crucial role. Well-established suppliers may charge a premium but often provide better support and warranty options, which can enhance long-term value.

-

Incoterms: Understanding Incoterms is vital for international transactions, as they define the responsibilities of buyers and sellers concerning shipping costs and risk. This knowledge can help buyers avoid unexpected costs.

What Are the Best Negotiation and Cost-Efficiency Tips for Buyers?

-

Leverage Volume Discounts: When possible, consolidate orders to achieve volume discounts. Forming partnerships with other businesses can also help achieve better pricing through collective purchasing.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the initial purchase price but the total cost of ownership, including installation, maintenance, and potential energy savings. A higher upfront cost may lead to lower operational costs over time.

-

Be Mindful of Pricing Nuances in International Markets: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of local economic conditions, currency fluctuations, and import regulations that can affect pricing.

-

Conduct Thorough Market Research: Understanding the market landscape helps in negotiating better terms. Knowing competitor pricing and offerings can provide leverage in discussions with suppliers.

-

Request Detailed Quotes: Ensure quotes include breakdowns of all costs, enabling better comparisons and negotiations with different suppliers.

Conclusion

Navigating the cost structure and pricing landscape for dust collection systems is complex but essential for making informed purchasing decisions. By understanding the components that influence costs and employing strategic negotiation tactics, B2B buyers can optimize their investments in dust collection solutions, ensuring both operational efficiency and compliance with health standards. Always remember that indicative prices may vary based on specific requirements and market conditions, so continuous engagement with suppliers is key to achieving the best outcomes.

Alternatives Analysis: Comparing dust collection system layout With Other Solutions

Exploring Alternatives to Dust Collection System Layouts: A Comparative Analysis

In the realm of industrial operations, effective dust management is crucial not only for maintaining a clean workspace but also for ensuring employee health and regulatory compliance. While a well-planned dust collection system layout is a popular choice, several alternative solutions exist that can achieve similar outcomes. This analysis compares the traditional dust collection system layout with two viable alternatives: portable dust collectors and air filtration systems.

| Comparison Aspect | Dust Collection System Layout | Portable Dust Collector | Air Filtration System |

|---|---|---|---|

| Performance | Highly efficient in capturing large and fine particles when properly designed. | Effective for localized dust control but may not handle larger volumes as well. | Primarily captures airborne particles but may not effectively eliminate larger dust debris. |

| Cost | Higher initial investment due to ductwork and installation. | Lower upfront cost; however, may require multiple units for larger spaces. | Moderate cost; typically lower than full dust collection systems but varies by model and filter type. |

| Ease of Implementation | Complex installation requiring professional assessment and design. | Simple setup; often plug-and-play with minimal assembly needed. | Easy to install but requires regular filter replacements and maintenance. |

| Maintenance | Requires periodic inspection of ductwork, collectors, and filters. | Low maintenance; filters need replacement based on usage. | Moderate maintenance; requires frequent filter changes to ensure efficiency. |

| Best Use Case | Ideal for larger workshops with multiple dust-producing tools. | Suitable for small workshops or specific tool stations. | Effective for enhancing air quality in enclosed spaces, especially where dust generation is intermittent. |

What Are the Benefits and Drawbacks of Portable Dust Collectors?

Portable dust collectors are designed for flexibility and ease of use, making them a convenient option for small workshops or specific job sites. They typically have lower upfront costs and are easy to install, requiring minimal setup. However, their performance is often limited to localized dust control, meaning they may not be as effective in larger areas with high dust generation. Furthermore, depending on the number of tools in use, multiple units may be necessary, which can increase overall costs in the long run.

Illustrative image related to dust collection system layout

How Do Air Filtration Systems Compare in Dust Management?

Air filtration systems focus primarily on improving air quality by capturing airborne dust particles. They are relatively easy to install and require minimal maintenance, making them an attractive choice for businesses looking for straightforward solutions. However, while they excel at filtering the air, they may not effectively manage larger debris or prevent dust accumulation on surfaces. This limitation means they are best used in conjunction with other dust management strategies rather than as standalone solutions.

Conclusion: Which Dust Management Solution Is Right for Your Business?

Choosing the right dust management solution requires careful consideration of your specific operational needs, workspace size, and budget constraints. A comprehensive dust collection system layout is ideal for larger facilities with multiple dust-generating tools, providing maximum efficiency and air quality control. Alternatively, portable dust collectors offer flexibility for smaller operations, while air filtration systems enhance air quality in less demanding environments. Assessing your unique requirements will enable you to select the most effective solution for maintaining a clean and safe workplace.

Essential Technical Properties and Trade Terminology for dust collection system layout

What Are the Essential Technical Properties of Dust Collection Systems?

When considering a dust collection system layout, understanding the technical properties is crucial for ensuring optimal performance and compliance with industry standards. Here are some critical specifications to consider:

Illustrative image related to dust collection system layout

1. Airflow (CFM)

Airflow, measured in cubic feet per minute (CFM), is the volume of air that a dust collector can move. This specification directly impacts the efficiency of dust removal from your workspace. For B2B buyers, selecting a system with adequate CFM ratings ensures that even the finest dust particles are effectively captured, enhancing workplace safety and compliance with health regulations.

2. Static Pressure (SP)

Static pressure, often measured in inches of water gauge (inWG), indicates the resistance to airflow within the ductwork. Higher static pressure can lead to reduced airflow, so it is vital for buyers to assess the static pressure of their duct layouts. This will help in selecting a collector that can overcome resistance and maintain effective dust extraction, preventing costly inefficiencies.

3. Duct Diameter

The diameter of the ductwork significantly affects airflow and system efficiency. Larger ducts reduce air velocity loss and allow for smoother airflow. B2B buyers should consider the tool ports’ size and ensure that the duct diameter is compatible with the dust collector to minimize performance issues and maximize efficiency.

4. Filter Efficiency

Filter efficiency is often classified by its ability to capture particles of specific sizes. HEPA filters, for instance, are certified to trap 99.97% of particles as small as 0.3 microns. Investing in high-efficiency filters is vital for maintaining air quality and protecting worker health, making it an essential consideration for buyers looking to comply with occupational safety standards.

5. Material Grade and Construction

The materials used in ductwork and collectors—such as galvanized steel, PVC, or aluminum—affect durability, performance, and cost. Higher-grade materials may offer better longevity and resistance to wear, which is essential for buyers looking to minimize maintenance and replacement costs over time.

What Common Trade Terms Should B2B Buyers Know for Dust Collection Systems?

Understanding the jargon associated with dust collection systems can facilitate smoother transactions and clearer communication between buyers and suppliers. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that are sold under another company’s brand. In the dust collection industry, knowing your OEM can be crucial for sourcing compatible parts and ensuring quality.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of goods a supplier is willing to sell. This term is significant for B2B buyers as it helps in budgeting and inventory planning. Understanding the MOQ can also influence purchasing decisions, particularly when evaluating multiple suppliers.

Illustrative image related to dust collection system layout

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. B2B buyers should utilize RFQs to gather competitive pricing, ensuring they receive the best value for their investment in dust collection systems.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping, insurance, and duties, which are critical for effective global supply chain management.

5. Static Pressure Loss

This term refers to the decrease in air pressure within the duct system due to friction and resistance. For B2B buyers, understanding static pressure loss is vital for selecting the appropriate dust collector that can handle the expected resistance in the layout, ensuring efficient dust extraction.

In conclusion, a solid grasp of both technical properties and industry terminology enables B2B buyers to make informed decisions when investing in dust collection systems, ultimately enhancing workplace safety and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the dust collection system layout Sector

What Are the Key Market Dynamics and Trends Affecting Dust Collection System Layouts?

The dust collection system layout market is experiencing significant growth, driven by increasing regulations on workplace safety and environmental standards across various industries. As global manufacturing and construction activities expand, particularly in regions like Africa, South America, the Middle East, and Europe, the demand for efficient dust collection systems has surged. This growth is further fueled by advancements in technology, such as the integration of IoT and automation, which enhance system efficiency and provide real-time monitoring capabilities. B2B buyers are increasingly seeking solutions that not only meet compliance requirements but also improve operational efficiency and reduce maintenance costs.

Emerging trends indicate a shift towards modular and customizable systems that can be tailored to specific operational needs. Buyers are looking for flexibility in installation and scalability to accommodate future growth. Additionally, there is a growing interest in smart dust collection systems that utilize sensors and data analytics to optimize performance and reduce energy consumption. The COVID-19 pandemic has also heightened awareness of air quality and health, leading to a greater emphasis on systems that capture fine particulate matter effectively.

How Is Sustainability and Ethical Sourcing Influencing the Dust Collection System Layout Market?

Sustainability and ethical sourcing have become pivotal considerations for B2B buyers in the dust collection sector. The environmental impact of dust collection systems, particularly regarding energy consumption and waste management, is under scrutiny. Companies are increasingly prioritizing solutions that minimize carbon footprints and enhance overall sustainability. This has led to a rise in demand for equipment that incorporates energy-efficient technologies and sustainable materials.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are now more inclined to partner with manufacturers who adhere to environmental standards and ethical labor practices. Certifications such as ISO 14001 for environmental management and the use of ‘green’ materials in manufacturing processes are becoming critical factors in purchasing decisions. This trend not only helps companies comply with regulations but also enhances their brand reputation among environmentally-conscious consumers and stakeholders.

How Has the Dust Collection System Layout Market Evolved Over Time?

The evolution of dust collection systems can be traced back to the early industrial era, where rudimentary methods were employed to manage dust and debris. Over the decades, technological advancements have revolutionized the industry, leading to the development of more sophisticated systems capable of capturing finer particles. The introduction of cyclone and baghouse systems marked significant milestones in efficiency and effectiveness.

In recent years, the focus has shifted towards creating integrated systems that not only collect dust but also improve air quality and worker safety. The advancement of filtration technology, particularly HEPA filters, has greatly improved the ability of dust collection systems to trap harmful particles. Today, B2B buyers are looking for comprehensive solutions that combine performance, sustainability, and adaptability to meet the diverse needs of modern industrial environments. This historical perspective underscores the importance of innovation and responsiveness to market demands in shaping the future of dust collection system layouts.

Frequently Asked Questions (FAQs) for B2B Buyers of dust collection system layout

-

How do I solve issues with dust collection efficiency in my layout?

To enhance dust collection efficiency, start by optimizing your layout. Position the dust collector centrally to minimize duct lengths and use the largest diameter pipes possible to reduce airflow resistance. Limit sharp turns in ductwork; prefer gradual bends with large-radius elbows. Regularly inspect for leaks and ensure that all connections are secure. Utilizing blast gates can also help focus airflow on the active tool, maximizing suction where it’s needed most. -

What is the best dust collection system for a medium-sized woodworking shop?

For a medium-sized woodworking shop, a cyclone dust collector with a minimum of 2 HP and a CFM rating of at least 1,300 is recommended. This setup provides robust airflow and effective filtration, capturing fine particles that could pose health risks. Ensure the system includes HEPA filters for optimal air quality. Consider the layout of your shop when selecting duct sizes and configurations to minimize resistance and maximize efficiency. -

How can I customize a dust collection system to fit my specific needs?

Customization of a dust collection system can be achieved by assessing your shop’s unique requirements, such as tool placement and dust generation levels. Work with suppliers who offer tailored solutions, including duct sizes, configurations, and collector types. Additionally, consider integrating blast gates and specialized hoods for difficult-to-connect tools. Always communicate your specific needs to the manufacturer or supplier to ensure the solution fits your operational requirements. -

What should I look for when vetting suppliers for dust collection systems?

When vetting suppliers, prioritize those with a proven track record in the dust collection industry. Check for certifications, customer testimonials, and case studies relevant to your industry. Evaluate their ability to provide support, including design services and after-sales assistance. Also, inquire about their compliance with international standards, especially if you are importing equipment to regions with strict regulations, such as Europe or the Middle East. -

What are the minimum order quantities (MOQ) for dust collection systems?

Minimum order quantities can vary significantly by supplier and the specific components you require. Some manufacturers may have an MOQ of one unit, while others might require a bulk order to provide competitive pricing. It’s essential to discuss your needs directly with suppliers, particularly if you’re looking to equip multiple locations or require additional components for future expansion. -

What payment terms should I expect when purchasing dust collection systems internationally?

Payment terms for international purchases typically vary based on the supplier’s policies and your negotiation. Common terms include upfront payment, a deposit followed by the balance upon delivery, or net 30/60 days after receipt. Make sure to clarify these terms before finalizing the order. Additionally, consider using secure payment methods that offer buyer protection, especially for larger transactions. -

How do I ensure quality assurance (QA) for my dust collection system?

To ensure quality assurance, request detailed specifications and certifications from your supplier, particularly regarding the filtration effectiveness and durability of materials used. It’s also beneficial to establish a QA process that includes inspections upon receipt of the equipment and regular maintenance checks. Engaging a third-party inspection service can provide additional assurance that the system meets all required standards before installation. -

What logistics considerations should I keep in mind when sourcing dust collection systems?

Logistics play a crucial role in the sourcing of dust collection systems. Consider the shipping methods available, as well as import duties and tariffs that may apply in your country. Evaluate the lead time for production and delivery to ensure it aligns with your project timelines. Additionally, discuss with the supplier about their capabilities to manage shipping logistics, including tracking and handling potential customs issues for smoother delivery.

Top 1 Dust Collection System Layout Manufacturers & Suppliers List

1. Reddit – Dust Collection Guidelines

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Dust Collection Guidelines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for dust collection system layout

In conclusion, an effective dust collection system layout is critical for optimizing operational efficiency, ensuring workplace safety, and enhancing product quality in diverse industries. Strategic sourcing plays a pivotal role in this process by facilitating informed decisions regarding the selection of high-quality dust collection equipment, ductwork, and accessories tailored to specific operational needs. Prioritizing factors such as airflow efficiency, system scalability, and filtration capabilities not only maximizes performance but also safeguards employee health and complies with regulatory standards.

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, investing in a well-planned dust collection system can lead to significant long-term cost savings and operational improvements. As industries worldwide increasingly prioritize sustainability and safety, the demand for advanced dust collection solutions will continue to rise.

Take proactive steps today by assessing your current systems, exploring reputable suppliers, and leveraging advanced technology to elevate your dust management practices. Embrace the opportunity to enhance your operational resilience and drive your business forward in an increasingly competitive market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.