Unlocking Value: A Strategic Analysis of the Do It Yourself Closed Cell Spray Foam Market

Introduction: Navigating the Global Market for do it yourself closed cell spray foam

In an increasingly competitive global market, sourcing high-quality do-it-yourself closed cell spray foam can pose significant challenges for B2B buyers, particularly those in emerging regions like Africa, South America, and the Middle East, as well as established markets in Europe such as Germany and Brazil. This guide is designed to empower international buyers by providing a comprehensive overview of the various types of closed cell spray foam insulation available, their applications, and practical insights into supplier vetting processes.

From understanding product specifications to evaluating cost structures and bulk purchasing options, this resource offers actionable strategies for making informed decisions tailored to your specific project needs. The market for spray foam insulation is diverse, with options ranging from fast-rise formulas ideal for new constructions to slow-rise products that facilitate retrofitting in older buildings. Additionally, the guide addresses the nuances of sourcing and logistics, ensuring that buyers can navigate potential barriers while maximizing their investment.

By leveraging the insights presented in this guide, B2B buyers will be equipped to identify reputable suppliers, negotiate favorable terms, and ultimately enhance their operational efficiency through effective use of closed cell spray foam. Whether you are looking to insulate residential properties or commercial spaces, this guide serves as a pivotal tool in your purchasing journey, enabling you to make choices that align with both your budget and project requirements.

Understanding do it yourself closed cell spray foam Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fast Rise Closed Cell Spray Foam | Quick expansion, ideal for new constructions and open surfaces. | Residential and commercial construction. | Pros: Fast application, effective insulation. Cons: Requires precision to avoid overspray. |

| Slow Rise Closed Cell Spray Foam | Expands slowly, filling cavities without damaging existing structures. | Retrofitting older buildings. | Pros: Better for tight spaces, less risk of damage. Cons: Longer application time. |

| Refillable Closed Cell Spray Foam | Customizable volume, suitable for varying project sizes. | Large-scale projects, contractors. | Pros: Economical for large applications. Cons: Requires more setup and calibration. |

| Low Pressure Closed Cell Spray Foam | Operates at lower pressure, reducing overspray and waste. | DIY projects, small renovations. | Pros: User-friendly, less waste. Cons: May require more time for curing. |

| High Density Closed Cell Spray Foam | Higher R-value per inch, providing superior insulation. | Industrial applications, cold storage. | Pros: Excellent thermal resistance, durable. Cons: Higher initial cost. |

What Are the Key Characteristics of Fast Rise Closed Cell Spray Foam?

Fast rise closed cell spray foam is characterized by its rapid expansion, making it ideal for new constructions or applications on open surfaces. It is designed for quick application, allowing contractors to complete projects efficiently. This type of foam is often favored for its high insulation value and air sealing capabilities, which can significantly reduce energy costs over time. B2B buyers should consider the precision required during application to avoid overspray, which can lead to additional cleanup costs.

How Does Slow Rise Closed Cell Spray Foam Benefit Retrofitting Projects?

Slow rise closed cell spray foam expands at a controlled rate, making it particularly suitable for retrofitting older buildings and filling cavities without compromising existing structures. This type of foam is advantageous in tight spaces, ensuring thorough coverage and insulation without the risk of damaging walls or ceilings. B2B buyers should assess the longer application time and ensure that their project timelines can accommodate this slower process, especially when dealing with extensive retrofitting.

Why Choose Refillable Closed Cell Spray Foam for Large Projects?

Refillable closed cell spray foam kits offer customizable volumes, making them an excellent choice for contractors engaged in large-scale projects. These kits allow users to adjust the amount of foam used, minimizing waste and optimizing costs. The ability to refill tanks also makes them more economical for extensive applications. Buyers should consider the additional setup and calibration requirements, which may necessitate training for staff to ensure effective use.

What Are the Advantages of Low Pressure Closed Cell Spray Foam?

Low pressure closed cell spray foam operates at reduced pressure, which minimizes overspray and waste during application. This user-friendly option is ideal for DIY projects and small renovations, making it accessible for contractors and homeowners alike. B2B buyers should note that while it is easier to handle, it may require more time for the foam to cure fully, which can affect project timelines.

When Is High Density Closed Cell Spray Foam the Right Choice?

High density closed cell spray foam provides a superior R-value per inch, making it an excellent option for industrial applications and cold storage facilities. Its durability and thermal resistance are key benefits for businesses looking to maintain temperature-controlled environments. While the initial investment may be higher, the long-term energy savings and performance make it a worthwhile consideration for B2B buyers focused on efficiency and sustainability.

Key Industrial Applications of do it yourself closed cell spray foam

| Industry/Sector | Specific Application of do it yourself closed cell spray foam | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Insulating walls and roofs in residential and commercial buildings | Reduces energy costs and enhances thermal efficiency | Ensure compliance with local building codes and standards |

| Agriculture | Insulating agricultural equipment and storage facilities | Protects temperature-sensitive goods and reduces energy use | Consider environmental impact and potential for moisture control |

| Automotive | Soundproofing and insulating vehicles | Improves comfort and reduces noise levels | Look for products that meet automotive safety standards |

| Marine | Insulating boats and ships | Increases energy efficiency and prevents condensation | Ensure marine-grade quality for durability in harsh conditions |

| Renewable Energy | Insulating solar panel installations and wind turbine bases | Enhances energy efficiency and lifespan of installations | Source products that are compatible with specific energy systems |

How is do it yourself closed cell spray foam used in the construction industry?

In the construction sector, do it yourself closed cell spray foam is widely utilized for insulating walls and roofs in both residential and commercial buildings. This application not only minimizes energy costs by creating a tight building envelope but also enhances thermal efficiency, which is crucial for maintaining comfortable indoor environments. For international buyers, particularly in regions like Africa and South America, it is essential to ensure compliance with local building codes and standards to avoid legal and safety issues.

What role does closed cell spray foam play in agriculture?

In agriculture, closed cell spray foam is employed to insulate equipment and storage facilities, safeguarding temperature-sensitive goods such as produce and chemicals. This insulation helps in reducing energy consumption, thereby lowering operational costs. Buyers in this sector should consider the environmental impact of the foam, especially in regions where moisture control is critical to prevent spoilage and maintain product quality.

How does closed cell spray foam enhance automotive applications?

The automotive industry benefits from do it yourself closed cell spray foam primarily through soundproofing and insulation of vehicles. By improving comfort levels and reducing noise, this application significantly enhances the driving experience. For businesses in the automotive sector, sourcing products that meet stringent automotive safety standards is crucial to ensure compliance and customer satisfaction.

Why is closed cell spray foam important for marine applications?

In marine applications, closed cell spray foam is used for insulating boats and ships, contributing to energy efficiency and preventing condensation that can lead to mold and structural damage. This is particularly valuable in harsh marine environments. Buyers should prioritize sourcing marine-grade quality products that offer durability and resistance to saltwater and other corrosive elements.

How does closed cell spray foam support renewable energy initiatives?

Do it yourself closed cell spray foam plays a vital role in the renewable energy sector, particularly in insulating solar panel installations and wind turbine bases. This insulation enhances the energy efficiency and lifespan of these systems, making them more effective in generating renewable energy. Buyers should ensure that the products sourced are compatible with specific energy systems to maximize their performance and sustainability benefits.

3 Common User Pain Points for ‘do it yourself closed cell spray foam’ & Their Solutions

Scenario 1: Difficulty in Proper Application and Coverage Estimation

The Problem: One common challenge faced by B2B buyers utilizing do-it-yourself closed cell spray foam is the difficulty in accurately estimating the amount of material needed for a project. Miscalculating coverage can lead to project delays, increased costs, and wasted resources. Buyers often struggle with the technical aspects of calculating board footage, especially when applying foam to irregularly shaped areas or when multiple layers are required for optimal insulation.

The Solution: To ensure efficient use of closed cell spray foam, B2B buyers should begin by meticulously measuring the surfaces to be insulated. Utilizing a coverage calculator provided by suppliers can help translate dimensions into board feet (BFT) requirements. It’s crucial to account for the thickness of the foam being applied—typically 1 inch yields approximately 7 R-value per inch. For projects involving complex shapes, segment the area into simpler geometric forms and calculate the necessary foam for each section before adding them together. Additionally, consider purchasing a slightly larger kit to avoid running short, especially for larger projects. Suppliers often provide bulk discounts for larger kits, which can be a cost-effective solution.

Scenario 2: Inconsistent Foam Quality and Performance

The Problem: Another pain point is the inconsistency in foam quality, which can significantly impact insulation performance. B2B buyers may find that the product they receive does not meet the expected specifications for density, rise time, or thermal resistance. This can lead to ineffective insulation and potential rework, resulting in increased labor costs and project timelines.

The Solution: To mitigate quality issues, B2B buyers should prioritize sourcing products from reputable manufacturers known for stringent quality control and transparency in their formulation processes. Before making a purchase, ask for product certifications, such as ASTM compliance, and request samples if possible. Additionally, consider investing in equipment that allows for better mixing and application control, such as dual-component spray guns that ensure a consistent blend of chemicals. Regularly reviewing supplier performance and customer feedback can also help in identifying reliable products that meet industry standards.

Scenario 3: Health and Safety Concerns During Application

The Problem: Health and safety during the application process is a critical concern for B2B buyers. Closed cell spray foam can release harmful chemicals if not handled properly, posing risks to workers’ health. Buyers often worry about ensuring compliance with local health regulations and providing adequate safety training for their teams.

The Solution: To address these health and safety issues, B2B buyers should implement a comprehensive safety training program that includes the proper handling of spray foam. This should cover the use of personal protective equipment (PPE), such as respirators, gloves, and goggles, to minimize exposure to harmful chemicals. Additionally, suppliers often provide safety data sheets (SDS) that outline the risks and safety measures associated with their products. It’s beneficial to establish a ventilation plan for the workspace to ensure that any fumes are adequately dispersed. Regular safety audits and compliance checks can help maintain a safe working environment and ensure adherence to regulations, ultimately protecting both employees and the company’s reputation.

Strategic Material Selection Guide for do it yourself closed cell spray foam

When selecting materials for do-it-yourself closed cell spray foam, it’s essential to consider the properties, advantages, and limitations of the various components involved. Here, we analyze four common materials used in closed cell spray foam applications, focusing on their performance characteristics and implications for international B2B buyers.

What Are the Key Properties of Polyurethane in Closed Cell Spray Foam?

Polyurethane is the most widely used material for closed cell spray foam. It exhibits excellent insulation properties, with an R-value of approximately 6 to 7 per inch, making it highly effective for thermal resistance. Polyurethane also has a good temperature rating, typically ranging from -50°F to 200°F (-45°C to 93°C), and is resistant to moisture and mold, which is crucial for maintaining the integrity of the insulation over time.

Pros: The durability and energy efficiency of polyurethane make it suitable for a variety of applications, from residential to commercial insulation. It is relatively easy to apply, especially with DIY kits that come with necessary equipment.

Cons: The complexity of the manufacturing process can lead to higher costs compared to other materials. Additionally, improper application can result in uneven insulation and potential waste.

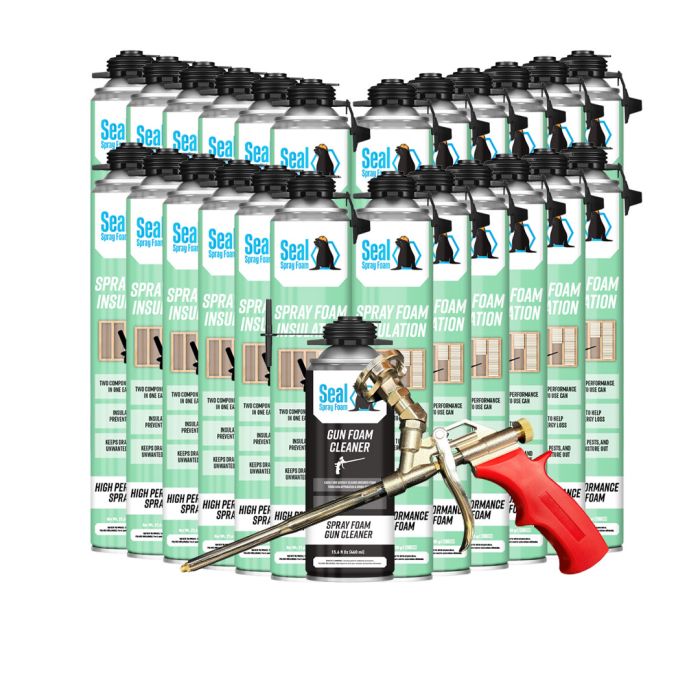

Illustrative image related to do it yourself closed cell spray foam

How Does Polyisocyanurate Compare in Terms of Performance?

Polyisocyanurate is another material used in closed cell foam formulations, known for its high thermal resistance and fire retardant properties. It typically offers an R-value slightly higher than polyurethane, around 7 to 8 per inch. This material also performs well under varying temperatures and has a good resistance to moisture.

Pros: Its fire-resistant properties make it a preferred choice for applications requiring compliance with strict safety regulations. Polyisocyanurate is also less prone to shrinking over time, which can enhance the longevity of the insulation.

Cons: The cost of polyisocyanurate can be higher than that of polyurethane, and its application requires careful handling to avoid issues during installation.

What Role Does Blowing Agent Play in Closed Cell Spray Foam?

Blowing agents are crucial in the production of closed cell spray foam, as they facilitate the expansion of the foam during application. Common blowing agents include HFCs, HCFCs, and more environmentally friendly options like HFOs. The choice of blowing agent can significantly affect the foam’s thermal performance and environmental impact.

Pros: The latest HFO blowing agents have a low global warming potential (GWP), making them more environmentally friendly and compliant with international regulations.

Cons: The transition to more eco-friendly blowing agents can lead to increased costs and manufacturing complexity. Additionally, some blowing agents may not be as effective in extreme temperatures.

What Are the Considerations for International B2B Buyers in Material Selection?

International B2B buyers must consider compliance with regional standards such as ASTM in the U.S., DIN in Germany, and other local regulations. For example, in Europe, the use of low-GWP blowing agents is becoming mandatory, which may affect material selection. Buyers from regions like Africa and South America should also be aware of the availability of materials and local supplier capabilities to ensure timely project execution.

Summary Table of Material Selection for Closed Cell Spray Foam

| Material | Typical Use Case for do it yourself closed cell spray foam | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane | Residential and commercial insulation | Excellent thermal resistance and ease of application | Higher manufacturing complexity and potential waste | Medium |

| Polyisocyanurate | Fire-sensitive applications and high-performance insulation | Higher R-value and fire resistance | Higher cost and careful handling required | High |

| HFO Blowing Agent | Environmentally friendly closed cell foam production | Low global warming potential and compliance with regulations | Increased costs and potential performance trade-offs | Medium to High |

| HCFC Blowing Agent | Traditional closed cell foam applications | Established performance and availability | High GWP and potential regulatory issues | Medium |

This strategic material selection guide provides B2B buyers with actionable insights into the materials used in closed cell spray foam, enabling informed decisions that align with their project requirements and regional regulations.

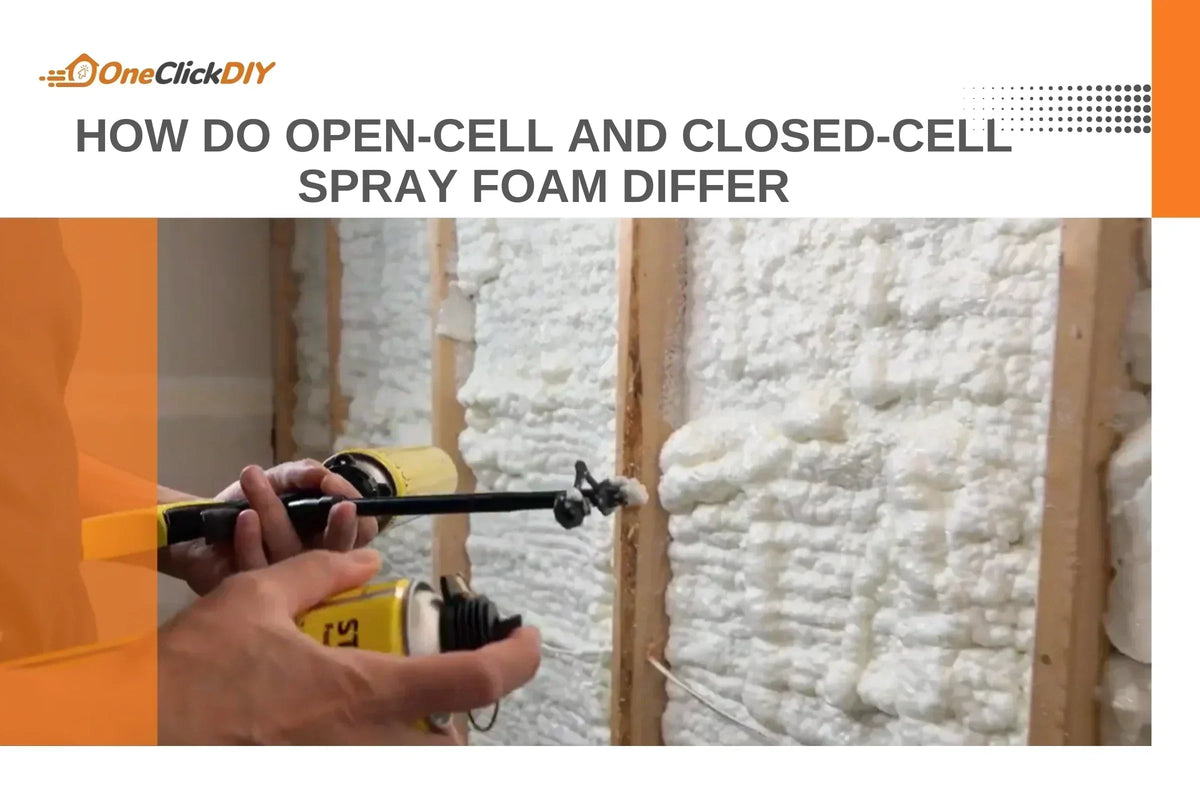

Illustrative image related to do it yourself closed cell spray foam

In-depth Look: Manufacturing Processes and Quality Assurance for do it yourself closed cell spray foam

What Are the Main Stages in the Manufacturing Process of Do It Yourself Closed Cell Spray Foam?

The manufacturing process for do it yourself closed cell spray foam involves several key stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: The initial phase involves sourcing high-quality raw materials, primarily polyols and isocyanates. These components must meet specific purity and performance standards to ensure optimal foam quality. Suppliers often utilize advanced chemical analysis techniques to assess the composition of these materials.

-

Forming: During this stage, the prepared materials are mixed in precise ratios. The formulation is critical since it affects the foam’s density, insulation properties, and curing time. Manufacturers often employ sophisticated mixing technologies, such as static or dynamic mixers, to achieve a uniform blend. The mixing process may also involve temperature control to ensure that the chemical reaction occurs optimally.

-

Assembly: Once the foam is formed, it is packaged into user-friendly kits. This includes filling the A and B component tanks, attaching hoses and spray guns, and providing necessary accessories such as nozzles and instructional materials. The packaging process is crucial, as it ensures that the components remain uncontaminated and are easy for consumers to use.

-

Finishing: The final stage involves quality checks and labeling. The foam kits are visually inspected for defects, and each kit is labeled with detailed usage instructions and safety guidelines. This stage may also include the application of protective coatings on the tanks to prevent corrosion and ensure longevity.

What Quality Control Measures Are Essential for Ensuring Do It Yourself Closed Cell Spray Foam Quality?

Quality control (QC) is paramount in the production of closed cell spray foam to meet industry standards and ensure customer satisfaction. Here are some essential measures:

-

International and Industry-Specific Standards: Adhering to international standards such as ISO 9001 is crucial for manufacturers. This standard emphasizes a process-oriented approach to quality management, ensuring consistent production and customer satisfaction. Additionally, industry-specific certifications like CE (Conformité Européenne) for the European market and API (American Petroleum Institute) certifications are often required, particularly for products intended for specific applications.

-

Quality Control Checkpoints: Manufacturers implement several QC checkpoints throughout the production process:

– Incoming Quality Control (IQC): This involves the inspection of raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Continuous monitoring during production helps identify issues early, allowing for immediate corrective actions.

– Final Quality Control (FQC): The final product undergoes rigorous testing to ensure it meets all specifications before packaging. -

Common Testing Methods: Various testing methods are employed to assess the foam’s properties, including:

– Density Testing: Ensures the foam meets the specified density for insulation effectiveness.

– Thermal Conductivity Testing: Measures the R-value, indicating the foam’s insulation efficiency.

– Fire Resistance Testing: Ensures compliance with fire safety standards, which is particularly important in construction applications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify the quality control practices of their suppliers:

-

Supplier Audits: Conducting on-site audits is one of the most effective ways to assess a supplier’s QC practices. This allows buyers to evaluate the manufacturing processes, equipment, and adherence to quality standards firsthand.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QC processes, including results from testing and compliance with standards. These reports should outline the testing methods used and the frequency of quality checks.

-

Third-Party Inspections: Engaging third-party inspection services can offer an impartial assessment of a supplier’s quality control. These organizations can conduct audits and testing, providing an additional layer of assurance regarding product quality.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers must be aware of specific nuances regarding QC and certifications, especially when sourcing from different regions:

Illustrative image related to do it yourself closed cell spray foam

-

Regional Standards Compliance: Different regions may have varying regulatory requirements. For instance, products sold in the European Union must comply with CE marking requirements, while those in North America may need to meet ASTM (American Society for Testing and Materials) standards. Buyers should ensure their suppliers are compliant with the relevant regulations in their target markets.

-

Cultural and Economic Considerations: In regions such as Africa and South America, suppliers may face different challenges, including varying levels of technological advancement and regulatory enforcement. Buyers should consider these factors when assessing the reliability of QC practices.

-

Language and Communication Barriers: Effective communication is critical in ensuring that quality standards are understood and met. Buyers should establish clear communication channels and consider language barriers that may affect quality assurance processes.

-

Documentation and Traceability: Ensuring that suppliers maintain comprehensive documentation of their QC processes is vital. This documentation should include batch records, inspection logs, and test results, which can be crucial for traceability and accountability in case of quality issues.

Conclusion

Understanding the manufacturing processes and quality assurance measures for do it yourself closed cell spray foam is essential for B2B buyers looking to ensure product quality and compliance with international standards. By focusing on robust QC practices and thorough supplier verification methods, buyers can mitigate risks and enhance their sourcing strategies in this competitive market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘do it yourself closed cell spray foam’

In the competitive landscape of construction and insulation, sourcing the right closed cell spray foam is critical for optimizing performance and cost-efficiency. This guide serves as a practical checklist to assist B2B buyers in navigating the procurement process for do-it-yourself closed cell spray foam insulation kits.

Step 1: Define Your Technical Specifications

Understanding your project requirements is the first step in sourcing closed cell spray foam. Consider factors such as the R-value needed, the size of the area to be insulated, and specific application methods. This clarity will guide you in selecting the appropriate product type and size, ensuring optimal insulation performance.

Illustrative image related to do it yourself closed cell spray foam

Step 2: Research Supplier Options

Conduct thorough research to identify potential suppliers specializing in spray foam insulation. Look for companies with a proven track record in your target regions, such as Africa, South America, the Middle East, and Europe. Consider their market reputation, product range, and customer reviews to build a shortlist of reliable suppliers.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, product specifications, and references from previous buyers in similar industries. Assess their ability to meet regulatory standards and certifications specific to your region, as this can impact the quality and safety of the insulation.

Step 4: Request Samples and Product Documentation

Obtain product samples and comprehensive documentation for the spray foam kits you’re considering. This should include technical data sheets, safety data sheets, and application instructions. Evaluating samples allows you to assess the foam’s quality, consistency, and performance characteristics firsthand, ensuring they meet your project standards.

Step 5: Assess Pricing and Bulk Discounts

Pricing can vary significantly among suppliers, so it’s vital to compare costs while considering the overall value. Inquire about bulk purchasing options and discounts, especially if you plan to use large quantities. Be cautious of prices that seem too low, as they may reflect lower quality products or lack of customer support.

Step 6: Verify After-Sales Support and Training

Quality after-sales support can be crucial for successful installation. Ensure that the supplier offers training resources, customer service, and technical support. This can include installation guides, troubleshooting assistance, and access to experts who can help resolve any issues during the application process.

Step 7: Confirm Shipping and Delivery Terms

Before finalizing your order, clarify shipping and delivery terms with the supplier. Understand lead times, shipping costs, and the logistics involved, particularly if you’re ordering internationally. Timely delivery is essential to keep your project on schedule, so ensure that the supplier can meet your timelines.

By following this checklist, B2B buyers can navigate the complexities of sourcing do-it-yourself closed cell spray foam effectively, ensuring they select the right products for their insulation needs while maximizing value and support from suppliers.

Comprehensive Cost and Pricing Analysis for do it yourself closed cell spray foam Sourcing

When considering the sourcing of do-it-yourself closed cell spray foam, it is crucial to understand the various cost components that contribute to the overall pricing structure. This analysis will cover the essential elements, price influencers, and practical tips for international buyers, particularly those from Africa, South America, the Middle East, and Europe.

Illustrative image related to do it yourself closed cell spray foam

What Are the Key Cost Components in Closed Cell Spray Foam Pricing?

-

Materials: The primary materials for closed cell spray foam include two components: isocyanate and polyol resin. The cost of these raw materials can fluctuate based on global market trends, availability, and supplier contracts. The quality of materials also affects pricing, as higher-grade components typically yield better insulation properties and durability.

-

Labor: While DIY kits minimize the need for professional labor, costs may still arise from training personnel or hiring skilled workers for larger projects. Labor costs can vary significantly by region, impacting the total cost of ownership.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can reduce overhead, allowing suppliers to offer more competitive pricing.

-

Tooling: Initial tooling costs for specialized equipment can be significant, especially for custom formulations or large-scale orders. However, these costs are often amortized over high-volume orders, leading to lower per-unit costs.

-

Quality Control (QC): Ensuring product quality through rigorous testing is essential, especially for insulation materials that must meet specific safety and performance standards. QC processes can add to the overall cost but are crucial for minimizing defects and ensuring compliance with certifications.

-

Logistics: Shipping costs can vary widely based on the destination, weight, and volume of the order. International buyers should consider the complexities of customs, import duties, and potential delays, which can affect the final price.

-

Margin: Suppliers will typically add a profit margin to cover their costs and ensure sustainability. This margin can vary based on market competition and the unique value proposition offered by the supplier.

What Influences the Pricing of Closed Cell Spray Foam?

-

Volume and Minimum Order Quantity (MOQ): Bulk orders generally attract significant discounts, making it essential for buyers to assess their project needs against MOQ requirements. Larger volumes can lead to lower per-unit costs.

-

Specifications and Customization: Specialized formulations or custom sizes can increase costs. Buyers should evaluate whether standard products meet their requirements before opting for custom solutions.

-

Material Quality and Certifications: Products that meet higher performance standards or possess certifications (e.g., ASTM E-84 for fire retardance) may come at a premium. Buyers should weigh the benefits of these certifications against their project requirements.

-

Supplier Factors: The reputation, reliability, and financial stability of suppliers can influence pricing. Established suppliers may charge more due to their track record and customer service capabilities.

-

Incoterms: Understanding shipping terms is vital for international transactions. Incoterms dictate responsibility for shipping costs, insurance, and risk, which can significantly impact the total landed cost.

What Tips Can Buyers Use to Optimize Their Sourcing Strategy?

-

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Many suppliers are open to negotiations and can provide better rates for established relationships.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the upfront price. This includes considering energy savings, durability, and installation costs, which can result in long-term savings.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa and South America should account for currency fluctuations, shipping times, and local regulations that may affect costs. Understanding local market conditions can help in negotiating better terms.

-

Research and Compare: Conduct thorough market research to compare prices, features, and reviews from multiple suppliers. This ensures that you choose a product that meets both quality standards and budget constraints.

-

Stay Informed on Market Trends: Keep abreast of global supply chain issues, material shortages, or changes in regulations that can affect pricing. Being proactive can help in making informed purchasing decisions.

In summary, understanding the cost structure and pricing dynamics of do-it-yourself closed cell spray foam is essential for B2B buyers. By considering the various cost components, price influencers, and employing strategic sourcing tips, buyers can optimize their purchasing decisions and achieve better value for their investments.

Alternatives Analysis: Comparing do it yourself closed cell spray foam With Other Solutions

Exploring Alternatives to Do It Yourself Closed Cell Spray Foam

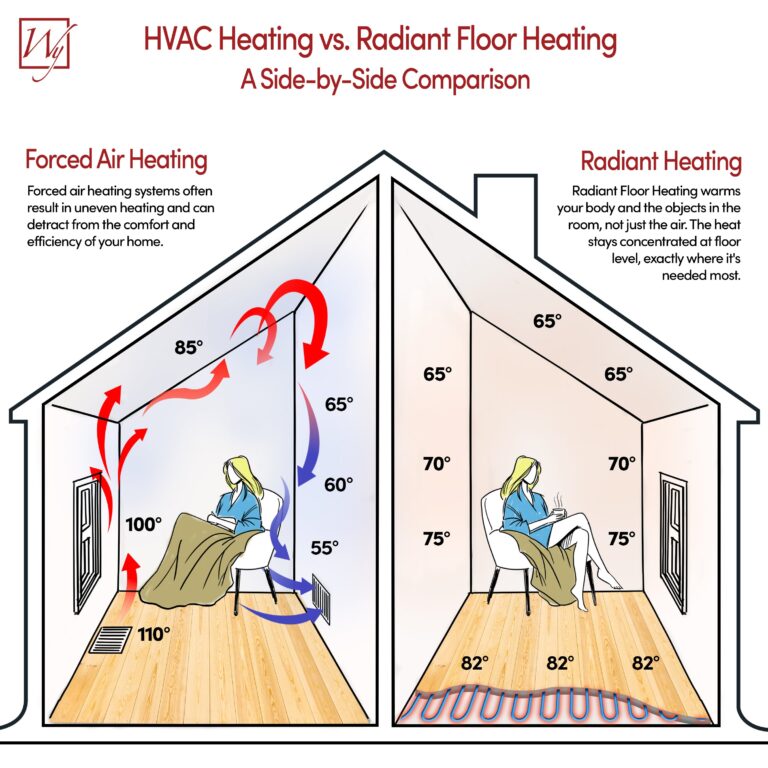

As businesses look for effective insulation solutions, it’s essential to consider various options available in the market. Do-it-yourself closed cell spray foam is a popular choice for its ease of use and efficiency, but alternative insulation methods may also be viable depending on specific project needs. This section compares do-it-yourself closed cell spray foam with two alternative solutions: fiberglass insulation and rigid foam board insulation.

| Comparison Aspect | Do It Yourself Closed Cell Spray Foam | Fiberglass Insulation | Rigid Foam Board Insulation |

|---|---|---|---|

| Performance | High R-value (approx. 7 per inch), excellent air sealant, moisture barrier | Moderate R-value (2.9-4.3 per inch), effective in soundproofing | High R-value (4-6.5 per inch), good thermal resistance |

| Cost | Moderate to high ($3.50-$5.00 per board foot) | Low to moderate ($0.50-$2.00 per board foot) | Moderate ($1.50-$3.00 per board foot) |

| Ease of Implementation | Requires some training for optimal application; can be messy | Easy to install; requires protective gear | Simple to install, but needs precise cutting and fitting |

| Maintenance | Minimal maintenance; durable over time | Prone to moisture issues if not properly installed | Low maintenance; highly durable |

| Best Use Case | Ideal for irregularly shaped spaces, high-performance applications | Best for standard wall cavities, attics, and ceilings | Suitable for exterior walls, foundations, and roofs |

What Are the Benefits and Drawbacks of Fiberglass Insulation?

Fiberglass insulation is one of the most traditional insulation methods. It consists of tiny glass fibers that trap air, providing thermal resistance. One of its main advantages is the low cost, making it accessible for large projects. However, fiberglass can be less effective in preventing air leaks compared to closed cell spray foam. It may also absorb moisture, leading to mold growth if not adequately protected, which can compromise its insulating properties.

Illustrative image related to do it yourself closed cell spray foam

How Does Rigid Foam Board Insulation Compare?

Rigid foam board insulation is another alternative that provides excellent thermal resistance. It comes in large sheets, making it easy to cover large areas quickly. Its high R-value per inch means it can be very effective in reducing energy costs. However, it requires careful installation to ensure gaps are sealed, as any air leaks can diminish its effectiveness. Additionally, it is more expensive than fiberglass but typically less than spray foam.

Making the Right Choice for Your Insulation Needs

Choosing the right insulation solution requires careful consideration of project specifics, including budget, space requirements, and desired performance outcomes. Do-it-yourself closed cell spray foam stands out for its high R-value and superior air sealing capabilities, making it an excellent choice for challenging applications. In contrast, fiberglass insulation may be suitable for budget-conscious projects where moisture exposure is minimal. Rigid foam board insulation can be an effective compromise, offering good performance with straightforward installation.

Ultimately, understanding the unique benefits and limitations of each option will empower B2B buyers to make informed decisions that align with their project goals and operational needs.

Essential Technical Properties and Trade Terminology for do it yourself closed cell spray foam

What Are the Key Technical Properties of Do It Yourself Closed Cell Spray Foam?

Closed cell spray foam insulation is a versatile solution widely used in various applications, from residential to commercial settings. Understanding its critical specifications is essential for businesses looking to make informed purchasing decisions.

1. R-Value

The R-value measures the thermal resistance of insulation materials. For closed cell spray foam, the R-value typically ranges from 6 to 7 per inch of thickness. A higher R-value indicates better insulation performance, which is crucial for energy efficiency in buildings. This metric is particularly important for B2B buyers looking to reduce energy costs and improve building performance.

2. Density

The density of closed cell spray foam usually varies between 1.5 to 3.0 pounds per cubic foot. Higher density foam offers superior structural integrity and moisture resistance, making it ideal for applications in humid climates or areas prone to water exposure. Understanding the density helps buyers assess the foam’s suitability for specific projects, ensuring compliance with local building codes.

3. Compressive Strength

Compressive strength indicates how much load the foam can bear without deforming. Closed cell spray foam typically has a compressive strength of 25 to 50 psi (pounds per square inch). This property is vital for applications where the foam will support weight, such as in roofing systems or as part of structural components in construction.

4. Expansion Ratio

The expansion ratio refers to how much the foam expands after being sprayed. Closed cell spray foam generally has an expansion ratio of about 30:1. This property is significant for B2B buyers, as it affects the amount of material needed for a project and influences installation efficiency.

5. VOC Content

Volatile Organic Compounds (VOCs) are chemicals released into the air as gases from certain solids or liquids. Closed cell spray foams with low VOC content are preferable for indoor applications, as they contribute to better indoor air quality. Buyers should consider VOC levels to comply with environmental regulations and ensure the safety of occupants.

Illustrative image related to do it yourself closed cell spray foam

What Are Common Trade Terms in the Closed Cell Spray Foam Industry?

Understanding industry jargon is crucial for effective communication and negotiation in the B2B space.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of spray foam, an OEM may provide the raw materials or equipment used in creating the foam kits. B2B buyers should evaluate OEM partnerships to ensure quality and reliability in their supply chain.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of product a supplier is willing to sell. For closed cell spray foam, MOQs can vary significantly depending on the supplier and product type. Understanding MOQs helps buyers plan their purchasing strategies and manage inventory effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. For businesses purchasing closed cell spray foam, issuing an RFQ can facilitate competitive bidding and ensure they receive the best pricing and service terms.

Illustrative image related to do it yourself closed cell spray foam

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers, especially those sourcing products from overseas suppliers, to avoid unexpected costs.

5. BFT (Board Feet)

A board foot is a unit of measure for lumber and insulation, equivalent to a volume of 1 square foot at 1-inch thickness. Understanding BFT is crucial for buyers to calculate the amount of closed cell spray foam required for their projects accurately.

By grasping these technical properties and trade terms, businesses can make informed decisions when sourcing closed cell spray foam, ensuring their projects meet both performance and regulatory requirements.

Illustrative image related to do it yourself closed cell spray foam

Navigating Market Dynamics and Sourcing Trends in the do it yourself closed cell spray foam Sector

What Are the Key Market Drivers and Trends in the Do It Yourself Closed Cell Spray Foam Sector?

The global market for do it yourself (DIY) closed cell spray foam insulation is experiencing significant growth, driven by several factors. Firstly, rising energy costs are prompting homeowners and businesses to seek efficient insulation solutions that reduce heating and cooling expenses. The DIY segment is particularly attractive as it empowers consumers to undertake insulation projects themselves, saving on labor costs while ensuring quality. Furthermore, advancements in spray foam technology, such as the development of low Global Warming Potential (GWP) formulations, are creating new opportunities for market expansion.

Emerging trends in sourcing indicate a shift towards customizable solutions. Suppliers are increasingly offering refillable kits and various sizes to cater to diverse project requirements, from small home renovations to large commercial applications. This customization allows buyers to optimize their purchases, minimizing waste and maximizing value. Additionally, the growth of e-commerce platforms is transforming the way international B2B buyers in regions like Africa, South America, the Middle East, and Europe source their materials. Online marketplaces provide access to a broader range of products and competitive pricing, essential for cost-conscious buyers.

How Is Sustainability Influencing Sourcing Decisions in the Closed Cell Spray Foam Market?

Sustainability is becoming a pivotal consideration in the sourcing of closed cell spray foam insulation. As environmental concerns rise, B2B buyers are increasingly prioritizing products that minimize ecological impact. This includes opting for spray foam formulations that are free from harmful chemicals and have lower GWP ratings. Buyers should actively seek out suppliers that provide transparency regarding their sourcing practices and offer certifications, such as GreenGuard or EcoSeal, which indicate adherence to environmental standards.

Ethical sourcing is equally important, as businesses recognize the value of supporting suppliers committed to sustainable practices. This not only enhances brand reputation but also aligns with the growing consumer demand for environmentally responsible products. Buyers are encouraged to evaluate suppliers based on their commitment to ethical labor practices, waste reduction, and energy-efficient manufacturing processes. By integrating sustainability into their procurement strategies, B2B buyers can contribute to a greener future while ensuring compliance with increasingly stringent regulations.

How Has the Do It Yourself Closed Cell Spray Foam Market Evolved Over Time?

The evolution of the do it yourself closed cell spray foam market can be traced back to the increasing awareness of energy efficiency in the late 20th century. Initially dominated by professional contractors, advancements in technology and the introduction of user-friendly spray foam kits have made these products accessible to the average consumer. Over the years, innovations such as fast-rise and slow-rise formulas have expanded the application possibilities, catering to various insulation needs, from new constructions to retrofitting older buildings.

The growth of the DIY culture, coupled with the rise of online marketplaces, has further democratized access to quality insulation solutions. Today’s consumers are not only more informed but also more engaged in their home improvement projects, leading to a significant shift in purchasing patterns. As the market continues to mature, the focus on sustainability and ethical sourcing is likely to shape future developments, ensuring that the DIY closed cell spray foam sector remains a relevant and responsible choice for insulation needs.

Illustrative image related to do it yourself closed cell spray foam

Frequently Asked Questions (FAQs) for B2B Buyers of do it yourself closed cell spray foam

-

How do I choose the right closed cell spray foam for my project?

Selecting the right closed cell spray foam involves considering the project’s specific requirements such as insulation needs, surface types, and climate conditions. Assess the R-value (thermal resistance) of different products, as higher R-values indicate better insulation performance. Additionally, evaluate the foam’s expansion characteristics—fast rise or slow rise—based on whether you’re working on new construction or retrofitting. Consulting with suppliers about your project’s scope can also help identify the most suitable product. -

What are the key benefits of using closed cell spray foam?

Closed cell spray foam offers numerous advantages, including superior insulation properties, moisture resistance, and structural integrity. It provides a high R-value per inch, effectively reducing energy costs. The foam also acts as a vapor barrier, preventing moisture infiltration and mold growth, which is crucial in humid climates. For B2B buyers, investing in closed cell spray foam can lead to long-term savings and improved building performance. -

What should I consider regarding minimum order quantities (MOQ) when sourcing spray foam?

When sourcing closed cell spray foam, MOQs can vary significantly among suppliers. It’s essential to clarify the MOQ before placing orders, especially if you’re managing smaller projects or testing a new product. Some suppliers may offer flexibility for first-time buyers or bulk discounts for larger orders. Engaging in discussions about your specific needs can help in negotiating favorable terms that align with your purchasing strategy. -

How can I ensure quality assurance (QA) when sourcing spray foam products internationally?

To ensure quality assurance when sourcing closed cell spray foam, request product certifications and test results from suppliers. Look for compliance with international standards such as ASTM or ISO, which can indicate product reliability. Additionally, consider ordering samples to assess foam properties like density and expansion behavior. Establishing a clear communication channel with the supplier for ongoing QA checks can further ensure product consistency and performance. -

What are the payment terms typically offered by suppliers of spray foam?

Payment terms for closed cell spray foam can vary widely, often influenced by the supplier’s location and your purchasing volume. Common terms include upfront payment, net 30, or net 60 days. For larger orders, suppliers may offer staggered payments or financing options. It’s advisable to discuss and negotiate terms that suit your cash flow while ensuring the supplier’s confidence in your commitment. -

How do I vet suppliers of closed cell spray foam for international trade?

Vetting suppliers for international trade involves conducting thorough research on their reputation, product quality, and customer service. Check online reviews and testimonials from other B2B clients. Request references and verify their production capabilities, certifications, and compliance with international shipping regulations. Engaging with local trade organizations or chambers of commerce can also provide insights into the supplier’s standing and reliability. -

What logistics considerations should I keep in mind when importing spray foam?

When importing closed cell spray foam, consider factors like shipping costs, customs duties, and regulations specific to hazardous materials. Ensure that the supplier provides necessary documentation for customs clearance. Additionally, evaluate the shipping methods available, including transit times and insurance options, to mitigate risks. Collaborating with a logistics partner experienced in handling chemical products can streamline the import process. -

Can I customize closed cell spray foam products for my specific needs?

Yes, many suppliers offer customization options for closed cell spray foam products to meet specific project requirements. This can include variations in density, color, or formulation to enhance particular properties, such as fire resistance or moisture control. Discuss your project specifications with suppliers to explore available customization options. Be mindful that customized orders may have different lead times and pricing structures compared to standard products.

Top 4 Do It Yourself Closed Cell Spray Foam Manufacturers & Suppliers List

1. Tiger Foam – TF600FR HFO Fast Rise Spray Foam Insulation Kit

Domain: tigerfoam.com

Registered: 2005 (20 years)

Introduction: [{‘name’: ‘TF600FR HFO Fast Rise Spray Foam Insulation Kit’, ‘price’: ‘From $875.00’, ‘description’: ‘Closed cell, fast rise foam designed for new construction and application to open surfaces. Kit includes a 15 ft gun/hose assembly, 8 dual-use nozzle tips, and kit preparation instructions.’}, {‘name’: ‘TF200FR HFO Fast Rise Formula Spray Foam Insulation Kit’, ‘price’: ‘$410.00’, ‘description’: ‘C…

2. Tiger Foam – DIY Closed Cell Spray Kit

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: DIY closed cell spray kit for insulating a cathedral ceiling in a garage. User is considering brands like Tiger Foam, Foam It Green, Froth-Pak, and Kraken. Needs approximately 1,000 board feet (330 sq ft at 3 inches thick). User wants a decent appearance as they plan to paint the foam and ceiling.

3. Green Building Advisor – Canned Closed Cell Spray Foam

Domain: greenbuildingadvisor.com

Registered: 1999 (26 years)

Introduction: Canned closed cell spray foam is available for DIY applications, such as sealing cathedral ceilings. It is similar to Great Stuff but comes in larger cans and expands more. Requires a specific foam gun for application. It is a one-part foam, not as dense as two-part closed cell spray foam from kits like FrothPak. While it can seal larger areas, it is not recommended for extensive insulation jobs d…

4. Facebook – Closed Cell DIY Spray Foam Kit

Strategic Sourcing Conclusion and Outlook for do it yourself closed cell spray foam

In the evolving landscape of do-it-yourself closed cell spray foam insulation, strategic sourcing plays a pivotal role in maximizing efficiency, cost-effectiveness, and sustainability. International buyers, particularly from Africa, South America, the Middle East, and Europe, can leverage a diverse range of spray foam kits tailored to various project scales and requirements. Understanding the nuances of product specifications, such as board feet coverage and foam density, allows businesses to make informed purchasing decisions that align with their operational goals.

As market demand for energy-efficient insulation solutions continues to rise, sourcing high-quality, competitively priced spray foam kits becomes essential. Engaging with reputable suppliers who offer bulk discounts and customization options can enhance profit margins and ensure the successful execution of projects.

Looking ahead, the future of do-it-yourself closed cell spray foam insulation is promising, driven by innovations in formulation and application techniques. We encourage international buyers to explore partnerships that prioritize quality and sustainability, ensuring they remain at the forefront of this dynamic industry. Embrace the opportunity to invest in advanced spray foam solutions today, and position your business for long-term success in the global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.