Unlocking Value: A Strategic Analysis of the Die-Stamping Machine Market

Introduction: Navigating the Global Market for die-stamping machine

In today’s competitive landscape, sourcing a die-stamping machine that meets your production needs can be a daunting task, especially for international B2B buyers in regions like Africa, South America, the Middle East, and Europe. The complexity of the die-stamping process, coupled with diverse market offerings, presents a significant challenge: how to choose the right equipment that balances quality, efficiency, and cost-effectiveness. This comprehensive guide is designed to illuminate the intricate world of die-stamping machines, exploring various types, their applications across industries, and essential considerations for supplier vetting.

As you navigate this guide, you will gain insights into the operational efficiencies of progressive die stamping, the advantages of using different materials, and how to evaluate the long-term cost implications of your investment. Additionally, we delve into the importance of understanding market trends and technological advancements that can impact your purchasing decisions.

By equipping you with the necessary knowledge, this guide empowers B2B buyers to make informed decisions, ensuring that you select a die-stamping machine that aligns with your production objectives and budgetary constraints. Whether you are a manufacturer in Brazil looking to enhance your production capabilities or a supplier in Nigeria seeking reliable machinery, this resource is tailored to facilitate your success in the global market.

Understanding die-stamping machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Progressive Die Stamping | Multiple stations for sequential operations; high-speed production | Automotive, Aerospace, Medical | Pros: High efficiency, low labor costs, minimal scrap. Cons: Higher initial investment for tooling. |

| Transfer Die Stamping | Uses a mechanical transfer system to move parts between stations | Electronics, Appliance Manufacturing | Pros: Versatile for complex parts. Cons: Slower than progressive stamping. |

| Single Stroke Die Stamping | One operation per press cycle; simpler tooling requirements | Low-volume production, Prototyping | Pros: Lower setup costs, ideal for simple parts. Cons: Inefficient for high-volume runs. |

| Compound Die Stamping | Combines multiple operations in a single stroke | General Manufacturing, Fabrication | Pros: Reduces cycle time, lowers costs. Cons: Limited to simpler designs. |

| Fourslide Die Stamping | Features four slides for intricate part shapes; high flexibility | Precision Parts, Medical Devices | Pros: Excellent for complex geometries. Cons: Slower production speeds. |

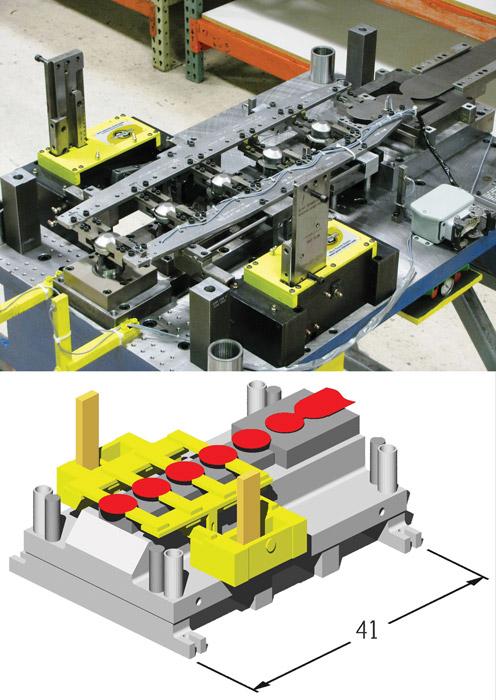

What are the Characteristics of Progressive Die Stamping Machines?

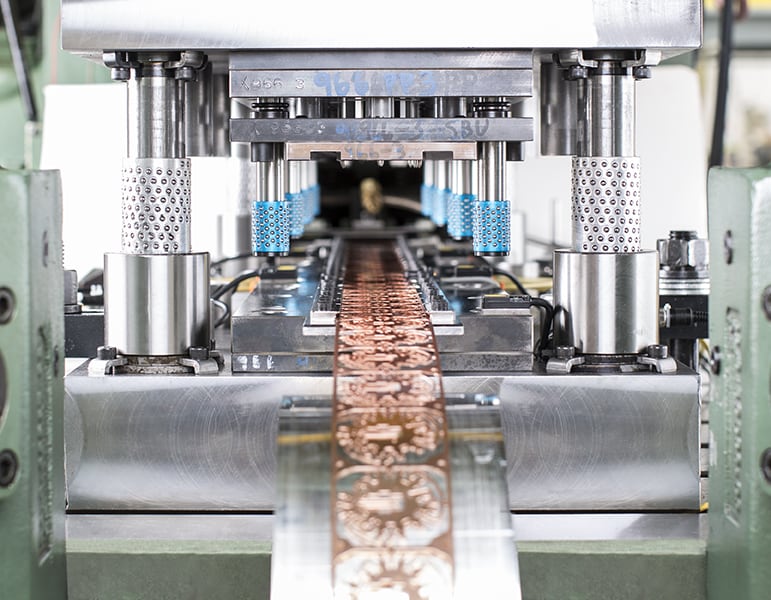

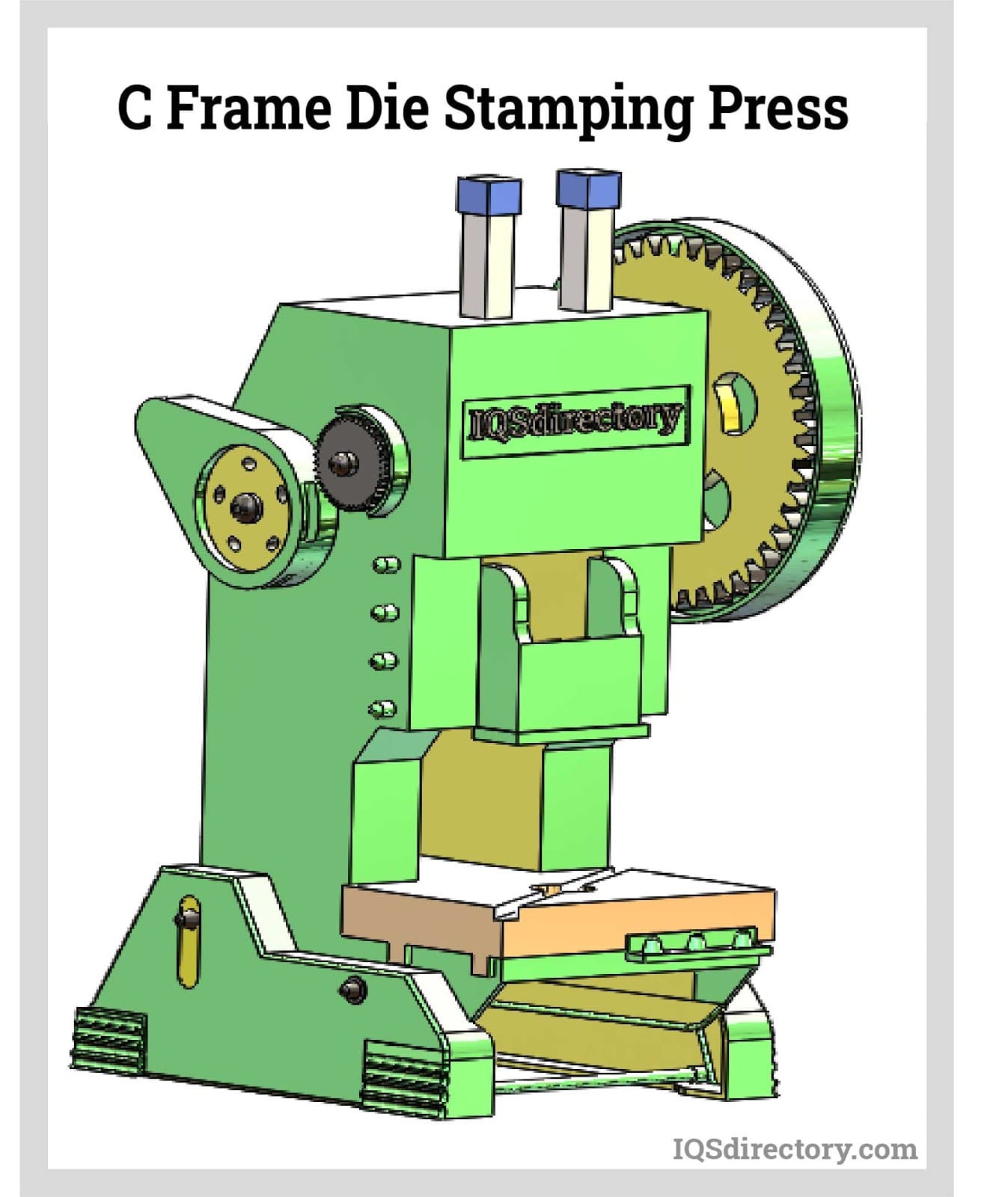

Progressive die stamping machines are designed to perform multiple operations in a single, continuous process. They utilize a series of stations that execute various cuts, bends, or punches on a metal strip fed from a coil. This method allows for high-speed production and is particularly suited for high-volume runs of small, complex parts, making it ideal for industries like automotive and aerospace. Buyers should consider the upfront investment in tooling versus the long-term savings in labor and material costs.

How Do Transfer Die Stamping Machines Operate?

Transfer die stamping machines employ a mechanical transfer system to move parts from one station to another, enabling multiple operations to be performed on each part. This type of machine is versatile and can handle complex shapes, making it suitable for electronics and appliance manufacturing. B2B buyers should assess the balance between flexibility for intricate designs and the potential slower production speeds compared to progressive die stamping.

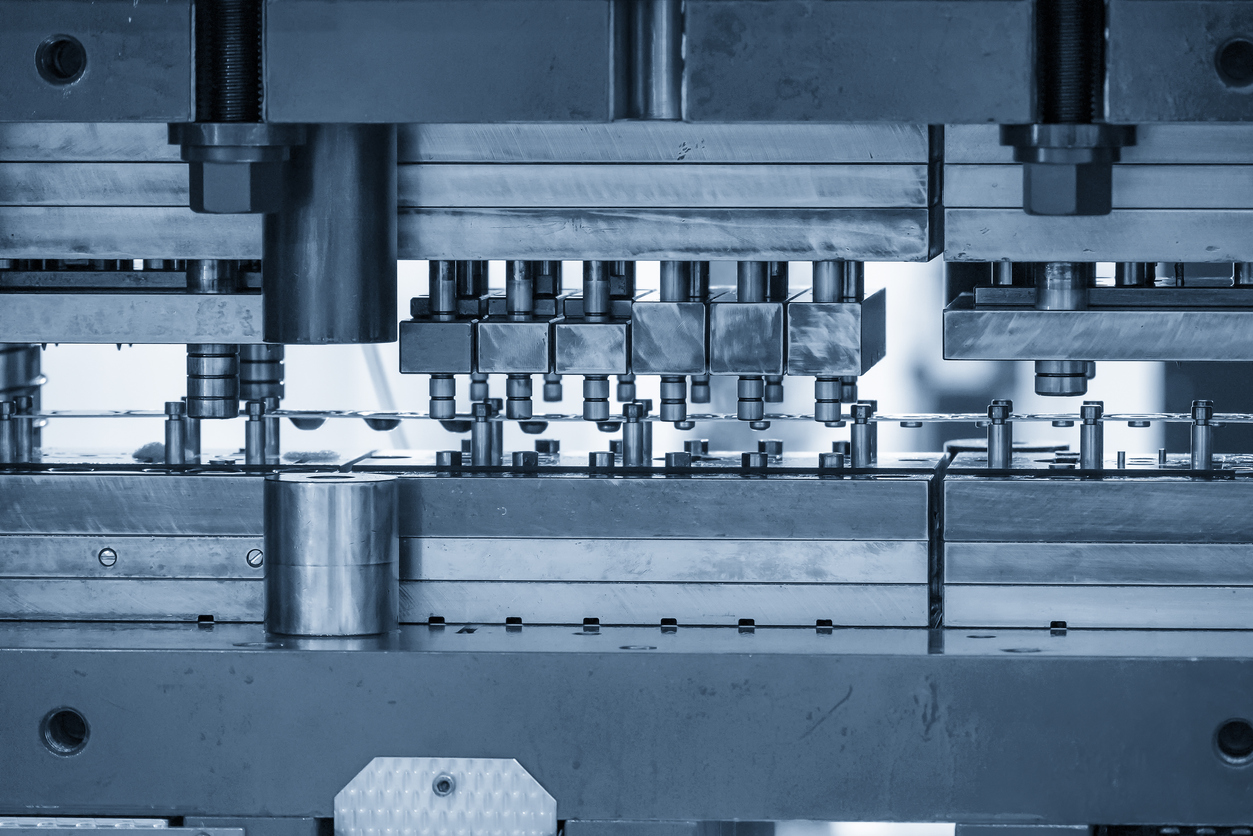

Illustrative image related to die-stamping machine

What Makes Single Stroke Die Stamping Machines Unique?

Single stroke die stamping machines are characterized by their capability to perform one operation at a time per press cycle. This simplicity makes them more cost-effective for low-volume production or prototyping, where the need for quick setup and lower tooling costs is paramount. However, they are not ideal for high-volume runs, as the efficiency decreases significantly with increased production demands.

Why Choose Compound Die Stamping Machines?

Compound die stamping machines integrate multiple operations into a single stroke, which significantly reduces cycle time and overall production costs. This efficiency makes them suitable for general manufacturing and fabrication needs. However, they are best suited for simpler designs, as the complexity of the parts may necessitate more specialized equipment.

What are the Benefits of Fourslide Die Stamping Machines?

Fourslide die stamping machines utilize four slides to create intricate part shapes, providing high flexibility in design. They excel in producing precision components for medical devices and other industries requiring tight tolerances. While they offer superior design capabilities, buyers should be aware of their slower production speeds compared to other stamping methods, which may impact overall throughput.

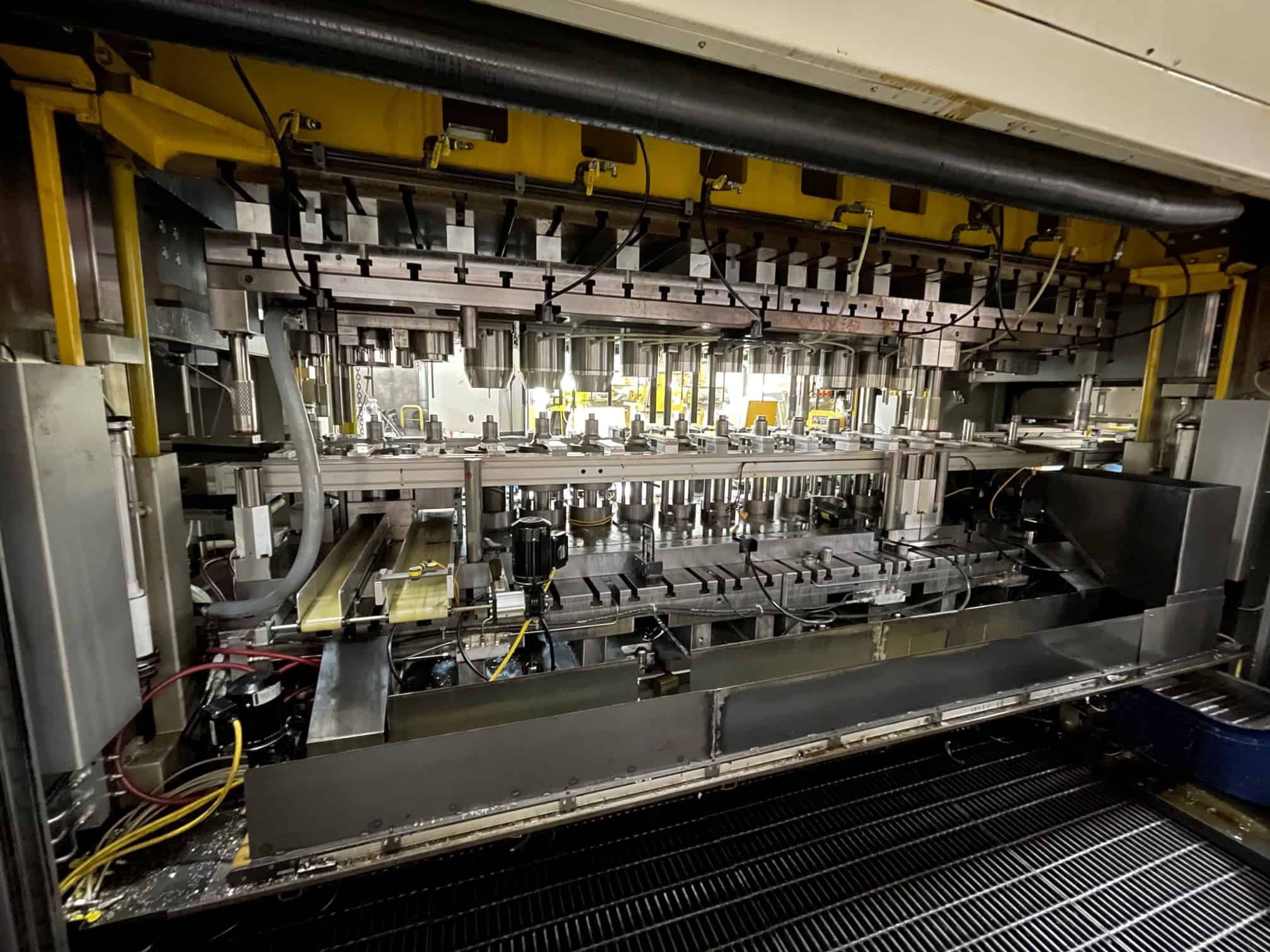

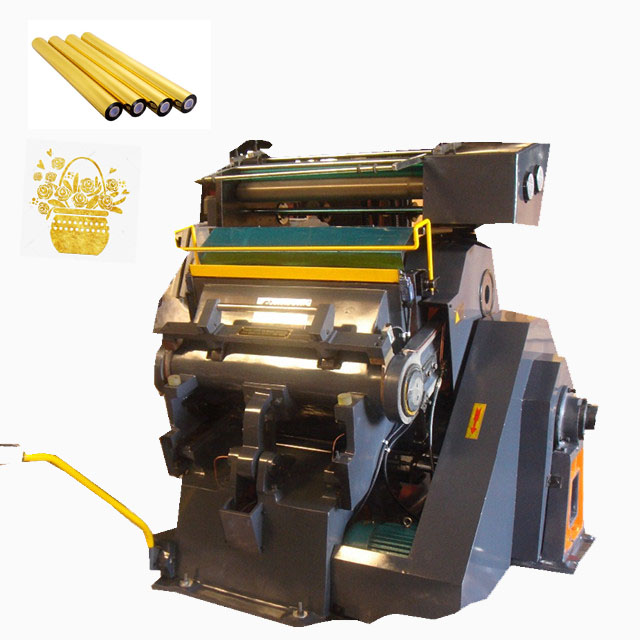

Illustrative image related to die-stamping machine

Key Industrial Applications of die-stamping machine

| Industry/Sector | Specific Application of die-stamping machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Production of metal brackets and fasteners | Streamlined assembly processes and reduced costs | Material compatibility, tooling precision, and lead times |

| Aerospace | Fabrication of complex parts for aircraft | High precision and reduced weight for better fuel efficiency | Certification standards, material strength, and tolerances |

| Medical Devices | Manufacturing of surgical instruments | Enhanced safety and reliability in critical applications | Biocompatibility, cleanliness standards, and design complexity |

| Electronics | Creation of connectors and housings | Improved functionality and reduced manufacturing time | Electrical conductivity, corrosion resistance, and dimensional accuracy |

| Construction | Production of metal shims and washers | Enhanced structural integrity and cost efficiency | Material availability, load-bearing capacity, and surface finish |

How is die-stamping machine used in the automotive sector?

In the automotive industry, die-stamping machines are crucial for producing components like metal brackets and fasteners. These parts are essential for vehicle assembly, contributing to the structural integrity and functionality of various systems. By employing die-stamping, manufacturers can achieve high-volume production with consistent quality, reducing both labor costs and lead times. Buyers should consider material compatibility, tooling precision, and the ability to meet stringent production schedules when sourcing these machines.

What role does die-stamping play in aerospace applications?

Die-stamping machines are instrumental in the aerospace sector for fabricating complex parts that require high precision, such as brackets and structural components. The lightweight yet strong materials used in aircraft construction are often shaped using this technology, which enhances fuel efficiency. International buyers must ensure that the machines meet strict certification standards and are capable of maintaining the necessary tolerances and material strength to comply with safety regulations.

How are die-stamping machines utilized in medical device manufacturing?

In the medical device industry, die-stamping machines are used to manufacture surgical instruments and other critical components. The precision and reliability of these machines ensure that the instruments meet stringent safety standards, which is vital in healthcare applications. Buyers in this sector should prioritize sourcing machines that can handle biocompatible materials, adhere to cleanliness standards, and accommodate complex designs that may be required for advanced medical technologies.

What are the applications of die-stamping in the electronics industry?

Die-stamping machines are widely used in the electronics sector for producing connectors, housings, and other essential components. The ability to create intricate designs quickly and accurately allows manufacturers to enhance product functionality while reducing overall production time. When sourcing die-stamping machines for this application, businesses should focus on factors such as electrical conductivity, corrosion resistance, and the dimensional accuracy of the parts produced.

How does die-stamping benefit the construction industry?

In construction, die-stamping machines are employed to produce metal shims and washers that are critical for ensuring structural integrity. These components help fill gaps and provide stability in various applications, thereby enhancing the overall quality of construction projects. Buyers should consider the availability of materials, load-bearing capacities, and the required surface finishes when sourcing die-stamping solutions for construction applications.

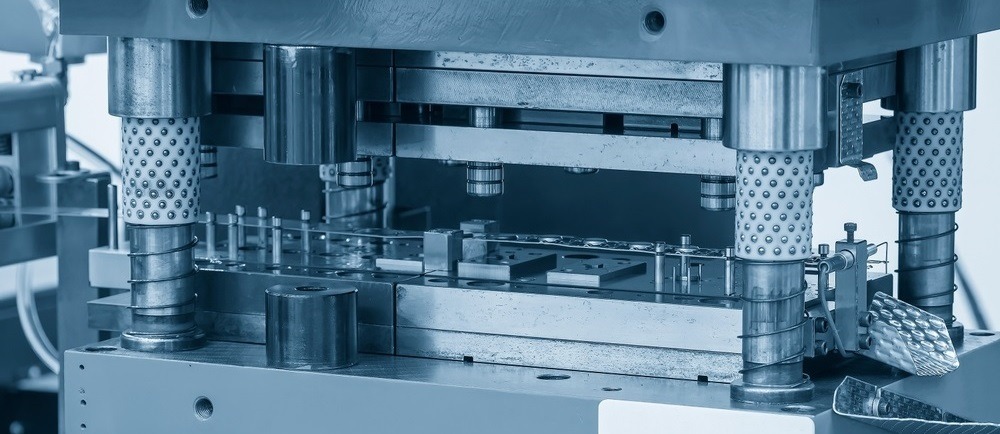

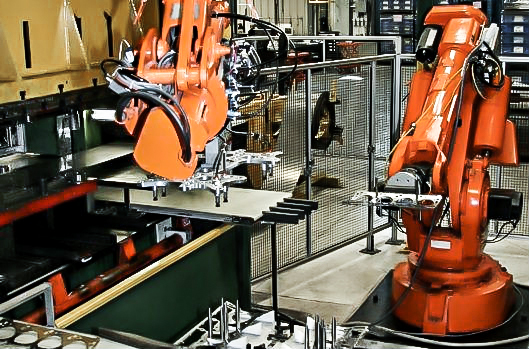

Illustrative image related to die-stamping machine

3 Common User Pain Points for ‘die-stamping machine’ & Their Solutions

Scenario 1: High Production Costs Due to Inefficiencies

The Problem: Many manufacturers experience high production costs due to inefficiencies in their die-stamping processes. Traditional stamping methods often require multiple setups, extensive manual labor, and long lead times, which can lead to significant overhead expenses. For B2B buyers, this translates to increased costs per part and reduced competitiveness in the market, particularly in regions where pricing pressure is intense.

The Solution: To combat these inefficiencies, buyers should consider investing in progressive die-stamping machines. This technology allows for a single setup to handle multiple operations in one continuous process, significantly reducing labor costs and machine downtime. When sourcing a die-stamping machine, look for options that include automatic feeding systems and integrated tooling to streamline operations. Additionally, work with suppliers who offer comprehensive training and support for your staff to ensure optimal utilization of the machine. This approach not only enhances production speed but also minimizes scrap rates, further driving down costs.

Scenario 2: Challenges with Complex Part Geometries

The Problem: In industries such as automotive and aerospace, the demand for complex part geometries is ever-increasing. However, many traditional die-stamping machines struggle to produce intricate designs without incurring high costs and extended lead times. B2B buyers often find themselves facing the dilemma of choosing between cost-effectiveness and the ability to meet design specifications, which can affect their ability to serve their clients effectively.

The Solution: To effectively address this issue, B2B buyers should prioritize sourcing progressive die-stamping machines that offer advanced capabilities for handling complex geometries. These machines utilize multiple stations that can perform various operations simultaneously, allowing for intricate designs to be produced in a single pass. When selecting a machine, inquire about the tool design and its adaptability to accommodate different materials and shapes. Engaging with manufacturers that provide customizable tooling solutions can also enhance flexibility and reduce the need for secondary operations, ultimately leading to faster turnaround times and higher quality products.

Scenario 3: Inconsistent Product Quality and Tolerances

The Problem: Maintaining consistent product quality and tight tolerances is a critical concern for manufacturers, especially those in highly regulated industries. Variability in part quality can lead to increased rework costs, customer dissatisfaction, and potential loss of contracts. B2B buyers often struggle with the trade-off between speed and quality, which can result in production delays and financial penalties.

The Solution: To ensure consistent quality and precision in die-stamped parts, buyers should invest in high-quality progressive die-stamping machines equipped with advanced monitoring and quality control systems. Implementing technology such as in-die inspection and automated feedback loops can significantly reduce defects and ensure that each part meets specified tolerances. When evaluating potential suppliers, it is essential to request information about their quality assurance processes, including adherence to standards like Six Sigma and Production Part Approval Process (PPAP). Additionally, consider establishing a close working relationship with the machine manufacturer for ongoing support and maintenance to sustain quality levels over time. This proactive approach will help mitigate risks associated with product variability and enhance overall operational efficiency.

Strategic Material Selection Guide for die-stamping machine

What Are the Key Properties of Common Materials Used in Die-Stamping Machines?

When selecting materials for die-stamping machines, it is crucial to consider their properties, performance characteristics, and suitability for specific applications. Here, we analyze four common materials—steel, aluminum, brass, and stainless steel—highlighting their key properties, advantages, disadvantages, and implications for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe.

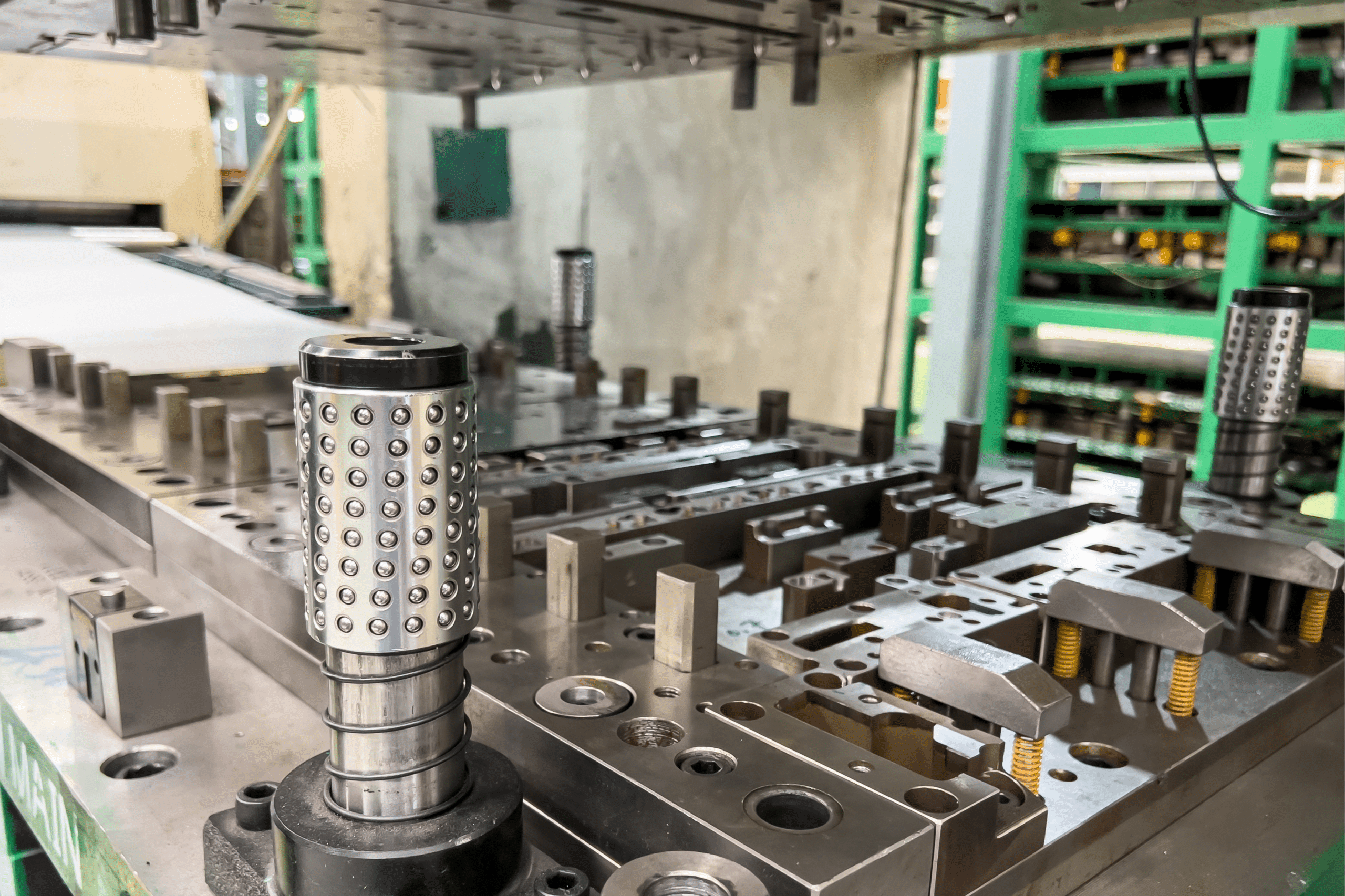

Illustrative image related to die-stamping machine

How Does Steel Perform in Die-Stamping Applications?

Steel is one of the most widely used materials in die-stamping due to its strength and durability. It offers excellent temperature and pressure ratings, making it suitable for high-stress applications. Steel is also highly resistant to deformation, which is critical for maintaining tight tolerances in stamped parts.

Pros: Steel is cost-effective, widely available, and can be easily machined or formed. It is ideal for producing a variety of components, from automotive parts to industrial machinery.

Cons: However, steel can be prone to corrosion if not properly treated, which may lead to premature failure in certain environments. Additionally, the weight of steel can be a disadvantage in applications where lightweight materials are preferred.

Impact on Application: Steel’s compatibility with various media makes it suitable for applications in automotive, aerospace, and heavy machinery sectors.

Illustrative image related to die-stamping machine

Considerations for Buyers: International buyers should ensure compliance with standards such as ASTM A36 or DIN 17100, particularly when sourcing from different regions.

What Advantages Does Aluminum Offer in Die-Stamping?

Aluminum is known for its lightweight properties and excellent corrosion resistance, making it an attractive option for die-stamping applications where weight reduction is essential. It has a good strength-to-weight ratio and performs well under moderate temperatures.

Pros: Aluminum is easy to machine and can be anodized for enhanced surface protection. Its low density reduces shipping costs, which can be a significant advantage for international transactions.

Cons: The main limitation of aluminum is its lower strength compared to steel, making it less suitable for high-stress applications. It can also be more expensive than steel, depending on market conditions.

Illustrative image related to die-stamping machine

Impact on Application: Aluminum is particularly well-suited for the automotive and aerospace industries, where weight savings can lead to improved fuel efficiency.

Considerations for Buyers: Buyers should be aware of the specific aluminum grades (such as 6061 or 7075) and ensure compliance with relevant international standards like JIS or EN.

Why Choose Brass for Die-Stamping Applications?

Brass, an alloy of copper and zinc, is another material used in die-stamping, especially for components requiring good electrical conductivity and corrosion resistance. Its excellent machinability allows for intricate designs and tight tolerances.

Pros: Brass provides a good balance of strength and ductility, making it suitable for intricate parts like connectors and fittings. It also exhibits good resistance to corrosion, particularly in marine environments.

Cons: Brass can be more expensive than steel and aluminum, which may impact overall project costs. Additionally, its lower strength limits its use in high-load applications.

Illustrative image related to die-stamping machine

Impact on Application: Brass is commonly used in electrical and plumbing applications, where conductivity and resistance to corrosion are critical.

Considerations for Buyers: Buyers should verify compliance with ASTM B36 or similar standards to ensure quality and performance.

What Makes Stainless Steel a Preferred Material in Die-Stamping?

Stainless steel is renowned for its corrosion resistance and high strength, making it suitable for die-stamping applications in harsh environments. It maintains its integrity under high temperatures and pressures, which is essential for many industrial applications.

Pros: The durability and aesthetic appeal of stainless steel make it ideal for applications in the food, medical, and automotive industries. Its resistance to corrosion extends the lifespan of stamped parts.

Cons: The primary drawback is the higher cost compared to other materials like carbon steel or aluminum. Additionally, stainless steel can be more challenging to machine, potentially increasing manufacturing complexity.

Impact on Application: Stainless steel is particularly valuable in applications where hygiene and corrosion resistance are paramount, such as in food processing equipment.

Considerations for Buyers: Buyers should confirm compliance with standards such as ASTM A240 or EN 10088 to ensure they meet industry requirements.

Summary of Material Selection for Die-Stamping Machines

| Material | Typical Use Case for die-stamping machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Automotive parts, industrial machinery | High strength and durability | Prone to corrosion | Medium |

| Aluminum | Aerospace, automotive lightweight parts | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium to High |

| Brass | Electrical connectors, plumbing fittings | Good conductivity and machinability | Higher cost and lower strength | High |

| Stainless Steel | Food processing, medical equipment | Excellent corrosion resistance | Higher cost and machining complexity | High |

This strategic material selection guide provides a comprehensive overview for B2B buyers considering die-stamping machines, helping them make informed decisions based on their specific requirements and regional considerations.

Illustrative image related to die-stamping machine

In-depth Look: Manufacturing Processes and Quality Assurance for die-stamping machine

What Are the Key Stages in the Manufacturing Process of Die-Stamping Machines?

The manufacturing process of die-stamping machines involves several critical stages, each designed to ensure efficiency and precision. Understanding these stages is essential for international B2B buyers looking to make informed procurement decisions.

1. Material Preparation: What Materials Are Used and How Are They Prepared?

Material selection is the first step in the die-stamping process. Common materials include various grades of steel, aluminum, brass, and copper, chosen based on the desired properties of the final product.

Once the material is selected, it undergoes preparation, which includes cutting the metal sheets to size and ensuring that they meet the specific thickness requirements. This preparation phase may also involve surface treatments to enhance adhesion or corrosion resistance, particularly for industries like automotive or aerospace, where durability is paramount.

2. Forming: How Is the Metal Shaped in Die-Stamping?

The forming stage is where the actual shaping of the metal takes place. Die-stamping machines utilize progressive stamping methods, where a continuous strip of metal is fed through multiple stations in a single operation. Each station performs a distinct function, such as cutting, punching, or bending, culminating in a finished part at the last station.

This process allows for high-speed production with minimal labor costs, as one operator can oversee multiple machines. The precision of die-stamping is particularly beneficial for producing intricate parts with tight tolerances, making it a preferred choice in industries requiring high-quality components.

Illustrative image related to die-stamping machine

3. Assembly: What Role Does Assembly Play in the Die-Stamping Process?

While die-stamping typically focuses on forming individual parts, assembly may be required for more complex products. In this stage, stamped components are joined together using various methods, including welding, riveting, or the use of adhesives.

This stage is crucial for ensuring that the final product meets functional and aesthetic requirements. For buyers, understanding the assembly capabilities of suppliers can be vital, particularly when multiple components must fit together seamlessly in the final application.

4. Finishing: How Is the Final Product Treated?

Finishing processes enhance the aesthetic and functional qualities of the stamped parts. Techniques may include painting, coating, or polishing, depending on the intended use of the product. For instance, automotive parts often require additional coatings for corrosion resistance, while decorative items may undergo polishing for aesthetic appeal.

Finishing not only improves the product’s appearance but also contributes to its longevity and performance, making it an essential consideration for B2B buyers focused on quality.

What Quality Assurance Measures Are Essential for Die-Stamping Machines?

Quality assurance is critical in the die-stamping process, ensuring that products meet both international standards and specific industry requirements. For B2B buyers, understanding these measures is vital for supplier evaluation.

Illustrative image related to die-stamping machine

1. What International Standards Should Buyers Be Aware Of?

International standards such as ISO 9001 are pivotal in ensuring quality management systems are in place. This standard emphasizes continuous improvement and customer satisfaction, which are critical for maintaining high-quality production processes.

Additionally, industry-specific certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for oil and gas applications add layers of credibility to a supplier’s quality assurance practices. Buyers should inquire about these certifications when evaluating potential suppliers.

2. What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) is implemented at various stages of the die-stamping process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses raw materials for compliance with specifications before they enter the production line.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC involves monitoring operations to ensure that they conform to quality standards. This can include inspections at various stages of the die-stamping process.

-

Final Quality Control (FQC): Once production is completed, FQC involves thorough inspections of the finished products to ensure they meet the required specifications and standards.

These checkpoints are essential for minimizing defects and ensuring that only high-quality products reach the market.

3. What Testing Methods Are Commonly Used in Quality Assurance?

Common testing methods in die-stamping include:

-

Dimensional Inspection: Utilizing tools such as calipers and gauges to measure the dimensions of the finished parts against specified tolerances.

-

Material Testing: Assessing the mechanical properties of materials used in production to ensure they meet required standards.

-

Functional Testing: For complex assemblies, functional tests confirm that parts operate as intended in real-world applications.

These testing methods help to ensure that products not only meet aesthetic and dimensional requirements but also perform reliably in their intended applications.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying the quality control measures of potential suppliers is crucial for B2B buyers, especially when sourcing from international markets. Here are some effective strategies:

Illustrative image related to die-stamping machine

1. Conducting Supplier Audits

Regular audits of suppliers can provide insights into their quality assurance processes. Buyers can assess whether suppliers adhere to international standards and industry-specific certifications. An audit can also reveal the efficiency of their manufacturing processes and their commitment to quality.

2. Requesting Quality Reports and Documentation

Suppliers should be willing to provide documentation related to their quality assurance processes, including test reports, inspection records, and compliance certifications. Reviewing these documents can give buyers confidence in the supplier’s ability to deliver consistent quality.

3. Engaging Third-Party Inspections

For added assurance, buyers may opt for third-party inspections. Independent inspectors can evaluate the manufacturing processes and product quality, providing an unbiased assessment that can help mitigate risks associated with international sourcing.

What Are the Specific QC and Certification Nuances for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate various nuances in quality control and certification. Understanding these factors can facilitate smoother procurement processes.

-

Cultural and Regulatory Differences: Buyers should be aware of the varying standards and expectations across different countries. For instance, regulatory requirements in Europe may differ significantly from those in South America, necessitating careful review of compliance issues.

-

Language Barriers: Effective communication is essential for ensuring quality. Buyers may need to consider language differences when discussing quality requirements and specifications with suppliers.

-

Logistics and Supply Chain Management: Understanding the logistics involved in international shipping and customs can impact quality assurance. Delays or mishandling during transport can affect product integrity, making it important for buyers to consider suppliers with robust logistics capabilities.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for die-stamping machines equips B2B buyers with the necessary tools to make informed purchasing decisions. By focusing on these aspects, buyers can enhance their procurement strategies, ensuring they select suppliers that align with their quality and operational standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘die-stamping machine’

In the competitive landscape of manufacturing, procuring a die-stamping machine requires careful consideration and strategic planning. This guide serves as a comprehensive checklist to help B2B buyers navigate the sourcing process effectively, ensuring that they select the right equipment for their production needs.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for the die-stamping machine. This includes determining the types of materials to be processed, the thickness of the metal, and the complexity of the parts to be produced. Understanding these specifications will help you identify machines that can meet your production goals and ensure compatibility with your manufacturing processes.

- Considerations:

- Material types (steel, aluminum, etc.)

- Required part tolerances and geometries

Step 2: Assess Production Volume Requirements

Evaluate your expected production volume to determine whether a high-volume progressive die-stamping machine is necessary. High-volume production demands machines that can operate at increased speeds with minimal downtime, which is crucial for maintaining efficiency and cost-effectiveness.

Illustrative image related to die-stamping machine

- Key Points:

- Estimate daily or monthly production needs

- Identify potential fluctuations in demand

Step 3: Research Supplier Capabilities

Conduct thorough research on potential suppliers. Look for manufacturers that specialize in die-stamping machinery and have a proven track record in your industry. Request company profiles, case studies, and references to gauge their expertise and reliability.

- Focus Areas:

- Experience in your specific industry (automotive, aerospace, etc.)

- Customer reviews and satisfaction ratings

Step 4: Verify Supplier Certifications and Compliance

Ensure that the suppliers you are considering comply with industry standards and hold relevant certifications. This verification process is essential for maintaining quality assurance and ensuring that the machines meet safety and environmental regulations.

- Certifications to Look For:

- ISO 9001 for quality management

- CE marking for compliance with European health, safety, and environmental standards

Step 5: Evaluate Machine Features and Technology

Assess the technological features of the die-stamping machines offered by potential suppliers. Look for automation capabilities, ease of operation, and maintenance requirements. Advanced features can enhance production efficiency and reduce operational costs in the long run.

- Important Features:

- Automatic feeding systems

- In-die monitoring for quality assurance

Step 6: Request Quotes and Compare Pricing

After narrowing down your options, request detailed quotes from multiple suppliers. Compare pricing not only on the machines themselves but also consider the total cost of ownership, which includes maintenance, operational costs, and potential downtime.

- Comparison Metrics:

- Initial purchase price

- Warranty and after-sales support

Step 7: Plan for Installation and Training

Finally, consider the installation process and training requirements for your team. A good supplier should provide comprehensive support during installation and offer training programs to ensure your staff can operate the machinery effectively.

- Considerations:

- Installation timelines and costs

- Availability of training resources and materials

By following this structured checklist, B2B buyers can make informed decisions when sourcing die-stamping machines, ensuring they choose the right equipment to meet their production needs efficiently.

Illustrative image related to die-stamping machine

Comprehensive Cost and Pricing Analysis for die-stamping machine Sourcing

What Are the Key Cost Components for Die-Stamping Machines?

When sourcing die-stamping machines, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The type of materials used for both the machine and the dies significantly impacts the overall cost. High-quality materials such as hardened steel for dies can lead to higher upfront costs but reduce long-term wear and tear.

-

Labor: Labor costs can vary based on location and the complexity of the machine. Skilled technicians are often required for setup and maintenance, which can add to operational expenses.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and administrative expenses. Buyers should inquire about how these costs are allocated in the pricing structure.

-

Tooling: Custom tooling can substantially influence the price. While standard dies may be less expensive, custom designs tailored to specific production needs can enhance efficiency and reduce scrap rates.

-

Quality Control (QC): Effective QC processes ensure that the produced parts meet specifications. This may involve additional costs for testing and certifications, particularly for industries requiring high precision like aerospace or medical manufacturing.

-

Logistics: Shipping costs can vary significantly depending on the origin and destination of the machines. Factors such as Incoterms and shipping methods also play a role in the overall logistics expenses.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the market average for these margins can aid buyers in negotiating better deals.

How Do Price Influencers Affect Die-Stamping Machine Costs?

Several factors influence the pricing of die-stamping machines, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Higher volumes often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to maximize their purchasing power.

-

Specifications and Customization: Machines with specific features or customizations tailored to unique production needs usually come with a premium. Clearly defining requirements upfront can help avoid unexpected costs.

-

Materials and Quality Certifications: The choice of materials and the availability of quality certifications can significantly impact pricing. High-grade materials that meet international standards often come at a higher cost but can reduce maintenance and replacement expenses.

-

Supplier Factors: The reputation and reliability of the supplier can influence costs. Established suppliers may charge more but often provide better support and warranty options.

-

Incoterms: Understanding the terms of shipping and delivery is crucial. Different Incoterms can shift costs and responsibilities, impacting the total cost of ownership.

What Tips Can Help Buyers Optimize Costs When Sourcing Die-Stamping Machines?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

-

Negotiate Effectively: Leverage multiple quotes from suppliers to negotiate better pricing. Don’t hesitate to discuss payment terms and discounts for bulk purchases.

-

Evaluate Total Cost of Ownership (TCO): Focus not just on the purchase price but also on maintenance, operational costs, and potential downtime. A slightly more expensive machine may prove more economical in the long run if it offers superior reliability.

-

Understand Pricing Nuances: Be aware of fluctuations in material costs, labor rates, and currency exchange rates that may affect pricing. Staying informed about market trends can provide leverage in negotiations.

-

Consider Local Suppliers: When possible, engage with local suppliers to reduce logistics costs and lead times. Local partnerships can also facilitate better service and support.

-

Focus on Long-Term Relationships: Building strong relationships with suppliers can lead to better pricing and service. Consider entering into long-term contracts for consistent pricing and stability.

Disclaimer

The prices and cost components discussed are indicative and subject to change based on market conditions, supplier negotiations, and specific project requirements. Always conduct thorough due diligence and seek multiple quotes before making purchasing decisions.

Alternatives Analysis: Comparing die-stamping machine With Other Solutions

Understanding Alternatives to Die-Stamping Machines

In the manufacturing landscape, die-stamping machines represent a critical technology for producing precision parts. However, businesses often face the challenge of selecting the most efficient and cost-effective solution for their specific production needs. This section explores various alternatives to die-stamping machines, allowing B2B buyers to make informed decisions based on their operational requirements.

Comparison Table

| Comparison Aspect | Die-Stamping Machine | Progressive Die Stamping | Metal Fabrication |

|---|---|---|---|

| Performance | High-speed operation with excellent repeatability | Very high speeds with simultaneous operations | Versatile for various shapes but generally slower |

| Cost | Higher initial investment with lower per-part costs for large runs | Moderate upfront costs; cost-effective for high volumes | Varies widely; lower initial cost but higher per-part costs |

| Ease of Implementation | Requires skilled setup and training | Requires specialized tooling and setup | More straightforward with general machinery |

| Maintenance | Regular maintenance needed for tooling | Requires periodic tool replacement but generally low maintenance | Maintenance depends on equipment used; can be labor-intensive |

| Best Use Case | Complex parts with high-volume needs | High-volume production of small, intricate parts | Custom, one-off designs or low-volume production |

In-Depth Analysis of Alternatives

Progressive Die Stamping

Progressive die stamping is an advanced technique that utilizes a series of stations on a single die to perform multiple operations on a strip of metal as it moves through the press. This method is particularly advantageous for high-volume production, as it significantly reduces cycle times and labor costs. The upfront investment can be moderate, but the long-term benefits include lower per-part costs and minimal scrap. However, it may not be suitable for very simple parts or those requiring deep drawing.

Metal Fabrication

Metal fabrication encompasses a range of processes including cutting, bending, and assembling metal components. This method is highly versatile and can accommodate various material types, making it ideal for custom projects. While the initial investment may be lower than that of die-stamping machines, the per-part costs can increase significantly for larger runs. Metal fabrication is best suited for businesses focusing on custom or low-volume production, but it lacks the speed and efficiency offered by die-stamping and progressive die stamping for high-volume needs.

Conclusion: Choosing the Right Solution for Your Needs

When evaluating alternatives to die-stamping machines, it’s crucial for B2B buyers to align their choice with their specific operational goals. Consider factors such as production volume, part complexity, and budget constraints. For high-volume production of intricate parts, progressive die stamping may be the best fit. In contrast, businesses that prioritize customization and flexibility might find metal fabrication more advantageous. Ultimately, a thorough understanding of each method’s strengths and weaknesses will empower buyers to select the most effective solution for their manufacturing requirements.

Essential Technical Properties and Trade Terminology for die-stamping machine

What Are the Essential Technical Properties of Die-Stamping Machines?

Understanding the technical properties of die-stamping machines is crucial for B2B buyers in order to make informed purchasing decisions. Here are key specifications that should be considered:

Illustrative image related to die-stamping machine

1. Material Grade

The material grade refers to the quality and composition of the metal used in the stamping process. Common materials include steel, aluminum, brass, and stainless steel. Each material has unique properties that affect durability, corrosion resistance, and weight. For instance, high-grade steel is often preferred for its strength and longevity, making it ideal for heavy-duty applications. Selecting the right material grade is essential for ensuring that the final product meets industry standards and customer expectations.

2. Tolerance

Tolerance defines the permissible limit of variation in a physical dimension of a part. In die-stamping, this often ranges from ±0.001 inches to ±0.005 inches, depending on the complexity of the part being produced. High tolerance levels are critical in industries such as aerospace and automotive, where precision is paramount. Understanding tolerance requirements can help buyers ensure that parts will fit properly and function as intended, reducing the risk of costly rework or failures.

3. Production Speed

Production speed indicates how quickly a die-stamping machine can produce parts, typically measured in parts per minute (PPM). High-speed machines can significantly reduce lead times, allowing manufacturers to meet tight deadlines and respond swiftly to market demands. This is particularly beneficial for high-volume production runs, where efficiency translates to cost savings. Buyers should evaluate the production speed in relation to their operational needs to optimize workflow and profitability.

4. Die Life

Die life refers to the longevity and durability of the stamping dies used in the process. High-quality dies can withstand thousands of cycles before needing replacement. Investing in machines with superior die life can lead to lower operational costs, as it reduces the frequency of die replacements and the associated downtime. Buyers should inquire about die life when assessing equipment, as it directly impacts production efficiency and overall cost-effectiveness.

5. Setup Time

Setup time is the duration required to prepare the machine for a new production run, including changing dies and adjusting settings. Machines with quick setup capabilities can switch between different parts rapidly, enhancing flexibility and responsiveness to changing production needs. This is especially important for businesses that produce a variety of parts or have fluctuating order volumes. Reducing setup time can lead to improved productivity and reduced costs.

What Common Trade Terms Should B2B Buyers Know in Die-Stamping?

Familiarity with industry terminology is essential for effective communication and negotiation in the die-stamping sector. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In die-stamping, OEMs play a crucial role in supplying components for various industries. Understanding OEM relationships can help buyers secure quality parts that meet their specifications.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers as it impacts inventory management and purchasing strategies. Knowing the MOQ can help businesses plan their orders effectively, avoiding excess inventory or stockouts.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers for specific products or services. In die-stamping, issuing an RFQ can help buyers compare costs and services from different manufacturers, ensuring they secure the best deal for their needs.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. They clarify aspects such as shipping costs, risk transfer, and delivery obligations. Understanding Incoterms is vital for B2B buyers involved in global sourcing, as it helps mitigate risks and clarify contractual obligations.

5. Lead Time

Lead time is the total time taken from placing an order to the delivery of the finished product. In die-stamping, shorter lead times can significantly enhance a company’s ability to respond to market demands. Buyers should consider lead time when evaluating suppliers to ensure timely delivery of essential components.

By grasping these technical properties and trade terms, B2B buyers can navigate the die-stamping market more effectively, fostering better partnerships and achieving operational success.

Navigating Market Dynamics and Sourcing Trends in the die-stamping machine Sector

What Are the Current Market Dynamics and Key Trends in the Die-Stamping Machine Sector?

The global die-stamping machine market is experiencing significant growth, driven by the rising demand for precision-engineered components across various industries, including automotive, aerospace, and electronics. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly focusing on sourcing advanced die-stamping technologies that enhance productivity and efficiency. Key trends include the adoption of progressive die stamping, which allows for high-speed production with minimal scrap, and the integration of automation and Industry 4.0 technologies, such as IoT and AI, to optimize production processes.

Another emerging trend is the shift towards contract manufacturing, where companies outsource their stamping needs to specialized manufacturers. This approach not only reduces overhead costs but also allows for flexibility in scaling production based on demand. Additionally, there is a growing emphasis on sourcing machinery that supports complex geometries and tighter tolerances, catering to industries that require high-quality components with minimal defects.

As international buyers navigate these dynamics, understanding regional market variations is essential. For example, buyers in Brazil and Nigeria may face different regulatory environments and supply chain challenges compared to their European counterparts. Therefore, aligning sourcing strategies with local market conditions and technological advancements is crucial for maximizing operational efficiency and competitiveness.

How Can Sustainability and Ethical Sourcing Impact the Die-Stamping Machine Sector?

Sustainability and ethical sourcing are becoming pivotal considerations in the die-stamping machine sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, has prompted companies to adopt greener practices. For B2B buyers, sourcing machines that utilize sustainable materials and efficient production techniques can significantly reduce the carbon footprint of their operations.

Buyers are increasingly looking for suppliers who can provide certifications for environmentally friendly practices, such as ISO 14001, which emphasizes effective environmental management systems. Additionally, the use of recycled materials in the production of die-stamping machines is gaining traction, aligning with the global push for circular economy principles.

Establishing ethical supply chains is equally important, as stakeholders demand transparency regarding labor practices and sourcing methods. By partnering with manufacturers that prioritize ethical standards, buyers can mitigate risks associated with reputational damage and supply chain disruptions. Ultimately, integrating sustainability into sourcing decisions not only contributes to environmental goals but also enhances brand reputation and customer loyalty.

What Is the Evolution of Die-Stamping Technology and Its Relevance to Today’s B2B Landscape?

The evolution of die-stamping technology can be traced back to the industrial revolution, when metal forming processes were first mechanized. Initially, the focus was on simple parts for industries like bicycle manufacturing. Over the decades, advancements in engineering and technology have led to the development of sophisticated stamping techniques, such as progressive die stamping, which allows for complex shapes and high-volume production.

Today, die-stamping machines are equipped with advanced features, including automated feeding systems and real-time monitoring capabilities, making them more efficient and reliable. This evolution is particularly relevant for B2B buyers, as it enables them to meet the increasing demand for precision components in a competitive marketplace. Understanding the historical context of die-stamping technology not only provides insights into its current capabilities but also informs future sourcing strategies aimed at leveraging these advancements for enhanced operational performance.

Frequently Asked Questions (FAQs) for B2B Buyers of die-stamping machine

-

How do I choose the right die-stamping machine for my production needs?

Choosing the right die-stamping machine requires evaluating several factors, including production volume, complexity of parts, and material types. For high-volume production of intricate components, progressive die stamping machines are ideal due to their efficiency and capability for complex geometries. Assess your specific requirements, such as part tolerances and cycle times, and consult with suppliers for their expertise in matching machine capabilities with your production goals. Additionally, consider the total cost of ownership, including maintenance and operational costs, to make an informed decision. -

What types of materials can be processed with die-stamping machines?

Die-stamping machines can process a wide variety of materials, including aluminum, steel, brass, copper, and specialty alloys like Inconel and titanium. The choice of material largely depends on the end-use application of the stamped parts. For example, automotive and aerospace industries often require high-strength materials, while electronics may use lighter metals. Ensure that the selected machine can handle the specific thickness and mechanical properties of your materials to achieve the desired part quality and performance. -

What are the typical lead times for ordering and receiving a die-stamping machine?

Lead times for die-stamping machines can vary significantly based on the complexity of the machine, customization requirements, and the manufacturer’s production schedule. Generally, standard machines may have a lead time of 6 to 12 weeks, while custom solutions can take longer, potentially extending to several months. It’s essential to communicate your timeline needs with suppliers and confirm their ability to meet your production schedule, especially if you are integrating the machine into an existing workflow. -

How can I ensure the quality of parts produced by my die-stamping machine?

To ensure high-quality parts, implement a comprehensive quality assurance (QA) process that includes regular machine maintenance, monitoring of production parameters, and adherence to industry standards. Utilize techniques like Production Part Approval Process (PPAP) and Failure Mode and Effects Analysis (FMEA) to identify potential issues early in production. Additionally, investing in advanced inspection technologies, such as in-die inspection or automated vision systems, can help maintain consistent part quality and reduce defect rates. -

What customization options are available for die-stamping machines?

Customization options for die-stamping machines can include modifications to the die design, tooling, and machine configurations to meet specific production requirements. Suppliers often offer tailored solutions to address unique part geometries, material types, and production volumes. When discussing customization, be clear about your specifications and performance expectations to ensure that the machine meets your operational needs effectively. -

What minimum order quantities (MOQs) should I expect when sourcing die-stamping machines?

Minimum order quantities (MOQs) for die-stamping machines can vary based on the manufacturer and the specific machine configuration. Typically, MOQs may range from one machine for standard models to higher quantities for custom or specialized machines. It’s essential to clarify MOQs upfront during negotiations with suppliers to align your purchasing strategy with their production capabilities, particularly if you’re operating within budget constraints. -

What payment terms are common when purchasing die-stamping machines internationally?

Payment terms for international purchases of die-stamping machines can vary widely, but common arrangements include upfront payments, partial payments with the balance upon delivery, or payment upon completion of installation. Many suppliers offer financing options to help manage costs. It’s advisable to negotiate terms that provide you with a balance of security and flexibility, considering factors such as currency fluctuations and shipping timelines. -

How should I approach logistics for importing die-stamping machines?

When importing die-stamping machines, it’s crucial to plan logistics carefully. Start by selecting a reliable freight forwarder experienced in handling industrial equipment. Ensure that you understand the shipping regulations and import duties in your country, as these can impact total costs and delivery timelines. Additionally, consider insurance options to protect your investment during transit. Clear communication with the supplier regarding shipping schedules and documentation will also facilitate a smoother import process.

Top 3 Die-Stamping Machine Manufacturers & Suppliers List

1. Esict – High Volume Progressive Die Stamping

Domain: esict.com

Registered: 1997 (28 years)

Introduction: High Volume Progressive Die Stamping

– High-speed production of small parts

– Efficient process with multiple stations for cutting, punching, and bending

– Ideal for high-volume production runs

– Capable of complex geometries and tight tolerances

– Reduced labor costs due to unattended operation

– Minimal scrap production

– Quick setup with only one setup required

– High part-to-part repeatability…

2. Transmatic – Progressive Die Presses

Domain: transmatic.com

Registered: 1997 (28 years)

Introduction: Progressive Die Presses utilize an automatic feeding system to push a strip of metal through multiple stamping stations, performing various operations until the final station cuts off the finished part. They can produce between 7 to 1,500 parts per minute, depending on the design. Key advantages include high speed, low labor costs, long run lengths, minimal scrap, low part costs, quick setup, the …

3. Manor Tool – Progressive Die Metal Stamping

Domain: manortool.com

Registered: 1997 (28 years)

Introduction: Progressive die metal stamping uses a continuous feed of material through multiple stations to form complete parts. The video showcases a Bliss 400-ton press setup with a compact servo feed line, utilizing 12″ coil steel. The process involves a 5 station progressive die that performs incremental changes to the part, achieving tolerances of ±.0005″. The company works with various materials includin…

Strategic Sourcing Conclusion and Outlook for die-stamping machine

As the global landscape for die-stamping machines continues to evolve, strategic sourcing emerges as a critical component for companies seeking efficiency and competitive advantage. The transition from traditional stamping methods to advanced progressive die stamping technology offers significant benefits, including increased production speeds, reduced labor costs, and enhanced precision. For B2B buyers, especially those in emerging markets like Africa and South America, investing in high-quality die-stamping machinery can lead to substantial operational improvements and cost savings.

Navigating the complexities of sourcing requires a keen understanding of market dynamics, supplier capabilities, and the unique demands of specific industries. As companies look to optimize their manufacturing processes, they must prioritize partnerships with suppliers who demonstrate innovation and reliability.

Illustrative image related to die-stamping machine

Looking ahead, the demand for precision-engineered components will only grow, driven by advancements in technology and the increasing need for customization across various sectors. International buyers are encouraged to leverage strategic sourcing not only to enhance production capabilities but also to foster long-term relationships with suppliers that can adapt to their evolving needs. Embrace this opportunity to elevate your operations and drive sustainable growth in your market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.