Unlocking Value: A Strategic Analysis of the Dc Electric Motor Parts Market

Introduction: Navigating the Global Market for dc electric motor parts

In today’s global marketplace, sourcing reliable DC electric motor parts can pose significant challenges for international B2B buyers. Factors such as varying quality standards, fluctuating prices, and the complexity of navigating supplier networks can complicate procurement processes, particularly for businesses in Africa, South America, the Middle East, and Europe, including key markets like Germany and Brazil. This comprehensive guide addresses these challenges head-on, offering insights into the diverse types of DC motor components available, their applications across industries, and practical strategies for effective supplier vetting.

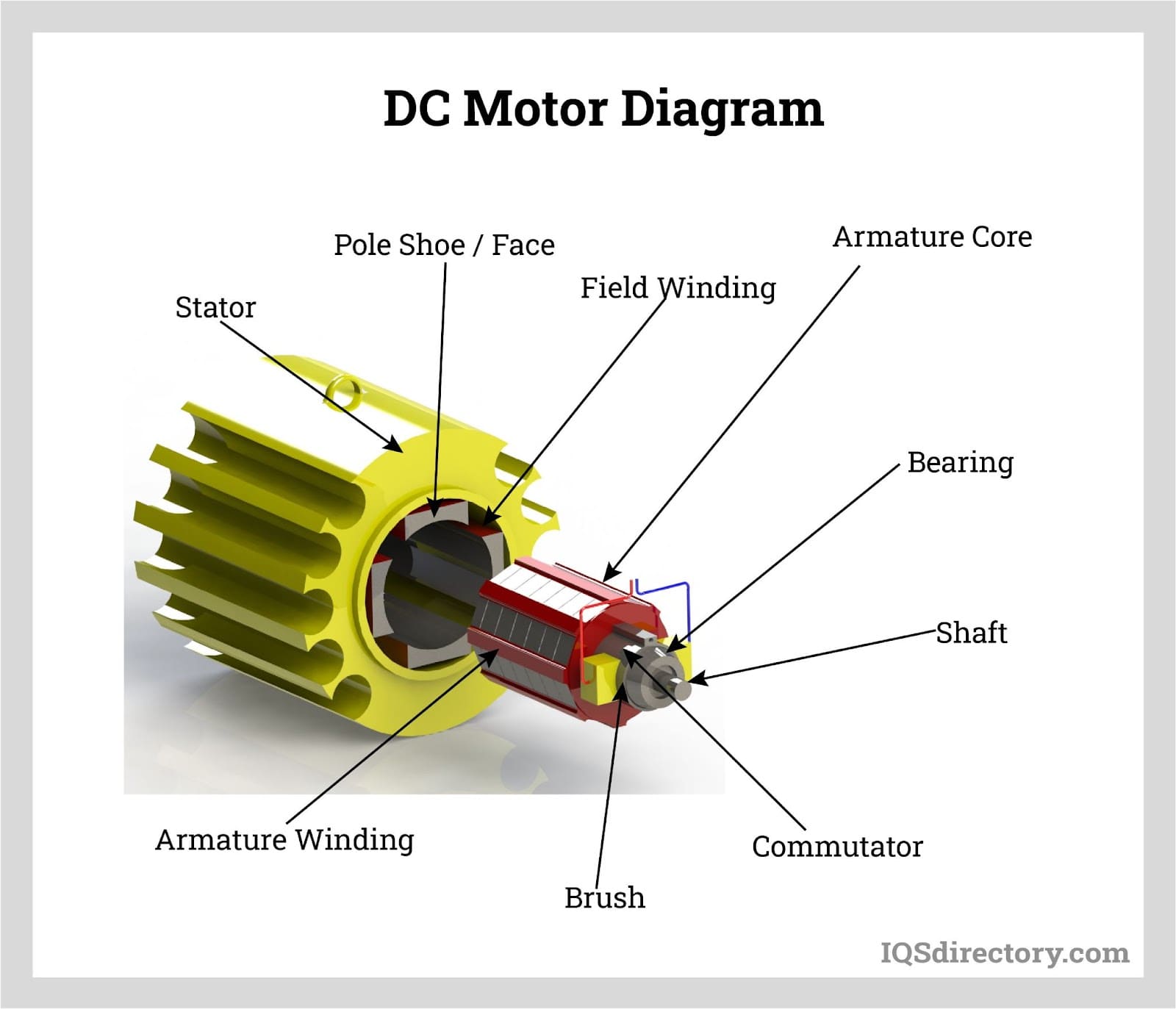

Throughout this guide, buyers will find valuable information on essential components such as brushes, commutators, armatures, and field windings, as well as tips for assessing product quality and performance. We will delve into cost considerations, ensuring that you can make informed decisions that align with your budgetary constraints while maintaining high operational standards. By empowering you with knowledge about the intricacies of DC electric motor parts, this guide aims to streamline your purchasing process, helping you build robust supplier relationships and ultimately enhancing the efficiency and reliability of your operations.

Whether you are a seasoned buyer or new to the market, this resource is designed to facilitate your journey in sourcing DC electric motor parts, ensuring your business remains competitive in an ever-evolving landscape.

Understanding dc electric motor parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Armature | Converts electrical energy into mechanical motion | Robotics, conveyor systems | Pros: High efficiency; customizable design. Cons: Requires precise winding for optimal performance. |

| Commutator | Reverses current direction for continuous rotor rotation | Electric vehicles, industrial motors | Pros: Essential for DC operation; reliable. Cons: Subject to wear; maintenance required. |

| Brushes | Maintain electrical contact with the commutator | Elevators, HVAC systems | Pros: Cost-effective; easy to replace. Cons: Wear over time; may require frequent replacements. |

| Field Windings | Generate magnetic fields for rotor interaction | Manufacturing, power generation | Pros: Adjustable magnetic strength; enhances torque. Cons: Complexity in design; impacts efficiency. |

| Stator | Provides a stationary magnetic field for rotor movement | Pumps, fans, and compressors | Pros: Durable; enhances motor stability. Cons: Fixed design limits flexibility in applications. |

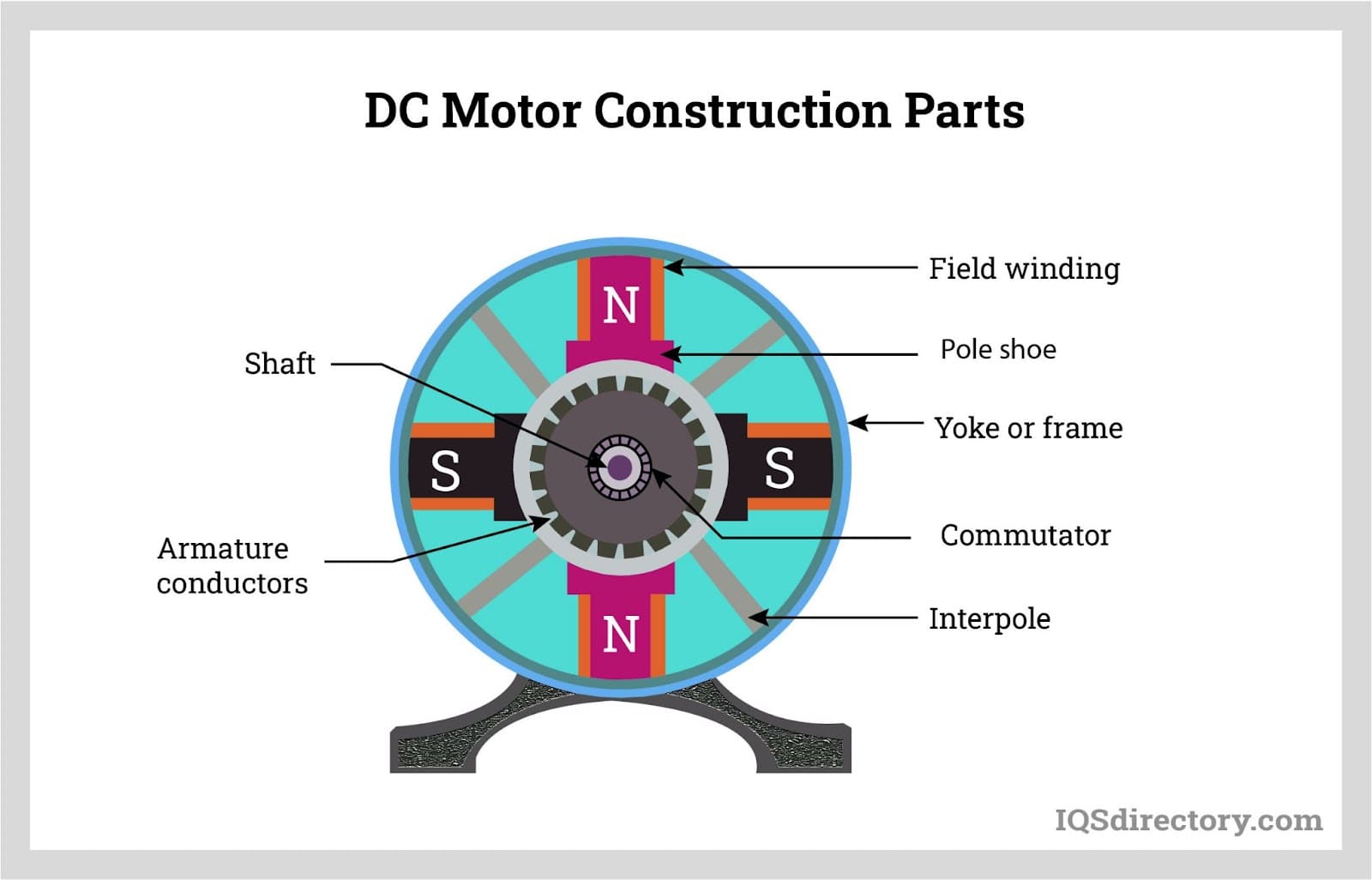

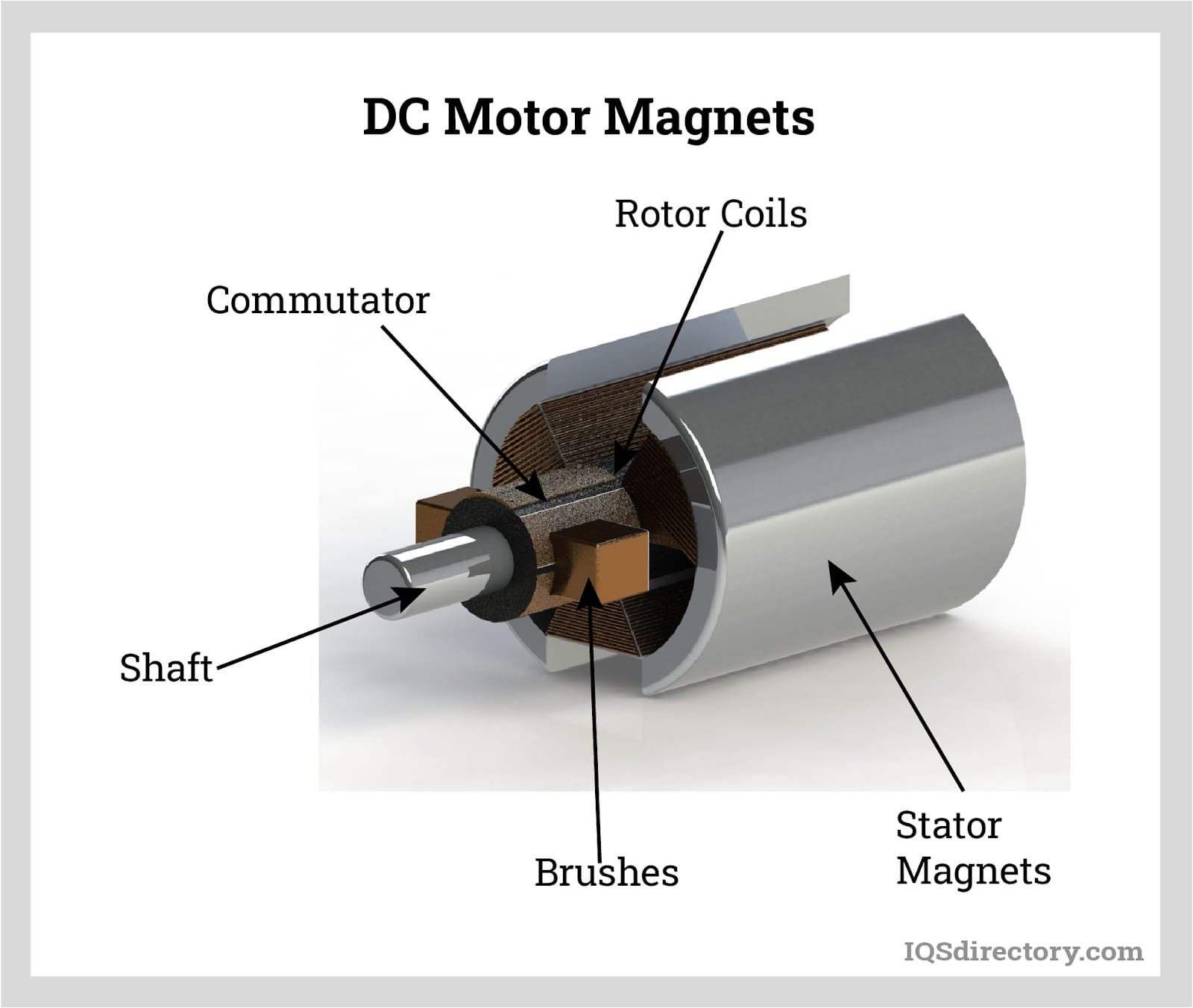

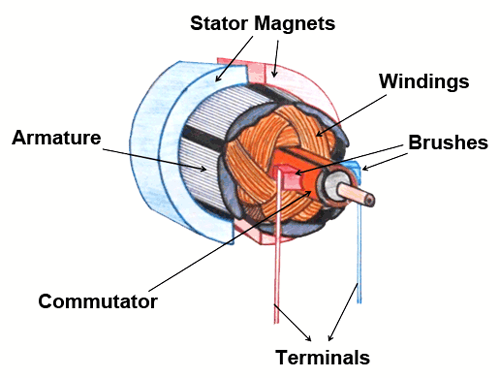

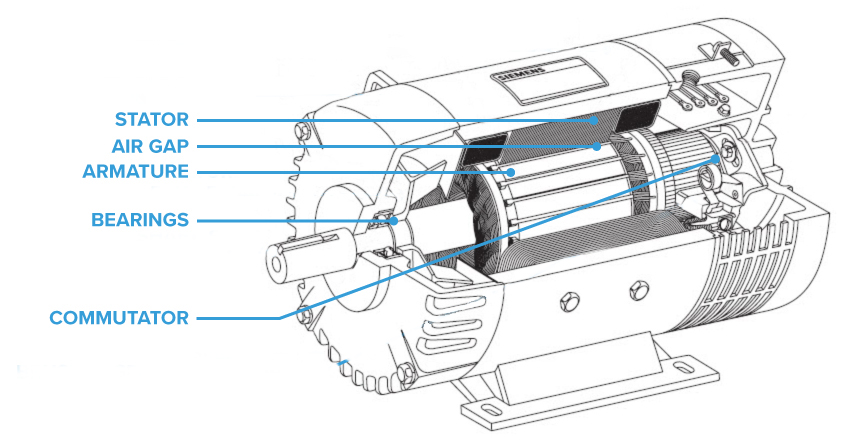

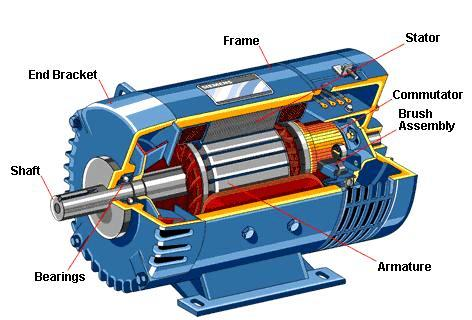

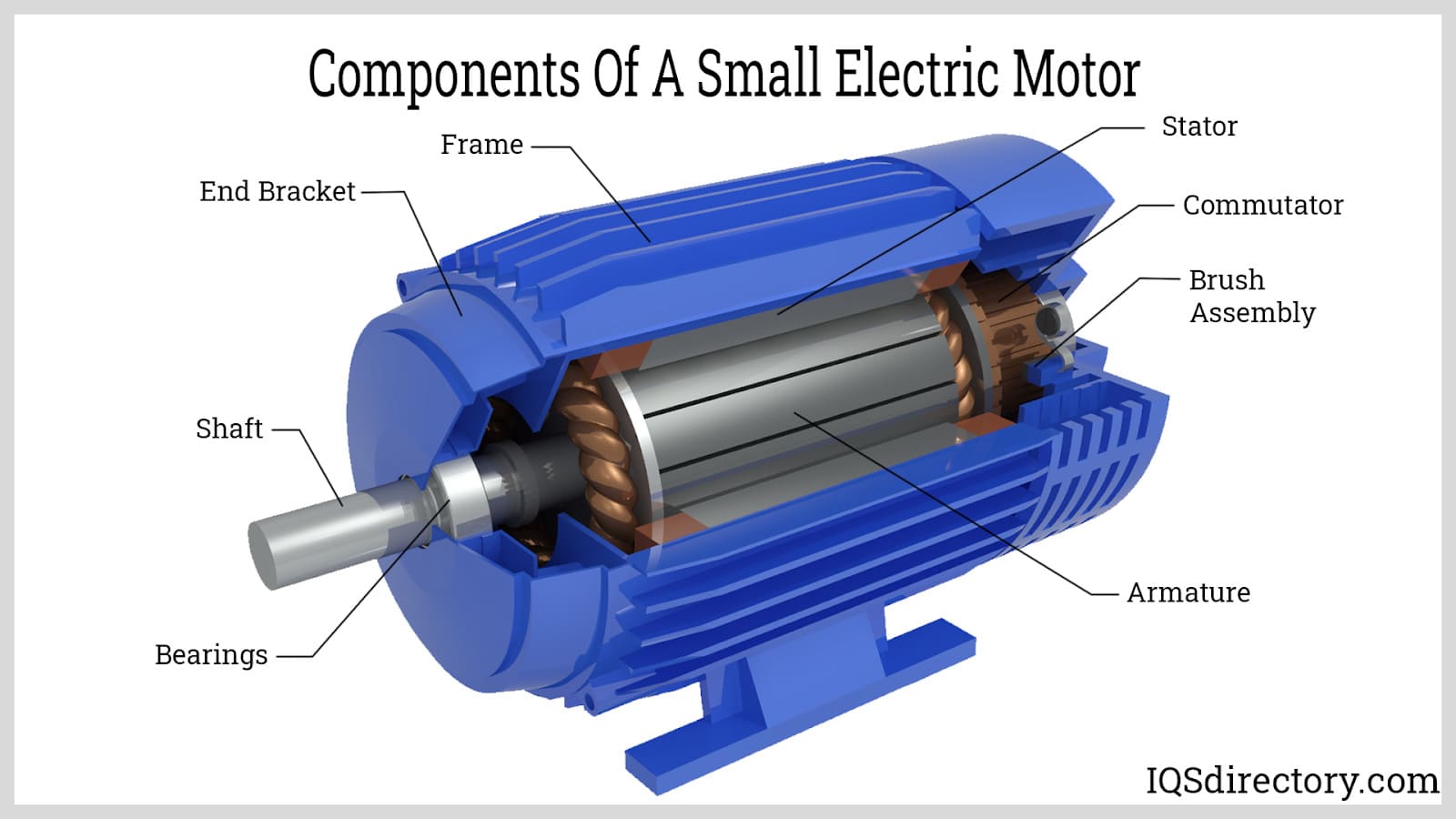

What Are the Characteristics of Armatures in DC Motors?

The armature is a fundamental component that converts electrical energy into mechanical motion. Typically constructed from thin, insulated metal sheets, it houses copper windings that enhance the magnetic field strength. B2B buyers must consider the armature’s winding techniques and materials, as these directly influence torque and speed. Customization options can cater to specific operational requirements, making armatures suitable for applications in robotics and conveyor systems.

Illustrative image related to dc electric motor parts

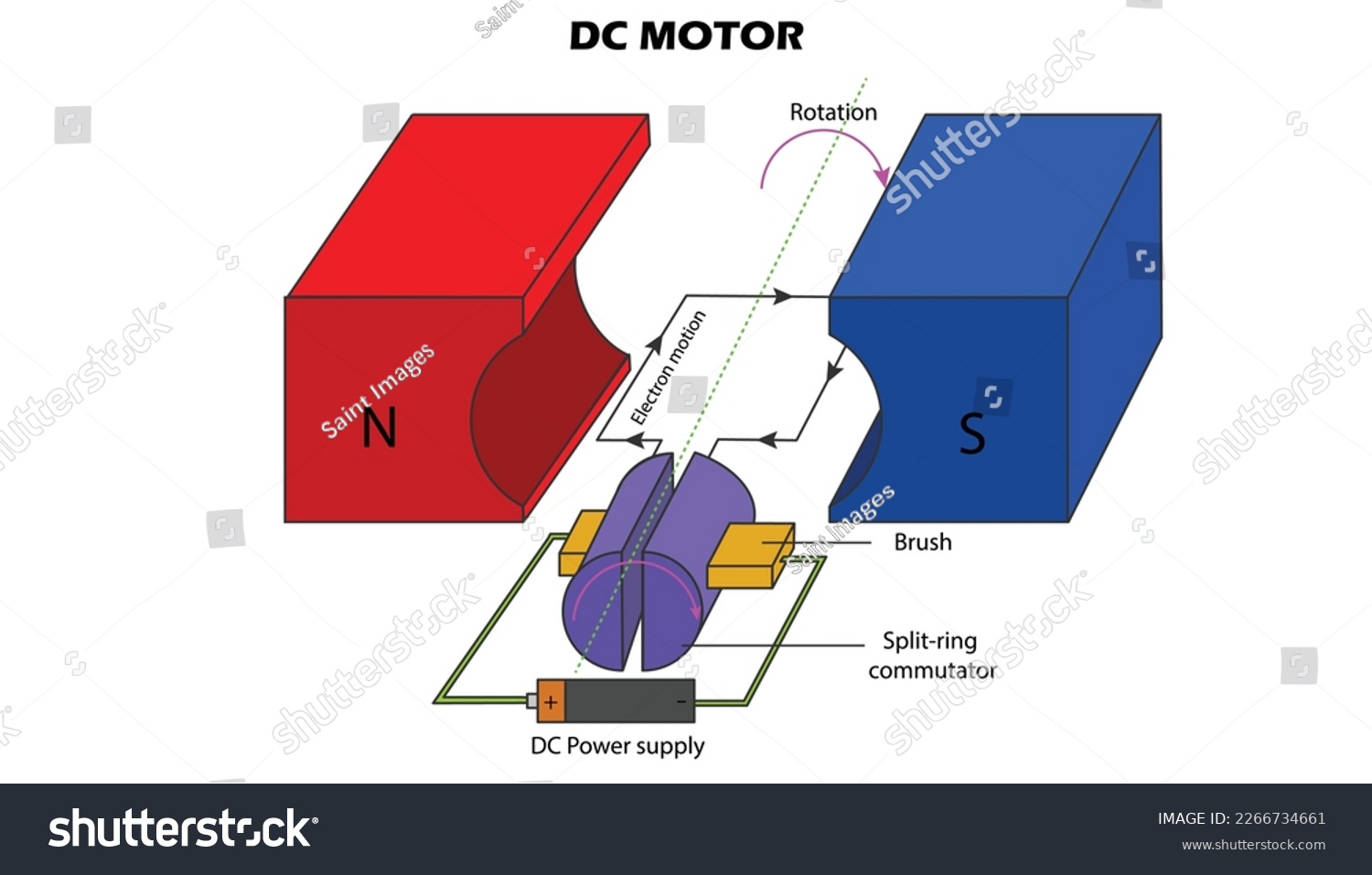

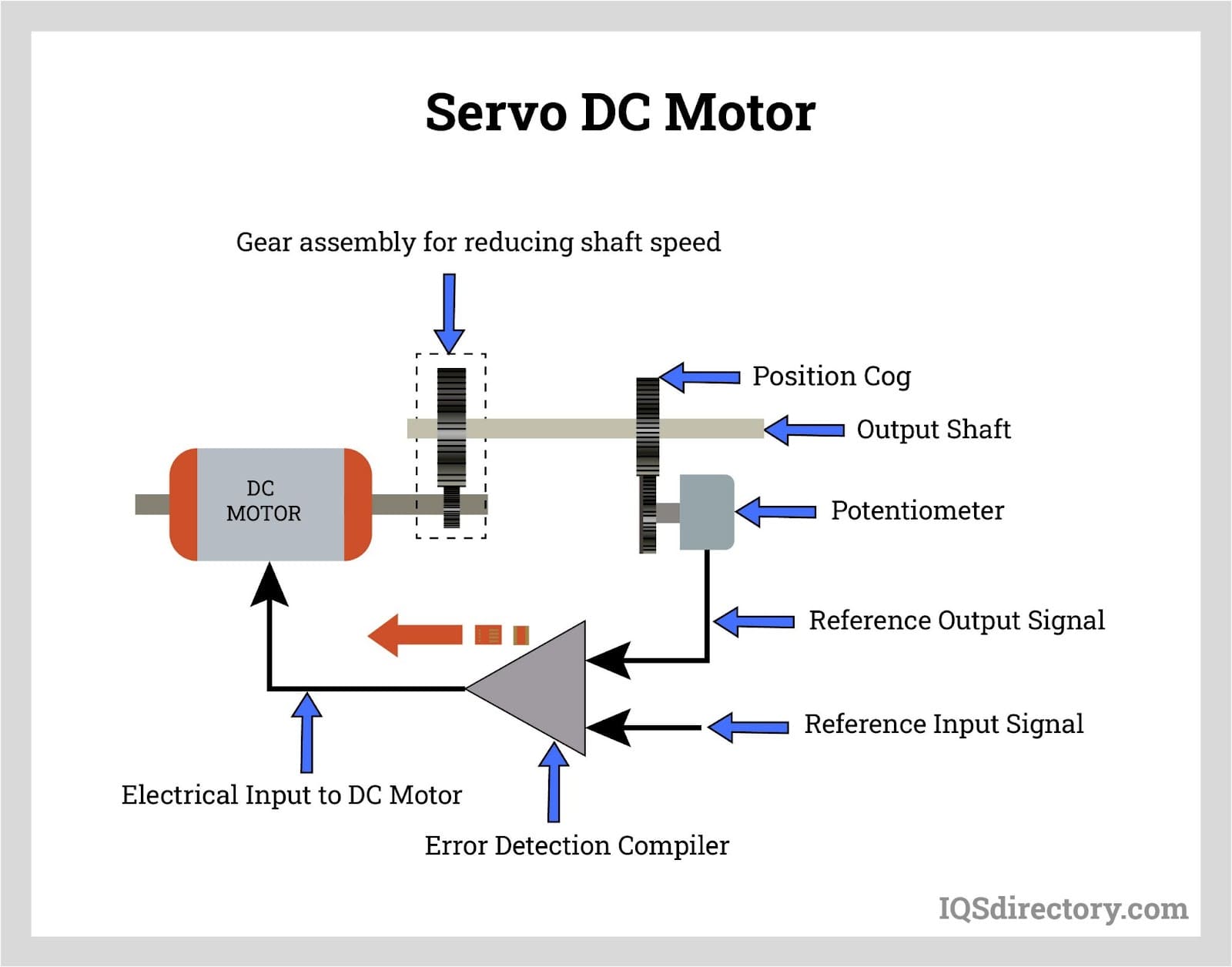

How Does the Commutator Function in DC Motors?

The commutator is essential for ensuring a continuous flow of current within the armature windings, allowing for uninterrupted rotor rotation. Made from copper segments, it reverses the current direction, which is crucial for DC motor functionality. For B2B buyers, understanding the commutator’s maintenance needs is vital, as wear and arcing can affect performance. While they are reliable, the necessity for regular inspections and potential replacements should be factored into purchasing decisions, especially for applications like electric vehicles.

Why Are Brushes Important in DC Motors?

Brushes are critical for maintaining electrical contact with the commutator, typically made of carbon or graphite. Their low-friction properties contribute to efficient motor operation. B2B buyers should consider the type of brush material based on application requirements, as carbon brushes are durable while graphite brushes are suited for low-friction needs. However, brushes wear over time, necessitating regular inspections and replacements, which can impact operational costs in applications such as elevators and HVAC systems.

What Role Do Field Windings Play in DC Motors?

Field windings are responsible for generating the magnetic field necessary for rotor movement. Comprised of coils wrapped around the stator, their design can be adjusted to control the magnetic field’s strength, directly affecting torque and speed. B2B buyers should assess the complexity of field winding designs, as they can influence overall motor efficiency. These components are particularly valuable in manufacturing and power generation applications, where precise control over motor performance is critical.

Illustrative image related to dc electric motor parts

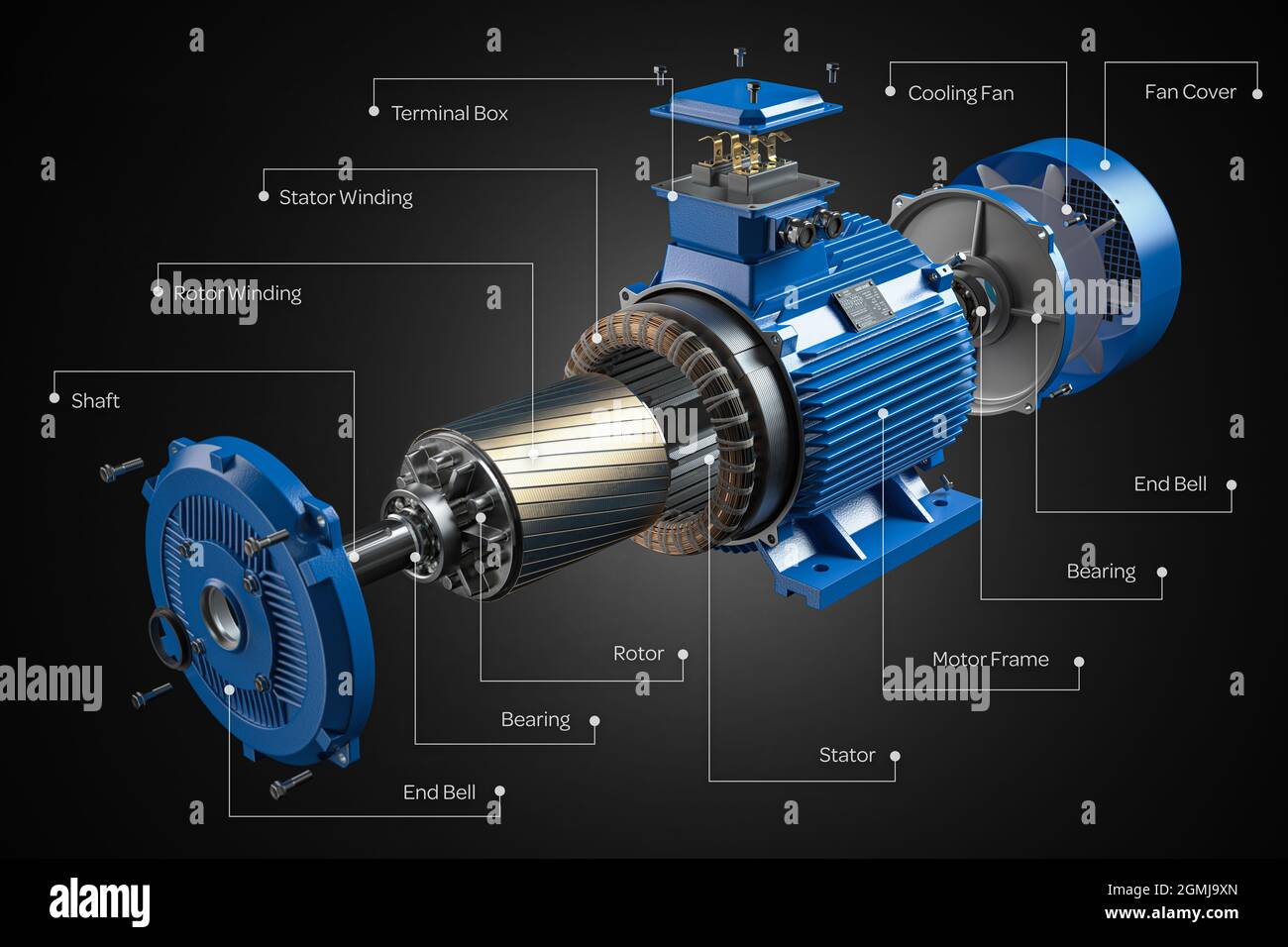

How Does the Stator Contribute to Motor Functionality?

The stator provides a stationary magnetic field that interacts with the rotor, enabling motion. Its design and material composition are crucial for motor stability and durability. B2B buyers should evaluate the stator’s construction and its impact on efficiency when selecting DC motors for pumps, fans, or compressors. While stators enhance operational reliability, their fixed design may limit flexibility in adapting to various applications, making it essential to match the stator’s specifications with operational needs.

Key Industrial Applications of dc electric motor parts

| Industry/Sector | Specific Application of dc electric motor parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Automated Assembly Lines | Increases production efficiency and reduces labor costs | Reliability of parts, lead times, and local availability |

| Mining | Conveyor Systems for Material Transport | Enhances operational efficiency and safety in harsh environments | Durability of components, resistance to dust and moisture |

| Agriculture | Irrigation Systems and Pumps | Ensures consistent water supply and improved crop yield | Energy efficiency, compatibility with existing systems |

| Automotive | Electric Vehicle (EV) Drive Systems | Supports the transition to sustainable transport solutions | Compliance with international standards and certifications |

| Robotics | Precision Motion Control in Robotic Arms | Improves accuracy and productivity in automated tasks | Precision of components, customization options |

How Are DC Electric Motor Parts Used in Manufacturing Applications?

In the manufacturing sector, DC electric motor parts are integral to automated assembly lines. These motors drive conveyors and robotic arms, facilitating the seamless movement of materials and components. By utilizing high-quality motor parts, businesses can significantly enhance production efficiency and reduce labor costs. International buyers should prioritize sourcing components that guarantee reliability and quick lead times, as delays can disrupt production schedules.

What Role Do DC Electric Motor Parts Play in Mining Operations?

In the mining industry, DC electric motor parts are essential for powering conveyor systems that transport materials from extraction sites to processing areas. These motors must operate efficiently in harsh environments, where dust and moisture can affect performance. Sourcing durable components that can withstand these conditions is crucial for maintaining operational efficiency and ensuring worker safety. Buyers should consider the resilience and maintenance needs of the parts to minimize downtime.

How Are DC Electric Motor Parts Utilized in Agriculture?

DC electric motor parts are vital in agricultural applications, particularly in irrigation systems and water pumps. These motors ensure a consistent water supply, which is crucial for maximizing crop yield. Buyers in this sector should focus on energy-efficient solutions that can reduce operational costs while meeting the demands of diverse agricultural environments. Compatibility with existing systems is also a critical consideration for international buyers looking to upgrade or expand their operations.

In What Ways Do DC Electric Motor Parts Support Electric Vehicles?

The automotive industry increasingly relies on DC electric motor parts in electric vehicle (EV) drive systems. These components are essential for converting electrical energy into mechanical power, enabling efficient vehicle operation. As the market shifts towards sustainable transport solutions, sourcing compliant and certified motor parts becomes vital for manufacturers. International buyers should ensure that the parts meet regional standards and can be integrated seamlessly into existing vehicle designs.

How Are DC Electric Motor Parts Important for Robotics?

In robotics, DC electric motor parts are crucial for precision motion control in robotic arms and automated systems. These motors allow for accurate movements, enhancing productivity in various applications, from manufacturing to healthcare. Buyers should look for components that offer customization options to suit specific robotic designs. Precision and reliability are key factors to consider, as they directly impact the performance and effectiveness of robotic systems in diverse industries.

3 Common User Pain Points for ‘dc electric motor parts’ & Their Solutions

Scenario 1: Sourcing Quality DC Motor Parts for Optimal Performance

The Problem: International B2B buyers often struggle to find reliable suppliers for high-quality DC motor parts. This challenge is compounded by varying standards and regulations across different regions, leading to uncertainty about product reliability and compatibility. Buyers may receive subpar components that do not meet their operational requirements, resulting in equipment downtime, increased maintenance costs, and lost productivity. Furthermore, language barriers and time zone differences can complicate communication with potential suppliers, making it harder to address concerns or verify product specifications.

The Solution: To overcome these challenges, B2B buyers should invest time in researching and establishing relationships with reputable suppliers who have a proven track record in the industry. Utilizing platforms that specialize in DC motor parts can help buyers access a wider range of options. It’s critical to request detailed product specifications, certifications, and performance data from suppliers to ensure the parts meet the necessary standards. Additionally, participating in industry forums and trade shows can facilitate direct communication with manufacturers, allowing buyers to assess quality firsthand and negotiate better terms. Establishing long-term partnerships with trusted suppliers can lead to consistent quality and reliability, ultimately enhancing operational efficiency.

Scenario 2: Understanding the Role of Specific Components in DC Motors

The Problem: Many B2B buyers lack a deep understanding of the individual components that make up DC motors, such as brushes, commutators, and field windings. This knowledge gap can result in purchasing the wrong parts, leading to compatibility issues and suboptimal motor performance. For example, selecting the incorrect brush material can cause excessive wear or insufficient electrical contact, ultimately leading to motor failure. Buyers may feel overwhelmed by technical specifications and the variety of options available, which can hinder their decision-making process.

The Solution: To bridge this knowledge gap, buyers should take advantage of educational resources provided by manufacturers and industry experts. Detailed product guides, webinars, and technical support can offer valuable insights into the function and importance of each motor component. Engaging with knowledgeable distributors or consultants can also provide tailored recommendations based on specific application needs. Moreover, creating a checklist of essential specifications for each component can help streamline the selection process, ensuring that the chosen parts align with operational requirements. By becoming more informed about DC motor components, buyers can make smarter purchasing decisions that enhance the overall performance and longevity of their equipment.

Scenario 3: Managing Inventory and Spare Parts for DC Motors

The Problem: Managing inventory for DC motor parts can be a significant pain point for B2B buyers, particularly in regions with longer lead times and logistical challenges. Companies may face situations where critical components are out of stock, resulting in halted production lines and delays in project timelines. Additionally, keeping track of various part numbers and specifications can become overwhelming, especially for businesses that operate multiple motors with different configurations. This inefficiency can lead to increased operational costs and frustration among team members.

The Solution: Implementing an effective inventory management system tailored to DC motor parts can mitigate these issues. Buyers should consider utilizing software solutions that allow for real-time tracking of inventory levels, reorder points, and lead times. Maintaining a minimum stock level of critical components, such as brushes and commutators, can help prevent unexpected downtime. Establishing relationships with local suppliers can also reduce lead times and ensure faster access to essential parts. Furthermore, conducting regular audits of inventory and analyzing usage patterns can help buyers optimize their stock levels, ensuring that they have the right parts on hand when needed. By proactively managing inventory, B2B buyers can enhance operational efficiency and reduce costs associated with downtime.

Strategic Material Selection Guide for dc electric motor parts

What Are the Key Materials Used in DC Electric Motor Parts?

When selecting materials for DC electric motor parts, it is crucial for international B2B buyers to consider the properties, advantages, and limitations of each material. Here, we analyze four common materials used in the manufacturing of DC motor components: copper, carbon, steel, and aluminum.

How Does Copper Benefit DC Electric Motor Parts?

Copper is widely used in DC motors, particularly for windings and electrical connections. Its excellent electrical conductivity (around 60% better than aluminum) ensures efficient current flow, which is essential for optimal motor performance. Copper also has good thermal conductivity, allowing for effective heat dissipation during operation.

Pros: Copper’s durability and high conductivity make it ideal for applications requiring reliable electrical performance. However, it is relatively expensive compared to other materials, which can increase overall production costs.

Cons: While copper is resistant to corrosion, it can still oxidize, which may affect electrical connections over time. Additionally, its weight may be a concern in applications where weight reduction is critical.

Impact on Application: Copper is suitable for high-performance applications where efficiency is paramount, such as in automotive and aerospace sectors.

Considerations for International Buyers: Buyers from regions like Europe and South America should ensure compliance with standards such as ASTM B170 for copper wire and consider local regulations regarding the sourcing and recycling of copper.

What Role Does Carbon Play in DC Motor Components?

Carbon, particularly in the form of carbon brushes, is essential for maintaining electrical contact within DC motors. Carbon brushes are known for their self-lubricating properties and ability to withstand high temperatures, making them suitable for various operational environments.

Pros: The low friction and wear characteristics of carbon brushes enhance the longevity of the motor. They are also relatively inexpensive and easy to manufacture.

Cons: Carbon brushes can wear out over time, necessitating regular maintenance and replacement. They may also be less effective in high-speed applications compared to other materials.

Impact on Application: Carbon brushes are commonly used in industrial applications, including mining and manufacturing, where durability and maintenance are key concerns.

Considerations for International Buyers: Buyers should look for compliance with standards like JIS C 4001 for carbon brushes and consider regional preferences for specific brush compositions based on local operational conditions.

Why Is Steel Important for DC Motor Parts?

Steel is a primary material for the structural components of DC motors, including the stator and housing. Its high strength and rigidity make it ideal for withstanding mechanical stresses.

Pros: Steel’s durability and ability to be machined into precise shapes make it suitable for a wide range of motor applications. It also offers good magnetic properties, enhancing the motor’s efficiency.

Illustrative image related to dc electric motor parts

Cons: Steel is heavier than other materials, which may limit its use in lightweight applications. Additionally, it is susceptible to corrosion unless adequately treated or coated.

Impact on Application: Steel is commonly used in heavy-duty applications, such as industrial machinery and agricultural equipment, where strength and durability are critical.

Considerations for International Buyers: Compliance with standards such as DIN 17100 for structural steel is essential, particularly for European buyers. Buyers should also consider the availability of corrosion-resistant coatings for enhanced durability in harsh environments.

How Does Aluminum Compare in DC Motor Parts?

Aluminum is increasingly being used in DC motor applications due to its lightweight and corrosion-resistant properties. It is often used for housings and other non-structural components.

Pros: The low weight of aluminum contributes to overall energy efficiency, making it ideal for portable and automotive applications. It is also relatively inexpensive and easy to fabricate.

Cons: While aluminum has good corrosion resistance, it has lower strength compared to steel, which may limit its use in high-stress applications. Its thermal conductivity is also lower than that of copper.

Impact on Application: Aluminum is well-suited for applications where weight savings are critical, such as in electric vehicles and consumer electronics.

Considerations for International Buyers: Buyers should ensure compliance with standards like ASTM B221 for aluminum extrusions and consider regional preferences for specific aluminum alloys based on application requirements.

Illustrative image related to dc electric motor parts

Summary Table of Material Selection for DC Electric Motor Parts

| Material | Typical Use Case for dc electric motor parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Windings, electrical connections | Excellent electrical conductivity | Expensive, can oxidize | High |

| Carbon | Brushes | Low friction, durable | Wears out over time | Low |

| Steel | Stator, housing | High strength, durable | Heavy, susceptible to corrosion | Medium |

| Aluminum | Housings, non-structural components | Lightweight, corrosion-resistant | Lower strength than steel | Medium |

This guide aims to provide B2B buyers with a comprehensive understanding of material selection for DC electric motor parts, facilitating informed decisions that align with their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for dc electric motor parts

What Are the Key Stages in the Manufacturing Process of DC Electric Motor Parts?

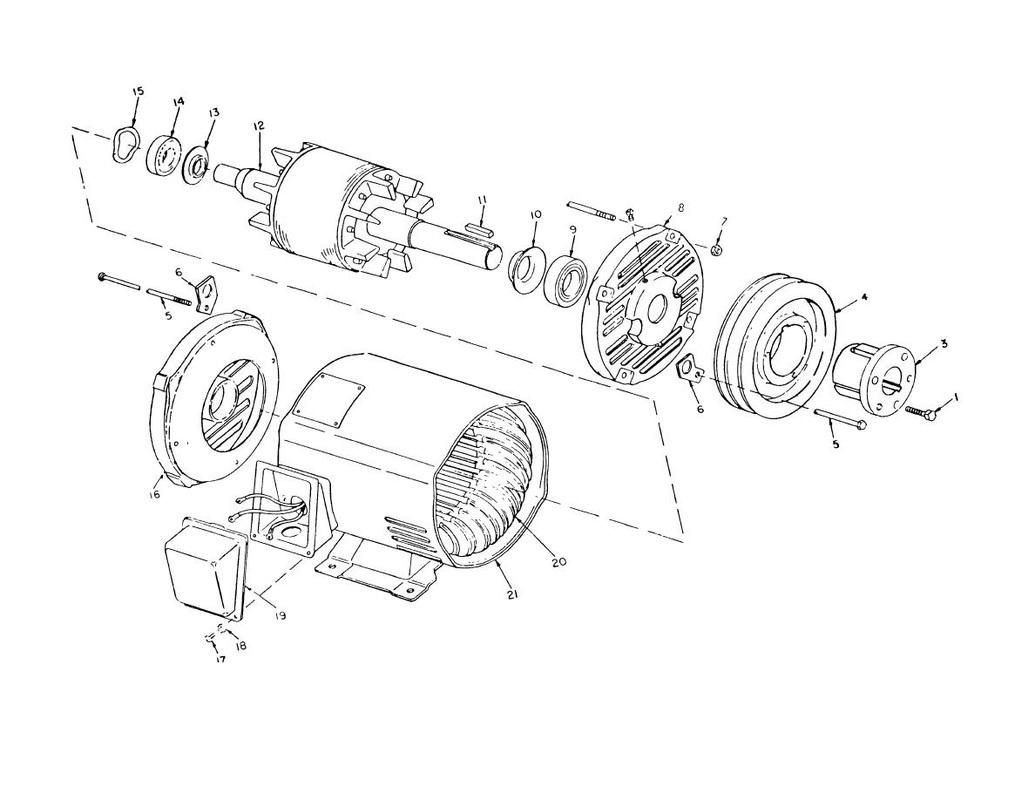

The manufacturing process for DC electric motor parts involves several critical stages, each requiring precision and attention to detail. Understanding these stages can help B2B buyers identify suppliers capable of delivering high-quality components.

Material Preparation: What Materials Are Used in DC Motor Parts?

The first step in manufacturing DC motor parts is material preparation. Typically, components such as armatures, stators, and commutators are made from high-grade steel, copper, and specialized composites. The choice of materials directly affects the performance and longevity of the motor.

During this stage, raw materials are sourced from reputable suppliers and subjected to quality checks to ensure they meet industry standards. Buyers should inquire about the material specifications and certifications, as these can vary significantly based on regional standards and supplier capabilities.

How Are DC Motor Parts Formed?

Following material preparation, the next stage is forming. This process includes machining, stamping, and forging, depending on the specific component being produced. For instance, armatures are often fabricated using precision machining techniques to ensure accurate dimensions for optimal performance.

In this stage, the use of advanced CNC (Computer Numerical Control) machines is prevalent. These machines enable high precision and repeatability, which are crucial for components that must fit together seamlessly. Buyers should assess whether their suppliers utilize modern machinery and technology, as this can greatly influence the quality of the finished parts.

What Does the Assembly Process Entail for DC Motor Components?

The assembly stage involves integrating various components, such as the armature, stator, brushes, and commutator. This process requires skilled labor and often employs automated systems to enhance efficiency and reduce human error.

Quality assurance begins at this stage, where components are checked for proper fit and alignment. Implementing a robust assembly process is critical, as any misalignment can lead to motor inefficiencies or failures. B2B buyers should ask suppliers about their assembly techniques and workforce training programs to ensure quality standards are upheld.

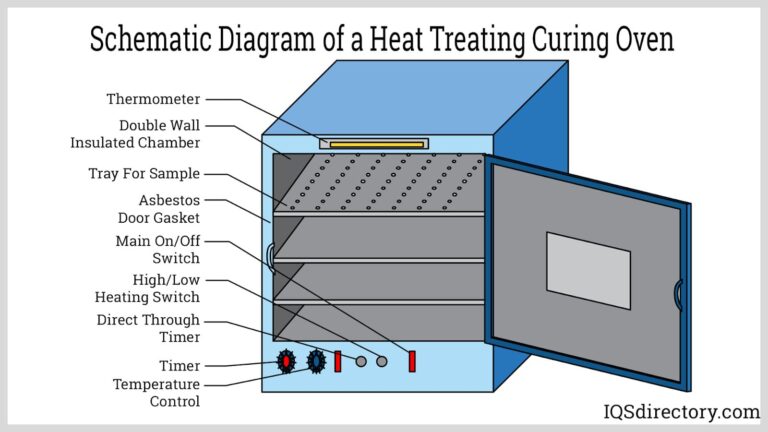

What Finishing Techniques Are Applied to DC Electric Motor Parts?

Finishing processes are essential for enhancing the durability and aesthetic quality of DC motor parts. Common finishing techniques include coating, plating, and heat treatment. These processes protect components from wear, corrosion, and environmental factors.

Illustrative image related to dc electric motor parts

For instance, applying a layer of insulation or a protective coating can significantly extend the lifespan of electrical components. Buyers should verify that suppliers adhere to finishing specifications that meet international standards, as this can impact the overall performance of the motor.

What Quality Assurance Measures Are in Place for DC Motor Parts?

Quality assurance (QA) is a crucial aspect of manufacturing DC electric motor parts. It ensures that all components meet predefined standards before they reach the customer. Understanding the QA measures can help B2B buyers evaluate potential suppliers effectively.

What International Standards Should B2B Buyers Be Aware Of?

Most manufacturers adhere to international standards such as ISO 9001, which outlines the requirements for a quality management system. Compliance with ISO standards is a strong indicator of a supplier’s commitment to quality. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are relevant for certain applications.

For international buyers, especially in regions such as Africa, South America, and the Middle East, it is essential to verify that suppliers possess the necessary certifications to avoid non-compliance issues.

What Quality Control Checkpoints Are Essential in Manufacturing?

Quality control (QC) is typically segmented into various checkpoints throughout the manufacturing process. These include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early.

- Final Quality Control (FQC): A comprehensive inspection of finished products before they are shipped to customers ensures all specifications are met.

B2B buyers should inquire about the specific QC processes implemented by suppliers to ensure that they are rigorous and thorough.

Illustrative image related to dc electric motor parts

What Common Testing Methods Are Used to Ensure Quality?

Testing methods vary depending on the component and its intended application. Common testing methods for DC motor parts include:

- Electrical Testing: Ensures proper current flow and insulation integrity.

- Mechanical Testing: Assesses the strength and durability of components.

- Thermal Testing: Evaluates performance under different temperature conditions.

Buyers should request test reports and certifications from suppliers to confirm that their products have undergone rigorous testing.

How Can B2B Buyers Verify Supplier Quality Assurance?

To establish trust in a supplier’s quality assurance practices, B2B buyers should consider several strategies:

Illustrative image related to dc electric motor parts

- Conduct Audits: Regular audits of suppliers can provide insight into their manufacturing and QC processes. This can be done either by the buyer or through third-party audit firms.

- Request Quality Reports: Suppliers should be willing to share quality reports, including IQC, IPQC, and FQC data.

- Third-Party Inspections: Engaging a third-party inspection service can provide an unbiased evaluation of the supplier’s processes and products.

What Are the Nuances of Quality Control for International B2B Buyers?

For international buyers, particularly those from diverse regions like Africa, South America, and Europe, understanding the nuances of quality control is vital. Different regions may have varying standards and expectations regarding quality assurance.

Buyers should familiarize themselves with local regulations and industry standards applicable in their regions. Moreover, cultural differences may influence communication and expectations, so establishing clear lines of communication with suppliers is essential.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices for DC electric motor parts is crucial for B2B buyers. By focusing on material preparation, forming, assembly, finishing, and rigorous QC, buyers can ensure they partner with suppliers who prioritize quality and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dc electric motor parts’

Introduction

This practical sourcing guide is designed to assist B2B buyers in procuring DC electric motor parts effectively. With a focus on ensuring optimal performance and reliability, this checklist outlines essential steps to take when sourcing components, enabling informed decisions that align with your operational requirements.

1. Define Your Technical Specifications

Before initiating the sourcing process, it’s vital to define the specific technical requirements of the DC electric motor parts you need. Consider factors such as voltage ratings, current capacity, and physical dimensions.

– Identify application needs: Understand the motor’s application to determine the right specifications.

– Consult with engineers: Engage with your engineering team to ensure all critical parameters are covered.

2. Research Reliable Suppliers

Conduct thorough research to identify potential suppliers of DC electric motor parts. Look for companies with a solid reputation and extensive experience in the field.

– Utilize industry directories: Websites and platforms dedicated to electrical components can provide a list of qualified suppliers.

– Check online reviews: Look for customer testimonials and case studies to gauge supplier reliability.

3. Evaluate Supplier Certifications

Confirm that potential suppliers hold relevant certifications, such as ISO 9001, which indicates a commitment to quality management.

– Request documentation: Ask suppliers to provide proof of certifications and compliance with international standards.

– Assess quality control processes: Understand their quality assurance procedures to ensure they align with your requirements.

4. Inquire About Product Availability and Lead Times

Understanding product availability and lead times is essential for planning and inventory management.

– Ask for stock levels: Inquire about the availability of specific parts to avoid delays in your operations.

– Clarify delivery timelines: Ensure suppliers can meet your project deadlines to maintain workflow continuity.

Illustrative image related to dc electric motor parts

5. Request Samples for Quality Assessment

Before making a bulk purchase, request samples of the DC electric motor parts to evaluate their quality.

– Conduct performance testing: Use the samples in your application to assess their functionality and durability.

– Inspect craftsmanship: Check the materials and assembly quality to ensure they meet your standards.

6. Negotiate Terms and Pricing

Once you have identified a suitable supplier, engage in negotiations to secure favorable terms and pricing.

– Discuss bulk order discounts: Leverage larger orders for better pricing and payment terms.

– Clarify warranty and return policies: Ensure you understand the terms regarding product defects or unsatisfactory performance.

7. Establish a Communication Plan

Maintaining clear communication with your suppliers is essential throughout the procurement process.

– Set regular check-ins: Schedule updates to discuss order status, delivery, and any potential issues.

– Utilize multiple communication channels: Ensure you can reach your supplier easily through email, phone, or messaging platforms.

By following this checklist, B2B buyers can effectively navigate the sourcing process for DC electric motor parts, ensuring they procure high-quality components that meet their operational needs.

Comprehensive Cost and Pricing Analysis for dc electric motor parts Sourcing

What Are the Key Cost Components in Sourcing DC Electric Motor Parts?

When evaluating the cost structure for sourcing DC electric motor parts, several key components contribute to the overall expense. These include:

-

Materials: The choice of materials—such as copper for windings or specialized alloys for housing—can significantly affect costs. High-quality materials may incur higher upfront costs but can enhance durability and performance.

-

Labor: Labor costs vary based on geographic location and the complexity of assembly. Skilled labor in regions with higher wage standards will increase manufacturing costs.

-

Manufacturing Overhead: This includes utilities, equipment depreciation, and other indirect costs associated with production. Efficient operations can help mitigate these expenses.

-

Tooling: Investment in specialized tooling for production can be substantial. Tooling costs are typically amortized over the production volume, so they become more manageable with larger orders.

-

Quality Control (QC): Ensuring compliance with international standards requires rigorous QC processes. While this may add to the upfront costs, it is essential for minimizing defects and ensuring product reliability.

-

Logistics: Transportation and shipping costs can vary dramatically based on distance, method, and the Incoterms used. For international transactions, these costs must be carefully calculated.

-

Margin: Suppliers will typically mark up their costs to ensure profitability. Understanding the typical margins within the industry can aid in negotiation.

How Do Volume and Customization Influence Pricing of DC Electric Motor Parts?

Pricing for DC electric motor parts is heavily influenced by order volume and the level of customization required. Larger orders often qualify for volume discounts, allowing buyers to reduce per-unit costs. On the other hand, customized parts—tailored for specific applications or specifications—can incur additional design and manufacturing costs.

The specifications of the components, including size, voltage, and performance criteria, also play a significant role in pricing. Parts that require unique materials or advanced engineering may attract higher costs. Buyers should assess their needs carefully to balance customization with cost-effectiveness.

Illustrative image related to dc electric motor parts

What Buyer Tips Can Enhance Cost-Efficiency in DC Electric Motor Parts Sourcing?

International B2B buyers should consider several strategies to enhance cost-efficiency when sourcing DC electric motor parts:

-

Negotiate Terms: Engaging in negotiations can lead to better pricing, especially for bulk orders. Establishing long-term relationships with suppliers can also yield favorable terms.

-

Consider Total Cost of Ownership (TCO): TCO encompasses not just the purchase price, but also maintenance, operational efficiency, and the expected lifespan of the components. Opting for higher-quality parts may result in lower TCO over time.

-

Understand Pricing Nuances for International Transactions: Pricing can vary significantly based on regional markets and currency fluctuations. Buyers from Africa, South America, the Middle East, and Europe should stay informed about local market conditions and consider hedging strategies for currency risks.

-

Evaluate Supplier Certifications: Certifications can indicate quality and compliance with international standards. Suppliers with relevant certifications may justify higher prices due to their commitment to quality.

-

Review Incoterms: Understanding Incoterms is crucial for clarifying responsibilities regarding shipping, insurance, and tariffs. This knowledge helps buyers avoid unexpected costs and delays.

Why Is It Important to Consider Indicative Prices When Sourcing?

While indicative prices can provide a benchmark, they should be approached with caution. Prices fluctuate based on market conditions, demand, and raw material costs. Additionally, the final price may vary based on negotiated terms, order size, and specific requirements. Buyers should request formal quotes and compare multiple suppliers to ensure they receive the best value for their investment.

By carefully analyzing these factors and implementing strategic sourcing practices, international buyers can optimize their procurement process for DC electric motor parts, achieving both quality and cost-effectiveness.

Alternatives Analysis: Comparing dc electric motor parts With Other Solutions

Understanding Alternatives to DC Electric Motor Parts

In the landscape of industrial machinery, DC electric motors are widely used for their reliability and efficiency. However, various alternatives exist that may better suit specific applications or operational needs. This analysis compares DC electric motor parts with two alternative solutions: AC electric motor parts and stepper motors. Each option presents unique characteristics that can influence a buyer’s decision based on performance requirements, cost considerations, and maintenance needs.

Comparison Table

| Comparison Aspect | Dc Electric Motor Parts | AC Electric Motor Parts | Stepper Motors |

|---|---|---|---|

| Performance | High torque at low speeds; variable speed control | Generally high efficiency; constant speed | Precise position control; excellent for low-speed applications |

| Cost | Moderate initial cost; higher maintenance costs | Generally lower initial cost; low maintenance | Higher initial cost; cost-effective for precision tasks |

| Ease of Implementation | Moderate complexity; requires specific wiring | Simple integration; widely available | Requires specialized control systems |

| Maintenance | Moderate; brushes need regular replacement | Low; fewer moving parts | Moderate; requires calibration and maintenance of control systems |

| Best Use Case | Applications needing variable speed and torque | Industrial applications with constant speed requirements | Applications requiring precise control and positioning |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of AC Electric Motor Parts?

AC electric motors are an excellent alternative for applications that require consistent speed and efficiency. They are typically less expensive to install and maintain compared to their DC counterparts, as they have fewer moving parts and do not require brushes, which can wear out over time. However, AC motors may not provide the same level of torque at low speeds as DC motors do, making them less suitable for applications requiring variable speed control. Their performance is often optimized for steady-state operations, which may limit their versatility in some industrial contexts.

Why Consider Stepper Motors as an Alternative?

Stepper motors offer distinct advantages in applications where precise control of position and speed is essential. They excel in low-speed scenarios and can be controlled to move in small increments, making them ideal for robotics and CNC machinery. However, they typically have a higher initial purchase price and require more complex control systems, which can be a barrier for some buyers. Maintenance is also needed to ensure that the control systems remain calibrated, but overall, stepper motors can provide significant benefits for applications demanding high precision.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the appropriate motor solution requires a thorough understanding of specific operational needs and constraints. B2B buyers should consider factors such as the required performance characteristics, budget limitations, and maintenance capabilities. For instance, if variable speed and torque are essential, DC electric motors might be the best choice. Conversely, for applications demanding precision and control, stepper motors would be preferable. Understanding the unique advantages and limitations of each option will empower buyers to make informed decisions that align with their operational objectives and budgetary constraints.

Essential Technical Properties and Trade Terminology for dc electric motor parts

What Are the Key Technical Properties of DC Electric Motor Parts?

Understanding the essential technical properties of DC electric motor parts is crucial for B2B buyers, particularly when making informed purchasing decisions. Here are some critical specifications to consider:

1. Material Grade

Material grade refers to the type of material used in the construction of motor components, such as brushes and armatures. Common materials include copper for windings and carbon for brushes. The material grade affects the part’s conductivity, durability, and overall performance. For instance, high-grade copper offers better conductivity, which can enhance the motor’s efficiency and lifespan, making it a vital consideration for buyers looking to optimize performance.

2. Tolerance

Tolerance defines the permissible limits of variation in a part’s dimensions. For DC motor components, tight tolerances ensure proper fit and function, reducing mechanical wear and enhancing reliability. In industries where precision is critical, such as aerospace or automotive, understanding tolerance specifications helps buyers select parts that meet stringent quality standards, ultimately leading to improved operational efficiency.

3. Voltage Rating

The voltage rating indicates the maximum voltage a motor part can handle without failure. It is essential for ensuring compatibility with the intended DC motor application. Selecting parts with appropriate voltage ratings helps prevent electrical failures and prolongs the life of the motor, making it a key factor for decision-makers focused on reliability and safety.

4. Current Rating

Current rating specifies the maximum current that a motor component can carry. It is critical for preventing overheating and ensuring that the motor operates within safe limits. For B2B buyers, understanding current ratings is vital for matching components to their specific applications, ensuring optimal performance and avoiding costly downtime due to equipment failure.

Illustrative image related to dc electric motor parts

5. Insulation Class

Insulation class defines the thermal limits of the insulation materials used in motor parts. Common classes include A, B, F, and H, with each class indicating a different maximum operating temperature. This property is important for buyers in high-temperature environments, as it impacts the longevity and reliability of the motor. Selecting parts with the right insulation class ensures that the motor can operate safely and effectively in its intended environment.

What Are Common Trade Terms in the DC Electric Motor Parts Industry?

Familiarity with industry-specific jargon is essential for effective communication and negotiation in the B2B marketplace. Here are several key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that are marketed under another company’s brand. Understanding OEM specifications is crucial for buyers looking to source replacement parts that meet original performance standards, ensuring compatibility and reliability in applications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is important for buyers to consider when budgeting for purchases, as it can affect inventory management and overall costs. Knowing the MOQ can help businesses plan their orders effectively to maintain adequate stock levels without overcommitting financially.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and availability for specific products. It is a critical tool for buyers in the procurement process, allowing them to compare offers and negotiate better terms. Understanding how to craft a compelling RFQ can lead to more favorable pricing and service terms.

4. Incoterms (International Commercial Terms)

Incoterms are standardized shipping terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping costs, risk management, and delivery obligations, making it easier to navigate global supply chains effectively.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. For buyers, understanding lead times is essential for project planning and ensuring that production schedules are met. Shorter lead times can provide a competitive advantage, allowing businesses to respond quickly to market demands.

By grasping these essential technical properties and trade terms, B2B buyers can make more informed decisions when sourcing DC electric motor parts, ultimately leading to enhanced operational efficiency and improved profitability.

Navigating Market Dynamics and Sourcing Trends in the dc electric motor parts Sector

What Are the Key Market Trends Affecting DC Electric Motor Parts?

The global market for DC electric motor parts is experiencing significant growth driven by increasing demand across various industries, including automotive, manufacturing, and renewable energy. The rise in electric vehicles (EVs) and automation technologies are primary catalysts propelling this trend. As nations push towards decarbonization and sustainability, the shift from traditional internal combustion engines to electric motors is becoming more pronounced, particularly in regions like Europe and South America. B2B buyers are now seeking suppliers who can provide high-quality parts that meet evolving standards for performance and reliability.

Illustrative image related to dc electric motor parts

Emerging technologies such as Industry 4.0 are reshaping sourcing strategies within the sector. The integration of IoT (Internet of Things) and AI (Artificial Intelligence) into manufacturing processes enhances predictive maintenance and optimizes supply chain management. This shift not only lowers operational costs but also improves the efficiency of sourcing and inventory management. Moreover, as businesses increasingly operate on a global scale, the importance of establishing robust international partnerships cannot be overstated. Buyers from Africa and the Middle East, for instance, are focusing on sourcing parts from manufacturers that can offer competitive pricing while ensuring timely delivery.

How Is Sustainability Shaping Sourcing Decisions in the DC Electric Motor Parts Industry?

Sustainability is becoming a central theme in the sourcing of DC electric motor parts, driven by both consumer demand and regulatory requirements. Environmental impact assessments are now critical for companies aiming to maintain competitive advantages. B2B buyers are prioritizing suppliers who demonstrate a commitment to ethical sourcing practices and environmental responsibility. This includes the use of recycled materials, low-emission manufacturing processes, and adherence to international environmental standards.

The trend towards ‘green’ certifications, such as ISO 14001 for environmental management, is gaining traction. Buyers are increasingly interested in suppliers who can provide products with certifications that guarantee minimal environmental impact. For instance, parts made from sustainable materials or those manufactured in facilities powered by renewable energy sources are highly sought after. Additionally, transparency in the supply chain is crucial; buyers want assurances that their suppliers uphold ethical labor practices and minimize waste throughout their operations.

How Has the DC Electric Motor Parts Market Evolved Over Time?

The evolution of the DC electric motor parts market can be traced back to the industrial revolution when electric motors first began to replace steam engines. This transition marked a significant shift in manufacturing and transportation, leading to the development of more efficient and reliable motor components. As technology advanced, innovations such as improved materials for brushes and commutators enhanced motor performance and longevity.

In recent decades, the rise of automation and digital technologies has transformed the landscape further, enabling manufacturers to produce more sophisticated and tailored motor components. Today, with the emphasis on sustainability and efficiency, the market is witnessing a renewed focus on innovation, particularly in areas such as lightweight materials and energy-efficient designs. As global markets continue to expand, understanding the historical context of DC electric motor parts can provide valuable insights for B2B buyers navigating current trends.

Frequently Asked Questions (FAQs) for B2B Buyers of dc electric motor parts

-

How do I solve issues with DC motor overheating?

To address overheating in DC motors, first check for proper ventilation and ensure that the motor is not overloaded beyond its rated capacity. Inspect the brushes for wear and ensure they maintain good contact with the commutator. Additionally, verify that the cooling system (if applicable) is functioning correctly. Regular maintenance, including cleaning dust and debris from the motor, can also help prevent overheating. If problems persist, consider consulting with a motor specialist to explore options for upgrading or replacing components. -

What is the best type of brush for my DC motor application?

The optimal brush type for your DC motor largely depends on the specific application and operating conditions. Carbon brushes are commonly used due to their excellent conductivity and durability, making them suitable for general applications. For high-speed or high-temperature environments, graphite brushes may be preferable due to their lower friction properties. Always consider the motor’s operational environment and consult with suppliers for recommendations tailored to your specific needs. -

How can I ensure the quality of DC motor parts when sourcing internationally?

To guarantee the quality of DC motor parts from international suppliers, conduct thorough due diligence. Request samples for testing before placing bulk orders and ask for certifications such as ISO 9001. Establish clear communication regarding quality standards and expectations. Additionally, consider visiting the supplier’s facility if feasible, or hire a third-party inspection service to evaluate the quality of the parts before shipment. -

What are the typical minimum order quantities (MOQs) for DC motor parts?

Minimum order quantities (MOQs) for DC motor parts can vary significantly based on the supplier and the type of parts. Generally, standard components like brushes may have lower MOQs, often ranging from 50 to 100 units, while specialized or custom parts may require higher MOQs. Always inquire directly with suppliers to understand their specific policies and negotiate terms that meet your operational needs. -

What payment terms should I expect when sourcing DC motor parts?

Payment terms can vary widely among suppliers, but common practices include 30% upfront payment and 70% upon delivery, or net 30/60 days after invoice. International buyers should also consider the implications of currency fluctuations and payment processing fees. It’s advisable to establish clear payment terms in the contract, and to use secure payment methods such as letters of credit or escrow services to mitigate risks. -

How do I vet potential suppliers for DC motor parts?

To effectively vet suppliers of DC motor parts, begin by researching their reputation and history in the industry. Check for customer reviews, testimonials, and any certifications they may hold. Establish a direct line of communication to discuss your requirements and gauge their responsiveness. Request references from previous clients and verify their ability to meet quality and delivery timelines. Conducting a site visit or engaging a third-party auditor can also provide valuable insights into their operations. -

What logistical considerations should I keep in mind when importing DC motor parts?

When importing DC motor parts, consider factors such as shipping times, customs regulations, and potential tariffs. Establish relationships with reliable freight forwarders who can assist with logistics and ensure compliance with international shipping laws. Be aware of the documentation required for customs clearance, including invoices, packing lists, and certificates of origin. Planning for potential delays in shipping and customs can help avoid disruptions in your supply chain. -

Can I customize DC motor parts to fit specific requirements?

Yes, many suppliers offer customization options for DC motor parts, allowing you to tailor components to meet your specific requirements. This can include modifications in size, material, or design to suit particular applications. When seeking customization, provide detailed specifications and work closely with the supplier to ensure that the final product meets your expectations. Keep in mind that custom parts may come with longer lead times and higher costs, so plan accordingly.

Top 7 Dc Electric Motor Parts Manufacturers & Suppliers List

1. US Motor – DC Motor Parts

Domain: usmotor.com

Registered: 1997 (28 years)

Introduction: DC Motor Parts include various components such as brush springs and brushes. Specific products listed are:

– A2631 Brush Spring – $65.00

– A2632 Brush Spring – $55.00

– A2633 Brush Spring – $51.00

– A2634 Brush Spring – $51.00

– A2635 Brush Spring – $75.00

– B10970-7 Brush – $24.00

– B15368-2 Brush – $70.00

– B15390-2 Brush – $26.00

– B15392-2 Brush – $36.00

– B15393-1 Brush – $44.00

– …

2. DC Motor Parts – Replacement Carbon Brushes

Domain: dcmotorparts.com

Registered: 2012 (13 years)

Introduction: DC Motor Parts offers replacement carbon brushes, brush holders, brush holder springs, rocker rings, insulators, and carbon brushes for electric motors. They provide over 900 styles of Helwig carbon brushes for various applications including industrial, mill, mining, traction, elevator, fractional, grounding, tach, servo, and slip ring. The company emphasizes low prices, no minimum order requireme…

3. DB Electrical – Replacement Parts and Motors

Domain: dbelectrical.com

Registered: 2000 (25 years)

Introduction: [{‘item_number’: ‘430-22044’, ‘price’: ‘$157.13’, ‘fitments’: ‘Replaces Hino X2772302, Bosch 0-204-788-062, Prestolite HYL5006’}, {‘item_number’: ‘430-20094’, ‘price’: ‘$153.18’, ‘fitments’: ‘P56SX401 12V,1/2HP Scott DC Reel Motor for Hannay Reels Various CCW Rotation’}, {‘item_number’: ‘LIA0010’, ‘price’: ‘$275.44’, ‘fitments’: ’24 Volt Insulated Ground Ventilated DC Motor for Haldex Barnes, Save…

4. ISL Products – DC Motor Components Overview

Domain: shop.islproducts.com

Registered: 1998 (27 years)

Introduction: DC Motor Components Overview: 1. Armature: Converts electrical energy into mechanical motion; constructed from insulated metal sheets; winding techniques impact torque, speed, and functionality. 2. Commutator: Ensures continuous electrical flow; made of copper segments; requires maintenance to prevent arcing and wear. 3. Brushes: Maintain contact with commutator; made of carbon or graphite; essent…

5. Byju’s – DC Motor Essentials

Domain: byjus.com

Registered: 2013 (12 years)

Introduction: A DC motor is an electrical machine that converts electrical energy into mechanical energy using direct current. Key components include: 1. Armature or Rotor – A rotating part insulated from magnetic laminations. 2. Field Coil or Stator – A non-moving part that produces a magnetic field. 3. Commutator – A cylindrical structure made of copper segments that supplies electrical current to the armatur…

6. Electric Motor Wholesale – Replacement Parts

Domain: electricmotorwholesale.com

Registered: 2005 (20 years)

Introduction: This company, Electric Motor Wholesale – Replacement Parts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Surplus Center – Key DC Motors

Domain: surpluscenter.com

Registered: 1996 (29 years)

Introduction: Key product details for DC Motors from Surplus Center include: 1. Various types of DC motors: Base Mount, Face Mount, DC Fan Motors, Special Purpose DC Motors, and Motor Speed Controllers. 2. Product examples: 0.015 HP 26 Volt DC 19000 RPM Motor ($1.99), 1/4 HP 24 Volt DC 1500 RPM Motor ($129.95), 1/3 HP 12 Volt DC 1800 RPM Motor ($294.40), and 1/2 HP 12 Volt DC 1800 RPM Motor ($391.20). 3. Availa…

Strategic Sourcing Conclusion and Outlook for dc electric motor parts

In conclusion, the strategic sourcing of DC electric motor parts is pivotal for businesses aiming to enhance operational efficiency and drive innovation. By focusing on high-quality components such as brushes, armatures, and commutators, buyers can significantly improve the reliability and performance of their electric motor systems. Moreover, understanding the specific requirements of various applications and maintaining strong supplier relationships can lead to cost savings and reduced downtime.

For international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe, leveraging strategic sourcing not only ensures access to premium parts but also fosters competitive advantage in a rapidly evolving landscape. As the demand for efficient and sustainable motor solutions grows, now is the time to evaluate your supply chain strategies and align them with your long-term business goals.

Embrace this opportunity to secure quality DC electric motor parts that meet your unique needs and propel your operations forward. Connect with trusted suppliers today to explore innovative solutions that will keep your business ahead of the curve.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.