Unlocking Value: A Strategic Analysis of the Cost Of Tungsten Market

Introduction: Navigating the Global Market for cost of tungsten

In an increasingly competitive global market, understanding the cost of tungsten is crucial for B2B buyers looking to optimize their procurement strategies. The challenge lies not only in sourcing high-quality tungsten but also in navigating the complexities of pricing, supplier reliability, and diverse applications across various industries. This guide is designed to equip international buyers, particularly from Africa, South America, the Middle East, and Europe—such as Vietnam and Saudi Arabia—with the insights necessary to make informed purchasing decisions.

Within this comprehensive resource, you will find detailed analyses of different tungsten types, including pure tungsten sheets, rods, and wires, along with their specific applications in sectors ranging from aerospace to electronics. We will explore the factors influencing tungsten pricing, including market demand, production costs, and geopolitical dynamics, which can significantly impact sourcing strategies. Additionally, we provide expert guidance on vetting suppliers to ensure you partner with reputable manufacturers who meet industry standards.

By leveraging this guide, B2B buyers can demystify the complexities surrounding tungsten procurement, allowing for strategic purchasing that aligns with operational needs and budget constraints. Whether you are a seasoned buyer or new to the market, understanding these dynamics will empower you to make decisions that enhance your competitive edge.

Understanding cost of tungsten Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pure Tungsten | High purity (99.95%), excellent conductivity | Aerospace, electronics, medical devices | Pros: High performance, versatile use. Cons: Higher cost compared to alloys. |

| Tungsten Carbide | Composite of tungsten and carbon, very hard | Cutting tools, mining, drilling | Pros: Exceptional hardness and wear resistance. Cons: Brittle, can break under impact. |

| Tungsten Alloys | Mixed with other metals for enhanced properties | Defense, automotive, aerospace | Pros: Tailored properties for specific applications. Cons: Cost varies significantly with alloy composition. |

| Tungsten Wire | Available in various diameters, high tensile strength | Lighting, electronics, thermionic emitters | Pros: Flexible, suitable for intricate applications. Cons: Requires precise handling and storage. |

| Tungsten Sheet/Plate | Available in various thicknesses, customizable | Industrial applications, manufacturing processes | Pros: Versatile, can be cut to size. Cons: Can be expensive for thicker sheets. |

What Are the Key Characteristics of Pure Tungsten and Its B2B Applications?

Pure tungsten, with a purity level of 99.95%, is renowned for its excellent electrical and thermal conductivity, making it ideal for high-performance applications in aerospace, electronics, and medical devices. B2B buyers should consider its versatility and high-temperature performance; however, its premium pricing may be a deterrent for budget-sensitive projects. When sourcing pure tungsten, it’s crucial to ensure the material meets industry standards to guarantee reliability in critical applications.

How Does Tungsten Carbide Compare in Terms of Cost and Use Cases?

Tungsten carbide is a composite material known for its exceptional hardness and wear resistance, making it a preferred choice for cutting tools, mining, and drilling operations. While it offers significant durability, B2B buyers should be aware of its brittleness, which can lead to failure under high-impact conditions. The cost of tungsten carbide can vary based on its composition, so understanding the specific requirements of your application is essential for making informed purchasing decisions.

What Advantages Do Tungsten Alloys Offer for Specialized Applications?

Tungsten alloys combine tungsten with other metals to enhance specific properties, catering to industries like defense, automotive, and aerospace. These alloys can be tailored to meet particular performance criteria, allowing for optimized solutions in demanding environments. However, the cost of tungsten alloys can fluctuate based on the alloying elements used, making it important for buyers to clearly define their application needs before procurement to ensure cost-effectiveness.

Why is Tungsten Wire Important for Electronics and Lighting?

Tungsten wire is available in various diameters and boasts high tensile strength, making it suitable for intricate applications such as lighting and thermionic emitters. Its flexibility allows for creative design solutions in electronic components. However, careful handling and storage are necessary to avoid damage, which can increase overall costs. Buyers should assess the specific diameter and purity required for their projects to ensure optimal performance.

How Can Tungsten Sheet/Plate Be Utilized in Manufacturing?

Tungsten sheets and plates come in various thicknesses and can be customized to meet specific manufacturing needs. Their versatility makes them suitable for a range of industrial applications, from components in high-temperature environments to shielding materials. While they offer significant benefits, thicker sheets can be costly. B2B buyers should evaluate their application requirements and consider potential savings from bulk purchasing to mitigate expenses.

Key Industrial Applications of cost of tungsten

| Industry/Sector | Specific Application of cost of tungsten | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | High-performance engine components | Ensures reliability and performance under extreme conditions | Look for suppliers with aerospace certifications and quality standards. |

| Electronics | Filaments and electrodes for lighting and displays | Enhances energy efficiency and longevity of products | Source high-purity tungsten to meet specific electrical conductivity needs. |

| Mining and Drilling | Tungsten carbide cutting tools | Increases durability and reduces downtime in operations | Consider the hardness and wear resistance ratings of tungsten products. |

| Defense and Military | Armor-piercing projectiles | Provides superior penetration and effectiveness in combat | Ensure compliance with international trade regulations and sourcing transparency. |

| Medical Devices | Radiation shielding and surgical instruments | Improves safety and precision in medical procedures | Verify material purity and certifications for use in medical applications. |

How is cost of tungsten utilized in the aerospace industry?

In the aerospace sector, tungsten is primarily used in high-performance engine components due to its exceptional density and high melting point. The cost of tungsten is a critical factor in sourcing materials for components that must withstand extreme temperatures and pressures during flight. International buyers should focus on suppliers that offer aerospace-grade tungsten, ensuring compliance with rigorous industry standards and certifications. This guarantees reliability and performance, essential for maintaining safety and efficiency in aerospace applications.

What role does tungsten play in the electronics industry?

Tungsten’s unique properties make it invaluable in the electronics industry, particularly in the manufacturing of filaments and electrodes used in lighting and display technologies. The cost of tungsten impacts the overall production expenses and product pricing. Buyers from regions such as Africa and South America should prioritize sourcing high-purity tungsten to ensure optimal electrical conductivity and longevity in their products. Establishing relationships with suppliers who understand the specific requirements of electronics manufacturing can lead to enhanced product performance and energy efficiency.

Why is tungsten important in mining and drilling applications?

In mining and drilling, tungsten carbide cutting tools are essential due to their hardness and wear resistance. The cost of tungsten directly influences the pricing of these tools, which are critical for reducing downtime and increasing productivity in harsh environments. B2B buyers should evaluate the hardness and wear resistance ratings of tungsten products to ensure they meet operational demands. Sourcing from reputable suppliers who can provide detailed specifications and performance data is crucial for maximizing the return on investment in this sector.

How does tungsten enhance defense and military applications?

Tungsten is used in defense applications, particularly in armor-piercing projectiles, where its density and hardness provide superior penetration capabilities. The cost of tungsten plays a significant role in the defense industry’s budgeting and procurement strategies. International buyers must ensure that their sourcing complies with trade regulations and ethical standards, as the defense sector is heavily scrutinized. Establishing transparent supply chains can help mitigate risks associated with sourcing tungsten for military applications.

What is the significance of tungsten in medical devices?

In the medical field, tungsten is utilized for radiation shielding and in surgical instruments due to its high density and effectiveness in blocking radiation. The cost of tungsten can influence the affordability of medical devices, which is especially relevant in emerging markets. Buyers should verify the purity and certification of tungsten materials to ensure safety and compliance with medical standards. Collaborating with suppliers experienced in medical applications can enhance product reliability and performance, ultimately benefiting patient safety and treatment efficacy.

3 Common User Pain Points for ‘cost of tungsten’ & Their Solutions

Scenario 1: Fluctuating Prices Impacting Budgeting

The Problem: B2B buyers in industries such as aerospace and manufacturing often face challenges due to the volatility of tungsten prices. A sudden spike in costs can disrupt carefully planned budgets and financial forecasts, leading to potential project delays and strained supplier relationships. These fluctuations can be exacerbated by geopolitical factors, supply chain disruptions, or changes in demand, making it difficult for buyers to secure materials at a stable price.

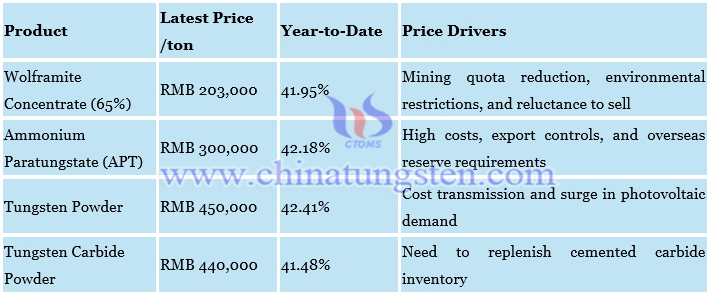

Illustrative image related to cost of tungsten

The Solution: To mitigate the impact of fluctuating tungsten prices, buyers should consider implementing a flexible purchasing strategy that includes long-term contracts with suppliers. Establishing relationships with multiple suppliers can also provide leverage in negotiations and allow for price comparisons, ensuring that buyers are getting the best value. Additionally, regularly monitoring market reports and pricing trends from reputable sources like FastMarkets can help buyers anticipate price movements and make informed purchasing decisions. By incorporating a mix of spot buying and forward contracts, companies can better manage their exposure to price volatility while ensuring a steady supply of tungsten for their operations.

Scenario 2: Inconsistent Quality of Tungsten Products

The Problem: Buyers often encounter difficulties in ensuring the quality of tungsten products, particularly when sourcing from multiple suppliers or regions. Variations in purity levels and processing methods can lead to subpar materials that do not meet industry standards, resulting in product failures or increased manufacturing costs. This inconsistency can also create delays in production and damage a company’s reputation.

The Solution: To combat quality inconsistencies, buyers should prioritize sourcing tungsten from established and reputable suppliers who provide certifications for their products. This includes documentation of purity levels and compliance with international standards, such as ASTM specifications. Conducting regular audits and quality checks of suppliers, as well as requesting samples for testing before bulk purchases, can further ensure that the materials meet the necessary specifications. Implementing a rigorous quality assurance process within the procurement strategy can help maintain high standards and reduce the risk of costly production issues.

Scenario 3: Complex Sourcing and Logistics Challenges

The Problem: International B2B buyers, particularly those in emerging markets, often face logistical challenges when sourcing tungsten from overseas suppliers. These challenges can include navigating customs regulations, managing shipping times, and dealing with unexpected tariffs or import fees, all of which can complicate the procurement process and lead to delays in receiving materials.

The Solution: To streamline sourcing and logistics, buyers should work with logistics partners who have expertise in international shipping and customs processes. Establishing a clear supply chain strategy that includes understanding the regulatory landscape in both the exporting and importing countries can help prevent delays. Additionally, using technology such as supply chain management software can enhance visibility into shipping statuses and help manage inventory levels more effectively. By aligning procurement timelines with logistics capabilities and maintaining open communication with suppliers and logistics providers, companies can ensure a more efficient and predictable supply of tungsten, reducing the risk of operational disruptions.

Illustrative image related to cost of tungsten

Strategic Material Selection Guide for cost of tungsten

What Are the Key Properties of Tungsten Materials for B2B Buyers?

Tungsten is renowned for its unique properties, making it an essential material in various industrial applications. The most common forms of tungsten include pure tungsten, tungsten carbide, tungsten alloys, and tungsten wire. Each of these materials has distinct characteristics that influence their performance, cost, and suitability for specific applications.

How Does Pure Tungsten Perform in Industrial Applications?

Pure tungsten boasts a melting point of 3,410°C, making it the metal with the highest melting point. It is characterized by excellent corrosion resistance and minimal thermal expansion, which is crucial for applications involving high temperatures, such as aerospace and medical devices. The primary advantage of pure tungsten is its high density and strength, which allows it to withstand extreme conditions.

However, pure tungsten can be brittle and challenging to machine, which may complicate manufacturing processes. Additionally, the cost of pure tungsten is relatively high, impacting overall project budgets. For international buyers, compliance with standards such as ASTM F288-96 is essential, as it ensures product quality and performance.

Illustrative image related to cost of tungsten

What Are the Advantages of Tungsten Carbide?

Tungsten carbide is a composite material made by combining tungsten with carbon. It is known for its exceptional hardness and wear resistance, making it ideal for cutting tools, mining equipment, and industrial machinery. The ability to withstand high pressures and temperatures without deforming is a significant advantage in demanding environments.

On the downside, tungsten carbide can be more expensive than other materials, and its brittleness can lead to fracture under certain conditions. Buyers should consider the specific application and the media compatibility, as tungsten carbide is not suitable for corrosive environments. Compliance with international standards is also crucial for ensuring reliability and performance.

How Do Tungsten Alloys Compare in Terms of Performance?

Tungsten alloys, which combine tungsten with other metals like nickel or copper, offer enhanced properties such as improved ductility and machinability. These alloys can be tailored for specific applications, making them versatile for industries ranging from defense to electronics. The ability to customize the alloy composition allows for optimized performance based on the required application.

However, the complexity of manufacturing tungsten alloys can lead to higher costs and longer lead times. Buyers must evaluate the specific performance requirements and the potential for customization when considering tungsten alloys. Additionally, understanding regional preferences and standards, such as DIN or JIS, is vital for ensuring compliance and market acceptance.

What Role Does Tungsten Wire Play in Industrial Applications?

Tungsten wire is often used in applications requiring high-temperature resistance and electrical conductivity, such as in lighting and electronic devices. The wire’s fine diameter and strength make it suitable for precision applications, including thermionic emitters and vacuum tubes. The primary advantage of tungsten wire is its ability to maintain performance under extreme conditions.

The main disadvantage is that tungsten wire can be relatively expensive compared to other conductive materials. Additionally, its brittleness can pose challenges during installation and handling. International buyers should be aware of the specifications required for tungsten wire, including diameter options and compliance with standards like ASTM, to ensure suitability for their applications.

Summary Table of Tungsten Materials

| Material | Typical Use Case for cost of tungsten | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Pure Tungsten | Aerospace components, medical devices | Highest melting point and excellent corrosion resistance | Brittle and challenging to machine | High |

| Tungsten Carbide | Cutting tools, mining equipment | Exceptional hardness and wear resistance | More expensive and brittle under certain conditions | High |

| Tungsten Alloys | Defense applications, electronics | Tailored properties for specific applications | Higher manufacturing complexity and cost | Medium to High |

| Tungsten Wire | Lighting, thermionic emitters | High-temperature resistance and electrical conductivity | Expensive and brittle during handling | Medium |

This comprehensive analysis of tungsten materials provides B2B buyers with valuable insights into their properties, advantages, and limitations, enabling informed decision-making for procurement and application in various industries.

In-depth Look: Manufacturing Processes and Quality Assurance for cost of tungsten

What Are the Main Stages in Tungsten Manufacturing Processes?

The manufacturing process for tungsten involves several key stages that ensure high-quality output suitable for various applications. The main stages include material preparation, forming, assembly, and finishing.

Illustrative image related to cost of tungsten

Material Preparation

The first step in tungsten manufacturing is the sourcing and preparation of raw materials. Tungsten is primarily obtained from minerals such as wolframite and scheelite. After mining, the ore undergoes a series of chemical processes, including crushing, grinding, and flotation, to extract tungsten concentrate. This concentrate is then subjected to chemical reduction, typically using hydrogen or carbon, to produce tungsten powder.

How Is Tungsten Formed?

Once the tungsten powder is prepared, it is ready for forming into various shapes. This can be accomplished through several techniques, including:

- Pressing and Sintering: The tungsten powder is compacted into molds and then heated in a controlled atmosphere to sinter the particles together, forming solid tungsten products.

- Extrusion: In this method, tungsten powder is forced through a die to create rods or wires of specific dimensions.

- Machining: For precision components, tungsten is often machined from solid bars or sheets, using techniques such as turning, milling, and grinding.

What Assembly Processes Are Involved?

Depending on the end product, further assembly may be required. For example, tungsten components used in electronic applications may need to be combined with other materials, such as ceramic insulators. This assembly can involve welding, soldering, or other joining methods to ensure a reliable connection and maintain the integrity of the tungsten.

How Is Tungsten Finished?

Finishing processes are critical for achieving the desired surface quality and dimensions. Common finishing techniques include:

Illustrative image related to cost of tungsten

- Surface Treatment: This may involve polishing or coating to improve corrosion resistance and surface finish.

- Heat Treatment: Some tungsten products may undergo heat treatment to enhance their mechanical properties, such as hardness and strength.

- Quality Cutting: Final dimensions are achieved through precision cutting techniques to ensure that products meet exact specifications.

What Quality Assurance Measures Are Typical in Tungsten Production?

Quality assurance (QA) is vital in tungsten manufacturing to ensure that products meet international standards and customer specifications. Various checkpoints and testing methods are employed throughout the production process.

What International Standards Should Be Considered?

B2B buyers should pay attention to internationally recognized quality standards, such as ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific standards may apply, including:

- CE Marking: Required for products sold in Europe, indicating compliance with health and safety standards.

- API Standards: Relevant for tungsten products used in the oil and gas sector.

These standards help ensure that products are consistently manufactured to meet quality requirements.

What Are the Key Quality Control Checkpoints?

The quality control process in tungsten manufacturing typically includes three main checkpoints:

- Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet predefined specifications.

- In-Process Quality Control (IPQC): During manufacturing, various parameters are monitored to detect any deviations from quality standards. This can include checking dimensions, surface finish, and material properties.

- Final Quality Control (FQC): Before products are shipped, a final inspection is conducted to verify that they meet all specifications and quality standards.

What Common Testing Methods Are Used in Tungsten Quality Assurance?

To ensure the integrity of tungsten products, various testing methods are employed, including:

- Mechanical Testing: This includes tensile strength, hardness, and impact tests to evaluate the material’s performance under stress.

- Chemical Analysis: Techniques such as X-ray fluorescence (XRF) or inductively coupled plasma (ICP) spectroscopy are used to determine the composition and purity of tungsten.

- Dimensional Inspection: Precision measurements using tools like calipers and micrometers ensure that products meet exact specifications.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial to ensure product reliability.

What Role Do Audits and Reports Play?

Conducting supplier audits can provide insights into the manufacturing processes and quality assurance measures in place. Buyers can request reports detailing quality control procedures, testing results, and certifications to evaluate compliance with relevant standards.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can further validate the quality of tungsten products. These independent organizations can conduct audits and testing to ensure that products meet specified standards and requirements. This adds an additional layer of assurance for buyers, particularly when sourcing from international suppliers.

What Quality Control and Certification Nuances Should International Buyers Consider?

For international B2B buyers, understanding the nuances of quality control and certification is essential. Different regions may have varying requirements for compliance, and certain certifications may be more recognized in specific markets.

How Can Buyers Navigate Different Certification Standards?

Buyers should familiarize themselves with the certification landscape in their target markets. For example, while ISO certifications are globally recognized, local regulations may impose additional requirements. It is advisable to work with suppliers who possess relevant certifications and can demonstrate a commitment to quality.

What Challenges Do International Buyers Face in Ensuring Quality?

International buyers may encounter challenges such as language barriers, cultural differences, and varying quality expectations. Establishing clear communication channels and defining quality expectations upfront can mitigate these challenges and ensure a smoother procurement process.

Conclusion

Understanding the manufacturing processes and quality assurance measures for tungsten is crucial for B2B buyers aiming to source high-quality products. By focusing on the key stages of manufacturing, relevant quality standards, and verification methods, buyers can make informed decisions that meet their specific needs. Building strong relationships with suppliers who prioritize quality can lead to successful partnerships and long-term benefits in various industries.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cost of tungsten’

Introduction

This practical sourcing guide is designed to assist B2B buyers in navigating the complexities of procuring tungsten at competitive prices. Understanding the cost factors and sourcing strategies can significantly impact your procurement decisions, ensuring you receive high-quality materials at favorable rates.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clearly define your technical specifications for tungsten. Consider factors such as purity levels, dimensions, and intended applications, as these will directly influence the cost and availability of the material.

– Purity Levels: Specify whether you require 99.95% pure tungsten or other grades, as higher purity can command a premium.

– Form and Size: Determine whether you need tungsten in sheets, rods, or custom shapes, as this will affect manufacturing processes and pricing.

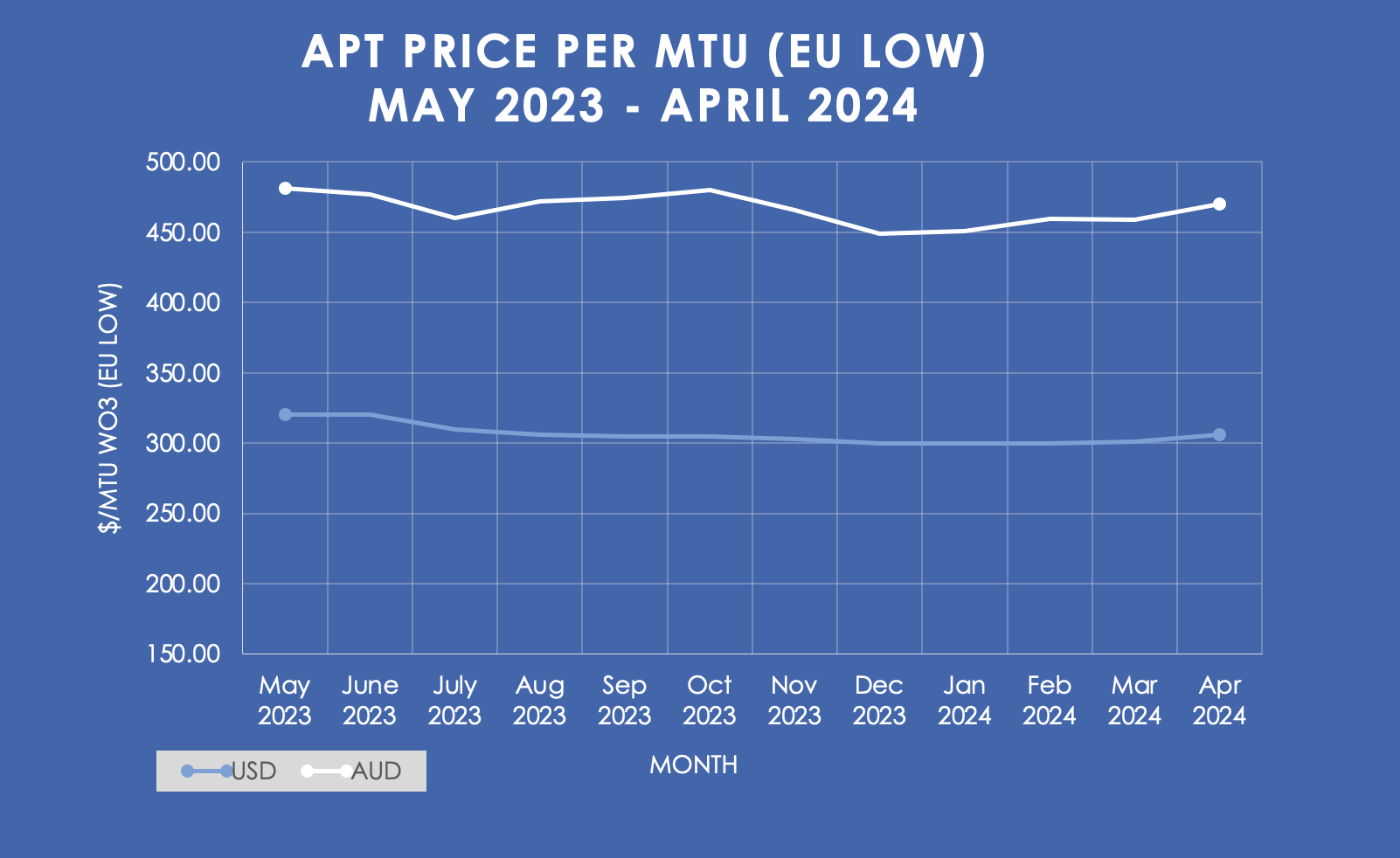

Step 2: Research Market Trends and Pricing

Stay informed about current market trends and pricing fluctuations for tungsten. Prices can vary significantly based on global supply and demand dynamics, particularly influenced by geopolitical factors or changes in the mining industry.

– Data Sources: Utilize reputable industry reports, market analysis platforms, and trading data from sources like FastMarkets to track price movements.

– Historical Data: Analyzing historical pricing trends can help you anticipate future price shifts and negotiate better deals.

Step 3: Identify and Evaluate Potential Suppliers

Conduct thorough research to identify suppliers who specialize in tungsten. Evaluating potential suppliers is critical to ensure reliability and product quality.

– Supplier Credentials: Check for certifications such as ISO 9001 or specific industry-related standards that validate a supplier’s quality management systems.

– Experience and Reputation: Look for suppliers with a proven track record in your region or industry, and request case studies or references from similar businesses.

Step 4: Request Quotes and Compare Costs

Once you have shortlisted potential suppliers, request detailed quotes that outline pricing, payment terms, and delivery timelines. Comparing these quotes will help you identify the best value for your needs.

– Inclusions in Quotes: Ensure that quotes include all relevant costs, including shipping, taxes, and any additional fees.

– Volume Discounts: Inquire about bulk purchase discounts, as many suppliers offer reduced rates for larger orders.

Step 5: Verify Supplier Certifications and Quality Control Measures

Before finalizing your order, it’s crucial to verify that your chosen supplier adheres to quality control measures. This step ensures that the tungsten you receive meets your specifications and industry standards.

– Quality Assurance Processes: Ask about their quality assurance processes and any testing they perform on their tungsten products.

– Compliance with Standards: Ensure that the supplier’s products comply with relevant industry standards, such as ASTM specifications for tungsten.

Step 6: Assess Logistics and Delivery Options

Evaluate the logistics and delivery options provided by your supplier to ensure timely and efficient procurement. Understanding the shipping process and lead times is vital to avoid disruptions in your supply chain.

– Shipping Methods: Discuss the available shipping methods and choose one that aligns with your timeline and budget.

– Customs and Duties: Be aware of any customs regulations or duties applicable in your region that could affect delivery times or costs.

Step 7: Establish Clear Communication and Follow-Up

Once you have placed your order, maintain clear communication with your supplier to address any questions or concerns that may arise. This ongoing dialogue can prevent misunderstandings and ensure a smoother procurement process.

– Regular Updates: Request regular updates on the status of your order, especially if there are any delays or changes.

– Feedback Loop: Establish a feedback loop for future orders, which can help improve the relationship and procurement process over time.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing tungsten, ensuring they make informed decisions that align with their operational needs and budgetary constraints.

Comprehensive Cost and Pricing Analysis for cost of tungsten Sourcing

What Are the Key Cost Components in Tungsten Sourcing?

When analyzing the cost structure of tungsten sourcing, various components contribute significantly to the overall price. The primary cost elements include:

-

Materials: The base material cost for tungsten is influenced by market demand, availability of raw tungsten ore (such as wolframite and scheelite), and fluctuations in the global market. Prices can vary widely depending on purity levels, with 99.95% pure tungsten commanding a premium.

-

Labor: Labor costs encompass the wages of workers involved in the extraction, processing, and manufacturing of tungsten products. Regions with higher labor costs, such as Europe, may see increased prices compared to regions with lower labor costs.

-

Manufacturing Overhead: This includes costs associated with the operation of manufacturing facilities, including utilities, equipment maintenance, and administrative expenses. Efficient production processes can mitigate these costs, leading to better pricing for buyers.

-

Tooling: Investment in specialized tooling for tungsten processing can be significant. Custom tooling for specific applications (like unique rod diameters or wire specifications) can further increase costs.

-

Quality Control (QC): Ensuring the quality and compliance of tungsten products incurs additional costs. Certifications, testing, and adherence to industry standards are essential, especially for applications in sensitive industries like aerospace and medical devices.

-

Logistics: Transportation of tungsten products can be a major cost driver, particularly for international shipments. Factors such as distance, shipping methods, and local tariffs can affect logistics costs.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. This margin can vary based on supplier competition, market demand, and the exclusivity of the tungsten product.

How Do Price Influencers Impact Tungsten Costs?

Several factors can significantly influence tungsten pricing:

-

Volume/MOQ (Minimum Order Quantity): Higher purchase volumes often lead to discounted rates. Buyers should negotiate for lower prices based on their ordering capacity.

-

Specifications and Customization: Tungsten products tailored to specific requirements (like size, shape, and purity) may incur additional costs. Custom orders typically require more resources and time, thus affecting pricing.

-

Quality and Certifications: Tungsten products that meet stringent quality standards or possess certifications (such as ASTM) often carry higher price tags. Buyers must balance the need for quality against their budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their proven track record, while new entrants may offer lower prices to gain market share.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can greatly influence the total cost of ownership. Understanding responsibilities related to shipping, customs, and risk can help buyers make informed decisions.

What Buyer Tips Can Enhance Cost-Efficiency in Tungsten Sourcing?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiation: Engage in open discussions with suppliers to negotiate better terms. Leverage your purchasing volume and long-term relationship potential to secure favorable pricing.

-

Total Cost of Ownership (TCO): Consider not only the initial purchase price but also the long-term costs associated with sourcing tungsten, such as maintenance, transportation, and potential wastage. A holistic view of TCO can lead to better decision-making.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and regional market conditions that could impact pricing. Understanding local market dynamics can provide leverage in negotiations.

-

Supplier Diversification: Establish relationships with multiple suppliers to reduce dependency and enhance bargaining power. This strategy can also safeguard against supply chain disruptions.

Disclaimer

The prices referenced in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific order requirements. Always conduct thorough research and obtain quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing cost of tungsten With Other Solutions

Understanding Alternatives to Tungsten: A Cost Comparison

In the quest for high-performance materials, tungsten is often a preferred choice due to its exceptional properties, including high density, melting point, and strength. However, it is essential for B2B buyers to consider viable alternatives that might offer similar benefits at different costs. This analysis will focus on comparing tungsten with two alternative materials: titanium and high-speed steel (HSS).

Comparison Table

| Comparison Aspect | Cost Of Tungsten | Titanium | High-Speed Steel (HSS) |

|---|---|---|---|

| Performance | Excellent high-temperature strength and hardness | Good corrosion resistance; lower density | Good toughness and wear resistance; less expensive than tungsten |

| Cost | $124.99 – $39,999.99 | $25 – $150 per kg | $5 – $30 per kg |

| Ease of Implementation | Requires specialized machining | Moderate; needs specific tools for cutting | Easy to machine with standard tools |

| Maintenance | Low; resistant to oxidation | Low; also resistant to corrosion | Moderate; can wear down faster than tungsten |

| Best Use Case | Aerospace, medical devices, and high-performance applications | Aerospace and marine applications | General manufacturing and cutting tools |

Detailed Breakdown of Alternatives

Titanium

Titanium is a lightweight metal known for its excellent corrosion resistance and high strength-to-weight ratio. It is commonly used in aerospace and marine applications where weight reduction is crucial. While titanium is less expensive than tungsten, it does not match tungsten’s performance at high temperatures. Moreover, titanium requires specialized tools for machining, which can add to the overall cost.

Pros:

– Lower cost than tungsten

– Good corrosion resistance and strength

– Lightweight, making it suitable for applications where weight is a concern

Cons:

– Lower performance at extreme temperatures compared to tungsten

– Machining requires specialized tools

Illustrative image related to cost of tungsten

High-Speed Steel (HSS)

High-speed steel is a versatile material primarily used for cutting tools and industrial applications. It is much more affordable than tungsten, with costs ranging from $5 to $30 per kg. HSS offers good toughness and wear resistance, making it suitable for various manufacturing processes. However, it does not possess the same high-temperature strength as tungsten and may require more frequent maintenance.

Pros:

– Significantly lower cost

– Easy to machine with standard equipment

– Suitable for a wide range of manufacturing applications

Cons:

– Less effective at high temperatures

– May wear out faster than tungsten under extreme conditions

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the right material for your specific applications, consider the performance requirements, cost constraints, and ease of implementation. Tungsten is ideal for high-performance applications that demand exceptional strength and heat resistance, while titanium serves well in weight-sensitive environments. On the other hand, high-speed steel offers a cost-effective solution for general manufacturing needs. Understanding the trade-offs and aligning them with your operational requirements will help you make an informed decision that balances performance and budget.

Essential Technical Properties and Trade Terminology for cost of tungsten

What Are the Key Technical Properties of Tungsten Relevant to B2B Buyers?

When evaluating tungsten for industrial applications, understanding its technical properties is crucial for making informed purchasing decisions. Here are several essential specifications:

1. Material Grade

Material grade refers to the purity and composition of tungsten. Common grades include 99.95% pure tungsten, which is preferred for high-performance applications like aerospace and medical devices. Higher grades often command a premium price due to their superior performance characteristics, such as increased tensile strength and corrosion resistance.

2. Density

Tungsten boasts the highest density of all engineering materials, at approximately 19.25 g/cm³. This property is significant in applications where weight and strength are critical, such as in counterweights and radiation shielding. Buyers need to consider density when calculating shipping costs and designing components for specific applications.

Illustrative image related to cost of tungsten

3. Melting Point

With a melting point of 3,410°C, tungsten is the metal with the highest melting temperature. This property makes it ideal for high-temperature applications, such as in furnace components and aerospace engineering. Buyers should evaluate the thermal requirements of their applications to ensure the selected tungsten grade can withstand operational conditions.

4. Tolerance

Tolerance refers to the allowable variation in the dimensions of tungsten products. Tight tolerances are essential for components that must fit precisely within assemblies, such as electrical contacts or cutting tools. Buyers should specify their tolerance requirements to ensure the final product meets their operational needs.

5. Corrosion Resistance

Tungsten exhibits excellent corrosion resistance, particularly against acids like nitric and sulfuric acid. This property is crucial for applications in harsh environments, such as chemical processing or oil drilling. Buyers should assess the chemical exposure of their applications to select the appropriate tungsten grade.

What Are Common Trade Terminology and Jargon in the Tungsten Market?

Understanding industry jargon can facilitate smoother transactions and negotiations. Here are several common terms:

Illustrative image related to cost of tungsten

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the tungsten market, OEMs often require high-quality materials for manufacturing components that meet stringent industry standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for buyers to understand as it can affect inventory costs and supply chain management. For tungsten products, MOQs can vary significantly based on the material grade and complexity of the items.

3. RFQ (Request for Quotation)

An RFQ is a formal process where a buyer requests pricing and terms from suppliers. This term is vital for B2B transactions, as it sets the stage for negotiations. Buyers should prepare detailed RFQs that specify material grades, quantities, and delivery timelines to receive accurate quotes.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers to avoid misunderstandings in international transactions involving tungsten products.

5. Lead Time

Lead time refers to the duration from placing an order to its delivery. Understanding lead times is crucial for production planning and inventory management. Buyers should consider lead times in conjunction with MOQs to optimize their supply chain.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing tungsten, ensuring they select the right materials for their specific applications while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the cost of tungsten Sector

What Are the Current Market Dynamics and Key Trends in the Cost of Tungsten?

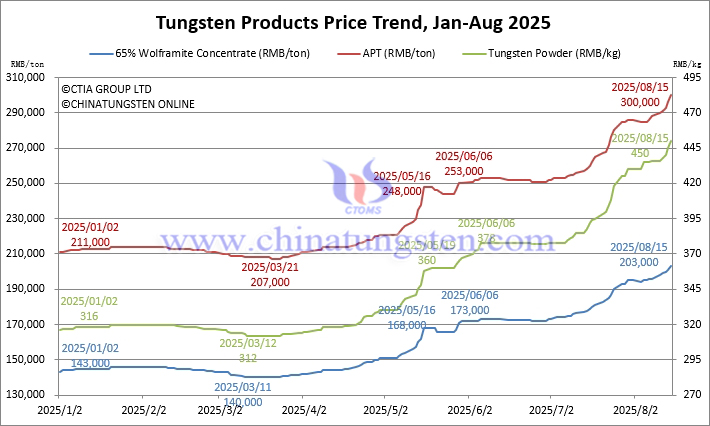

The tungsten market is currently influenced by several global drivers, including technological advancements, geopolitical tensions, and shifting supply chains. The demand for tungsten remains robust, especially in industries such as aerospace, electronics, and defense, where its unique properties—such as high melting point and tensile strength—are irreplaceable. Emerging markets in Africa and South America are beginning to leverage local tungsten resources, which could reshape global supply dynamics. Additionally, the ongoing shift towards digitalization in sourcing—utilizing platforms for real-time price tracking and supplier transparency—has become a critical trend for international B2B buyers. This digital transformation is enabling buyers to make more informed purchasing decisions, ensuring they can act swiftly in response to market fluctuations.

As international buyers, especially those from regions like Vietnam and Saudi Arabia, seek to optimize their supply chains, understanding the nuances of tungsten pricing becomes imperative. Recent trends indicate a volatile pricing landscape, driven by fluctuating production levels in China—the largest producer of tungsten—and increasing demand for tungsten-based materials for high-performance applications. Buyers must stay updated on market reports and pricing indexes, such as those provided by FastMarkets, to navigate these dynamics effectively.

How Do Sustainability and Ethical Sourcing Impact the Tungsten Supply Chain?

Sustainability and ethical sourcing are increasingly paramount for B2B buyers in the tungsten sector. As global awareness of environmental issues grows, the demand for ethically sourced tungsten is gaining traction. This demand is particularly relevant for buyers in Europe and the Middle East, where regulations around sourcing practices are tightening. Companies are now prioritizing suppliers that adhere to responsible mining practices, which include minimizing environmental degradation and ensuring fair labor conditions.

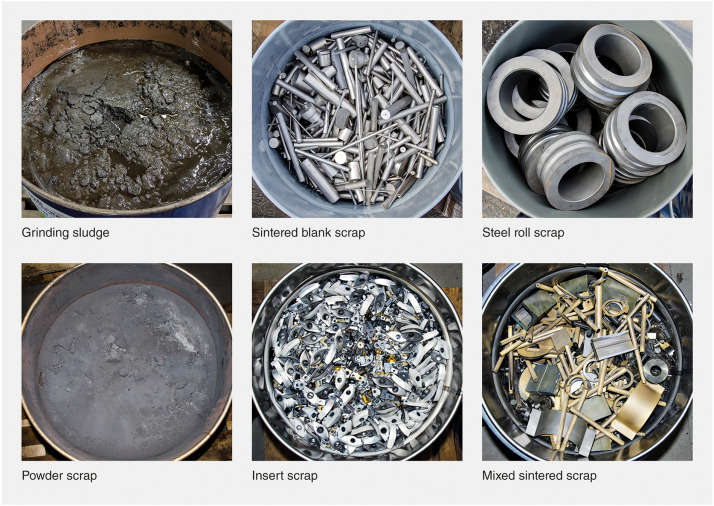

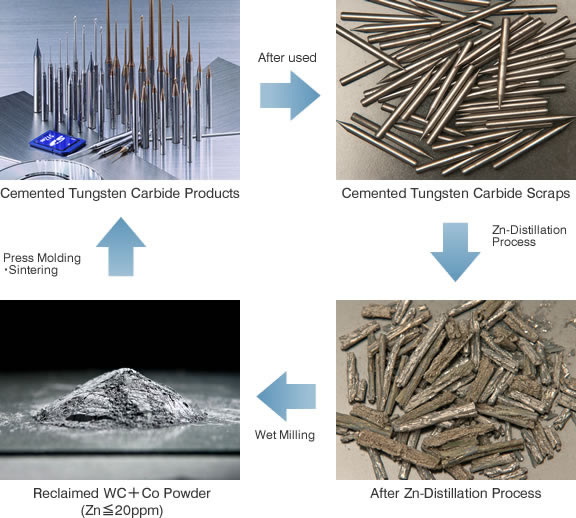

The environmental impact of tungsten mining—often associated with habitat destruction and pollution—necessitates a commitment to sustainable practices. Buyers should actively seek suppliers who possess certifications that reflect their commitment to sustainability, such as ISO 14001 for environmental management systems. Furthermore, the use of recycled tungsten is becoming a viable alternative, as it significantly reduces the ecological footprint associated with raw material extraction. By prioritizing sustainability and ethical sourcing, B2B buyers can enhance their brand reputation and appeal to a growing segment of environmentally conscious consumers.

Illustrative image related to cost of tungsten

What Is the Historical Context of Tungsten’s Market Evolution?

The evolution of tungsten as a critical industrial metal has been marked by significant technological advancements and geopolitical factors. Initially recognized in the 18th century, tungsten gained prominence during World War II due to its strategic importance in military applications. Post-war, the industrial boom led to a surge in tungsten demand, particularly for cemented carbides used in cutting tools and machinery.

Over the years, tungsten’s applications have expanded into diverse sectors, including electronics and aerospace, driven by ongoing innovations. The late 20th century saw China emerge as a dominant force in tungsten production, shaping global pricing and availability. Today, as industries strive for greater efficiency and performance, tungsten remains a cornerstone material, underscoring its enduring value in modern manufacturing and technology. Understanding this historical context can provide B2B buyers with insights into current market trends and future opportunities in the tungsten sector.

Frequently Asked Questions (FAQs) for B2B Buyers of cost of tungsten

-

How do I determine the current market price of tungsten?

To ascertain the current market price of tungsten, it’s advisable to consult reliable industry sources such as FastMarkets or market reports from metallurgical firms. Prices can fluctuate based on global supply and demand, geopolitical factors, and raw material availability. It’s also beneficial to engage with suppliers who provide weekly updates on pricing trends. Joining industry associations or forums can help you stay informed about price movements and future forecasts, enabling more strategic purchasing decisions. -

What factors influence the cost of tungsten?

The cost of tungsten is influenced by several factors, including mining production levels, the purity of the tungsten being sourced, and global demand from sectors such as aerospace, electronics, and defense. Additionally, geopolitical stability in major tungsten-producing countries, such as China, plays a crucial role in price fluctuations. Transportation costs, tariffs, and the complexity of the supply chain can further impact the overall cost, making it essential to consider these elements when budgeting for tungsten purchases. -

What are the minimum order quantities (MOQ) for tungsten products?

Minimum order quantities for tungsten products can vary widely depending on the supplier and the specific product type. Typically, suppliers may set MOQs to ensure cost-effectiveness in manufacturing and shipping. For instance, bulk orders of tungsten sheets or rods may have higher MOQs compared to smaller items like tungsten wire or electrodes. It’s best to communicate directly with suppliers to understand their specific MOQ policies and explore options for custom orders that meet your business needs. -

How can I vet tungsten suppliers for quality and reliability?

To vet tungsten suppliers effectively, start by reviewing their certifications, such as ISO standards, which indicate adherence to quality management systems. Request references or case studies from previous clients to assess their reliability. Conducting site visits can provide insights into their manufacturing processes and quality control measures. Additionally, engaging with industry networks or trade associations can help identify reputable suppliers and gather feedback on their performance from other businesses. -

What payment terms are commonly offered by tungsten suppliers?

Payment terms can differ significantly among tungsten suppliers, often influenced by factors such as order size and customer relationship. Common arrangements include payment upfront, net 30, or net 60 days following delivery. Some suppliers may offer discounts for early payment or extended credit terms for long-standing clients. It’s crucial to negotiate favorable terms that align with your cash flow and operational needs while ensuring clarity in the contract to avoid any misunderstandings. -

Can tungsten products be customized to specific requirements?

Many suppliers offer customization options for tungsten products, allowing you to specify dimensions, shapes, and purity levels to meet your project needs. Discuss your requirements with potential suppliers to determine their capabilities and any additional costs associated with customization. Be sure to request samples or prototypes if possible, to ensure that the products meet your specifications before placing a larger order. -

What quality assurance measures should I expect from tungsten suppliers?

Quality assurance measures from tungsten suppliers should include material testing, certification of purity, and adherence to international standards. Suppliers should conduct regular quality checks throughout the manufacturing process and provide documentation to verify compliance with specifications. Inquire about their quality control processes and whether they offer warranties or guarantees on their products to safeguard against defects or discrepancies in quality. -

What logistics considerations should I keep in mind when sourcing tungsten internationally?

When sourcing tungsten internationally, consider logistics aspects such as shipping methods, lead times, and customs regulations. Ensure that the supplier is experienced in exporting to your region and can handle necessary documentation for customs clearance. Evaluate shipping costs and delivery timelines, as these can significantly impact your overall project schedule. Additionally, understanding the local regulations and tariffs can help you avoid unexpected expenses and delays during the import process.

Top 7 Cost Of Tungsten Manufacturers & Suppliers List

1. Tungsten – Pure Tungsten Bars and Rods

Domain: shop.tungsten.com

Registered: 1997 (28 years)

Introduction: 99.95% Pure Tungsten; Categories: Pure Tungsten Bars, Discs, Rod, Sheet/Plate, Wire, Powder; Subcategories: Chrome Plated Tungsten Rods, Tungsten Heavy Alloy, Pure Tantalum, Pure Molybdenum, Vacuum Furnace Components, TIG Welding; Diameter Options: 0.0003″ to 0.0012″; Height/Thickness: 0.001″ to 0.02″; Width: 0.335″ to 21″; Length: 1 kg (spool), 1 meter, various lengths; Products: Pure Tungsten Sh…

2. Statista – Tungsten Price Trends

Domain: statista.com

Registered: 2005 (20 years)

Introduction: In 2024, the average price of tungsten was around *** U.S. dollars per metric ton unit of tungsten trioxide, a decrease of some ***** percent in comparison to the previous year. Tungsten is a rare metal that has the highest melting and boiling point of all known elements. Tungsten was historically used for making the filaments of old-style incandescent light bulbs, and today it is used in various …

3. Online Metals – Tungsten Carbide Bar Stock

Domain: onlinemetals.com

Registered: 1997 (28 years)

Introduction: Tungsten Carbide Bar Stock | Ground and Unground. Tungsten Carbide is a cemented, composite material known for exceptional hardness, high melting point, and resistance to wear and corrosion, making it ideal for cutting tools, industrial machinery, and wear-resistant parts. Offered in C2 & Standard Micrograin (10% Cobalt). Shapes available: Round & Rectangle Bar. Example product: 0.0625″ x 0.75″ Tu…

4. RR Carbide – Scrap Prices & Key Materials

Domain: rrcarbide.com

Registered: 2021 (4 years)

Introduction: {“scrap_prices”: {“Carbide Inserts & Shapes”: “$9.40/lb”, “Tungsten-Based Turnings”: “$7.30-$9.20/lb”, “Pure Tungsten”: “$4.65-$10.05/lb”, “High Speed Steel”: “$0.15/lb”, “Cobalt”: “$1.50-$5.00/lb”, “Larger Bits”: “$5.80-$9.55/lb”}, “materials”: [“Carbide Filter Materials”, “Carbide Solids”, “Cobalt”, “Elkonite”, “End Mills”, “Germanium”, “Hastelloy”, “Hevimet/Densalloy”, “High Speed Steel”, “Inco…

5. Business Analytiq – Tungsten Ore Price Index

Domain: businessanalytiq.com

Registered: 2020 (5 years)

Introduction: Tungsten ore price index: North America: US$22.54/KG, -1.1% down; Europe: US$15.64/KG, -1.1% down; Northeast Asia: US$29.15/KG, 15.2% up; South America: US$26.82/KG, 10.4% up. Tungsten ore refers to natural deposits containing significant amounts of tungsten, typically found in minerals such as Scheelite (CaWO₄), Wolframite ((Fe,Mn)WO₄), and Ferberite (FeWO₄). Tungsten is mined through underground…

6. Argus Media – Tungsten APT Prices

Domain: argusmedia.com

Registered: 2007 (18 years)

Introduction: Tungsten APT fob China (per mtu WO3) prices, USD/mtu, independent price assessments, unbiased reporting, various currency options available.

7. Luciteria – Tungsten .9995 1 Oz Bar

Domain: luciteria.com

Registered: 2014 (11 years)

Introduction: {“name”: “Tungsten .9995 1 Oz Bar”, “price”: “$22.00”, “origin”: “China”, “purity”: “.9995”, “weight”: “1 Oz”, “description”: “Tungsten is primarily used to make tools due to its hardness. Recent events, including environmental restrictions in China and pandemic-related supply chain issues, have impacted tungsten supply and pricing. The introduction of tungsten bullion bars may create a new demand…

Strategic Sourcing Conclusion and Outlook for cost of tungsten

How Can Strategic Sourcing Enhance Your Tungsten Procurement?

In conclusion, understanding the cost dynamics of tungsten is crucial for international B2B buyers. The fluctuating prices, influenced by supply chain variables and geopolitical factors, necessitate a proactive sourcing strategy. By leveraging strategic sourcing, businesses can negotiate better pricing, secure reliable suppliers, and mitigate risks associated with price volatility.

For buyers in Africa, South America, the Middle East, and Europe, this approach is particularly beneficial. Engaging with suppliers who offer high-purity tungsten products can ensure that your operations benefit from superior quality and performance. As industries increasingly turn to tungsten for its unique properties, from aerospace applications to advanced electronics, the demand will likely rise, making early engagement with trusted suppliers even more critical.

Looking forward, businesses must stay informed on market trends and establish long-term partnerships to navigate the complexities of tungsten procurement effectively. By prioritizing strategic sourcing, you not only enhance your operational resilience but also position your company for future success in a competitive landscape. Take action today to secure your tungsten supply chain for tomorrow’s needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to cost of tungsten