Unlocking Value: A Strategic Analysis of the Copper Sheet Satisfactory Market

Introduction: Navigating the Global Market for copper sheet satisfactory

In the ever-evolving landscape of industrial manufacturing, sourcing high-quality copper sheets can pose significant challenges for B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, including key markets like Germany and Saudi Arabia. The demand for copper sheets, essential for constructing pipelines and fluid-related buildings, continues to rise, driven by advancements in technology and infrastructure development. This guide delves into the intricate world of copper sheet satisfactory, equipping international buyers with the insights needed to navigate supplier options, evaluate costs, and understand various applications.

This comprehensive resource explores the different types of copper sheets available, their diverse applications across industries, and effective strategies for supplier vetting. By addressing critical factors such as quality assurance, pricing structures, and logistical considerations, this guide empowers buyers to make informed purchasing decisions. Additionally, it highlights the importance of understanding regional market dynamics and supplier capabilities, ensuring that buyers can secure the best deals without compromising on quality or reliability.

With a focus on actionable insights and expert recommendations, this guide serves as a vital tool for B2B buyers seeking to optimize their sourcing processes and enhance their competitive edge in the global market.

Understanding copper sheet satisfactory Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Copper Sheet | Made from 2 Copper Ingots; basic construction material | Pipelines, fluid containers, machinery parts | Pros: Cost-effective, widely available. Cons: Limited heat resistance. |

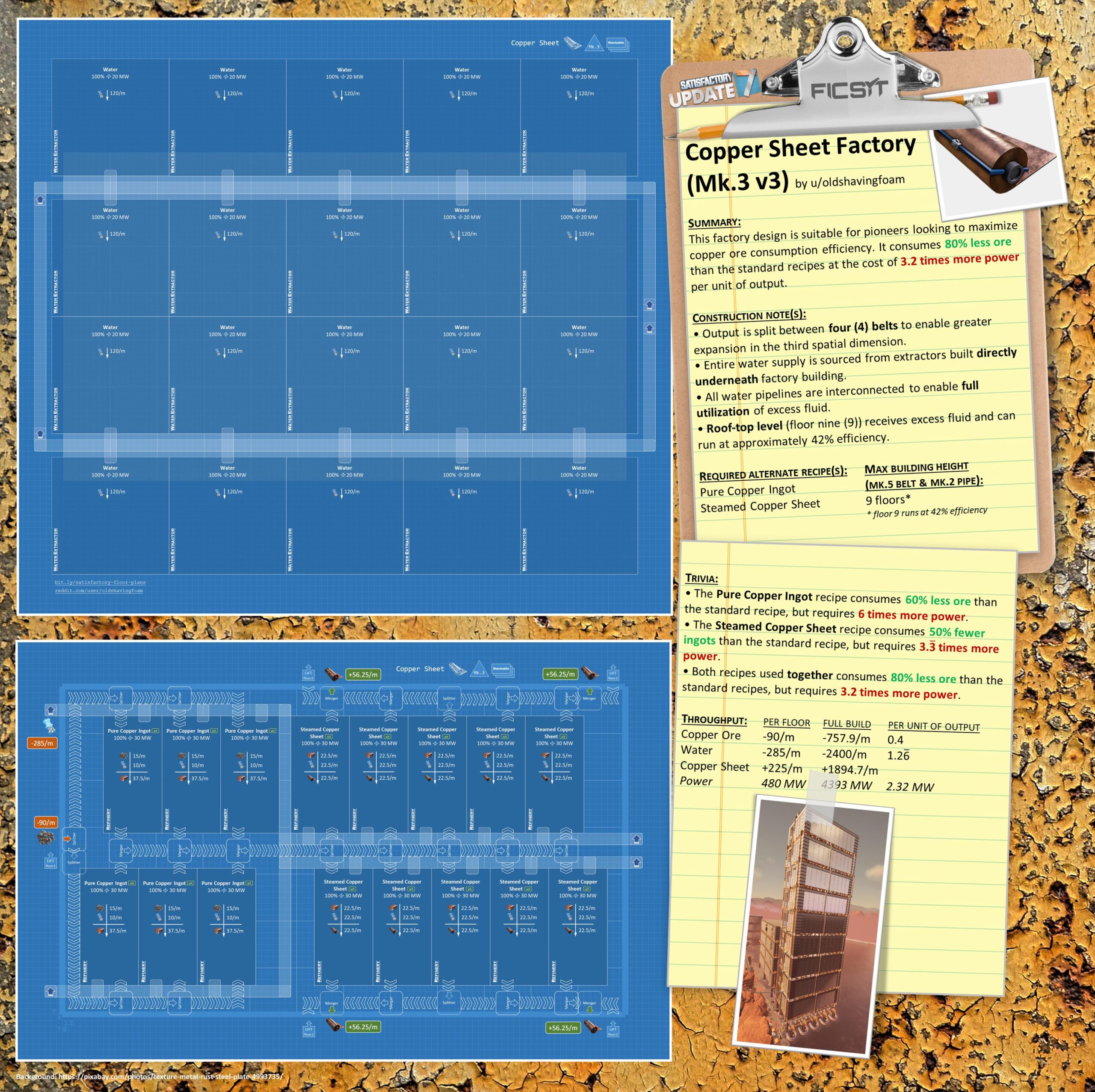

| Steamed Copper Sheet | Requires water; produces 3 sheets per 3 ingots | Advanced fluid systems, heat exchangers | Pros: Higher efficiency, better for complex systems. Cons: Requires additional setup and resources. |

| Copper Sheet for Electronics | Thin, high-purity copper; used in circuit boards | Electronics manufacturing, circuit design | Pros: Excellent conductivity, essential for electronic components. Cons: Higher cost, specific sourcing needed. |

| Coated Copper Sheet | Coated with protective layer; corrosion-resistant | Outdoor applications, electrical installations | Pros: Enhanced durability, longer lifespan. Cons: Higher initial investment. |

| Custom Copper Sheet | Tailored dimensions and specifications | Specialized industrial applications | Pros: Meets unique project requirements, flexibility in design. Cons: Longer lead times, potential for higher costs. |

What Are the Key Characteristics of Standard Copper Sheets?

Standard copper sheets are the foundational product in the copper sheet market, typically produced from two copper ingots. They are predominantly used in the construction of pipelines and fluid-related buildings, making them essential for industries such as plumbing and manufacturing. Buyers appreciate their cost-effectiveness and availability, but they should consider their limited resistance to heat when planning applications that involve high temperatures.

How Do Steamed Copper Sheets Enhance Fluid Management?

Steamed copper sheets are produced using a more complex recipe that incorporates water, allowing for a higher output of sheets per ingot. This type is particularly advantageous for advanced fluid systems and heat exchangers, where efficiency is paramount. While they offer increased production rates, buyers must account for the additional resources required for setup, which may involve higher initial investments in infrastructure.

Why Are Copper Sheets Essential for Electronics Manufacturing?

Copper sheets designed for electronics are characterized by their thinness and high purity, making them ideal for circuit boards and electronic components. Their excellent electrical conductivity is crucial for performance in electronic applications. However, buyers should be prepared for a higher cost and the need for specific sourcing to ensure quality, as this type of copper sheet is less common than its standard counterpart.

What Advantages Do Coated Copper Sheets Offer for Outdoor Use?

Coated copper sheets come with a protective layer that enhances their resistance to corrosion, making them suitable for outdoor applications and electrical installations exposed to the elements. The main advantage is their increased durability and longer lifespan, which can translate to lower maintenance costs over time. However, buyers should be aware of the higher initial investment required for these specialized sheets.

How Can Custom Copper Sheets Meet Unique Industrial Needs?

Custom copper sheets are tailored to specific dimensions and specifications, catering to specialized industrial applications. This flexibility allows businesses to meet unique project requirements that standard sizes cannot fulfill. While they provide significant advantages in terms of design and functionality, buyers should be prepared for longer lead times and potentially higher costs associated with custom manufacturing processes.

Key Industrial Applications of copper sheet satisfactory

| Industry/Sector | Specific Application of copper sheet satisfactory | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Construction of pipelines for fluid transport | Enhances efficiency and reliability in fluid systems | Ensure compliance with international standards and quality control |

| Energy | Fabrication of geothermal generators and power systems | Supports sustainable energy solutions and reduces costs | Assess material compatibility with local environmental conditions |

| Automotive | Use in electrical systems and connectors | Improves safety and performance of automotive components | Verify certifications for automotive-grade materials |

| Electronics | Production of circuit boards and electronic components | Increases durability and conductivity of electronic devices | Source from suppliers with proven track records in electronics |

| Construction | Structural applications in building frameworks | Provides strength and durability in construction projects | Consider local sourcing options to reduce lead times and costs |

How is Copper Sheet Satisfactory Used in Manufacturing Pipelines?

In the manufacturing sector, copper sheet satisfactory is primarily utilized in the construction of pipelines for transporting fluids. Its excellent thermal and electrical conductivity makes it ideal for applications requiring efficient fluid flow. Businesses benefit from reduced maintenance costs and improved system reliability. For international buyers, particularly in Africa and South America, ensuring that suppliers adhere to quality standards is essential to avoid operational disruptions.

What Role Does Copper Sheet Play in Energy Solutions?

In the energy sector, copper sheets are critical in the fabrication of geothermal generators and other power systems. Their high conductivity and resistance to corrosion enable the development of efficient and sustainable energy solutions. This application not only helps in reducing operational costs but also aligns with global sustainability goals. Buyers from Europe and the Middle East should look for suppliers who understand local energy regulations and can provide materials that meet specific environmental standards.

How is Copper Sheet Used in Automotive Applications?

Copper sheets find extensive use in automotive electrical systems and connectors, where their conductivity is vital for performance and safety. The automotive industry demands high-quality materials to ensure longevity and reliability in vehicles. International buyers must ensure that the copper sheets sourced meet stringent automotive industry certifications to avoid potential safety issues and enhance product performance.

Why is Copper Sheet Important for Electronics Manufacturing?

In the electronics industry, copper sheet satisfactory is essential for producing circuit boards and various electronic components. The material’s durability and conductivity significantly improve the performance and lifespan of electronic devices. B2B buyers should prioritize sourcing from suppliers with a strong reputation in electronics manufacturing to guarantee compliance with industry standards and ensure the reliability of their products.

What are the Construction Applications of Copper Sheet?

In construction, copper sheets are used for structural applications, providing strength and durability in building frameworks. Their resistance to corrosion makes them an ideal choice for both residential and commercial projects. For businesses in this sector, sourcing copper sheets locally can help minimize lead times and costs, while ensuring compliance with local building regulations and standards is crucial for successful project execution.

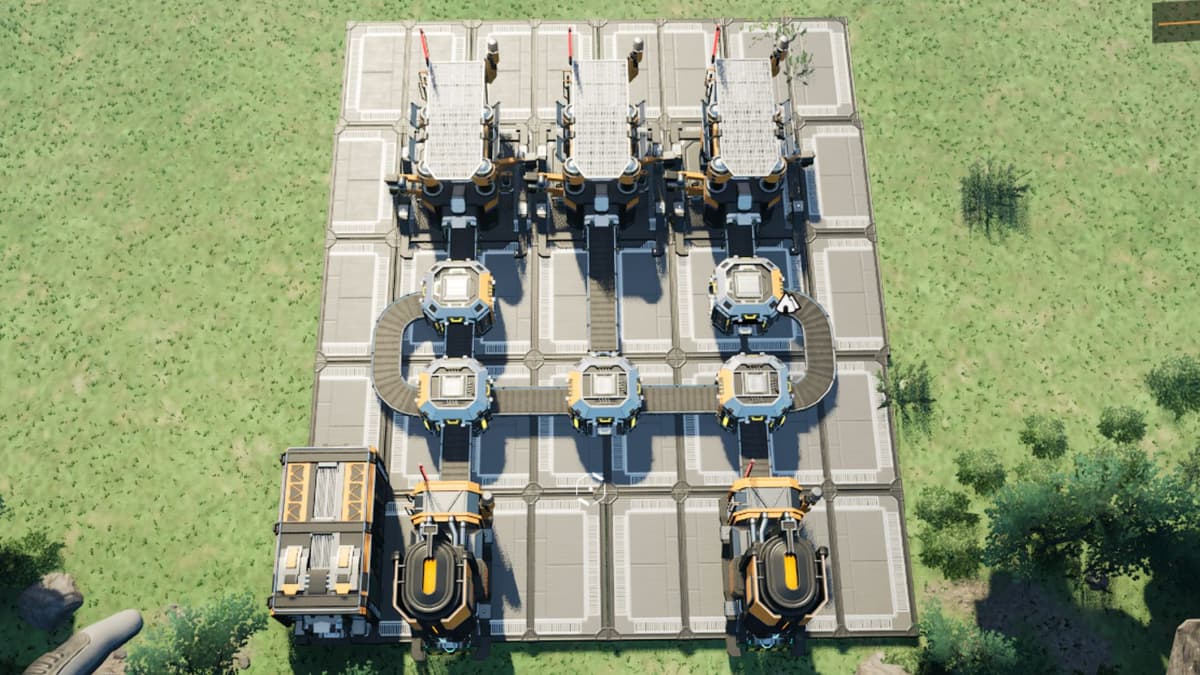

Illustrative image related to copper sheet satisfactory

3 Common User Pain Points for ‘copper sheet satisfactory’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Copper Sheets

The Problem: B2B buyers often face challenges in sourcing high-quality copper sheets that meet specific industry standards. This issue can arise due to a lack of reliable suppliers, variations in material quality, and the potential for high shipping costs, especially when dealing with international suppliers. Buyers may also struggle with inconsistent product specifications, which can lead to production delays and increased costs if the copper sheets do not meet the necessary requirements for their applications.

The Solution: To mitigate these sourcing challenges, buyers should prioritize building relationships with reputable suppliers who can provide certification for their products. Requesting samples before placing larger orders is essential to verify quality. Utilizing online platforms and trade shows can help in identifying reliable suppliers, especially those with a strong reputation in regions like Europe or the Middle East, where standards are often stringent. Additionally, buyers should specify their requirements clearly, including thickness, purity, and intended use, to ensure the supplier understands their needs. Establishing long-term partnerships with trusted suppliers can also lead to better pricing and priority during shortages.

Scenario 2: Inefficient Production Processes Using Copper Sheets

The Problem: Many companies encounter inefficiencies in their production processes due to improper handling and usage of copper sheets. This can manifest as excessive waste, delays in production timelines, and increased labor costs. For instance, if the sheets are not cut or processed correctly, it could lead to scrap material that not only wastes resources but also impacts the overall profitability of projects.

The Solution: Implementing a standardized process for handling and processing copper sheets can significantly enhance efficiency. This includes investing in proper cutting tools and machinery that are designed for copper. Training employees on best practices for handling the material can reduce waste and improve accuracy during production. Furthermore, adopting lean manufacturing principles can help identify and eliminate wasteful practices, ensuring that the use of copper sheets aligns with production goals. Regular audits of the production process can also help in identifying bottlenecks and areas for improvement.

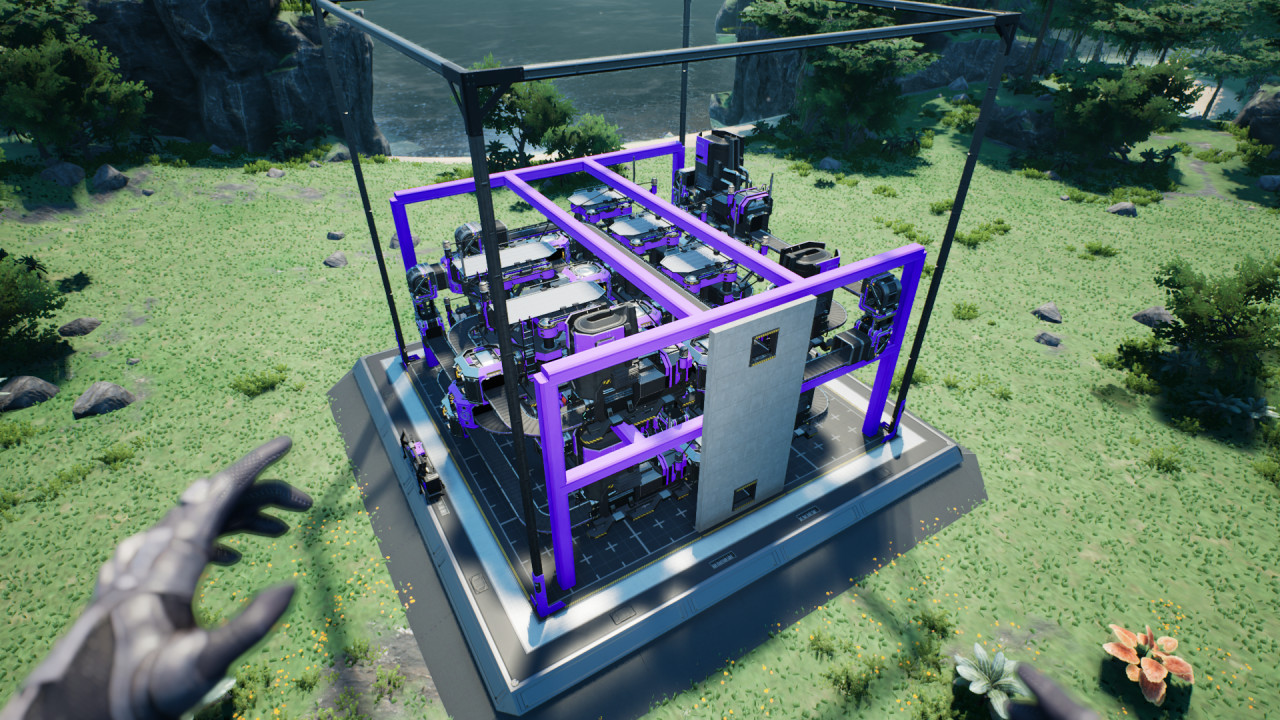

Illustrative image related to copper sheet satisfactory

Scenario 3: Challenges with Compliance and Regulatory Standards

The Problem: Navigating compliance with local and international regulations can be a daunting task for B2B buyers of copper sheets. Regulations regarding material properties, safety standards, and environmental impacts can vary widely across regions, particularly in diverse markets such as Africa and South America. Failure to comply with these regulations can result in fines, shipment delays, or even the rejection of materials, causing disruptions in the supply chain.

The Solution: Buyers must stay informed about the relevant regulatory frameworks in the markets they operate in. This can be achieved through regular training sessions for procurement teams and maintaining open lines of communication with legal advisors familiar with industry standards. It is also beneficial to work with suppliers who have a proven track record of compliance and can provide documentation such as Material Safety Data Sheets (MSDS) and certificates of conformity. Engaging in proactive risk management, such as conducting regular compliance audits and collaborating with industry associations, can help buyers anticipate regulatory changes and adjust their sourcing strategies accordingly.

Strategic Material Selection Guide for copper sheet satisfactory

What are the Key Materials for Producing Copper Sheets?

When considering the production of copper sheets for satisfactory applications, several materials come into play. Each material has distinct properties, advantages, and disadvantages that can impact their suitability for specific applications. Below, we analyze four common materials relevant to the production of copper sheets, focusing on their performance, cost, and implications for international B2B buyers.

1. Copper Ingot

Key Properties:

Copper ingots are characterized by excellent thermal and electrical conductivity, making them ideal for fluid-related applications. They also offer good corrosion resistance and can withstand moderate temperatures, typically up to 200°C.

Pros & Cons:

The primary advantage of copper ingots is their high conductivity, which is essential for applications in pipelines and electrical components. However, they can be relatively expensive compared to other metals, and their manufacturing process can be complex, requiring specialized equipment and expertise.

Illustrative image related to copper sheet satisfactory

Impact on Application:

Copper sheets made from ingots are suitable for a wide range of media, including water and various chemicals, due to their corrosion resistance. However, they may not be suitable for high-pressure applications without adequate reinforcement.

Considerations for International Buyers:

Buyers in regions like Germany and Saudi Arabia should ensure compliance with standards such as ASTM B152 for copper sheet specifications. Understanding local market conditions and sourcing copper ingots from reputable suppliers is crucial for maintaining quality.

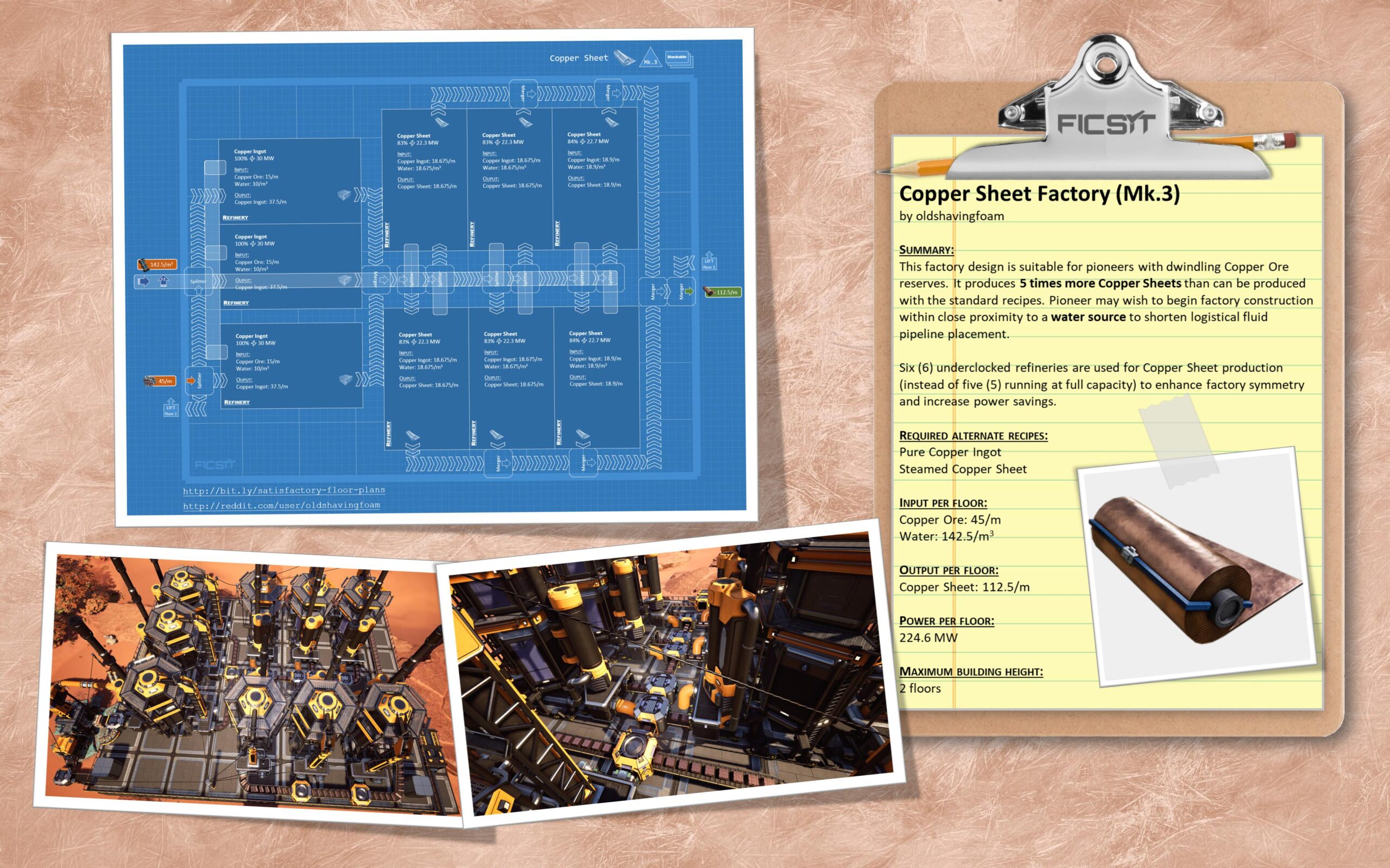

2. Steamed Copper Sheet

Key Properties:

Steamed copper sheets are produced using a process that combines copper ingots with water, enhancing their production efficiency. This method can yield sheets with improved mechanical properties and a slightly higher temperature tolerance.

Illustrative image related to copper sheet satisfactory

Pros & Cons:

The main advantage of steamed copper sheets is their higher yield per ore, making them more cost-effective in large-scale production. However, the process requires additional infrastructure for water management, which can complicate manufacturing.

Impact on Application:

These sheets are particularly suitable for applications requiring moderate pressure and temperature resistance, such as fluid transport systems. Their enhanced properties can lead to longer service life in demanding environments.

Considerations for International Buyers:

B2B buyers should consider the environmental impact of water usage in production, especially in arid regions. Compliance with local environmental regulations is essential, along with adherence to international standards.

3. Aluminum Clad Copper Sheet

Key Properties:

Aluminum clad copper sheets combine the conductivity of copper with the lightweight and corrosion resistance of aluminum. This hybrid material offers unique properties, such as improved durability and resistance to environmental factors.

Pros & Cons:

The key advantage of aluminum clad sheets is their reduced weight, which can lower shipping costs and ease installation. However, they may have limitations in high-temperature applications due to aluminum’s lower melting point compared to pure copper.

Impact on Application:

These sheets are ideal for applications that require both conductivity and resistance to corrosion, such as in coastal environments. However, the bonding process between aluminum and copper must be carefully managed to ensure performance.

Considerations for International Buyers:

Buyers should verify that the aluminum clad copper sheets meet international standards, such as JIS H 3100, to ensure compatibility with local regulations. Understanding the market demand for hybrid materials in specific regions can also influence purchasing decisions.

4. Copper Alloy Sheets

Key Properties:

Copper alloy sheets, which include elements like nickel or zinc, offer enhanced mechanical properties and corrosion resistance compared to pure copper. These alloys can withstand higher temperatures and pressures.

Pros & Cons:

The main advantage of copper alloys is their versatility and strength, making them suitable for a broader range of applications. However, they can be more expensive than pure copper sheets and may require specialized manufacturing techniques.

Illustrative image related to copper sheet satisfactory

Impact on Application:

Alloy sheets are particularly beneficial in high-stress environments, such as in aerospace or marine applications, where durability is crucial. Their enhanced properties can lead to improved performance and longevity.

Considerations for International Buyers:

Buyers should be aware of the specific alloy compositions and their compliance with standards such as ASTM B370. Understanding local market preferences for alloy types can also impact procurement strategies.

Summary Table

| Material | Typical Use Case for copper sheet satisfactory | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper Ingot | Electrical components, pipelines | High conductivity | Expensive, complex manufacturing | High |

| Steamed Copper Sheet | Fluid transport systems | Cost-effective production | Requires water management | Medium |

| Aluminum Clad Copper Sheet | Coastal applications, lightweight structures | Reduced weight | Limited high-temperature use | Medium |

| Copper Alloy Sheets | Aerospace, marine applications | Enhanced strength and durability | Higher cost, specialized techniques | High |

This analysis provides valuable insights for B2B buyers in various regions, helping them make informed decisions when selecting materials for copper sheets in satisfactory applications. Understanding the properties, advantages, and regional considerations can lead to more effective sourcing strategies and improved product performance.

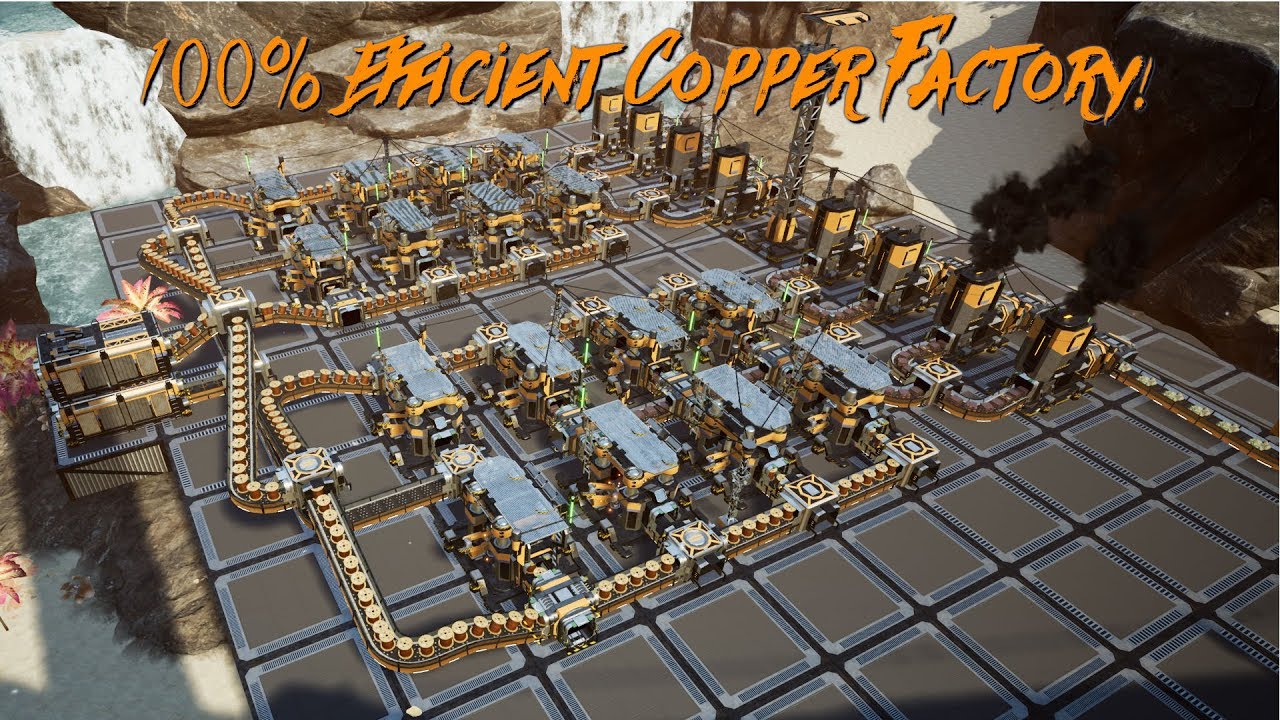

Illustrative image related to copper sheet satisfactory

In-depth Look: Manufacturing Processes and Quality Assurance for copper sheet satisfactory

What Are the Main Stages of the Manufacturing Process for Copper Sheets?

The manufacturing process for copper sheets involves several critical stages, each designed to ensure the production of high-quality, reliable products. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Copper Sheet Manufacturing?

The first step in the production of copper sheets is material preparation. This involves sourcing high-purity copper ore, which is then processed to extract copper ingots. The quality of the copper ingots is essential, as impurities can affect the performance of the final product. Advanced techniques, such as electrolysis and smelting, are often used to refine the copper.

Once the copper ingots are obtained, they are subjected to further treatments such as annealing to enhance their ductility and malleability. This ensures that the copper can be easily formed into sheets without cracking or losing structural integrity.

What Forming Techniques Are Utilized in Copper Sheet Production?

Forming is a crucial stage in the manufacturing of copper sheets. The primary technique used is rolling, where the prepared copper ingots are passed through a series of rollers to achieve the desired thickness. There are two types of rolling processes: hot rolling and cold rolling.

Illustrative image related to copper sheet satisfactory

-

Hot Rolling: This technique is performed at elevated temperatures, allowing for easier shaping and deformation of the copper. It is typically used for thicker sheets.

-

Cold Rolling: This process occurs at room temperature and is used to create thinner, more precise sheets. Cold-rolled copper sheets often exhibit improved surface finishes and mechanical properties.

After rolling, the sheets are cut to size according to specifications, which may vary based on the intended application, such as pipelines or fluid-related buildings.

What Quality Control Measures Are Standard in Copper Sheet Manufacturing?

Quality assurance is paramount in the manufacturing of copper sheets, particularly for B2B transactions where product reliability is critical. Adhering to international standards, such as ISO 9001, helps ensure that manufacturers maintain high-quality processes.

Which International Standards Should B2B Buyers Be Aware Of?

ISO 9001 is a widely recognized standard for quality management systems. It focuses on meeting customer requirements and enhancing satisfaction. In addition to ISO 9001, industry-specific certifications such as CE marking (European Conformity) and API (American Petroleum Institute) standards may also be relevant, particularly for suppliers targeting markets in Europe and the Middle East.

These standards ensure that the products meet safety, health, and environmental protection requirements, making them suitable for various applications, including construction and manufacturing.

What Are the Key Quality Control Checkpoints in the Production Process?

Quality control (QC) is an ongoing process throughout the manufacturing cycle, typically divided into three main checkpoints:

Illustrative image related to copper sheet satisfactory

-

Incoming Quality Control (IQC): This initial checkpoint focuses on the materials received from suppliers. Verification of the quality of copper ingots is crucial, as subpar materials can compromise the entire production process.

-

In-Process Quality Control (IPQC): During manufacturing, various parameters are monitored, including thickness, surface quality, and mechanical properties. Operators conduct regular inspections to ensure that the production processes remain within specified tolerances.

-

Final Quality Control (FQC): Once the copper sheets are produced, they undergo final inspections before packaging and shipment. This step includes testing for dimensional accuracy, surface defects, and adherence to specifications.

What Testing Methods Are Commonly Used for Copper Sheets?

Several testing methods are employed to ensure the quality of copper sheets. Common techniques include:

-

Dimensional Inspection: Using calipers and micrometers to measure thickness, width, and length.

-

Visual Inspection: Assessing surface quality for scratches, dents, or discoloration.

-

Mechanical Testing: This includes tensile tests to evaluate the strength and ductility of the copper sheets.

-

Chemical Analysis: Conducting tests to determine the purity of the copper and identify any impurities present.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those in international markets such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are several strategies:

-

Supplier Audits: Regular audits can be conducted to assess the supplier’s manufacturing processes and quality management systems. This can include both on-site inspections and reviewing documentation.

-

Quality Reports: Requesting quality reports can provide insights into the supplier’s QC processes. These reports should detail inspection results, testing methods, and compliance with relevant standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. This is particularly useful when sourcing from regions where buyers may not have direct oversight.

What Nuances Should International B2B Buyers Consider Regarding QC and Certification?

International buyers must navigate various nuances when it comes to quality control and certification. Here are some key considerations:

-

Regulatory Compliance: Different regions may have varying regulatory requirements. Understanding local laws and regulations is crucial for ensuring compliance.

-

Cultural Differences: Business practices and quality expectations can vary significantly across cultures. Buyers should be aware of these differences to foster better supplier relationships.

-

Language Barriers: Effective communication is vital for quality assurance. Buyers should ensure that all documentation is clear and that there is a mutual understanding of specifications and quality standards.

In conclusion, the manufacturing processes and quality assurance practices for copper sheets are multifaceted and critical for B2B buyers looking for reliable suppliers. By understanding the stages of production, quality control measures, and testing methods, buyers can make informed decisions and ensure that they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘copper sheet satisfactory’

To assist B2B buyers in procuring copper sheets for satisfactory applications, this guide offers a structured checklist. Following these steps will ensure a smooth sourcing process, tailored to meet specific operational needs and quality standards.

Step 1: Define Your Technical Specifications

Establish clear technical specifications for the copper sheets you require. This includes dimensions, thickness, and any specific standards or certifications needed for your industry. Precise specifications help prevent miscommunication and ensure that the materials meet your operational requirements.

- Common dimensions: Determine the standard sizes needed for your projects.

- Thickness: Specify the gauge required for your applications, as this affects durability and performance.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in copper sheets. Investigate their reputation, market presence, and any feedback from previous clients. A well-established supplier is more likely to provide reliable products and services.

- Industry expertise: Focus on suppliers with experience in your specific sector.

- Geographical considerations: Evaluate suppliers based on their shipping capabilities to your region.

Step 3: Evaluate Supplier Certifications

Before finalizing any agreements, verify that potential suppliers possess relevant certifications. This ensures that their products comply with international standards, which is crucial for maintaining quality and safety in your operations.

- ISO certifications: Look for suppliers with ISO 9001 for quality management and ISO 14001 for environmental management.

- Material certifications: Ensure that the copper sheets meet required industry standards, such as ASTM or EN specifications.

Step 4: Request Samples and Test Quality

Always request samples before making a large purchase. Testing the quality of the copper sheets ensures they meet your specifications and perform as expected in your applications.

Illustrative image related to copper sheet satisfactory

- Physical properties: Assess characteristics like conductivity, tensile strength, and corrosion resistance.

- Dimensional accuracy: Verify that samples meet the specified dimensions and tolerances.

Step 5: Assess Pricing and Payment Terms

Obtain detailed quotes from shortlisted suppliers and compare pricing structures. While cost is important, consider the total value offered, including quality, shipping, and after-sales service.

- Volume discounts: Inquire about pricing breaks for larger orders.

- Payment terms: Ensure the terms align with your financial practices to avoid cash flow issues.

Step 6: Establish a Communication Plan

Set up a clear communication plan with your chosen supplier. Effective communication helps in addressing any issues that may arise during the procurement process and fosters a stronger working relationship.

- Point of contact: Designate a representative from both sides for streamlined communication.

- Regular updates: Schedule periodic check-ins to discuss order status and any concerns.

Step 7: Finalize Contracts and Agreements

Once all details are agreed upon, finalize contracts to formalize the procurement process. Ensure that all terms, including delivery timelines, pricing, and quality expectations, are clearly outlined.

- Legal review: Have legal counsel review contracts to safeguard your interests.

- Exit clauses: Include clauses that allow for adjustments or terminations if expectations are not met.

By following this checklist, B2B buyers can effectively navigate the sourcing process for copper sheets, ensuring that they acquire high-quality materials that meet their operational needs.

Illustrative image related to copper sheet satisfactory

Comprehensive Cost and Pricing Analysis for copper sheet satisfactory Sourcing

What Are the Key Cost Components in Sourcing Copper Sheets?

When sourcing copper sheets for satisfactory manufacturing, understanding the cost structure is crucial. The primary cost components include:

-

Materials: The largest portion of the cost is typically raw materials. For copper sheets, this involves copper ingots, which can vary significantly in price based on global copper market fluctuations.

-

Labor: Labor costs encompass both skilled and unskilled workers involved in the production process. Labor rates can differ by region; for instance, labor is generally more expensive in Europe compared to parts of Africa and South America.

-

Manufacturing Overhead: This includes costs associated with utilities, equipment maintenance, and factory operations. Overhead can be lower in developing regions, potentially affecting pricing strategies.

-

Tooling: The initial investment in tooling and machinery used for producing copper sheets can be substantial. Custom tooling for specific sheet sizes or specifications can further increase this cost.

-

Quality Control (QC): Ensuring that the copper sheets meet specific industry standards involves QC procedures, which add to the overall cost. Certificates of compliance may also be necessary for international buyers.

-

Logistics: Transportation costs must be factored in, particularly for international shipments. These costs can include freight, insurance, and potential customs duties, which vary depending on the destination.

-

Margin: Suppliers typically add a margin to cover their business expenses and profit. This margin can fluctuate based on market demand and competition.

How Do Price Influencers Affect Copper Sheet Sourcing?

Several factors can influence the pricing of copper sheets in B2B transactions:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their production needs.

-

Specifications and Customization: Custom sizes or specialized coatings can increase costs. Buyers should consider their specific needs and how these might affect pricing.

-

Quality and Certifications: Higher quality materials or certified products (like those adhering to ISO standards) typically command a premium price. Buyers need to weigh the benefits of certifications against their project budgets.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more, but they often provide better service and quality assurance.

-

Incoterms: The agreed terms of shipment, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), can significantly influence the overall cost. Buyers should understand their responsibilities under each term to avoid unexpected expenses.

What Tips Can Help International Buyers Optimize Costs?

For international buyers, particularly those in Africa, South America, the Middle East, and Europe, the following strategies can enhance cost-efficiency:

-

Negotiate Pricing: Engage in discussions with suppliers to negotiate better rates, especially for bulk purchases. Building long-term relationships can also lead to favorable terms.

-

Consider Total Cost of Ownership (TCO): Evaluate the complete cost associated with sourcing, including shipping, handling, and potential tariffs. A lower initial price may not always translate to lower overall costs.

-

Understand Pricing Nuances: Be aware of the pricing dynamics in different regions. For instance, European suppliers may offer higher quality but at a premium, while suppliers from developing countries might provide cost-effective alternatives.

-

Conduct Market Research: Stay informed about copper market trends and forecasted price changes. This knowledge can aid in timing purchases to secure better rates.

-

Leverage Technology: Utilize digital tools and platforms to compare suppliers, assess product specifications, and streamline the sourcing process.

Disclaimer

Prices and cost components mentioned are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and analysis before finalizing any sourcing decisions.

Alternatives Analysis: Comparing copper sheet satisfactory With Other Solutions

Exploring Alternatives to Copper Sheet Satisfactory

In the pursuit of efficient manufacturing and construction solutions, B2B buyers often explore various alternatives to copper sheet satisfactory. The choice of materials and methods can significantly impact production efficiency, cost-effectiveness, and overall project success. This section evaluates copper sheet satisfactory against two alternative materials: aluminum sheets and composite materials, providing insights into their respective benefits and drawbacks.

| Comparison Aspect | Copper Sheet Satisfactory | Aluminum Sheet | Composite Materials |

|---|---|---|---|

| Performance | Good thermal conductivity; ideal for pipelines and fluid systems | Excellent strength-to-weight ratio; versatile | Lightweight; tailored properties based on composition |

| Cost | Moderate cost due to raw material and processing | Generally lower cost; fluctuates with market demand | Can be more expensive due to complex manufacturing |

| Ease of Implementation | Requires specific tools for shaping and installation | Easily cut and formed; widely available | Requires specialized skills for production and assembly |

| Maintenance | Durable, but may corrode over time without treatment | Resistant to corrosion; low maintenance | Varies widely based on type; some may degrade under UV exposure |

| Best Use Case | Ideal for plumbing and electrical applications | Suitable for structural applications and lightweight designs | Best for specialized applications requiring specific performance traits |

In-Depth Analysis of Alternatives

Aluminum Sheets

Aluminum sheets are a popular alternative to copper sheets due to their lightweight and corrosion-resistant properties. They offer excellent strength-to-weight ratios, making them suitable for a variety of applications, including structural components and packaging. The cost of aluminum is often lower than copper, though it can fluctuate based on market conditions. Their ease of implementation is another significant advantage; aluminum can be easily cut, shaped, and welded, making it an attractive option for manufacturers. However, while aluminum is durable, it may not provide the same thermal conductivity as copper, which can be a drawback in specific applications.

Illustrative image related to copper sheet satisfactory

Composite Materials

Composite materials represent another viable alternative, offering customizable properties that can be tailored to meet specific needs. These materials can be engineered for lightweight applications, making them ideal for industries such as aerospace and automotive. Composites can also provide superior resistance to environmental factors compared to metals. However, the complexity of producing composites often leads to higher costs and requires specialized skills for manufacturing and installation. Additionally, some composites may degrade over time under UV light or extreme conditions, necessitating careful consideration of their long-term durability.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the right material for a project, B2B buyers must consider their specific application requirements, budget constraints, and long-term maintenance needs. Copper sheets excel in thermal conductivity and durability but come with moderate costs and potential corrosion issues. Aluminum sheets provide a cost-effective and versatile alternative, while composite materials offer tailored solutions for specialized applications. By weighing the pros and cons of each option against project specifications, buyers can make informed decisions that align with their operational goals and budgetary constraints.

Essential Technical Properties and Trade Terminology for copper sheet satisfactory

What Are the Key Technical Properties of Copper Sheets in Satisfactory?

1. Material Grade

Copper sheets are typically categorized by their material grade, which indicates the purity and composition of the copper used. In the context of “Satisfactory,” the most common grades are based on the copper ingots used for crafting. Higher-grade copper sheets provide better conductivity and resistance to corrosion, which is crucial for applications involving fluid transport and electrical connections. For B2B buyers, selecting the appropriate material grade ensures that the copper sheets will meet the performance requirements of their specific applications.

2. Thickness and Tolerance

The thickness of copper sheets plays a significant role in their application. Standard thicknesses can range from 0.5 mm to several millimeters, depending on the intended use. Tolerance, the allowable deviation from specified dimensions, is equally important as it affects the fitting and assembly of components. For instance, precise tolerances are essential in industries that require exact specifications for pipelines and electrical connections. Understanding these properties helps buyers ensure that the copper sheets will integrate seamlessly into their projects.

3. Yield Strength and Ductility

Yield strength measures the maximum stress that a material can withstand before deforming, while ductility refers to how much a material can be stretched or deformed without breaking. For copper sheets, a balance between yield strength and ductility is vital for applications that involve bending or forming. B2B buyers should assess these properties to ensure that the copper sheets will maintain structural integrity under operational conditions.

Illustrative image related to copper sheet satisfactory

4. Conductivity

Copper is renowned for its excellent electrical and thermal conductivity. The level of conductivity is crucial for applications in electrical wiring and heat exchangers. B2B buyers should prioritize suppliers that can provide sheets with high conductivity ratings, as this directly influences the efficiency of electrical systems and thermal management solutions.

5. Corrosion Resistance

Copper sheets possess inherent resistance to corrosion, but this can vary based on the specific alloy and surface treatment. Corrosion resistance is particularly important in environments exposed to moisture or chemical agents. Buyers should verify the corrosion resistance specifications to ensure longevity and reliability in their applications.

What Are Common Trade Terms Related to Copper Sheets?

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces components or products that are used in another company’s end product. In the context of copper sheets, buyers may work with OEMs to ensure that the sheets meet specific design and quality standards required for their applications. Understanding this term helps buyers establish partnerships that align with their manufacturing needs.

Illustrative image related to copper sheet satisfactory

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers, as it directly impacts inventory management and cash flow. Buyers should consider their project requirements and budget when negotiating MOQs with suppliers.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for a specific quantity of goods. For copper sheets, an RFQ allows buyers to compare offers from different suppliers and negotiate better pricing. This process is essential for strategic sourcing and cost management.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. They cover aspects such as shipping costs, insurance, and delivery points. B2B buyers should familiarize themselves with Incoterms to understand their obligations and rights in the procurement process, especially when sourcing copper sheets from international suppliers.

Illustrative image related to copper sheet satisfactory

5. Lead Time

Lead time refers to the time taken from placing an order until the goods are delivered. This term is vital for B2B buyers who need to plan their production schedules and inventory levels accurately. Understanding lead times helps in managing expectations and ensuring timely project completion.

By grasping these essential technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing copper sheets for their projects, ensuring quality, efficiency, and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the copper sheet satisfactory Sector

What are the Global Drivers and Key Trends Affecting the Copper Sheet Market?

The copper sheet market is experiencing dynamic shifts influenced by several global drivers. A notable trend is the increasing demand for copper sheets in the construction and manufacturing sectors, particularly in fluid-related applications. The rise of smart infrastructure projects and the push for renewable energy sources are propelling the use of copper materials, given their excellent conductivity and durability. Additionally, emerging technologies such as automation and advanced manufacturing processes are enhancing production efficiencies, leading to cost-effective sourcing solutions for international buyers.

Illustrative image related to copper sheet satisfactory

B2B tech trends are also shaping sourcing strategies. Digital platforms for procurement are gaining traction, enabling buyers from regions such as Africa, South America, the Middle East, and Europe to access a broader network of suppliers. These platforms facilitate real-time price comparisons, supplier ratings, and streamlined logistics, thus optimizing the purchasing process. Furthermore, the growing emphasis on Just-in-Time (JIT) inventory systems is encouraging companies to maintain leaner supply chains, minimizing excess inventory while ensuring timely delivery of copper sheets.

Market dynamics are also affected by geopolitical factors, including trade tariffs and regulations. For instance, buyers in Europe and the Middle East may face varying import duties, influencing sourcing decisions. Understanding these dynamics is crucial for international buyers to navigate potential risks and leverage opportunities in the copper sheet market effectively.

How Can Sustainability and Ethical Sourcing Impact Your B2B Copper Sheet Procurement?

Sustainability and ethical sourcing are increasingly pivotal in the copper sheet sector, aligning with global efforts to combat climate change and promote responsible manufacturing. The environmental impact of copper extraction and processing is significant, with concerns about habitat destruction, water usage, and carbon emissions. As such, B2B buyers are prioritizing suppliers who adhere to sustainable practices, including responsible mining and production methods that minimize environmental footprints.

Ethical supply chains are becoming a critical consideration for businesses. Buyers are looking for partners who can provide transparency in their sourcing processes and demonstrate compliance with international labor standards. Certifications such as ISO 14001 for environmental management and the Responsible Minerals Initiative (RMI) for ethical sourcing are valuable indicators of a supplier’s commitment to sustainability.

Illustrative image related to copper sheet satisfactory

Moreover, the demand for ‘green’ materials is rising, with companies increasingly opting for recycled copper sheets. These products not only reduce the reliance on virgin materials but also contribute to a circular economy, appealing to environmentally conscious buyers. By integrating sustainability into procurement strategies, businesses can enhance their brand reputation and meet the growing expectations of stakeholders regarding corporate responsibility.

What is the Brief History and Evolution of the Copper Sheet Market?

The history of copper sheets dates back thousands of years, with their use in various cultures for both decorative and functional purposes. In modern times, the industrial revolution catalyzed the mass production of copper sheets, leading to their widespread application in electrical, construction, and manufacturing sectors. Over the past few decades, advancements in extraction and refining technologies have significantly improved the quality and availability of copper sheets.

Today, the copper sheet market continues to evolve with innovations in production techniques, including the use of alternative recipes that enhance efficiency and reduce waste. The introduction of digital procurement tools has further transformed the landscape, allowing international buyers to streamline their sourcing processes and adapt to the rapidly changing market dynamics. As the demand for copper sheets grows, particularly in emerging markets, understanding this evolution is essential for B2B buyers seeking to make informed procurement decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of copper sheet satisfactory

-

How do I determine the right specifications for copper sheets in my project?

When sourcing copper sheets, it’s crucial to evaluate the specific requirements of your project. Consider factors such as thickness, dimensions, and purity levels. Review the applications you have in mind—whether for electrical, plumbing, or structural purposes—as these will dictate the necessary specifications. Collaborate closely with your suppliers to ensure that the copper sheets meet industry standards and certifications, particularly if you require compliance with regional regulations. -

What are the typical applications for copper sheets in industrial settings?

Copper sheets are widely used in various industrial applications, including the manufacturing of electrical components, plumbing systems, and architectural elements. Their excellent conductivity makes them ideal for electrical wiring and circuit boards, while their corrosion resistance makes them suitable for plumbing and roofing. Understanding your specific application will help you select the right type of copper sheet and ensure optimal performance in your projects. -

What factors should I consider when vetting suppliers of copper sheets?

To effectively vet suppliers, evaluate their reputation, experience, and compliance with industry standards. Check for certifications such as ISO, which can indicate quality management practices. Additionally, inquire about their sourcing practices for raw materials and their ability to provide traceability. Request references from previous clients to gauge customer satisfaction and service reliability. A thorough vetting process minimizes risks and ensures you partner with a trustworthy supplier. -

What is the minimum order quantity (MOQ) for copper sheets, and how does it vary by supplier?

The MOQ for copper sheets can vary significantly between suppliers, typically ranging from a few hundred kilograms to several tons. Factors influencing MOQ include the supplier’s production capacity, inventory levels, and the specific type of copper sheet required. When negotiating, communicate your project needs clearly and explore options for smaller orders if necessary. Some suppliers may offer flexibility, especially if you establish a long-term relationship. -

What payment terms are commonly offered by suppliers of copper sheets?

Payment terms can vary widely among suppliers, but common options include upfront payments, partial payments, or payment upon delivery. Some suppliers may offer credit terms for established clients, allowing payment within 30 to 90 days. It’s essential to discuss and negotiate payment terms early in the procurement process to align with your cash flow and budget constraints. Ensure that all terms are clearly documented in the purchase agreement to avoid misunderstandings. -

How can I ensure quality assurance (QA) for the copper sheets I purchase?

To ensure quality assurance, request material test reports and certifications that confirm the copper sheets meet specified standards. Establish clear quality criteria with your supplier, including tolerance levels, surface finish, and any necessary testing protocols. Consider implementing a third-party inspection process to validate quality before shipment. Regular communication with the supplier throughout the production and delivery process can also help address any potential quality issues proactively. -

What logistics considerations should I keep in mind when sourcing copper sheets internationally?

International logistics can present challenges such as customs clearance, tariffs, and shipping times. Work closely with your supplier to understand their shipping capabilities and any associated costs. Ensure that all necessary documentation, such as bills of lading and customs declarations, is prepared accurately to facilitate smooth importation. Additionally, consider the mode of transport (air, sea, or land) based on your urgency and budget, and account for insurance to mitigate potential risks during transit. -

Can I request customization for my copper sheet orders?

Yes, many suppliers offer customization options for copper sheets, including specific dimensions, thicknesses, and finishes. When requesting customization, provide detailed specifications to ensure your needs are met accurately. Discuss lead times, as customized orders may require additional processing time. Collaborating closely with your supplier during the design phase can help streamline production and ensure that the final product aligns with your project’s requirements.

Top 4 Copper Sheet Satisfactory Manufacturers & Suppliers List

1. Satisfactory – Copper Sheet

Domain: satisfactory.wiki.gg

Introduction: Copper Sheet is an early-game item used primarily in the construction of Pipelines and fluid-related buildings. It is unlocked by Tier 2 – Part Assembly and has a class name of Desc_CopperSheet_C. The item stack size is 200, and it provides 24 sink points. Copper Sheets are crafted using 2 Copper Ingots in a Constructor, producing 10 Copper Sheets per minute with a crafting time of 6 seconds. An a…

2. Satisfactory – Copper Sheet

Domain: satisfactory.fandom.com

Registered: 1996 (29 years)

Introduction: Copper Sheet is an early-game item used primarily in the construction of Pipelines and fluid-related buildings. It is unlocked at Tier 2 and has a stack size of 200. The item is crafted using 2 Copper Ingots in a Constructor, taking 6 seconds to produce 1 Copper Sheet. It has a sink value of 24 points and is primarily used for crafting various items such as Circuit Boards, Gas Masks, and different…

3. Satisfactory – Copper Sheet

Domain: satisfactory-calculator.com

Registered: 2019 (6 years)

Introduction: This company, Satisfactory – Copper Sheet, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Satisfactory Tools – Copper Sheet

Domain: satisfactorytools.com

Registered: 2019 (6 years)

Introduction: {“name”: “Copper Sheet”, “type”: “Item”, “category”: “Manufactured”, “description”: “A flat sheet made of copper, used in various recipes.”, “crafting”: {“crafting_time”: “1s”, “ingredients”: [{“item”: “Copper Ingots”, “amount”: 2}], “result”: {“item”: “Copper Sheet”, “amount”: 1}}, “usage”: “Used in various advanced recipes and constructions.”}

Strategic Sourcing Conclusion and Outlook for copper sheet satisfactory

As the demand for copper sheets continues to rise across various industries, particularly in fluid-related construction and manufacturing, the importance of strategic sourcing cannot be overstated. By leveraging efficient procurement strategies and understanding the diverse production methods—such as the standard and alternate recipes for copper sheets—international B2B buyers can optimize their supply chains and reduce costs.

Investing in quality copper sheets not only enhances the durability and functionality of projects but also contributes to sustainable practices through improved material utilization. Buyers from regions such as Africa, South America, the Middle East, and Europe—especially Germany and Saudi Arabia—should prioritize partnerships with reliable suppliers who can provide high-quality products and flexible sourcing options.

Looking ahead, the global marketplace for copper sheets offers significant opportunities for growth and innovation. Companies that embrace strategic sourcing will be better positioned to navigate market fluctuations and technological advancements. Engage with your suppliers today to explore customized solutions that can meet your specific needs and enhance your operational efficiency. The future of your projects depends on the strategic decisions you make now.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.