Unlocking Value: A Strategic Analysis of the Copper Embossing Market

Introduction: Navigating the Global Market for copper embossing

Navigating the global market for copper embossing presents unique challenges for B2B buyers seeking quality materials and reliable suppliers. With the increasing demand for artistic and functional applications of embossed copper—from decorative art pieces to architectural elements—sourcing the right copper embossing tools and materials becomes crucial. This guide aims to demystify the complexities of the copper embossing industry, providing insights into various types of copper sheets, the tools required for effective embossing, and the diverse applications that can enhance your product offerings.

Understanding the intricacies of supplier vetting, cost analysis, and quality assurance is essential for international buyers, particularly those operating in dynamic markets across Africa, South America, the Middle East, and Europe, including key players like Germany and Nigeria. By offering a comprehensive overview of the copper embossing landscape, this guide empowers businesses to make informed purchasing decisions that align with their operational needs and artistic aspirations. Whether you are looking to enhance your manufacturing capabilities or expand your artistic portfolio, the information presented here will serve as a valuable resource, enabling you to navigate this vibrant market with confidence and precision.

Understanding copper embossing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Copper Embossing | Utilizes hand tools for detailed designs; often involves manual techniques. | Art installations, custom décor, sign-making. | Pros: High craftsmanship, customizable. Cons: Time-consuming, labor-intensive. |

| Machine-Embossed Copper | Employs industrial machinery for consistent patterns and mass production. | Architectural elements, automotive parts, decorative panels. | Pros: High efficiency, uniformity. Cons: Less customization, potential higher upfront costs. |

| Textured Copper Embossing | Focuses on creating surface textures for visual and tactile effects. | Jewelry making, artistic panels, home décor. | Pros: Unique aesthetics, enhances product appeal. Cons: May require specialized tools and techniques. |

| Patinated Copper Embossing | Involves applying chemical treatments for color and texture variations. | Sculpture, art pieces, architectural detailing. | Pros: Distinctive finish, adds character. Cons: Requires maintenance to prevent oxidation. |

| Copper Foil Embossing | Uses thinner copper sheets for lightweight applications and intricate designs. | Craft projects, small-scale art, decorative items. | Pros: Easy to work with, cost-effective. Cons: Less durable than thicker options, may not withstand heavy use. |

What are the Characteristics of Traditional Copper Embossing?

Traditional copper embossing is characterized by its reliance on hand tools, allowing artisans to create intricate and personalized designs. This method is particularly suitable for small-scale projects such as custom art installations and decorative signage. B2B buyers should consider the craftsmanship and unique appeal of these products, recognizing that while they offer high levels of customization, the process is labor-intensive and time-consuming, which may affect lead times.

How Does Machine-Embossed Copper Differ from Other Types?

Machine-embossed copper utilizes industrial machinery to produce consistent patterns, making it ideal for large-scale applications like architectural elements and automotive parts. Buyers in sectors requiring uniformity and efficiency should consider this method, as it significantly reduces production time and costs. However, the trade-off is a decrease in customization options compared to traditional methods.

What Makes Textured Copper Embossing Unique?

Textured copper embossing focuses on creating distinct surface textures that enhance both visual and tactile qualities. This technique is popular in jewelry making and artistic panels, appealing to buyers looking for unique and aesthetically pleasing products. While it can elevate the overall product appeal, it may require specialized tools and expertise, which could influence purchasing decisions.

Why Consider Patinated Copper Embossing?

Patinated copper embossing introduces chemical treatments that create variations in color and texture, resulting in visually striking pieces. This method is often employed in sculptures and architectural detailing, appealing to buyers interested in distinctive finishes that add character to their products. However, it is essential to consider the need for maintenance to prevent oxidation, which could impact long-term value.

What are the Benefits of Copper Foil Embossing?

Copper foil embossing utilizes thinner copper sheets, making it suitable for lightweight applications and intricate designs. This method is particularly appealing to craft-oriented businesses and small-scale art projects due to its cost-effectiveness and ease of use. While it allows for creative freedom, buyers should be aware that the durability may be less than that of thicker copper options, which could limit its application in more demanding environments.

Key Industrial Applications of copper embossing

| Industry/Sector | Specific Application of Copper Embossing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Arts and Crafts | Decorative Art Pieces | Enhances aesthetic appeal and uniqueness of products | Quality of copper sheets and availability of embossing tools |

| Electronics | Custom Circuit Board Design | Provides durable and conductive pathways for electronics | Precision in embossing for functionality and reliability |

| Architectural Design | Facades and Signage | Creates visually striking architectural features | Thickness of copper and weather resistance properties |

| Automotive Industry | Decorative Trim and Components | Adds luxury and brand distinction to vehicles | Compliance with industry standards and cost-effectiveness |

| Jewelry and Fashion | Custom Jewelry Designs | Allows for intricate detailing and personalization | Sourcing skilled artisans and quality copper materials |

How is Copper Embossing Used in Arts and Crafts?

In the arts and crafts sector, copper embossing is utilized to create decorative art pieces that stand out due to their unique textures and designs. Artists use thin copper sheets to create intricate patterns and relief designs, enhancing the visual appeal of their work. For international buyers, especially from regions like Africa and South America, sourcing high-quality copper sheets and specialized embossing tools is crucial to achieving desired artistic effects. This practice not only allows for artistic expression but also caters to a growing market for handmade and unique art pieces.

What Role Does Copper Embossing Play in Electronics?

Copper embossing is fundamental in the electronics industry, particularly for creating custom circuit board designs. Embossed copper provides reliable and conductive pathways essential for the functionality of electronic devices. International buyers must consider precision in the embossing process to ensure the reliability of the circuits. Additionally, the sourcing of high-quality copper that meets industry standards is critical to prevent issues such as conductivity failures, which could lead to significant operational losses.

How is Copper Embossing Applied in Architectural Design?

In architectural design, copper embossing is employed for creating distinctive facades and signage that enhance the aesthetic value of buildings. The embossed copper can be shaped into intricate designs that not only beautify structures but also improve their durability against weather conditions. For buyers in Europe and the Middle East, sourcing copper that is both aesthetically pleasing and resistant to corrosion is paramount. Additionally, understanding local regulations regarding materials used in construction can influence sourcing decisions.

What Benefits Does Copper Embossing Provide in the Automotive Industry?

The automotive industry leverages copper embossing for decorative trims and components that add luxury and brand distinction to vehicles. Embossed copper elements can be found in dashboards, door panels, and other interior designs, providing an upscale look. For B2B buyers, particularly in regions like Germany, ensuring compliance with automotive industry standards and sourcing cost-effective yet high-quality materials is essential. The ability to customize designs through embossing also allows manufacturers to differentiate their products in a competitive market.

How is Copper Embossing Utilized in Jewelry and Fashion?

In the jewelry and fashion sectors, copper embossing is used to create custom jewelry designs that feature intricate detailing and personalization. This technique allows artisans to produce unique pieces that cater to niche markets seeking bespoke items. Buyers need to focus on sourcing skilled artisans who can execute detailed designs and ensure the use of high-quality copper that meets durability standards. Additionally, understanding market trends in jewelry design can help buyers align their sourcing strategies with consumer preferences.

3 Common User Pain Points for ‘copper embossing’ & Their Solutions

Scenario 1: Difficulty in Achieving Precision in Design

The Problem: B2B buyers often face challenges in achieving the desired precision and detail in their copper embossing projects. This can stem from using inferior tools or materials, leading to inconsistent results that do not meet the quality standards expected by their clients. For instance, a manufacturer producing decorative copper panels may find that their designs lack the intricate detailing required, resulting in customer dissatisfaction and potential loss of contracts.

The Solution: To overcome this challenge, it is crucial to invest in high-quality embossing tools specifically designed for copper. A professional-grade stylus set with varying ball sizes allows for greater control and precision when working on detailed designs. Buyers should also consider sourcing copper sheets of the appropriate gauge; thinner sheets (like 36 or 40 gauge) provide better malleability for fine detail without tearing. Additionally, employing a dual-sided technique—working from both the front and back of the copper sheet—can enhance the depth of the embossing. By utilizing these techniques, manufacturers can ensure their designs meet client expectations and maintain their competitive edge in the market.

Scenario 2: Challenges with Material Sourcing and Quality

The Problem: Many B2B buyers encounter difficulties in sourcing high-quality copper sheets and embossing tools that meet their project specifications. In regions such as Africa or South America, access to reliable suppliers can be limited, resulting in delays and subpar materials that affect the final product. This can lead to increased production costs and project timelines, ultimately impacting the bottom line and customer satisfaction.

The Solution: To navigate this issue, buyers should prioritize establishing relationships with reputable suppliers who specialize in copper embossing materials. Conducting thorough research, including checking reviews and testimonials, can help identify reliable sources. Additionally, leveraging online platforms or trade shows can provide access to a wider network of suppliers. When selecting materials, it is advisable to request samples before making bulk purchases to ensure the quality meets industry standards. Implementing a just-in-time inventory system can also reduce the risk of material shortages and help maintain production schedules.

Scenario 3: Inefficient Embossing Techniques Leading to Waste

The Problem: Many manufacturers struggle with inefficient embossing techniques that result in wasted materials and increased costs. Inexperienced workers may not fully understand the best practices for embossing copper, leading to errors such as over-embossing or tearing the sheets. This not only wastes valuable resources but can also lead to costly rework and delays in project completion.

The Solution: To enhance efficiency and minimize waste, it is essential to invest in training programs for employees involved in the embossing process. Workshops that focus on proper techniques, tool handling, and material management can significantly improve skill levels and reduce errors. Moreover, implementing a standardized process, such as creating templates for common designs, can streamline operations and ensure consistency across projects. Buyers should also consider using a soft backing material, like foam, when embossing to minimize the risk of tearing and to achieve cleaner results. By fostering a culture of continuous improvement and skill development, manufacturers can optimize their embossing processes and reduce waste, ultimately enhancing their profitability.

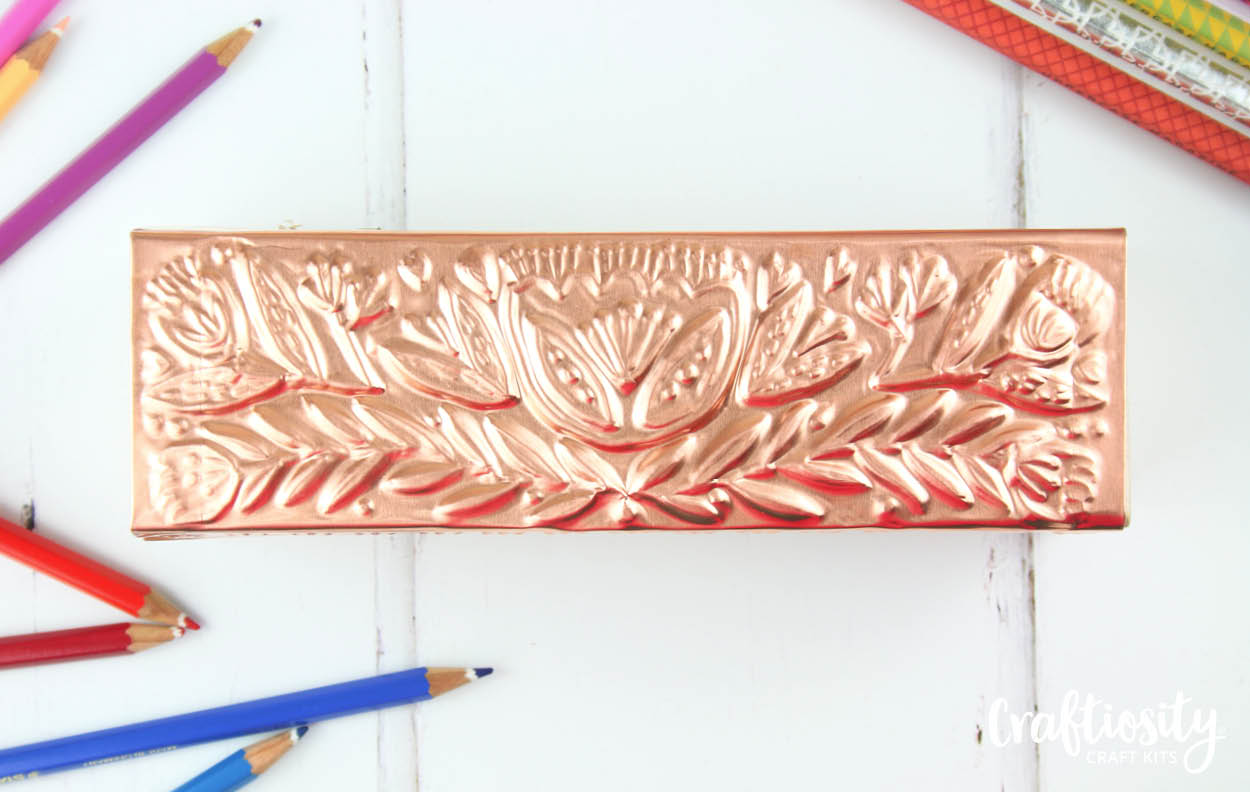

Illustrative image related to copper embossing

Strategic Material Selection Guide for copper embossing

What Are the Key Materials Used in Copper Embossing?

When it comes to copper embossing, the selection of materials is crucial for achieving desired results in terms of durability, aesthetics, and functionality. Below are analyses of four common materials used in the copper embossing process, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Copper Foil

Key Properties:

Copper foil typically comes in various gauges, with 36 to 40 gauge being common for embossing. This thinness allows for detailed designs while still being sturdy enough to withstand the embossing process without tearing.

Pros & Cons:

Copper foil is highly malleable, making it easy to shape and emboss. It also has excellent corrosion resistance, which is vital for longevity. However, the thinness can be a disadvantage as it may be more susceptible to damage during handling and transport.

Impact on Application:

Copper foil is compatible with a variety of embossing tools and techniques, allowing for intricate designs. It can be used in both artistic and functional applications, such as decorative panels and architectural elements.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM for material quality. In regions like Europe and the Middle East, preferences may lean towards higher gauge foils for more durability, while markets in Africa and South America might prioritize cost-effectiveness.

2. Embossing Tools (Stylus Sets)

Key Properties:

Embossing tools typically feature various ball stylus tips, which allow for different depths and textures in the embossing process. The materials used for these tools can vary but often include wood or metal.

Pros & Cons:

High-quality stylus sets enable precision in design and can significantly enhance the final product’s aesthetic. However, they require careful handling and maintenance, which could increase manufacturing complexity.

Impact on Application:

The choice of tools directly affects the quality of the embossed design. Different stylus sizes can create varied textures, making them suitable for both fine art and industrial applications.

Illustrative image related to copper embossing

Considerations for International Buyers:

Buyers should look for tools that meet local manufacturing standards and consider the availability of replacement parts. In regions with less access to specialized tools, investing in versatile, durable options can be beneficial.

3. Adhesives and Sealants

Key Properties:

Adhesives used in copper embossing must offer strong bonding capabilities and resistance to environmental factors like moisture and temperature fluctuations. Common types include epoxy and acrylic-based adhesives.

Pros & Cons:

These adhesives provide excellent durability and can improve the longevity of the embossed product. However, they may require specific application conditions and curing times, which can complicate the manufacturing process.

Impact on Application:

The choice of adhesive can affect the final product’s finish and durability. Sealants can also enhance the appearance, providing a protective layer that prevents tarnishing.

Considerations for International Buyers:

Adhesives must comply with local regulations regarding VOC emissions and safety standards. Buyers in regions like Germany may have stricter compliance requirements, making it essential to source adhesives that meet these standards.

4. Copper Sheets

Key Properties:

Copper sheets are available in varying thicknesses and are often used for larger embossing projects. They provide a robust substrate for detailed work while maintaining the ability to be shaped.

Pros & Cons:

Copper sheets are durable and can withstand significant manipulation without losing structural integrity. However, they can be costlier than foil, and the weight may complicate shipping and handling.

Impact on Application:

Copper sheets are ideal for larger-scale projects, such as architectural features or larger art installations. Their thickness allows for more substantial designs but may limit the level of detail compared to thinner foils.

Considerations for International Buyers:

Buyers should consider shipping costs and potential tariffs on heavier materials. Compliance with local standards for thickness and quality is also essential, particularly in markets like Europe where regulations are stringent.

Summary Table

| Material | Typical Use Case for copper embossing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper Foil | Decorative panels, artistic designs | Highly malleable for intricate designs | Susceptible to damage during transport | Medium |

| Embossing Tools | Fine art, industrial applications | Precision in design | Requires careful handling | Medium |

| Adhesives and Sealants | Final product assembly, protection | Strong bonding and durability | Specific application conditions needed | Medium |

| Copper Sheets | Large-scale projects, architectural features | Durable and robust | Heavier, complicates shipping | High |

This guide aims to provide B2B buyers with actionable insights into material selection for copper embossing, ensuring they can make informed decisions that align with their project requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for copper embossing

What are the Main Stages of the Copper Embossing Manufacturing Process?

Copper embossing involves several critical stages, each ensuring that the final product meets quality and design specifications. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: How is Copper Sheet Prepared for Embossing?

The first step in the copper embossing process is the selection and preparation of copper sheets. Typically, 36 to 40 gauge copper sheets are chosen due to their malleability and durability. The sheets are cut to size using precision cutting tools to minimize waste. Prior to embossing, the surface of the copper is often cleaned and prepped to remove any oxidation or contaminants that could affect the embossing quality. This step is crucial, as any imperfections can lead to defects in the final product.

Illustrative image related to copper embossing

Forming: What Techniques Are Used for Copper Embossing?

The forming stage is where the actual embossing occurs. This process involves the use of various tools, including styluses and hammers, to create raised designs on the copper surface. The tools may vary in size and shape to allow for intricate detailing. Craftsmen often work from both the front and back of the sheet, utilizing leather or foam surfaces to achieve the desired three-dimensional effects. Techniques such as pushing and pulling the metal, as well as using chemical patinas for coloring, are common. The ability to manipulate the copper sheet in this way is essential for producing high-quality, detailed artwork.

Assembly: How is the Embossed Copper Prepared for Final Products?

Once the embossing is complete, the next stage is assembly. In many cases, the embossed copper pieces are adhered to substrates like Masonite or wood, which provide additional support and aesthetic appeal. This process may involve using adhesives that are compatible with both the copper and the substrate material. Depending on the design requirements, additional elements such as framing or protective coatings may also be applied at this stage to enhance durability and visual appeal.

Finishing: What Quality Assurance Processes Are Involved?

The finishing stage is where the final touches are applied. This includes polishing the surface to enhance shine and detail, applying a protective clear sealant to prevent oxidation, and ensuring that the piece meets design specifications. This stage is crucial for ensuring that the product can withstand the test of time and environmental factors, especially for international shipping and use.

How is Quality Assurance Implemented in Copper Embossing?

Quality assurance (QA) is a critical component of the copper embossing manufacturing process, ensuring that products meet both international standards and customer specifications.

What International Standards Are Relevant to Copper Embossing?

For B2B buyers, particularly those operating in international markets, compliance with standards like ISO 9001 is crucial. This standard outlines requirements for a quality management system (QMS) and is recognized globally. Additionally, industry-specific certifications such as CE marking (which indicates conformity with health, safety, and environmental protection standards) may also be relevant. For buyers from regions like Africa and South America, understanding these standards can help in evaluating supplier capabilities.

What are the Key QC Checkpoints in Copper Embossing?

Quality control in copper embossing typically involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This stage involves the inspection of raw materials, such as copper sheets, to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): During the embossing process, periodic checks are conducted to ensure that the embossing techniques and tools are functioning correctly, and that the designs are being accurately replicated.

-

Final Quality Control (FQC): After the final assembly and finishing, products undergo a comprehensive inspection to verify that they meet design specifications and quality standards. This may involve visual inspections, dimensional checks, and functional tests.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify the quality control practices of suppliers:

-

Conduct Audits: Regular audits of suppliers can provide insights into their quality management processes and adherence to international standards. This can include both scheduled and surprise audits.

-

Request Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including results from IQC, IPQC, and FQC checks. These reports can help buyers assess the reliability of the supplier.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control practices. These services often provide detailed reports that can be invaluable for decision-making.

What Are the Unique QC Considerations for International Buyers?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, there are specific nuances to consider in quality control:

-

Cultural and Regional Standards: Different regions may have varying expectations regarding quality and compliance. Understanding these can help in negotiating and setting clear expectations with suppliers.

-

Logistical Challenges: Shipping and handling of embossed copper products can introduce risks of damage. Suppliers should implement robust packaging and shipping practices to mitigate these risks.

-

Regulatory Compliance: Buyers must ensure that products comply with local regulations in their respective countries, which may differ from international standards. This can include specific material safety standards or import regulations.

In conclusion, understanding the manufacturing processes and quality assurance practices in copper embossing is essential for B2B buyers. By focusing on the stages of production and the relevant quality control measures, buyers can make informed decisions that enhance their procurement strategies and ensure the delivery of high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘copper embossing’

To assist B2B buyers in procuring copper embossing materials and tools effectively, this guide provides a step-by-step checklist designed to streamline the sourcing process. Each step is focused on critical aspects that ensure quality, compliance, and suitability for your specific needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s essential to outline your technical requirements. This includes the gauge of copper sheets, dimensions, and any specific design intricacies you require. Clarity in these specifications will help suppliers provide accurate quotes and avoid misunderstandings during the procurement process.

- Gauge Options: Consider whether you need 36-gauge or 40-gauge copper, as this affects durability and detail.

- Design Complexity: Specify whether you need simple or intricate embossing designs.

Step 2: Research and Identify Suppliers

Conduct thorough research to identify potential suppliers that specialize in copper embossing tools and materials. Look for companies with a strong reputation in the industry, particularly those that have experience serving international markets, including Africa, South America, the Middle East, and Europe.

- Supplier Reviews: Check online reviews and testimonials to gauge supplier reliability and product quality.

- Industry Focus: Prioritize suppliers that cater specifically to your niche to ensure they understand your unique requirements.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet your shortlisted suppliers. Request detailed company profiles, case studies, and references from clients in similar industries or regions. This step helps you gauge their capability and credibility.

- Certifications: Ensure suppliers have relevant certifications that comply with international standards.

- Portfolio Review: Examine their previous projects to assess the quality of their work.

Step 4: Request Samples

Once you have narrowed down your options, request samples of the copper sheets and embossing tools. This allows you to evaluate the quality firsthand and determine if it meets your technical specifications and quality standards.

- Material Quality: Look for signs of durability and ease of manipulation in the samples.

- Tool Effectiveness: Test the embossing tools for comfort and precision in creating your desired designs.

Step 5: Negotiate Terms and Pricing

Engage in discussions with your preferred suppliers regarding pricing, payment terms, and lead times. It’s crucial to ensure that the terms are favorable and align with your budget and project timelines.

- Bulk Discounts: Inquire about pricing structures for larger orders, as many suppliers offer discounts.

- Delivery Timelines: Confirm lead times to ensure they align with your project schedules.

Step 6: Verify Compliance and Shipping Options

Before finalizing your order, verify that the supplier complies with international shipping regulations and can deliver to your location without issues. This step is crucial for avoiding delays or additional costs.

- Customs Documentation: Ensure that the supplier provides all necessary customs paperwork.

- Shipping Partners: Inquire about their logistics partners to assess reliability.

Step 7: Establish a Quality Control Process

Once you receive your order, implement a quality control process to inspect the materials and tools. This will help identify any discrepancies or defects before starting your projects.

- Inspection Criteria: Develop a checklist based on your initial specifications to assess the received items.

- Feedback Loop: Maintain communication with the supplier for any potential issues or future orders.

By following this checklist, B2B buyers can ensure a smooth and efficient sourcing process for copper embossing materials and tools, ultimately leading to successful project outcomes.

Illustrative image related to copper embossing

Comprehensive Cost and Pricing Analysis for copper embossing Sourcing

What Are the Key Cost Components in Copper Embossing?

When evaluating the cost structure of copper embossing, several components come into play. Materials are the primary cost driver, particularly the copper sheets, which vary in thickness (gauges) and quality. Costs can fluctuate based on global copper prices, which are influenced by supply chain dynamics and market demand. For instance, 40-gauge copper is often preferred for its balance between durability and detail, while thicker gauges may be necessary for more robust applications.

Labor costs also represent a significant portion of the overall expenses. Skilled artisans are required to create intricate designs, and their expertise can command higher wages. The time taken to complete a project can vary widely based on complexity, impacting labor costs directly.

Manufacturing overhead includes utilities, equipment maintenance, and facility costs, which should be factored into the pricing model. Additionally, tooling costs for specialized embossing tools can add to the initial investment, particularly for businesses looking to produce unique designs or high-quality outputs.

Quality Control (QC) processes are essential to ensure that the final product meets required specifications. Investing in QC can prevent costly reworks or returns, impacting overall profitability.

Logistics also plays a crucial role, especially for international buyers. Shipping costs can vary significantly depending on the distance, chosen Incoterms, and whether customs duties apply. These logistics costs should be carefully calculated to avoid unexpected expenses.

Illustrative image related to copper embossing

How Do Price Influencers Affect Copper Embossing Costs?

Several factors influence the pricing of copper embossing products. Volume and Minimum Order Quantity (MOQ) are critical; larger orders often result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQs with suppliers to align with their production needs and budget constraints.

Specifications and customization also impact pricing. Custom designs or specific requests can lead to higher costs due to additional labor and material requirements. Buyers should be clear about their specifications to avoid scope creep, which can inflate costs.

Material quality and certifications are increasingly important in the B2B landscape. Suppliers offering certified materials may charge a premium, but this can be a worthwhile investment for ensuring product reliability and compliance with industry standards.

Supplier factors such as reputation, reliability, and geographic location can also affect pricing. Established suppliers may offer better quality assurance but at a higher cost. Buyers should conduct due diligence when selecting suppliers to ensure that they balance cost and quality effectively.

What Are the Best Buyer Tips for Cost-Efficiency in Copper Embossing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding pricing nuances is essential. One effective strategy is to negotiate prices based on long-term partnerships or bulk orders. Building a strong relationship with suppliers can also lead to better pricing and terms.

It’s crucial to consider the Total Cost of Ownership (TCO) when evaluating suppliers. This includes not only the purchase price but also shipping, handling, potential tariffs, and the cost of any necessary modifications. A lower upfront price may not always lead to the best overall value.

Buyers should remain aware of pricing fluctuations in the copper market, which can impact costs significantly. Keeping abreast of market trends and establishing flexible contracts can help mitigate risks associated with price volatility.

Finally, understanding Incoterms is vital for international transactions. Different terms can affect shipping costs, delivery times, and liability, all of which play a role in the total cost structure. Selecting the right Incoterm can lead to substantial savings and smoother transactions.

Disclaimer

Prices for copper embossing materials and services can vary widely based on market conditions, supplier capabilities, and specific project requirements. The information provided here serves as a guideline and may not reflect current market prices. Always conduct thorough research and obtain multiple quotes to ensure accurate budgeting and cost management.

Alternatives Analysis: Comparing copper embossing With Other Solutions

Exploring Alternatives to Copper Embossing: Key Comparisons

When considering copper embossing for decorative or functional applications, it is essential to evaluate other methods that may achieve similar results. This analysis compares copper embossing against two viable alternatives: aluminum embossing and laser engraving. Each method has unique characteristics that can impact your decision based on performance, cost, and practicality.

Illustrative image related to copper embossing

| Comparison Aspect | Copper Embossing | Aluminum Embossing | Laser Engraving |

|---|---|---|---|

| Performance | Excellent detail; flexible designs; 3D texture | Good detail; less flexible than copper; lightweight | High precision; intricate designs; no physical texture |

| Cost | Moderate; material and tools can be expensive | Generally lower; aluminum sheets are cheaper | Higher initial setup cost; machine investment needed |

| Ease of Implementation | Requires specific tools and techniques; moderate skill level | Easier to work with; basic tools sufficient | Requires specialized equipment and training |

| Maintenance | Requires sealing to prevent oxidation; periodic maintenance | Low maintenance; corrosion-resistant | Minimal maintenance; durable results |

| Best Use Case | Artistic projects; high-end decor | Signage, packaging, and crafts | Custom gifts, promotional items, and intricate designs |

In-Depth Analysis of Alternative Solutions

Aluminum Embossing: A Cost-Effective Alternative

Aluminum embossing uses thin sheets of aluminum and is a popular choice for businesses looking for a more budget-friendly option. The process is relatively straightforward, requiring fewer specialized tools compared to copper embossing. However, while aluminum can achieve reasonable detail, it lacks the same depth and texture as copper. Its lightweight nature makes it ideal for signage and packaging, but it may not convey the same premium feel that copper provides.

Laser Engraving: Precision Meets Versatility

Laser engraving employs advanced technology to etch designs onto various materials, including metal, wood, and plastic. This method offers unparalleled precision and can produce intricate designs that are difficult to achieve with traditional embossing techniques. However, the initial investment in laser engraving equipment can be substantial, making it less accessible for smaller businesses. While maintenance is minimal, the lack of physical texture means that it might not be suitable for projects requiring a tactile element.

Making the Right Choice for Your Business Needs

When selecting between copper embossing and its alternatives, consider the specific requirements of your projects. If your focus is on high-quality, textured artwork that exudes luxury, copper embossing is likely the best option. On the other hand, if budget constraints and ease of implementation are your primary concerns, aluminum embossing may be the ideal solution. For businesses aiming for precision and detail without the need for physical texture, laser engraving stands out as a versatile choice. Ultimately, aligning your decision with your project goals, budget, and available resources will guide you in selecting the most suitable method for your needs.

Essential Technical Properties and Trade Terminology for copper embossing

What Are the Key Technical Properties of Copper Used in Embossing?

Understanding the technical properties of copper is crucial for B2B buyers involved in copper embossing. Here are some of the essential specifications to consider:

-

Material Grade

Copper used in embossing typically falls under specific grades, such as C11000 (Electrolytic Tough Pitch). This grade is preferred for its high electrical and thermal conductivity. Selecting the right grade is vital for ensuring quality and performance in the final embossed product. -

Thickness (Gauge)

Copper sheets are available in various thicknesses, commonly measured in gauges. For embossing, gauges such as 36, 40, and 32 are standard. A thinner gauge (like 40) allows for finer details but may be more fragile, while thicker gauges (like 32) provide durability. Understanding the appropriate gauge for your project is essential for achieving the desired aesthetic and structural integrity. -

Tensile Strength

This refers to the maximum amount of tensile (pulling) stress that a material can withstand before failure. For copper used in embossing, a tensile strength of around 200-210 MPa is common. Knowing the tensile strength helps manufacturers gauge how much manipulation the copper can endure during the embossing process without tearing or deforming. -

Surface Finish

The surface finish of copper sheets can impact the embossing process. A smooth finish is preferable for detailed designs, while a textured surface can create unique effects. Buyers should consider the required surface finish to meet aesthetic or functional requirements. -

Thermal Conductivity

Copper is known for its excellent thermal conductivity, which can be significant during embossing processes that involve heat (like patina application). Understanding thermal properties helps in selecting the right tools and methods, ensuring optimal results in the final product.

What Are Common Trade Terms in Copper Embossing?

Familiarity with trade terminology enhances communication between buyers and suppliers. Here are some common terms relevant to copper embossing:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In copper embossing, OEMs are often responsible for producing customized designs and components that meet specific client needs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to ensure that they meet supplier requirements, which can affect pricing and availability. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to suppliers requesting pricing and terms for specific quantities of products. For copper embossing, submitting an RFQ can help buyers compare prices and terms from multiple suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for managing logistics, shipping costs, and delivery timelines in global copper embossing orders. -

Lead Time

This term refers to the time it takes from placing an order to receiving the product. Understanding lead times in copper embossing is critical for project planning and inventory management, particularly when sourcing from international suppliers. -

Patina

Patina refers to the chemical treatment applied to copper to achieve a desired color or finish. This is particularly relevant in copper embossing, as different patinas can enhance the visual appeal of embossed designs. Knowing how to specify patina options can differentiate products in a competitive market.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions and effectively communicate with suppliers, ultimately leading to successful copper embossing projects.

Navigating Market Dynamics and Sourcing Trends in the copper embossing Sector

What Are the Key Trends Influencing the Global Copper Embossing Market?

The copper embossing market is witnessing significant growth driven by various global factors. Increased demand for customized decorative elements in architecture and interior design is propelling the use of copper embossing in both residential and commercial sectors. Furthermore, the rise of artisanal craftsmanship is leading to a resurgence in traditional techniques, appealing to consumers seeking unique, handcrafted products. Technological advancements also play a crucial role; digital tools and software are streamlining the design process, allowing for more intricate patterns and designs that cater to the specific tastes of international buyers.

In terms of sourcing trends, there is a noticeable shift towards local suppliers, especially in regions like Africa and South America. This change is largely due to the growing emphasis on reducing lead times and shipping costs. Additionally, international buyers are increasingly leveraging e-commerce platforms for sourcing, which enhances accessibility to a wider range of products and suppliers. For instance, platforms that facilitate direct communication with artisans or manufacturers can provide a competitive edge, allowing buyers to negotiate terms and customize orders more effectively.

Illustrative image related to copper embossing

How Is Sustainability Influencing Sourcing in the Copper Embossing Industry?

Sustainability is becoming a critical consideration in the copper embossing sector. The environmental impact of mining and processing copper is significant, which has led to increased scrutiny from both consumers and regulatory bodies. International buyers are now prioritizing suppliers that adhere to sustainable practices and demonstrate a commitment to ethical sourcing. This includes utilizing recycled materials and ensuring that the copper is sourced from mines that follow responsible environmental and labor practices.

Ethical supply chains are further enhanced by certifications that indicate a product’s sustainability credentials. Buyers are advised to look for ‘green’ certifications that verify the environmental impact of the sourcing process. This not only meets the growing consumer demand for sustainable products but also mitigates risks associated with non-compliance with regulations. By adopting these practices, companies can enhance their brand reputation and appeal to a more conscientious consumer base.

What Is the Historical Context of Copper Embossing Relevant to Today’s Market?

Copper embossing has a rich history that dates back thousands of years, with its origins rooted in ancient civilizations that utilized this technique for decorative and functional purposes. Over time, the craft has evolved, integrating various artistic styles and techniques. The transition from functional uses to artistic applications in the modern era has opened new markets for international buyers.

In recent decades, the revival of interest in handcrafted and artisanal goods has breathed new life into the copper embossing industry. This trend is particularly relevant for B2B buyers who are seeking unique products that reflect cultural heritage and craftsmanship. By understanding the historical context of copper embossing, buyers can better appreciate the value of the products they are sourcing and the stories behind them, which can be a significant selling point in today’s market.

Illustrative image related to copper embossing

In summary, the copper embossing sector is characterized by dynamic market trends driven by consumer preferences, technological advancements, and a growing focus on sustainability. For international B2B buyers, leveraging these insights can lead to more informed sourcing decisions and enhanced competitiveness in their respective markets.

Frequently Asked Questions (FAQs) for B2B Buyers of copper embossing

-

1. How do I choose the right copper embossing supplier?

When selecting a supplier for copper embossing, consider their experience and expertise in the field. Look for suppliers who specialize in copper materials and have a proven track record of delivering high-quality products. Check reviews and testimonials from previous clients to gauge reliability. Additionally, assess their production capabilities, lead times, and willingness to accommodate custom designs. Establish clear communication channels to ensure that your specifications are understood and met throughout the process. -

2. What is the minimum order quantity (MOQ) for copper embossing products?

Minimum order quantities can vary significantly between suppliers. Many manufacturers may set an MOQ based on production costs and material usage, often ranging from 100 to 500 units. However, some suppliers may offer flexibility for smaller businesses or custom projects. It’s essential to discuss your specific requirements with potential suppliers and confirm their MOQs to ensure they align with your business needs. -

3. What are the typical payment terms for international copper embossing orders?

Payment terms for international copper embossing orders can vary based on supplier policies and the buyer’s location. Common terms include a deposit (usually 30-50%) upfront, with the balance due upon completion or prior to shipping. Some suppliers may offer payment via letters of credit or escrow services for added security. Always clarify payment terms before finalizing orders to avoid any misunderstandings and ensure a smooth transaction. -

4. How can I ensure the quality of my copper embossing products?

To ensure quality, request samples from potential suppliers before placing a bulk order. Review their quality assurance processes and certifications, such as ISO standards. Establish clear specifications for your products, including dimensions, design intricacies, and material thickness. Regular communication and updates during the production process can help address any potential issues early, ensuring that the final products meet your expectations. -

5. What customization options are available for copper embossing designs?

Customization options for copper embossing can include various design intricacies, sizes, and finishes. Many suppliers allow you to submit your designs or collaborate on new concepts. You can also specify the thickness of the copper sheet and any desired textures or patinas. Discuss your requirements with suppliers to explore their capabilities and ensure that your vision can be accurately realized. -

6. How do I manage logistics and shipping for international copper embossing orders?

Managing logistics for international orders involves coordinating with suppliers on shipping options, costs, and delivery timelines. Consider using freight forwarders who specialize in international shipping to streamline the process. Be aware of customs regulations and duties in your country, as these can affect delivery times and overall costs. Maintain clear communication with your supplier regarding shipping methods, tracking, and expected arrival dates. -

7. What are the common applications for copper embossing in various industries?

Copper embossing is widely used in art, architecture, and decorative items. It can be found in custom signage, architectural elements, jewelry, and interior design features. Industries such as hospitality and retail often use embossed copper for unique branding elements. Understanding the applications relevant to your business can help you source the right products and designs that align with market trends and customer preferences. -

8. How can I effectively communicate my design requirements to a copper embossing supplier?

Effective communication starts with providing detailed design specifications, including sketches or digital files. Clearly outline dimensions, textures, and any specific techniques you want to be used in the embossing process. Use visual references to illustrate your vision and discuss any potential challenges upfront. Establish regular check-ins with the supplier to ensure alignment throughout the design and production phases, allowing for adjustments as needed.

Top 4 Copper Embossing Manufacturers & Suppliers List

1. Basic Copper – Christmas Tree Ornament Craft Kit

Domain: basiccopper.com

Registered: 2006 (19 years)

Introduction: Copper Christmas Tree Ornament Craft Kit: Sale Price: $35.99; Embossing Pad- Black Neoprene: Sale Price: $6.04; Paper Stump Texture Tool: Sale Price: $2.99; Copper Embossing Tool Kit- (8) Larger Ball Stylus Tips: Sale Price: $8.25; Copper Embossing Tool Grab Bag-5 piece: Sale Price: $29.89; Embossed Metal Backing Paste- 4 oz.: Sale Price: $15.99; Copper Embossing Stylus Set- (10) Ball Tips: Sale P…

2. Deborah Shapiro Art – Foil Embossing Essentials

Domain: deborahshapiroart.com

Registered: 2014 (11 years)

Introduction: • Copper or silver foil (available at local art and crafts stores or on Amazon) • Tracing paper (found at fabric stores) • Large piece of foam core • Embossing tools (wood sculpting items for clay) • Sharp pointed tool (like a pen) • Hammer • Maid-O-Metal Plastic Luster

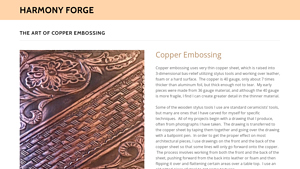

3. Harmony Forge – Copper Embossing Solutions

Domain: harmonyforge.com

Registered: 1999 (26 years)

Introduction: Copper embossing utilizes very thin 40 gauge copper sheet, which is about 7 times thicker than aluminum foil but not prone to tearing. The process involves creating 3-dimensional bas-relief designs using stylus tools on leather, foam, or hard surfaces. The artist begins with a drawing, often based on photographs, which is transferred to the copper sheet. Techniques include working from both sides …

4. OWOSSO – High Quality Copper Dies

Domain: owosso.com

Registered: 1995 (30 years)

Introduction: OWOSSO produces high quality copper dies for embossing with next day production on nearly 100 percent of orders. Copper dies are suitable for longer press runs and more durable metal requirements. Available as single dies or with a fiberglass counter die, they are made from ¼ inch copper. Factors to consider when choosing between copper, magnesium, or brass dies include surface area pressure, artw…

Strategic Sourcing Conclusion and Outlook for copper embossing

As the demand for copper embossing continues to rise across various industries, the importance of strategic sourcing cannot be overstated. By focusing on high-quality materials, such as 40-gauge copper sheets, and utilizing specialized tools like dual-ended stylus sets, businesses can enhance their production capabilities and deliver exceptional products. This approach not only fosters innovation but also positions companies to meet the unique needs of diverse markets, including those in Africa, South America, the Middle East, and Europe.

Moreover, international buyers should prioritize partnerships with reliable suppliers who understand the nuances of the embossing process and can provide consistent quality and support. Investing in advanced techniques and sustainable sourcing methods will be vital for staying competitive in an evolving landscape.

Looking ahead, the copper embossing market is set to expand, driven by trends in architecture, art, and design. B2B buyers are encouraged to explore these opportunities, ensuring they are well-equipped to capitalize on the growing interest in embossed copper products. Embrace the future of copper embossing—connect with suppliers today to enhance your offerings and drive your business forward.

Illustrative image related to copper embossing

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.