Unlocking Value: A Strategic Analysis of the Conveyor Screws Market

Introduction: Navigating the Global Market for conveyor screws

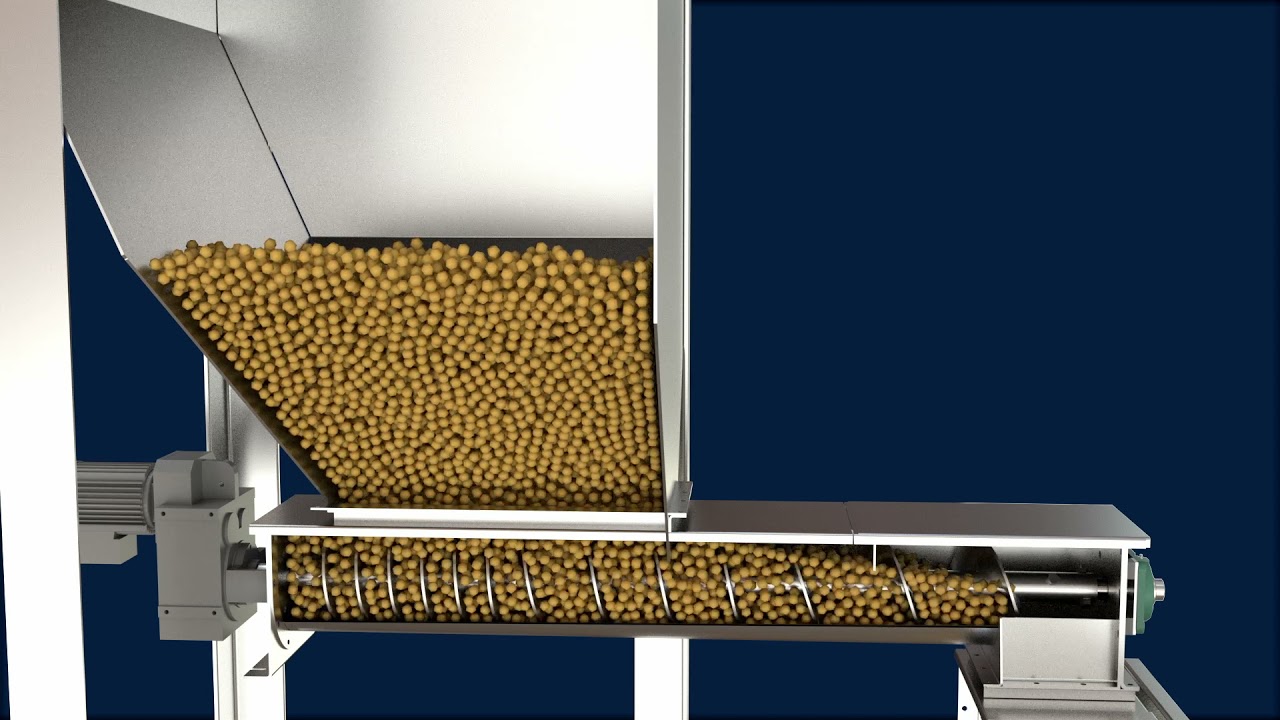

In the ever-evolving landscape of global commerce, sourcing the right conveyor screws can be a daunting challenge for B2B buyers. With their critical role in facilitating efficient material handling across various industries, understanding the nuances of conveyor screw options is essential. This guide is designed to demystify the complexities surrounding conveyor screws, covering a broad spectrum of topics including types, applications, supplier vetting, and cost considerations.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe—encompassing countries such as Germany and Nigeria—face unique challenges in finding reliable suppliers and ensuring product quality. This comprehensive resource empowers you to navigate these challenges effectively, offering actionable insights to streamline your purchasing decisions.

From selecting the ideal screw type based on application needs to evaluating suppliers and understanding pricing structures, this guide provides the expertise necessary to make informed choices. By leveraging the knowledge within these pages, you can enhance operational efficiency and ensure that your conveyor systems operate at peak performance, ultimately leading to greater business success.

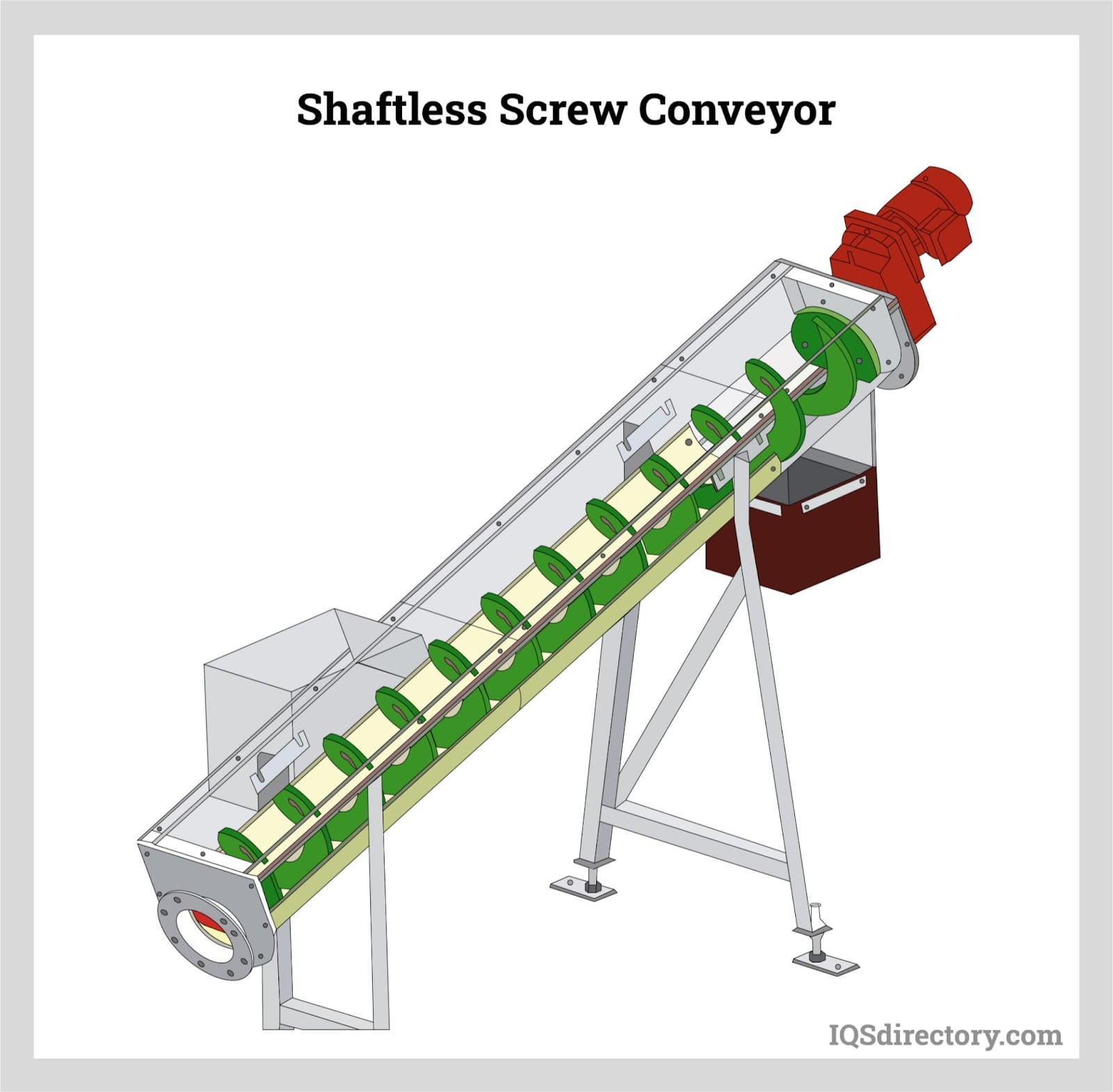

Understanding conveyor screws Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Helicoid Screws | Continuous spiral design, suitable for light to medium-duty applications | Grain handling, food processing | Pros: Cost-effective, easy to install. Cons: Limited in heavy-duty applications. |

| Sectional Screws | Composed of individual sections, customizable configurations | Heavy industrial applications, mining | Pros: Versatile, can handle various materials. Cons: More expensive, requires more assembly time. |

| Quick Change Screws | Designed for easy replacement without disassembling the conveyor | Manufacturing, recycling | Pros: Minimizes downtime, enhances maintenance efficiency. Cons: Initial cost may be higher. |

| Ribbon Screws | Feature a flat spiral design, ideal for mixing and agitation | Chemical processing, food production | Pros: Effective for blending materials. Cons: May not be suitable for all material types. |

| Left-Hand Screws | Reverse spiral design, used for specific directional needs | Specialty applications, niche markets | Pros: Tailored for unique flow requirements. Cons: Less common, may have limited availability. |

What Are the Characteristics of Helicoid Screws?

Helicoid screws are characterized by their continuous spiral design, which allows for efficient material movement in light to medium-duty applications. They are commonly used in grain handling and food processing due to their straightforward installation and cost-effectiveness. B2B buyers should consider the load capacity and material compatibility when selecting helicoid screws, ensuring they meet the specific needs of their operations without exceeding budget constraints.

Illustrative image related to conveyor screws

How Do Sectional Screws Differ from Other Types?

Sectional screws consist of individual sections that can be configured to meet various application requirements. This adaptability makes them ideal for heavy industrial environments, such as mining and bulk material handling. While they offer versatility and the ability to handle abrasive materials, buyers should weigh the higher costs and assembly time against the benefits of tailored solutions for their operations.

Why Choose Quick Change Screws for Your Operations?

Quick change screws are designed for rapid replacement, allowing businesses to minimize downtime during maintenance. This feature is particularly valuable in manufacturing and recycling sectors, where operational efficiency is critical. While they may come with a higher initial investment, the long-term savings in maintenance time and increased productivity can justify the cost for many B2B buyers.

What Are the Benefits of Using Ribbon Screws?

Ribbon screws, with their flat spiral design, excel in applications requiring mixing and agitation, such as in chemical processing and food production. Their ability to blend materials effectively makes them a preferred choice for manufacturers looking to enhance product quality. However, buyers should consider whether ribbon screws suit their specific material types and operational needs, as they may not be universally applicable.

When Should You Consider Left-Hand Screws?

Left-hand screws are designed with a reverse spiral to accommodate specific directional flow needs. These specialized screws are ideal for niche markets and applications where conventional right-hand screws may not suffice. While they can provide tailored solutions, buyers should be aware of their less common availability and potential sourcing challenges, especially in regions with limited suppliers.

Key Industrial Applications of conveyor screws

| Industry/Sector | Specific Application of Conveyor Screws | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Transporting bulk ingredients like grains and powders | Ensures hygienic, efficient, and accurate material handling | Compliance with food safety standards, material quality, and easy cleaning features |

| Agriculture | Moving fertilizers and animal feed | Increases productivity and minimizes waste | Durability for abrasive materials, customization for specific bulk types |

| Mining | Conveying minerals and ores | Enhances operational efficiency and reduces labor costs | Resistance to wear and tear, ability to handle heavy loads, and adaptability to various terrains |

| Chemical Manufacturing | Transporting chemicals and powders | Maintains safety and precision in handling hazardous materials | Material compatibility, corrosion resistance, and compliance with safety regulations |

| Waste Management | Moving and sorting recyclables and waste materials | Improves recycling efficiency and reduces operational downtime | Customization for different waste types, ease of maintenance, and robust construction |

How Are Conveyor Screws Used in Food Processing?

In the food processing industry, conveyor screws play a crucial role in the transportation of bulk ingredients such as grains, sugar, and flour. Their design allows for hygienic handling, ensuring that food products remain uncontaminated during transit. This sector often requires compliance with stringent food safety standards, making it essential for buyers to source conveyor screws made from food-grade materials that are easy to clean and maintain. Additionally, the ability to customize screw designs for specific ingredient types can enhance efficiency and reduce waste.

What Are the Applications of Conveyor Screws in Agriculture?

Conveyor screws are widely used in agriculture for transporting fertilizers, seeds, and animal feed. Their effectiveness in moving bulk materials helps farmers increase productivity while minimizing waste during the handling process. Buyers in this sector should consider the durability of the conveyor screws, as they often deal with abrasive materials that can wear down equipment quickly. Customization options, such as flight design and pitch, can also optimize performance for specific agricultural applications.

How Do Conveyor Screws Benefit the Mining Industry?

In mining operations, conveyor screws are essential for the efficient transportation of minerals and ores from extraction sites to processing facilities. These systems enhance operational efficiency by reducing the need for manual labor and minimizing the risk of material loss. Buyers must prioritize sourcing conveyor screws that are resistant to wear and tear, capable of handling heavy loads, and adaptable to various terrains. The right specifications can significantly impact productivity and operational costs.

What Is the Role of Conveyor Screws in Chemical Manufacturing?

Chemical manufacturing relies on conveyor screws to transport various chemicals and powders safely and accurately. These screws must be constructed from materials that can withstand corrosive substances while ensuring safety throughout the handling process. For B2B buyers in this sector, it is vital to consider material compatibility, corrosion resistance, and compliance with industry-specific safety regulations. Proper sourcing can mitigate risks associated with hazardous materials and enhance overall operational efficiency.

How Are Conveyor Screws Utilized in Waste Management?

In waste management, conveyor screws are instrumental in the efficient movement and sorting of recyclables and waste materials. They improve recycling efficiency by streamlining the process, reducing operational downtime, and optimizing resource recovery. Buyers should focus on sourcing conveyor screws that can be customized for different waste types, ensuring robust construction for long-lasting performance. Ease of maintenance and adaptability to various waste handling systems are also critical considerations for effective waste management operations.

3 Common User Pain Points for ‘conveyor screws’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Screw Type for Specific Applications

The Problem: B2B buyers often face challenges when selecting the appropriate type of conveyor screw for their specific application needs. With a wide range of screw types—such as helicoid, sectional, and ribbon screws—understanding the best fit for material characteristics and operational requirements can be overwhelming. Incorrect selection can lead to inefficiencies, increased wear and tear, and ultimately, costly downtime in production.

The Solution: To effectively source the right conveyor screw, buyers should begin by conducting a thorough assessment of the materials they intend to transport. Key factors include the material’s bulk density, flow characteristics, and abrasiveness. For light to medium-duty applications, helicoid screws are often the most economical choice, while sectional screws are better suited for heavy-duty or abrasive materials due to their customizable features. Collaborating with manufacturers who offer comprehensive product guides and consultation services can also aid in making informed decisions. Additionally, buyers should request samples or prototypes to test compatibility with their systems before committing to larger orders.

Scenario 2: Frequent Maintenance Issues Leading to Operational Downtime

The Problem: Many B2B buyers experience frequent maintenance issues with their conveyor systems due to the complexity and wear of traditional screw designs. Dismantling the entire conveyor system for repairs can be a daunting and time-consuming task, leading to significant operational downtime and increased labor costs. This is particularly problematic in industries where continuous material flow is crucial, such as food processing or mining.

The Solution: Investing in quick-change conveyor screws can significantly alleviate maintenance challenges. These screws are designed with a clamping key system that allows for easy removal and replacement without the need to disassemble the entire conveyor. Buyers should look for suppliers who offer quick-change solutions and ensure that these components are placed strategically in the conveyor system for easy access. Regular training for maintenance staff on the quick-change process can also enhance efficiency, ensuring minimal disruption during repairs.

Scenario 3: Inadequate Customization Options for Unique Applications

The Problem: In many cases, B2B buyers find that standard conveyor screw options do not meet their specific operational requirements. Factors such as unique material properties, environmental conditions, and specific space constraints often necessitate customized solutions. Without the ability to customize, businesses may experience inefficiencies, which can lead to increased operational costs and reduced productivity.

The Solution: Buyers should prioritize suppliers that offer extensive customization options for conveyor screws. This includes the ability to modify screw flight design, materials used (such as stainless steel for corrosive environments), and even screw length and diameter to fit specific space constraints. Engaging with manufacturers early in the design process can facilitate tailored solutions that align with operational needs. Additionally, utilizing software tools for modeling and simulation can help visualize how customized screws will perform in their specific systems, further ensuring that investments are well-aligned with operational goals.

By addressing these common pain points with actionable solutions, B2B buyers can enhance their material handling efficiency, reduce maintenance costs, and ensure their conveyor systems are optimized for their unique applications.

Strategic Material Selection Guide for conveyor screws

When selecting materials for conveyor screws, it is essential to consider various factors that impact performance, durability, and cost. Below, we analyze four common materials used in the manufacturing of conveyor screws, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What are the Key Properties of Carbon Steel for Conveyor Screws?

Carbon Steel is one of the most widely used materials for conveyor screws due to its excellent strength and versatility. It typically has a temperature rating of up to 400°F (204°C) and can withstand moderate pressure. Carbon steel offers good wear resistance, making it suitable for transporting bulk materials.

Illustrative image related to conveyor screws

Pros include its high durability and relatively low cost, making it an economical choice for many applications. However, cons involve its susceptibility to corrosion, which can limit its use in humid or corrosive environments unless properly coated or treated. For international buyers, compliance with standards such as ASTM A36 is crucial, especially in regions like Germany and Nigeria, where material quality is strictly regulated.

How Does Stainless Steel Compare for Conveyor Screws?

Stainless Steel, particularly grades like 304 and 316, is known for its exceptional corrosion resistance and ability to maintain strength at high temperatures (up to 1500°F or 815°C). This makes it ideal for applications involving food processing, pharmaceuticals, or any environment where hygiene is critical.

The key advantage of stainless steel is its longevity and minimal maintenance requirements. However, the key disadvantage is its higher cost compared to carbon steel, which may be a consideration for budget-sensitive projects. For B2B buyers in regions like the Middle East, where corrosion is a significant concern due to environmental conditions, stainless steel is often the preferred choice. Compliance with standards like ASTM A240 is essential for ensuring material quality and safety.

What are the Benefits and Limitations of Aluminum for Conveyor Screws?

Aluminum is a lightweight material that offers excellent resistance to corrosion and is easy to fabricate. It can operate effectively at temperatures up to 400°F (204°C) and is suitable for applications where weight reduction is a priority.

The key advantage of aluminum is its low weight, which reduces energy costs during operation and allows for easier installation. However, its key disadvantage is lower strength compared to steel, which may limit its use in heavy-duty applications. International buyers should consider the availability of aluminum grades that comply with standards such as ASTM B221, particularly in regions like South America, where material sourcing can vary.

When Should You Use Plastic for Conveyor Screws?

Plastic, specifically high-density polyethylene (HDPE) or polyvinyl chloride (PVC), is increasingly used for conveyor screws in applications involving food, chemicals, or pharmaceuticals due to its excellent chemical resistance and lightweight nature. Plastic screws can typically handle temperatures up to 180°F (82°C).

Illustrative image related to conveyor screws

The key advantage of plastic is its resistance to corrosion and chemicals, making it suitable for a wide range of media. However, the key disadvantage is its lower mechanical strength, which may not be suitable for heavy or abrasive materials. For international buyers, understanding local regulations regarding plastic materials in food-grade applications is critical, particularly in Europe, where compliance with FDA or EU standards is mandatory.

Summary Table of Material Selection for Conveyor Screws

| Material | Typical Use Case for conveyor screws | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General bulk material handling | High durability | Susceptible to corrosion | Low |

| Stainless Steel | Food processing and corrosive environments | Exceptional corrosion resistance | Higher cost | High |

| Aluminum | Lightweight applications, energy-efficient use | Low weight | Lower strength | Medium |

| Plastic | Chemical handling and food applications | Excellent chemical resistance | Lower mechanical strength | Medium |

This guide provides a comprehensive overview of material options for conveyor screws, enabling international B2B buyers to make informed decisions based on their specific operational needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for conveyor screws

What Are the Main Stages in the Manufacturing Process of Conveyor Screws?

The manufacturing process of conveyor screws involves several critical stages that ensure the final product meets the required specifications and quality standards. Understanding these stages is essential for B2B buyers looking to partner with reliable suppliers.

Material Preparation: What Raw Materials Are Used?

The first step in manufacturing conveyor screws is material preparation. Common materials used include carbon steel, stainless steel, and various alloys, depending on the application requirements. For instance, stainless steel is preferred for applications involving corrosive materials, while carbon steel is often used for standard applications due to its cost-effectiveness.

Before production, raw materials undergo rigorous inspection to ensure they meet the specifications. This may involve checking for chemical composition and mechanical properties, which are critical for the durability and performance of the conveyor screws. Suppliers should provide material certificates to verify compliance with industry standards.

Illustrative image related to conveyor screws

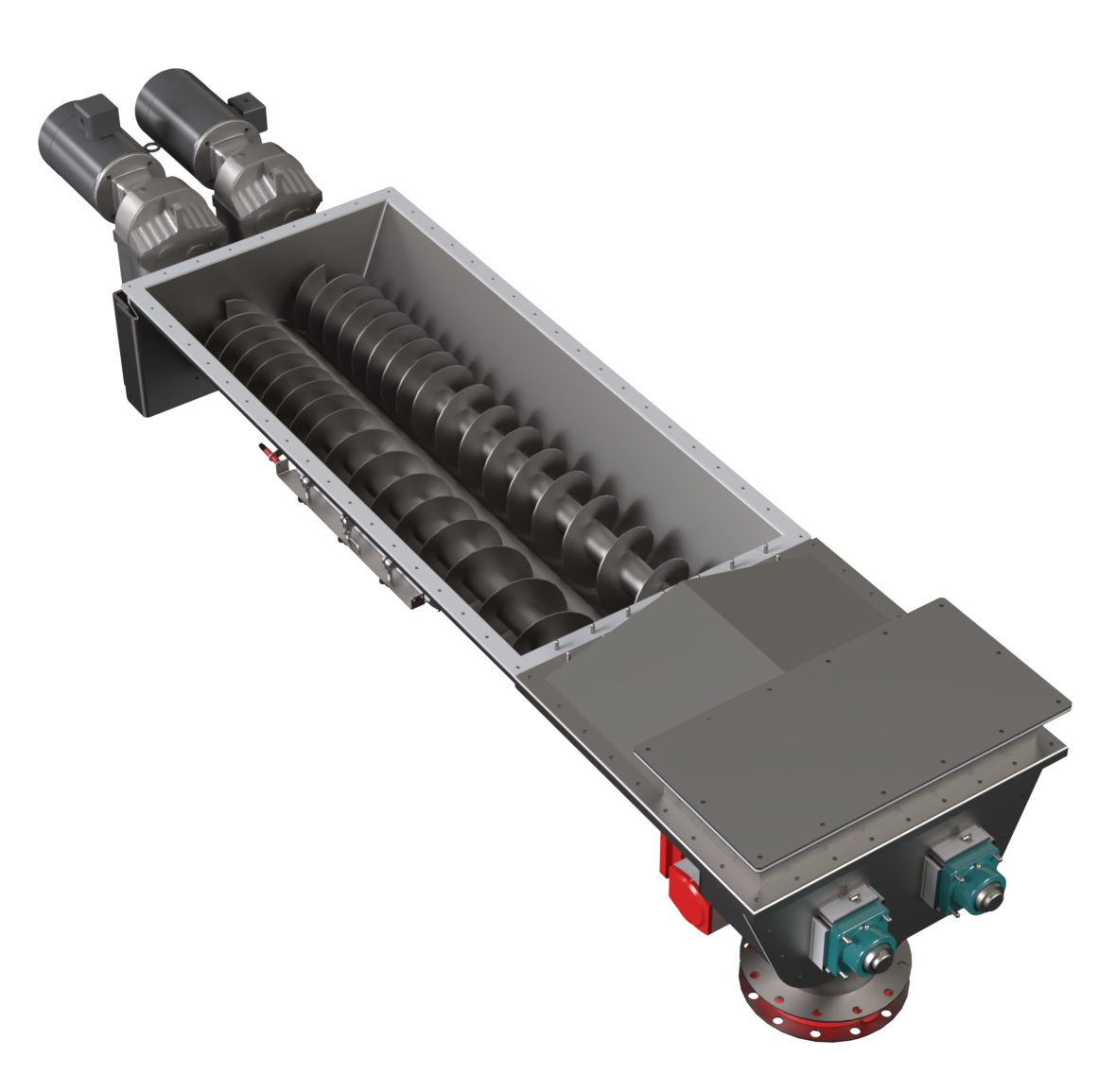

Forming: How Are Conveyor Screws Shaped?

The forming stage involves shaping the raw materials into the desired screw profiles. This process typically employs techniques such as:

- Machining: Involves cutting the material to create the helical flight and shaft. CNC (Computer Numerical Control) machines are often used for precision.

- Forging: This method enhances material strength by shaping it under high pressure, which can improve fatigue resistance.

- Welding: For sectional screws, welding may be employed to join different sections, allowing for custom lengths and configurations.

Each method has its advantages, and the choice depends on the intended use of the conveyor screw. For example, welded screws allow for greater flexibility in design but may require additional quality checks to ensure joint integrity.

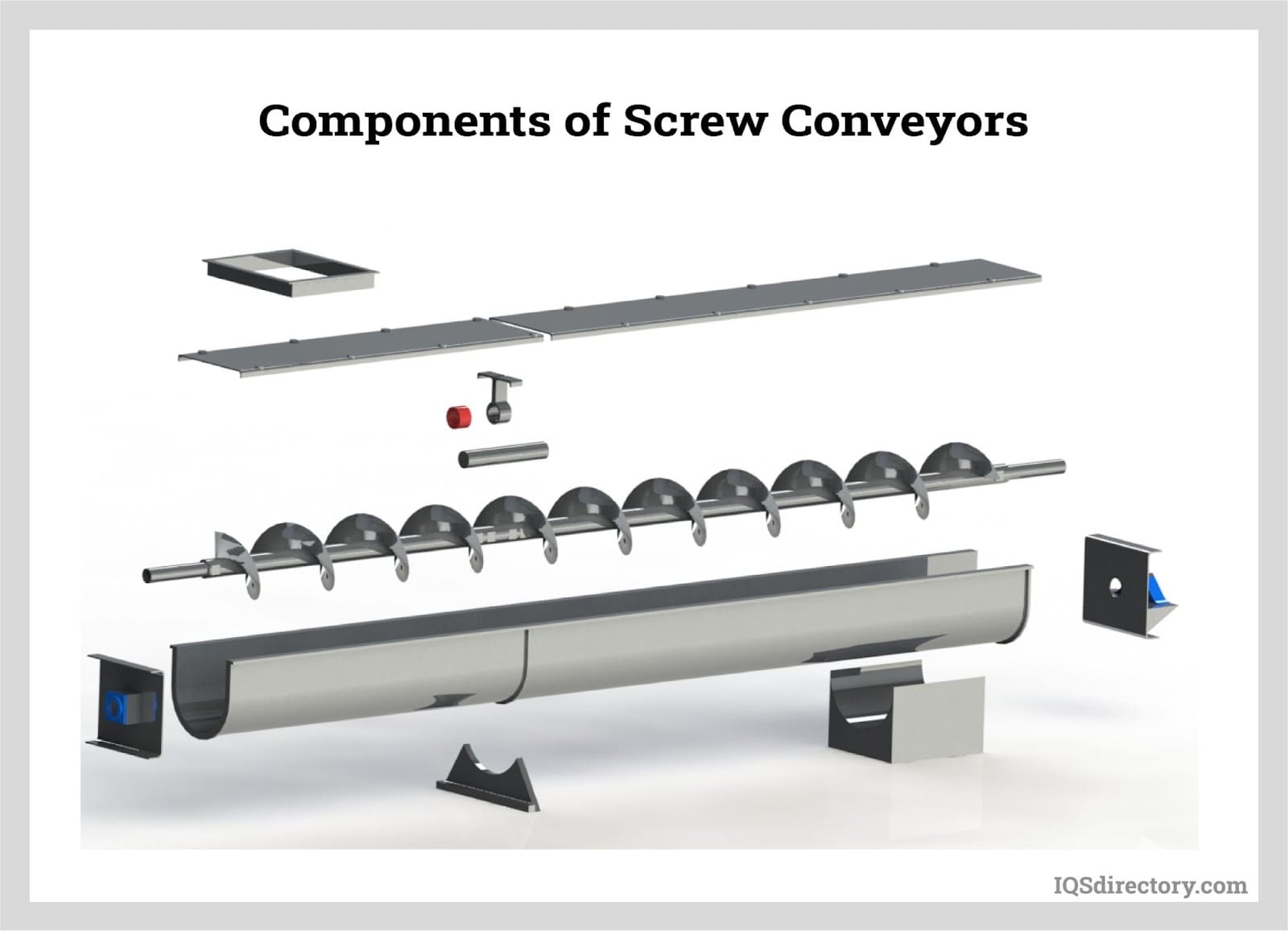

Assembly: What Are the Key Steps?

Once the individual components are formed, the assembly process begins. This stage includes:

- Fitting the Flights to the Shaft: Ensuring the flights are securely attached to the shaft to prevent slippage during operation.

- Installing Hanger Bearings: These are critical for supporting the screw and ensuring smooth operation. The choice of bearings, such as UHMW or wood, can affect performance and maintenance needs.

- Quality Checks During Assembly: Assemblers conduct visual inspections to identify any defects or misalignments before moving to the next stage.

Effective assembly techniques are crucial for ensuring the longevity and reliability of conveyor screws in demanding environments.

Finishing: How Is the Surface Prepared?

The finishing stage involves surface treatments to enhance durability and performance. Common techniques include:

- Coating: Applying protective coatings, such as powder coating or galvanization, helps prevent corrosion and wear, particularly in harsh environments.

- Grinding and Polishing: These processes improve surface smoothness, reducing friction and wear during operation.

Finishing processes should comply with relevant international standards, ensuring the screws perform optimally in their intended applications.

What Quality Assurance Practices Are Commonly Used?

Quality assurance is a critical aspect of the manufacturing process for conveyor screws. B2B buyers should be aware of the relevant standards and practices to ensure they partner with reputable suppliers.

Illustrative image related to conveyor screws

Which International Standards Should Suppliers Comply With?

Suppliers should adhere to international quality management standards such as ISO 9001, which outlines the requirements for a quality management system (QMS). Compliance with ISO 9001 ensures that manufacturers consistently meet customer and regulatory requirements.

In addition to ISO, industry-specific certifications like CE marking for European markets and API standards for oil and gas applications are essential. These certifications demonstrate that the products meet safety, health, and environmental protection standards.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are essential throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet specifications before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing ensures that any deviations from standards are identified and corrected promptly.

- Final Quality Control (FQC): The finished products undergo rigorous testing and inspection to confirm they meet all specified requirements before shipment.

B2B buyers should request detailed reports on these QC processes to ensure they align with their expectations and requirements.

What Common Testing Methods Are Used?

Various testing methods are employed to validate the quality and performance of conveyor screws. Common methods include:

- Tensile Testing: Measures the strength of materials to ensure they can withstand operational stresses.

- Hardness Testing: Assesses the resistance of the material to deformation, which is crucial for durability.

- Dimensional Inspection: Ensures that all components meet specified tolerances, which is critical for compatibility and performance.

These testing methods provide insight into the structural integrity and reliability of the conveyor screws.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying the quality control processes of potential suppliers is essential for ensuring product reliability. Here are effective ways to conduct this verification:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control systems, and overall operational practices.

- Requesting Quality Reports: Buyers should ask for detailed quality assurance reports that outline the QC procedures, testing results, and any certifications held by the supplier.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality practices and product compliance.

What Are the Quality Control Nuances for International Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of the nuances in quality control that may affect their procurement decisions. Differences in regulatory standards, material availability, and manufacturing capabilities can impact the quality of conveyor screws. It is crucial to establish clear communication with suppliers regarding specific requirements and expectations, especially when dealing with international shipping and customs regulations.

In conclusion, understanding the manufacturing processes and quality assurance practices for conveyor screws is vital for B2B buyers. By focusing on these areas, buyers can make informed decisions and select reliable suppliers that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘conveyor screws’

To ensure a successful procurement process for conveyor screws, it is essential to follow a structured approach. This guide outlines the critical steps that B2B buyers should consider to make informed decisions, ensuring that they select the most suitable products for their applications.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is crucial. Consider the type of materials to be conveyed, the required screw diameter, and the necessary length and pitch. These factors will influence the performance and efficiency of your conveyor system.

- Material Characteristics: Identify whether the materials are abrasive, free-flowing, or heavy. This will determine the type of screw (helicoid or sectional) and material (e.g., stainless steel) you should select.

- Operating Environment: Consider factors such as temperature, humidity, and potential exposure to corrosive substances, which may affect material choice.

Step 2: Identify Your Application Needs

Different applications require different configurations of conveyor screws. Assess whether your application is light-duty, medium-duty, or heavy-duty to ensure optimal performance.

- Screw Type: Choose between helicoid and sectional screws based on the application’s complexity. Helicoid screws are typically more cost-effective for lighter applications.

- Special Features: Determine if you need specific features like quick-change designs for easier maintenance or custom lengths for unique installations.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they meet your quality and service expectations.

- Company Reputation: Look for reviews and testimonials from other B2B buyers within your industry. A supplier with a strong reputation is likely to provide reliable products and services.

- Certifications and Standards: Verify that the supplier adheres to industry standards and certifications, which can be indicative of quality assurance.

Step 4: Request Detailed Quotes

Once you have shortlisted potential suppliers, request detailed quotes. This will help you compare pricing and understand what is included in each offer.

- Breakdown of Costs: Ensure that the quote includes all costs associated with the screw, including shipping, handling, and any additional components needed.

- Lead Times: Inquire about production and delivery timelines, especially if you have urgent needs.

Step 5: Assess After-Sales Support and Warranty

Consider the level of support and warranty provided by the supplier. A reliable after-sales service can save you time and money in the long run.

- Technical Support: Ensure the supplier offers technical assistance for installation and maintenance.

- Warranty Terms: Review warranty coverage carefully to understand what is protected and for how long, as this can impact your long-term operational costs.

Step 6: Confirm Payment Terms and Conditions

Understanding the payment structure is vital to avoid any financial surprises.

- Flexible Payment Options: Look for suppliers that offer flexible payment terms, which can help manage cash flow.

- Contractual Obligations: Carefully read the terms of the contract to ensure that there are no hidden fees or unfavorable conditions.

Step 7: Establish Communication Channels

Effective communication is key throughout the procurement process.

- Point of Contact: Establish a clear point of contact within the supplier’s organization for any questions or issues that may arise.

- Regular Updates: Agree on how often you will receive updates regarding the status of your order, which can help in planning your operations.

By following these steps, B2B buyers can streamline their sourcing process for conveyor screws, ensuring they select the right products and suppliers for their specific needs.

Comprehensive Cost and Pricing Analysis for conveyor screws Sourcing

What Are the Key Cost Components in Sourcing Conveyor Screws?

When sourcing conveyor screws, understanding the cost structure is essential for international B2B buyers. The main cost components include:

-

Materials: The type of material used for manufacturing conveyor screws significantly impacts pricing. Common materials include carbon steel, stainless steel, and specialized alloys, with stainless steel typically commanding a higher price due to its durability and resistance to corrosion.

-

Labor: Labor costs can vary by region, reflecting the local wage levels and the complexity of manufacturing processes. Skilled labor may be necessary for specialized screw designs or customizations, which can increase labor costs.

-

Manufacturing Overhead: This encompasses costs related to factory operations, including utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can help mitigate overhead costs, which is crucial for competitive pricing.

-

Tooling: Custom tooling for specific screw designs or sizes can add to initial costs. However, investing in quality tooling can lead to better product consistency and lower per-unit costs over time.

-

Quality Control (QC): Rigorous quality control processes ensure that the screws meet required specifications and certifications. The costs associated with QC should be factored into the overall pricing, as they help prevent defects and enhance reliability.

-

Logistics: Shipping costs, including freight, insurance, and customs duties, are vital to consider, especially for international buyers. Logistics costs can vary widely depending on the shipment’s distance and the chosen Incoterms.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the average margins within the industry can help buyers gauge the competitiveness of quotes received.

How Do Price Influencers Affect Conveyor Screws Pricing?

Several factors can influence the pricing of conveyor screws, including:

-

Volume/MOQ: Bulk orders often result in lower per-unit costs. Suppliers are usually more willing to negotiate pricing for higher volume commitments, making it essential for buyers to assess their needs accurately.

-

Specifications and Customization: Custom designs or unique specifications can lead to higher costs due to the need for specialized production processes or materials. Buyers should clearly communicate their requirements to receive accurate quotes.

-

Materials and Quality/Certifications: Higher-quality materials or specific certifications (e.g., FDA, ISO) can increase costs. Buyers should weigh the benefits of these certifications against their operational requirements and budget.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may offer higher prices due to their proven track record, while newer suppliers might provide competitive rates to gain market share.

-

Incoterms: The choice of Incoterms affects logistics costs and responsibilities. Buyers should understand the implications of terms like FOB (Free on Board) versus CIF (Cost, Insurance, and Freight) to evaluate total landed costs accurately.

What Are the Best Negotiation Tips for International B2B Buyers?

International buyers can enhance their procurement strategies by implementing the following tips:

-

Research and Benchmarking: Conduct thorough market research to understand average pricing and quality levels. This knowledge empowers buyers during negotiations.

-

Leverage Volume Discounts: If possible, consolidate orders to meet minimum order quantities (MOQs) and leverage bulk pricing. Long-term contracts may also be beneficial for securing better rates.

-

Explore Total Cost of Ownership (TCO): Consider not just the initial purchase price but also maintenance, operational costs, and the lifespan of the conveyor screws. A lower upfront cost may not always translate to better overall value.

-

Be Cautious with Customization: While custom features can enhance performance, they often lead to increased costs. Assess whether standard options can meet your needs before committing to custom designs.

-

Understand Regional Pricing Nuances: Be aware of regional market dynamics, such as tariffs, currency fluctuations, and local regulations, which can affect pricing. This knowledge is especially critical for buyers in Africa, South America, the Middle East, and Europe, where economic conditions can vary widely.

Disclaimer on Indicative Prices

Prices for conveyor screws can fluctuate based on market conditions, supplier pricing strategies, and material costs. The figures provided in this analysis are indicative and may not reflect actual market prices at the time of inquiry. Buyers are encouraged to obtain multiple quotes and consider the total cost of ownership when making purchasing decisions.

Alternatives Analysis: Comparing conveyor screws With Other Solutions

Exploring Alternatives to Conveyor Screws in Material Handling Solutions

In material handling, the choice of technology can significantly impact operational efficiency and cost-effectiveness. While conveyor screws are a popular solution for transporting bulk materials, alternative systems may offer advantages depending on specific needs. This analysis explores three viable alternatives—belt conveyors, pneumatic conveyors, and bucket elevators—highlighting their comparative performance, cost, implementation ease, maintenance requirements, and best use cases.

Illustrative image related to conveyor screws

| Comparison Aspect | Conveyor Screws | Belt Conveyors | Pneumatic Conveyors | Bucket Elevators |

|---|---|---|---|---|

| Performance | High precision in material flow; suitable for bulk solids. | Versatile; effective for various materials, including bulk and packaged goods. | Ideal for powdered or granular materials over long distances. | Efficient for vertical lifting of bulk materials. |

| Cost | Moderate initial investment; competitive long-term operational costs. | Generally lower initial cost; higher energy consumption. | Higher setup costs; energy-efficient for long-distance transport. | Moderate to high cost depending on design and capacity. |

| Ease of Implementation | Requires some assembly; minor cutting and welding. | Relatively easy to install; often requires minimal modifications. | Complex installation; requires careful design considerations. | Installation can be straightforward but may require specialized equipment. |

| Maintenance | Moderate; requires regular inspection of screws and bearings. | Low maintenance; belts need periodic replacement. | Higher maintenance; filters and blowers require regular servicing. | Moderate; requires inspection of buckets and chains. |

| Best Use Case | Ideal for handling viscous, heavy, or abrasive materials. | Best for general material handling and packaging applications. | Suitable for enclosed transport of fine powders and materials sensitive to air exposure. | Effective for vertical transport of bulk materials like grains and aggregates. |

Detailed Breakdown of Alternatives

Belt Conveyors

Belt conveyors are one of the most common material handling systems due to their versatility and relatively low initial cost. They can transport a wide variety of materials, making them suitable for both bulk and packaged goods. However, they generally consume more energy than conveyor screws, particularly when moving heavy loads over long distances. Maintenance is relatively low, but the belts may require periodic replacement, which can incur additional costs over time.

Pneumatic Conveyors

Pneumatic conveyors use air pressure to transport materials through tubes, making them ideal for powdered or granular materials, especially in industries like food processing and pharmaceuticals. They are efficient for long-distance transport and can maintain product integrity by minimizing exposure to contaminants. However, the initial setup costs are higher, and the system requires careful design to ensure efficiency. Maintenance can be more complex due to the need for regular servicing of filters and blowers.

Bucket Elevators

Bucket elevators are designed for vertical lifting of bulk materials, making them highly effective for transporting heavy loads like grains, aggregates, and fertilizers. They offer efficient space utilization and can handle large volumes of material. While their installation can be straightforward, they may require specialized equipment and maintenance to ensure smooth operation. Depending on the design and capacity, costs can vary widely, making them a moderate to high investment.

Conclusion: How to Choose the Right Material Handling Solution

When selecting a material handling solution, B2B buyers must consider their specific operational needs, including the type of materials being transported, the required transport distance, and budget constraints. Conveyor screws offer precision and reliability for heavy and abrasive materials, while belt conveyors provide versatility for various applications. Pneumatic conveyors excel in transporting fine powders, and bucket elevators are ideal for vertical lifting. By assessing these factors, buyers can make informed decisions that align with their operational goals and enhance efficiency in their processes.

Essential Technical Properties and Trade Terminology for conveyor screws

Understanding the key technical properties and terminology of conveyor screws is essential for making informed purchasing decisions in the B2B landscape. This section will highlight critical specifications and common industry terms relevant to conveyor screws, aiding buyers in their selection process.

What Are the Key Technical Properties of Conveyor Screws?

1. Material Grade

The material grade of conveyor screws is pivotal for determining their durability and resistance to wear and tear. Common materials include carbon steel, stainless steel (like 304 and 316), and abrasion-resistant alloys. The choice of material impacts the screw’s performance in various applications, especially in industries dealing with corrosive substances or abrasive materials. Buyers should select a material that aligns with the operational environment to minimize maintenance costs and downtime.

2. Diameter

The diameter of a conveyor screw directly influences its capacity and the type of materials it can handle. Standard diameters range from 6 inches to 24 inches, with larger diameters suitable for heavier loads and more substantial material flows. For businesses, selecting the appropriate diameter is crucial for ensuring optimal efficiency and avoiding bottlenecks in material handling processes.

Illustrative image related to conveyor screws

3. Pitch

Pitch refers to the distance between the flights of the screw. A shorter pitch allows for a more compact design and is ideal for conveying fine materials, while a longer pitch is suited for bulkier loads. Understanding the correct pitch is vital for achieving the desired flow rate and ensuring that the conveyor operates smoothly under its intended load conditions.

4. Flight Design

The flight design, including options like helicoid or sectional screws, affects material movement and handling efficiency. Helicoid screws are generally more cost-effective for light to medium-duty applications, while sectional screws can be customized for specific applications, including those requiring specialized features like ribbon or cut-and-folded flighting. Selecting the right flight design can enhance performance and reduce operational issues.

5. Length and Configuration

The length of the conveyor screw can vary based on the specific application, with standard lengths available for immediate shipment. Custom lengths may be required for unique setups. Understanding the layout of the conveyor system is essential for ensuring that the screw fits properly and functions effectively within the overall material handling system.

What Are Common Trade Terms Associated with Conveyor Screws?

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of conveyor screws, understanding OEM specifications ensures compatibility with existing systems and compliance with industry standards.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. This term is crucial for buyers, as it affects inventory management and overall project budgeting. Knowing the MOQ helps businesses plan their purchases more effectively.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where a buyer requests price proposals from suppliers for specific products or services. For B2B buyers of conveyor screws, submitting an RFQ can facilitate competitive pricing and ensure that all specifications are met.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms is essential for international buyers to avoid misunderstandings and ensure smooth transactions.

5. CEMA (Conveyor Equipment Manufacturers Association)

CEMA provides industry standards and guidelines for conveyor equipment. Understanding CEMA standards helps buyers ensure that the conveyor screws they purchase meet established quality and safety benchmarks, thereby reducing the risk of operational issues.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing conveyor screws, ensuring they meet their operational needs effectively.

Navigating Market Dynamics and Sourcing Trends in the conveyor screws Sector

What are the Key Market Dynamics and Trends Impacting Conveyor Screws?

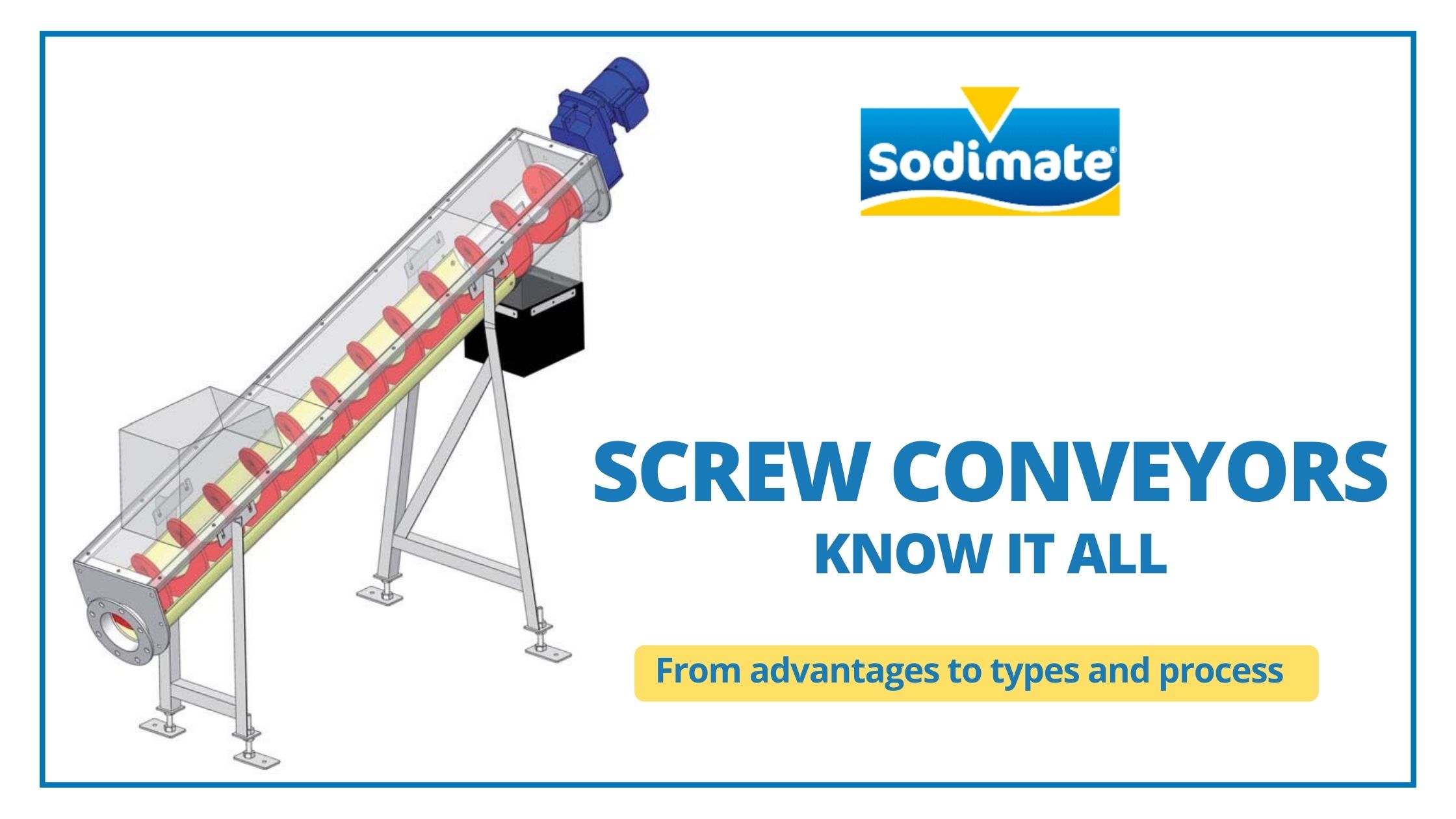

The conveyor screws market is witnessing transformative growth driven by several global dynamics. One significant factor is the increasing demand for automation across various industries, including food processing, agriculture, and mining. This shift towards automated material handling systems is propelling the need for efficient, reliable conveyor solutions. Furthermore, rapid urbanization and industrialization in regions like Africa and South America are fostering infrastructure development, which in turn drives the demand for conveyor systems, including screws.

Illustrative image related to conveyor screws

Emerging technologies such as IoT and AI are also influencing the conveyor screws sector. Smart conveyor systems equipped with sensors can monitor performance and predict maintenance needs, thereby reducing downtime and enhancing operational efficiency. International buyers are increasingly seeking suppliers who can provide innovative solutions that integrate these technologies into their conveyor systems.

Additionally, there is a notable trend towards customization. Buyers are looking for conveyor screws that can be tailored to specific applications, such as those made from specialized materials like stainless steel or with unique flight configurations. This demand for tailored solutions presents opportunities for suppliers who can offer a diverse range of products.

How is Sustainability Influencing Sourcing Decisions in the Conveyor Screws Market?

Sustainability has become a critical consideration for international B2B buyers in the conveyor screws market. The environmental impact of manufacturing processes and materials used in conveyor systems is under scrutiny, prompting companies to seek suppliers that prioritize eco-friendly practices. This includes the use of sustainable materials, energy-efficient manufacturing processes, and waste reduction strategies.

Ethical sourcing is increasingly important as companies aim to enhance their brand reputation and align with consumer expectations for corporate responsibility. Buyers are actively looking for suppliers who can demonstrate compliance with sustainability standards and certifications, such as ISO 14001, which focuses on environmental management. Moreover, the adoption of ‘green’ materials in conveyor screw manufacturing, such as recyclable plastics or sustainably sourced metals, is gaining traction.

In addition to environmental considerations, ethical labor practices are also influencing sourcing decisions. Buyers are more likely to partner with manufacturers that ensure fair labor conditions and transparency in their supply chains. These factors not only contribute to a positive brand image but also mitigate risks associated with supply chain disruptions.

Illustrative image related to conveyor screws

What is the Historical Context of Conveyor Screws in B2B Applications?

The evolution of conveyor screws can be traced back to the early industrial revolution, where the need for efficient material handling solutions became apparent. Initially, these systems were rudimentary and primarily utilized in agriculture for grain transport. Over the years, advancements in engineering and materials science led to the development of more sophisticated screw designs, capable of handling a wider range of materials and applications.

By the mid-20th century, conveyor screws became integral to various industries, including mining and manufacturing, as they provided a reliable means for bulk material transport. The introduction of new materials, such as stainless steel and specialized alloys, further enhanced their durability and performance. Today, conveyor screws are a staple in modern material handling systems, reflecting a continuous evolution driven by technological advancements and changing market needs.

Conclusion: Navigating the Future of Conveyor Screws

As international B2B buyers navigate the conveyor screws market, understanding these dynamics, sustainability considerations, and the historical context will be crucial in making informed sourcing decisions. By aligning with suppliers who prioritize innovation, customization, and ethical practices, businesses can enhance operational efficiency while contributing to a more sustainable future.

Frequently Asked Questions (FAQs) for B2B Buyers of conveyor screws

-

How do I select the right conveyor screw for my application?

Choosing the appropriate conveyor screw involves assessing several factors, including the type of material to be transported, the required conveying distance, and the environmental conditions. For lighter materials, helicoid screws are typically more cost-effective, while sectional screws are better suited for heavier or more abrasive materials. Additionally, consider the screw’s diameter and pitch, as these will affect the flow rate and efficiency. Consulting with a supplier who can offer customized solutions based on your specific needs can also enhance performance and reduce downtime. -

What is the best material for conveyor screws in harsh environments?

For applications in harsh environments, stainless steel (such as 316 stainless) or high-strength alloys like AR-235 are recommended due to their resistance to corrosion and wear. These materials provide longevity and reliability, especially when transporting abrasive or corrosive materials. It’s crucial to assess the specific conditions of your operation, including temperature extremes and exposure to chemicals, to select the most suitable material for your conveyor screws. -

What customization options are available for conveyor screws?

Conveyor screws can be tailored to meet specific operational requirements. Customization options include variations in diameter, length, pitch, and flight design (e.g., ribbon or cut-and-folded flighting). Suppliers often provide custom lengths and specialized materials to enhance performance. Additionally, features like quick-change designs can be implemented to facilitate easier maintenance and repairs. Engaging with your supplier early in the design process can help ensure that the custom screw meets your exact specifications. -

What are the minimum order quantities (MOQ) for conveyor screws?

Minimum order quantities for conveyor screws can vary significantly between suppliers and depend on the type and customization of the screws. Standard screws may have lower MOQs, while custom or specialized options might require larger orders to justify production costs. It’s advisable to communicate directly with potential suppliers to understand their MOQ policies and explore options for bulk orders or shared shipments, which can help reduce overall costs. -

What payment terms should I expect when sourcing conveyor screws internationally?

Payment terms can vary widely based on the supplier’s policies and your relationship with them. Common practices include upfront payments, net 30 or net 60 days, and letters of credit for larger orders. It’s important to clarify payment terms before finalizing your order to avoid potential cash flow issues. Establishing a good rapport with suppliers can also lead to more flexible terms, especially for repeat business or larger contracts. -

How can I ensure quality assurance (QA) when sourcing conveyor screws?

To ensure quality assurance when sourcing conveyor screws, it is essential to vet suppliers thoroughly. Request certifications, such as ISO 9001, which indicate adherence to international quality standards. Additionally, ask for samples or detailed product specifications before placing larger orders. Implementing a quality control process upon receipt of the screws can also help identify any issues early, ensuring that they meet your operational requirements. -

What logistics considerations should I keep in mind for international shipments of conveyor screws?

When planning for international shipments, consider factors such as shipping method, customs regulations, and potential tariffs that may apply to your order. Working with suppliers who have experience in international logistics can streamline the process. It’s also wise to factor in lead times for production and shipping to ensure that your operations are not disrupted. Establishing a reliable logistics partner can help mitigate delays and ensure that your conveyor screws arrive on time and in good condition. -

How do I vet suppliers when sourcing conveyor screws from different regions?

Vetting suppliers involves researching their reputation, production capabilities, and customer reviews. Look for suppliers with a proven track record in your specific industry and check for certifications that demonstrate quality and compliance with international standards. Additionally, consider visiting the supplier’s facility if possible or requesting a virtual tour. Engaging with existing customers can provide insights into the supplier’s reliability and support services, helping you make an informed decision.

Top 5 Conveyor Screws Manufacturers & Suppliers List

1. Motion – Screw Conveyor Screws

Domain: motion.com

Registered: 1994 (31 years)

Introduction: Screw conveyor screws are designed for use in any position, delivering reliable and precise material movement in conveyor systems. They are the rotating helical blades within a conveyor system, responsible for moving materials along the trough. Key specifications include:

– Material: Steel

– Screw Direction: Right Hand

– Various Screw Diameters: 4.0000 in, 6.0000 in, 9.0000 in, 10.0000 in, 12.0…

2. McMaster – Conveyor Screws

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Conveyor Screws, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. USA Roller Chain – Quick Change Conveyor Screws

4. Martin – Modular Plastic Screw Conveyors

Domain: martinsprocket.com

Registered: 1995 (30 years)

Introduction: Martin Modular Plastic Screw Conveyors are plastic modules consisting of a helical flight spiraling around a hollow square hub. Advantages include:

– All-plastic material that does not corrode and is impervious to acids, caustics, and other chemicals.

– FDA approved for food contact.

– Highly resistant to corrosion with a slick surface for easy cleaning.

– Bonded construction screws that are heat…

5. CHL Systems – Screw Conveyors

Domain: chlsystems.com

Registered: 1999 (26 years)

Introduction: Screw Conveyors are stainless-steel solutions designed for hygiene and material handling. They can transport ingredients across any distance or incline, customizable to specific production needs. Key features include:

– Configurable infeed and discharge

– Various screw types: mixer, shaftless, paddle, etc.

– Configurable screw speed

– Loading capacity: 30A% 151 CFH (cubic feet per hour)

– Incline …

Strategic Sourcing Conclusion and Outlook for conveyor screws

What Are the Key Takeaways for Strategic Sourcing of Conveyor Screws?

In the rapidly evolving landscape of bulk material handling, strategic sourcing of conveyor screws is essential for optimizing operational efficiency and cost-effectiveness. Understanding the different types of screws, such as helicoid and sectional, allows buyers to choose the right solution tailored to their specific applications. Moreover, the availability of quick-change designs can significantly reduce downtime, enhancing productivity and minimizing operational disruptions.

Why Is Strategic Sourcing Crucial for International B2B Buyers?

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, leveraging strategic sourcing can lead to substantial competitive advantages. By building relationships with reliable manufacturers and suppliers, companies can ensure access to high-quality materials and innovative designs that meet local and global industry standards. Additionally, understanding the unique requirements of different markets will facilitate better negotiation and procurement strategies.

Illustrative image related to conveyor screws

How Can Buyers Prepare for the Future of Conveyor Screws?

Looking ahead, it’s vital for buyers to stay informed about emerging technologies and advancements in material handling solutions. Engaging with industry experts and participating in relevant trade shows can provide valuable insights into new trends. By prioritizing strategic sourcing, B2B buyers can not only enhance their supply chain resilience but also drive long-term growth and sustainability in their operations. Embrace the opportunity to connect with leading suppliers today and position your business for success in the future of conveyor systems.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.